Microstructure of Multi-Pass Friction-Stir-Processed Al-Zn-Mg-Cu Alloys Reinforced by Nano-Sized TiB2 Particles and the Effect of T6 Heat Treatment

Abstract

1. Introduction

2. Experiments

3. Results and Discussion

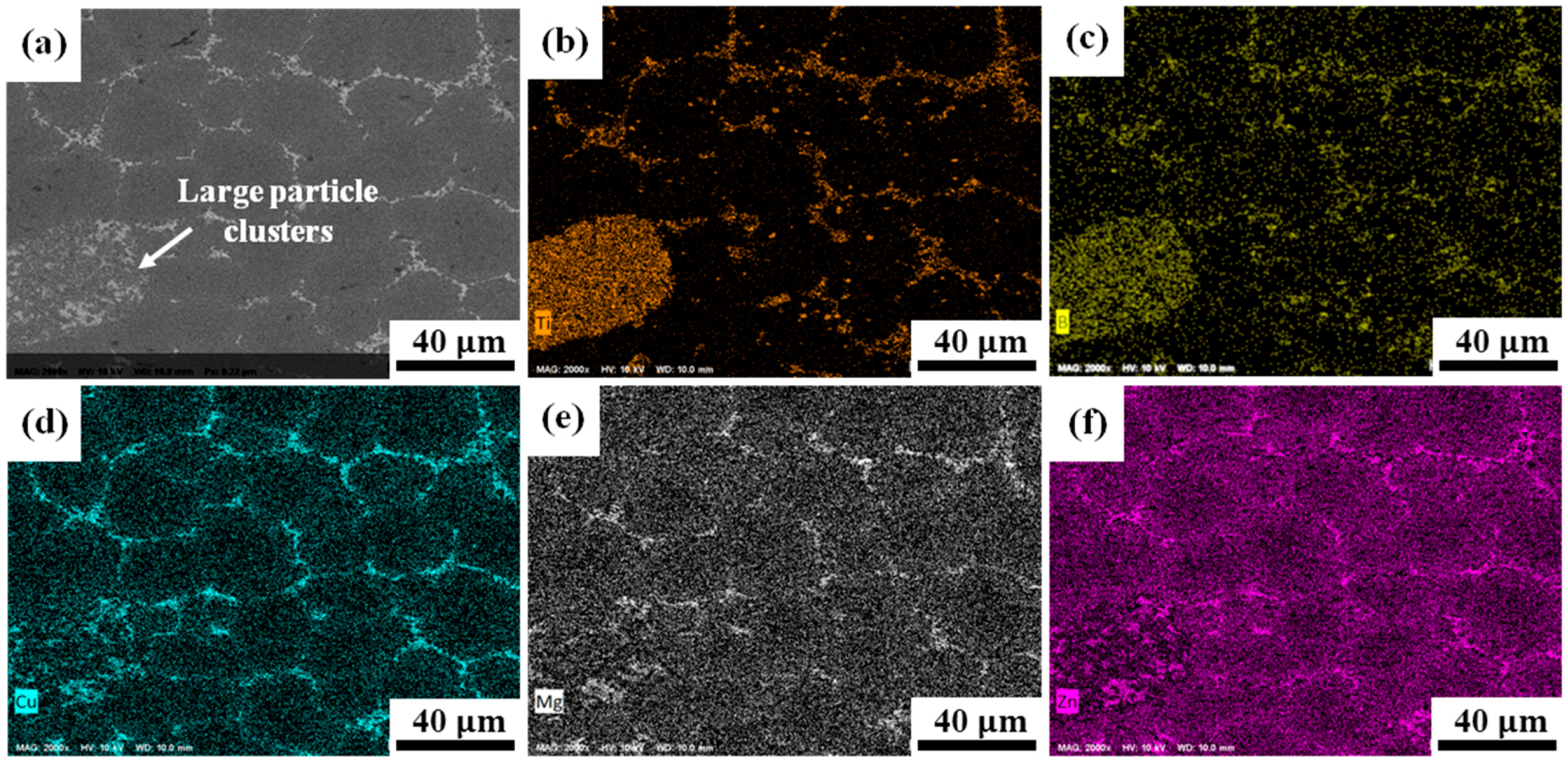

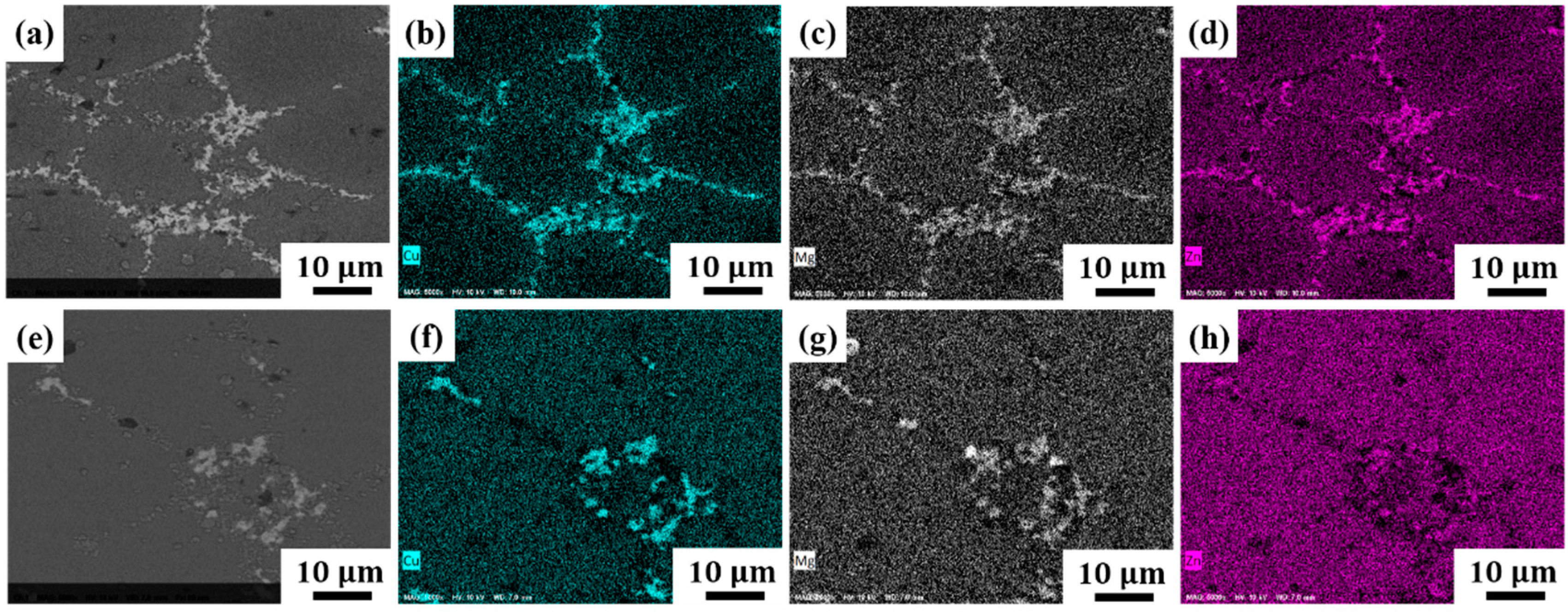

3.1. Microstructure of the As-Cast PR Alloy Samples

3.2. Microstructure of the FSP-Treated PR Alloy Samples

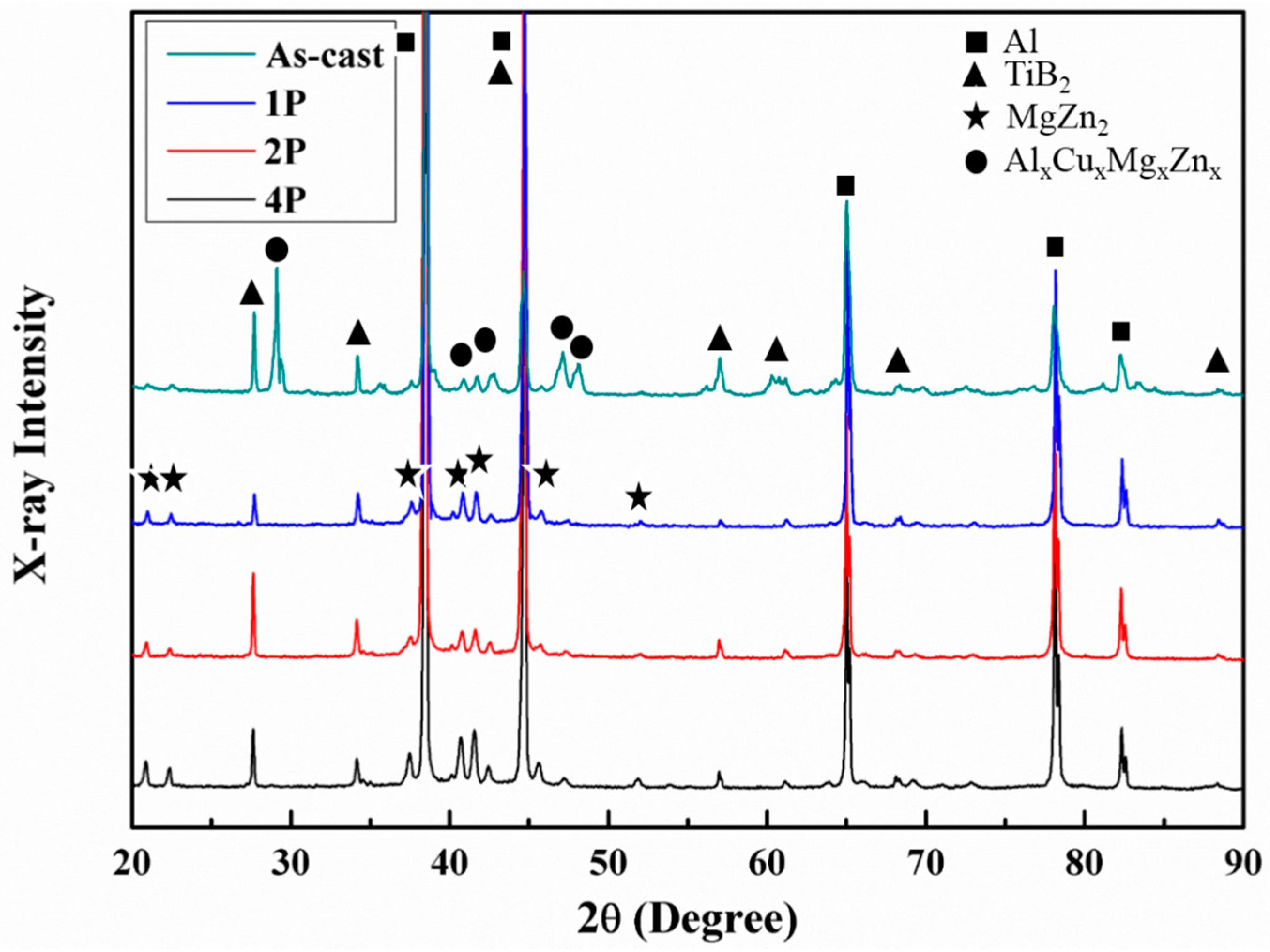

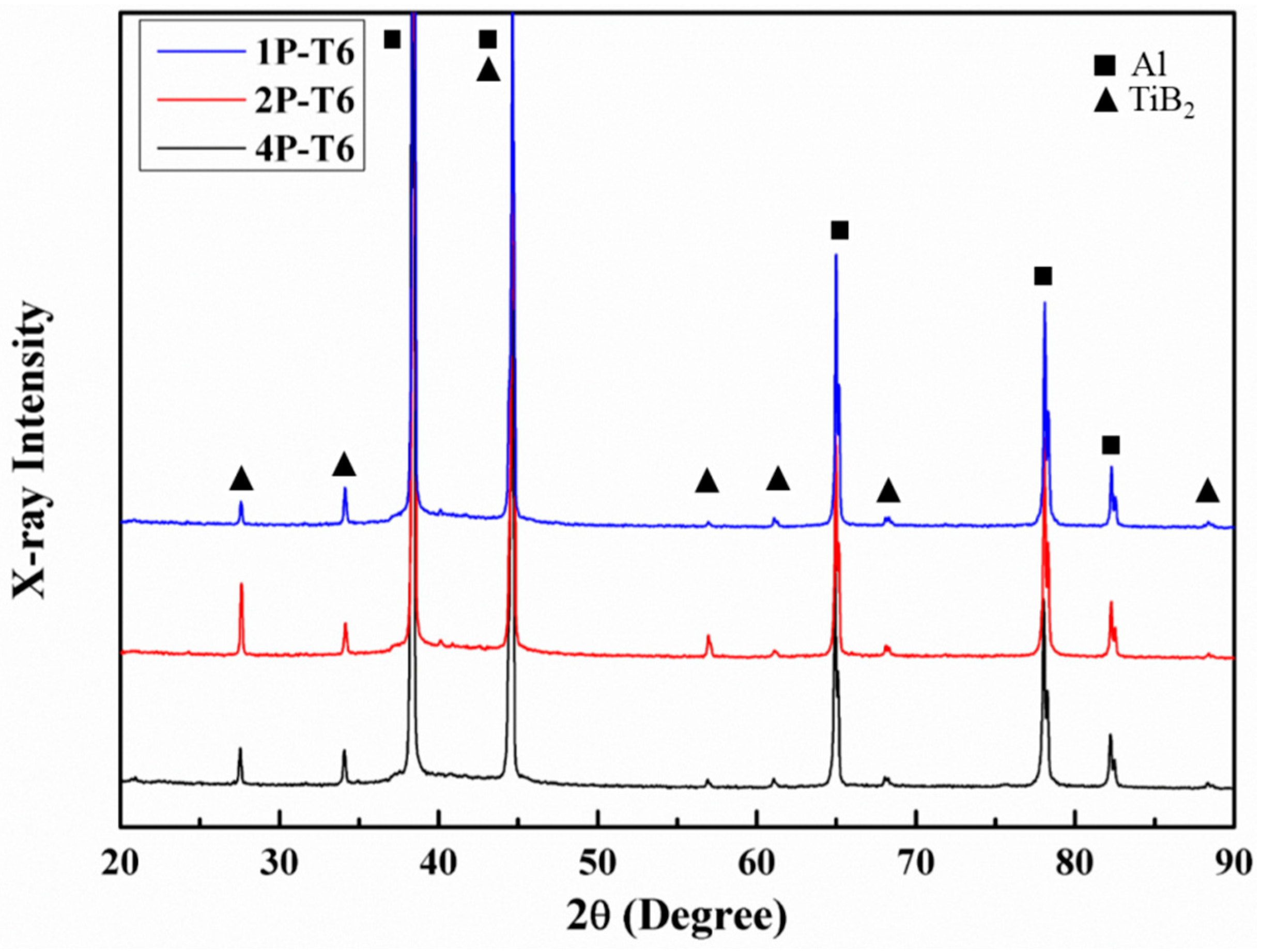

3.2.1. X-ray Diffraction Characterization

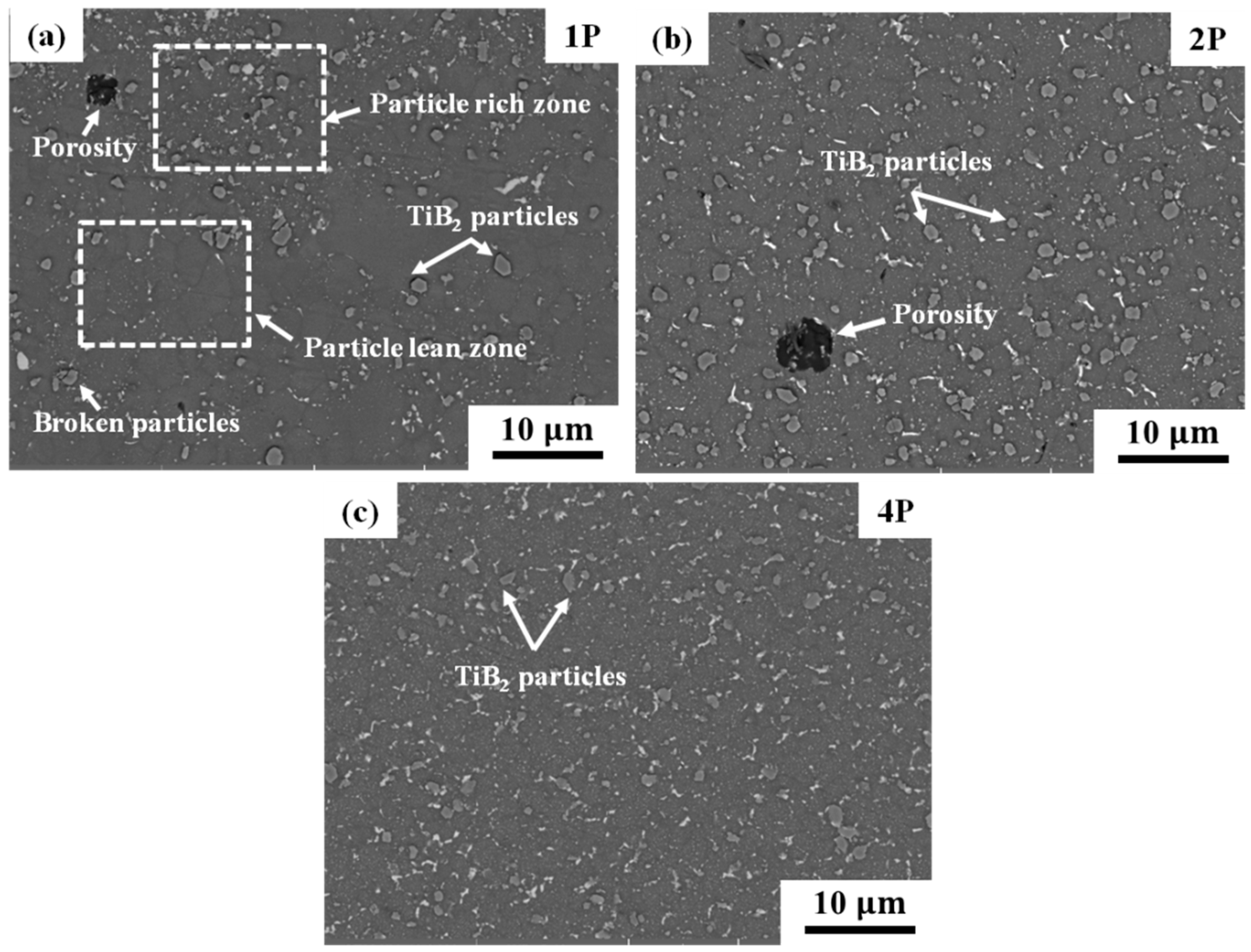

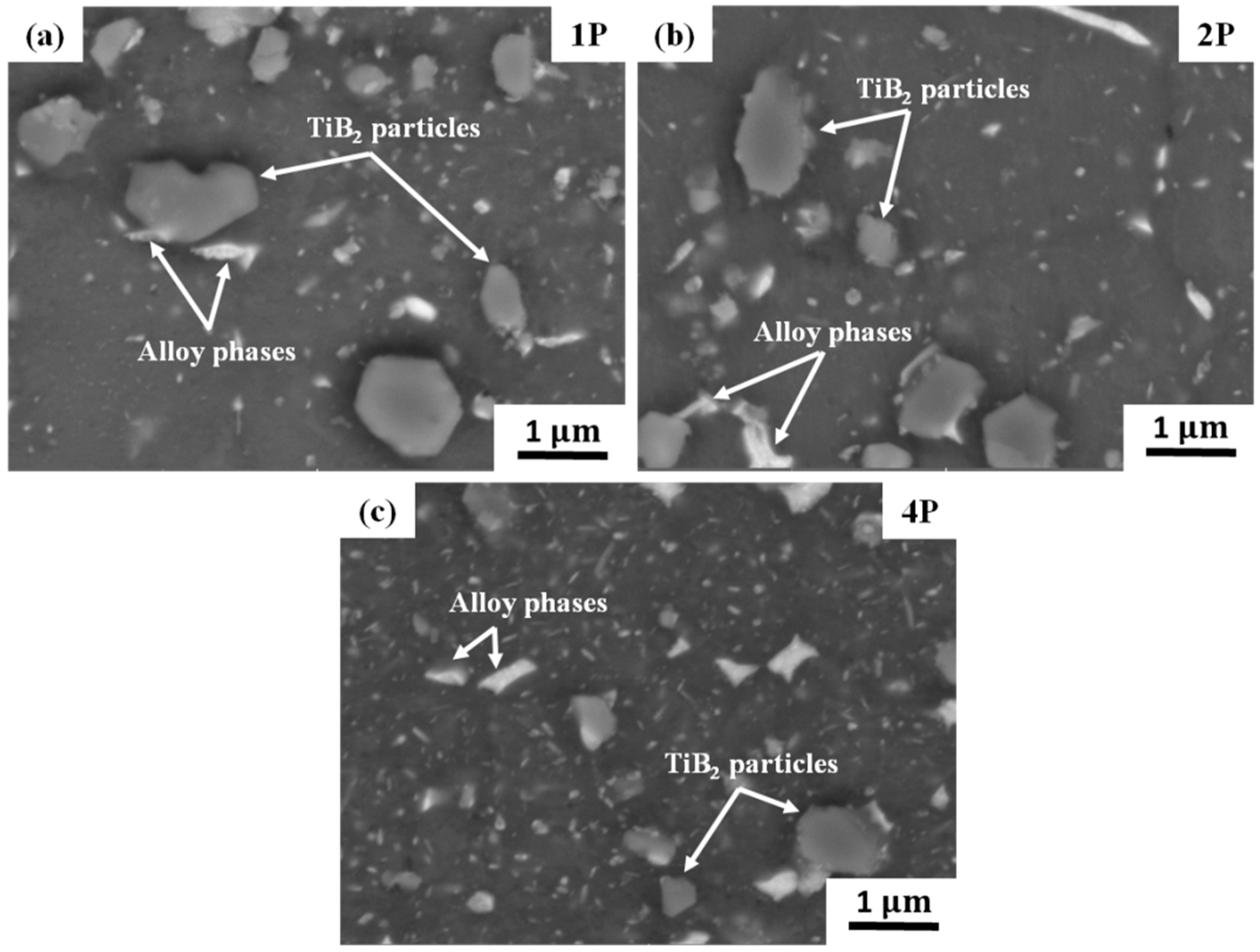

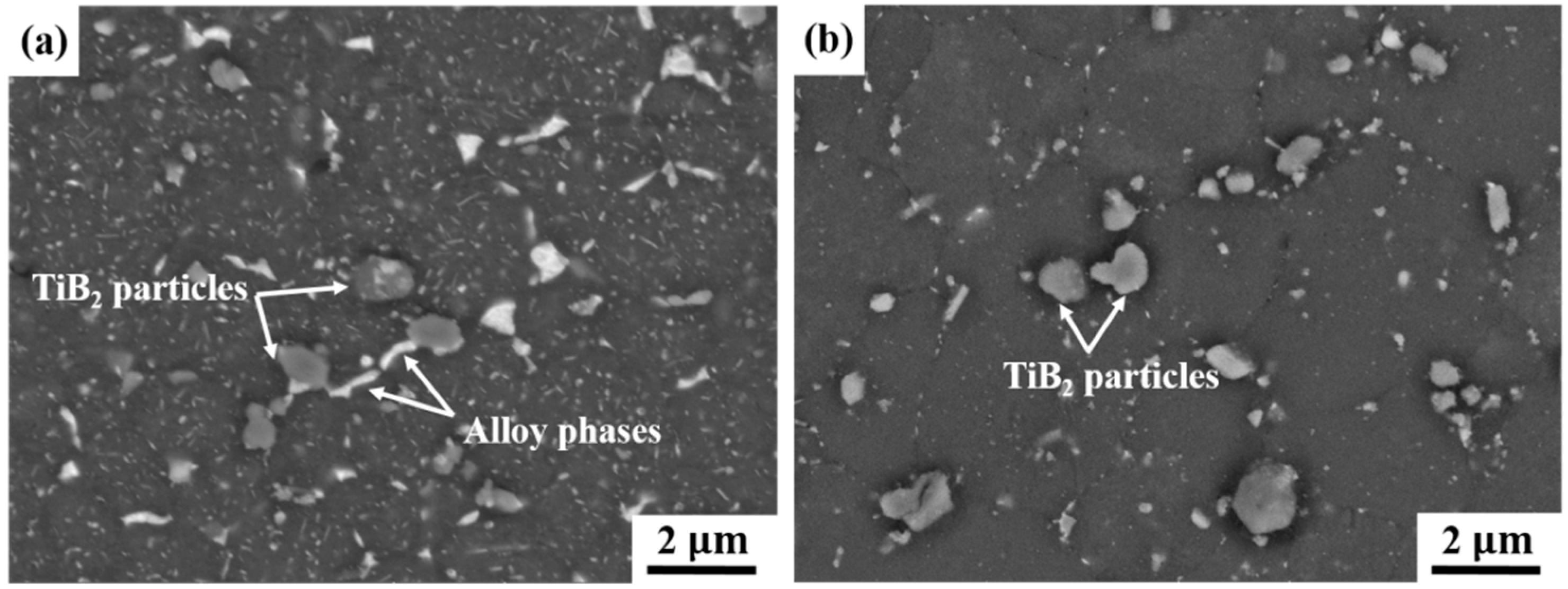

3.2.2. TiB2 Distributions Characterized by Scanning Electron Microscopy

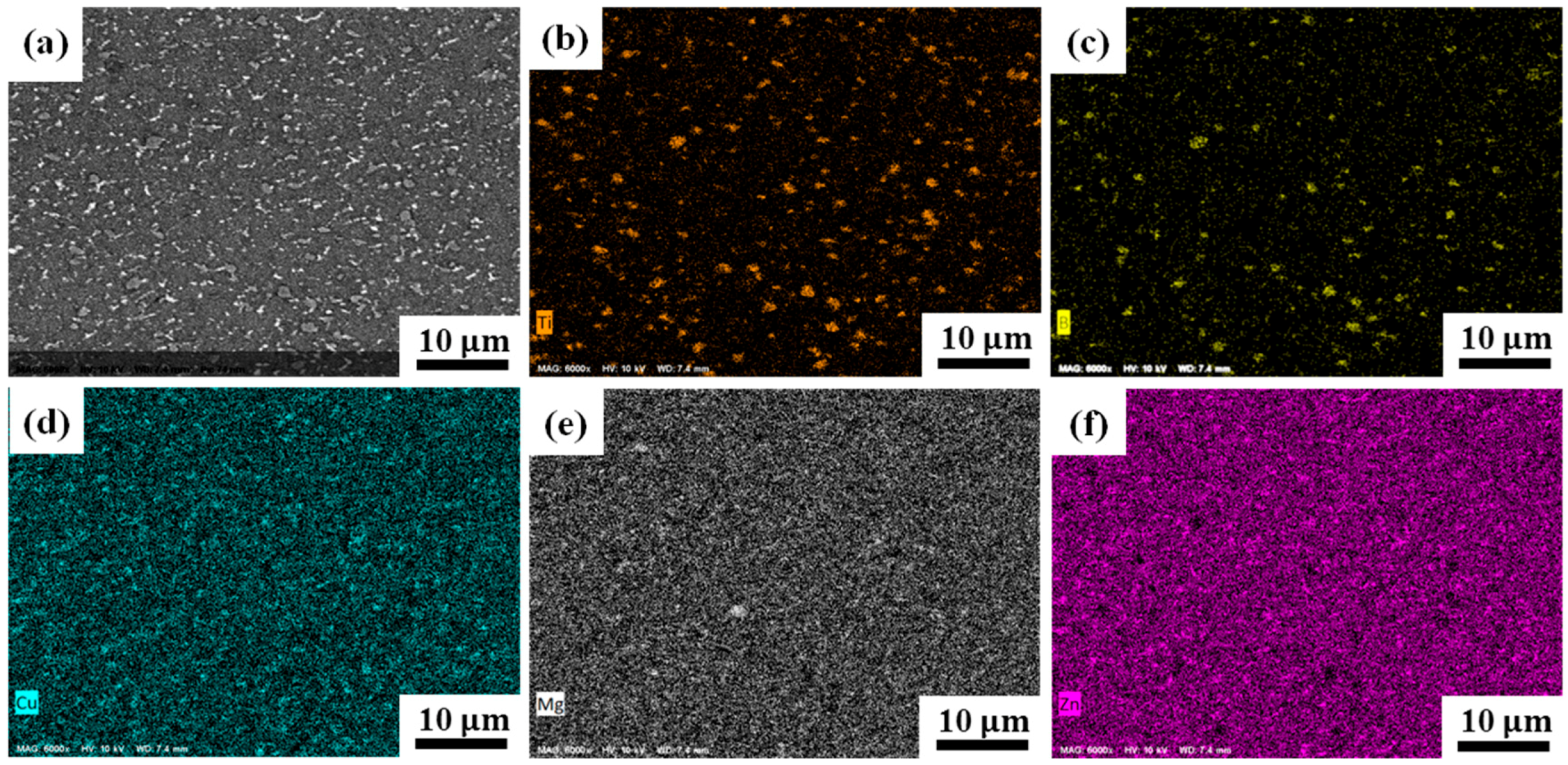

3.2.3. Alloy Element Distributions Characterized by SEM/EDS

3.2.4. Grain Size and Misorientation Distributions Characterized by EBSD

3.3. Thermal Stability of the Microstructure

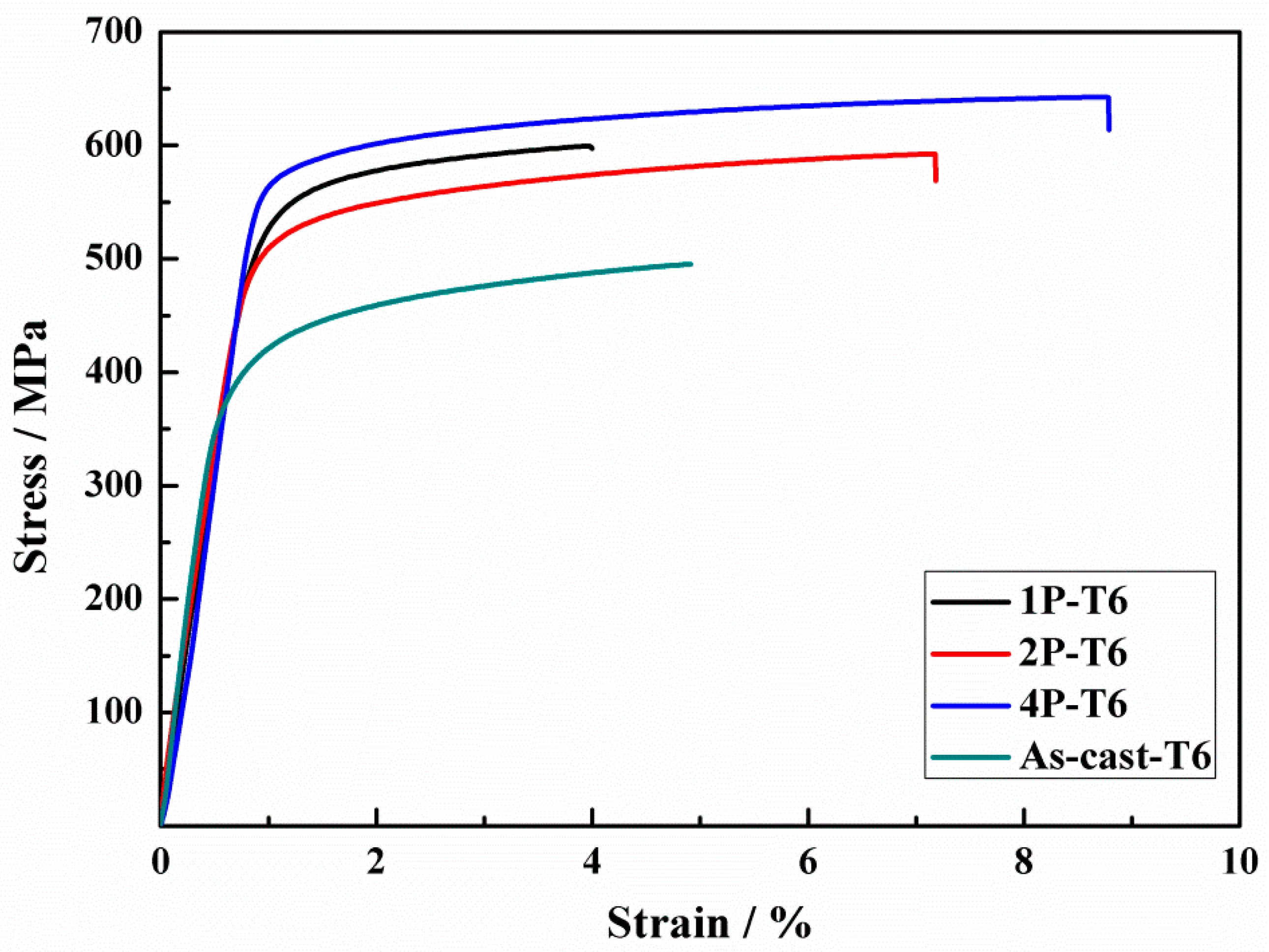

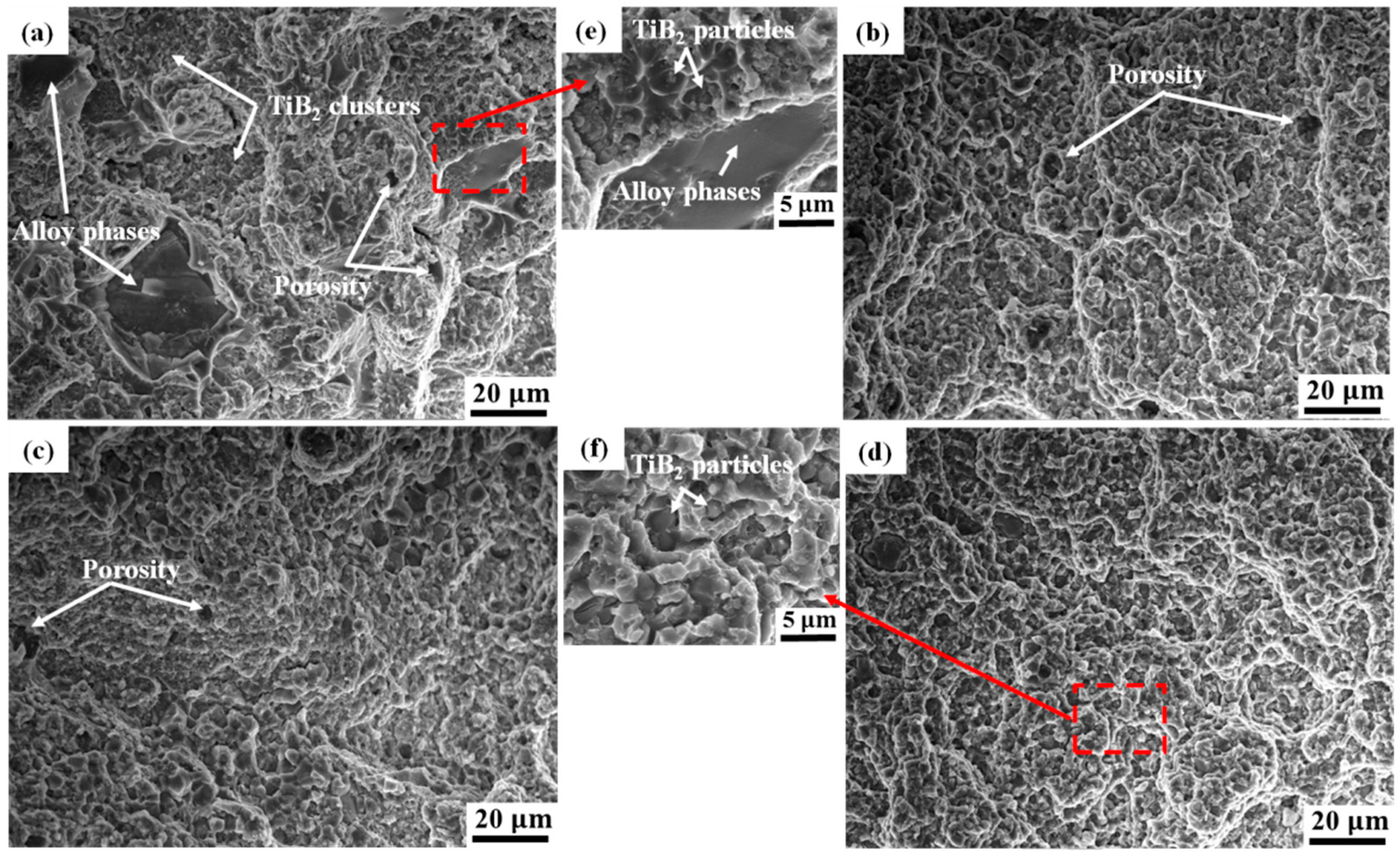

3.4. Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, P.; Chen, T. Tensile properties and fracture behavior of a powder-thixoformed 2024Al/SiCp composite at elevated temperatures. Metals 2017, 7, 408. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, J.M.; Cho, Y.H.; Kim, J.J.; Kim, S.H.; Lee, J.C. Effects of processing parameters on the fabrication of in-situ Al/TiC composites by thermally activated combustion reaction process in an aluminium melt using Al-TiO2-C powder mixtures. J. Korean Inst. Met. Mater. 2012, 50, 677–684. [Google Scholar]

- Liu, G.; Zhang, G.J.; Jiang, F.; Ding, X.D.; Sun, Y.J.; Sun, J.; Ma, E. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat. Mater. 2013, 12, 344–350. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.Y.; Xu, J.Q.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.-M.; Mathaudhu, S.; Li, X.-C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Hu, Y.; Zhang, G.; Wang, Z. Formation of nanoscale metallic glassy particle reinforced Al-based composite powders by high-energy milling. Metals 2017, 7, 425. [Google Scholar] [CrossRef]

- Huang, G.; Shen, Y.; Guo, R.; Guan, W. Fabrication of tungsten particles reinforced aluminum matrix composites using multi-pass friction stir processing: Evaluation of microstructural, mechanical and electrical behavior. Mater. Sci. Eng. A 2016, 674, 504–513. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Rajan, H.B.M.; Dinaharan, I.; Ramabalan, S.; Akinlabi, E.T. Influence of friction stir processing on microstructure and properties of AA7075/TiB2 in situ composite. J. Alloys Compd. 2016, 657, 250–260. [Google Scholar] [CrossRef]

- Wang, M.; Chen, D.; Chen, Z.; Wu, Y.; Wang, F.; Ma, N.; Wang, H. Mechanical properties of in-situ TiB2/A356 composites. Mater. Sci. Eng. A 2014, 590, 246–254. [Google Scholar] [CrossRef]

- Hong, T.; Li, X.; Wang, H.; Chen, D. Influence of solution temperature on microstructure and properties of in-situ TiB2/2009 composites. Mater. Sci. Eng. A 2015, 634, 1–4. [Google Scholar] [CrossRef]

- Geng, J.; Hong, T.; Ma, Y.; Wang, M.; Chen, D.; Ma, N.; Wang, H. The solution treatment of in-situ sub-micron TiB2/2024 Al composite. Mater. Des. 2016, 98, 186–193. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Chen, X.G.; da Silva, M.; Gougeon, P.; St-Georges, L. Microstructure and mechanical properties of friction stir welded AA6063–B4C metal matrix composites. Mater. Sci. Eng. A 2009, 518, 174–184. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. Effect of friction stir processing with SiC particles on microstructure and hardness of AZ31. Mater. Sci. Eng. A 2006, 433, 50–54. [Google Scholar] [CrossRef]

- Ma, S.M.; Zhang, P.; Ji, G.; Chen, Z.; Sun, G.A.; Zhong, S.Y.; Ji, V.; Wang, H.W. Microstructure and mechanical properties of friction stir processed Al–Mg–Si alloys dispersion-strengthened by nanosized TiB2 particles. J. Alloys Compd. 2014, 616, 128–136. [Google Scholar] [CrossRef]

- Du, Z.; Tan, M.J.; Guo, J.F.; Bi, G.; Wei, J. Fabrication of a new Al-Al2O3-CNTs composite using friction stir processing (FSP). Mater. Sci. Eng. A 2016, 667, 125–131. [Google Scholar] [CrossRef]

- Carlone, P.; Astarita, A.; Rubino, F.; Pasquino, N. Microstructural Aspects in FSW and TIG Welding of Cast ZE41AMagnesium Alloy. Metall. Mater. Trans. B 2016, 47, 1340–1346. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. Low temperature superplasticity in a friction-stir-processed ultrafine grained Al–Zn–Mg–Sc alloy. Acta Mater. 2005, 53, 4211–4223. [Google Scholar] [CrossRef]

- Hassan, K.A.A.; Norman, A.F.; Price, D.A.; Prangnell, P.B. Stability of nugget zone grain structures in high strength Al-alloy friction stir welds during solution treatment. Acta Mater. 2003, 51, 1923–1936. [Google Scholar] [CrossRef]

- Luo, C.; Dong, F.; Guo, L. Study on Heat Treatment of Aerospace Aluminum Alloy Welded FSW. MATEC Web Conf. 2017, 114, 03010. [Google Scholar] [CrossRef]

- Nikoo, M.F.; Azizi, H.; Parvin, N.; Naghibi, H.Y. The influence of heat treatment on microstructure and wear properties of friction stir welded AA6061-T6/Al2O3 nanocomposite joint at four different traveling speed. J. Manuf. Processes 2016, 22, 90–98. [Google Scholar] [CrossRef]

- Moradi, M.M.; Aval, H.J.; Jamaati, R. Effect of pre and post welding heat treatment in SiC-fortified dissimilar AA6061-AA2024 FSW butt joint. J. Manuf. Process. 2017, 30, 97–105. [Google Scholar] [CrossRef]

- Cui, G.R.; Ma, Z.Y.; Li, S.X. The origin of non-uniform microstructure and its effects on the mechanical properties of a friction stir processed Al–Mg alloy. Acta Mater. 2009, 57, 5718–5729. [Google Scholar] [CrossRef]

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P.J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater. 2003, 51, 4791–4801. [Google Scholar] [CrossRef]

- Rhodes, C. Fine-grain evolution in friction-stir processed 7050 aluminum. Scr. Mater. 2003, 48, 1451–1455. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. Abnormal grain growth in friction stir processed alloys. Scr. Mater. 2008, 58, 367–371. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, G.; Wu, Y.; Mathon, M.; Borbely, A.; Chen, D.; Ji, G.; Wang, M.; Zhong, S.; Wang, H. Multi-scale study of microstructure evolution in hot extruded nano-sized TiB2 particle reinforced aluminum composites. Mater. Des. 2017, 116, 577–590. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, Z.; Borbély, A.; Ji, G.; Zhong, S.Y.; Schryvers, D.; Ji, V.; Wang, H.W. Quantitative study of particle size distribution in an in-situ grown Al–TiB2 composite by synchrotron X-ray diffraction and electron microscopy. Mater. Charact. 2015, 102, 131–136. [Google Scholar] [CrossRef]

- Schaffer, P.L.; Miller, D.N.; Dahle, A.K. Crystallography of engulfed and pushed TiB2 particles in aluminium. Scr. Mater. 2007, 57, 1129–1132. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.; Cong, F. Intermetallic phase evolution of 7050 aluminum alloy during homogenization. Intermetallics 2012, 26, 114–121. [Google Scholar] [CrossRef]

- Mondal, C.; Mukhopadhyay, A.K. On the nature of T(Al2Mg3Zn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater. Sci. Eng. A 2005, 391, 367–376. [Google Scholar] [CrossRef]

- Cong, F.; Zhao, G.; Jiang, F.; Tian, N.; Li, R. Effect of homogenization treatment on microstructure and mechanical properties of DC cast 7X50 aluminum alloy. Nonferrous Met. Soc. China 2015, 25, 1027–1034. [Google Scholar] [CrossRef]

- Li, X.M.; Starink, M.J. Effect of compositional variations on characteristics of coarse intermetallic particles in overaged 7000 aluminium alloys. Mater. Sci. Technol. 2001, 17, 1324–1328. [Google Scholar] [CrossRef]

- Li, Y.Y.; Kovarik, L.; Phillips, P.J.; Hsu, Y.F.; Wang, W.H.; Mills, M.J. High resolution characterization of the precipitation behavior of an Al-Zn-Mg-Cu alloy. Philos. Mag. Lett. 2012, 92, 166–178. [Google Scholar] [CrossRef]

- Su, J.Q.; Nelson, T.W.; Mishra, R.; Mahoney, M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003, 51, 713–729. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, R.; Guo, Y.; Chen, G.; Lei, Y.; Cheng, Y.; Yue, Y. Microstructural evolution and mechanical properties of ZrB2/6061Al nanocomposites processed by multi-pass friction stir processing. Mater. Sci. Eng. A 2017, 689, 411–418. [Google Scholar] [CrossRef]

- Prater, T. Solid-state joining of metal matrix composites: A survey of challenges and potential solutions. Mater. Manuf. Process. 2011, 26, 636–648. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Li, H.; Cao, F.; Guo, S.; Ning, Z.; Liu, Z.; Jia, Y.; Scudino, S.; Gemming, T.; Sun, J. Microstructures and properties evolution of spray-deposited Al-Zn-Mg-Cu-Zr alloys with scandium addition. J. Alloys Compd. 2017, 691, 482–488. [Google Scholar] [CrossRef]

- Johannes, L.B.; Mishra, R.S. Multiple passes of friction stir processing for the creation of superplastic 7075 aluminum. Mater. Sci. Eng. A 2007, 464, 255–260. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Pilchak, A.L.; Juhas, M.C.; Williams, J.C. Microstructural refinement and property enhancement of cast light alloys via friction stir processing. Scr. Mater. 2008, 58, 361–366. [Google Scholar] [CrossRef]

- McNelley, T.R.; Swaminathan, S.; Su, J.Q. Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr. Mater. 2008, 58, 349–354. [Google Scholar] [CrossRef]

- Shafiei-Zarghani, A.; Kashani-Bozorg, S.F.; Zarei-Hanzaki, A. Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater. Sci. Eng. A 2009, 500, 84–91. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Mishra, R.S.; Liu, F.C. Superplastic behavior of micro-regions in two-pass friction stir processed 7075Al alloy. Mater. Sci. Eng. A 2009, 505, 70–78. [Google Scholar] [CrossRef]

- Lang, P.; Povoden-Karadeniz, E.; Falahati, A.; Kozeschnik, E. Simulation of the effect of composition on the precipitation in 6xxx Al alloys during continuous-heating DSC. J. Alloys Compd. 2014, 612, 443–449. [Google Scholar] [CrossRef]

- Rollett, A.; Humphreys, F.; Rohrer, G.S.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Ltd.: Oxford, UK, 2004; pp. 248–249. [Google Scholar]

- Chen, Z.; Li, J.; Borbely, A.; Ji, G.; Zhong, S.Y.; Wu, Y.; Wang, M.L.; Wang, H.W. The effects of nanosized particles on microstructural evolution of an in-situ TiB2/6063Al composite produced by friction stir processing. Mater. Des. 2015, 88, 999–1007. [Google Scholar] [CrossRef]

- Mackenzie, J. Second paper on statistics associated with the random disorientation of cubes. Biometrika 1958, 45, 229–240. [Google Scholar] [CrossRef]

- Liu, F.C.; Ma, Z.Y. Contribution of grain boundary sliding in low-temperature superplasticity of ultrafine-grained aluminum alloys. Scr. Mater. 2010, 62, 125–128. [Google Scholar] [CrossRef]

- Mahoney, M.; Rhodes, C.; Flintoff, J.; Bingel, W.; Spurling, R. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S.; Mahoney, M.W. Multi-sheet structures in 7475 aluminum by friction stir welding in concert with post-weld superplastic forming. Scr. Mater. 2002, 47, 631–636. [Google Scholar] [CrossRef]

- Humphreys, F. A unified theory of recovery, recrystallization and grain growth, based on the stability and growth of cellular microstructures—II. The effect of second-phase particles. Acta Mater. 1997, 45, 5031–5039. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, Y.H.; Zhu, Y.T.; Ma, E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 2007, 55, 5822–5832. [Google Scholar] [CrossRef]

- Barmouz, M.; Givi, M.K.B.; Seyfi, J. On the role of processing parameters in producing Cu/SiC metal matrix composites via friction stir processing: Investigating microstructure, microhardness, wear and tensile behavior. Mater. Charact. 2011, 62, 108–117. [Google Scholar] [CrossRef]

- Guo, J.; Chen, H.; Sun, C.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

| Material | Fraction of HAGB (%) | Average Grain Size (μm) | Average Aspect Ratio |

|---|---|---|---|

| As-cast | - | 27.2 | - |

| 1-pass | 95 | 2.5 | 1.50 |

| 2-pass | 96 | 2.9 | 1.47 |

| 4-pass | 96 | 2.1 | 1.44 |

| 1-pass-T6 | 95 | 2.7 | 1.28 |

| 2-pass-T6 | 96 | 2.9 | 1.40 |

| 4-pass-T6 | 96 | 2.8 | 1.45 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, X.; Zhang, F.; Chen, Z.; Ji, G.; Wang, M.; Wu, Y.; Zhong, S.; Wang, H. Microstructure of Multi-Pass Friction-Stir-Processed Al-Zn-Mg-Cu Alloys Reinforced by Nano-Sized TiB2 Particles and the Effect of T6 Heat Treatment. Metals 2017, 7, 530. https://doi.org/10.3390/met7120530

Ju X, Zhang F, Chen Z, Ji G, Wang M, Wu Y, Zhong S, Wang H. Microstructure of Multi-Pass Friction-Stir-Processed Al-Zn-Mg-Cu Alloys Reinforced by Nano-Sized TiB2 Particles and the Effect of T6 Heat Treatment. Metals. 2017; 7(12):530. https://doi.org/10.3390/met7120530

Chicago/Turabian StyleJu, Xiaofei, Fengguo Zhang, Zhe Chen, Gang Ji, Mingliang Wang, Yi Wu, Shengyi Zhong, and Haowei Wang. 2017. "Microstructure of Multi-Pass Friction-Stir-Processed Al-Zn-Mg-Cu Alloys Reinforced by Nano-Sized TiB2 Particles and the Effect of T6 Heat Treatment" Metals 7, no. 12: 530. https://doi.org/10.3390/met7120530

APA StyleJu, X., Zhang, F., Chen, Z., Ji, G., Wang, M., Wu, Y., Zhong, S., & Wang, H. (2017). Microstructure of Multi-Pass Friction-Stir-Processed Al-Zn-Mg-Cu Alloys Reinforced by Nano-Sized TiB2 Particles and the Effect of T6 Heat Treatment. Metals, 7(12), 530. https://doi.org/10.3390/met7120530