Experimental Investigation of Laser Ablation Characteristics on Nickel-Coated Beryllium Copper

Abstract

:1. Introduction

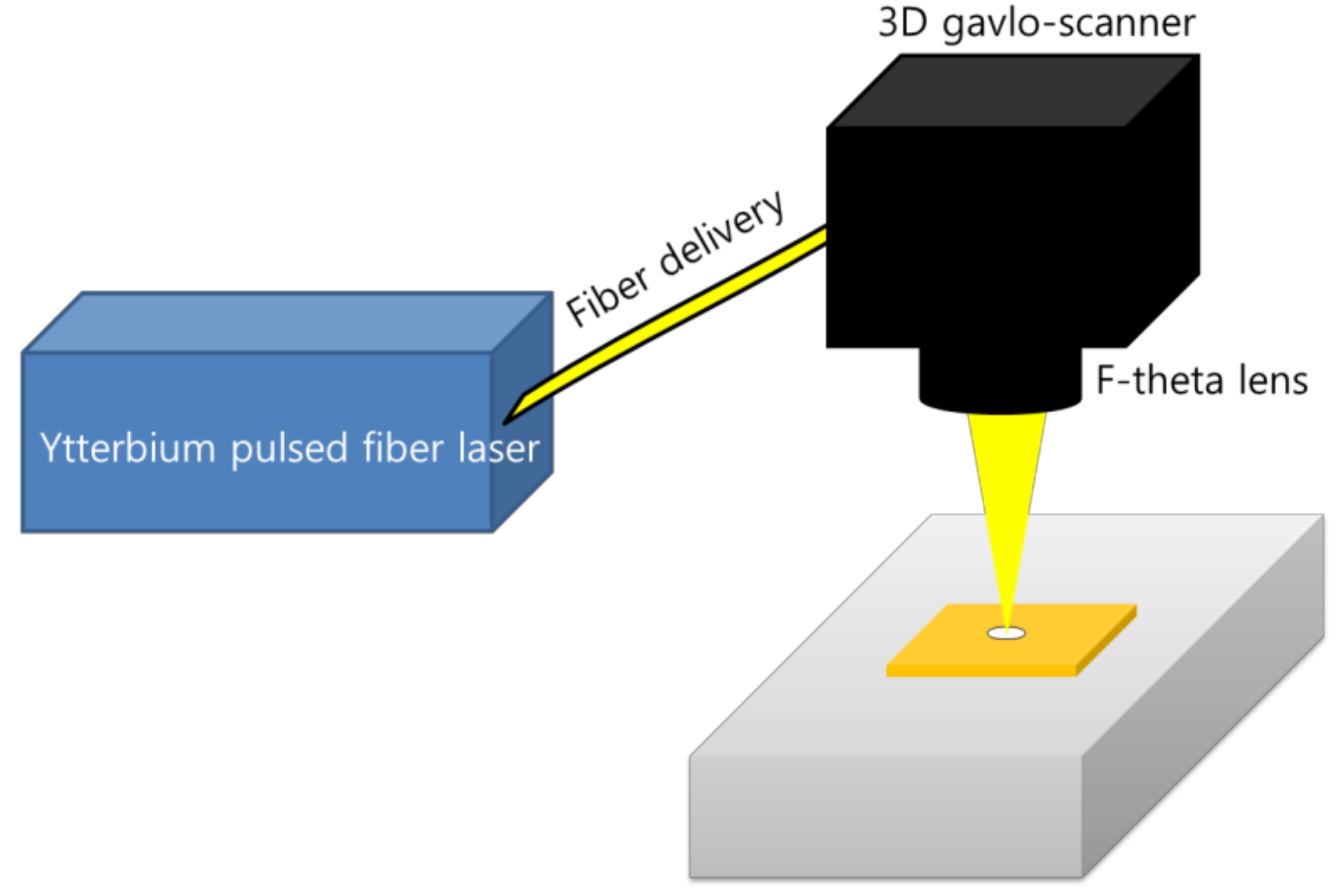

2. Experiment

2.1. Material and Experimental Method

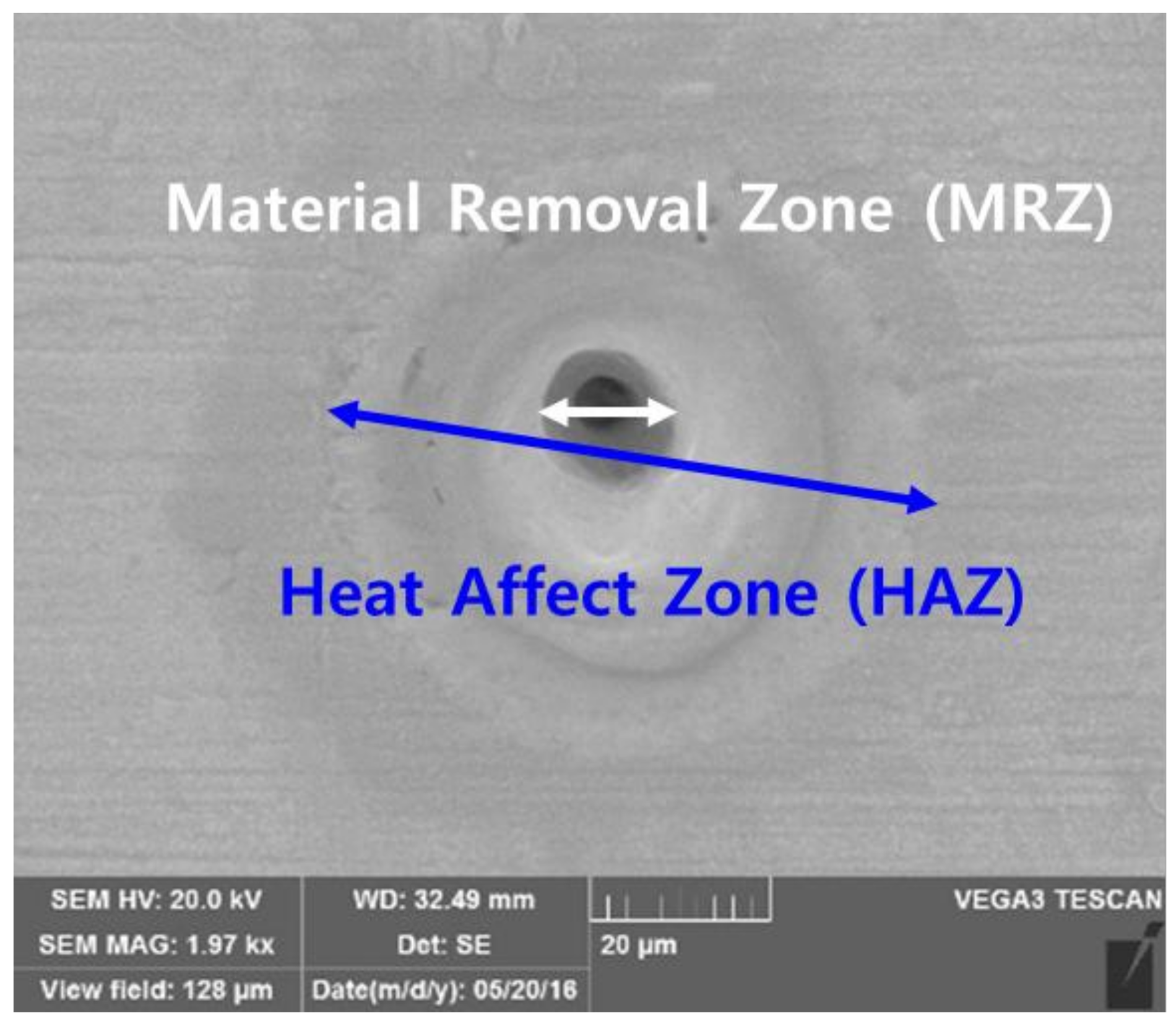

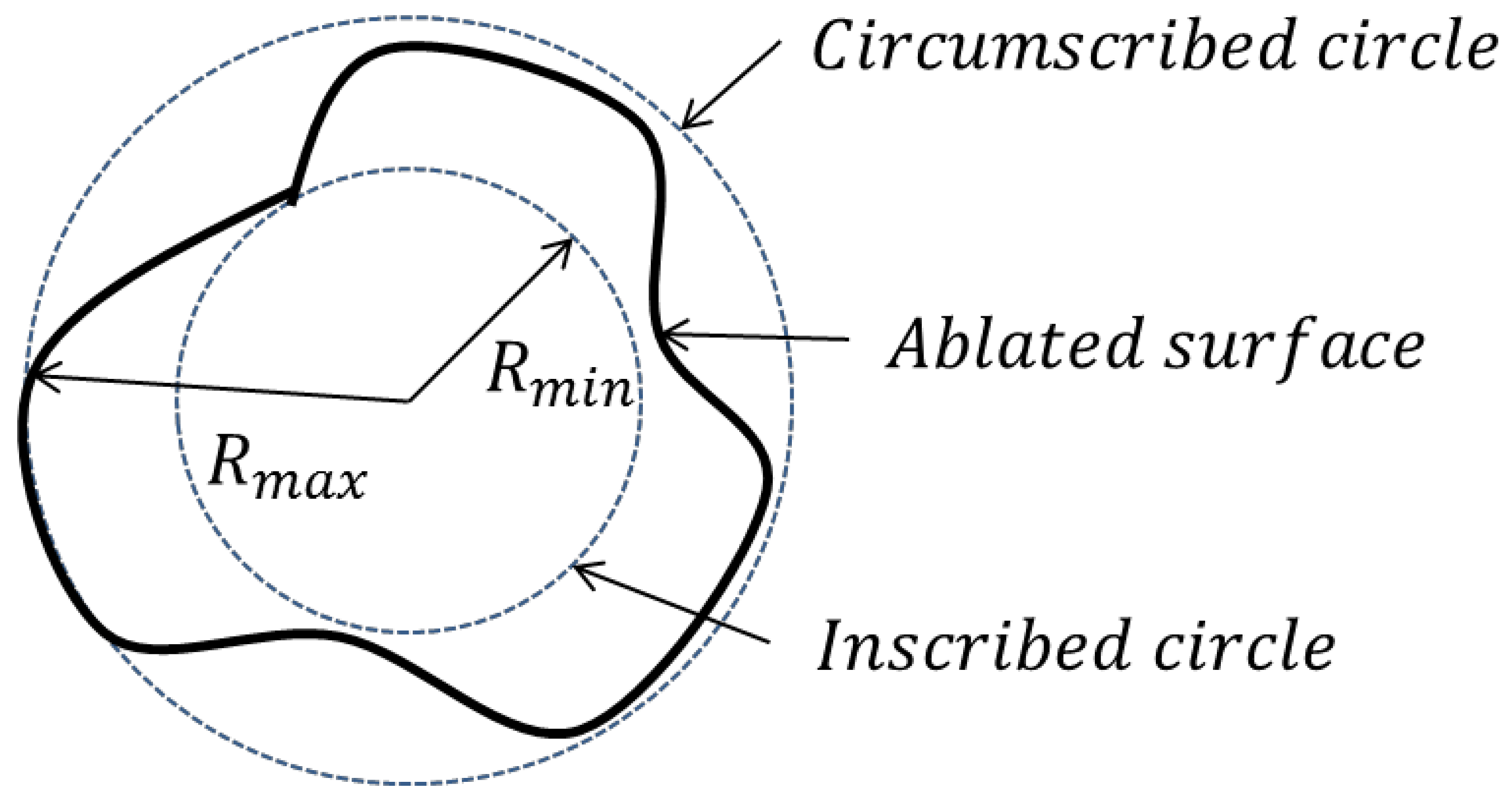

2.2. Analysis Method

3. Results and Discussions

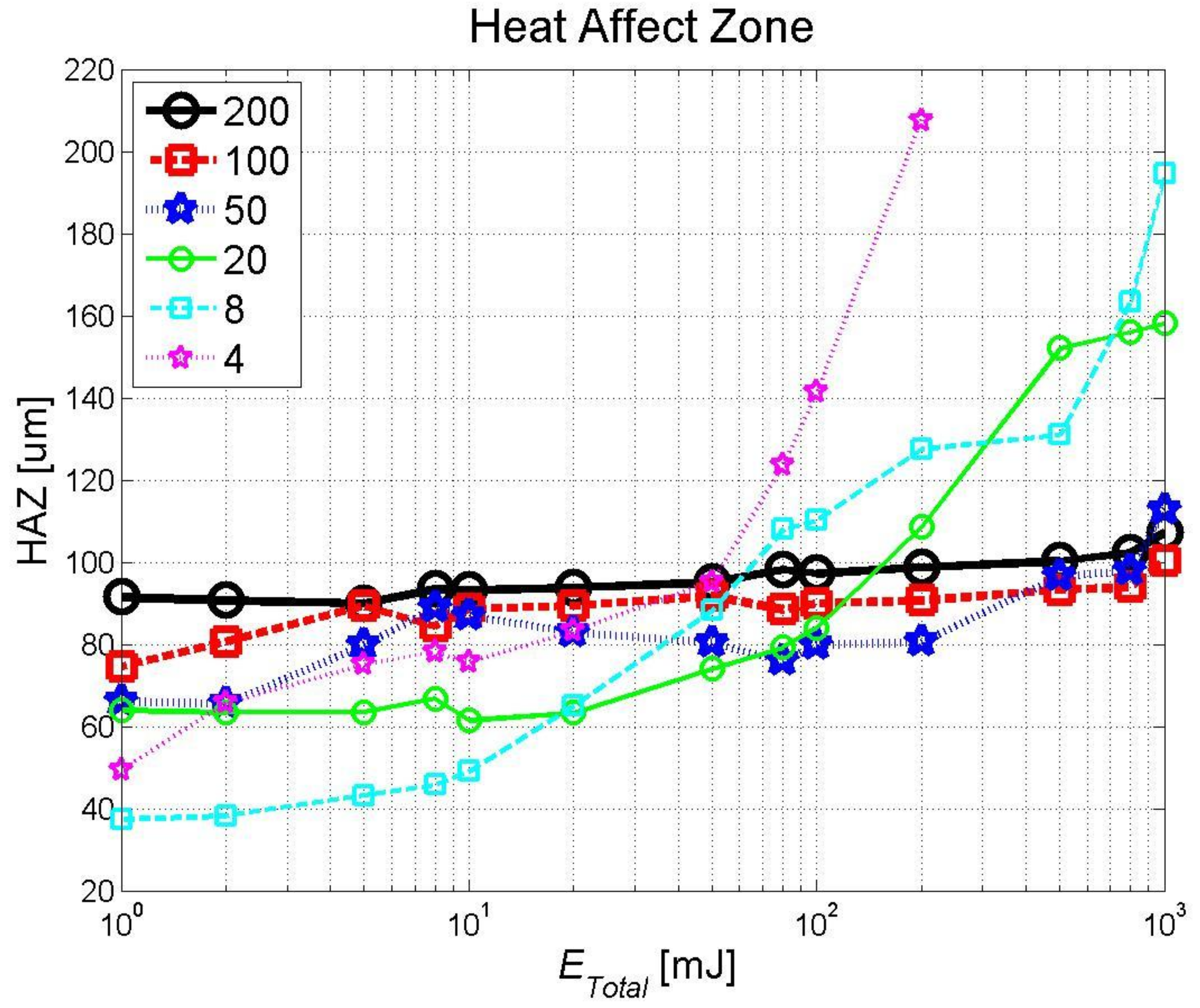

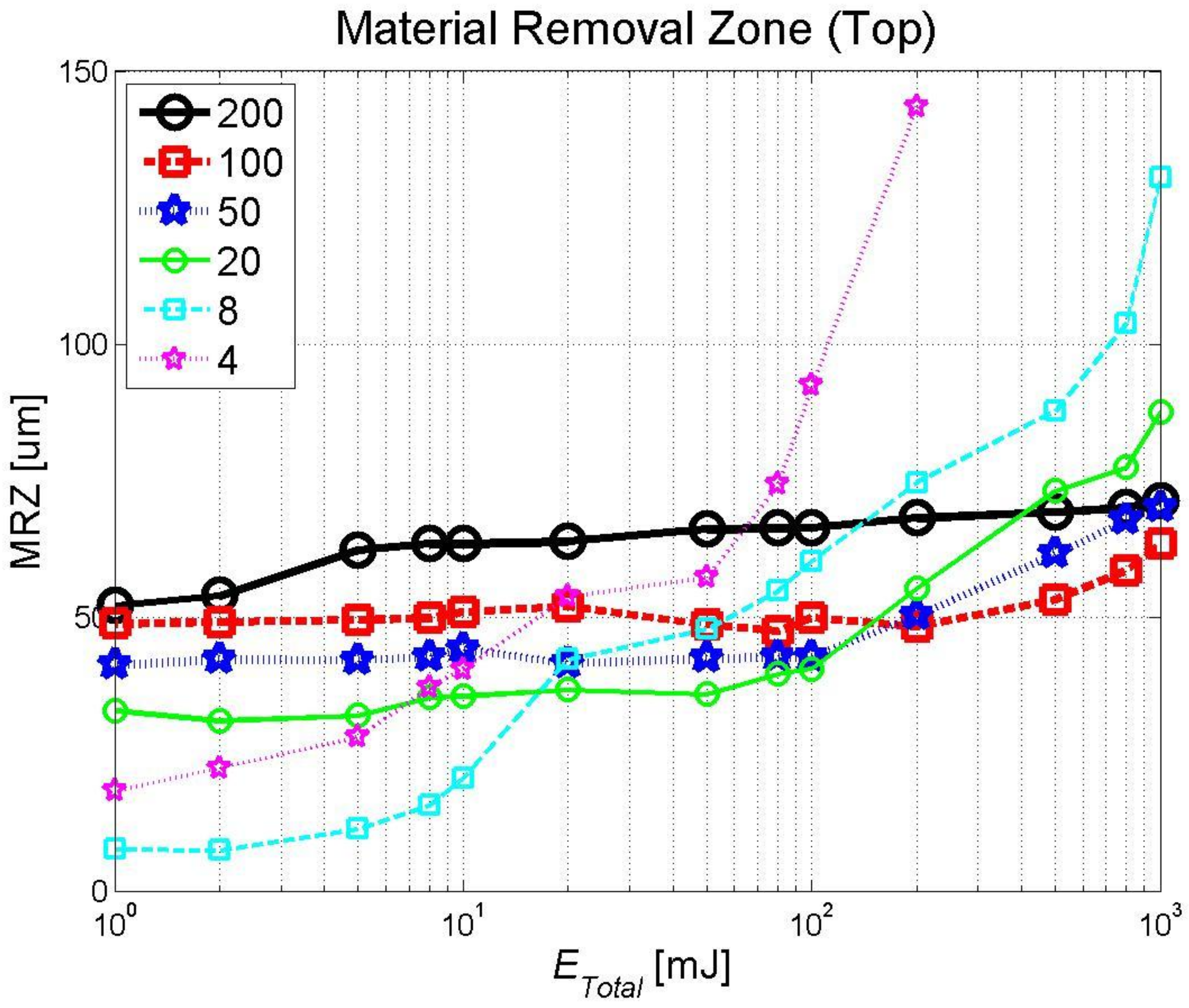

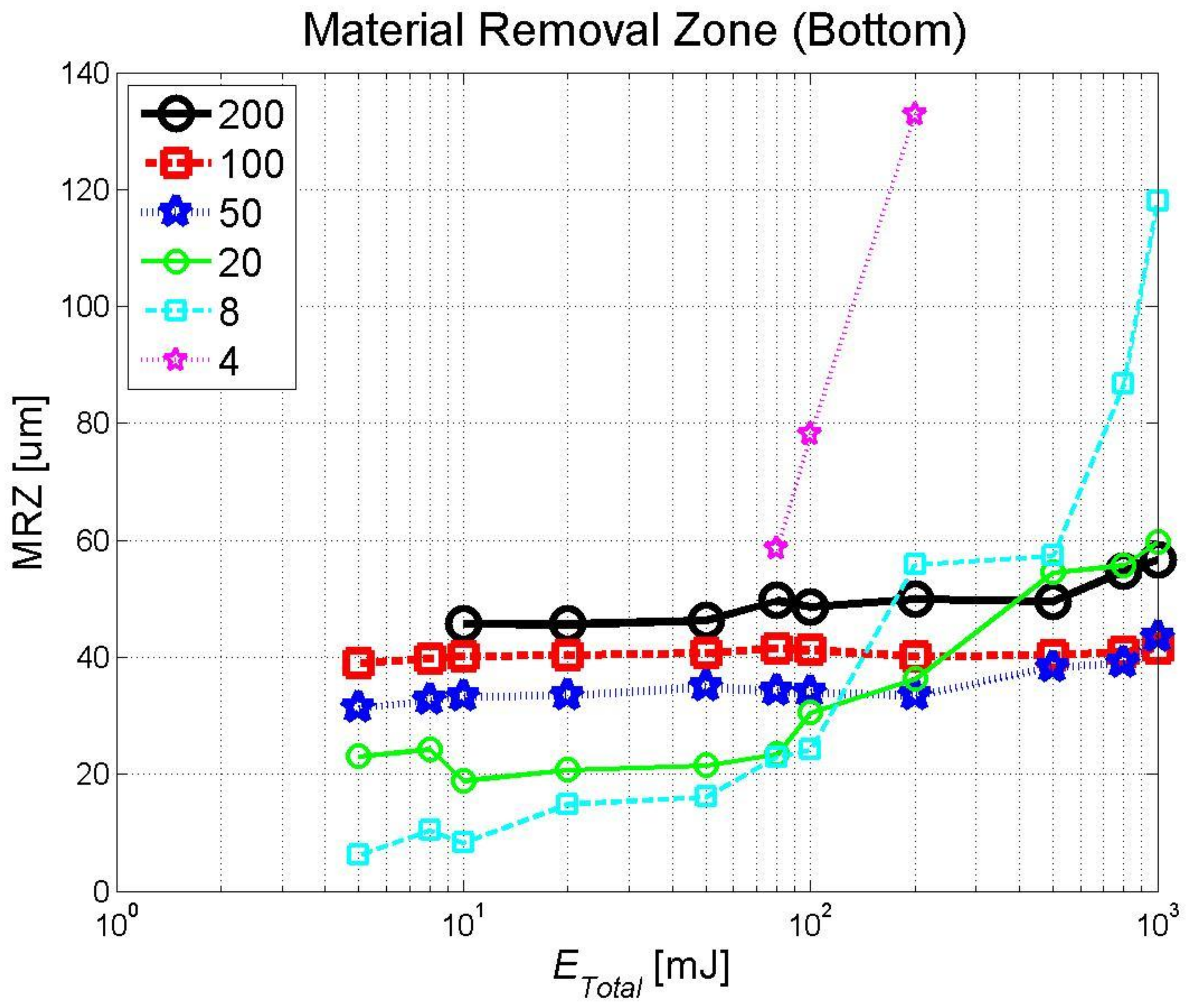

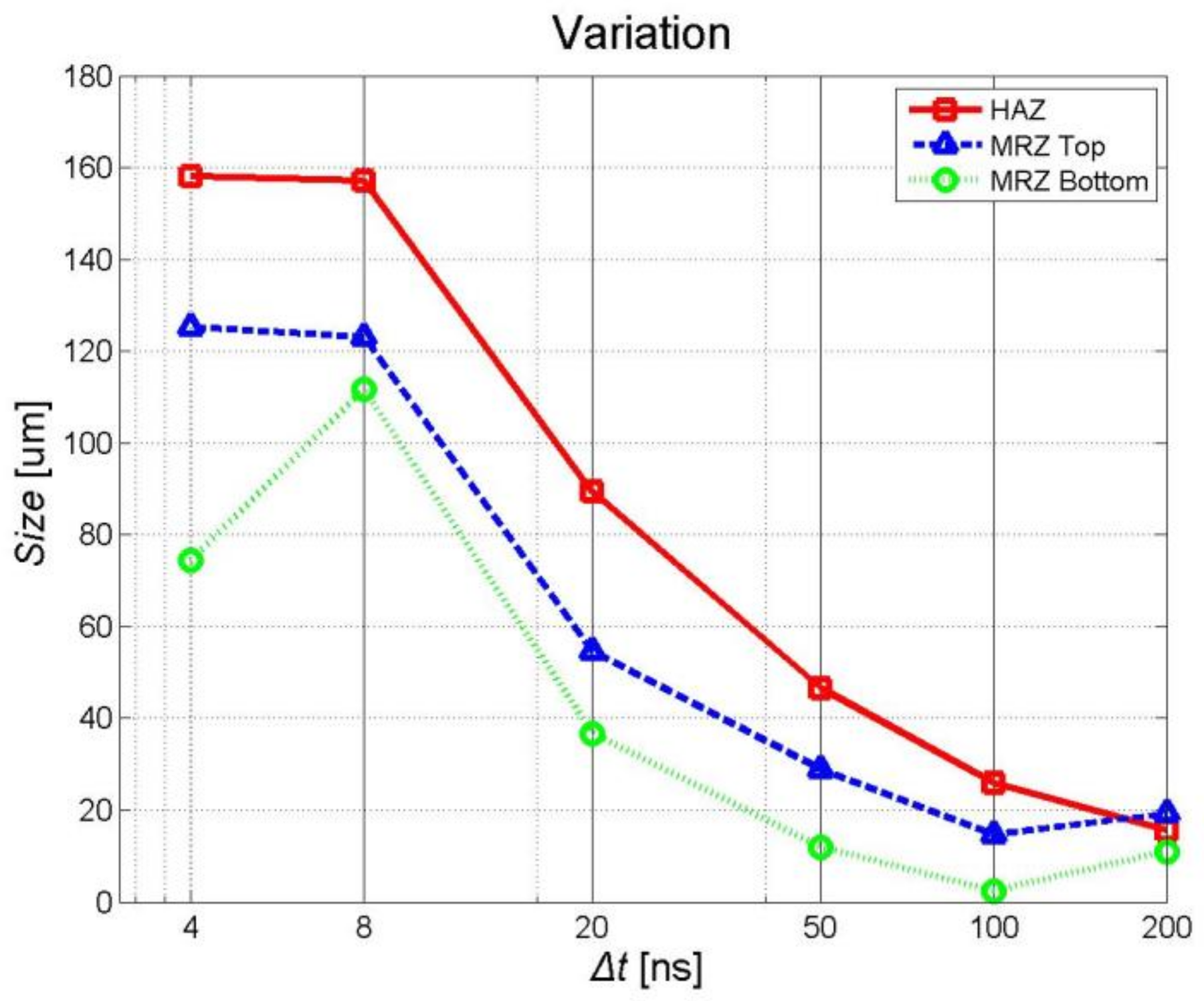

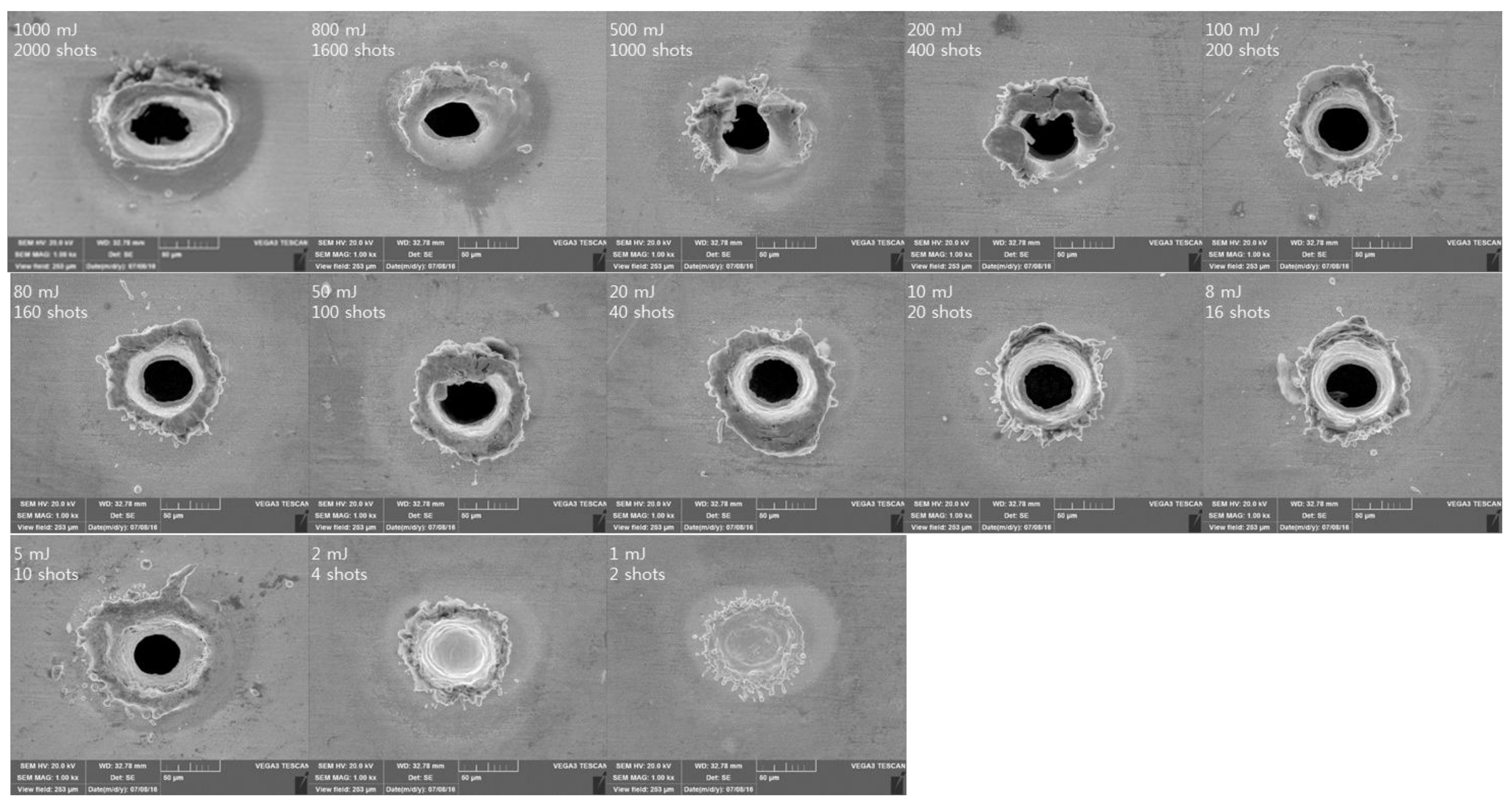

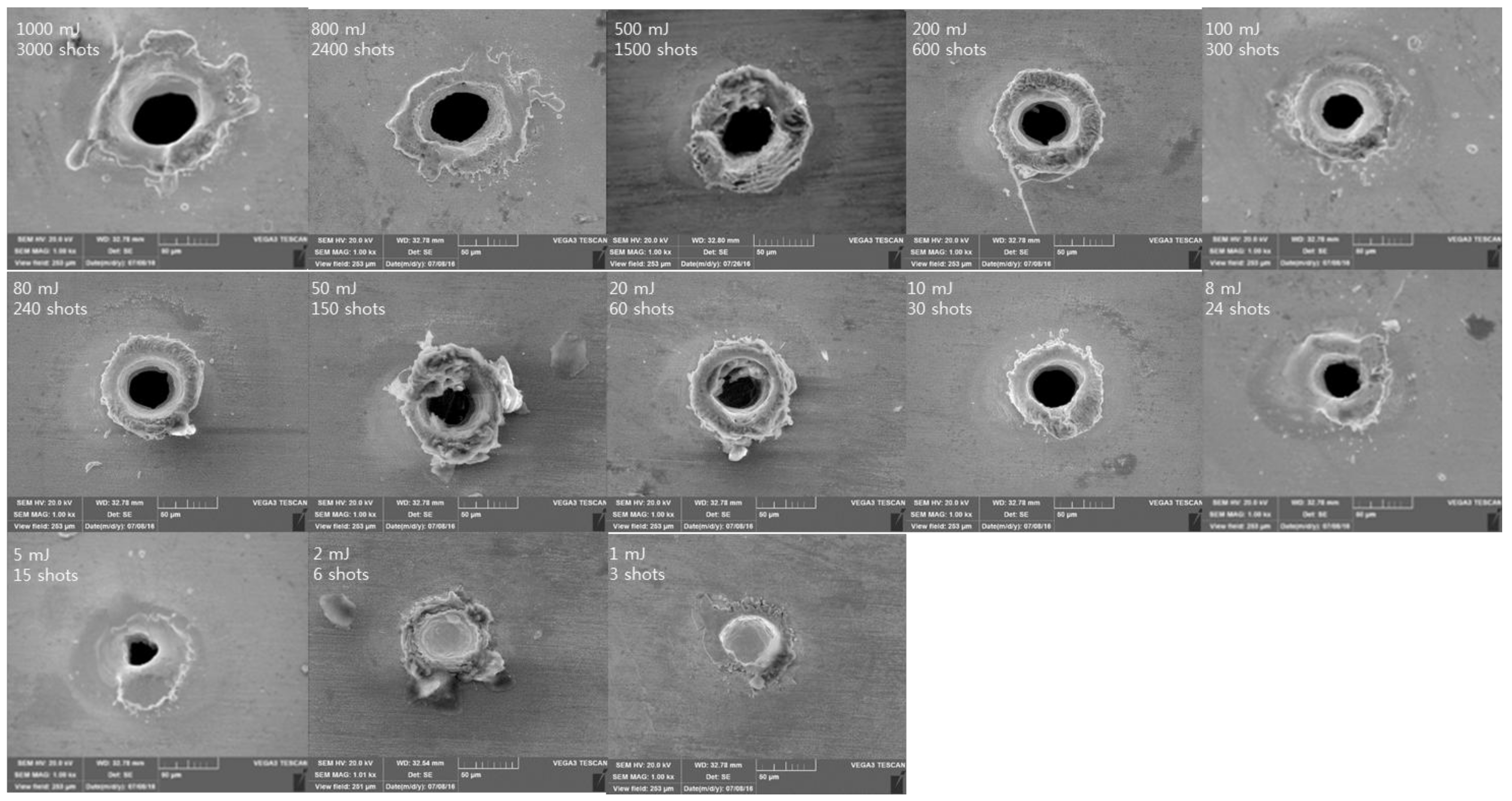

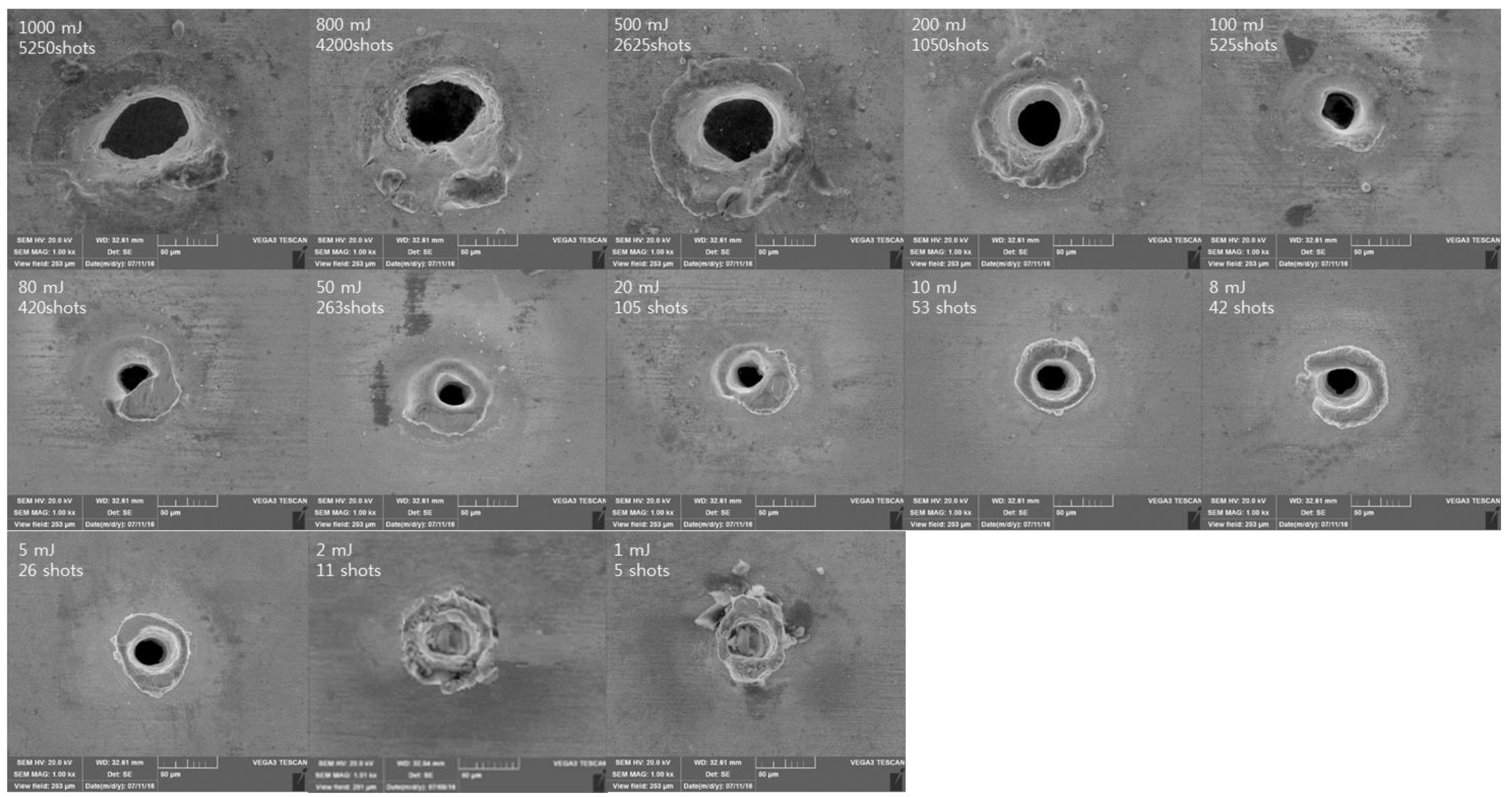

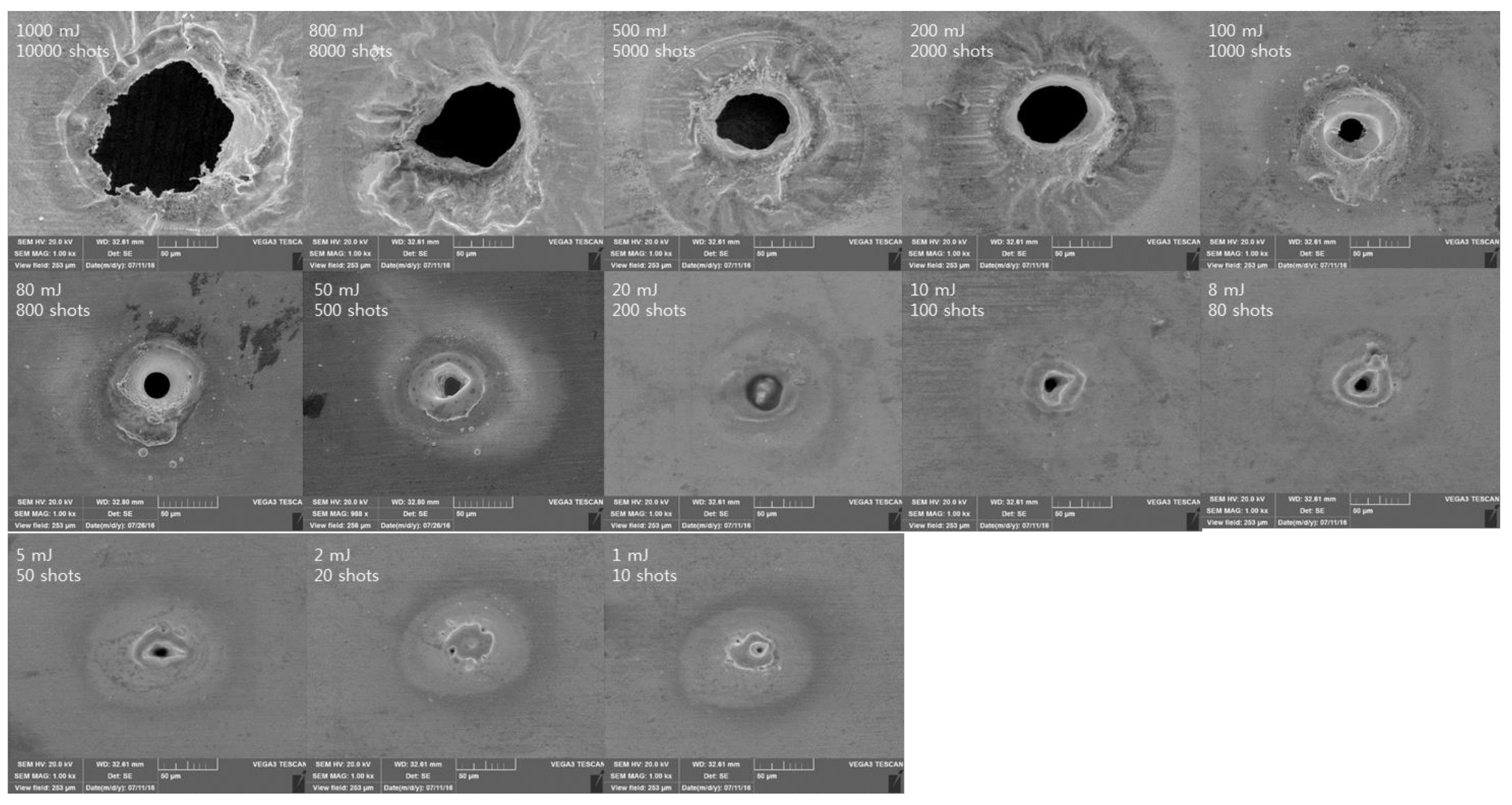

3.1. Heat Affected Zone, Material Removal Zone, and Roundness

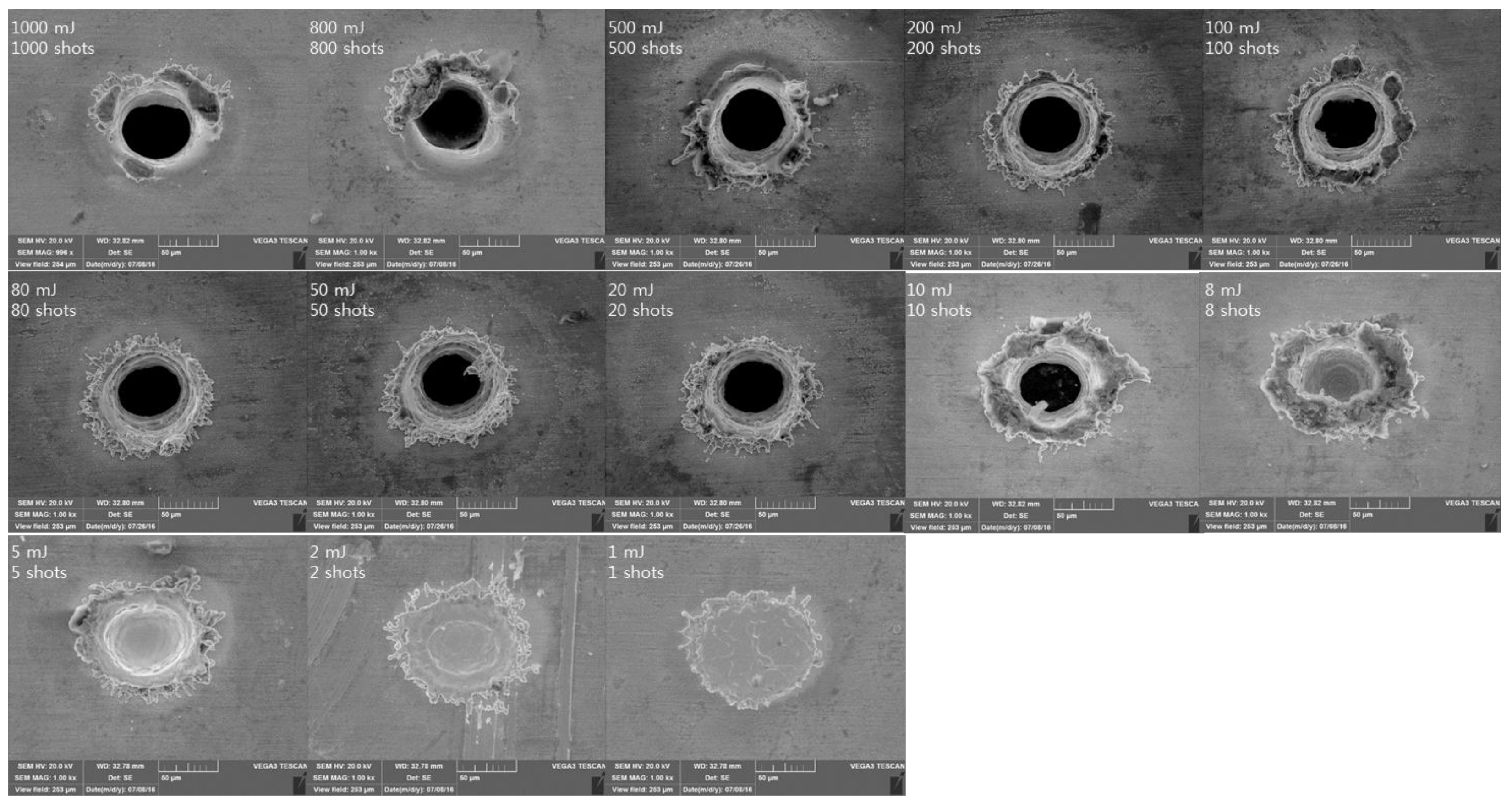

3.2. Observation of Surface Characteristics

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, D.; Cho, J.; Kim, C.H.; Lee, S.H. Application of laser spot cutting on spring contact probe for semiconductor package inspection. Opt. Laser Technol. 2017, 97, 90–96. [Google Scholar] [CrossRef]

- Lee, C.-M.; Kim, D.-H.; Baek, J.-T.; Kim, E.-J. Laser assisted milling device: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 199–208. [Google Scholar] [CrossRef]

- Jeong, Y.C.; Cho, Y.T.; Jung, Y.G. Design of stitch welded shape with laser-ARC hybrid welding for ultra-high strength steel. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 193–197. [Google Scholar] [CrossRef]

- Steen, W.M. Laser Material Processing, 3rd ed.; Springer: London, UK, 2003. [Google Scholar]

- Kannatey-Asibu, E.; Wiley InterScience (Online Service). Principles of Laser Materials Processing; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Choi, J.-H.; Moon, Y.; Lee, S.-H.; In, J.H.; Jeong, S. Wavelength dependence of the ablation characteristics of Cu (In, Ga) Se2 solar cell films and its effects on laser induced breakdown spectroscopy analysis. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 167–171. [Google Scholar] [CrossRef]

- Lee, D. Experimental Investigation of Laser Spot Welding of Ni and Au-Sn-Ni Alloy. J. Weld. Join. 2017, 35, 1–5. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Dross-free submerged laser cutting of AZ31 Mg alloy for biodegradable stents. J. Laser Appl. 2016, 28, 032001. [Google Scholar] [CrossRef]

- Lee, D.; Mazumder, J. Effects of momentum transfer on sizing of current collectors for lithium-ion batteries during laser cutting. Opt. Laser Technol. 2018, 99, 315–325. [Google Scholar] [CrossRef]

- Lee, D.; Pyo, S. Experimental Investigation of Multi-mode Fiber Laser Cutting of Cement Mortar. Materials 2018, 11, 278. [Google Scholar] [CrossRef] [PubMed]

- Lee, D. Investigation of Laser Ablation on Acrylonitrile Butadiene Styrene Plastic Used for 3D Printing. J. KWJS 2018, 36, 50–56. [Google Scholar]

- Lee, D. Investigation of Physical Phenomena and Cutting Efficiency for Laser Cutting on Anode for Li-Ion Batteries. Appl. Sci. 2018, 8, 266. [Google Scholar] [CrossRef]

- Lee, D.; Ahn, S. Investigation of Laser Cutting Width of LiCoO2 Coated Aluminum for Lithium-Ion Batteries. Appl. Sci. 2017, 7, 914. [Google Scholar] [CrossRef]

- Lee, D.; Patwa, R.; Herfurth, H.; Mazumder, J. Parameter optimization for high speed remote laser cutting of electrodes for lithium-ion batteries. J. Laser Appl. 2016, 28, 022006. [Google Scholar] [CrossRef]

- Lee, D.; Patwa, R.; Herfurth, H.; Mazumder, J. Computational and experimental studies of laser cutting of the current collectors for lithium-ion batteries. J. Power Sources 2012, 210, 327–338. [Google Scholar] [CrossRef]

- Karimzad Ghavidel, A.; Navidfar, A.; Shabgard, M.; Azdast, T. Role of CO2 laser cutting conditions on anisotropic properties of nanocomposite contain carbon nanotubes. J. Laser Appl. 2016, 28, 032006. [Google Scholar] [CrossRef]

- Staehr, R.; Bluemel, S.; Jaeschke, P.; Suttmann, O.; Overmeyer, L. Laser cutting of composites—Two approaches toward an industrial establishment. J. Laser Appl. 2016, 28, 022203. [Google Scholar] [CrossRef]

- Zhang, C.; Wen, P.; Yao, Z.; Yuan, Y.; Fan, X. Visualization of flow separation inside cut kerf during laser cutting of thick sections. J. Laser Appl. 2016, 28, 022204. [Google Scholar] [CrossRef]

- Rodrigues, C.G.; Duflou, J.R. Into polarization control in laser cutting with direct diode lasers. J. Laser Appl. 2016, 28, 022207. [Google Scholar] [CrossRef]

- Lee, D.; Mazumder, J. Dataset demonstrating effects of momentum transfer on sizing of current collector for lithium-ion batteries during laser cutting. Data Brief 2018, 17, 6–14. [Google Scholar] [CrossRef] [PubMed]

- Ghaderi, M.; Rezagholizadeh, M.; Monir Vaghefi, S.M.; Heidary, A. Investigation of high temperature wear resistance of electroless nickel coating with different contents of phosphorous. Prot. Met. Phys. Chem. Surf. 2016, 52, 538–542. [Google Scholar] [CrossRef]

- Li, B.; Zheng, M.; Xue, H.; Pang, H. High performance electrochemical capacitor materials focusing on nickel based materials. Inorg. Chem. Front. 2016, 3, 175–202. [Google Scholar] [CrossRef]

- Chai, L.; Rae, A.; Wilson, J.M. Methods for Manufacture a Capacitor with Three-Dimensional High Surface Area Electrodes. U.S. Patent 9,343,231, 17 May 2016. [Google Scholar]

- Stowers, J.P.; Burgers, H.T.; Blackard, P.D. Coaxial Double-Headed Spring Contact Probe Assembly and Coaxial Surface Contact for Engagement Therewith. U.S. Patent 5,936,421, 10 August 1999. [Google Scholar]

- Carbonero, J.L.; Morin, G.; Cabon, B. Comparison between beryllium-copper and tungsten high frequency air coplanar probes. IEEE Trans. Microw. Theory Tech. 1995, 43, 2786–2793. [Google Scholar] [CrossRef]

- Ki, H.; Mohanty, P.S.; Mazumder, J. Multiple reflection and its influence on keyhole evolution. J. Laser Appl. 2002, 14, 39–45. [Google Scholar] [CrossRef]

- Ki, H.; Mohanty, P.S.; Mazumder, J. Modeling of laser keyhole welding: Part I. Mathematical modeling, numerical methodology, role of recoil pressure, multiple reflections, and free surface evolution. Metall. Mater. Trans. A 2002, 33, 1817–1830. [Google Scholar] [CrossRef]

- Ki, H.; Mohanty, P.S.; Mazumder, J. Modeling of laser keyhole welding: Part II. Simulation of keyhole evolution, velocity, temperature profile, and experimental verification. Metall. Mater. Trans. A 2002, 33, 1831–1842. [Google Scholar] [CrossRef]

- Lee, D.; Mazumder, J. Effects of laser beam spatial distribution on laser-material interaction. J. Laser Appl. 2016, 28, 032003. [Google Scholar] [CrossRef]

- Weber, R.; Graf, T.; Berger, P.; Onuseit, V.; Wiedenmann, M.; Freitag, C.; Feuer, A. Heat accumulation during pulsed laser materials processing. Opt. Express 2014, 22, 11312–11324. [Google Scholar] [CrossRef] [PubMed]

| Pulse Duration (ns) | Repetition Rate (kHz) | Pulse Energy (uJ) | Total E (mJ) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1000 | 800 | 500 | 200 | 100 | 80 | 50 | 20 | 10 | 8 | 5 | 2 | 1 | |||

| Number of Pulse (#) | |||||||||||||||

| 200 | 20 | 1000 | 1000 | 800 | 500 | 200 | 100 | 80 | 50 | 20 | 10 | 8 | 5 | 2 | 1 |

| 100 | 40 | 500 | 2000 | 1600 | 1000 | 400 | 200 | 160 | 100 | 40 | 20 | 16 | 10 | 4 | 2 |

| 50 | 60 | 333.3 | 3000 | 2400 | 1500 | 600 | 300 | 240 | 150 | 60 | 30 | 24 | 15 | 6 | 3 |

| 20 | 105 | 190.5 | 5250 | 4200 | 2625 | 1050 | 525 | 420 | 263 | 105 | 53 | 42 | 26 | 11 | 5 |

| 8 | 200 | 100 | 10,000 | 8000 | 5000 | 2000 | 1000 | 800 | 500 | 200 | 100 | 80 | 50 | 20 | 10 |

| 4 | 500 | 40 | 25,000 | 20,000 | 12,500 | 5000 | 2500 | 2000 | 1250 | 500 | 250 | 200 | 125 | 50 | 25 |

| Pulse Duration (ns) | ΔHAZ (μm) | Δ(MRZ)Top (μm) | Δ(MRZ)Bottom (μm) |

|---|---|---|---|

| 200 | 15.656 | 19.221 | 10.958 |

| 100 | 25.932 | 14.687 | 2.362 |

| 50 | 46.583 | 28.84 | 12.008 |

| 20 | 89.307 | 54.58 | 36.682 |

| 8 | 157.133 | 123.019 | 111.748 |

| 4 | 158.073 | 125.15 | 74.305 |

| Pulse Duration (ns) | Total E (mJ) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1000 | 800 | 500 | 200 | 100 | 80 | 50 | 20 | 10 | 8 | 5 | 2 | 1 | |

| Roundness (%) | |||||||||||||

| 200 | 61.43 | 62.07 | 68.9 | 69.85 | 67.21 | 66.13 | 69.3 | 68.33 | 66.67 | - | - | - | - |

| 100 | 47.89 | 48.21 | 60 | 70.4 | 71.15 | 68.75 | 73.91 | 70 | 67 | 68.27 | 69.57 | - | - |

| 50 | 50.66 | 51.56 | 58.65 | 66.36 | 71.43 | 74.7 | 72.63 | 77.32 | 72.94 | 71.6 | 71.23 | - | - |

| 20 | 48.89 | 54.76 | 62.16 | 78.89 | 72.97 | 71.19 | 68.63 | 67.35 | 68.42 | 67.24 | 67.65 | - | - |

| 8 | 57.96 | 54.39 | 54.43 | 61.11 | 71.15 | 78.85 | 76.32 | 75.68 | 75.4 | 74.07 | 73.91 | - | - |

| 4 | No Exp | No Exp | No Exp | 55 | 64.44 | 69.05 | - | - | - | - | - | - | - |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D. Experimental Investigation of Laser Ablation Characteristics on Nickel-Coated Beryllium Copper. Metals 2018, 8, 211. https://doi.org/10.3390/met8040211

Lee D. Experimental Investigation of Laser Ablation Characteristics on Nickel-Coated Beryllium Copper. Metals. 2018; 8(4):211. https://doi.org/10.3390/met8040211

Chicago/Turabian StyleLee, Dongkyoung. 2018. "Experimental Investigation of Laser Ablation Characteristics on Nickel-Coated Beryllium Copper" Metals 8, no. 4: 211. https://doi.org/10.3390/met8040211

APA StyleLee, D. (2018). Experimental Investigation of Laser Ablation Characteristics on Nickel-Coated Beryllium Copper. Metals, 8(4), 211. https://doi.org/10.3390/met8040211