Study on the Size Effects of H-Shaped Fusion Zone of Fiber Laser Welded AZ31 Joint

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Welding Test

2.2. Microstructure Examination and Microhardness Test

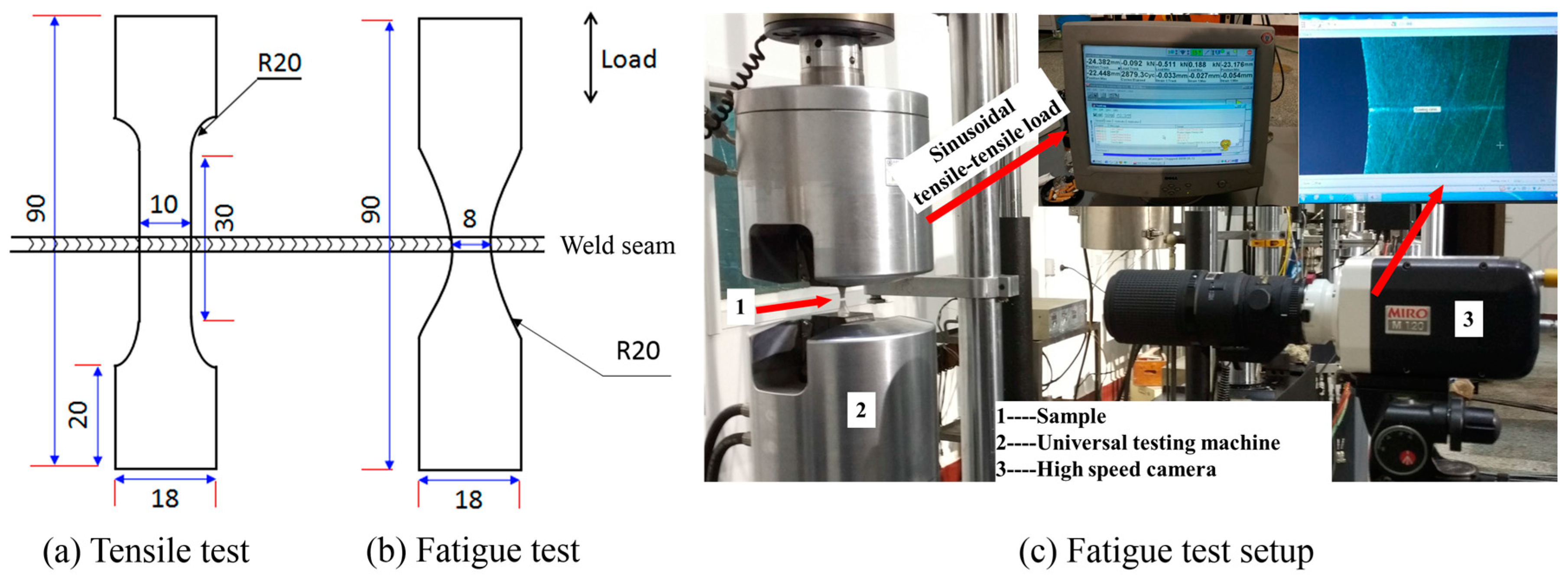

2.3. Mechanical Property Test

3. Results and Discussion

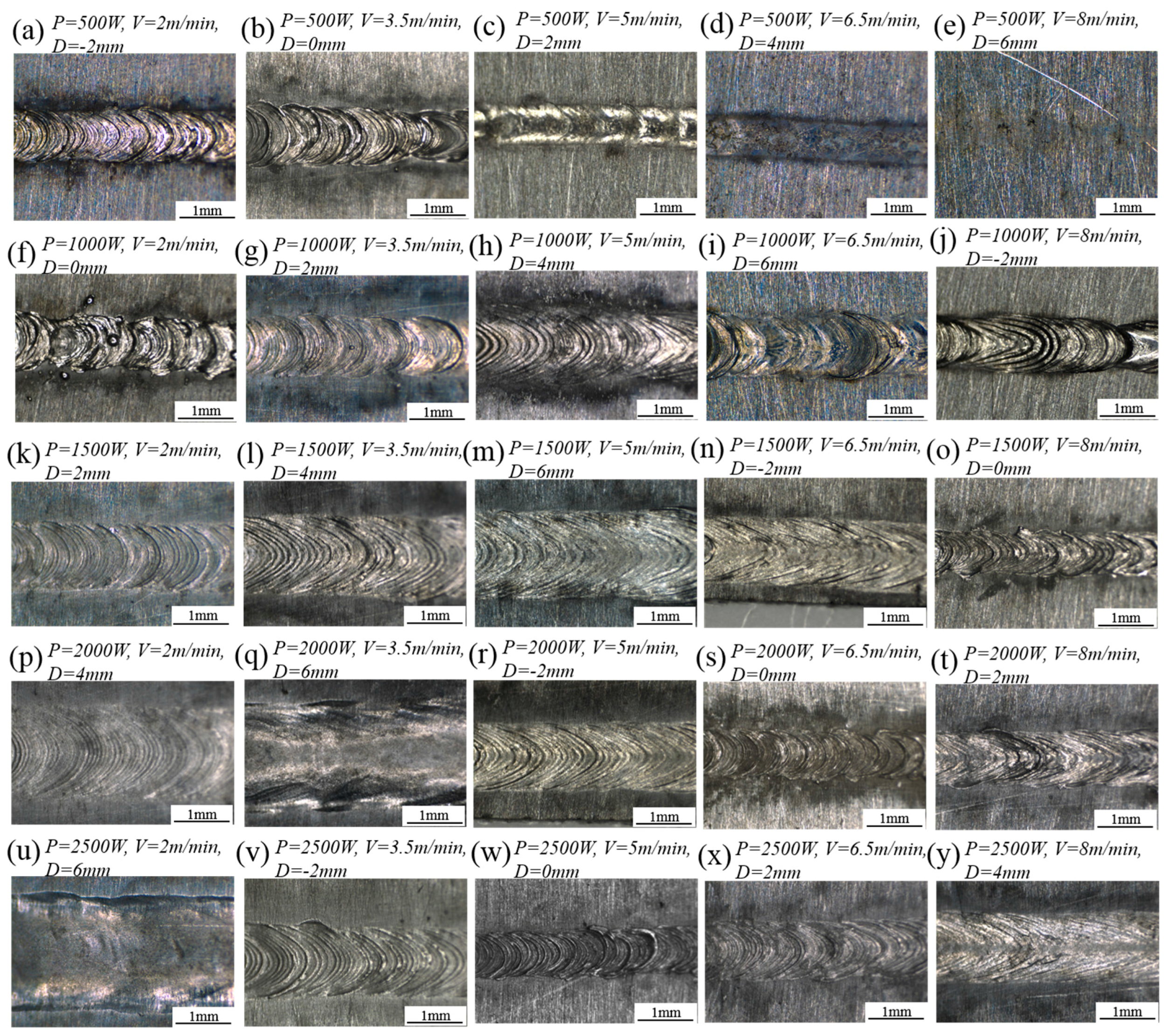

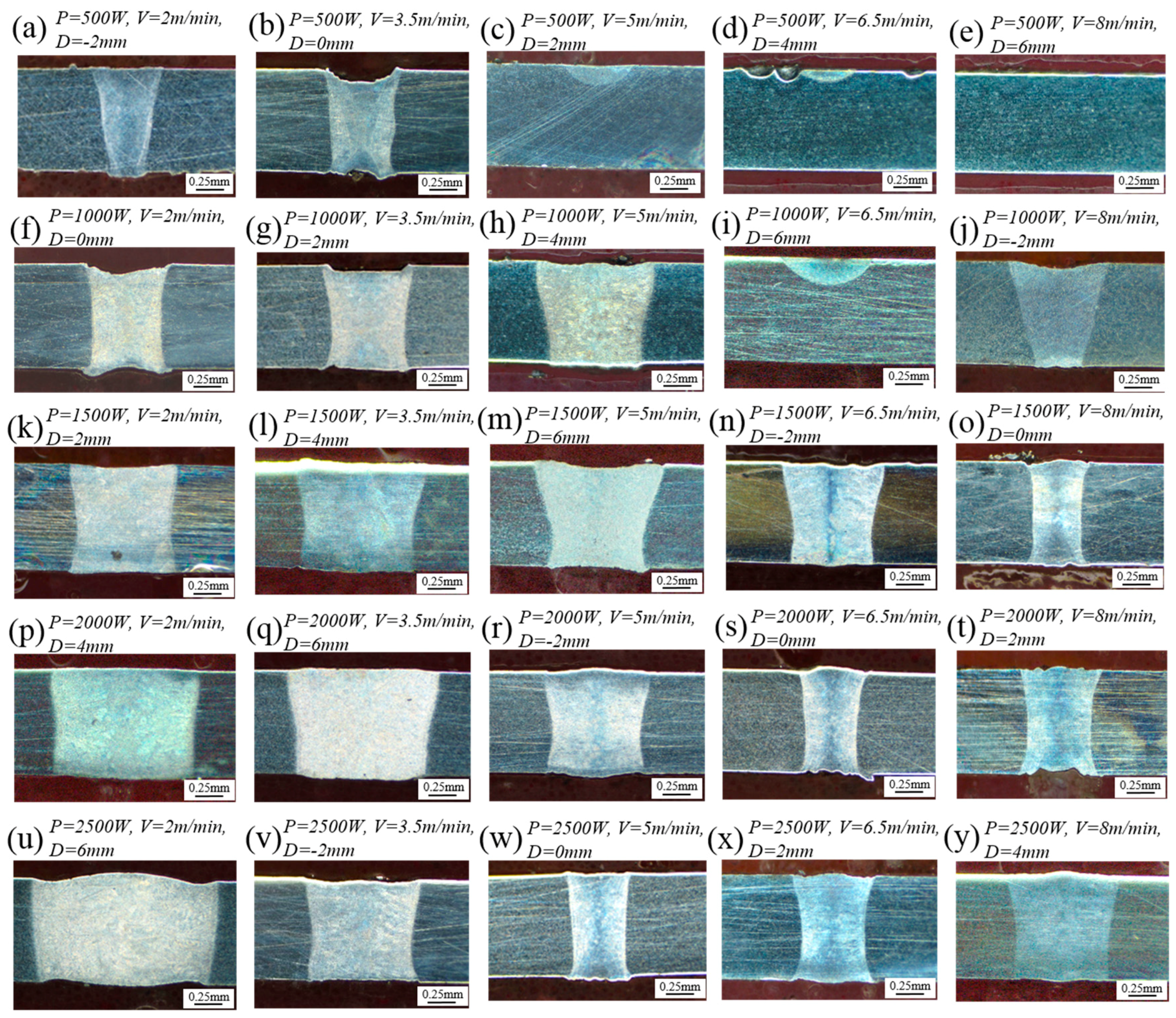

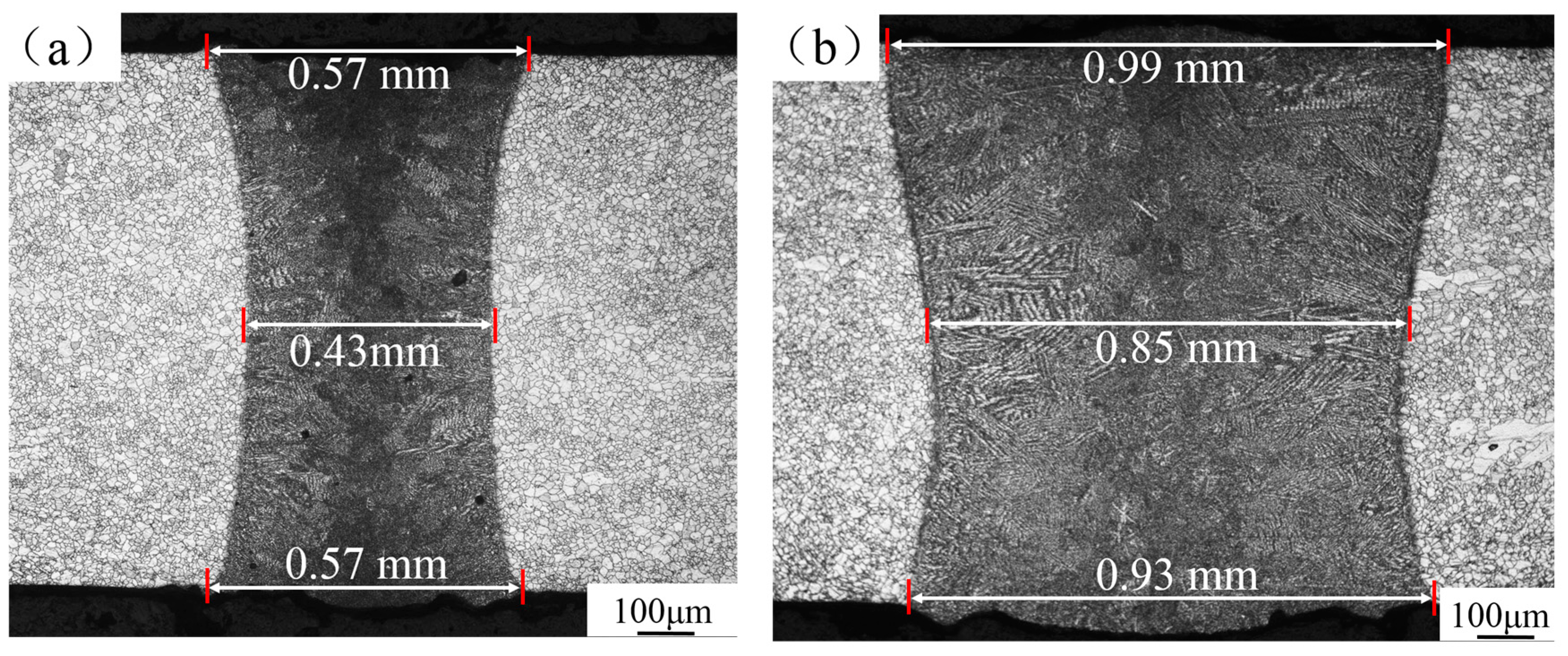

3.1. Effect of Parameters on Weld Shape

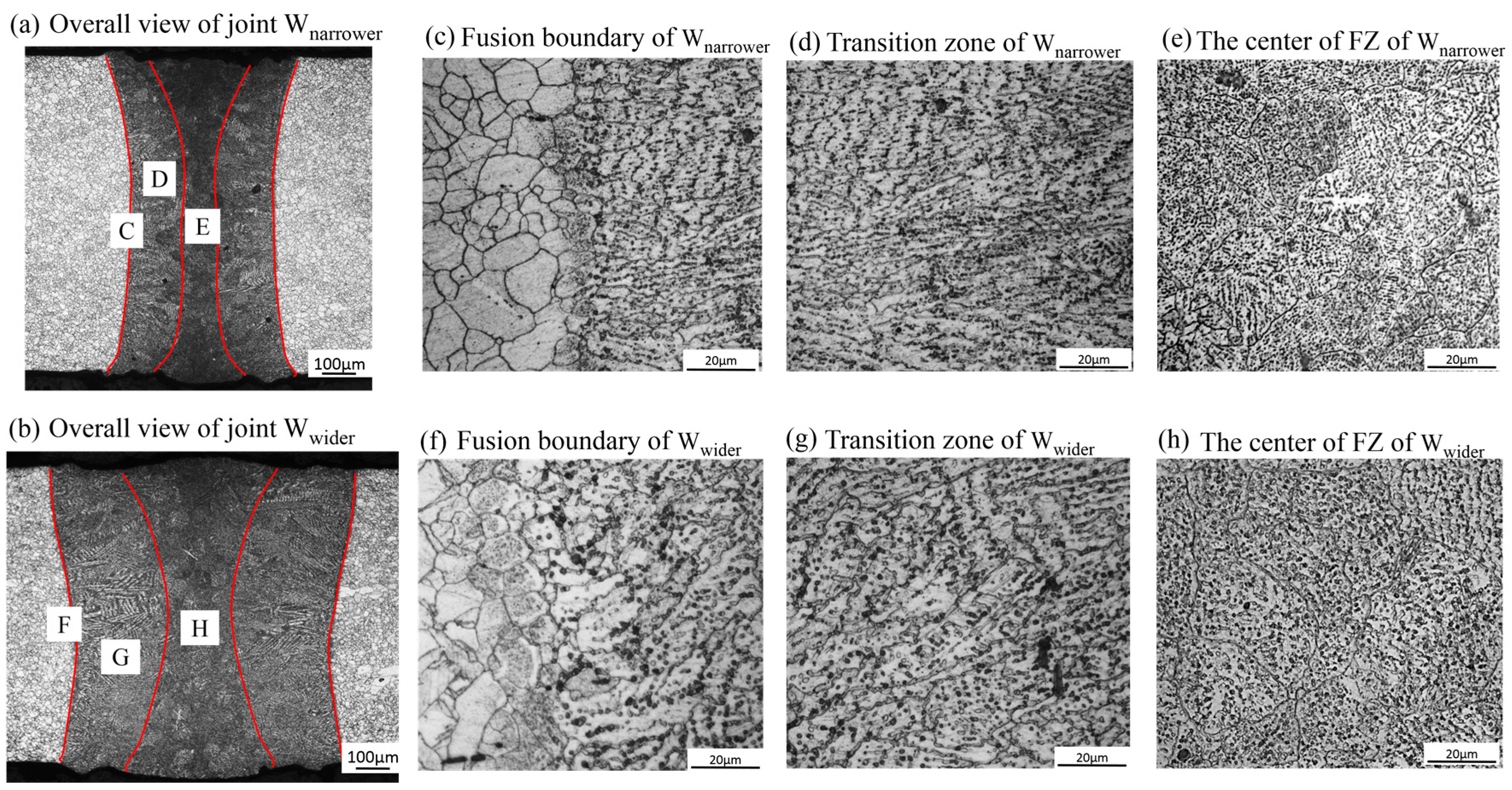

3.2. Microstructure

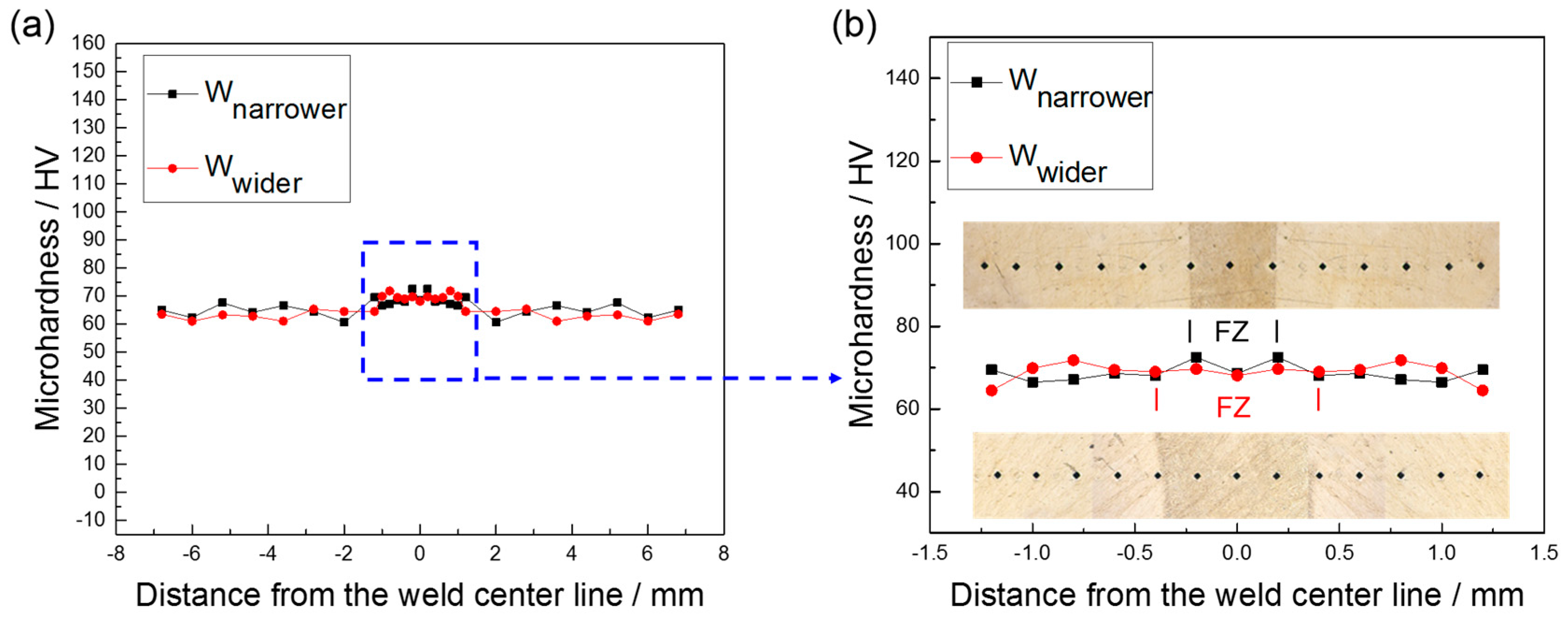

3.3. Microhardness

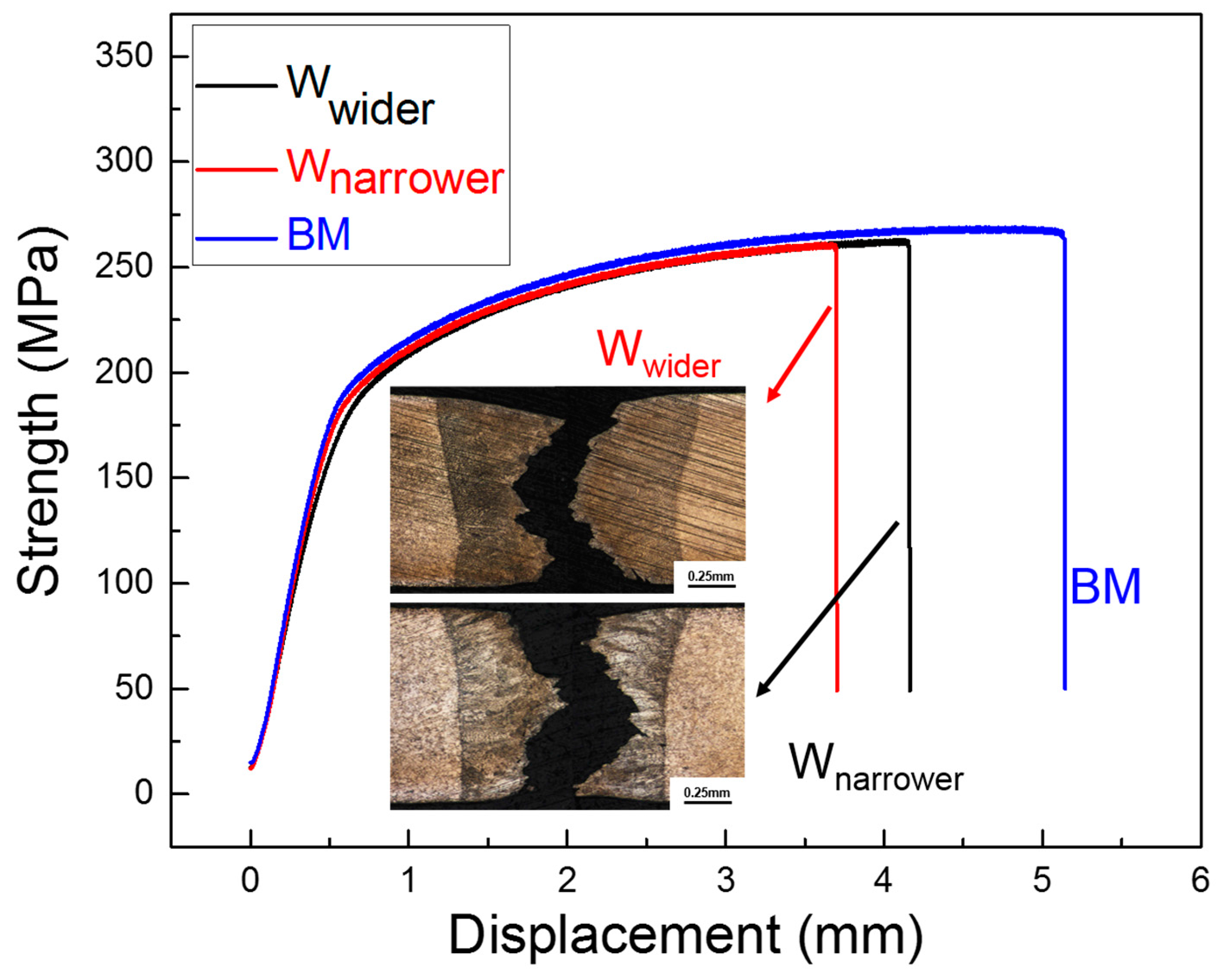

3.4. Tensile Test

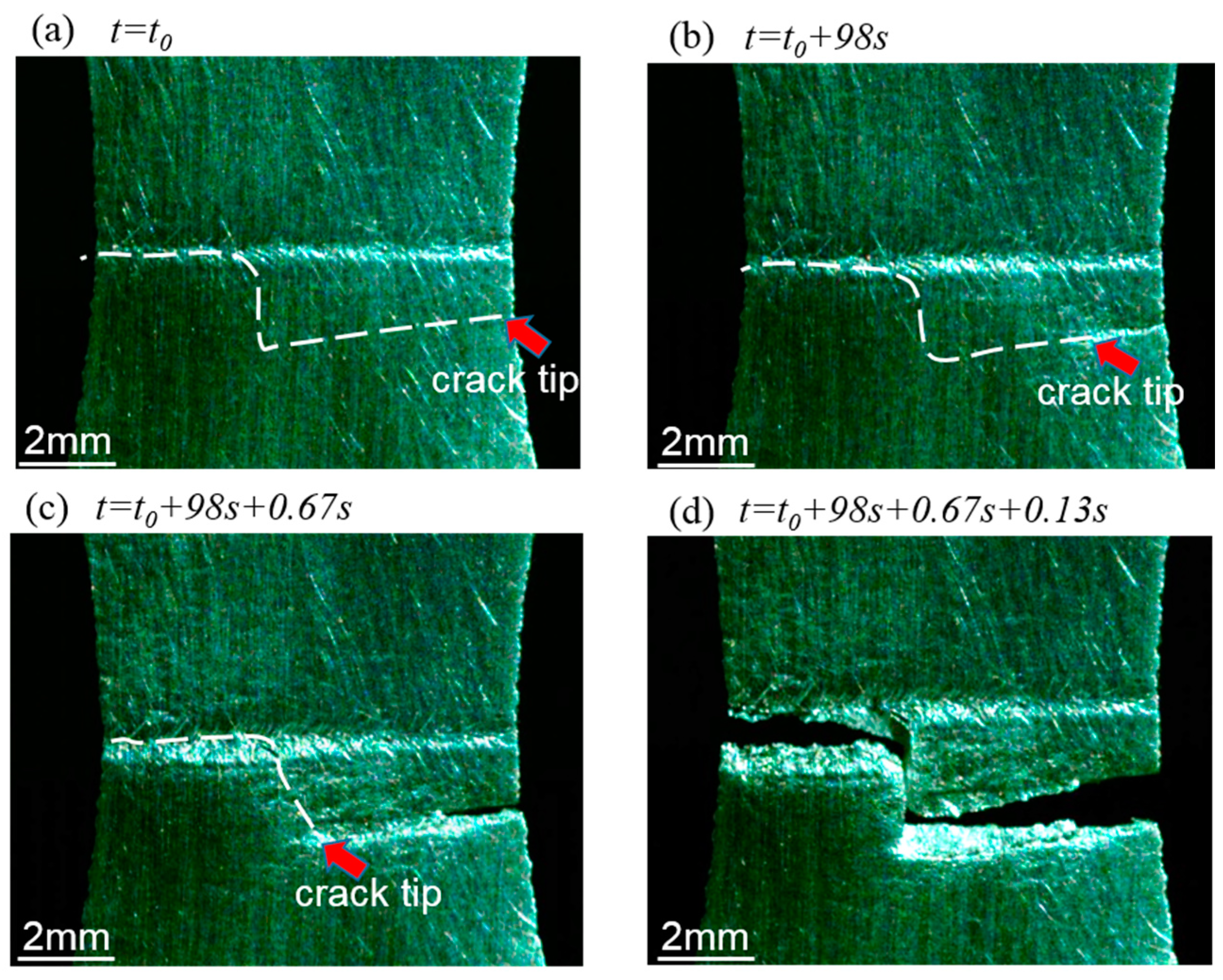

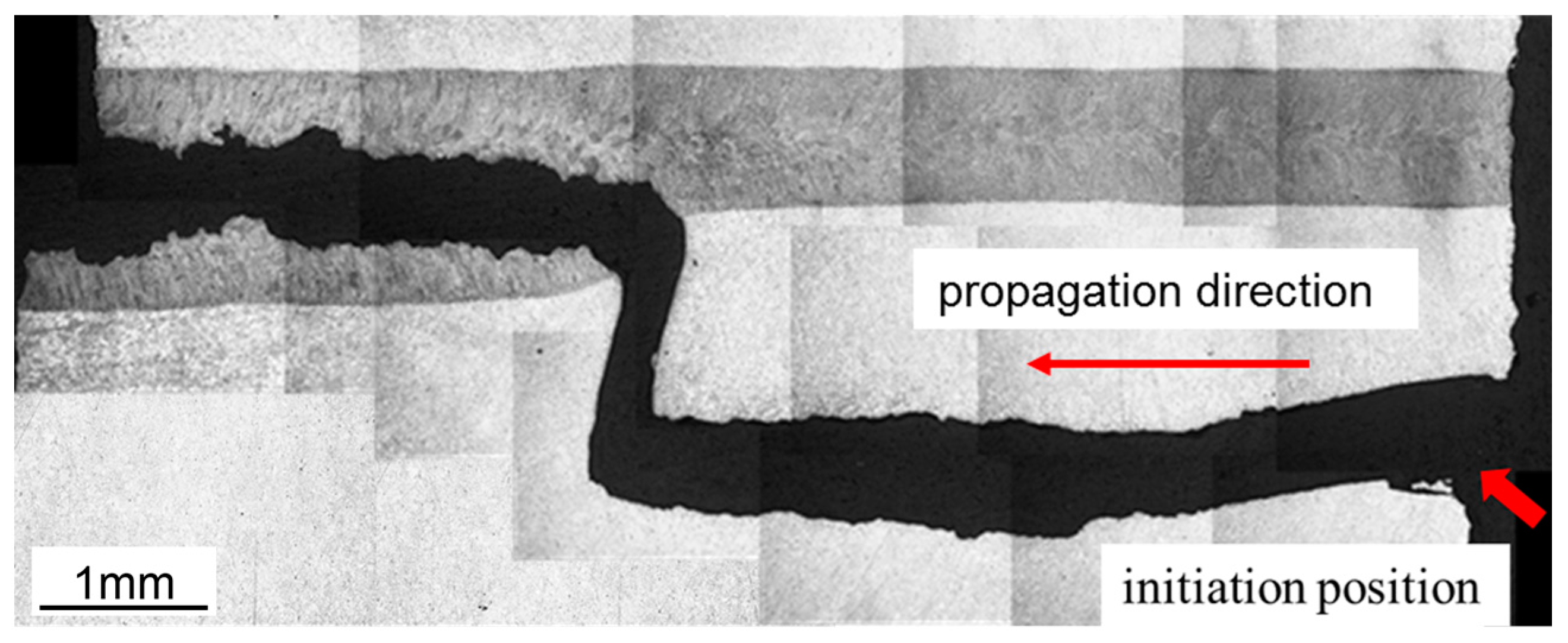

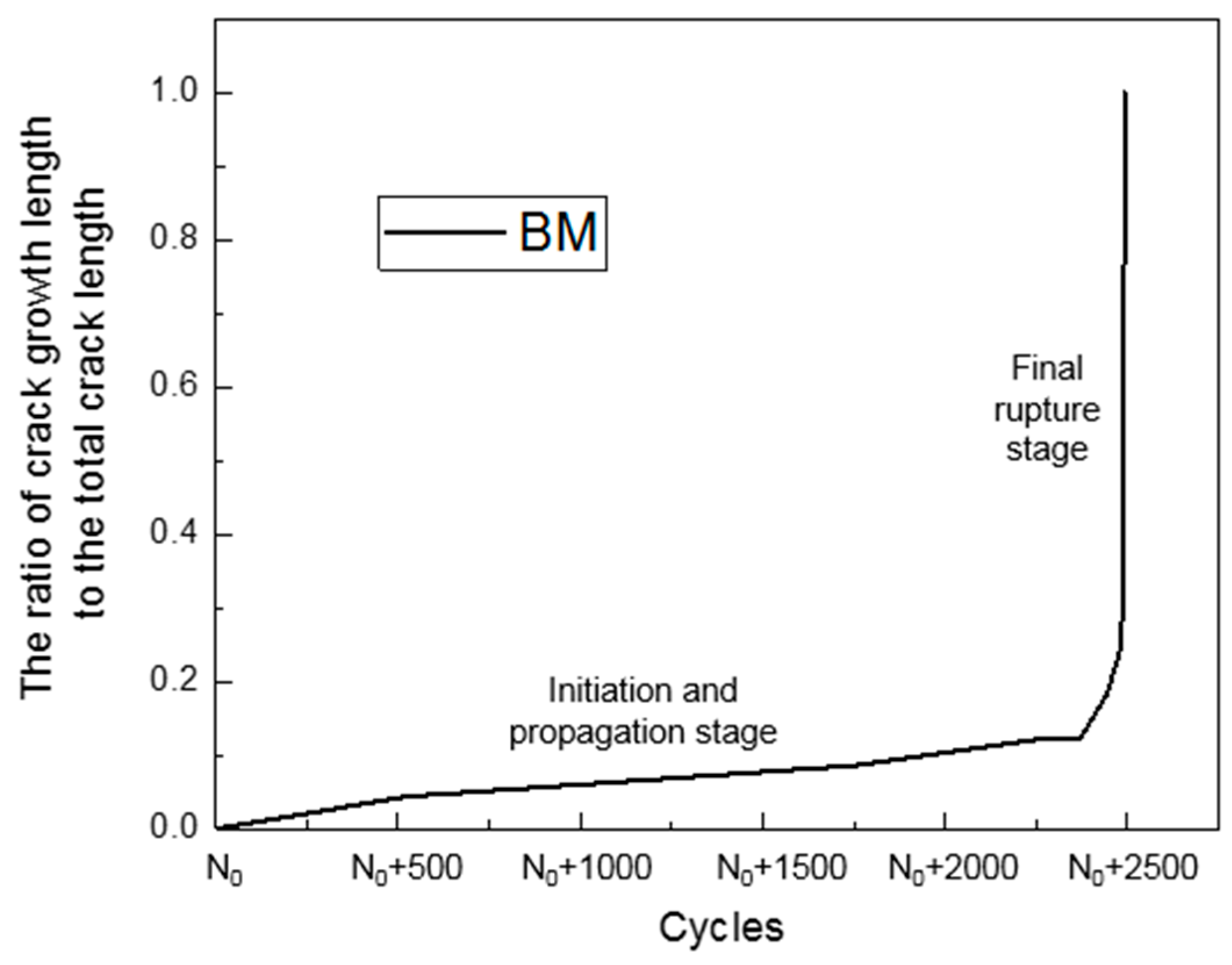

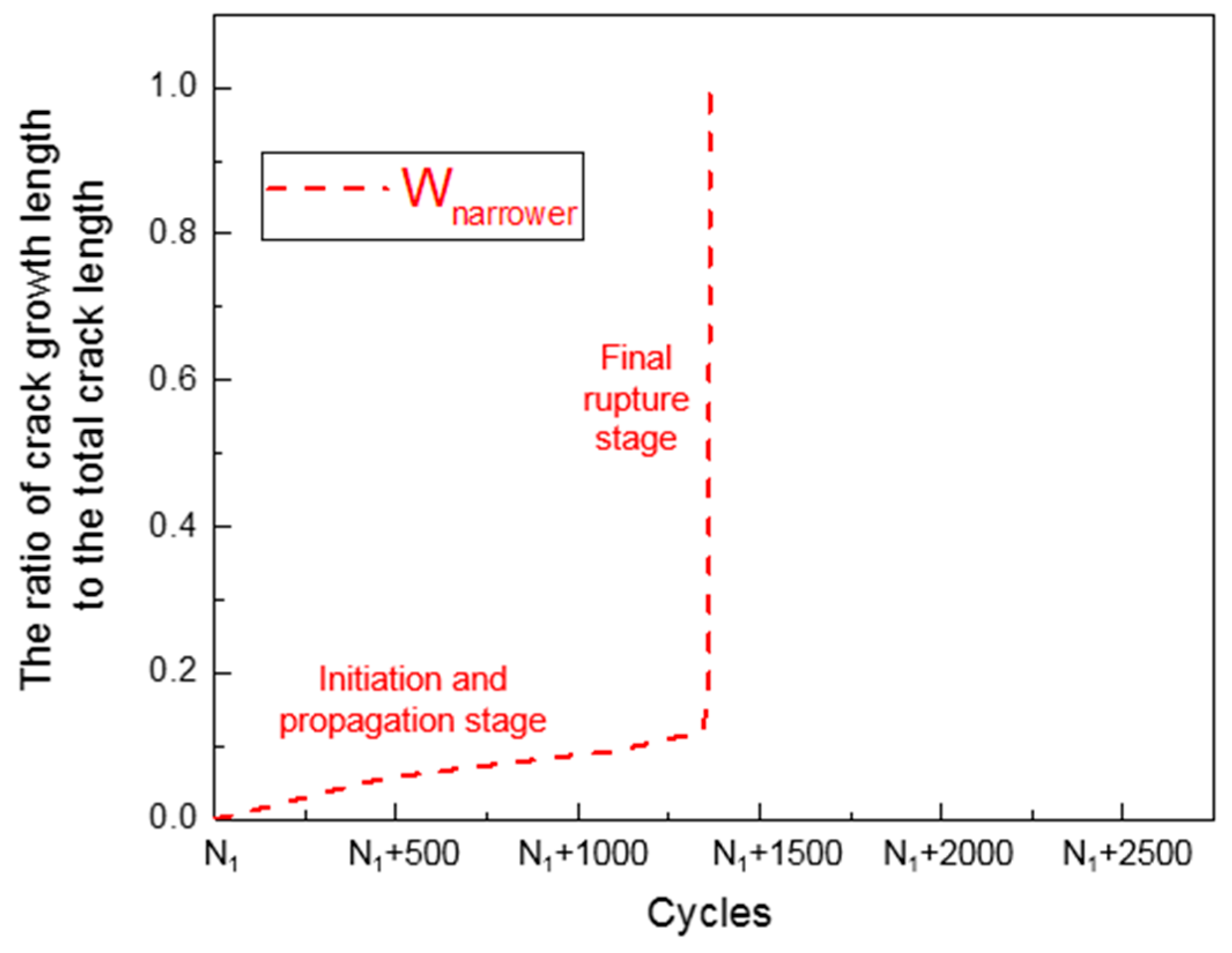

3.5. Fatigue Test

4. Conclusions

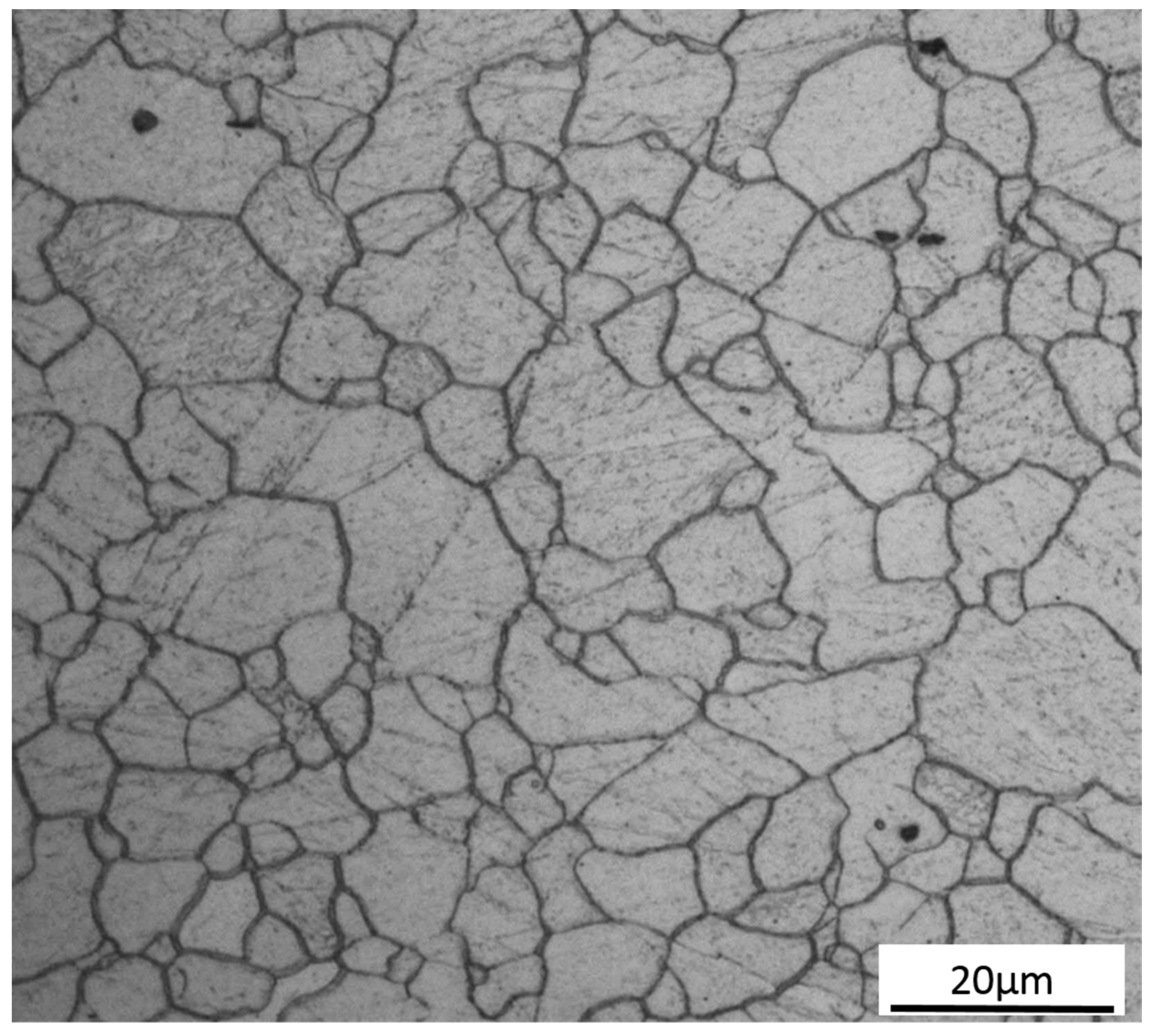

- The fusion zone of the welded joint is composed of two different zones. The transition zone is composed of columnar grains and are distributed on both sides of the fusion zone. The center of the fusion zone is composed of equiaxed grains. Many precipitated phases were found on the fusion zone. The equiaxed grains next to the fusion boundary on the base metal side did not show obvious growth. The fusion zones of the two welded joints show similar microhardness.

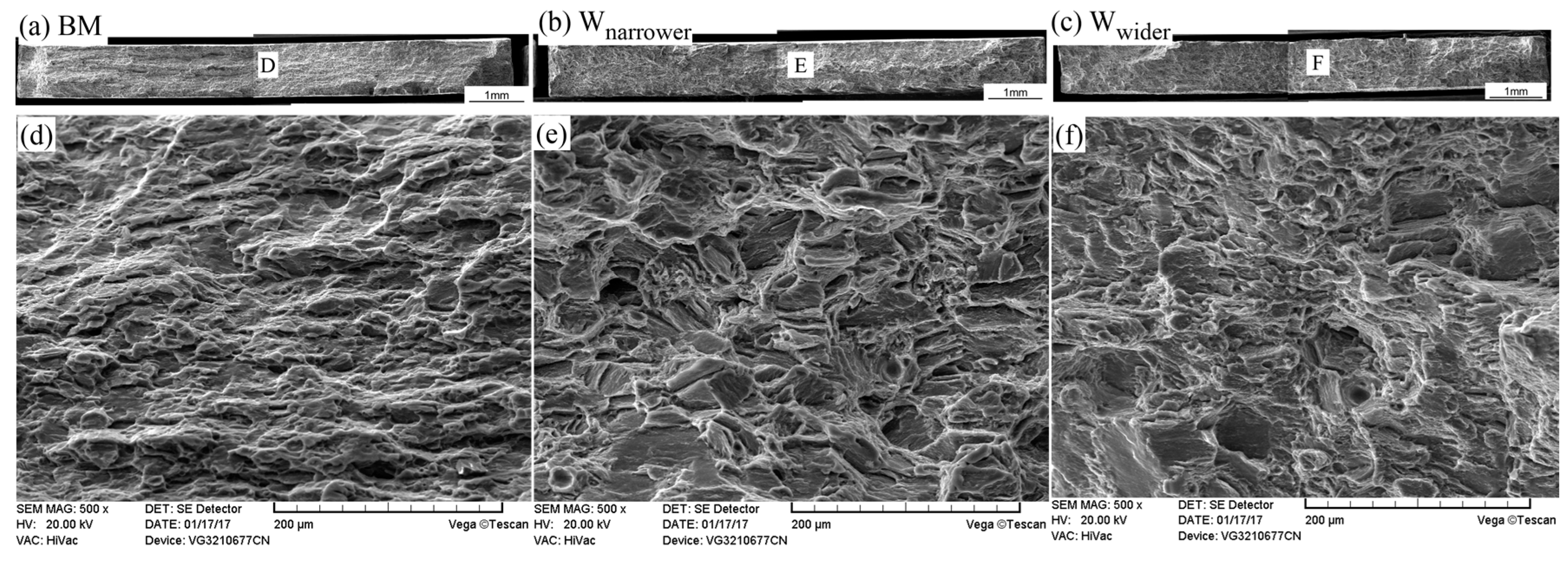

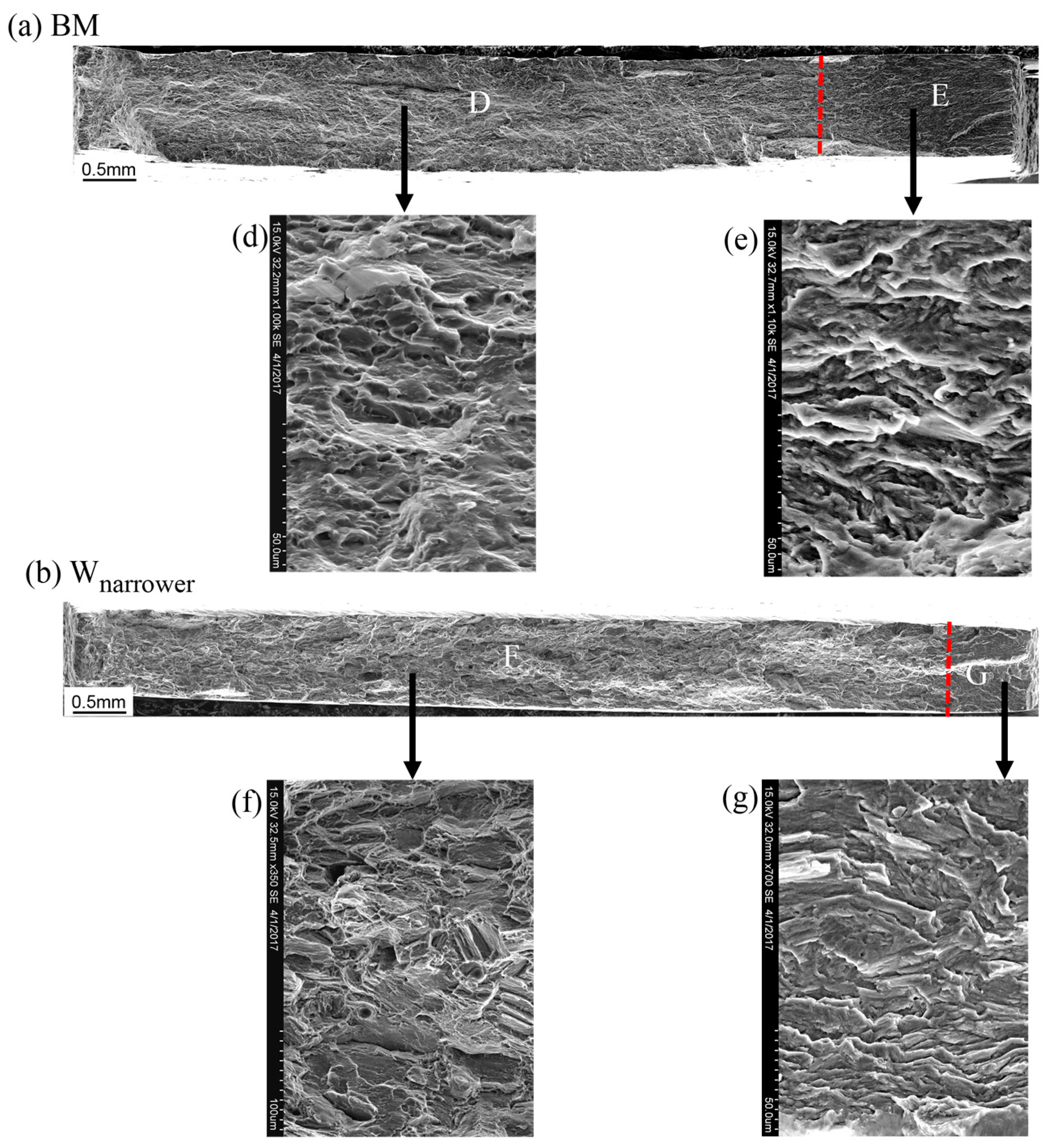

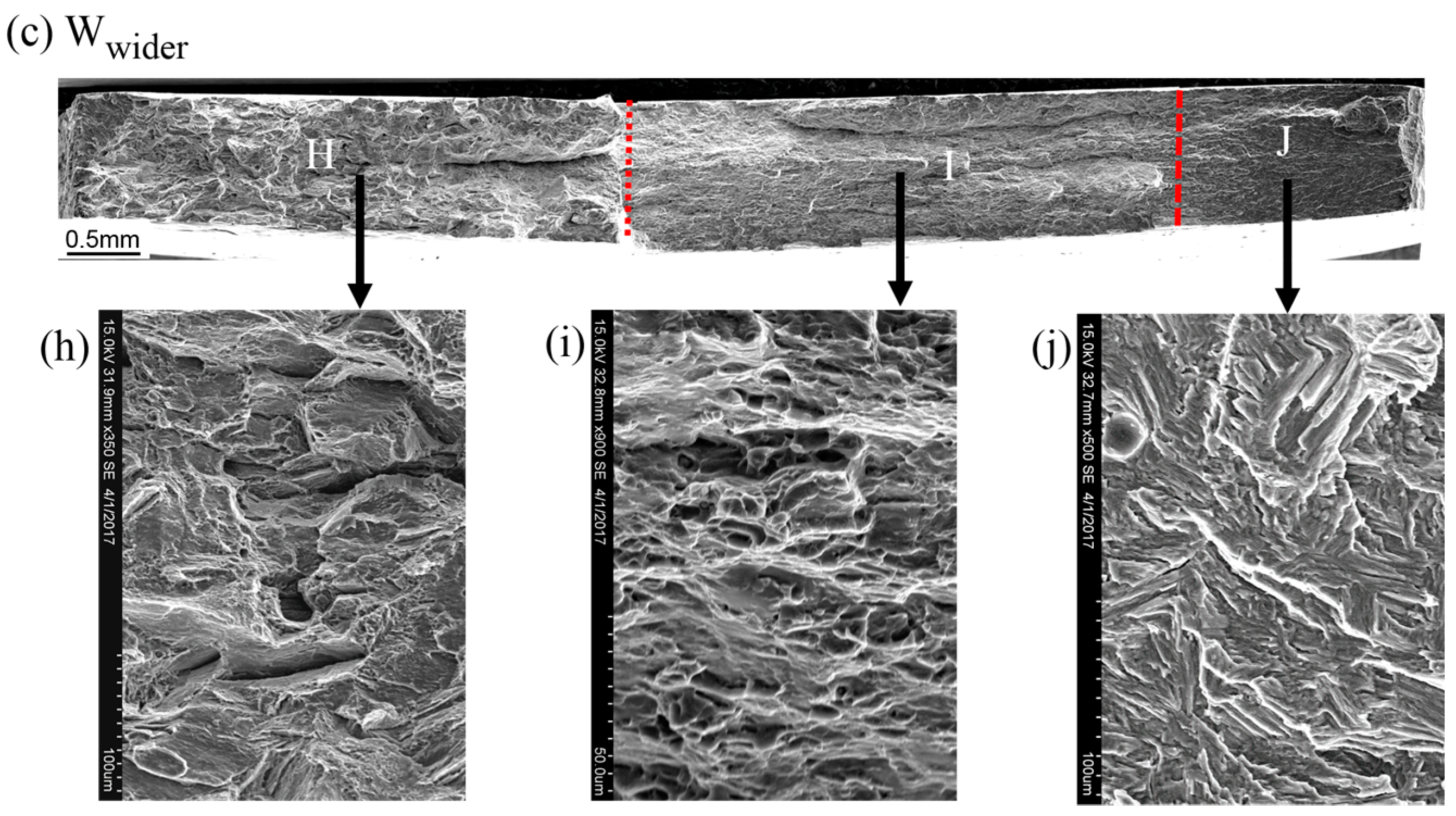

- The tensile strengths of both two joints exceed 90% that of base metal. The elongation rate of the joint Wwider is about 80.9% that of the base metal slightly larger than that of the joint Wnarrower which is up to 72% that of the base metal. The fracture of the base metal is composed of many small and dense dimples. However, the fracture of joint Wnarrower shows a cleavage fracture pattern. The fracture of joint Wwider shows characteristics of both of these two fracture patterns.

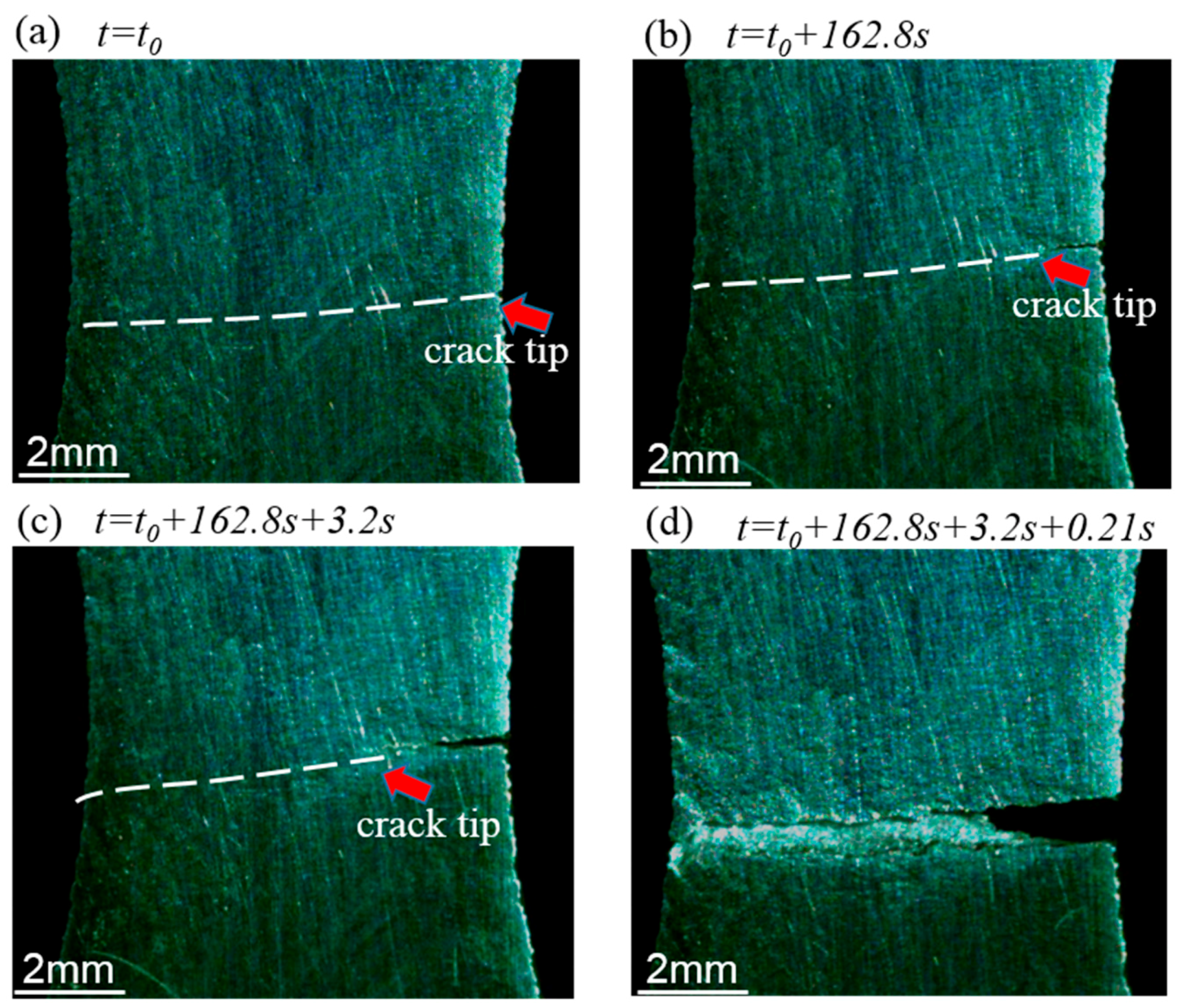

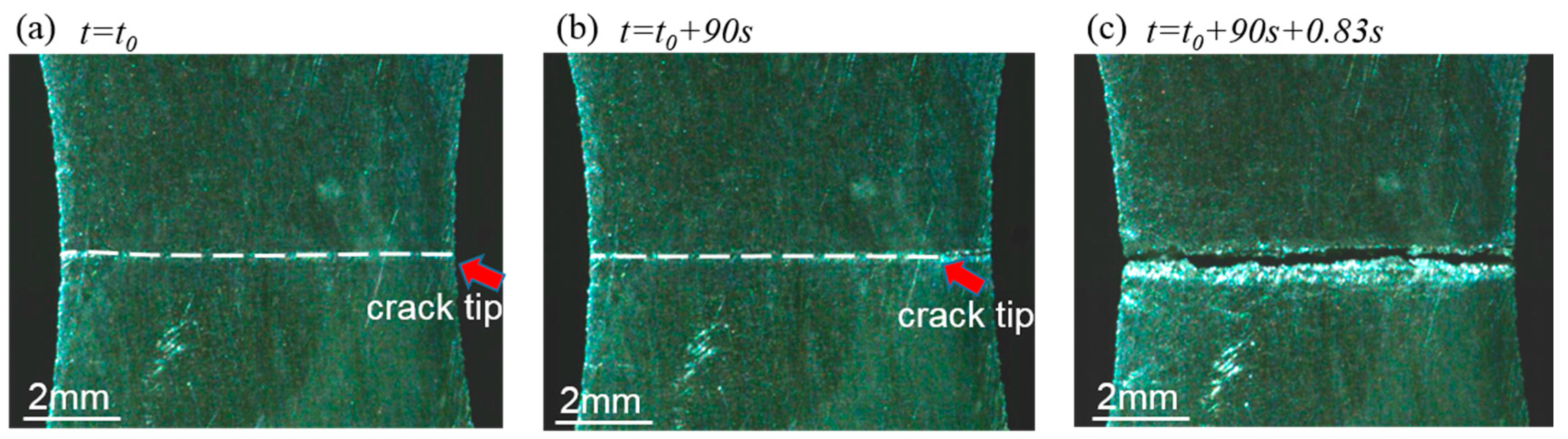

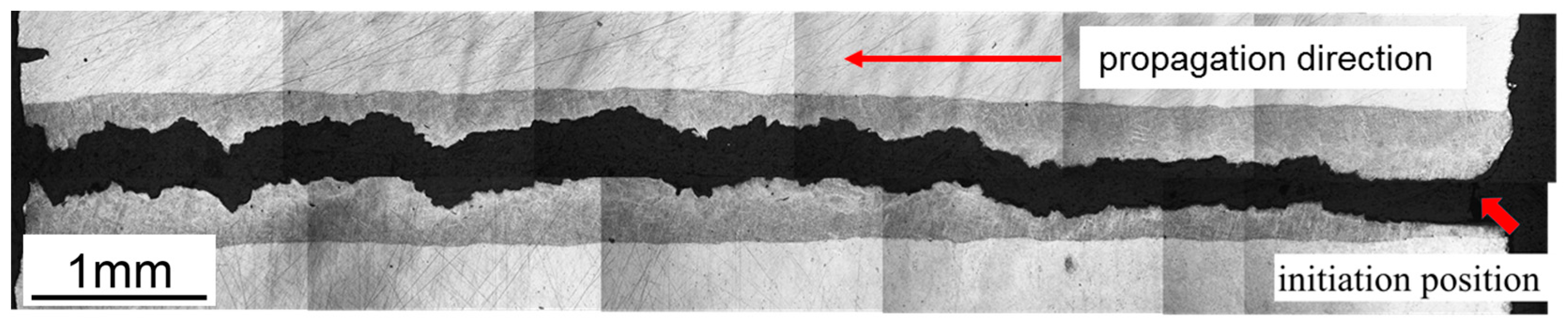

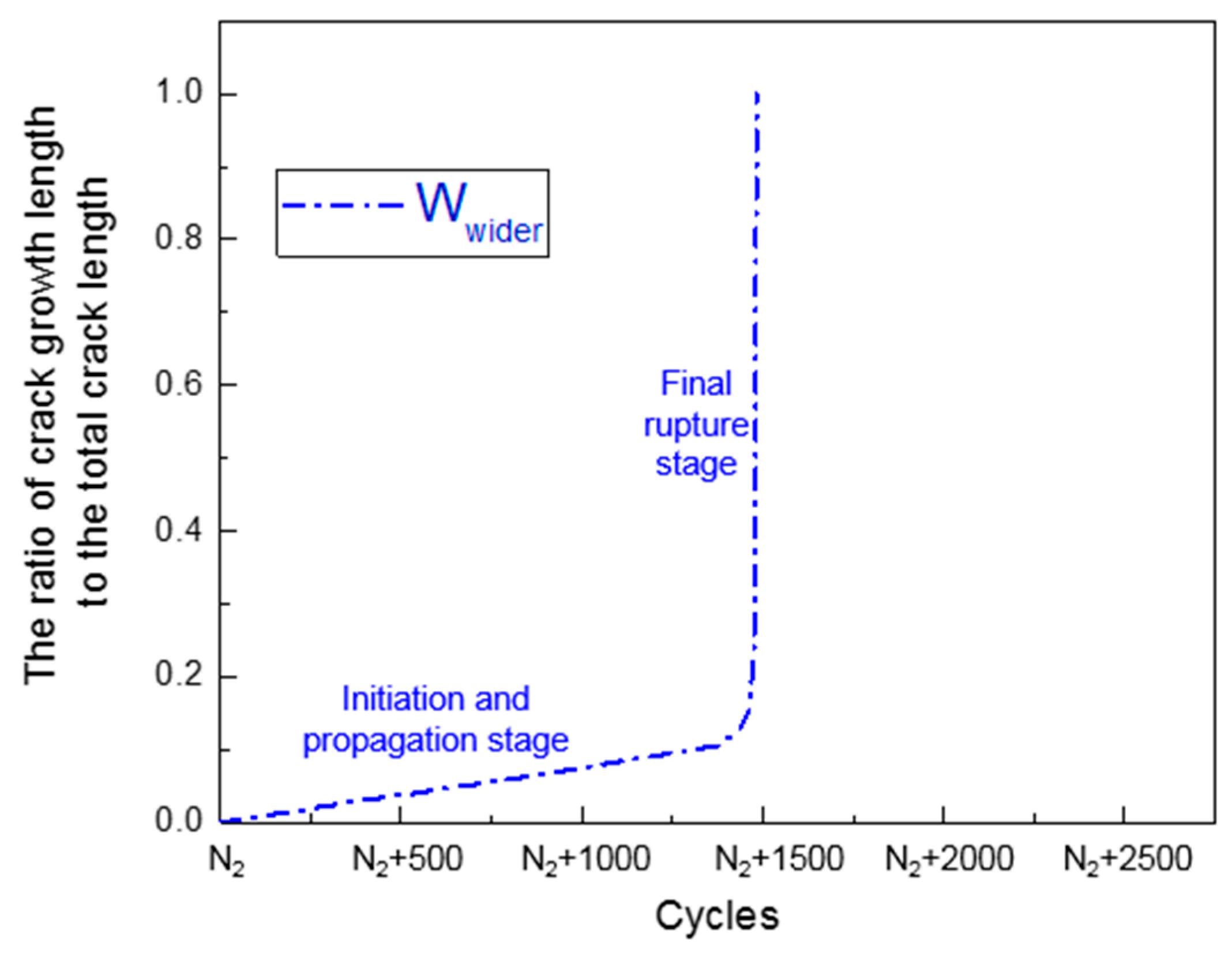

- The low-cycle fatigue life of the base metal, the joint Wnarrower and the joint Wwider are 3377.5 cycles, 2825 cycles and 3155.3 cycles, respectively. The initiation and propagation of the fatigue crack of joint Wnarrower is inside the fusion zone. However, the fatigue crack of the joint Wwider initiated at the edge of the base metal and propagated for a distance on the base metal before propagating inside the fusion zone.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M.S.J. Effect of laser welding parameters on the heat input and weld-bead profile. J. Mater. Process. Technol. 2005, 164, 978–985. [Google Scholar] [CrossRef]

- Hann, D.B.; Iammi, J.; Folkes, J. A simple methodology for predicting laser-weld properties from material and laser parameters. J. Phys. D Appl. Phys. 2011, 44, 445401. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Zhou, C. Effects of welding parameters on weld geometry during high-power laser welding of thick plate. Int. J. Adv. Manuf. Technol. 2015, 79, 177–182. [Google Scholar] [CrossRef]

- Kim, J.; Ki, H. Scaling law for penetration depth in laser welding. J. Mater. Process. Technol. 2014, 214, 2908–2914. [Google Scholar] [CrossRef]

- Volpp, J.; Vollertsen, F. Analytical Modeling of the Keyhole Including Multiple Reflections for Analysis of the Influence of Different Laser Intensity Distributions on Keyhole Geometry. Phys. Procedia 2013, 41, 453–461. [Google Scholar] [CrossRef]

- Ayoola, W.A.; Suder, W.J.; Williams, S.W. Parameters controlling weld bead profile in conduction laser welding. J. Mater. Process. Technol. 2017, 249, 522–530. [Google Scholar] [CrossRef]

- Ngoula, D.T.; Beier, H.T.; Vormwald, M. Fatigue crack growth in cruciform welded joints: Influence of residual stresses and of the weld toe geometry. Int. J. Fatigue 2016, 101, 253–262. [Google Scholar] [CrossRef]

- Matsuoka, S.; Okamoto, Y.; Okada, A. Influence of Weld Bead Geometry on Thermal Deformation in Laser Micro-Welding. Procedia CIRP 2013, 6, 492–497. [Google Scholar] [CrossRef]

- Okamoto, Y.; Matsuoka, S.; Otowa, T.; Okada, A. Influence of Bead Geometry on Weld Distortion in Laser Micro-welding of Thin Stainless Steel Sheet with High-speed Scanning. Int. J. Electr. Mach. 2017, 20, 9–15. [Google Scholar] [CrossRef][Green Version]

- Liu, S.; Mi, G.; Yan, F.; Wang, C.; Jiang, P. Correlation of high power laser welding parameters with real weld geometry and microstructure. Opt. Laser Technol. 2017, 94, 59–67. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, G.; Zhou, Y.; Li, S. Direct observation of keyhole characteristics in deep penetration laser welding with a 10 kW fiber laser. Opt. Express 2013, 21, 19997–20004. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.J.; Bai, Q.L.; Ning, J.; Wang, A.; Yang, J.N.; Yin, X.Q.; Zhang, J.X. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater. Des. 2016, 110, 35–50. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Shao, X.; Gong, S.; Xiao, J. Dynamics of vapor plume in transient keyhole during laser welding of stainless steel: Local evaporation, plume swing and gas entrapment into porosity. Opt. Lasers Eng. 2016, 82, 28–40. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.Y.; Song, X.G.; Tan, C.W.; He, Z.Z.; Huang, Y.X.; Feng, J.C. Influence of laser offset on laser welding-brazing of Al/brass dissimilar alloys. J. Alloy. Compd. 2017, 717, 78–92. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Li, W.; Shao, X.; Gong, S. Efficient multiple time scale method for modeling compressible vapor plume dynamics inside transient keyhole during fiber laser welding. Opt. Laser Technol. 2016, 77, 203–214. [Google Scholar] [CrossRef]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser welded S960 high strength steel. Mater. Des. 2015, 85, 534–548. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on the weld quality during hybrid laser welding of an Al–Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

- Casalino, G.; Guglielmi, P.; Lorusso, V.D.; Mortello, M.; Peyre, P.; Sorgente, D. Laser offset welding of AZ31B magnesium alloy to 316 stainless steel. J. Mater. Process. Technol. 2017, 242, 49–59. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Campanelli, S.L. Ytterbium fiber laser welding of Ti6Al4V alloy. J. Manuf. Process. 2015, 20, 250–256. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Mortello, M.; Angelastro, A.; Ludovico, A.D. Microstructural Characteristics and Mechanical Properties of Ti6Al4V Alloy Fiber Laser Welds. Procedia CIRP 2015, 33, 428–433. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Ludovico, A.D. Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int. J. Adv. Manuf. Technol. 2013, 68, 209–216. [Google Scholar] [CrossRef]

- Krasnoperov, M.Y.; Pieters, R.R.G.M.; Richardson, I.M. Weld pool geometry during keyhole laser welding of thin steel sheets. Sci. Technol. Weld. Join. 2014, 9, 501–506. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhang, L.J.; Liu, J.; Zhang, J.X. Effects of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. Int. J. Adv. Manuf. Technol. 2014, 72, 895–903. [Google Scholar] [CrossRef]

- Quan, Y.J.; Chen, Z.H.; Gong, X.S.; Yu, Z.H. Effects of heat input on microstructure and tensile properties of laser welded magnesium alloy AZ31. Mater. Charact. 2008, 59, 1491–1497. [Google Scholar] [CrossRef]

- Wang, X.; Wang, K. Microstructure and properties of friction stir butt-welded AZ31 magnesium alloy. Mater. Sci. Eng. A 2006, 431, 114–117. [Google Scholar]

- Ning, J.; Zhang, L.J.; Bai, Q.L.; Yin, X.Q.; Niu, J.; Zhang, J.X. Comparison of the microstructure and mechanical performance of 2A97 Al-Li alloy joints between autogenous and non-autogenous laser welding. Mater. Des. 2017, 120, 144–156. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Si | Fe | Cu | Ca | Be | Mg |

|---|---|---|---|---|---|---|---|---|

| 3.19% | 0.81% | 0.34% | 0.02% | 0.005% | 0.05% | 0.04% | 0.1% | Balance |

| Welded Joint Number | Welding Power/W | Welding Speed/m/min | Defocusing Amount/mm |

|---|---|---|---|

| 1 | 500 | 2 | −2 |

| 2 | 500 | 3.5 | 0 |

| 3 | 500 | 5 | 2 |

| 4 | 500 | 6.5 | 4 |

| 5 | 500 | 8 | 6 |

| 6 | 1000 | 2 | 0 |

| 7 | 1000 | 3.5 | 2 |

| 8 | 1000 | 5 | 4 |

| 9 | 1000 | 6.5 | 6 |

| 10 | 1000 | 8 | −2 |

| 11 | 1500 | 2 | 2 |

| 12 | 1500 | 3.5 | 4 |

| 13 | 1500 | 5 | 6 |

| 14 | 1500 | 6.5 | −2 |

| 15 | 1500 | 8 | 0 |

| 16 | 2000 | 2 | 4 |

| 17 | 2000 | 3.5 | 6 |

| 18 | 2000 | 5 | −2 |

| 19 | 2000 | 6.5 | 0 |

| 20 | 2000 | 8 | 2 |

| 21 | 2500 | 2 | 6 |

| 22 | 2500 | 3.5 | −2 |

| 23 | 2500 | 5 | 0 |

| 24 | 2500 | 6.5 | 2 |

| 25 | 2500 | 8 | 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, G.-F.; Zhang, L.-J.; Pei, Y.; Ning, J.; Zhang, J.-X. Study on the Size Effects of H-Shaped Fusion Zone of Fiber Laser Welded AZ31 Joint. Metals 2018, 8, 198. https://doi.org/10.3390/met8040198

Lu G-F, Zhang L-J, Pei Y, Ning J, Zhang J-X. Study on the Size Effects of H-Shaped Fusion Zone of Fiber Laser Welded AZ31 Joint. Metals. 2018; 8(4):198. https://doi.org/10.3390/met8040198

Chicago/Turabian StyleLu, Guang-Feng, Lin-Jie Zhang, Yi Pei, Jie Ning, and Jian-Xun Zhang. 2018. "Study on the Size Effects of H-Shaped Fusion Zone of Fiber Laser Welded AZ31 Joint" Metals 8, no. 4: 198. https://doi.org/10.3390/met8040198

APA StyleLu, G.-F., Zhang, L.-J., Pei, Y., Ning, J., & Zhang, J.-X. (2018). Study on the Size Effects of H-Shaped Fusion Zone of Fiber Laser Welded AZ31 Joint. Metals, 8(4), 198. https://doi.org/10.3390/met8040198