3D Multiphysical Modelling of Fluid Dynamics and Mass Transfer in Laser Welding of Dissimilar Materials

Abstract

1. Introduction

2. Experimental Procedure

3. Model Description

- (1)

- The effect of side shielding gas on the behavior of keyhole and molten pool is ignored.

- (2)

- The calculated fluid is Newtonian and incompressible and is in local thermal equilibrium; furthermore, this fluid satisfies the basic equations of fluid motion.

- (3)

- The temperature-dependent thermo-physical parameters are calculated, derived from the JMatPro software (Release Version 7.0.0, Sente Software Ltd., Guildford, UK).

- (4)

- In the simulation, only iron and titanium components are considered, and other alloy elements are ignored.

3.1. Laser Heat Source Model

3.2. Governing Equation

3.3. Boundary Conditions

3.4. Numerical Method

4. Results and Discussion

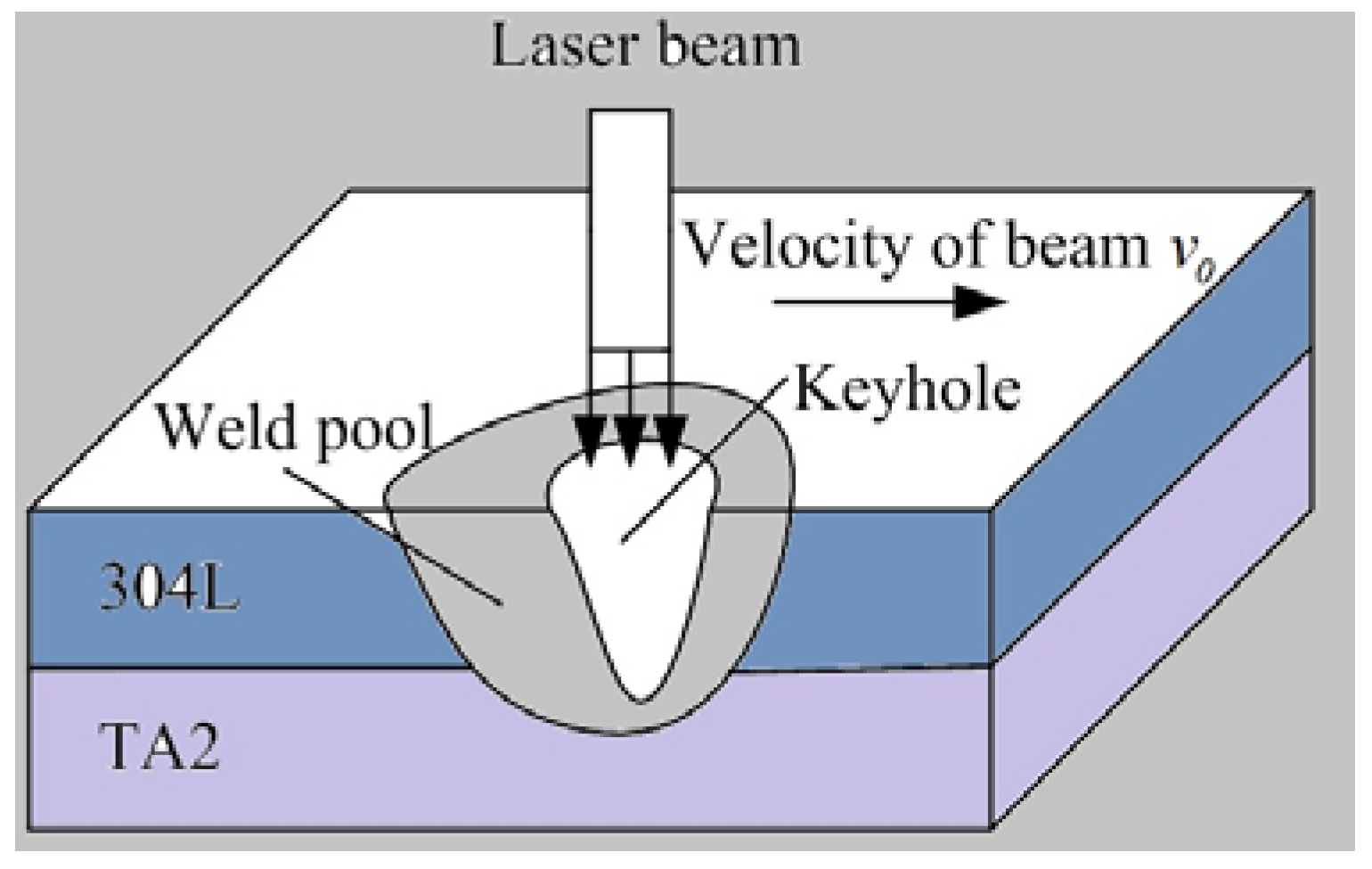

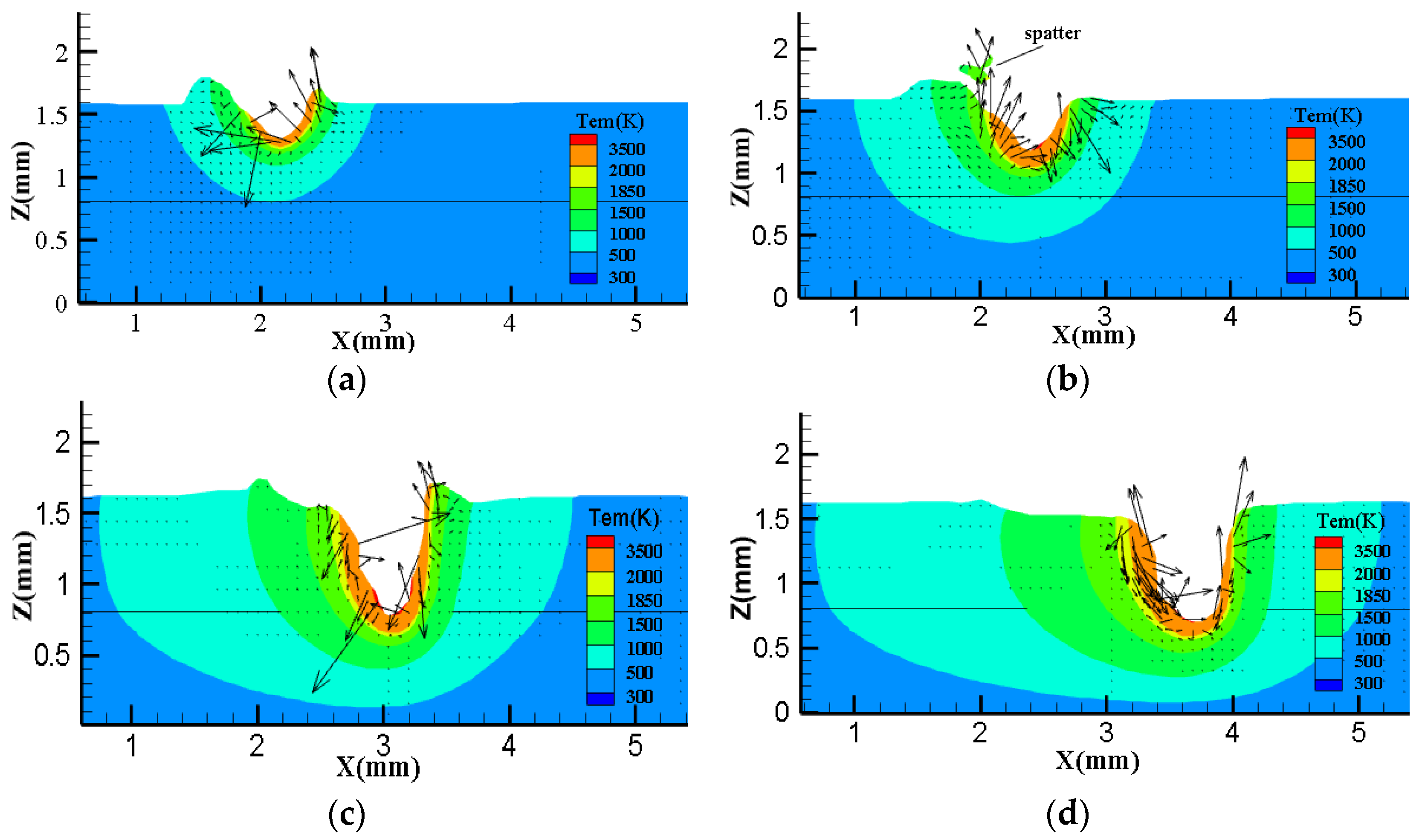

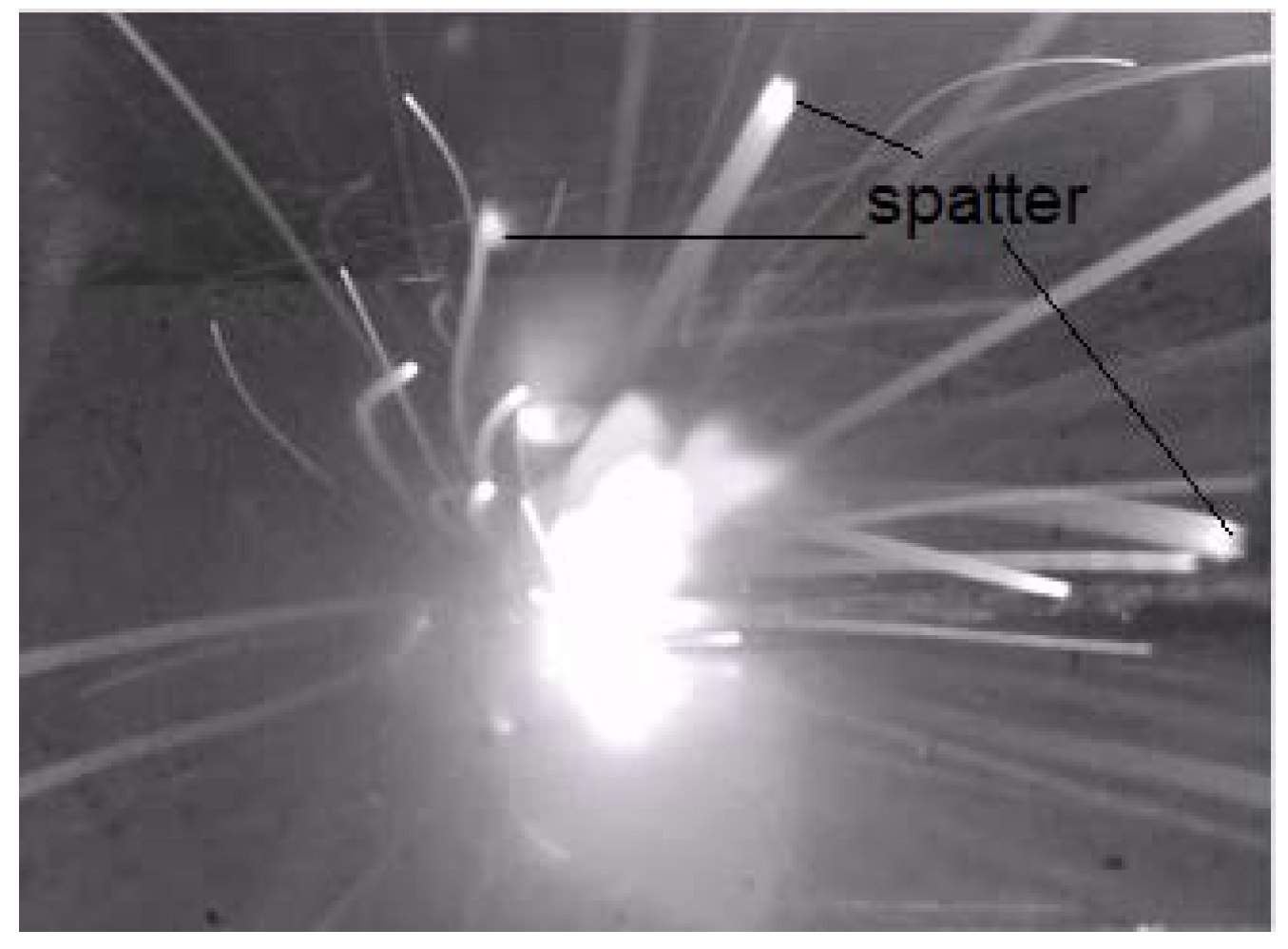

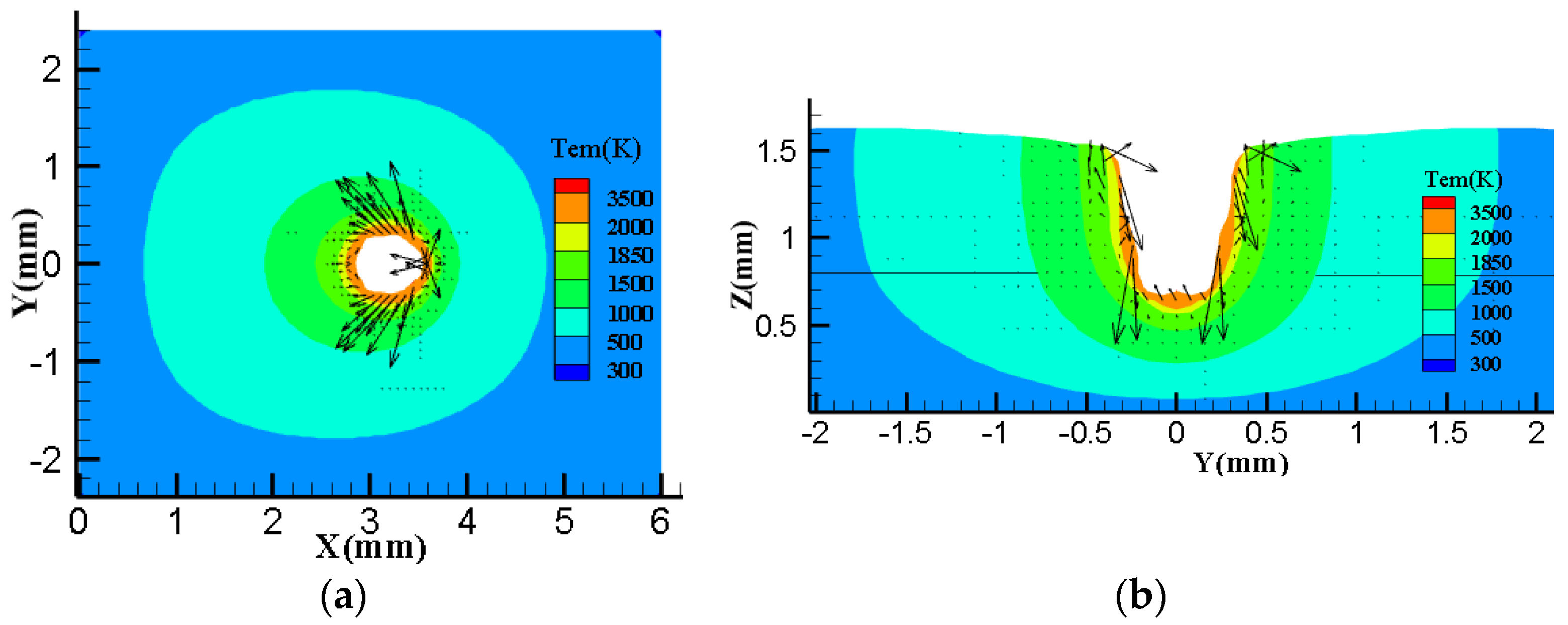

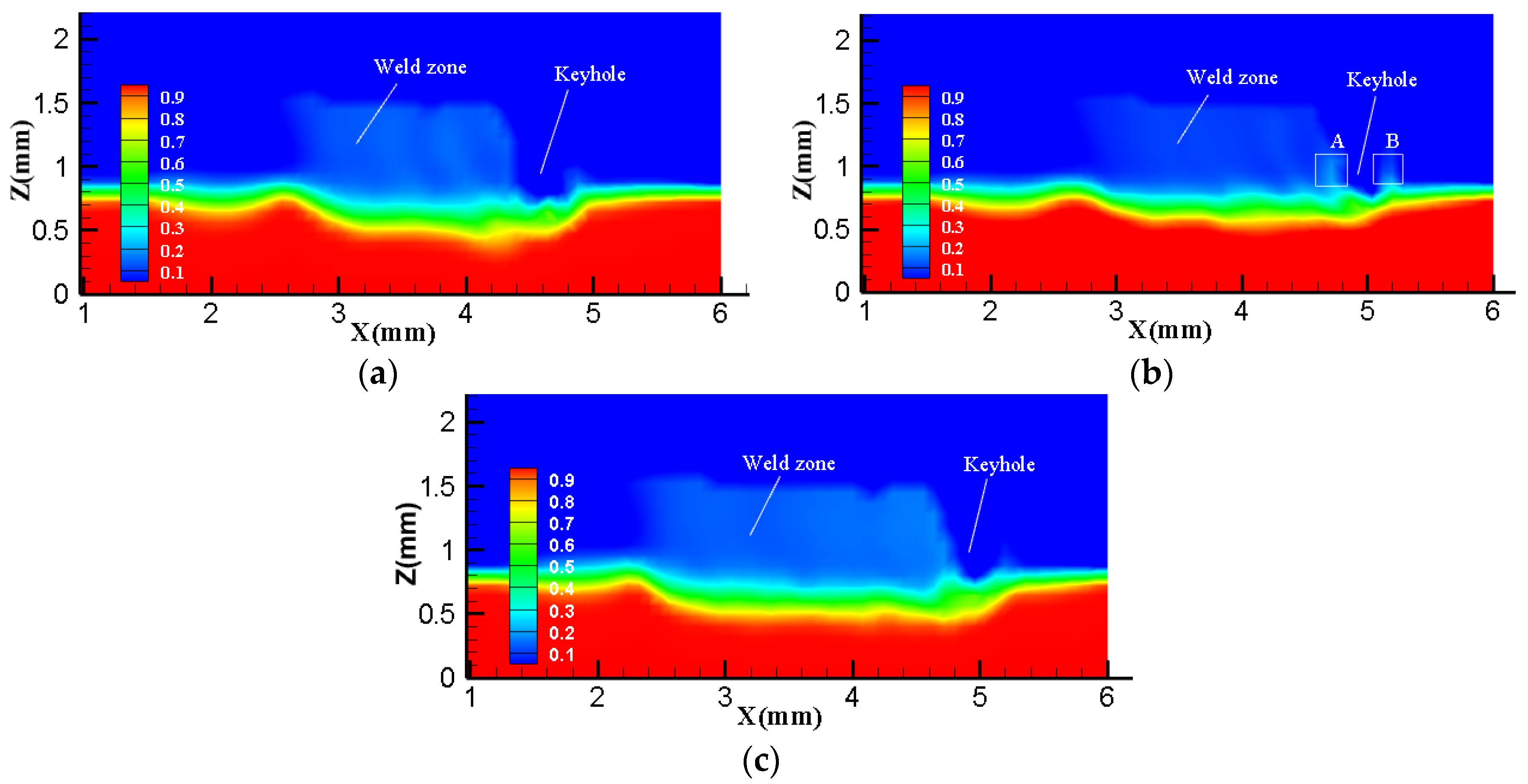

4.1. Keyhole Formation and Weld Pool Dynamics

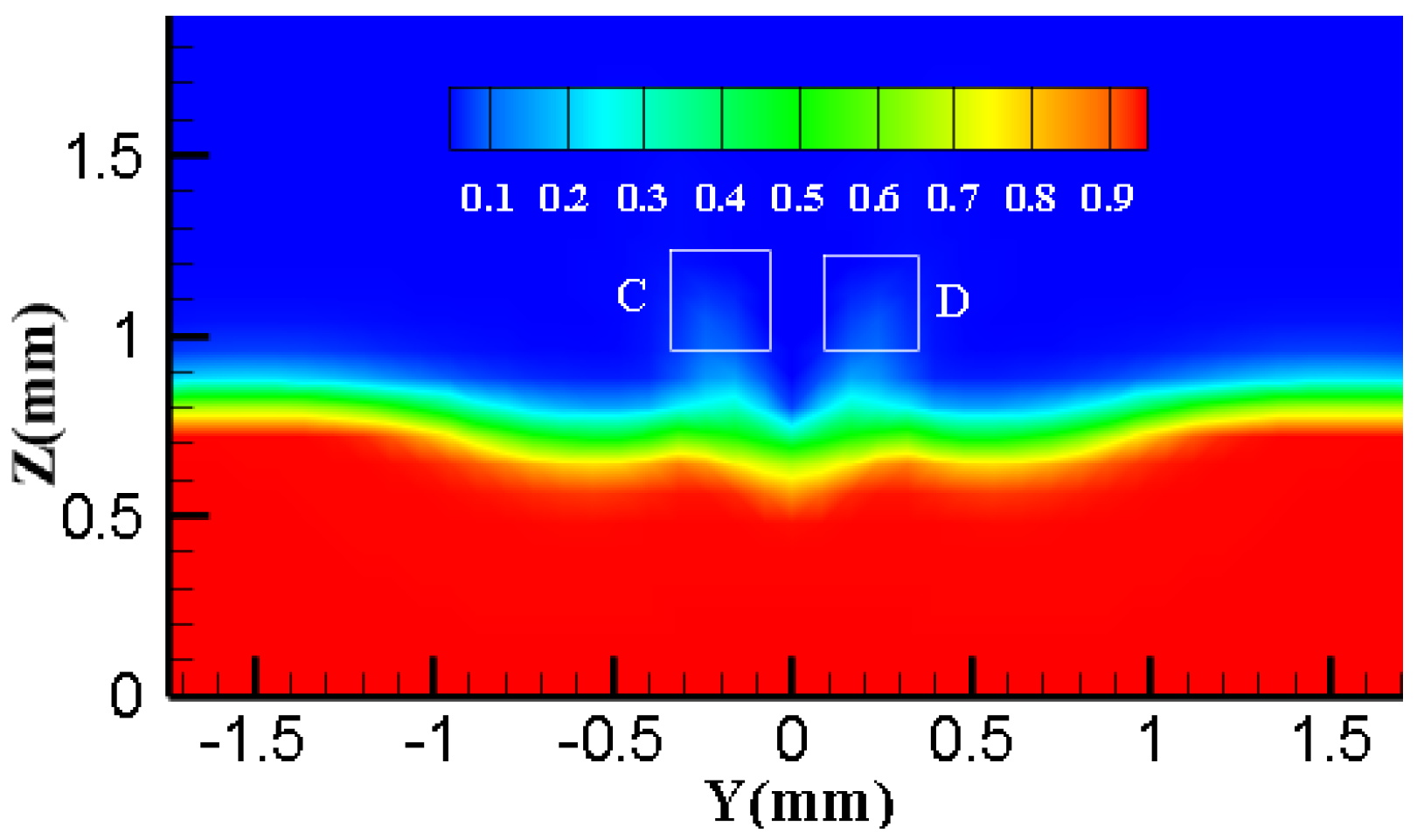

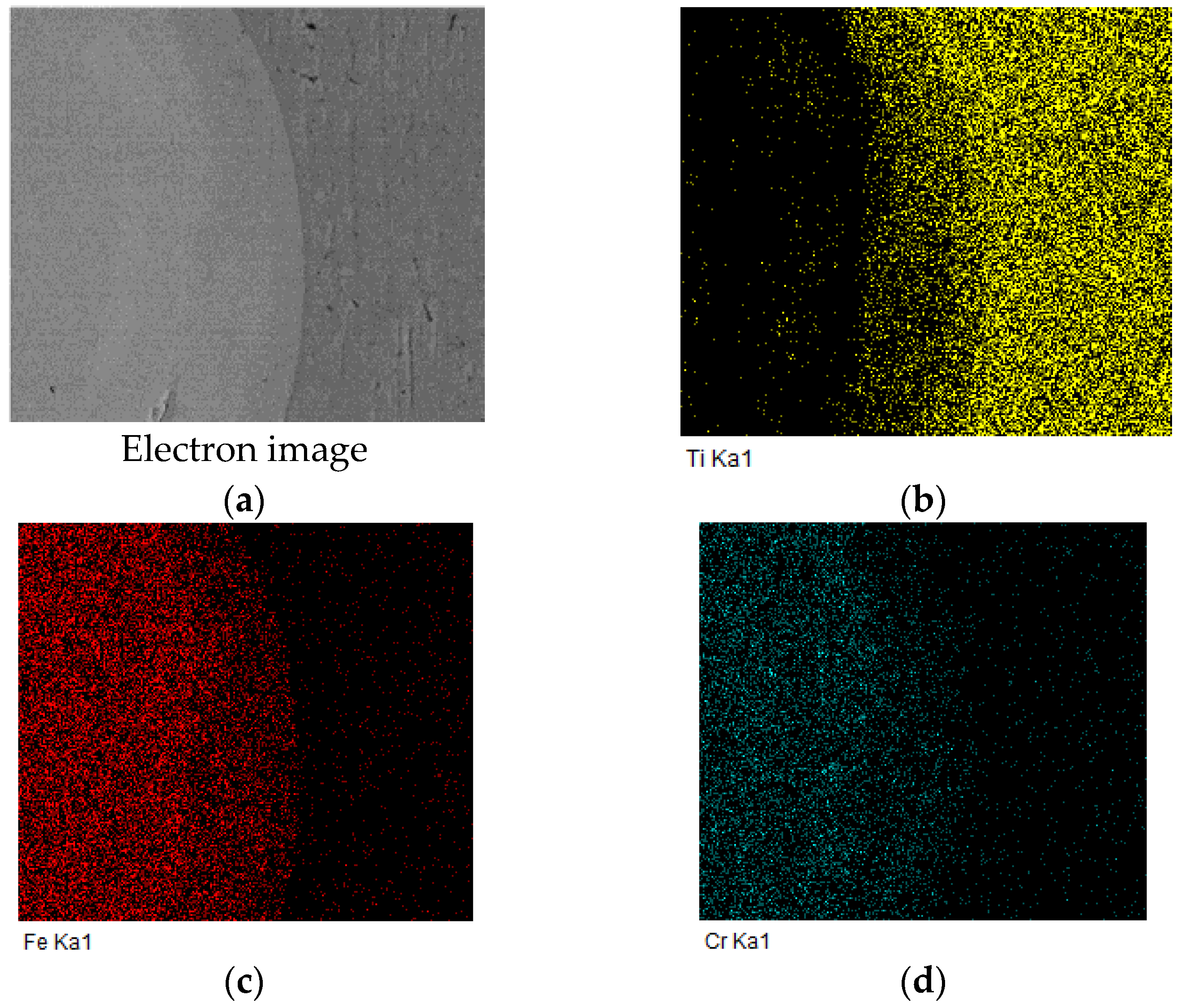

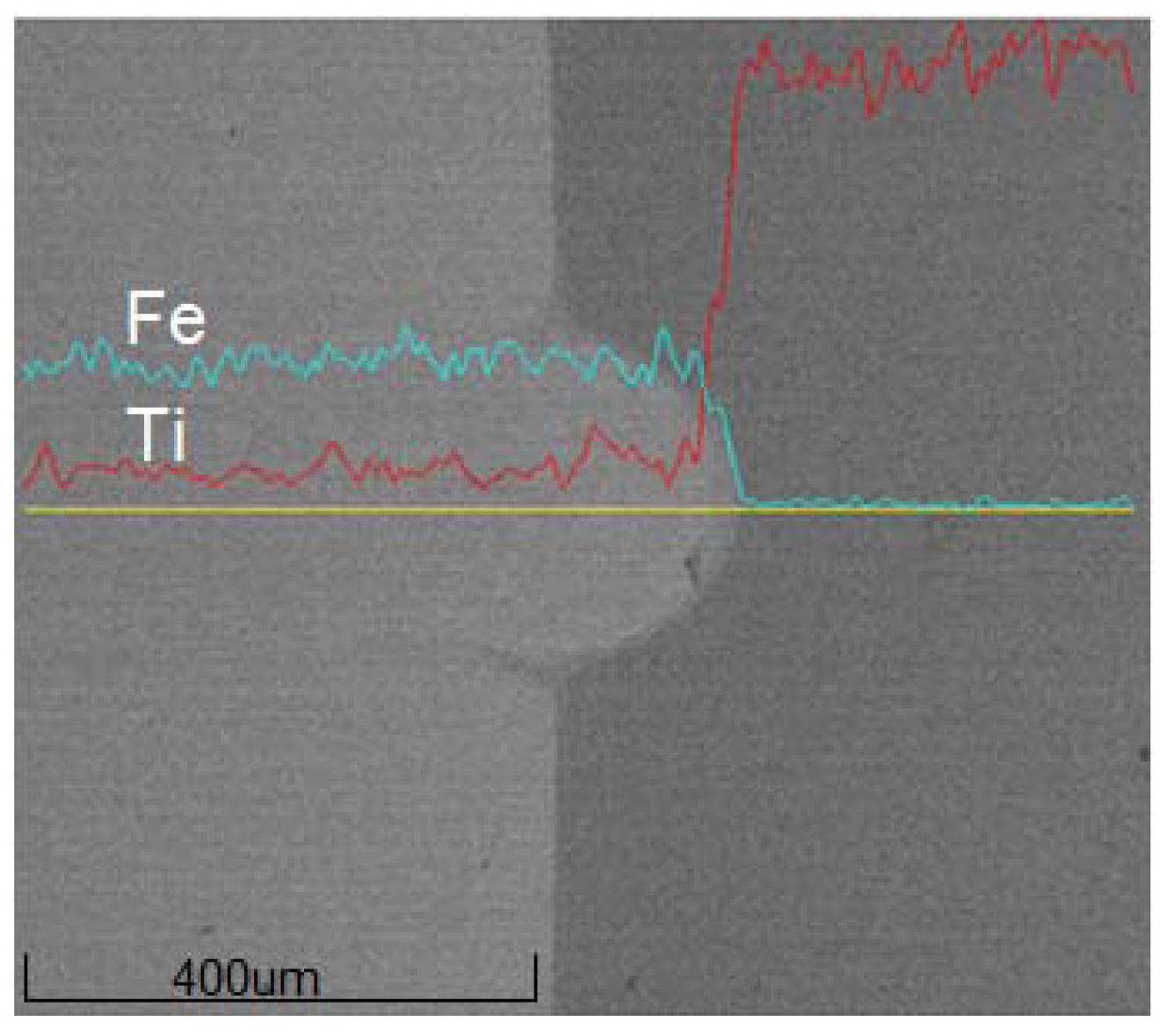

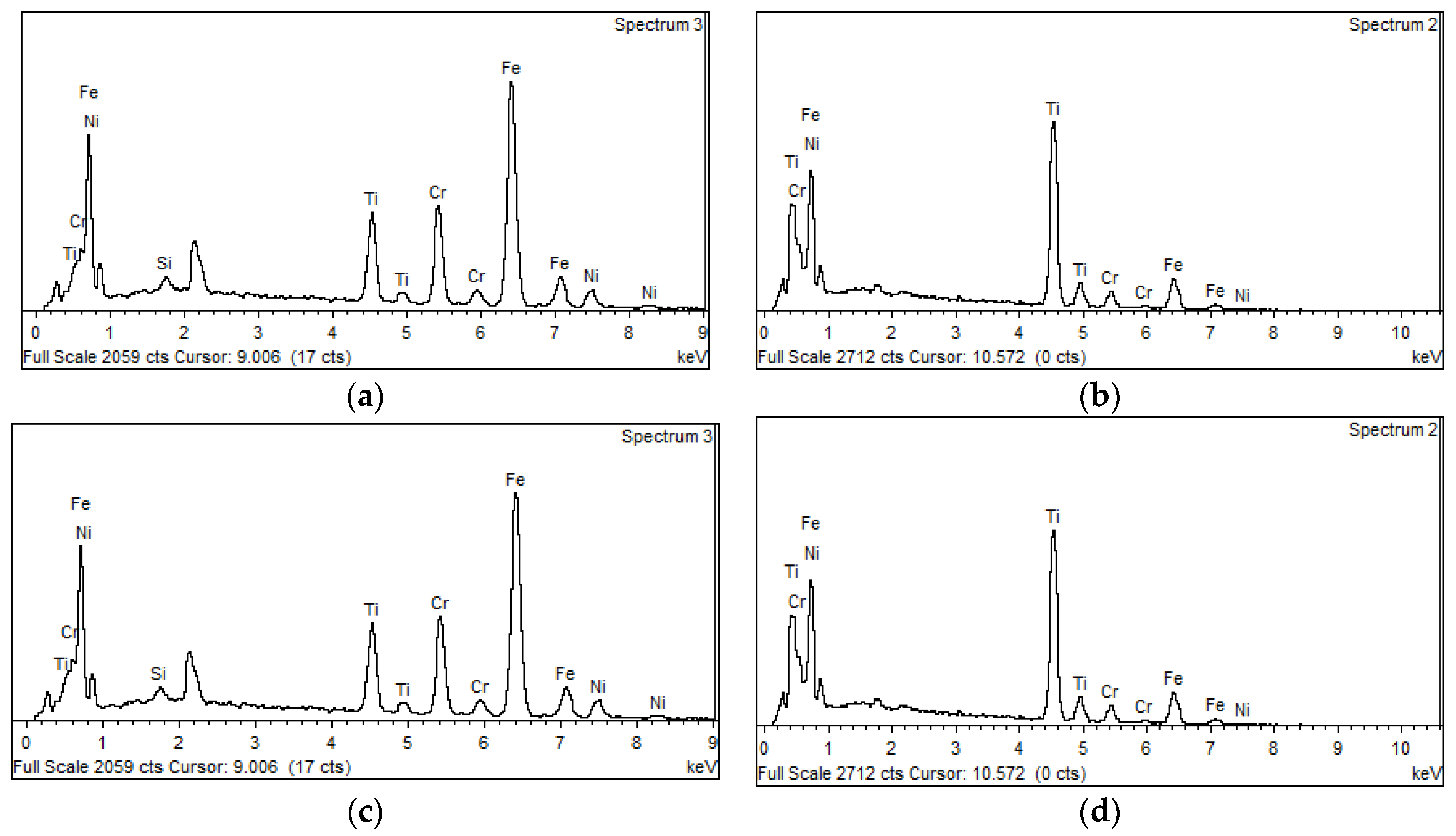

4.2. Mass Transfer

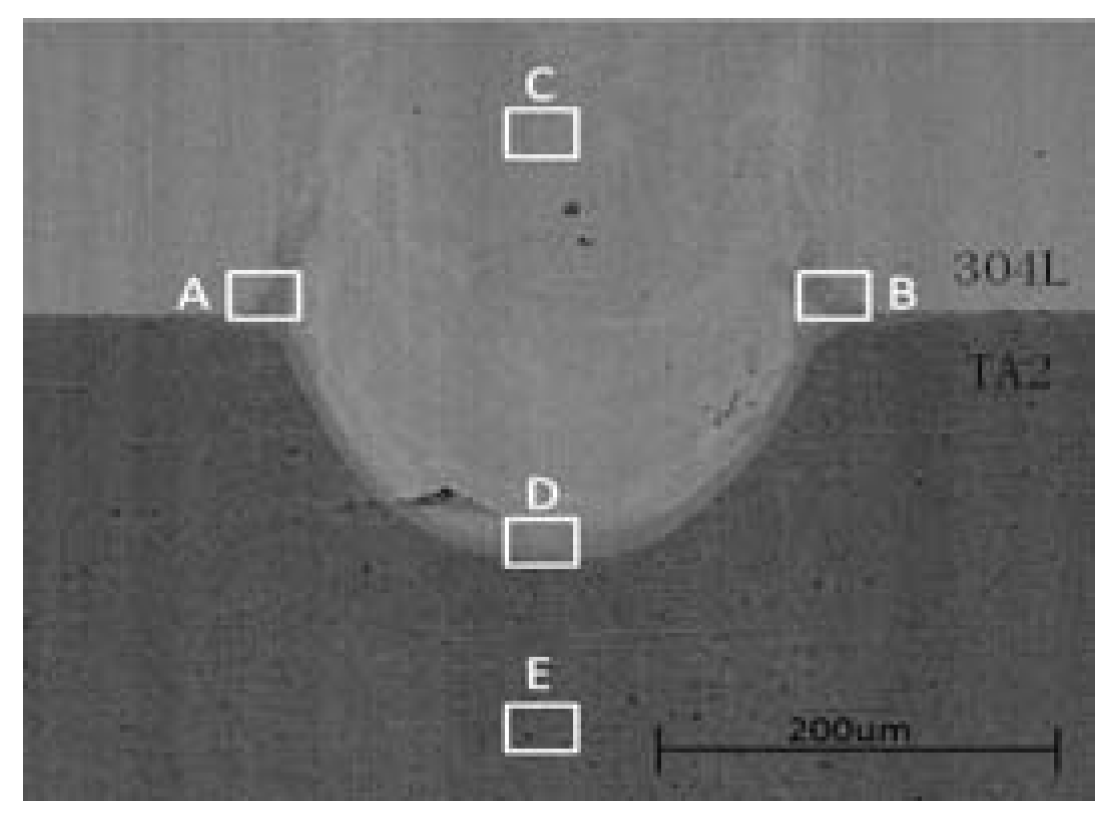

4.3. Validation of Simulation Results

5. Conclusions

- (1)

- Recoil pressure is the driving force for keyhole formation. The laser beam heats the workpiece through the keyhole wall, and the flow of the molten pool has an important effect on energy transmission.

- (2)

- Fluid flow and diffusion are two important mechanisms of mass transport. As the laser line energy increases, the thickness of the intermetallic reaction layer and the diffusion of elements in the weld will increase. Accurate control of laser energy is the key to reduce the formation of intermetallic compounds.

- (3)

- In the premise of ensuring connection strength and avoiding the burning of alloying elements, the depth of the keyhole in the lower region should be controlled accurately, and the melted metal in the lower region should also be prevented from entering the upper region in large quantities.

Author Contributions

Acknowledgments

Conflicts of Interest

Symbol

| Symbols | Meaning | Symbols | Meaning |

| Maximum heat flux density of the laser beam | Recoil pressure components along the x-axis | ||

| Radius | Volume fraction gradient along the x-axis | ||

| Waist radius | Volume fraction of cells | ||

| Heat flux density at radius | Mass source | ||

| Beam quality factor | Mass source | ||

| Longitudinal coordinate of the waist | Cell mass | ||

| Rayleigh constant | Liquid volume fraction of cells | ||

| Welding speed | A tiny number | ||

| Welding time | Porous medium constant | ||

| Density | Specific heat | ||

| Velocity vector | Mass fraction of the species | ||

| Mass source | Vector normal | ||

| Pressure | Convection heat transfer coefficient | ||

| Gravity constant | Ambient temperature | ||

| Dynamic viscosity | Boltzmann constant | ||

| Momentum source | Emissivity of radiation | ||

| Enthalpy | Speed of evaporation | ||

| Coefficient of thermal conductivity | Latent heat of evaporation | ||

| Temperature | Surface tension | ||

| Energy source | Surface curvature | ||

| Mass fraction of species | Temperature-dependent surface tension coefficient | ||

| Diffusion flux of species | Adjustment coefficient | ||

| Mass diffusion coefficient for species | Evaporation constant | ||

| Thermal diffusion coefficient | Temperature of the keyhole surface | ||

| Recoil pressure | Constant related to the material |

References

- Rai, R.; Elmer, J.W.; Palmer, T.A.; DebRoy, T. Heat transfer and fluid flow during keyhole mode laser welding of tantalum, Ti-6AI-4V, 304L stainless and vanadium. J. Phys. D Appl. Phys. 2007, 40, 5753–5766. [Google Scholar] [CrossRef]

- Rai, R.; Burgardt, P.; Milewski, J.O.; DebRoy, T. Heat transfer and fluid flow during electron beam welding of 21Cr-6Ni-9Mn steel and Ti-6AI-4V alloy. J. Phys. D Appl. Phys. 2009, 42, 025503. [Google Scholar] [CrossRef]

- Cho, W.I.; Na, S.J.; Thomy, C. Numerical simulation of molten pool dynamics in high power disk laser welding. J. Mater. Process. Technol. 2012, 212, 262–275. [Google Scholar] [CrossRef]

- Cho, J.H.; Na, S.J. Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole. J. Phys. D Appl. Phys. 2006, 39, 5372–5378. [Google Scholar] [CrossRef]

- Pang, S.Y.; Chen, L.L.; Zhou, J.X. A three dimensional sharp interface model for self consistent keyhole and weld pool dynamics in deep penetration laser welding. J. Phys. D Appl. Phys. 2011, 44, 025301. [Google Scholar] [CrossRef]

- Pang, S.Y.; Chen, W.D.; Zhou, J.X. Self consistent modeling of keyhole and weld pool dynamics in tandem dual beam laser welding of aluminum alloy. J. Mater. Process. Technol. 2015, 217, 131–143. [Google Scholar] [CrossRef]

- Pang, S.Y.; Chen, X.; Zhou, J.X. 3D transient multiphase model for keyhole, vapor plume, and weld pool dynamics in laser welding including the ambient pressure effect. Opt. Lasers Eng. 2015, 74, 47–58. [Google Scholar] [CrossRef]

- Wu, D.Y.; Hua, X.M.; Fang, L. Understanding of spatter formation in fiber laser welding of 5083 aluminum alloy. Int. J. Heat Mass Transfer. 2017, 113, 730–740. [Google Scholar] [CrossRef]

- Wu, D.Y.; Hua, X.M.; Huang, L.J. Numerical simulation of spatter formation during fiber laser welding of 5083 aluminum alloy at full penetration condition. Opt. Laser Technol. 2018, 100, 157–164. [Google Scholar] [CrossRef]

- Li, S.C.; Chen, G.Y.; Katayama, S.J. Relation between spatter formation and dynamic molten pool during high-power deep-penetration laser welding. Appl. Surf. Sci. 2014, 303, 481–488. [Google Scholar] [CrossRef]

- Hu, Y.W.; He, X.L.; Yu, G. Heat and mass transfer in dissimilar welding of stainless and nickel. Appl. Surf. Sci. 2012, 258, 5914–5922. [Google Scholar] [CrossRef]

- Zhao, S.S.; Yu, G.; H, X.L. Numerical simulation and experimental investigation of laser overlap welding of Ti6Ai4V and 42CrMo. J. Mater. Process. Technol. 2011, 211, 530–537. [Google Scholar] [CrossRef]

- Esfahani, N.M.R.; Coupland, J.; Marimuthu, S. Numerical simulation of alloy composition in dissimilar laser welding. J. Mater. Process. Technol. 2015, 224, 135–142. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Jouvard, J.M. Multiphysical modeling of dissimilar welding via interlayer. J. Mater. Process. Technol. 2011, 211, 1796–1803. [Google Scholar] [CrossRef]

- Iseav, V.I.; Cherepanov, A.N.; Shapeev, V.P. Numerical study of heat models of laser welding of dissimilar metals with an intermediate insert. Int. J. Heat Mass Transfer. 2016, 99, 711–720. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, J.M.; Jouvard, J.M. The simulation of morphology of dissimilar copper-steel electron beam welds using level set method. Comput. Mater. Sci. 2010, 48, 827–836. [Google Scholar] [CrossRef]

- Siegman, A.E. Defining, measuring, and optimizing laser beam quality. SPIE 1990, 1224, 2–13. [Google Scholar]

- Zhou, J.; Tsai, H.L. Investigation of mixing and diffusion processes in hybrid spot laser-MIG keyhole welding. J. Phys. D Appl. Phys. 2009, 42, 095502. [Google Scholar] [CrossRef]

- Semak, V.; Matsunawa, A. The role of recoil pressure in energy balance during laser materials processing. J. Phys. D Appl. Phys. 1997, 30, 2541–22252. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Niu, W.C.; Zhang, B. Modelling of keyhole dynamics and porosity formation considering the adaptive keyhole shape and three-phase coupling during deep-penetration laser welding. J. Phys. D Appl. Phys. 2011, 44, 485302. [Google Scholar] [CrossRef]

- Tan, W.D.; Shin, Y.C. Analysis of multi-phase interaction and its effects on keyhole dynamics with a multi-physics numerical model. J. Phys. D Appl. Phys. 2014, 47, 345501. [Google Scholar] [CrossRef]

- Cho, J.H.; Farson, D.F.; Hollis, K.J. Numerical analysis of weld pool oscillation in laser welding. J. Mech. Sci. Technol. 2015, 29, 1715–1722. [Google Scholar] [CrossRef]

- Naito, Y.; Katayama, S.; Matsunawa, A. Keyhole behavior and liquid flow in molten pool during laser arc hybrid welding. Proc. SPIE. 2003, 3888, 34–45. [Google Scholar] [CrossRef]

- Yang, J.; Li, Y.L.; Zhang, H. Microstructure and mechanical properties of pulsed laser welded Al/steel dissimilar joint. Trans. Nonferr. Met. Soc. China 2016, 26, 994–1002. [Google Scholar] [CrossRef]

- Zhou, K.; Cai, L.L. Online Nugget Diameter Control System for Resistance Spot Welding. Int. J. Adv. Manuf. Technol. 2013, 68, 2571–2588. [Google Scholar] [CrossRef]

- Cui, L.; Chen, B.X.; Qian, W. Microstructures and mechanical properties of dissimilar Al/Steel butt joints produced by autogenous laser keyhole welding. Metals 2017, 7, 492. [Google Scholar] [CrossRef]

- Xue, Z.Q.; Hu, S.S.; Lee, D.K. Molten pool characterization of laser lap welded copper and aluminum. J. Phys. D Appl. Phys. 2013, 46, 495501. [Google Scholar] [CrossRef]

- Kobayashi, S.; Yakou, T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment. Mater. Sci. Eng. A 2002, 338, 44–53. [Google Scholar] [CrossRef]

| 304L | |||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | Fe |

| ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 8.00~11.00 | 18.00~20.00 | balance |

| TA2 | |||||||

| Fe | C | N | H | O | Si | Ti | |

| ≤0.30 | ≤0.10 | ≤0.05 | ≤0.015 | ≤0.25 | ≤0.015 | balance | |

| Power (W) | Welding Speed (m/min) | Beam Defocus (mm) | Gas Flux Rate (L/min) |

|---|---|---|---|

| 500 | 3.2 | 0 | 15 |

| 500 | 3.6 | 0 | 15 |

| 520 | 3.6 | 0 | 15 |

| Physical Properties | 304L | TA2 |

|---|---|---|

| Density (kg/m3) | 7000 | 4110 |

| Specific heat (J/(kg·K)) | 712 | 594 |

| Heat conductivity (W/(m·K)) | 29 | 40 |

| Dynamic viscosity (N·s/m2) | 0.007 | 0.005 |

| Boiling point (K) | 3100 | 3315 |

| Surface tension (N/m) | 1.4 | 1.65 |

| Surface tension temperature coefficient (N (m·K)) | −4.9 × 10−4 | −2.6 × 10−4 |

| Coefficient of thermal expansion (/K) | 1.96 × 10−5 | 1.1 × 10−5 |

| Melting latent (J/kg) | 2.47 × 105 | 3.89 × 105 |

| Evaporation latent (J/kg) | 6.34 × 106 | 8.88 × 106 |

| Nomenclature | Value |

|---|---|

| Laser beam radius at focus (mm) | 0.2 |

| Planck constant (J·s) | 5.67 × 10−8 |

| Stefan-Boltzmann constant (W/(m2·K4)) | 1.38 × 10−23 |

| Ambient temperature (K) | 300 |

| Density of plasma (kg/m3) | 0.06 |

| Specific heat of plasma (J/(kg·K)) | 610 |

| Heat conductivity of plasma (W/(m·K)) | 3.72 |

| Convective heat transfer coefficient (W/(m2·K)) | 60 |

| Radiation Emissivity | 0.4 |

| Gas constant (J/(kg·mol)) | 8.3 × 103 |

| Element | A | B | C | D | E |

|---|---|---|---|---|---|

| Fe | 44.45 | 45.39 | 62.50 | 37.73 | 0 |

| Ti | 33.22 | 41.82 | 11.23 | 40.71 | 100 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Zhang, H.; Feng, Y.; Luo, B. 3D Multiphysical Modelling of Fluid Dynamics and Mass Transfer in Laser Welding of Dissimilar Materials. Metals 2018, 8, 443. https://doi.org/10.3390/met8060443

Wu J, Zhang H, Feng Y, Luo B. 3D Multiphysical Modelling of Fluid Dynamics and Mass Transfer in Laser Welding of Dissimilar Materials. Metals. 2018; 8(6):443. https://doi.org/10.3390/met8060443

Chicago/Turabian StyleWu, Jiazhou, Hua Zhang, Yan Feng, and Bingbing Luo. 2018. "3D Multiphysical Modelling of Fluid Dynamics and Mass Transfer in Laser Welding of Dissimilar Materials" Metals 8, no. 6: 443. https://doi.org/10.3390/met8060443

APA StyleWu, J., Zhang, H., Feng, Y., & Luo, B. (2018). 3D Multiphysical Modelling of Fluid Dynamics and Mass Transfer in Laser Welding of Dissimilar Materials. Metals, 8(6), 443. https://doi.org/10.3390/met8060443