Effect of Temperature and Dwell Time on Fatigue Crack Growth Behavior of CP-Ti

Abstract

:1. Introduction

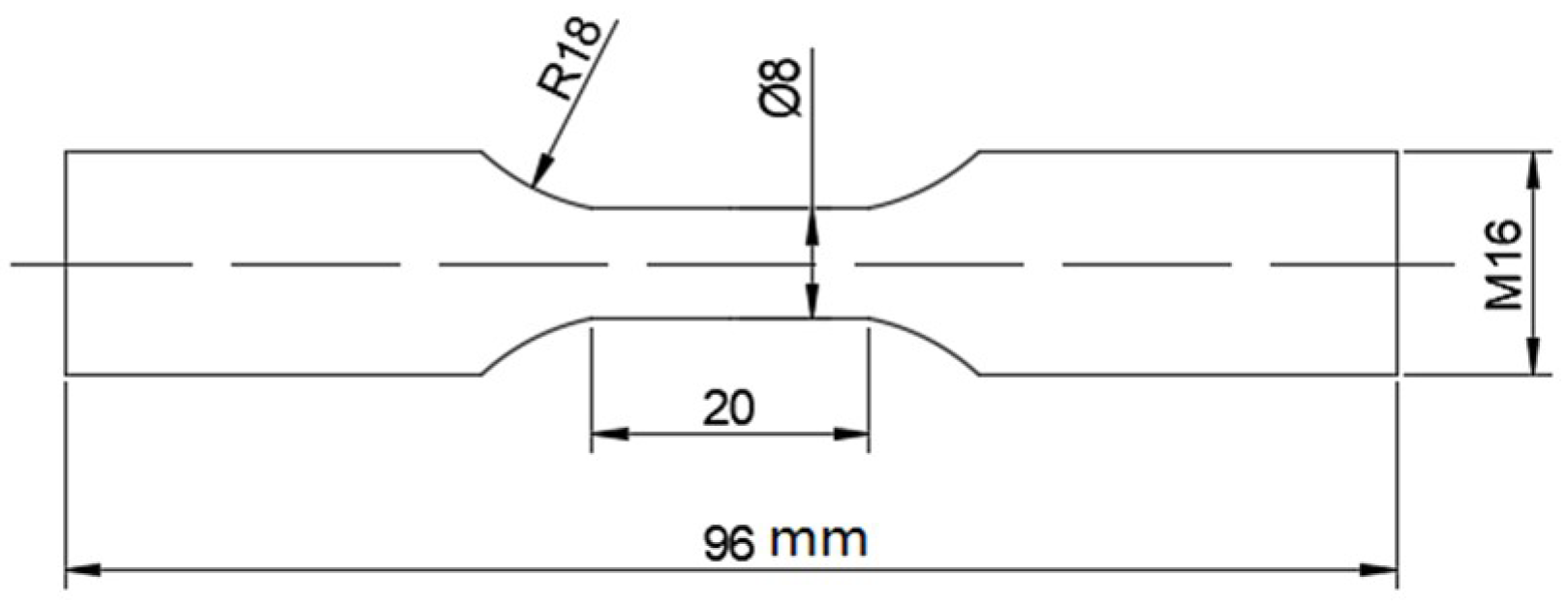

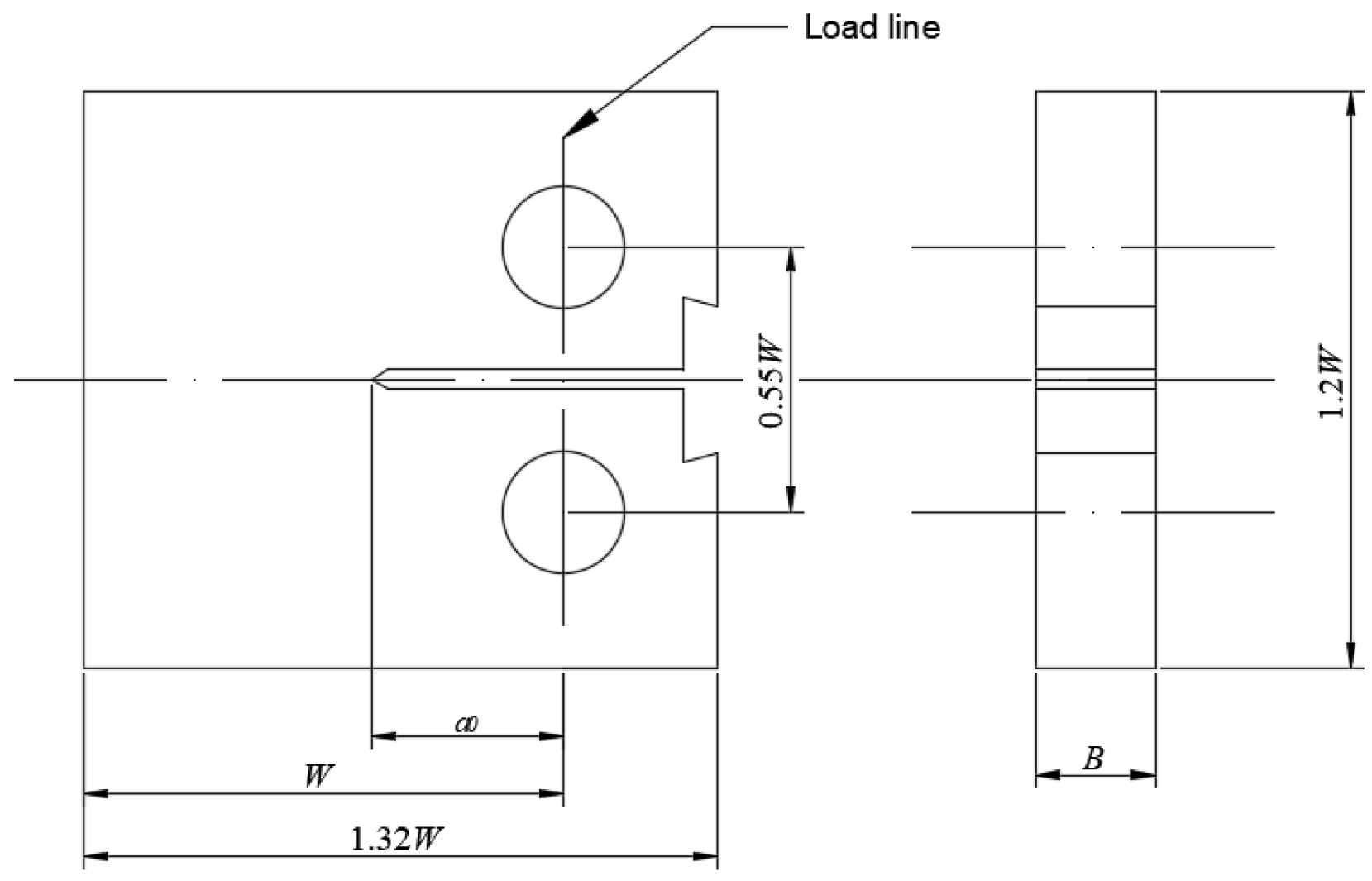

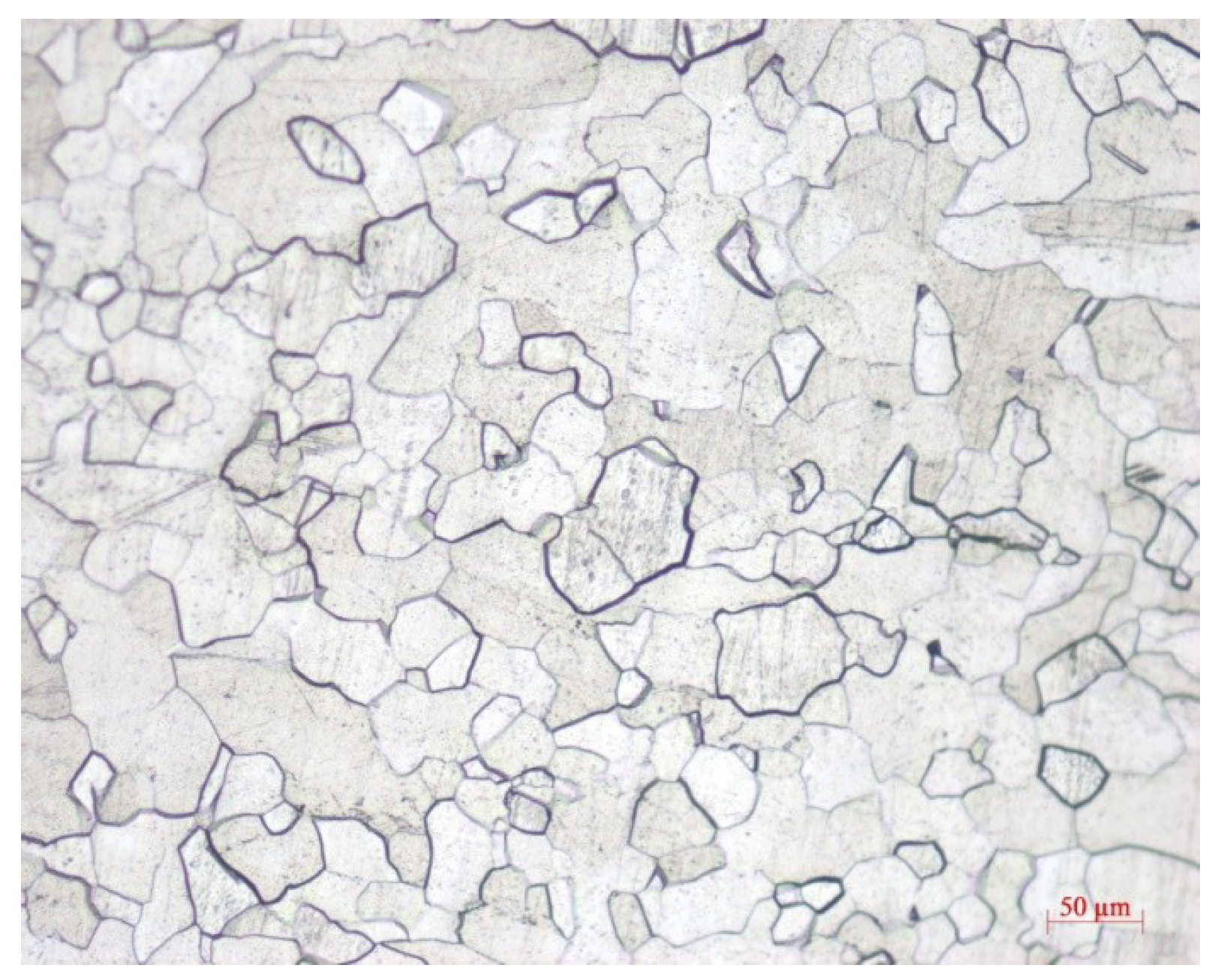

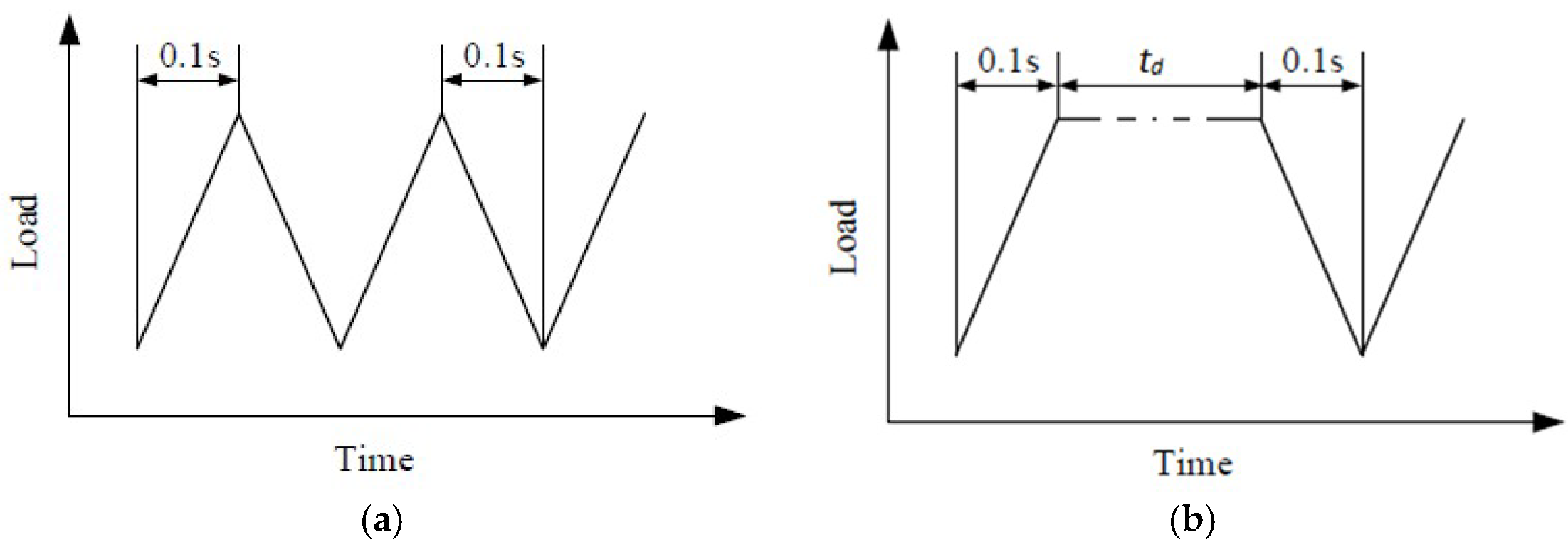

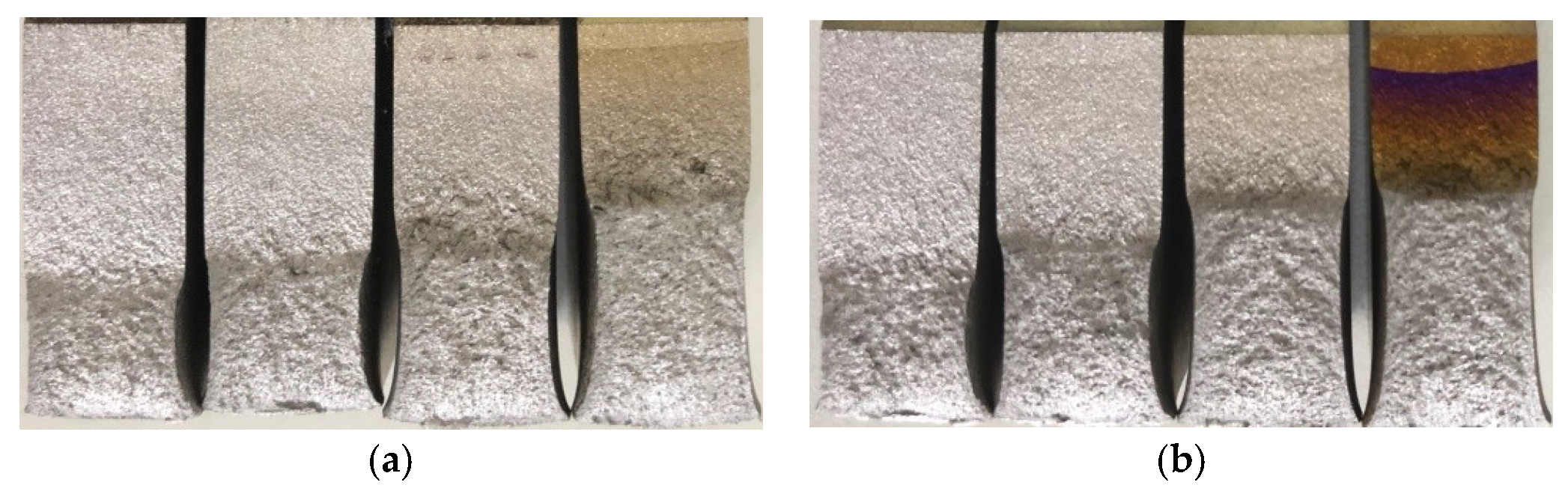

2. Experiment Details

3. Results and Discussion

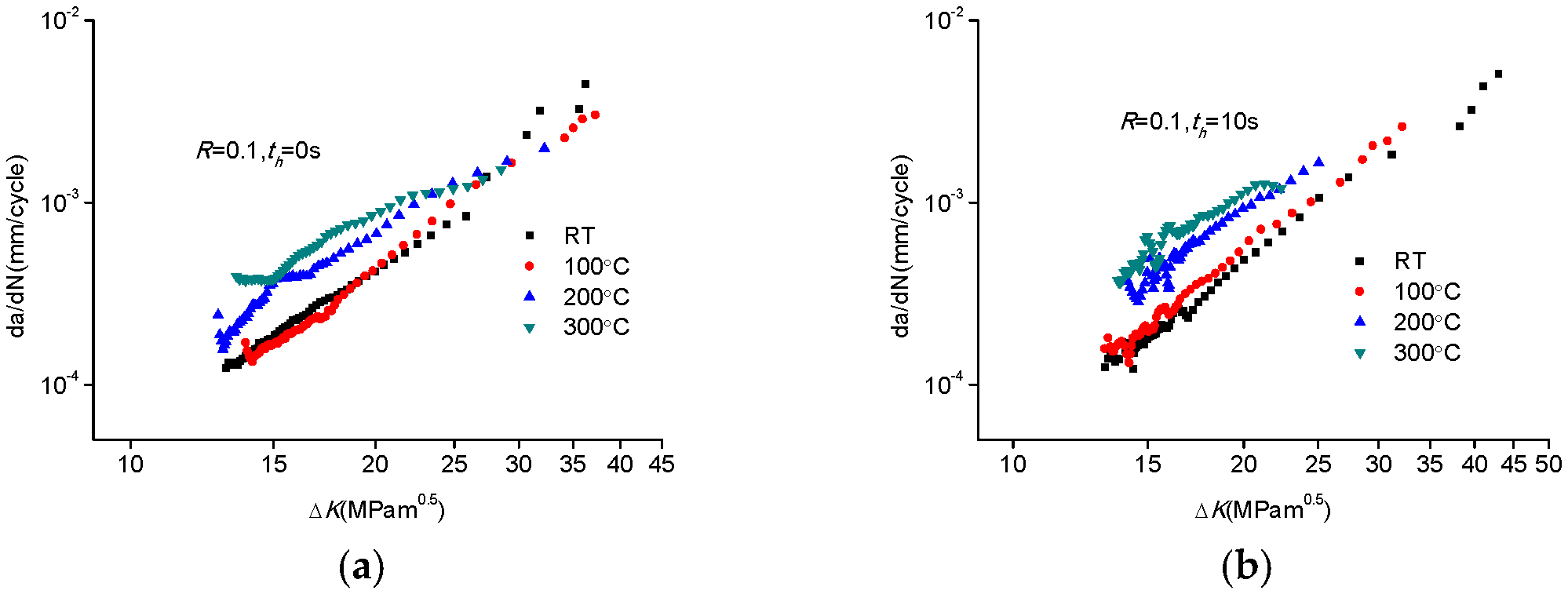

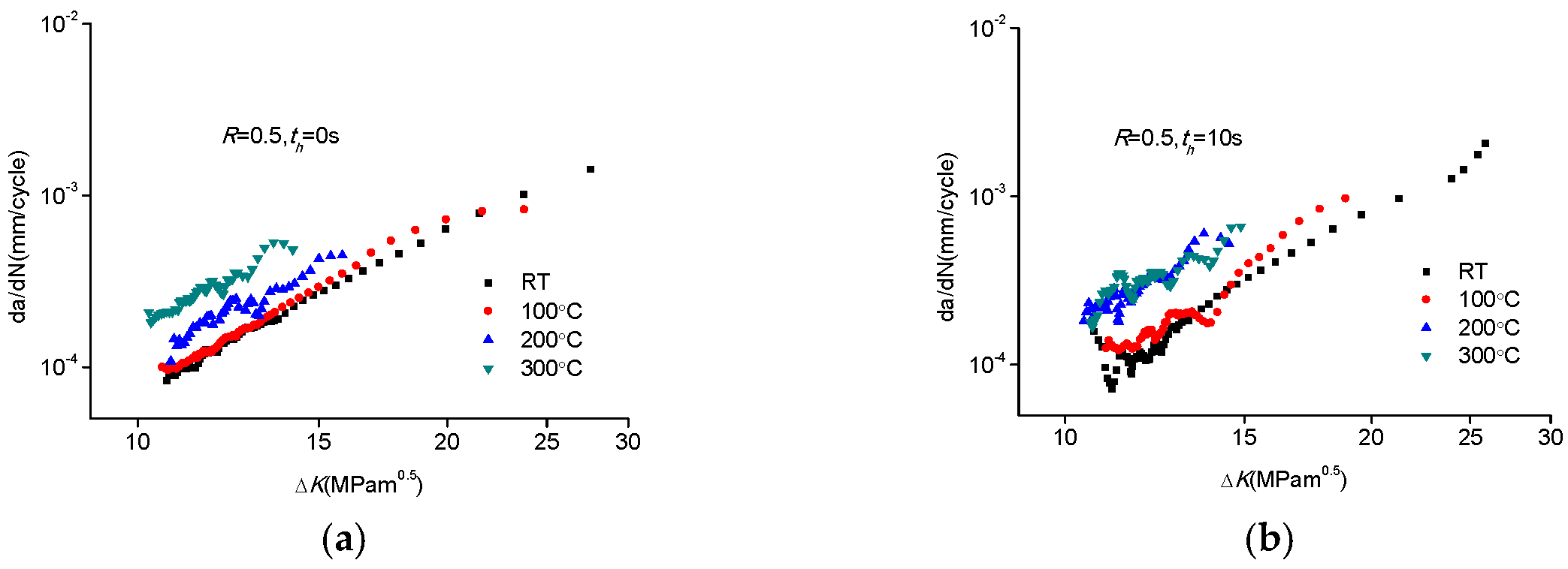

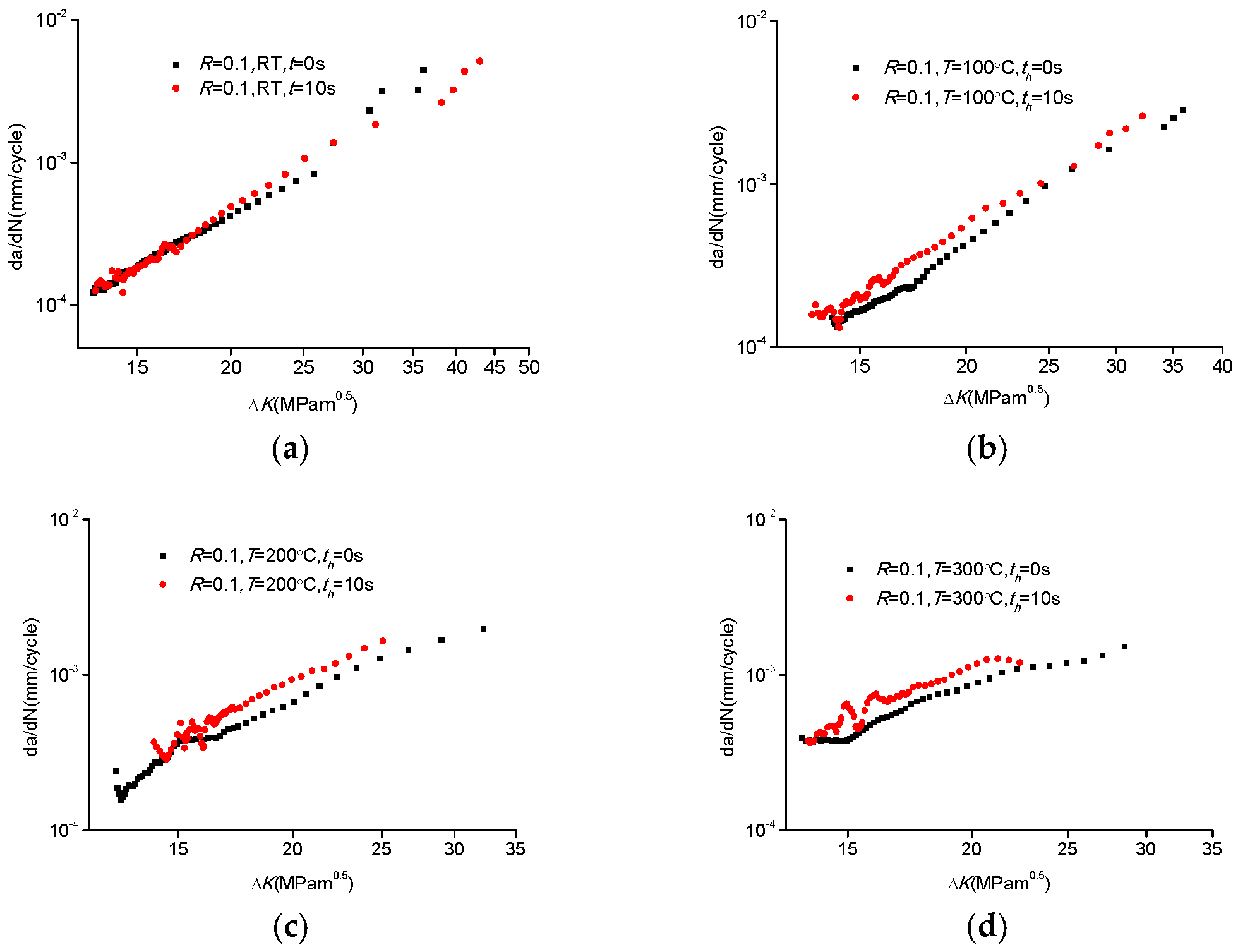

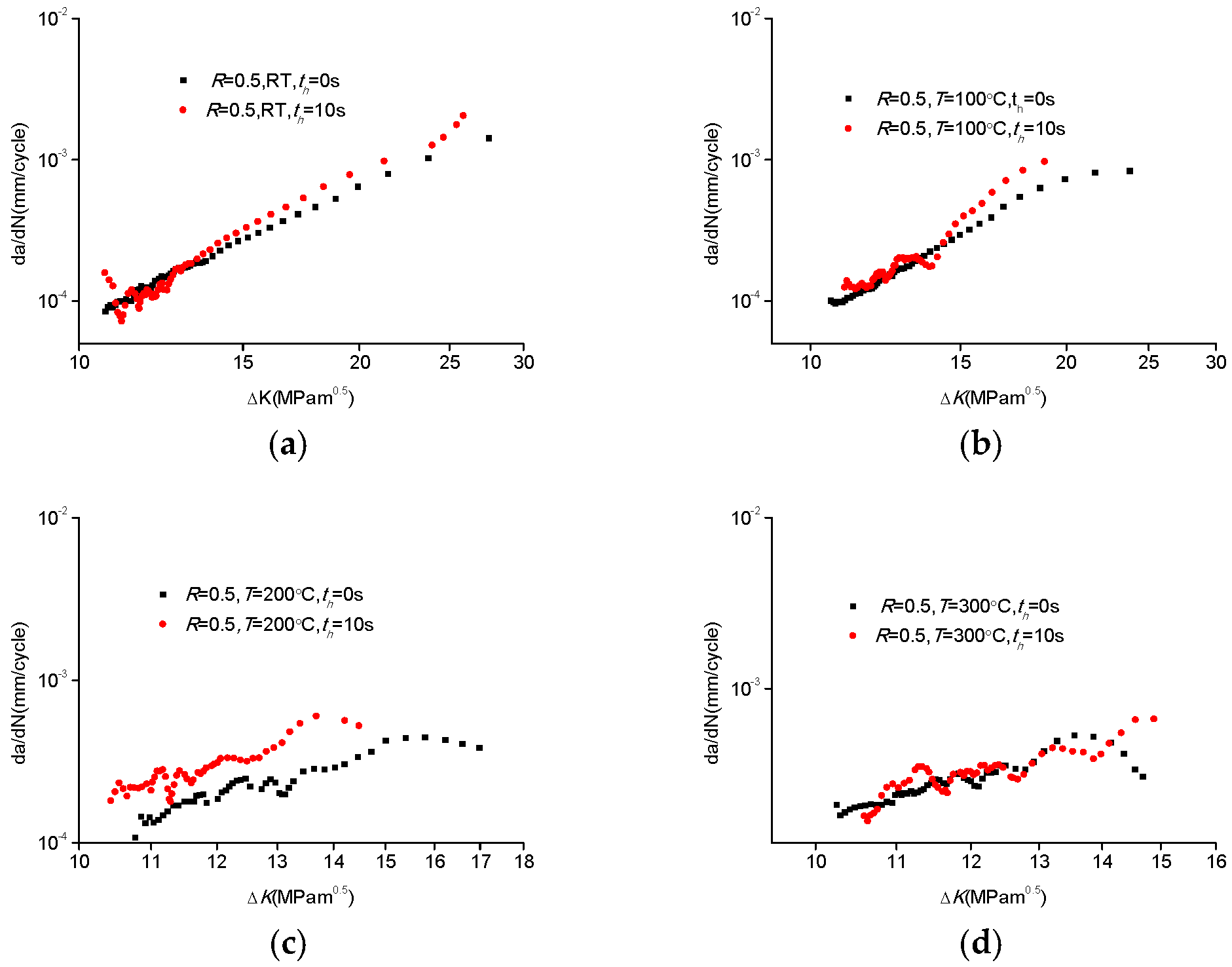

3.1. Temperature Sensitivity of CP-Ti under Pure Fatigue and Dwell FCG

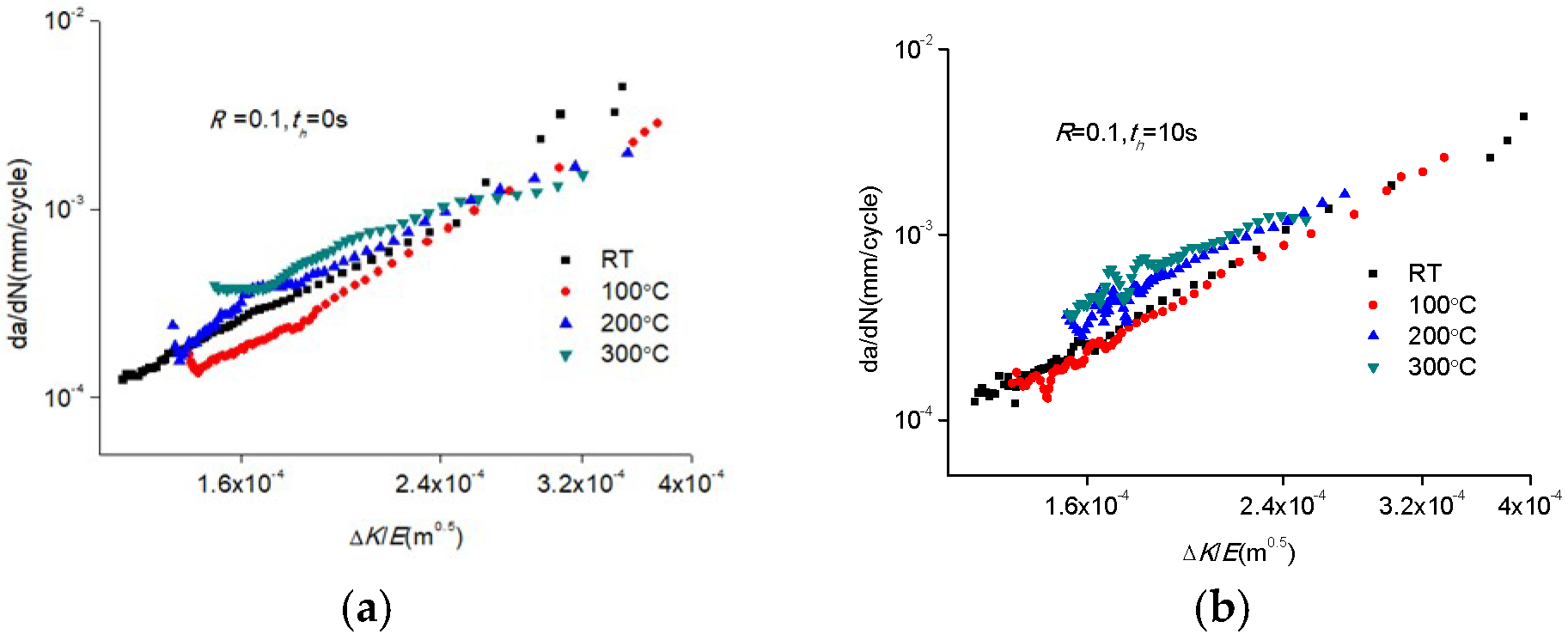

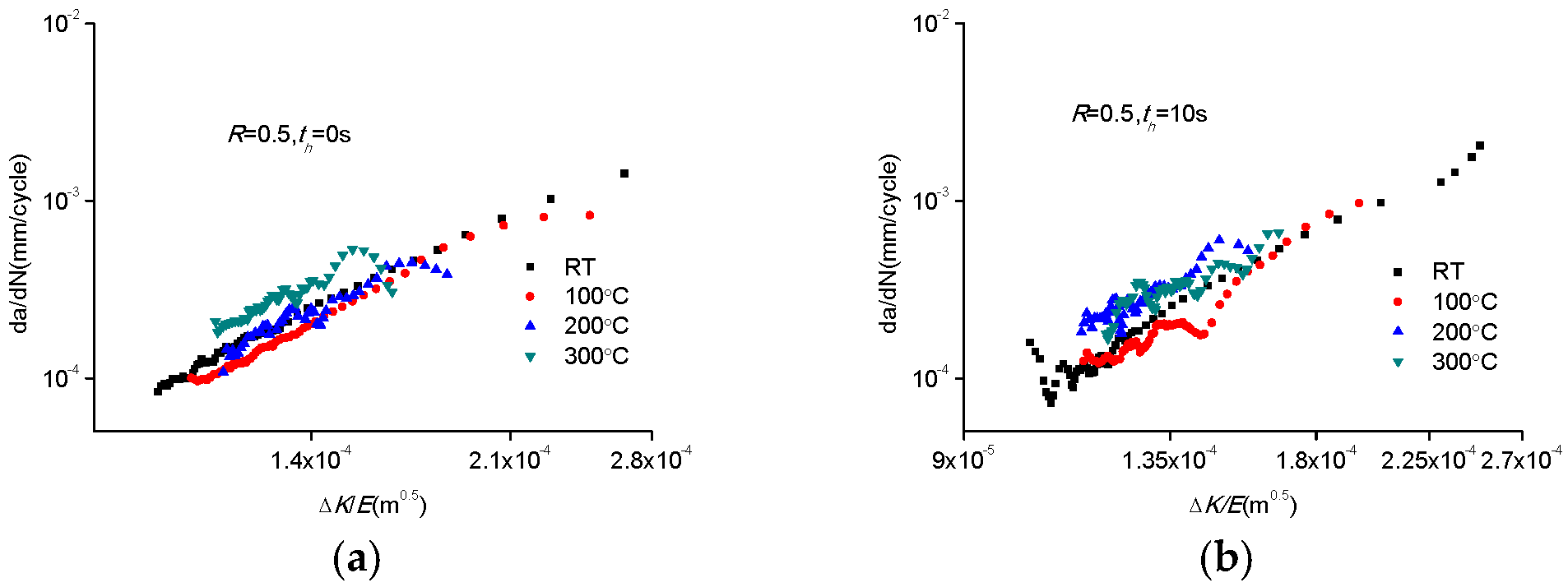

3.2. Effect of Temperature and Oxidation on the FCG Behavior of CP-Ti

3.3. Effect of Dwell Time on the FCG Behavior of CP-Ti

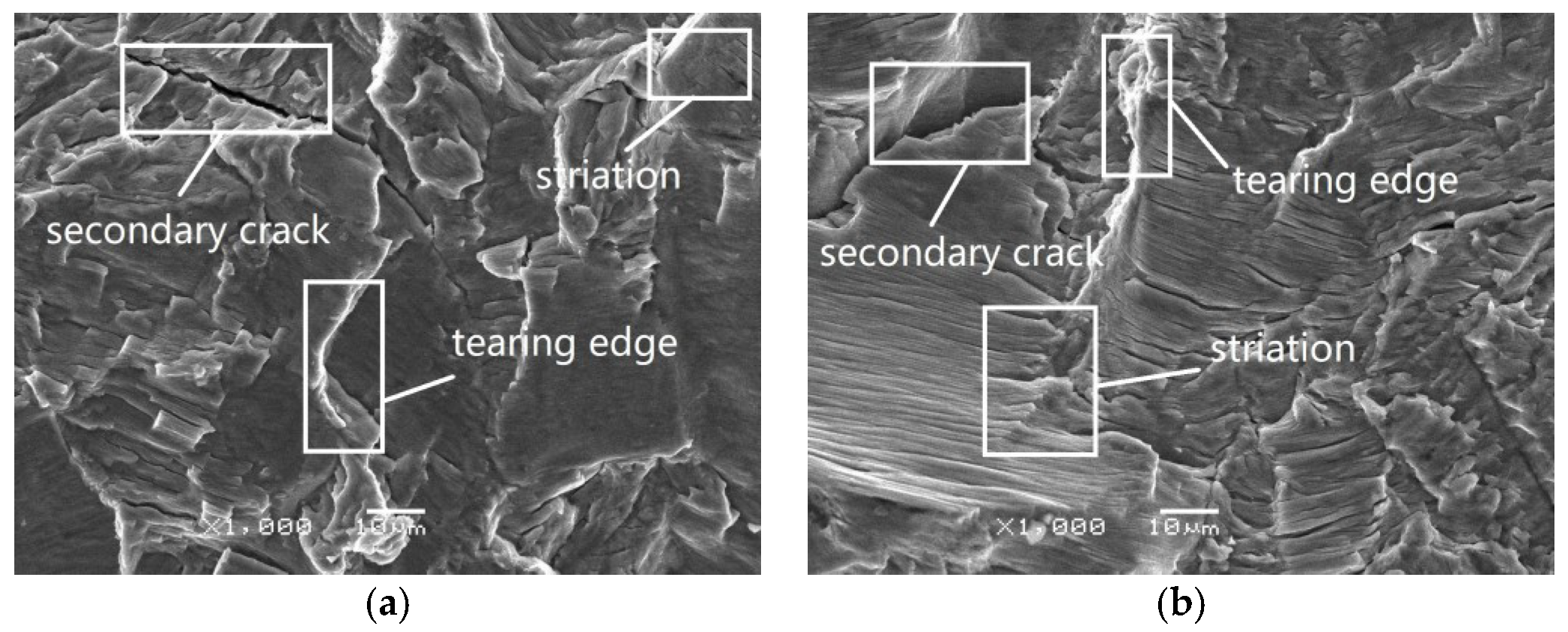

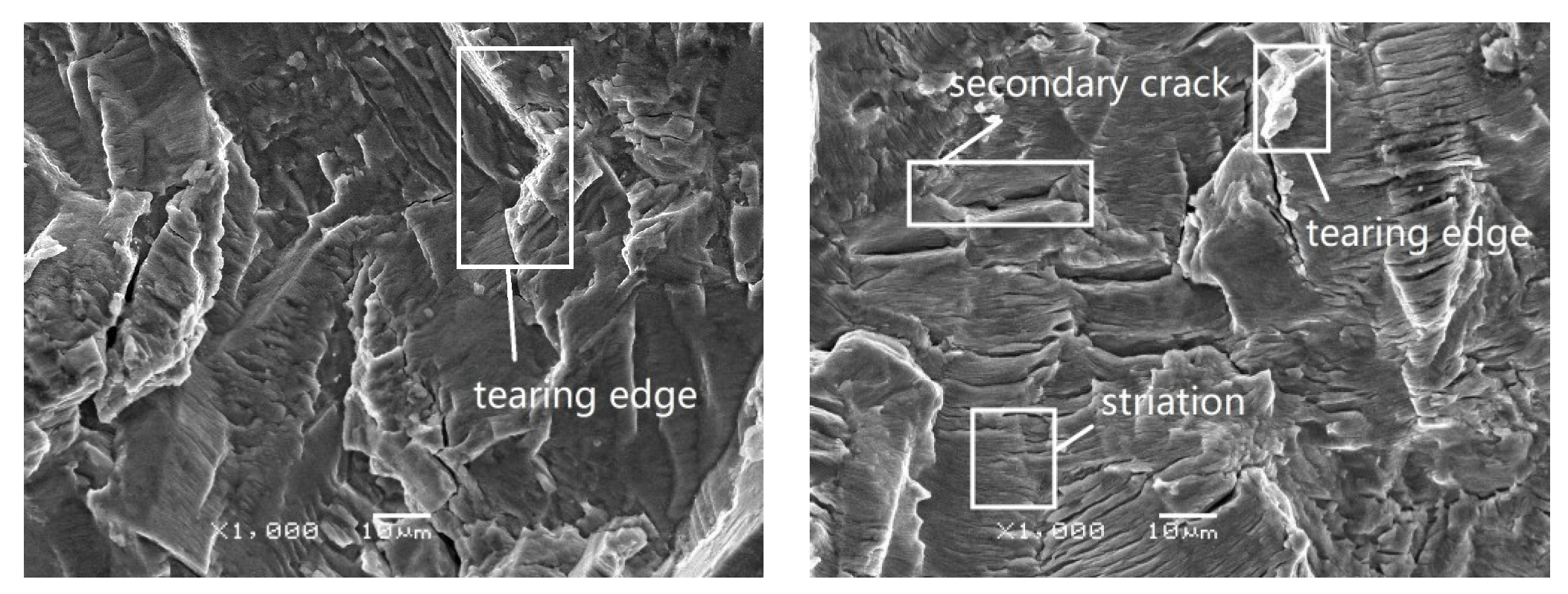

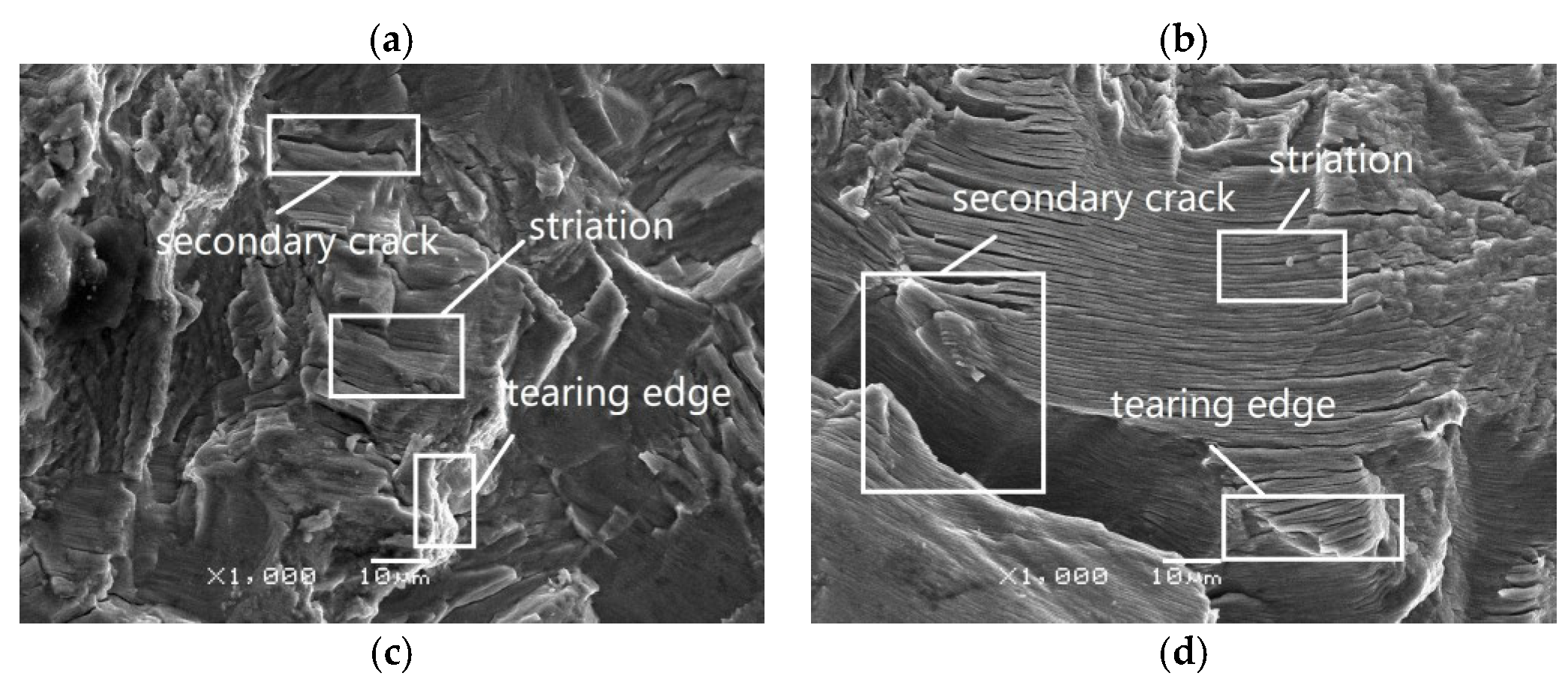

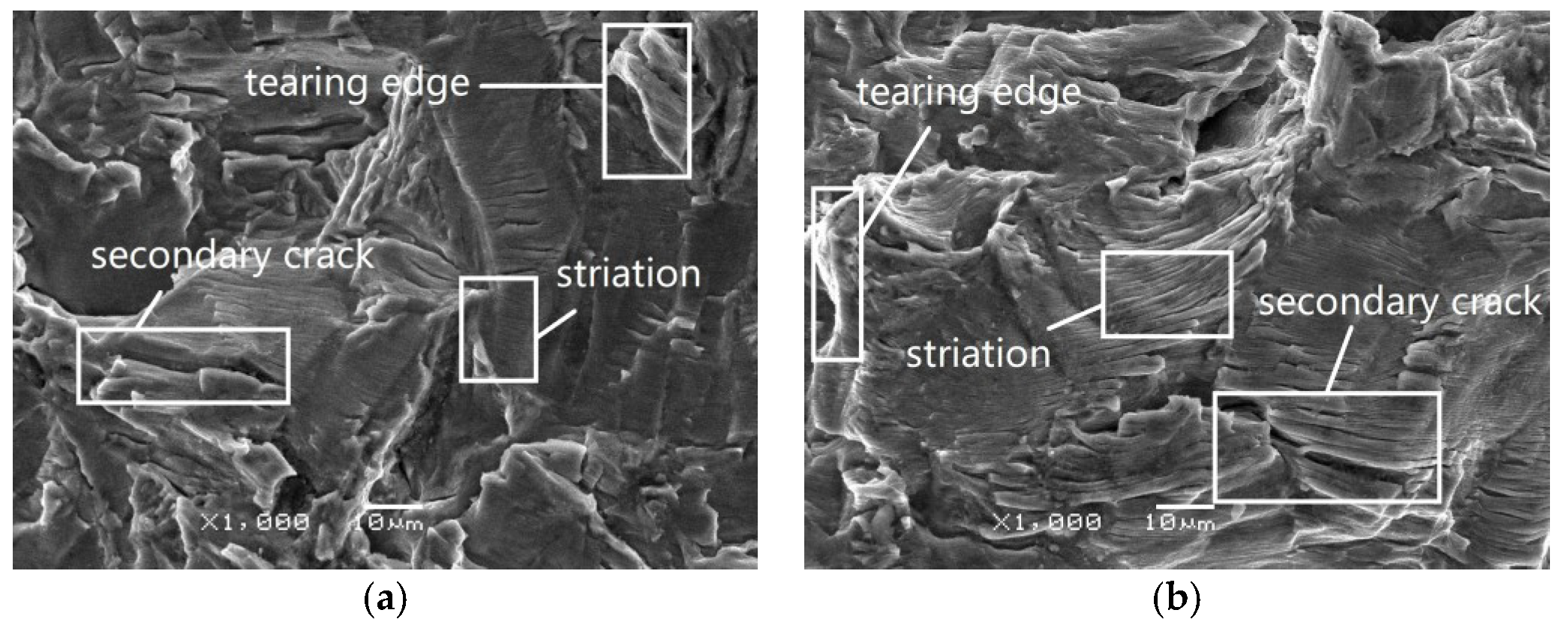

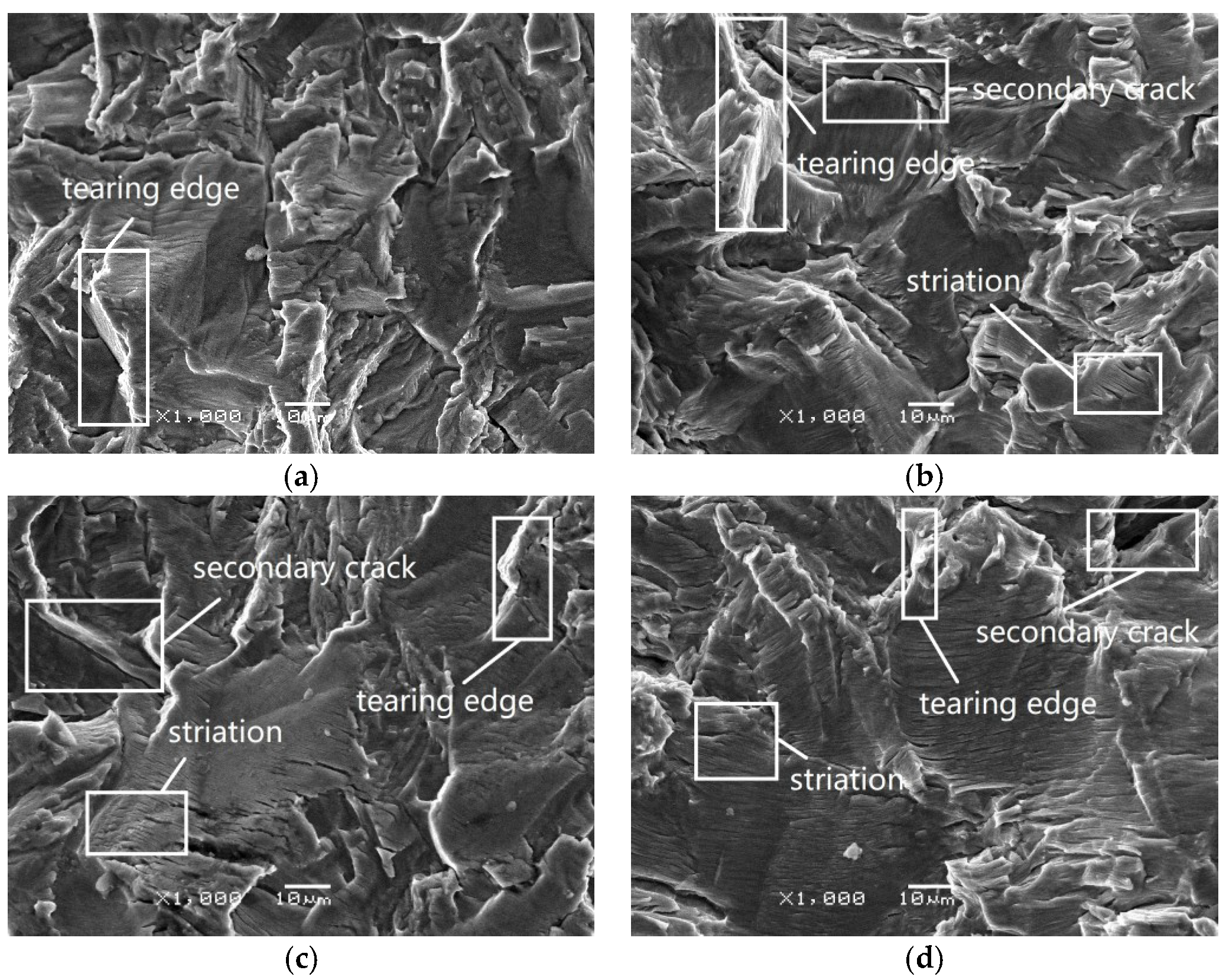

3.4. SEM Observation of the Fracture Surface

4. Conclusions

- (1)

- Considering the temperature sensitivity of pure fatigue and dwell fatigue crack growth behavior of CP-Ti, the overall FCG rate increased with temperature under low load ratio. Under high load ratio, the FCG rate of CP-Ti was much higher than under low load ratio.

- (2)

- The da/dN–ΔK/E FCG curves of CP-Ti had a tendency to approach each other under different load ratios, which indicated that E-modulus is an important reason for the difference of FCG behavior. The oxidation resistance of CP-Ti obviously weakened with temperature increase. Besides, the overall oxidation effect on the crack tip and the grain boundary was higher than the oxidation-induced crack closure effect, which led to the FCG rate increase at different temperatures under different load ratios.

- (3)

- The dwell fatigue crack growth rate was higher than that of pure fatigue under low load ratio, and the creep deformation mechanism of CP-Ti played a major role in the dwell fatigue crack growth behavior from room temperature to 300 °C. Under high load ratio, the effect of dwell time on the FCG rate was most significant at 200 °C. However, the dwell FCG rate of CP-Ti at 300 °C was almost close to that of pure fatigue due to creep saturation and oxidation-induced crack closure.

- (4)

- For the pure fatigue condition under low load ratio, there was no difference in the fracture surface morphology, which means that the fatigue fracture mode has typical linear elastic fracture characteristics. Besides, there were many secondary cracks, and the length or depth of some secondary cracks increased with the temperature. Under high load ratio, the secondary cracks and fatigue striations were more obvious with the increase of temperature and dwell time, as the load ratio increased. The effect of the creep on the FCG was also enhanced. Besides, plastic deformation became more pronounced in the final stage.

Author Contributions

Funding

Conflicts of Interest

References

- Li, J.; Zhang, P.; Lu, L.; Lv, F.; Miao, X.T.; Chang, L.; Zhou, B.B.; He, X.H. Effect of pre-strain on FCG behavior for commercial pure titanium at ambient temperature. Int. J. Fatigue 2018, 117, 27–38. [Google Scholar] [CrossRef]

- Zhu, Y.; Xiong, J.; Lv, Z.; Zhao, Y. Testing and evaluation for fatigue crack propagation of Ti-6Al-4V/ELI and 7050-T7452 alloys at high temperatures. Chin. J. Aeronaut. 2017, 31, 1388–1398. [Google Scholar] [CrossRef]

- Foerch, R.; Madsen, A.; Ghonem, H. Environmental interactions in high-temperature FCG of Ti-1100. Met. Trans. A 1993, 24, 1321–1332. [Google Scholar] [CrossRef]

- Ogawa, T.; Hayashi, Y.; Tokaji, K.; Hirose, M. FCG of Ti-6Al-4V Alloy at Elevated Temperatures. J. Soc. Mater. Sci. Jpn. 1993, 42, 1186–1192. [Google Scholar] [CrossRef]

- Zhu, S.J.; Peng, L.M.; Moriya, T.; Mutoh, Y. Effect of stress ratio on FCG in TiAl intermetallics at room and elevated temperatures. Mater. Sci. Eng. A 2000, 290, 198–206. [Google Scholar] [CrossRef]

- Arakere, N.K.; Goswami, T.; Krohn, J.; Ramachandran, N. High Temperature FCG Behavior of Ti-6Al-4V. High Temp. Mater. Process. 2002, 21, 229–236. [Google Scholar]

- Sinha, V.; Mills, M.J.; Williams, J.C.; Spowart, J.E. Observations on the faceted initiation site in the dwell-fatigue tested Ti-6242 alloy: Crystallographic orientation and size effects. Met. Mater. Trans. A 2006, 37, 1507–1518. [Google Scholar] [CrossRef]

- Evans, W.J.; Bache, M.R. Dwell-sensitive fatigue under biaxial loads in the nearalpha titanium alloy IMI685. Int. J. Fatigue 1994, 16, 443–452. [Google Scholar] [CrossRef]

- Guo, T.C.; Deng, Y.L.; Zhang, X.M.; Zhong, Y.Y. Creep behavior of Mg-2Nd-0.5Zn-0.4Zr at ambient temperature. Mater. Sci. Eng. A 2010, 527, 5801–5804. [Google Scholar] [CrossRef]

- Neeraj, T.; Hou, D.-H.; Daehn, G.S.; Mills, M.J. Phenomenological and microstructural analysis of room temperature creep in titanium alloys. Acta Mater. 2000, 48, 1225–1238. [Google Scholar] [CrossRef]

- Bache, M.R.; Cope, M.; Davies, H.M.; Evans, W.J.; Harrison, G. Dwell sensitive fatigue in a near alpha titanium alloy at ambient temperature. Int. J. Fatigue 1997, 19, 83–88. [Google Scholar] [CrossRef]

- Lefranc, P.; Sarrazin-Baudoux, C.; Doquet, V.; Petit, J. Investigation of the dwell period’s influence on the FCG of a titanium alloy. Scr. Mater. 2009, 60, 281–284. [Google Scholar] [CrossRef]

- Wang, K.; Wang, F.; Cui, W.C.; Tian, A.-L. Prediction of Cold Dwell-FCG of Titanium Alloys. Acta Met. Sin. 2015, 28, 619–627. [Google Scholar] [CrossRef]

- Wang, Z.; Yue, Y.; Li, Y. Prediction of Load-FCG Rate of Titanium Alloy Based on Zencrack. Chin. Ocean Platf. 2018, 1, 22–28. [Google Scholar]

- Li, J.; Lu, L.; Zhang, P.; Miao, X.T.; Chang, L.; Zhou, B.B.; Wang, Y.Z.; He, X.H.; Zhou, C.Y. Effect of cold creep on FCG behavior for commercial pure titanium. Theor. Appl. Fract. Mech. 2018, 97, 177–188. [Google Scholar] [CrossRef]

- Er, Q.L.; Dong, J.X.; Zhang, M.C.; Zheng, L.; Yao, Z.H.; Qu, J.L. Temperature sensitivity of FCG rate of GH4720Li alloy. Rare Met. Mater. Eng. 2017, 46, 2915–2921. [Google Scholar]

- Xu, C.; Qi, Q.L.; Yao, Z.H.; Jiang, H.; Dong, J.X. Effect of grain boundary oxidation on FCG of GH4738 superalloy. Acta Met. Sin. 2017, 53, 1453–1460. [Google Scholar]

- ASTM. Standard Test Method for Measurement of FCG Rates (E647-15); Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2015; Volume 3, pp. 647–695. [Google Scholar]

- Wu, H.; Zhao, Y.Q.; Zeng, W.D.; Li, Q. FCG behavior of Ti40 alloy at different Temperatures. Rare Met. Mater. Eng. 2008, 37, 1403–1406. [Google Scholar]

- Soboyejo, W.O.; Deffeyes, J.E.; Aswath, P.B. Investigation of room- and elevated-temperature FCG in Ti48Al. Mater. Sci. Eng. A 1991, 138, 95–101. [Google Scholar] [CrossRef]

- Mabru, C.; Bertheau, D.; Pautrot, S.; Petit, J.; Henaff, G. Influence of temperature and environment on fatigue crack propagation in a TiAl-based alloy. Eng. Fract. Mech. 1999, 64, 23–47. [Google Scholar] [CrossRef]

- Mercer, C.; Allameh, S.M.; Lou, J.; Soboyejo, W.O. Effects of temperature on the FCG behavior of cast gamma-based titanium aluminides. Met. Mater. Trans. A 2001, 32, 2781–2794. [Google Scholar] [CrossRef]

- Peng, J.; Zhou, C.Y.; Dai, Q.; He, X.H. Isochronic stress-strain curve of low-temperature creep of commercial pure titanium. Rare Met. Mater. Eng. 2016, 45, 346–352. [Google Scholar]

- Chang, L.; Zhou, C.Y.; Peng, J.; Li, J.; He, X.H. Study on cold creep characteristics of commercial pure titanium TA2. Rare Met. Mater. Eng. 2017, 7, 1463–1468. [Google Scholar]

- Jiang, R.; Everitt, S.; Lewandowski, M.; Gao, N.; Reed, P.A.S. Grain size effects in a Ni-based turbine disc alloy in the time and cycle dependent crack growth regimes. Int. J. Fatigue 2014, 62, 217–227. [Google Scholar] [CrossRef]

- Lu, Y.L.; Chen, L.J.; Liaw, P.K.; Wang, G.Y.; Brooks, C.R.; Thompson, S.A.; Blust, J.W.; Browning, P.F.; Bhattacharya, A.K.; Aurrecoechea, J.M.; et al. Effects of temperature and hold time on creep-fatigue crack-growth behavior of HAYNES® 230® alloy. Mater. Sci. Eng. A 2006, 429, 1–10. [Google Scholar] [CrossRef]

| Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|

| 0.08 | 0.01 | 0.02 | 0.001 | 0.01 | Other |

| Temperature (°C) | E-Modulus (MPa) | Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| RT | 104,000 | 303.2 | 413.4 | 23.6 |

| 100 | 96,250 | 258.4 | 351.5 | 22.5 |

| 200 | 92,000 | 175.3 | 248.1 | 38.8 |

| 300 | 89,000 | 105.9 | 185.9 | 35.3 |

| Specimen No. | Load Ratio | Temperature (°C) | Dwell Time (s) |

|---|---|---|---|

| 001 | Low (0.1) | RT | 0 |

| 002 | - | - | 10 |

| 003 | - | 100 | 0 |

| 004 | - | - | 10 |

| 005 | - | 200 | 0 |

| 006 | - | - | 10 |

| 007 | - | 300 | 0 |

| 008 | - | - | 10 |

| 009 | High (0.5) | RT | 0 |

| 010 | - | - | 10 |

| 011 | - | 100 | 0 |

| 012 | - | - | 10 |

| 013 | - | 200 | 0 |

| 014 | - | - | 10 |

| 015 | - | 300 | 0 |

| 016 | - | - | 10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, C.-Y.; Zhou, C.-Y.; Lu, L.; Li, J.; Sun, P.-Y.; He, X.-H. Effect of Temperature and Dwell Time on Fatigue Crack Growth Behavior of CP-Ti. Metals 2018, 8, 1031. https://doi.org/10.3390/met8121031

Su C-Y, Zhou C-Y, Lu L, Li J, Sun P-Y, He X-H. Effect of Temperature and Dwell Time on Fatigue Crack Growth Behavior of CP-Ti. Metals. 2018; 8(12):1031. https://doi.org/10.3390/met8121031

Chicago/Turabian StyleSu, Chuan-Yi, Chang-Yu Zhou, Lei Lu, Jian Li, Peng-Yan Sun, and Xiao-Hua He. 2018. "Effect of Temperature and Dwell Time on Fatigue Crack Growth Behavior of CP-Ti" Metals 8, no. 12: 1031. https://doi.org/10.3390/met8121031

APA StyleSu, C.-Y., Zhou, C.-Y., Lu, L., Li, J., Sun, P.-Y., & He, X.-H. (2018). Effect of Temperature and Dwell Time on Fatigue Crack Growth Behavior of CP-Ti. Metals, 8(12), 1031. https://doi.org/10.3390/met8121031