Influence of Intercritical Annealing Temperature on Microstructure and Mechanical Properties of a Cold-Rolled Medium-Mn Steel

Abstract

:1. Introduction

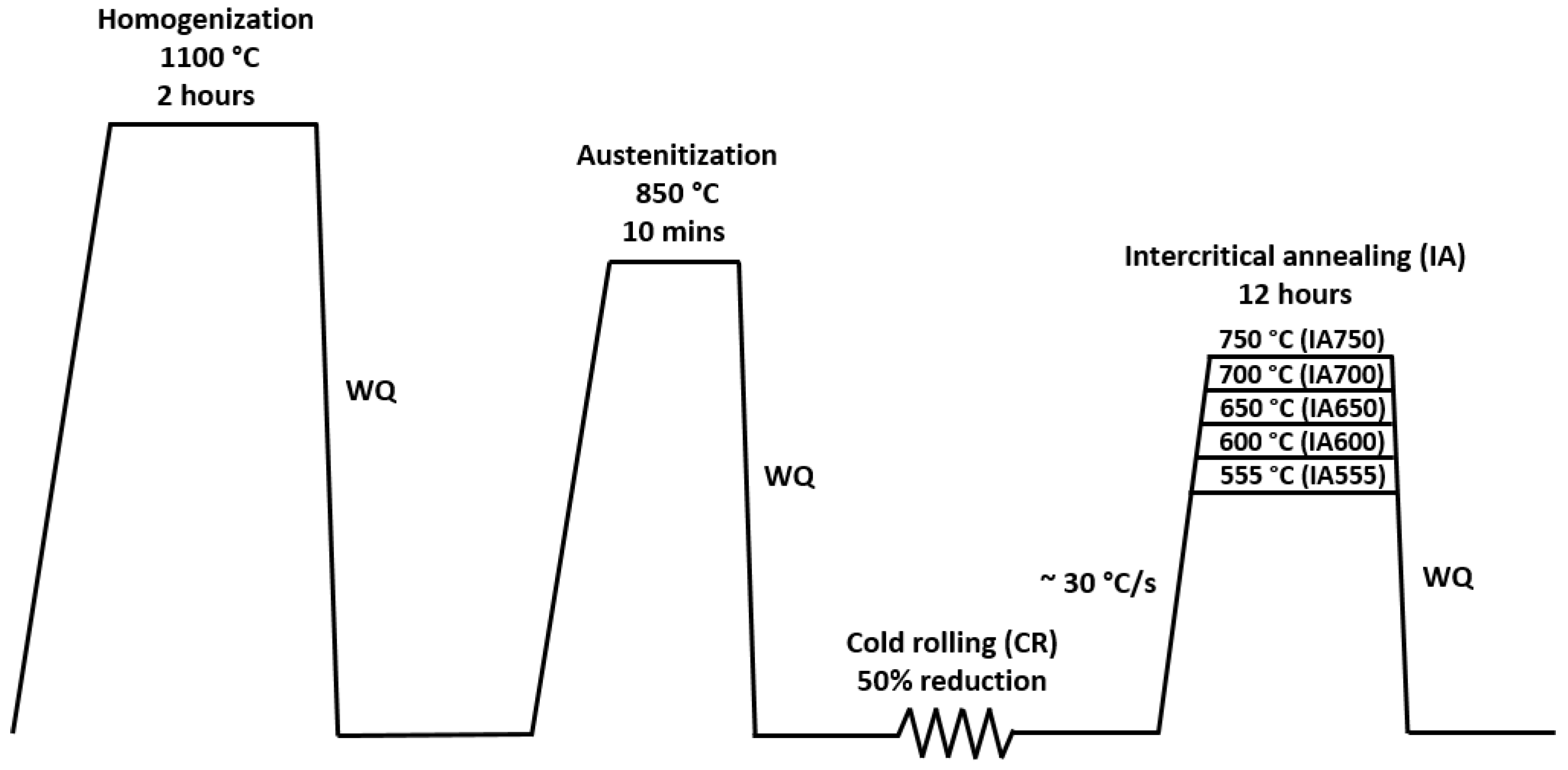

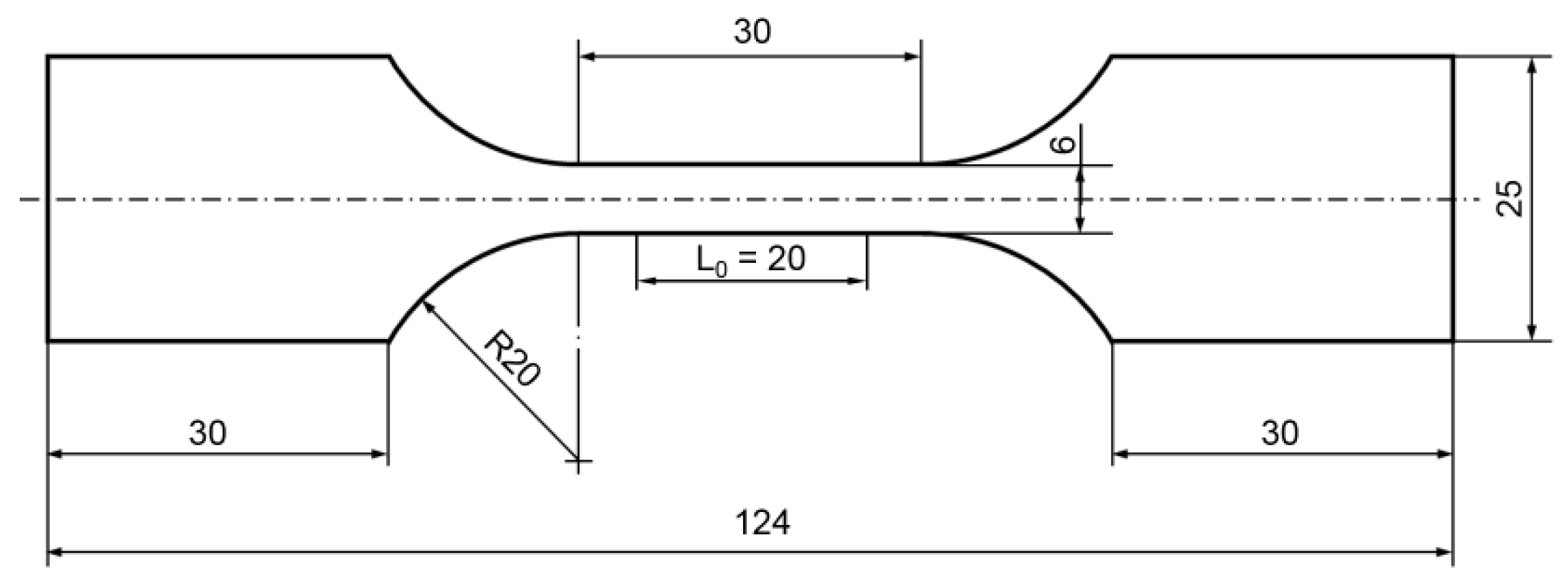

2. Material and Methods

3. Results

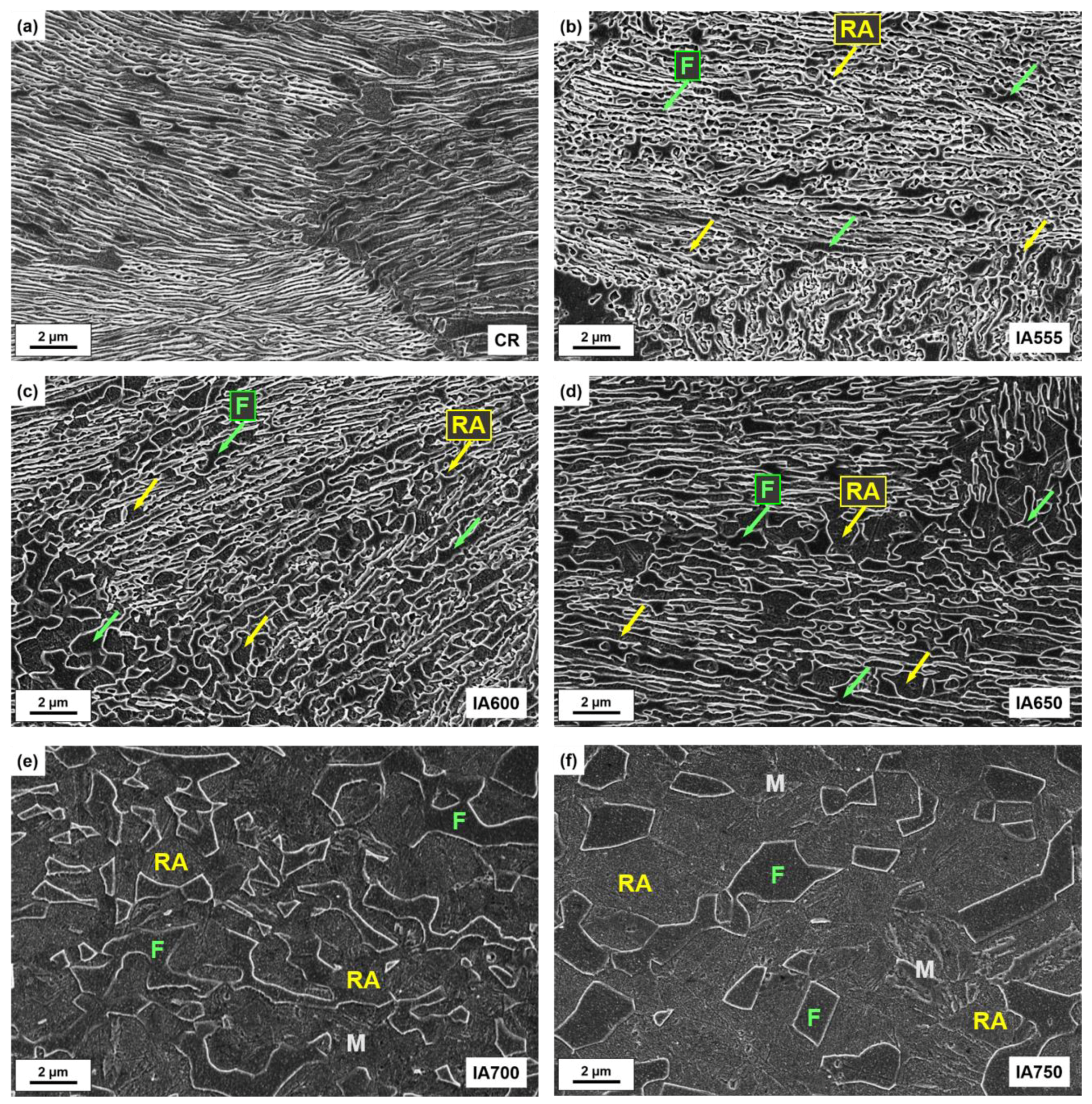

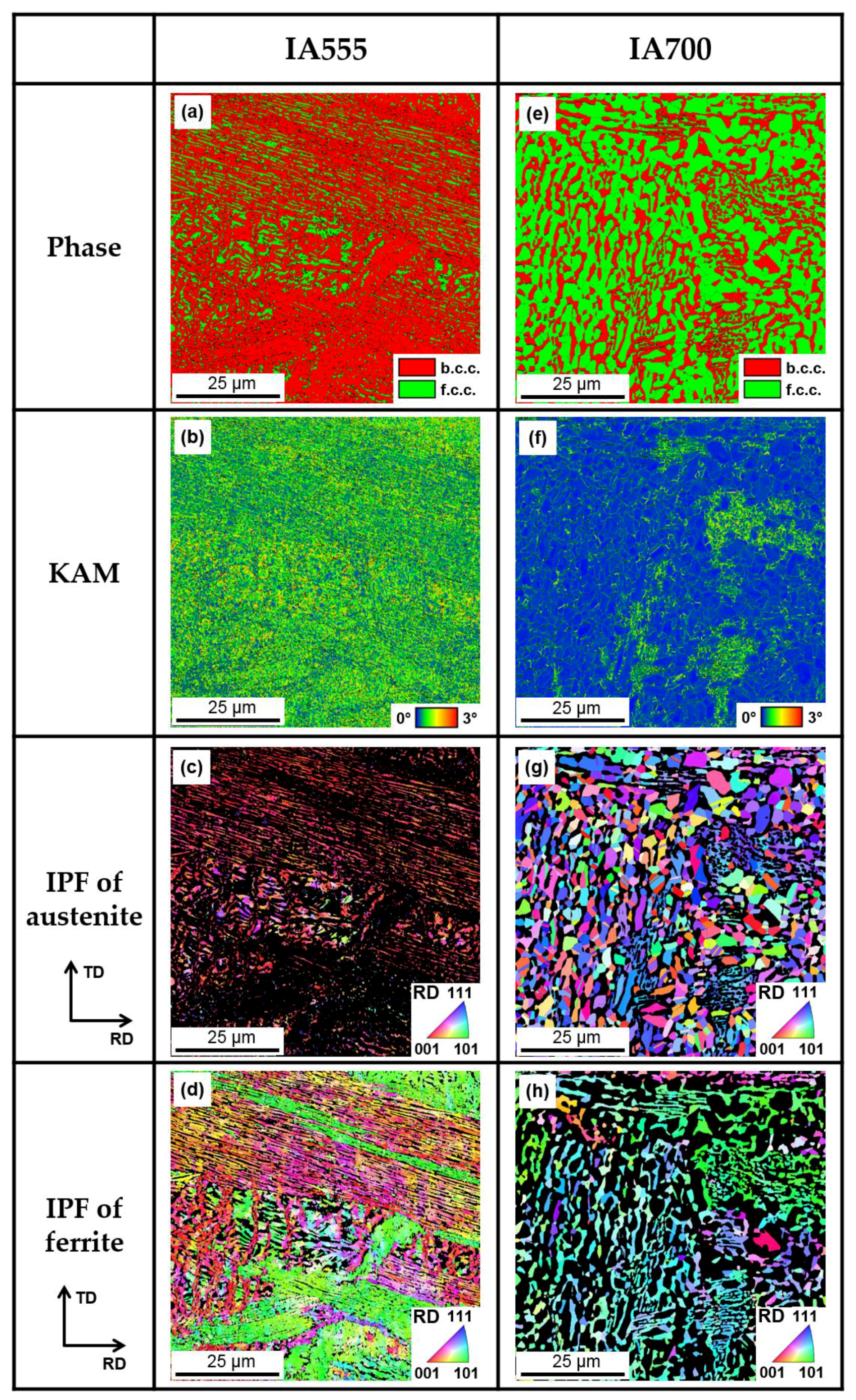

3.1. Microstructure Analysis of the Intercritically Annealed Specimens

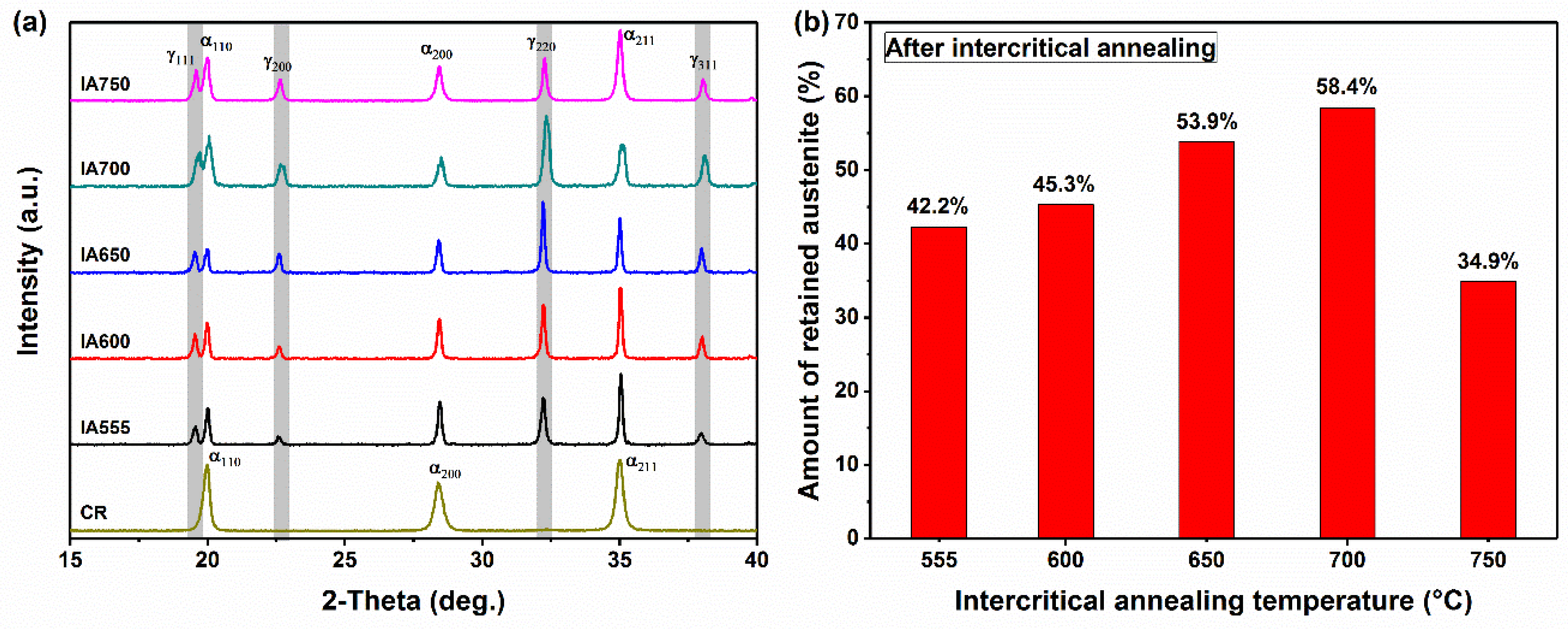

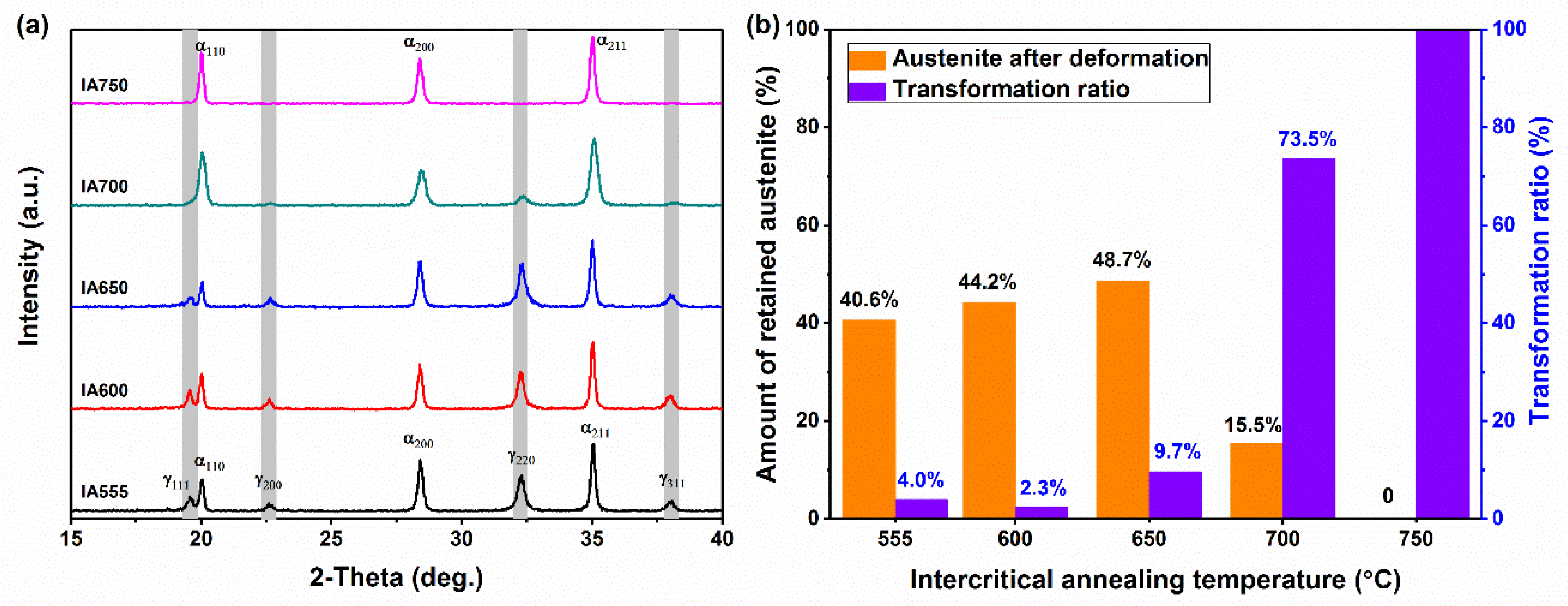

3.2. Amount of Retained Austenite in the Intercritically Annealed Specimens

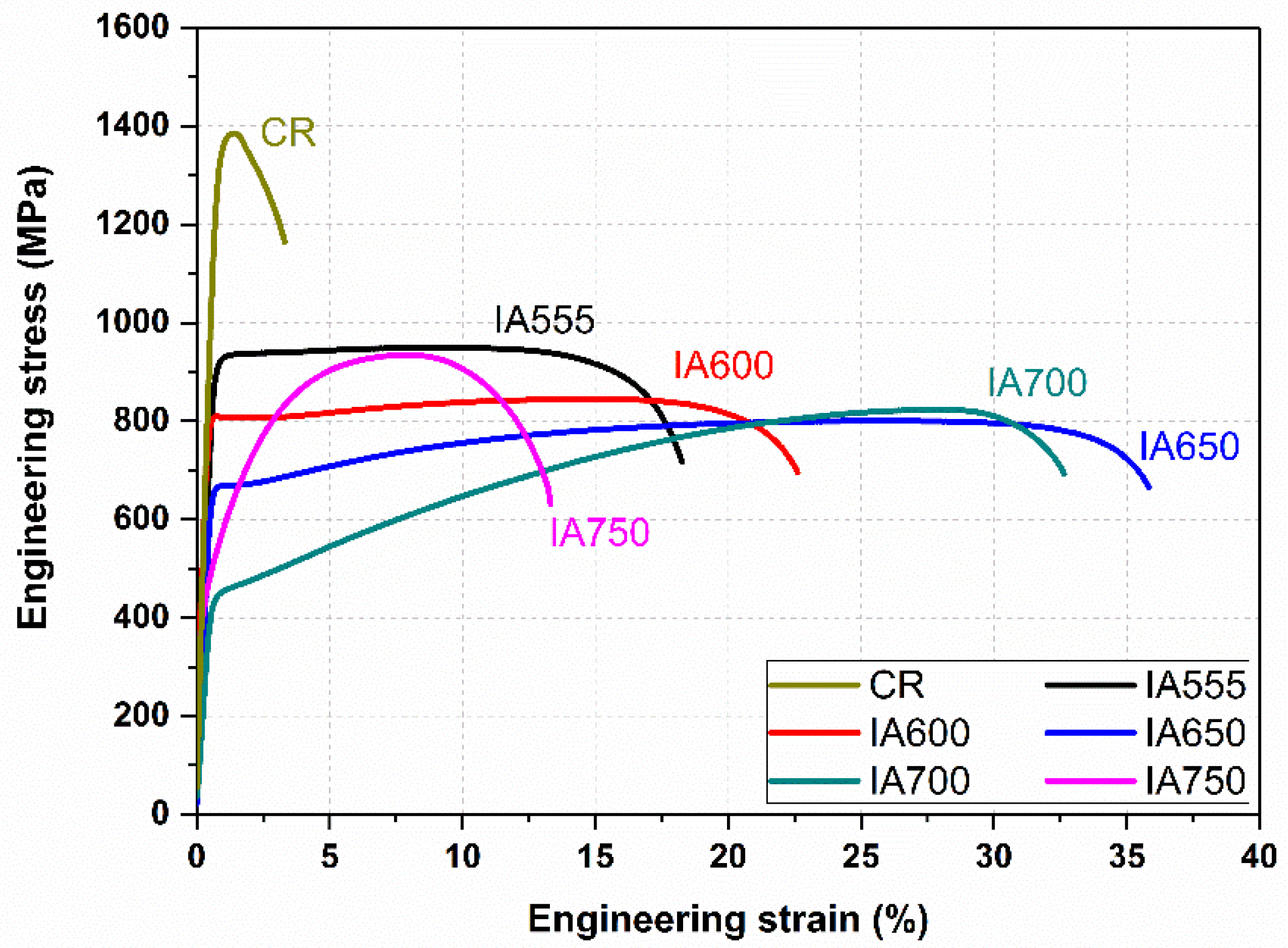

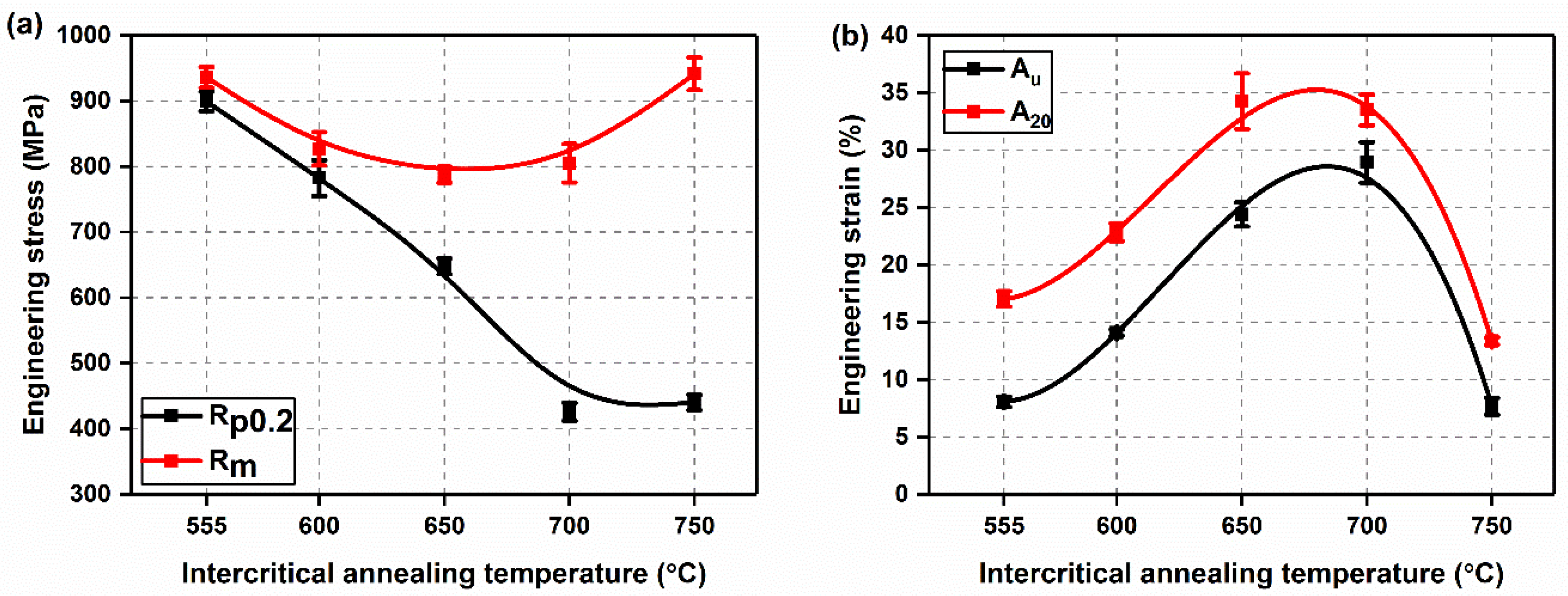

3.3. Mechanical Properties

3.4. Amount of Retained Austenite in the Deformed Specimens

4. Discussion

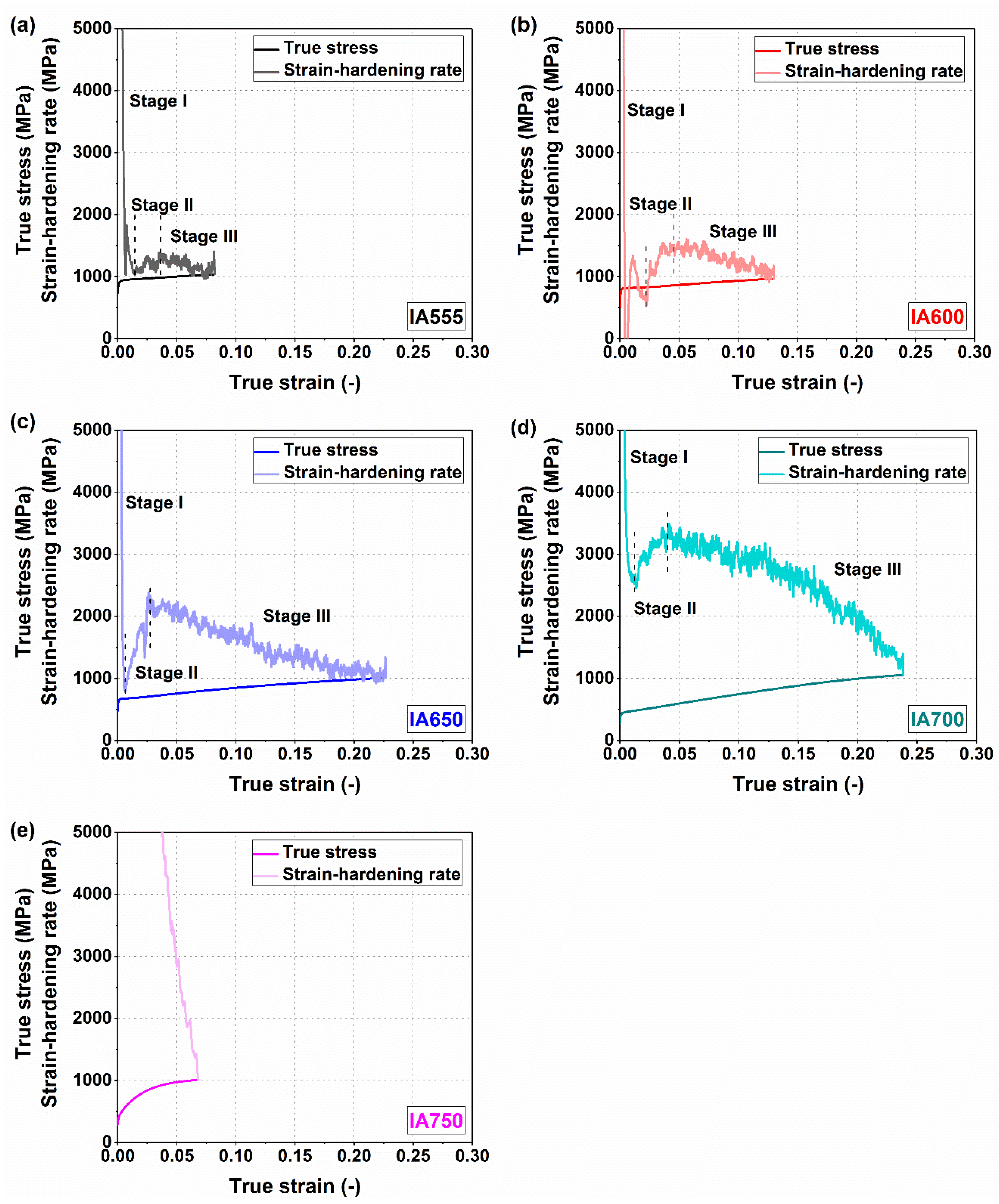

4.1. Influence of Intercritical Annealing Temperature on the Thermal Stability of Austenite and Deformation Mechanisms

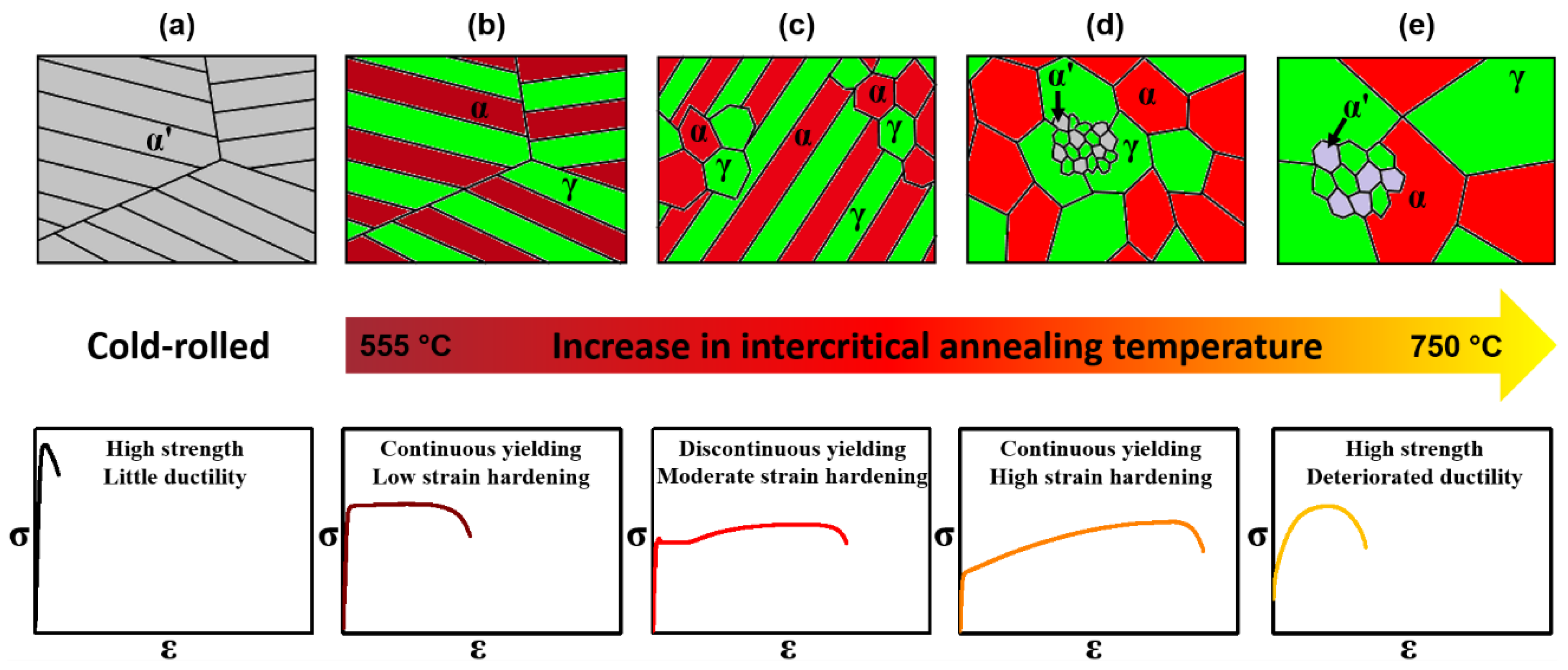

4.2. Influence of Intercritical Annealing Temperature on Microstructure and Mechanical Properties of the Medium-Mn Steel

5. Conclusions

- The intercritical annealing temperature has a great influence on the microstructure of the cold-rolled medium-Mn steel, in terms of amount and stability of retained austenite, as well as the microstructural morphology. As a consequence, the mechanical properties exhibit a strong dependence on the intercritical annealing temperature.

- The intercritical annealing at 555 °C below recrystallization temperature results in the duplex microstructure of ferrite and austenite both with an elongated morphology, which inherits the lath structure of the cold-rolled steels.

- An increase in intercritical annealing temperature leads to the activation of recrystallization, indicated by the duplex microstructure with an equiaxed morphology.

- The relatively high austenite stability obtained at low intercritical annealing temperature (555 °C) results in a low strain-hardening rate, whereas an increase in the intercritical annealing temperature up to 700 °C leads to an increase in strain-hardening rate and ductility in the medium-Mn steel, which is due to the effective TRIP effect.

- Intercritical annealing at the very high temperature (750 °C) leads to a decrease in both thermal and mechanical stability of austenite and a deterioration of the mechanical properties.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bouaziz, O.; Zurob, H.; Huang, M. Driving force and logic of development of advanced high strength steels for automotive applications. Steel Res. Int. 2013, 12, 937–947. [Google Scholar] [CrossRef]

- Matlock, D.K.; Speer, J.G.; De Moor, E.; Gibbs, P.J. Recent developments in advanced high strength sheet steels for automotive applications: An overview. Jestech 2012, 15, 1–12. [Google Scholar]

- Bleck, W.; Guo, X.; Ma, Y. The TRIP Effect and Its Application in Cold Formable Sheet Steels. Steel Res. Int. 2017, 88, 1700218. [Google Scholar] [CrossRef]

- Matlock, D.K.; Speer, J.G. Third generation of AHSS: Microstructure design concepts. In Microstructure and Texture in Steels; Haldar, A., Suwas, S., Bhattacharjee, D., Eds.; Springer: London, UK, 2009; pp. 185–205. [Google Scholar]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Ma, Y. Medium-manganese steels processed by austenite-reverted-transformation annealing for automotive applications. Mater. Sci. Technol. 2017, 33, 1713–1727. [Google Scholar] [CrossRef]

- Miller, R.L. Ultrafine-grained microstructures and mechanical properties of alloy steels. Metall. Mater. Trans. B 1972, 3, 905–912. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. On the selection of the optimal intercritical annealing temperature for medium mn TRIP steel. Metall. Mater. Trans. A 2013, 44, 5018–5024. [Google Scholar] [CrossRef]

- Gibbs, P.J.; de Moor, E.; Merwin, M.J.; Clausen, B.; Speer, J.G.; Matlock, D.K. Austenite stability effects on tensile behavior of manganese-enriched-austenite transformation-induced plasticity steel. Metall. Mater. Trans. A 2011, 42, 3691–3702. [Google Scholar] [CrossRef]

- Cao, W.; Wang, C.; Shi, J.; Wang, M.; Hui, W.; Dong, H. Microstructure and mechanical properties of Fe-0.2C-5Mn steel processed by ART-annealing. Mater. Sci. Eng. A 2011, 528, 6661–6666. [Google Scholar] [CrossRef]

- Haupt, M.; Dutta, A.; Ponge, D.; Sandlöbes, S.; Nellessen, M.; Hirt, G. Influence of Intercritical Annealing on Microstructure and Mechanical Properties of a Medium Manganese Steel. Procedia Eng. 2017, 207, 1803–1808. [Google Scholar] [CrossRef]

- Suh, D.W.; Park, S.-J.; Lee, T.-H.; Oh, C.-S.; Kim, S.-J. Influence of Al on the Microstructural Evolution and Mechanical Behavior of Low-Carbon, Manganese Transformation-Induced-Plasticity Steel. Metall. Mater. Trans. A 2010, 41, 397–408. [Google Scholar] [CrossRef]

- Choi, H.; Lee, S.; Lee, J.; Barlat, F.; De Cooman, B.C. Characterization of fracture in medium Mn steel. Mater. Sci. Eng. A 2017, 687, 200–210. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. Annealing temperature dependence of the tensile behavior of 10 pct Mn multi-phase TWIP-TRIP steel. Metall. Mater. Trans. A 2014, 45, 6039–6052. [Google Scholar] [CrossRef]

- Sun, B.; Fazeli, F.; Scott, C.; Brodusch, N.; Gauvin, R.; Yue, S. The influence of silicon additions on the deformation behavior of austenite-ferrite duplex medium manganese steels. Acta Mater. 2018, 148, 249–262. [Google Scholar] [CrossRef]

- Shi, J.; Sun, X.; Wang, M.; Hui, W.; Dong, H.; Cao, W. Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite. Scr. Mater. 2010, 63, 815–818. [Google Scholar] [CrossRef]

- Suh, D.-W.; Kim, S.-J. Medium Mn transformation-induced plasticity steels: Recent progress and challenges. Scr. Mater. 2017, 126, 63–67. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Han, J. Current opinion in medium manganese steel. Mater. Sci. Technol. 2015, 31, 843–856. [Google Scholar] [CrossRef]

- Bugat, S.; Besson, J.; Gourgues, A.-F.; N’Guyen, F.; Pineau, A. Microstructure and damage initiation in duplex stainless steels. Mater. Sci. Eng. A 2001, 317, 32–36. [Google Scholar] [CrossRef]

- Bugat, S.; Besson, J.; Pineau, A. Micromechanical modeling of the behavior of duplex stainless steels. Comput. Mater. Sci. 1999, 16, 158–166. [Google Scholar] [CrossRef]

- Knobbe, H.; Starke, P.; Hereñú, S.; Christ, H.-J.; Eifler, D. Cyclic deformation behaviour, microstructural evolution and fatigue life of duplex steel AISI 329 LN. Int. J. Fatigue 2015, 80, 81–89. [Google Scholar] [CrossRef]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R Rep. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. Tensile behavior of intercritically annealed ultra-fine grained 8% Mn multi-phase steel. Steel Res. Int. 2015, 86, 1170–1178. [Google Scholar] [CrossRef]

- Luo, H.; Dong, H.; Huang, M. Effect of intercritical annealing on the Lüders strains of medium Mn transformation-induced plasticity steels. Mater. Des. 2015, 83, 42–48. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. Effect of the intercritical annealing temperature on the mechanical properties of 10 pct Mn multi-phase steel. Metall. Mater. Trans. A 2014, 45, 5009–5016. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.-J.; Santhosh K, S.; Lee, K.; De Cooman, B.C. Localized deformation in multiphase, ultra-fine-grained 6 pct Mn transformation-induced plasticity steel. Metall. Mater. Trans. A 2011, 42, 3638–3651. [Google Scholar] [CrossRef]

- Suh, D.W.; Ryu, J.H.; Joo, M.S.; Yang, H.S.; Lee, K.; Bhadeshia, H.K.D.H. Medium-alloy manganese-rich transformation-induced plasticity steels. Metall. Mater. Trans. A 2013, 44, 286–293. [Google Scholar] [CrossRef]

- Luo, H.; Shi, J.; Wang, C.; Cao, W.; Sun, X.; Dong, H. Experimental and numerical analysis on formation of stable austenite during the intercritical annealing of 5Mn steel. Acta Mater. 2011, 59, 4002–4014. [Google Scholar] [CrossRef]

- Han, J.; Lee, S.-J.; Jung, J.-G.; Lee, Y.-K. The effects of the initial martensite microstructure on the microstructure and tensile properties of intercritically annealed Fe-9Mn-0.05C steel. Acta Mater. 2014, 78, 369–377. [Google Scholar] [CrossRef]

- Han, J.; Lee, S.-J.; Lee, C.-Y.; Lee, S.; Jo, S.Y.; Lee, Y.K. The size effect of initial martensite constituents on the microstructure and tensile properties of intercritically annealed Fe-9Mn-0.05C steel. Mater. Sci. Eng. A 2015, 633, 9–16. [Google Scholar] [CrossRef]

- Han, J.; Lee, Y.-K. The effects of the heating rate on the reverse transformation mechanism and the phase stability of reverted austenite in medium Mn steels. Acta Mater. 2014, 67, 354–361. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, C.; Cao, W.; Yang, Z.; Dong, H.; Weng, Y. Austenite thermal stabilization through the concentration of manganese and carbon in the 0.2C–5Mn steel. ISIJ Int. 2014, 54, 2875–2880. [Google Scholar] [CrossRef]

- Wang, C.; Shi, J.; Hui, W.; Wang, M.; Dong, H.; Cao, W. Development of ultrafine lamellar ferrite and austenite duplex structure in 0.2C5Mn steel during ART-annealing. ISIJ Int. 2011, 51, 651–656. [Google Scholar] [CrossRef]

- Dong, H.; Cao, W.; Shi, J. Formation of an ultrafine-grained austenite-containing microstructure from a cold-rolled medium-manganese steel processed using intercritical annealing. Mater. Sci. Forum 2013, 762, 31–37. [Google Scholar] [CrossRef]

- He, B.; Luo, H.; Huang, M. Experimental investigation on a novel medium Mn steel combining transformation-induced plasticity and twinning-induced plasticity effects. Int. J. Plast. 2016, 78, 173–186. [Google Scholar] [CrossRef]

- Sun, R.; Xu, W.; Wang, C.; Shi, J.; Dong, H.; Cao, W. Work hardening behavior of ultrafine grained duplex medium-Mn steels processed by ART-annealing. Steel Res. Int. 2012, 83, 316–321. [Google Scholar] [CrossRef]

- Shao, C.; Hui, W.; Zhang, Y.; Zhao, X.; Weng, Y. Microstructure and mechanical properties of hot-rolled medium-Mn steel containing 3% aluminum. Mater. Sci. Eng. A 2017, 682, 45–53. [Google Scholar] [CrossRef]

- Tsuchiyama, T.; Inoue, T.; Tobata, J.; Akama, D.; Takaki, S. Microstructure and mechanical properties of a medium manganese steel treated with interrupted quenching and intercritical annealing. Scr. Mater. 2016, 122, 36–39. [Google Scholar] [CrossRef]

- Han, J.; Kwiatkowski da Silva, A.; Ponge, D.; Raabe, D.; Lee, S.-M.; Lee, Y.-K.; Lee, S.-I.; Hwang, B. The effects of prior austenite grain boundaries and microstructural morphology on the impact toughness of intercritically annealed medium Mn steel. Acta Mater. 2017, 122, 199–206. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H. Microstructures and mechanical properties of 7Mn steel manufactured by different rolling processes. Metals 2017, 7, 464. [Google Scholar] [CrossRef]

- Cai, Z.; Ding, H.; Misra, R.D.K.; Ying, Z. Austenite stability and deformation behavior in a cold-rolled transformation-induced plasticity steel with medium manganese content. Acta Mater. 2015, 84, 229–236. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. Tensile behavior of intercritically annealed 10 pct Mn multi-phase steel. Metall. Mater. Trans. A 2014, 45, 709–716. [Google Scholar] [CrossRef]

- De Meyer, M.; Vanderschueren, D.; De Blauwe, K.; De Cooman, B.C. The characterization of retained austenite in TRIP steels by X-ray diffraction. In Proceedings of the ISS, 41st Mechanical Working and Steel Processing Conference, Baltimore, MD, USA, 24–27 October 1999; Volume XXXXVII, pp. 265–276. [Google Scholar]

- Lee, S. Contribution to the Physical Metallurgy of Ultrafine-Grained Medium Mn TRIP Steel. Ph.D. Thesis, Pohang University of Science and Technology, Pohang, Korea, 2015. [Google Scholar]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and variation in composition-dependent stacking fault energy maps based on subregular solution model in high-manganese steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Song, W.; Ingendahl, T.; Bleck, W. Control of strain hardening behavior in high-Mn austenitic steels. Acta Metall. Sin. 2014, 27, 546–556. [Google Scholar] [CrossRef]

- Callahan, M.; Hubert, O.; Hild, F.; Perlade, A.; Schmitt, J. Coincidence of strain-induced TRIP and propagative PLC bands in Medium Mn steels. Mater. Sci. Eng. A 2017, 704, 391–400. [Google Scholar] [CrossRef]

- Lee, S.; Lee, K.; De Cooman, B.C. Observation of the TWIP + TRIP plasticity-enhancement mechanism in Al-added 6 wt pct medium Mn steel. Metall. Mater. Trans. A 2015, 46, 2356–2363. [Google Scholar] [CrossRef]

- Li, Z.; Ding, H.; Misra, R.D.K.; Cai, Z. Deformation behavior in cold-rolled medium-manganese TRIP steel and effect of pre-strain on the Lüders bands. Mater. Sci. Eng. A 2017, 679, 230–239. [Google Scholar] [CrossRef]

- Yang, F.; Luo, H.; Hu, C.; Pu, E.; Dong, H. Effects of intercritical annealing process on microstructures and tensile properties of cold-rolled 7Mn steel. Mater. Sci. Eng. A 2017, 685, 115–122. [Google Scholar] [CrossRef]

- Moor, E.D.; Matlock, D.K.; Speer, J.G.; Merwin, M.J. Austenite stabilization through manganese enrichment. Scr. Mater. 2011, 64, 185–188. [Google Scholar] [CrossRef]

- Emo, J.; Maugis, P.; Perlade, A. Austenite growth and stability in medium Mn, medium Al Fe-C-Mn-Al steels. Comput. Mater. Sci. 2016, 125, 206–217. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, J.I.; Kim, H.S.; Oh, C.-S.; Bhadeshia, H.K.D.H.; Suh, D.-W. Austenite stability and heterogeneous deformation in fine-grained transformation-induced plasticity-assisted steel. Scr. Mater. 2013, 68, 933–936. [Google Scholar] [CrossRef]

| Element | Fe | C | Si | Mn | P | S | Al |

|---|---|---|---|---|---|---|---|

| wt % | Bal. | 0.064 | 0.2 | 11.7 | 0.006 | 0.003 | 2.9 |

| IA Temp. (°C) | Austenite under Equilibrium | Ms Temp. (°C) | Amount of MF (vol %) | Amount of RA (vol %) | SFE (mJ/m2) | Deformation Mechanisms | |||

|---|---|---|---|---|---|---|---|---|---|

| Amount (vol %) | Chemistry, Fe Bal. (wt %) | ||||||||

| C | Mn | Al | |||||||

| 555 | 43 | 0.150 | 21.8 | 2.1 | −218 | 0 | 43 | 24 | TWIP/TRIP |

| 600 | 52 | 0.123 | 18.5 | 2.3 | −106 | 0 | 52 | 18 | TWIP/TRIP |

| 650 | 64 | 0.099 | 15.3 | 2.5 | −2 | 0 | 64 | 13 | TRIP |

| 700 | 79 | 0.081 | 13.2 | 2.7 | 72 | 40 | 39 | 11 | TRIP |

| 750 | 97 | 0.066 | 11.9 | 2.9 | 121 | 65 | 32 | 10 | TRIP |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Song, W.; Zhou, S.; Schwedt, A.; Bleck, W. Influence of Intercritical Annealing Temperature on Microstructure and Mechanical Properties of a Cold-Rolled Medium-Mn Steel. Metals 2018, 8, 357. https://doi.org/10.3390/met8050357

Ma Y, Song W, Zhou S, Schwedt A, Bleck W. Influence of Intercritical Annealing Temperature on Microstructure and Mechanical Properties of a Cold-Rolled Medium-Mn Steel. Metals. 2018; 8(5):357. https://doi.org/10.3390/met8050357

Chicago/Turabian StyleMa, Yan, Wenwen Song, Shixin Zhou, Alexander Schwedt, and Wolfgang Bleck. 2018. "Influence of Intercritical Annealing Temperature on Microstructure and Mechanical Properties of a Cold-Rolled Medium-Mn Steel" Metals 8, no. 5: 357. https://doi.org/10.3390/met8050357

APA StyleMa, Y., Song, W., Zhou, S., Schwedt, A., & Bleck, W. (2018). Influence of Intercritical Annealing Temperature on Microstructure and Mechanical Properties of a Cold-Rolled Medium-Mn Steel. Metals, 8(5), 357. https://doi.org/10.3390/met8050357