Techno-Economic Analysis of High-Pressure Metal Hydride Compression Systems

Abstract

1. Introduction

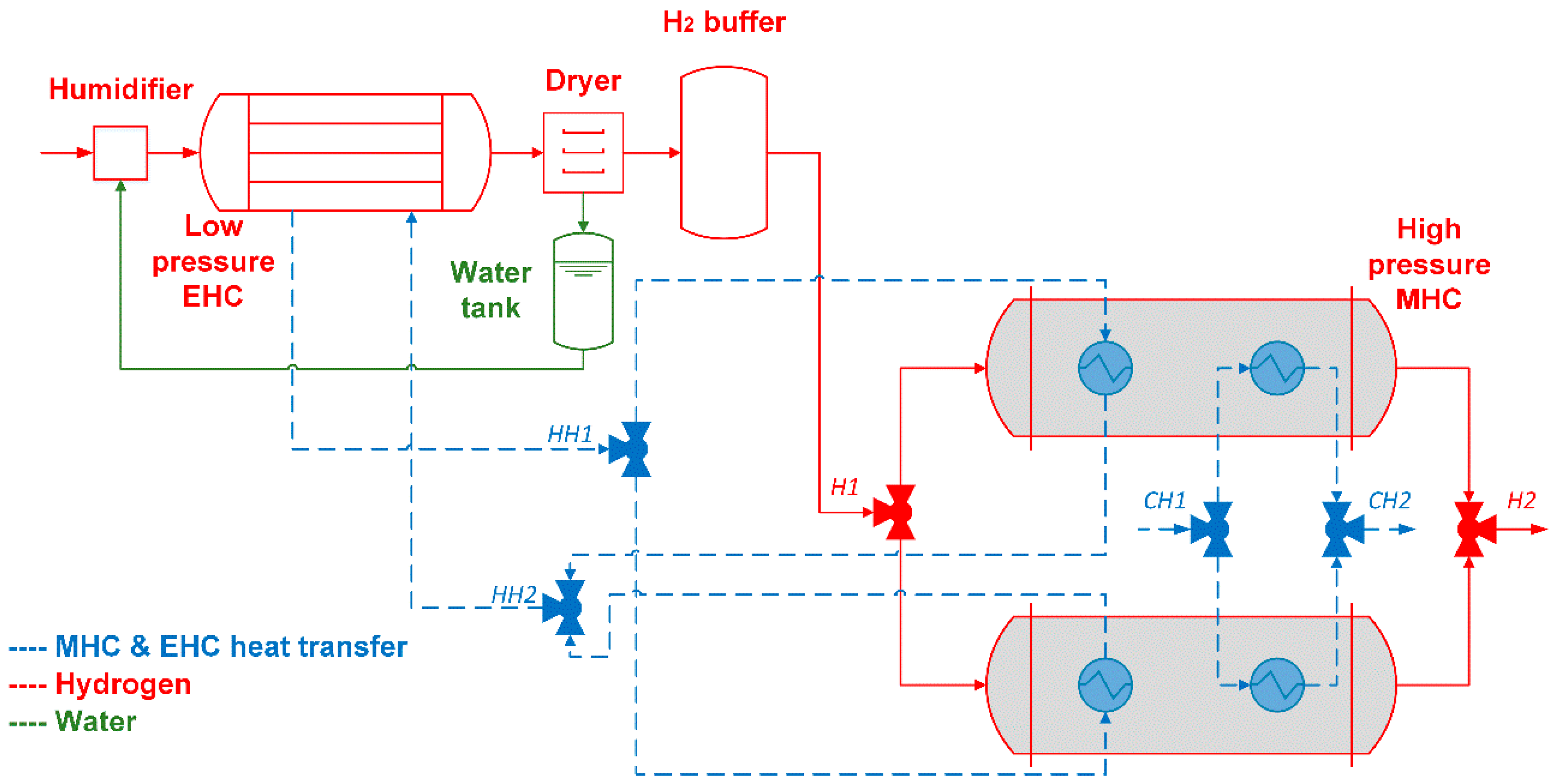

2. The Hybrid Hydrogen Compressor Concept

3. The Techno-Economic Analysis Model

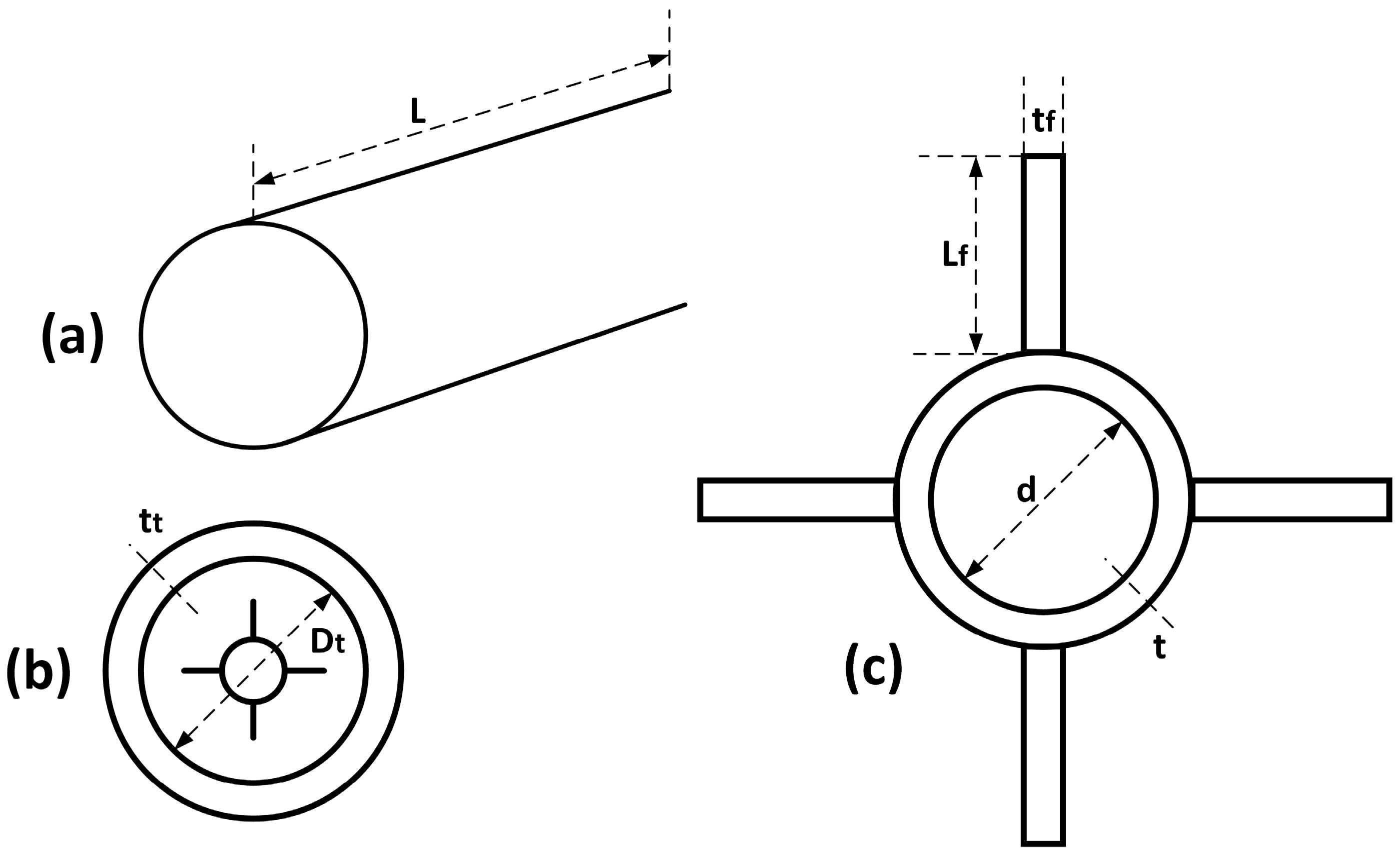

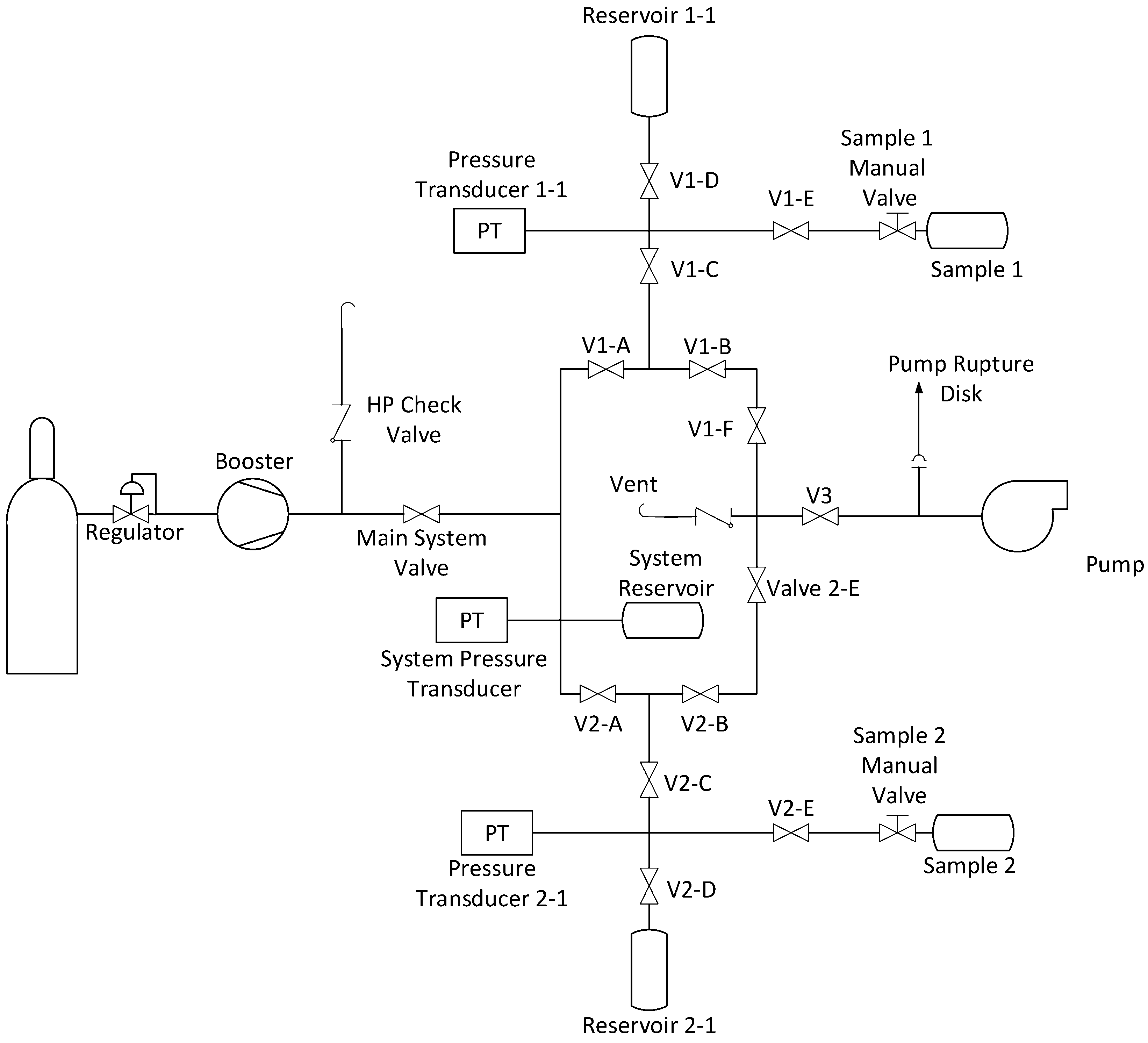

3.1. Metal Hydride Compressor System Technical Performance Model

3.2. Metal Hydride Compressor System Economic Model

4. Results

4.1. Initial Downselected Materials

4.2. Technical Analysis Results

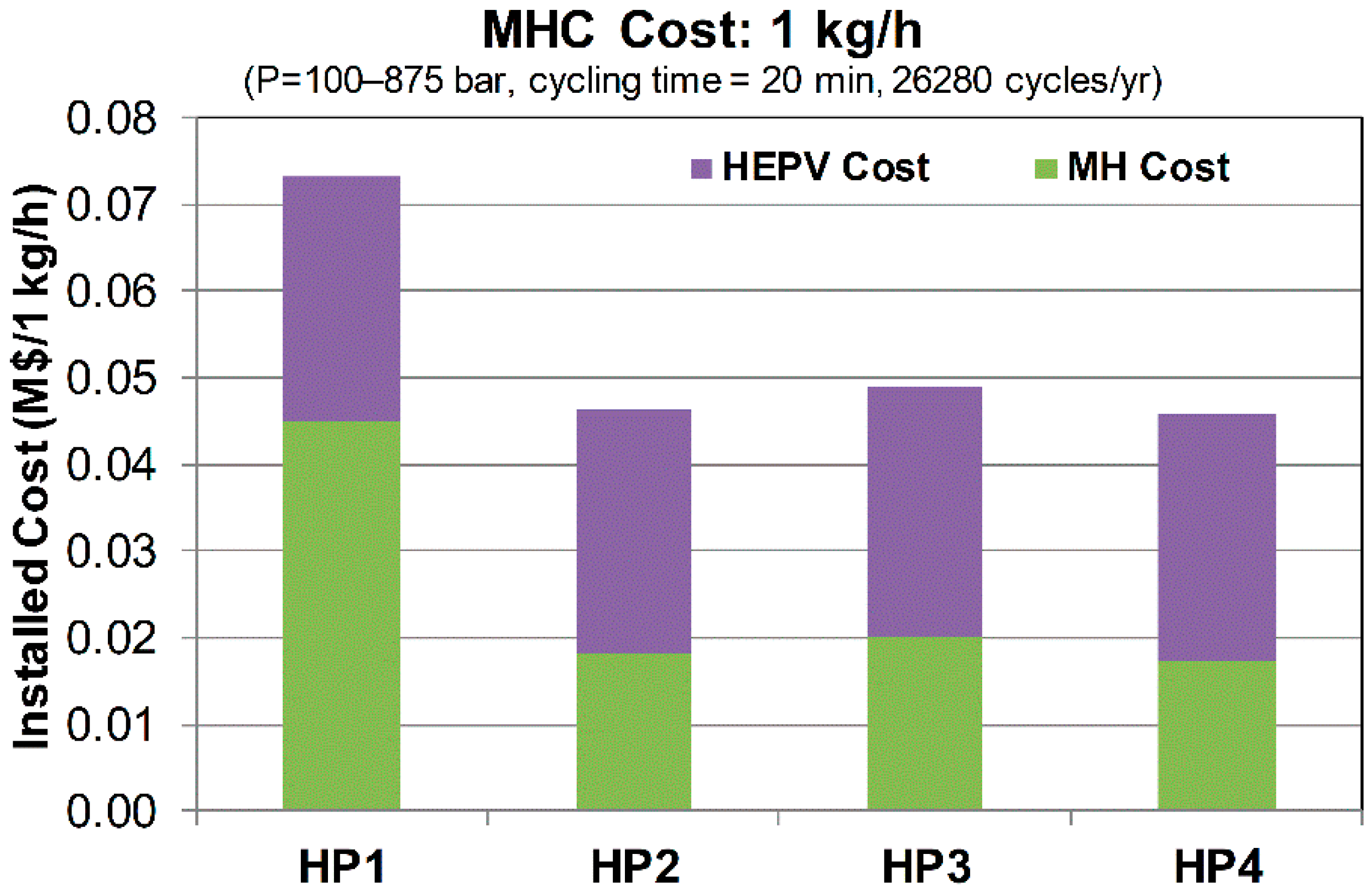

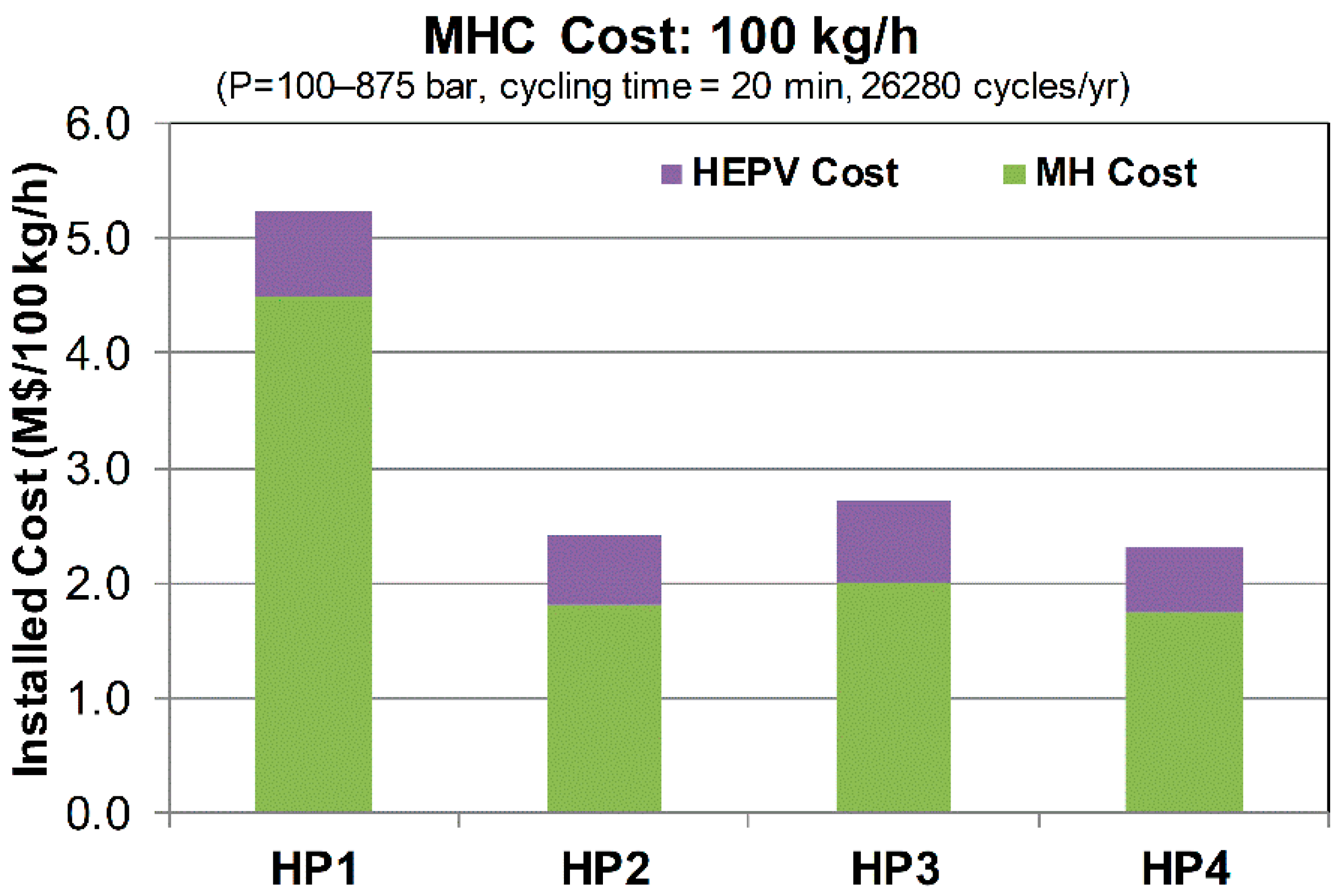

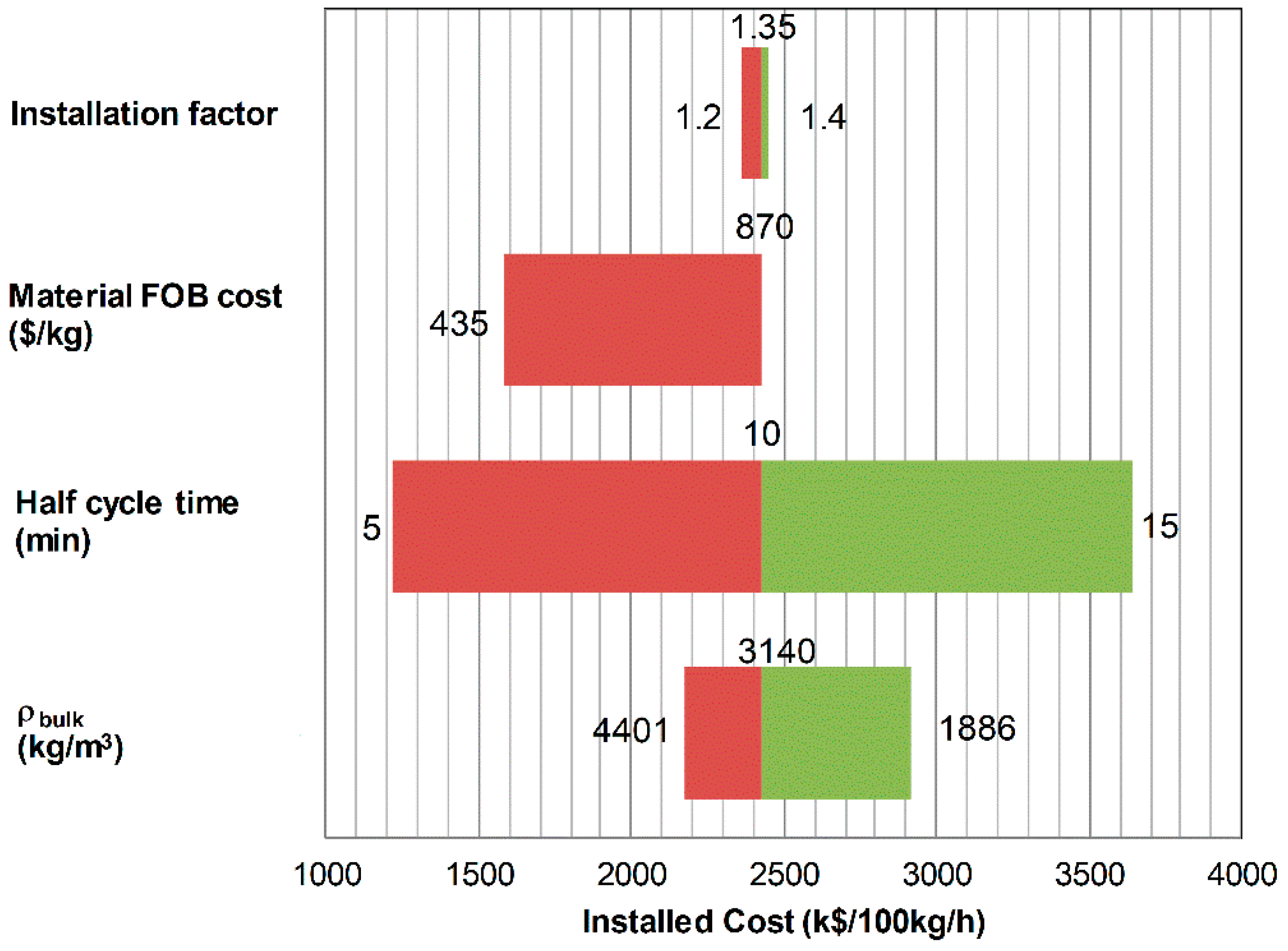

4.3. Economic Analysis Results

5. Discussion and Future Work

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| C | Cost ($) |

| Cinst | Installed cost ($) |

| CP | Specific heat (kJ/kg∙K) |

| DOE | U.S. Department of Energy |

| EHC | Electrochemical hydrogen compressor |

| finst | Cost installation factor |

| FOB | Free on board |

| h | Specific enthalpy (kJ/kg), or heat transfer coefficient (W/m2∙K) |

| k | Thermal conductivity (W/m∙K) |

| LMTD | Log mean temperature difference (°C or K) |

| Mass flow rate (kg/s) | |

| M | Mass (kg) |

| MH | Metal hydride |

| MHC | Metal hydride hydrogen compressor |

| nf | Number of fins per tube |

| NT | Number of tubes |

| P | Equilibrium pressure (bar) |

| R | Gas constant (8.314 J/mol∙K) |

| S | Heat transfer surface area (m2) |

| V | Volume (m3) |

| wt | Weight capacity (kgH2/kgMH) |

| Greek letters | |

| ΔH | Reaction enthalpy (kJ/molH2 or kJ/kgH2) |

| ΔS | Reaction entropy (kJ/molH2∙K or kJ/kgH2∙K) |

| Δt | Time (s) |

| ηv | Volumetric efficiency |

| ρ | Density (kg/m3) |

| Subscript | |

| abs | Absorption |

| bulk | Bulk |

| CH | Cold utility |

| des | Desorption |

| HEPV | Heat exchanger and pressure vessel |

| HF | Heat transfer fluid |

| HH | Hot utility |

| MH | Metal hydride |

References

- U.S. Department of Energy Fuel Cell Technologies Office Multi-Year Research, Development and Demonstration Plan—3.2 Hydrogen Delivery. 2015. Available online: https://www.energy.gov/sites/prod/files/2015/08/f25/fcto_myrdd_delivery.pdf (accessed on 18 March 2018).

- Lototskyy, M.V.; Yartys, V.A.; Pollet, B.G.; Bowman, R.C. Metal hydride hydrogen compressors: A review. Int. J. Hydrog. Energy 2014, 39, 5818–5851. [Google Scholar] [CrossRef]

- Corgnale, C.; Greenway, S.; Motyka, T.; Sulic, M.; Hardy, B.; Molter, T.; Ludlow, D. Technical performance of a hybrid thermo-electrochemical system for high pressure hydrogen compression. ECS Trans. 2017, 80, 41–54. [Google Scholar] [CrossRef]

- Hattrick-Simpers, J.; Choudhary, K.; Corgnale, C. A simple constrained machine learning model for predicting high-pressure-hydrogen-compressor materials. Mol. Syst. Des. Eng. 2018. [CrossRef]

- Gkanas, E.I.; Grant, D.M.; Stuart, A.D.; Eastwick, C.N.; Book, D.; Nayebossadri, S.; Pickering, L.; Walkera, G.S. Numerical Study on a Two-Stage Metal Hydride Hydrogen Compression System. J. Alloy Compd. 2015, 645, S18–S22. [Google Scholar] [CrossRef]

- Karagiorgis, G.; Christodoulou, C.N.; von Storch, H.; Tzamalis, G.; Deligiannis, K.; Hadjipetrou, D.; Odysseos, M.; Roeb, M.; Sattler, C. Design, development, construction and operation of a novel metal hydride compressor. Int. J. Hydrog. Energy 2017, 42, 12364–12374. [Google Scholar] [CrossRef]

- Galvis, A.R.; Leardini, F.; Ares, J.R.; Cuevas, F.; Fernandez, J.F. Simulation and design of a three-stage metal hydride hydrogen compressor based on experimental thermodynamic data. Int. J. Hydrog. Energy 2018, 43, 6666–6676. [Google Scholar] [CrossRef]

- Shah, R.K.; London, A.L. Laminar Flow Forced Convection in Ducts, Supplement 1 to Advances in Heat Transfer; Acedemic Press: New York, NY, USA, 1978. [Google Scholar]

- Aspen in Plant Cost Estimator. ASPEN Tech Manual. Available online: https://www.aspentech.com/en/products/pages/aspen-in-plant-cost-estimator (accessed on 18 May 2018).

- JMC Alloy. Personal communication, 2017.

- Grainger Catalog. Available online: https://www.grainger.com/category/aluminum-tubing/tubing/pipe-tubing-and-fittings/plumbing/ecatalog/N-qwo (accessed on 18 May 2018).

- Swagelok Catalog. Available online: https://www.swagelok.com/downloads/webcatalogs/EN/MS-01-174.PDF (accessed on 18 May 2018).

- Friedlmeier, G.; Manthey, A.; Wanner, M.; Groll, M. Cyclic stability of various application-relevant metal hydrides. J. Alloy Compd. 1995, 231, 880–887. [Google Scholar] [CrossRef]

- Hydrogen Storage Materials Database. Available online: http://hydrogenmaterialssearch.govtools.us/search.aspx (accessed on 18 March 2018).

- Johnson, J.R.; Reilly, J.J.; Reidinger, F.; Corliss, L.M.; Hastings, J.M. On the existence of f.c.c. TiCr1.8H5.3. J. Less Common Met. 1982, 88, 107–114. [Google Scholar] [CrossRef]

- Beeri, O.; Cohen, D.; Gavra, Z.; Mintz, M.H. Sites occupation and thermodynamic properties of the TiCr2-xMnx-H2 (0 ≤ x ≤ 1) system: Statistical thermodynamics analysis. J. Alloy Compd. 2003, 1, 111–122. [Google Scholar] [CrossRef]

- Corgnale, C.; Hattrick-Simpers, J.; Sulic, M.; Weidner, J.; Lopata, J. Experimental assessment of thin film high pressure metal hydride material properties. Int. J. Hydrog. Energy, 2018; under review. [Google Scholar]

- Wang, X.; Chen, R.; Zhang, Y.; Chen, C.; Wang, Q. Hydrogen storage alloys for high-pressure suprapure hydrogen compressor. J. Alloy Compd. 2006, 420, 322–325. [Google Scholar] [CrossRef]

- Cao, Z.; Ouyang, L.; Wang, H.; Liu, J.; Sun, D.; Zhang, Q. Advanced high-pressure metal hydride fabricated via Ti-Cr-Mn alloys for hybrid tank. Int. J. Hydrog. Energy 2015, 40, 2717–2728. [Google Scholar] [CrossRef]

- Vanhanen, J.P.; Hagstrom, M.T.; Lund, P.D. Combined hydrogen compressing and heat transforming through metal hydrides. Int. J. Hydrog. Energy 1999, 24, 441–448. [Google Scholar] [CrossRef]

- Pasini, JM.; Corgnale, C.; van Hassel, B.; Motyka, T.; Kumar, S.; Simmons, K. Metal hydride material requirements for automotive hydrogen storage systems. Int. J. Hydrog. Energy 2013, 38, 9755–9765. [Google Scholar] [CrossRef]

- Corgnale, C.; Hardy, B.J.; Tamburello, D.A.; Garrison, S.L.; Anton, D.L. Acceptability envelope for metal hydride-based hydrogen storage systems. Int. J. Hydrog. Energy 2012, 37, 2812–2824. [Google Scholar] [CrossRef]

- Corgnale, C.; Motyka, T.; Greenway, S.; Perez-Berrios, J.; Nakano, A.; Ito, I. Metal hydride bed system model for renewable source driven Regenerative Fuel Cell. J. Alloy Compd. 2013, 580, 406S–409S. [Google Scholar] [CrossRef]

| Material | ΔHabs/ΔHdes (kJ/molH2) | ΔSabs/ΔSdes (kJ/molH2) | wt (%) | Equilibrium P (bar)/T (°C) |

|---|---|---|---|---|

| HP1: TiCr1.9 | 26.2 | 122.0 | 1.4 | 100/40–875/125 |

| HP2: (Ti0.97Zr0.03)1.1Cr1.6Mn0.4 | 23.4 | 115.0 | 1.7 | 100/32–875/125 |

| HP3: Ti1.1CrMn | 22.9 | 114.7 | 1.5 | 100/27–875/119 |

| HP4: TiCrMn0.4Fe0.4V0.2 | 20.2/22.0 | 103.0/109.0 | 1.9 | 100/39–875/145 |

| Material | ρbulk (kg/m3) | kMH (W/m∙K) | CpMH (J/kg∙K) |

|---|---|---|---|

| HP1: TiCr1.9 | 3130 | 8.0 | 486 |

| HP2: (Ti0.97Zr0.03)1.1Cr1.6Mn0.4 | 3140 | 8.0 | 485 |

| HP3: Ti1.1CrMn | 3170 | 8.0 | 493 |

| HP4: TiCrMn0.4Fe0.4V0.2 | 3170 | 8.0 | 491 |

| Material | Sensible Power (kW) (100 kgH2/h) | Reaction Power (kW) (100 kgH2/h) | Total Power (kW) (100 kgH2/h) |

|---|---|---|---|

| HP1: TiCr1.9 | 130.8 | 366.8 | 497.6 |

| HP2: (Ti0.97Zr0.03)1.1Cr1.6Mn0.4 | 117.4 | 327.6 | 445.0 |

| HP3: Ti1.1CrMn | 139.2 | 320.6 | 459.8 |

| HP4: TiCrMn0.4Fe0.4V0.2 | 127.5 1 | 308.0 1 | 435.5 1 |

| Material | Number of Tubes 1 (1 kg/h–100 kg/h) | Number of Fins 2 (1 kg/h–100 kg/h) | Length, L 1 (m) (1 kg/h–100 kg/h) | Water Flow 1 (g/s) (1 kg/h–100 kg/h) |

|---|---|---|---|---|

| HP1: TiCr1.9 | 15–1474 | 4–4 | 1.60–1.55 | 28.7–2866 |

| HP2: (Ti0.97Zr0.03)1.1Cr1.6Mn0.4 | 16–1550 | 4–4 | 1.20–1.20 | 51.3–5127 |

| HP3: Ti1.1CrMn | 14–1444 | 8–8 | 1.60–1.50 | 53.0–5297 |

| HP4: TiCrMn0.4Fe0.4V0.2 | 14–1565 | 10–10 | 1.30–1.20 | 62.7–6271 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corgnale, C.; Sulic, M. Techno-Economic Analysis of High-Pressure Metal Hydride Compression Systems. Metals 2018, 8, 469. https://doi.org/10.3390/met8060469

Corgnale C, Sulic M. Techno-Economic Analysis of High-Pressure Metal Hydride Compression Systems. Metals. 2018; 8(6):469. https://doi.org/10.3390/met8060469

Chicago/Turabian StyleCorgnale, Claudio, and Martin Sulic. 2018. "Techno-Economic Analysis of High-Pressure Metal Hydride Compression Systems" Metals 8, no. 6: 469. https://doi.org/10.3390/met8060469

APA StyleCorgnale, C., & Sulic, M. (2018). Techno-Economic Analysis of High-Pressure Metal Hydride Compression Systems. Metals, 8(6), 469. https://doi.org/10.3390/met8060469