Effects of Pre-Strain on the Aging Behavior of Al 7075 Alloy for Hot-Stamping Capability

Abstract

:1. Introduction

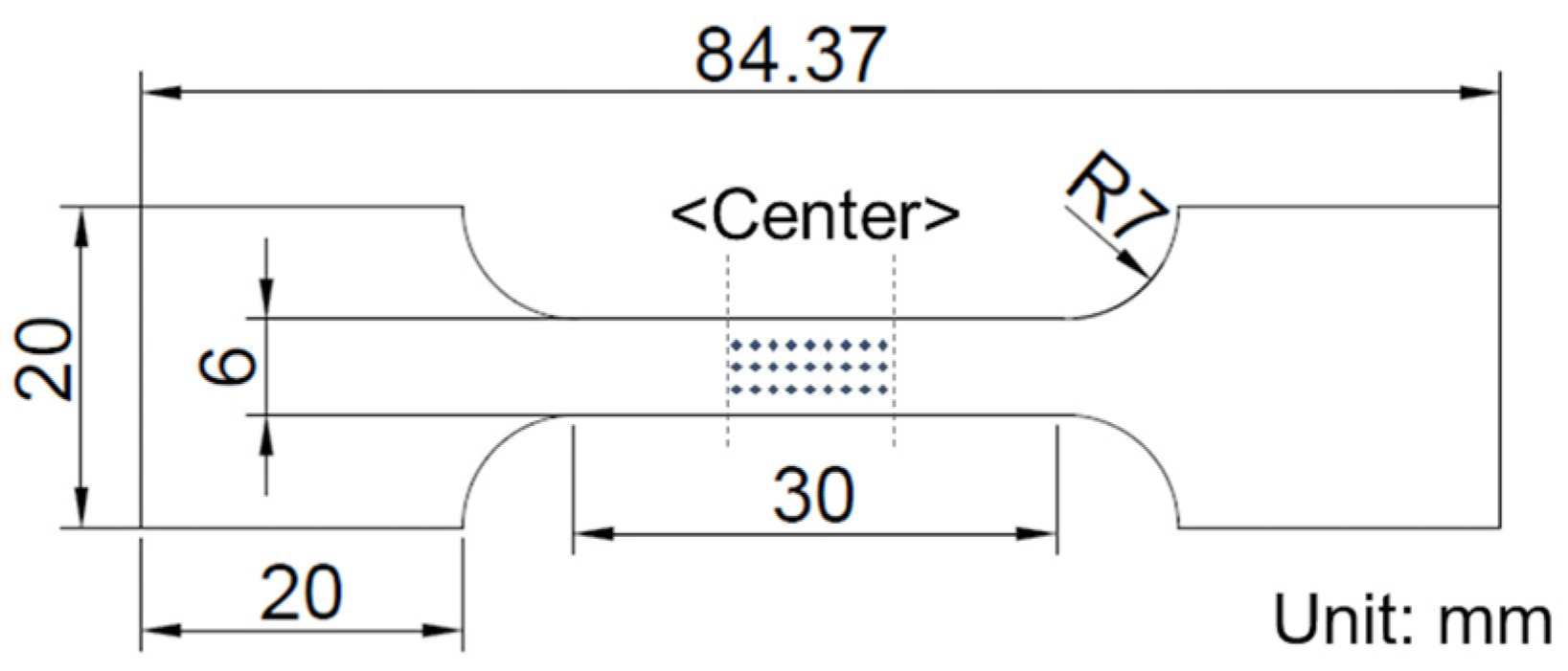

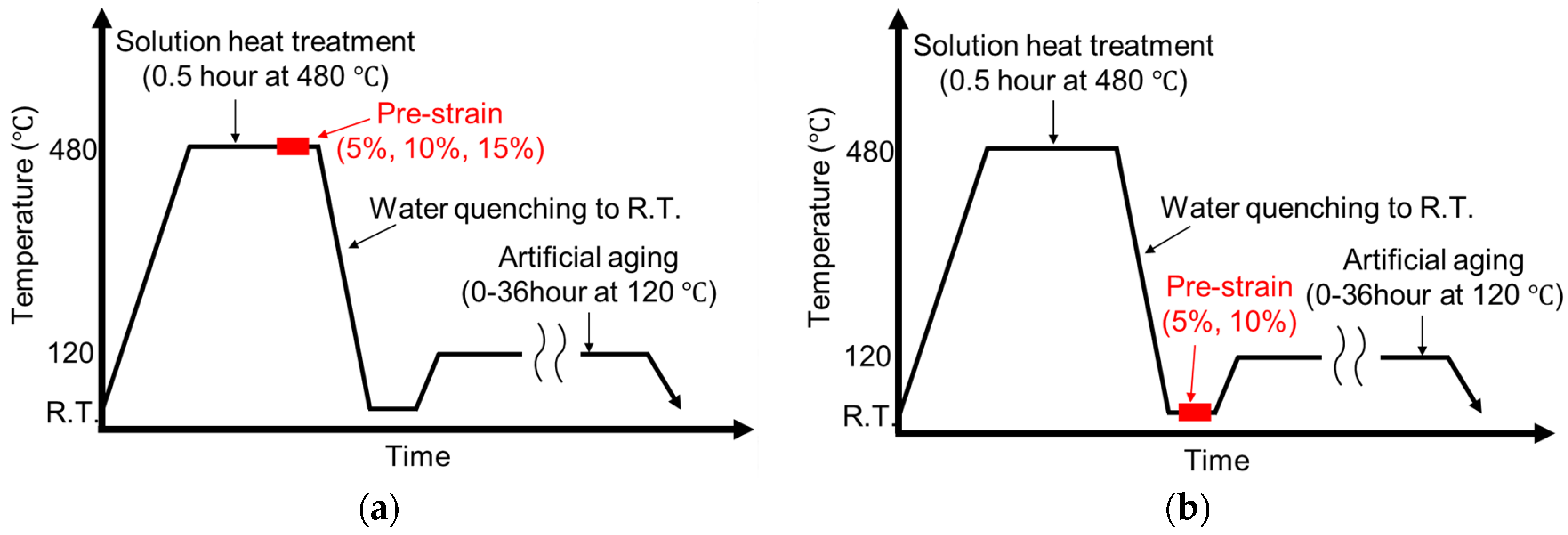

2. Experimental Material and Procedure

3. Results and Discussion

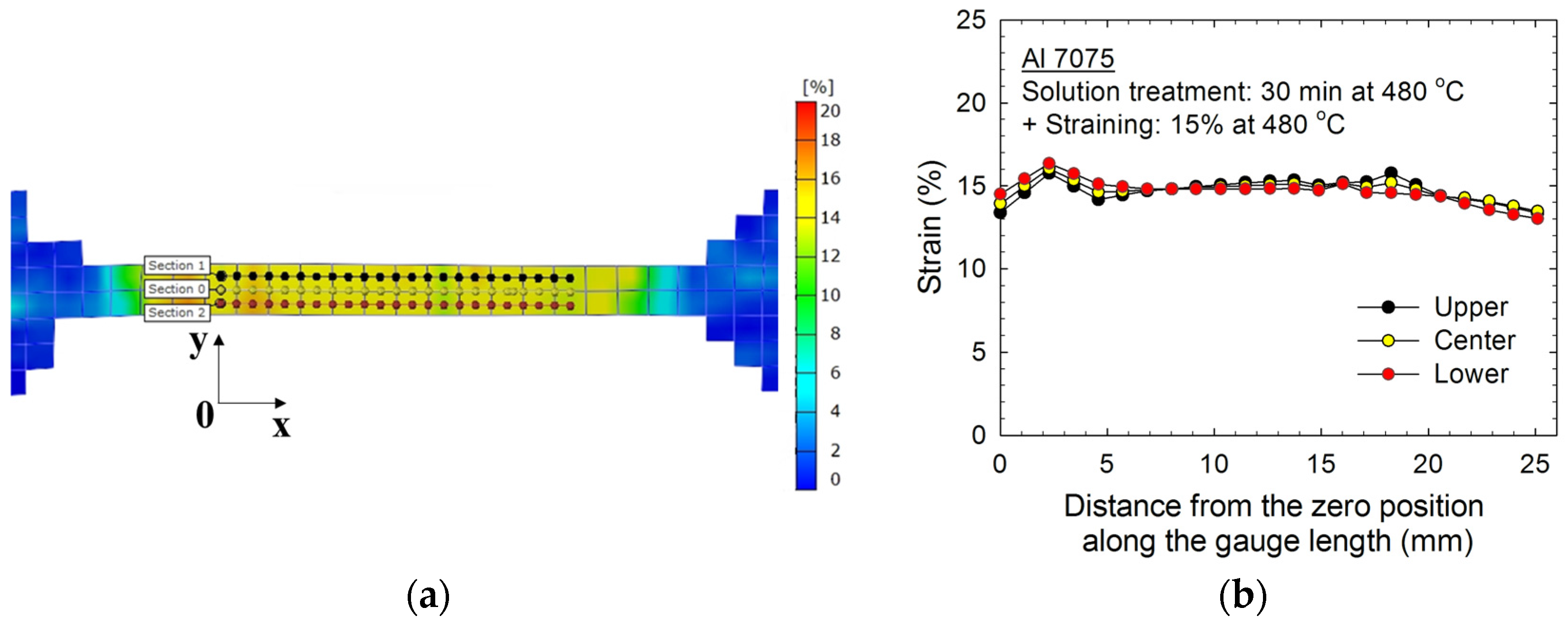

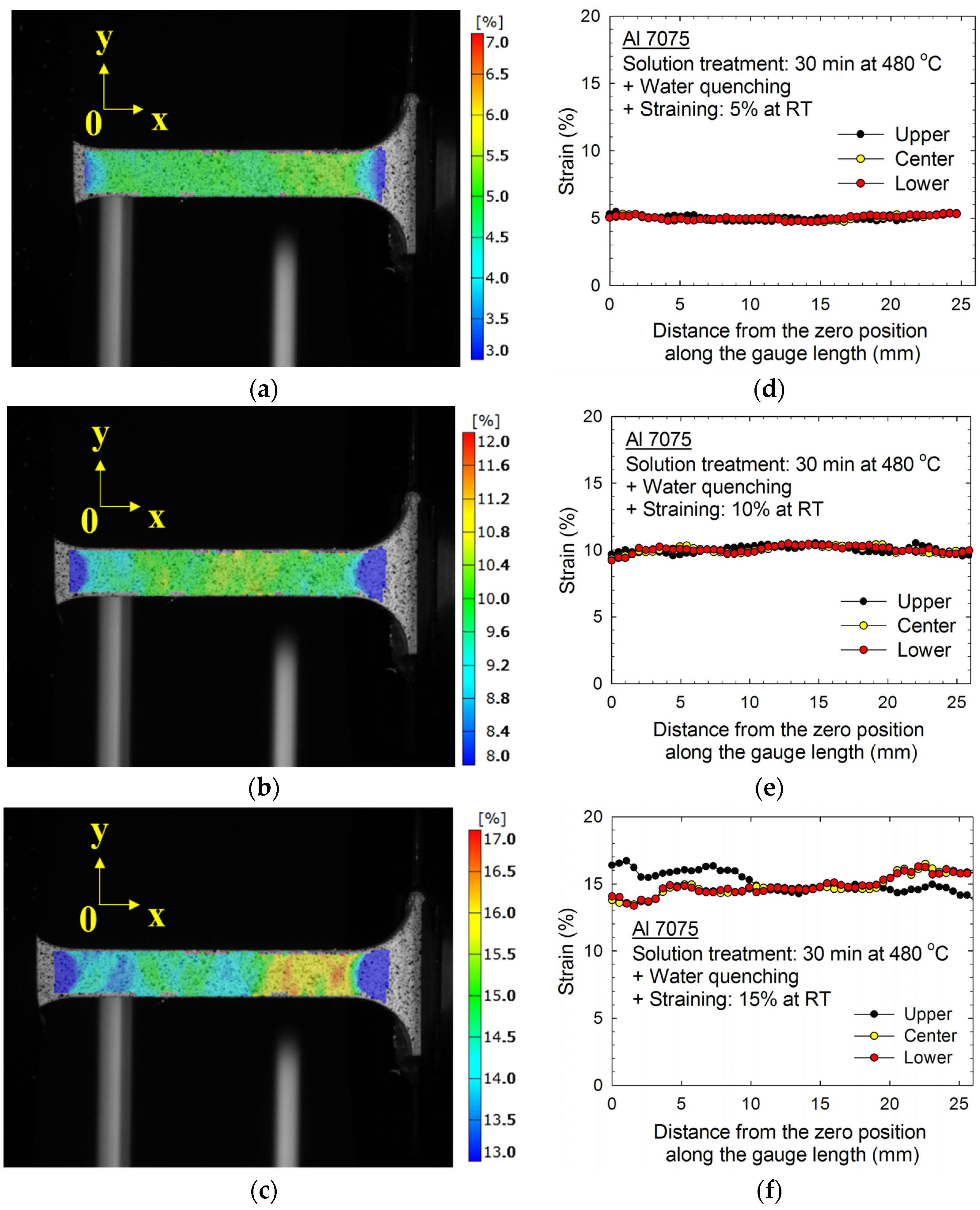

3.1. Strain Distribution with Different Strain Levels in Al 7075 Alloy

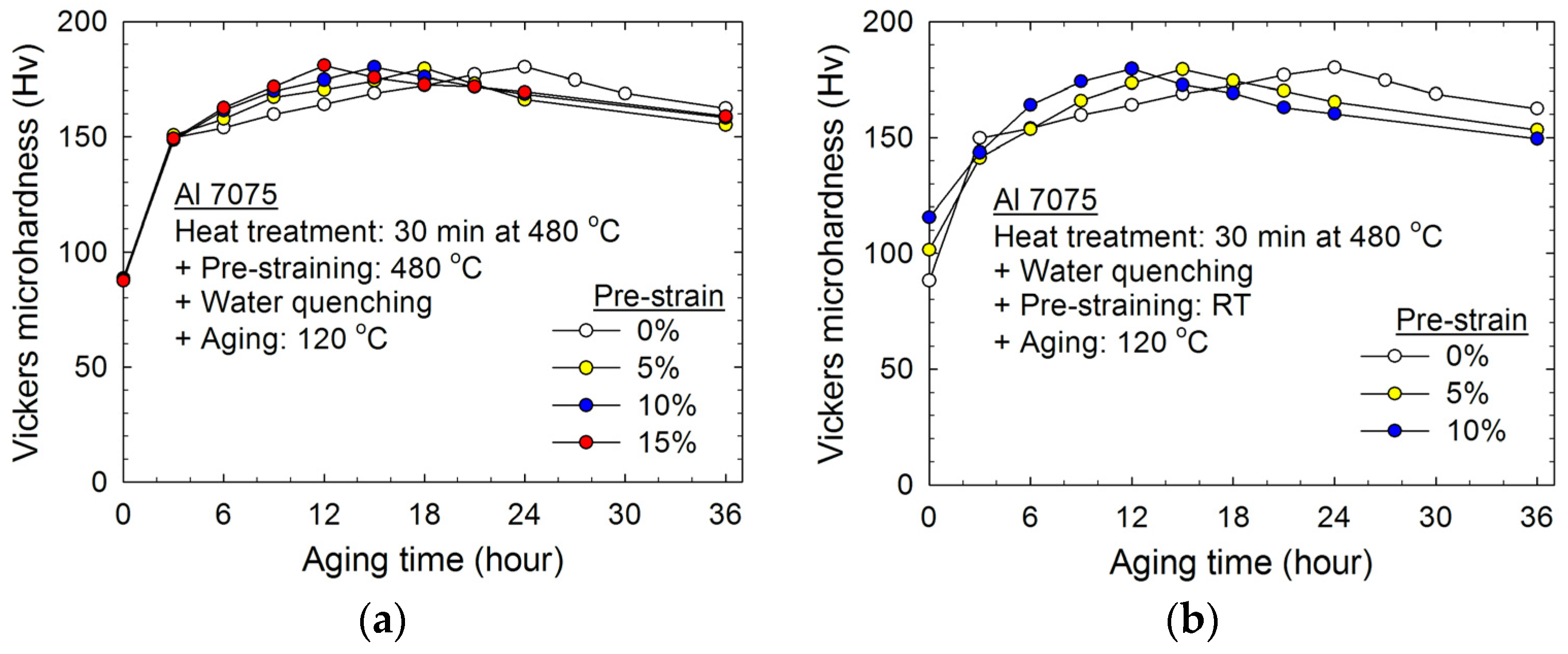

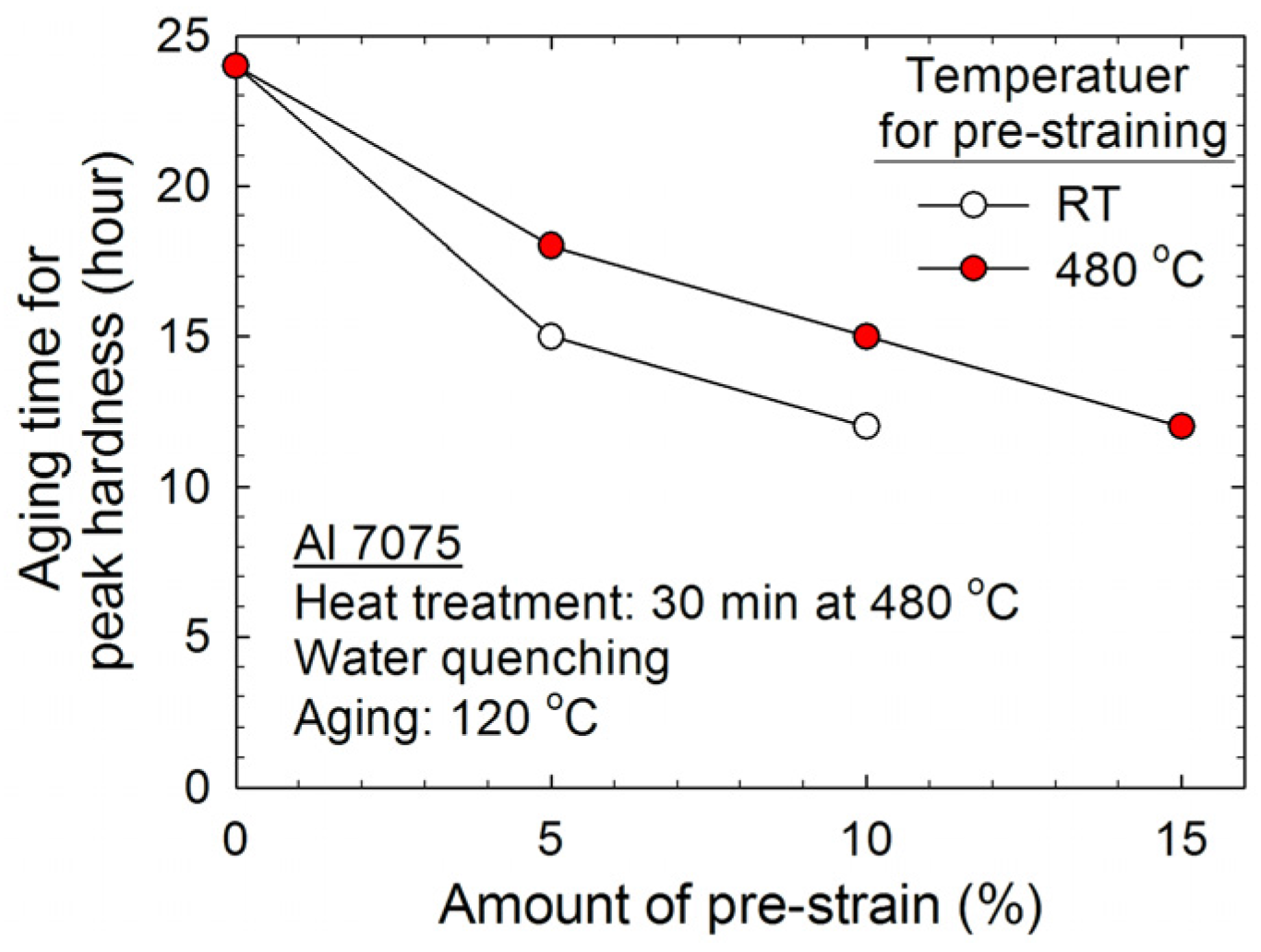

3.2. Peak Aging Hardness and Aging Time

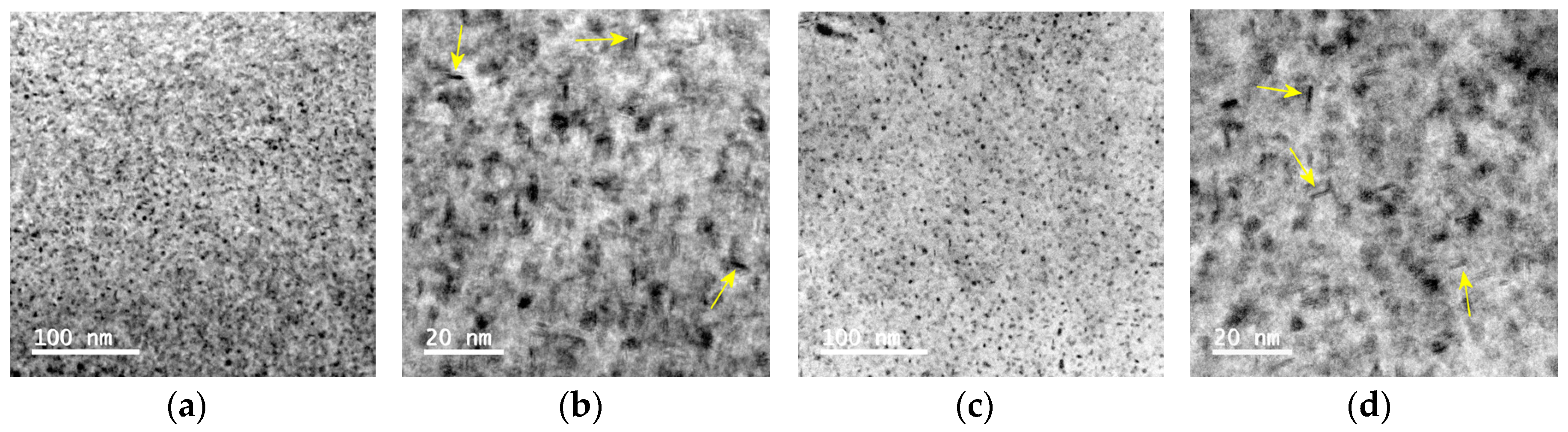

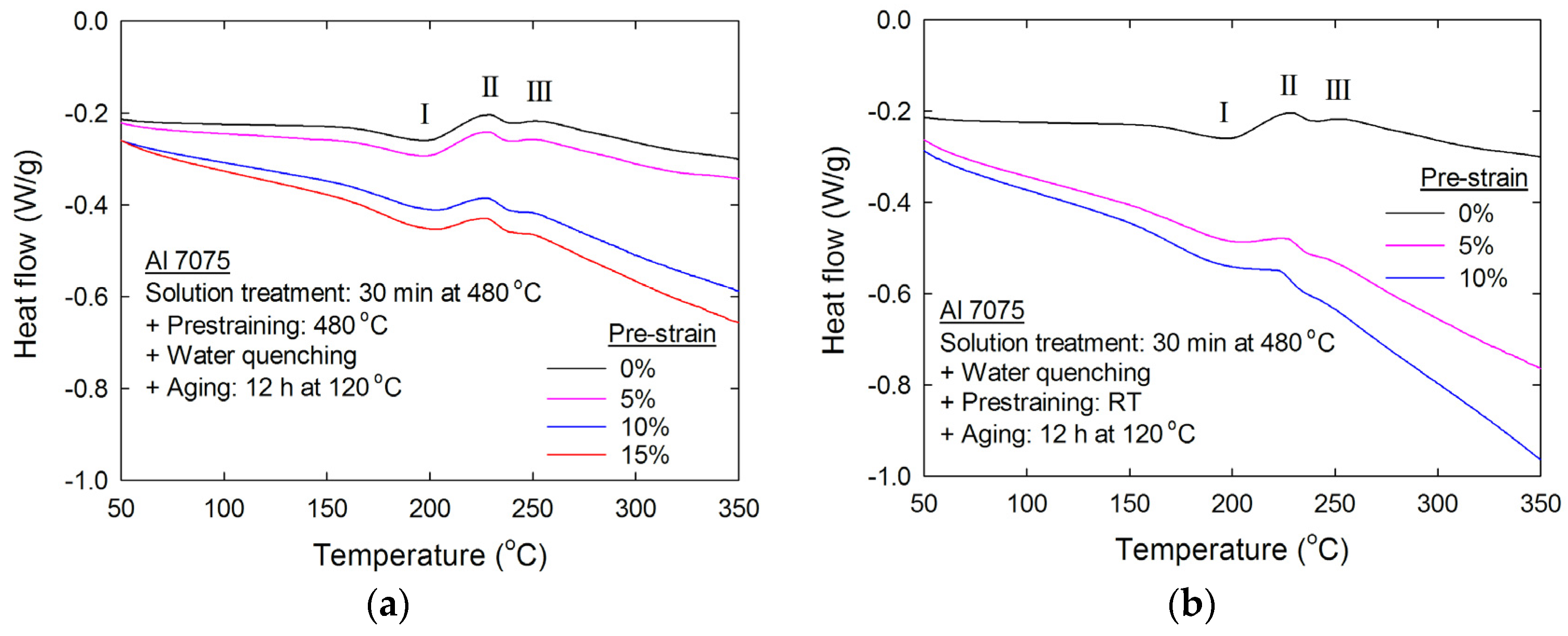

3.3. Microstructure and Precipitation Behavior

4. Summary and Conclusions

- The present study examined the effect of pre-straining on the aging behavior of an Al 7075 alloy for evaluating the applicability of the hot-stamping technique. The general age hardening procedures were utilized with addition of straining at the end of the solution heat treatment. The strain homogeneity, hardness, microstructure, and precipitation reactions of the pre-strained samples were analyzed and compared with the alloy after the consistent aging treatment with pre-straining at RT immediately after quenching.

- Homogeneous distribution of straining was observed throughout the gauge lengths for at least up to 15% at 480 °C before quenching, whereas there was a localized straining leading to necking at the gauge of the alloy after straining for 15% at RT. In terms of metal forming, the high applicable amount and homogeneity of strain is essential, and thus the result demonstrated the potential of hot-stamping for a forming process of the Al alloy.

- The aging time for achieving the peak hardness was dramatically reduced for 50% when the samples are pre-strained for the highest amounts of 15% and 10% at high temperature and RT, respectively, in comparison with the alloy in T6 without pre-straining.

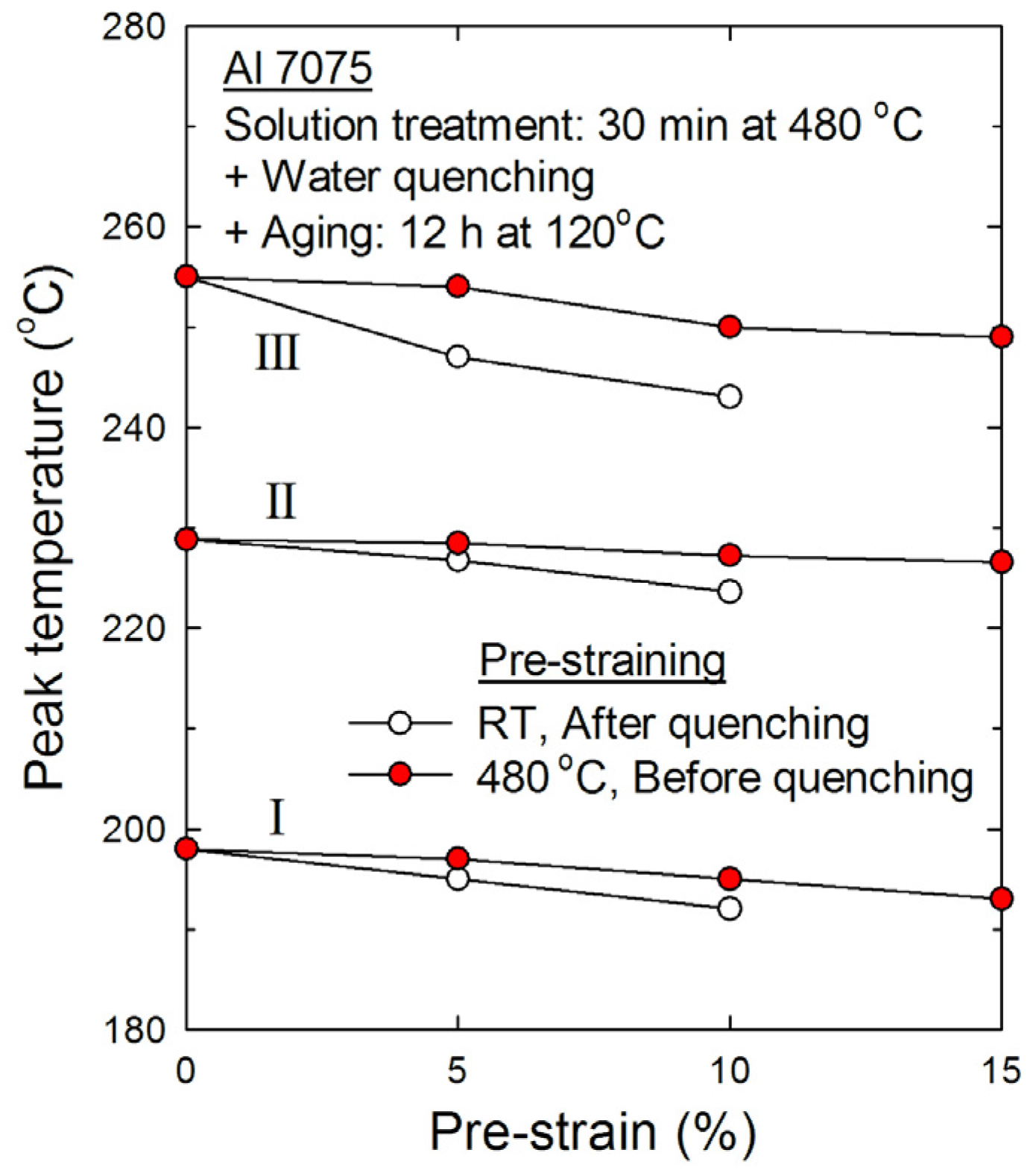

- The peak hardness after pre-straining was consistent with the hardness of Al 7075-T6, and the reasonably similar microstructure was observed by the TEM analysis between the samples at peak aging. The DSC analysis demonstrated the accelerated reactions leading to lower reaction temperatures for GPZs and precipitates in the alloy with increasing amounts of pre-strain producing higher dislocation densities in the Al 7075 alloy. The results support the accelerated peak aging time for the alloy with pre-straining.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Immarigeon, J.-P.; Holt, R.T.; Koul, A.K.; Zhao, L.; Wallace, W.; Beddoes, J.C. Lightweight materials for aircraft applications. Mater. Charact. 1995, 35, 41–67. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuanga, L.; Bottema, J.; Wittebrood, A.J.; de Smet, P.; Haszler, A.; Vieregg, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A., Jr. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Goede, M.; Stehlin, M.; Rafflenbeul, L.; Kopp, G.; Beeh, E. Super Light Car—Lightweight construction thanks to a multi-material design and function integration. Eur. Transp. Res. Rev. 2009, 1, 5–10. [Google Scholar] [CrossRef]

- Clinch, M.R.; Daval, R.; Harris, S.J.; Hepples, W.; Holroyd, N.J.H.; Lawday, M.J.; Noble, B. A microstructural engineering-based approach to 7xxx series alloy optimization. Mater. Forum 2004, 28, 145–151. [Google Scholar]

- McQueen, H.J.; Celliers, O.C. Application of hot workability studies to extrusion processing. Part III: Physical and mechanical metallurgy of Al-Mg-Si and Al-Zn-Mg alloys. Can. Metall. Q. 1997, 36, 73–86. [Google Scholar]

- Jin, N.; Zhang, H.; Han, Y.; Wu, W.; Chen, J. Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature. Mater. Charact. 2009, 60, 530–536. [Google Scholar] [CrossRef]

- Harrison, N.R.; Luckey, S.G. Hot stamping of a B-pillar outer from high strength aluminum sheet AA7075. SAE Int. J. Mater. Manuf. 2014, 7, 567–573. [Google Scholar] [CrossRef]

- Hossein, K.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar]

- Neugebauer, R.; Schieck, F.; Rautenstrauch, A.; Bach, M. Hot sheet metal forming: The formulation of graded component characteristics based on strategic temperature management for tool-based and incremental forming operations. CIRP J. Manuf. Sci. Technol. 2011, 4, 180–188. [Google Scholar] [CrossRef]

- Merklein, M.; Lechler, J. Investigation of the thermo-mechanical properties of hot stamping steels. J. Mater. Process. Technol. 2006, 177, 452–455. [Google Scholar] [CrossRef]

- Kaçar, R.; Güleryüz, K. Effect of quenching rate and pre-strain on the strain ageing behaviors of 7075 aluminum alloys. Mater. Res. 2015, 18, 328–333. [Google Scholar] [CrossRef]

- Keci, A.; Harrison, N.R.; George Luckey, S. Experimental Evaluation of the Quench Rate of AA7075; SAE Technical Paper 2014-01-0984; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Wang, D.; Ni, D.R.; Ma, Z.Y. Effect of pre-strain and two-step aging on microstructure and stress corrosion cracking of 7050 alloy. Mater. Sci. Eng. A 2008, 494, 360–366. [Google Scholar] [CrossRef]

- Dehghani, K.; Nekahi, A.; Mirzaie, M.A.M. Optimizing the bake hardening behavior of Al7075 using response surface methodology. Mater. Des. 2010, 31, 1768–1775. [Google Scholar] [CrossRef]

- Birol, Y. Pre-straining to improve the bake hardening response of a twin-roll cast Al–Mg–Si alloy. Scr. Mater. 2005, 52, 169–173. [Google Scholar] [CrossRef]

- Yin, D.; Xiao, Q.; Chen, Y.; Liu, H.; Yi, D.; Wang, B.; Pan, S. Effect of natural ageing and pre-straining on the hardening behaviour and microstructural response during artificial ageing of an Al–Mg–Si–Cu alloy. Mater. Des. 2016, 95, 329–339. [Google Scholar] [CrossRef]

- Andreatta, F.; Terryn, H.; de Wit, J.H.W. Effect of solution heat treatment on galvanic coupling between intermetallics and matrix in AA7075-T6. Corros. Sci. 2003, 45, 1733–1746. [Google Scholar] [CrossRef]

- McCormick, N.; Lord, J. Digital image correlation. Mater. Today 2010, 13, 52–54. [Google Scholar] [CrossRef]

- De, A.K.; de Blauwe, K.; Vandeputte, S.; de Cooman, B.C. Effect of dislocation density on the low temperature aging behavior of an ultra low carbon bake hardening steel. J. Alloys Compd. 2000, 310, 405–410. [Google Scholar] [CrossRef]

- El-Baradie, Z.M.; El-Sayed, M. Effect of double thermomechanical treatments on the properties. J. Mater. Process. Technol. 1996, 62, 76–80. [Google Scholar] [CrossRef]

- ASM International. Metals Handbook, Vol. 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, 10th ed.; ASM International: Warrendale, PA, USA, 1990; ISBN 978-0-87170-378-1. [Google Scholar]

- Rajan, T.V.; Sharma, C.P.; Sharma, A. Heat Treatment: Principles and Techniques; PHI Learning Pvt. Ltd.: New Delhi, India, 2011. [Google Scholar]

- Emani, S.V.; Benedyk, J.; Nash, P.; Chen, D. Double aging and thermomechanical heat treatment of AA7075 aluminum alloy extrusions. J. Mater. Sci. 2009, 44, 6384–6391. [Google Scholar] [CrossRef]

- Degischer, H.P.; Lacom, W.; Zahra, A.; Zahra, C.Y. Decomposition processes in an Al-5% Zn-1% Mg alloy. II. Electronmicroscopic investigations. Z. Metallk. 1980, 71, 231–238. [Google Scholar]

- Sha, G.; Cerezo, A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004, 52, 4503–4516. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Lendvai, J.; Ping, D.H.; Hono, K. The effect of Cu on mechanical and precipitation properties. J. Alloys Compd. 2004, 378, 52–60. [Google Scholar] [CrossRef]

- Lloyd, D.J.; Chaturvedi, M.C. A calorimetric study of aluminium alloy AA-7075. J. Mater. Sci. 1982, 17, 1819–1824. [Google Scholar] [CrossRef]

- García-cordovilla, C.; Louis, E. Kinetics of retrogression in Al-Zn-Mg-(Cu) alloys. Metall. Trans. A 1990, 21, 2277–2280. [Google Scholar] [CrossRef]

- Viana, F.; Pinto, A.M.P.; Santos, H.M.C.; Lopes, A.B. Retrogression and re-aging of 7075 aluminum alloy: Microstructural characterization. J. Mater. Process. Technol. 1999, 92–93, 54–59. [Google Scholar] [CrossRef]

- Berg, L.K.; Gjønnes, J.; Hansen, V.; Li, X.Z.; Knutson-Wedel, M.; Waterloo, G.; Schryvers, D.; Wallenberg, L.R. GP-zones in Al–Zn–Mg alloys and their role in artificial aging. Acta Mater. 2001, 49, 3443–3451. [Google Scholar] [CrossRef]

- Katz, Z.; Ryum, N. Precipitation kinetics in Al-alloys. Scr. Metall. 1981, 15, 265–268. [Google Scholar] [CrossRef]

| Mg | Zn | Cu | Si | Fe | Mn | Ti | Zr | Cr | V | Etc. |

|---|---|---|---|---|---|---|---|---|---|---|

| 2.39 | 5.61 | 1.36 | 0.095 | 0.18 | 0.042 | 0.032 | 0.016 | 0.2 | 0.011 | 0.064 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, S.-H.; Lee, J.; Kawasaki, M. Effects of Pre-Strain on the Aging Behavior of Al 7075 Alloy for Hot-Stamping Capability. Metals 2018, 8, 137. https://doi.org/10.3390/met8020137

Jung S-H, Lee J, Kawasaki M. Effects of Pre-Strain on the Aging Behavior of Al 7075 Alloy for Hot-Stamping Capability. Metals. 2018; 8(2):137. https://doi.org/10.3390/met8020137

Chicago/Turabian StyleJung, Seon-Ho, Jongsup Lee, and Megumi Kawasaki. 2018. "Effects of Pre-Strain on the Aging Behavior of Al 7075 Alloy for Hot-Stamping Capability" Metals 8, no. 2: 137. https://doi.org/10.3390/met8020137

APA StyleJung, S.-H., Lee, J., & Kawasaki, M. (2018). Effects of Pre-Strain on the Aging Behavior of Al 7075 Alloy for Hot-Stamping Capability. Metals, 8(2), 137. https://doi.org/10.3390/met8020137