Enhancing Mechanical Response of Monolithic Magnesium Using Nano-NiTi (Nitinol) Particles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Processing

2.2. Material Characterization

2.2.1. Density Measurements

2.2.2. Microstructural Characterization

2.2.3. Coefficient of Thermal Expansion

2.2.4. Mechanical Properties

3. Results and Discussion

3.1. Density and Porosity

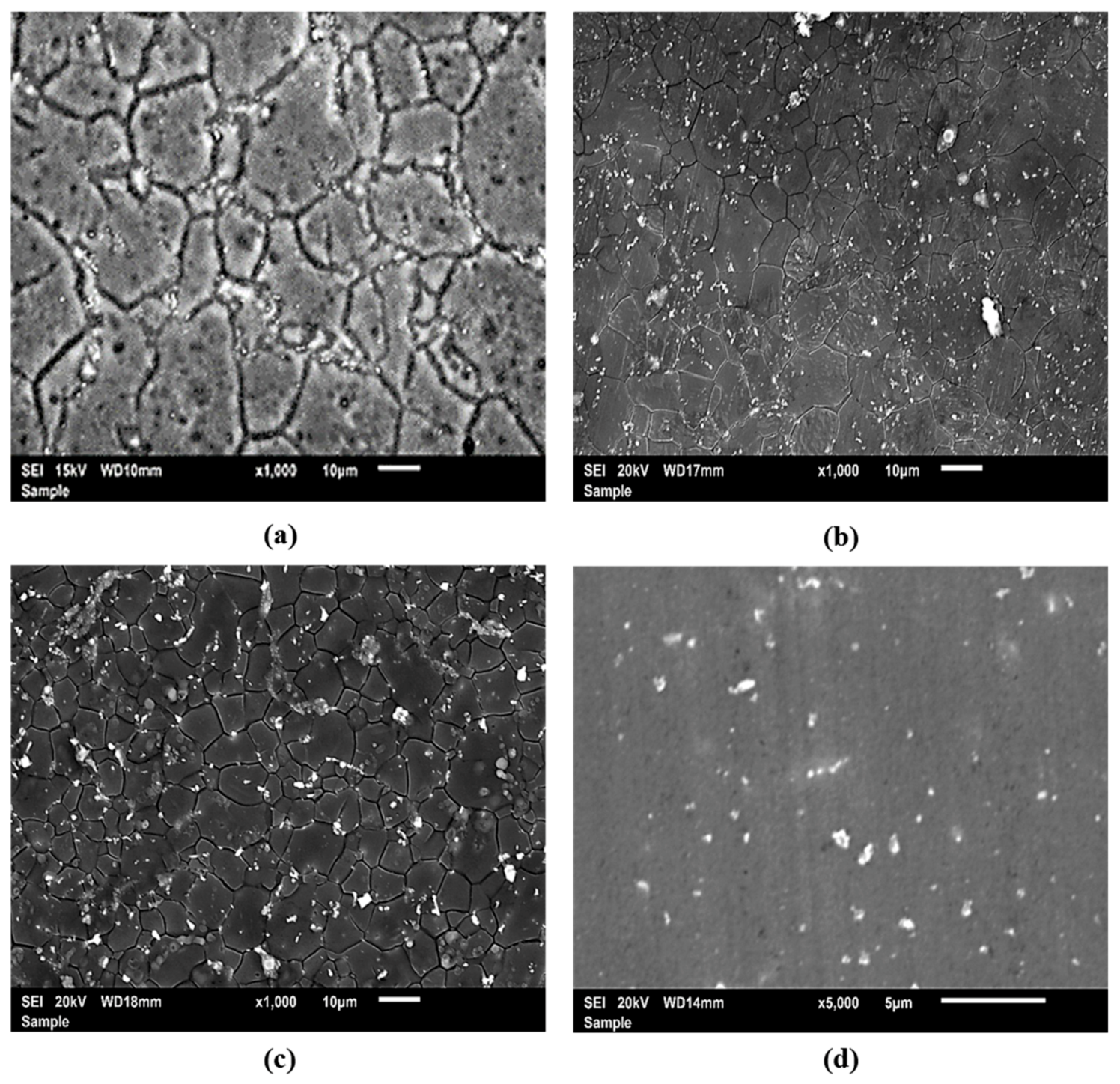

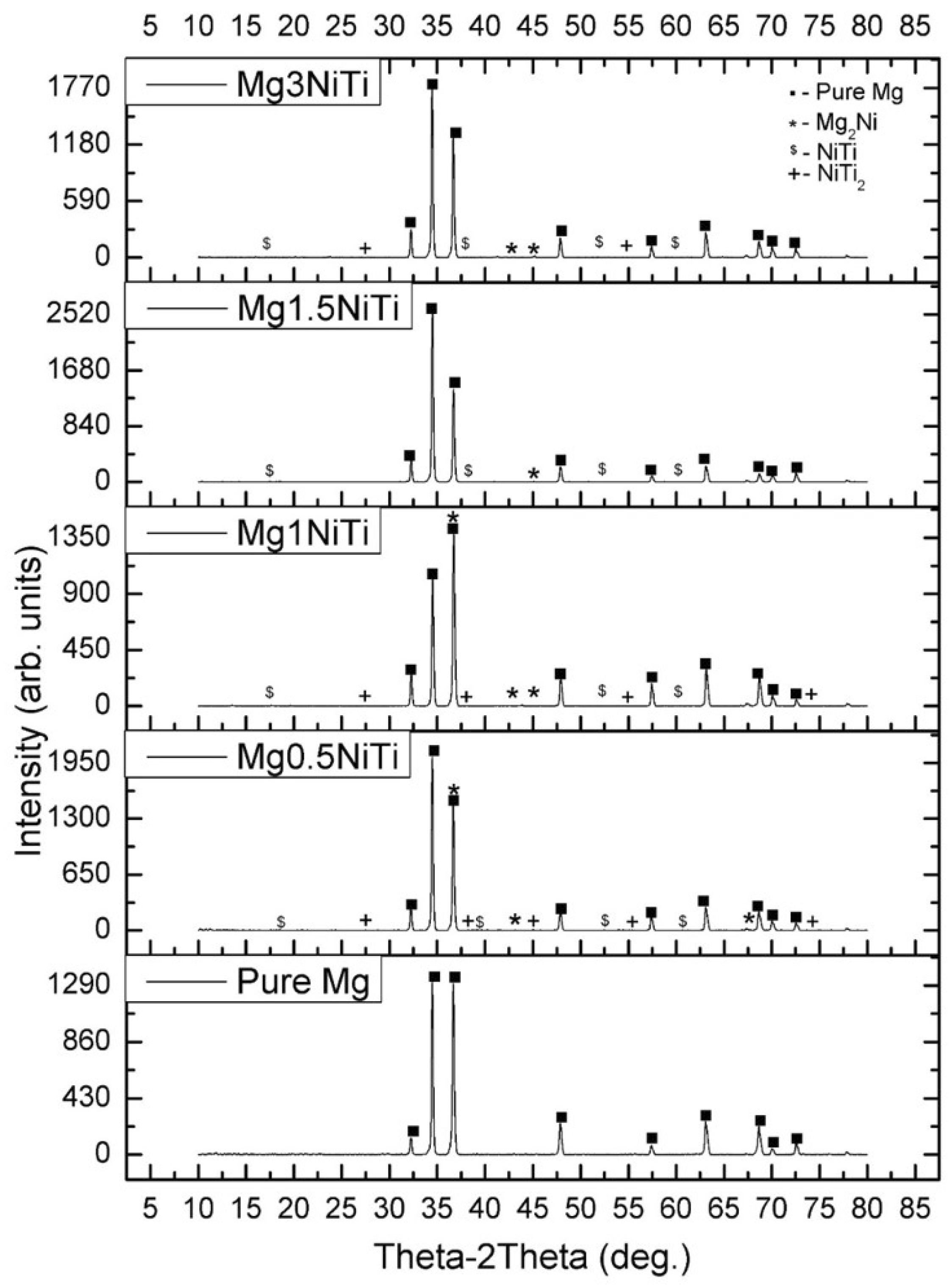

3.2. Microstructural Characterisation

3.3. Coefficient of Thermal Expansion

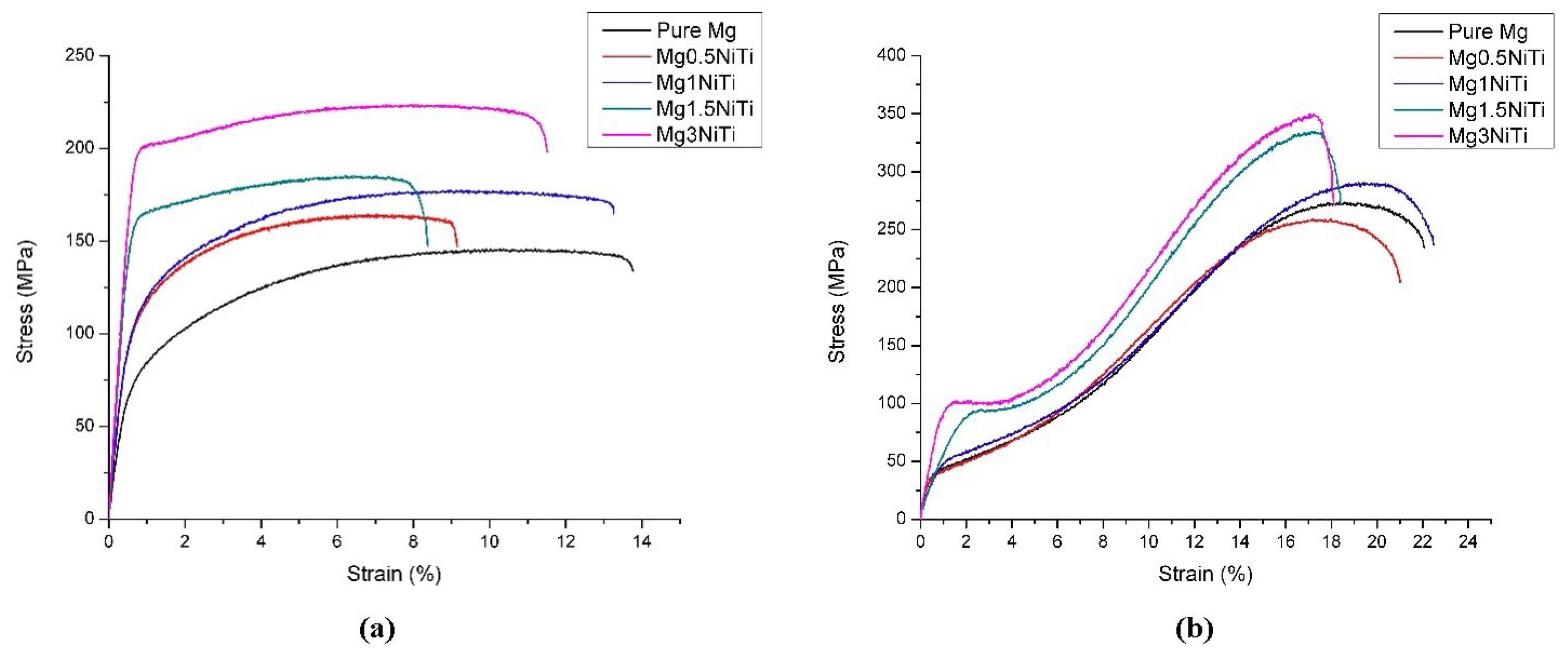

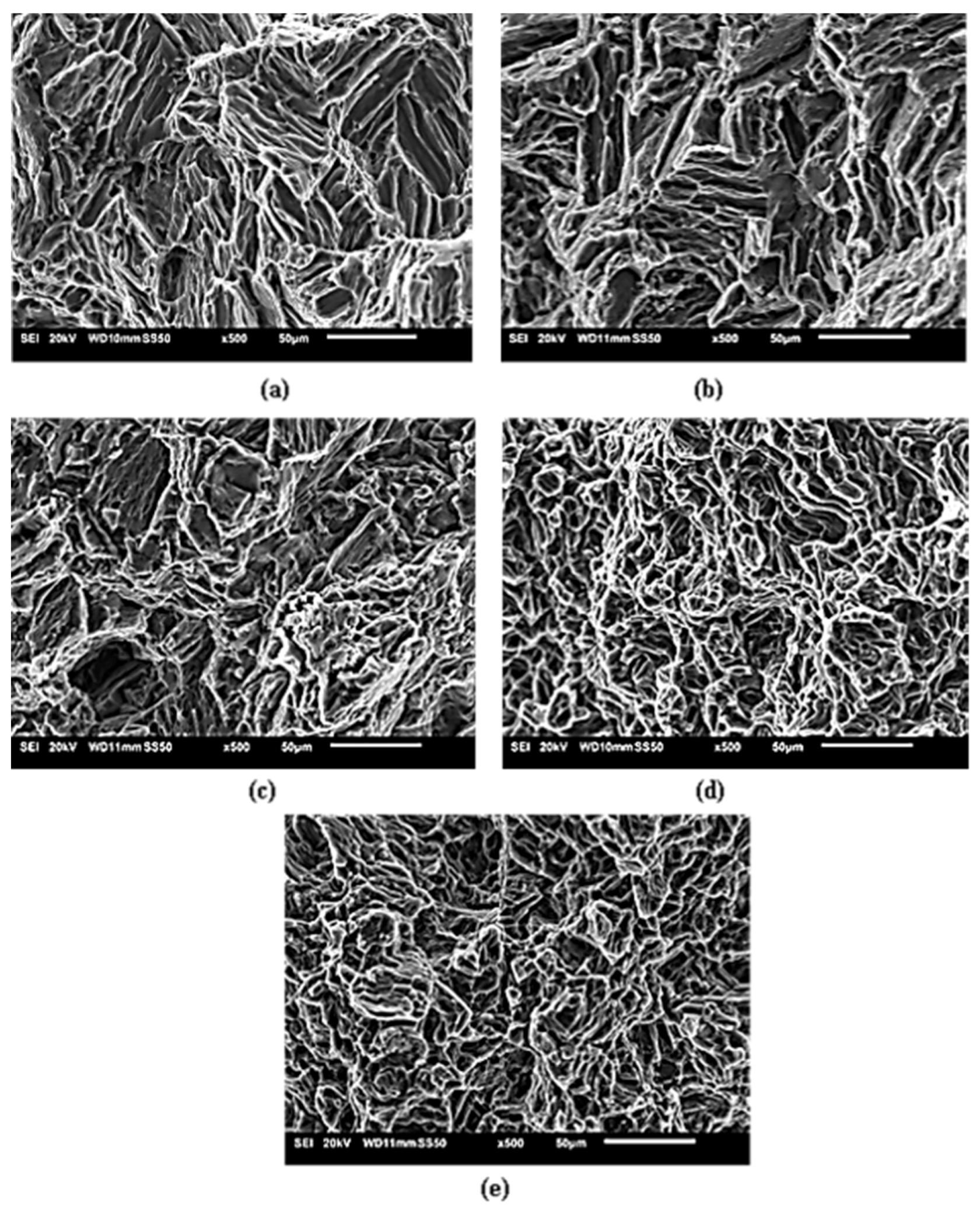

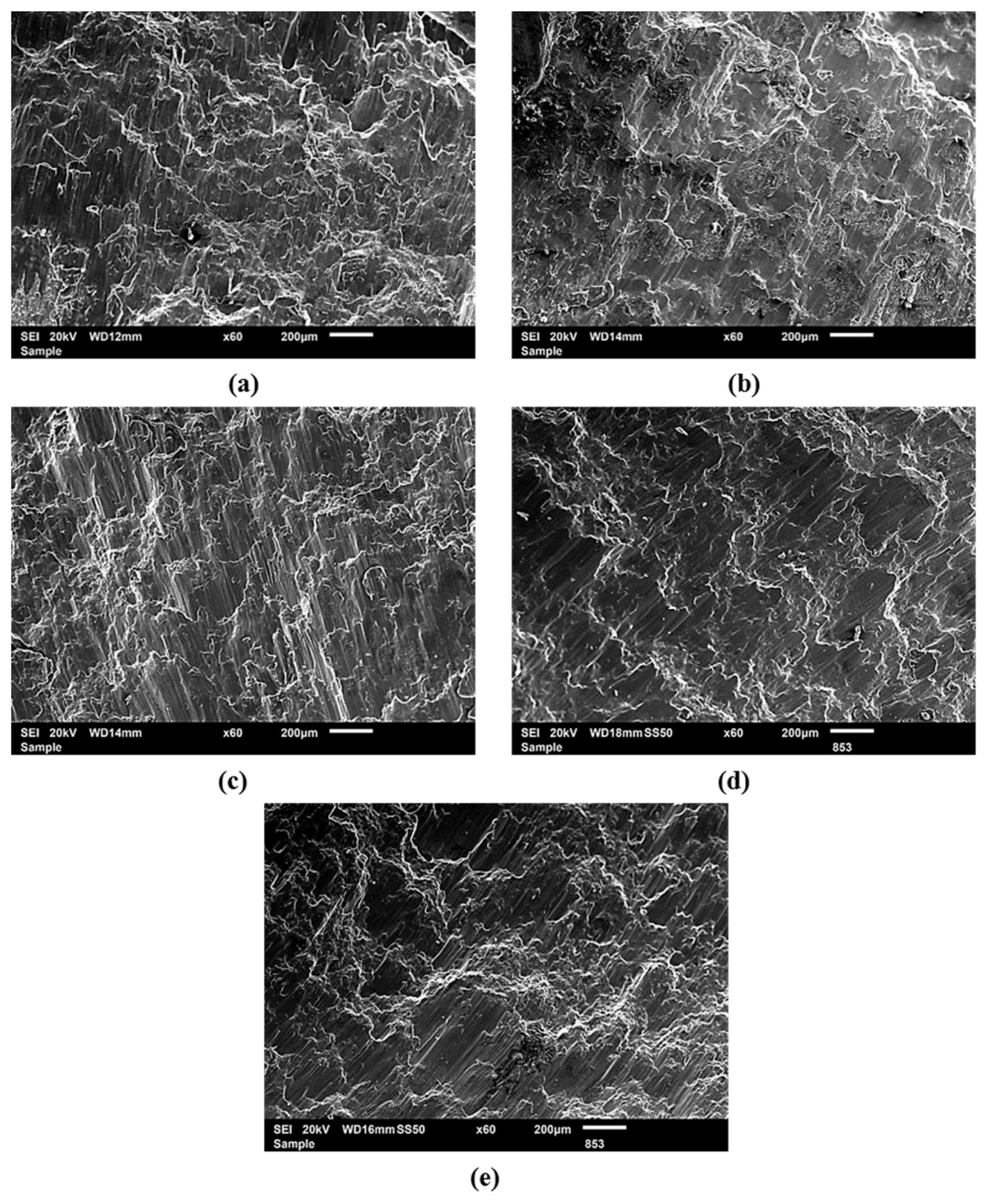

3.4. Mechanical Properties

4. Conclusions

- By the progressive addition of NiTi, highly dense material is obtained with limited porosity (<1%).

- The strong basal texture is retained in most of the Mg-NiTi nanocomposites with a high intensity corresponding to the pyramidal plane. High strength secondary phases like Mg2Ni and NiTi2 were formed.

- A near uniform distribution of NiTi nanoparticles in the magnesium matrix was observed. The NiTi nanoparticles were observed to pin the grain boundaries to restrict the grain growth and aids in the dispersion strengthening of the nanocomposite.

- Mg3NiTi nanocomposite displays a near 31% enhancement in microhardness values when compared to that of pure Mg, indicating a superior response to localized plastic deformation.

- Improved tensile strength (both yield and ultimate) properties and improved compressive strength (both yield and ultimate) were observed with Mg3NiTi nanocomposite displaying the maximum strength values in comparison with other developed nanocomposites.

- The fracture strain values for the nanocomposites in both tensile and compression mode were similar to that of pure Mg and significant enhancement or decrement was not observed.

Author Contributions

Conflicts of Interest

References

- Guo, Y.C.; Nie, K.B.; Kang, X.K.; Deng, K.K.; Han, J.G.; Zhu, Z.H. Achieving high-strength magnesium matrix nanocomposite through synergistical effect of external hybrid (sic+tic) nanoparticles and dynamic precipitated phase. J. Alloys Compd. 2019, 771, 847–856. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Gupta, M. Selective laser melting of magnesium and magnesium alloy powders: A review. Metals 2016, 7, 2. [Google Scholar] [CrossRef]

- Tekumalla, S.; Seetharaman, S.; Almajid, A.; Gupta, M. Mechanical properties of magnesium-rare earth alloy systems: A review. Metals 2014, 5, 1–39. [Google Scholar] [CrossRef]

- Bohlen, J.; Yi, S.; Letzig, D.; Kainer, K.U. Effect of rare earth elements on the microstructure and texture development in magnesium–manganese alloys during extrusion. Mater. Sci. Eng. A 2010, 527, 7092–7098. [Google Scholar] [CrossRef]

- Atrens, A.; Song, G.-L.; Liu, M.; Shi, Z.; Cao, F.; Dargusch, M.S. Review of recent developments in the field of magnesium corrosion. Adv. Eng. Mater. 2015, 17, 400–453. [Google Scholar] [CrossRef]

- Liu, M.; Shih, D.S.; Parish, C.; Atrens, A. The ignition temperature of mg alloys WE43, AZ31 and AZ91. Corros. Sci. 2012, 54, 139–142. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Kopparthy, S.D.S.; Gupta, M. Utilizing low-cost eggshell particles to enhance the mechanical response of Mg-2.5Zn magnesium alloy matrix. Adv. Eng. Mater. 2017, 20, 1700919. [Google Scholar] [CrossRef]

- Huang, S.-J.; Lin, C.-C.; Huang, J.-Y.; Tenne, R. Mechanical behavior enhancement of AZ31/WS2 and AZ61/WS2 magnesium metal matrix nanocomposites. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Guo, E.; Shuai, S.; Kazantsev, D.; Karagadde, S.; Phillion, A.B.; Jing, T.; Li, W.; Lee, P.D. The influence of nanoparticles on dendritic grain growth in mg alloys. Acta Mater. 2018, 152, 127–137. [Google Scholar] [CrossRef]

- Du, X.; Du, W.; Wang, Z.; Liu, K.; Li, S. Ultra-high strengthening efficiency of graphene nanoplatelets reinforced magnesium matrix composites. Mater. Sci. Eng. A 2018, 711, 633–642. [Google Scholar] [CrossRef]

- Goh, C.; Wei, J.; Lee, L.; Gupta, M.J.N. Development of novel carbon nanotube reinforced magnesium nanocomposites using the powder metallurgy technique. Nanotechnology 2005, 17, 7. [Google Scholar] [CrossRef]

- Kumar Meenashisundaram, G.; Hou Damien Ong, T.; Parande, G.; Manakari, V.; Xiang, S.; Gupta, M. Using lanthanum to enhance the overall ignition, hardness, tensile and compressive strengths of Mg-0.5Zr alloy. J. Rare Earths 2017, 35, 723–732. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Doddamani, M.; Gupta, M. Enhancing the ignition, hardness and compressive response of magnesium by reinforcing with hollow glass microballoons. Materials 2017, 10, 997. [Google Scholar] [CrossRef] [PubMed]

- Tun, K.; Zhang, Y.; Parande, G.; Manakari, V.; Gupta, M. Enhancing the hardness and compressive response of magnesium using complex composition alloy reinforcement. Metals 2018, 8, 276. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Gupta, H.; Gupta, M. Magnesium-β-tricalcium phosphate composites as a potential orthopedic implant: A mechanical/damping/immersion perspective. Metals 2018, 8, 343. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Sahu, S.; Sankaranarayanan, S.; Gupta, S.; Gupta, M. Development of novel Mg–Ni60Nb40 amorphous particle reinforced composites with enhanced hardness and compressive response. Mater. Design 2014, 53, 849–855. [Google Scholar] [CrossRef]

- Gupta, M.; Parande, G.; Manakari, V. An insight into high performance magnesium alloy/nano-metastable-syntactic composites. In Proceedings of the 17th Australian International Aerospace Congress, Melbourne, Australia, 26–28 February 2017; p. 270. [Google Scholar]

- Parande, G.; Manakari, V.; Meenashisundaram, G.K.; Gupta, M. Enhancing the tensile and ignition response of monolithic magnesium by reinforcing with silica nanoparticulates. J. Mater. Res. 2017, 32, 2169–2178. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Gupta, M. Emerging environment friendly, magnesium-based composite technology for present and future generations. JOM 2016, 68, 1890–1901. [Google Scholar] [CrossRef]

- Gupta, M.; Wong, W.L.E. Magnesium-based nanocomposites: Lightweight materials of the future. Mater. Charact. 2015, 105, 30–46. [Google Scholar] [CrossRef]

- Kaviti, R.V.P.; Jeyasimman, D.; Parande, G.; Gupta, M.; Narayanasamy, R. Investigation on dry sliding wear behavior of Mg/Bn nanocomposites. J. Mag. Alloys. 2018, 6, 263–276. [Google Scholar] [CrossRef]

- Kujur, M.S.; Mallick, A.; Manakari, V.; Parande, G.; Tun, K.S.; Gupta, M. Significantly enhancing the ignition/compression/damping response of monolithic magnesium by addition of Sm2O3 nanoparticles. Metals 2017, 7, 357. [Google Scholar] [CrossRef]

- Kujur, M.S.; Manakari, V.; Parande, G.; Tun, K.S.; Mallick, A.; Gupta, M. Enhancement of thermal, mechanical, ignition and damping response of magnesium using nano-ceria particles. Ceram. Int. 2018, 44, 15035–15043. [Google Scholar] [CrossRef]

- Chakif, M.; Essaidi, A.; Gurevich, E.; Ostendorf, A.; Prymak, O.; Epple, M. Generation of niti nanoparticles by femtosecond laser ablation in liquid. J. Mater. Eng. Perform. 2014, 23, 2482–2486. [Google Scholar] [CrossRef]

- Huang, W. On the selection of shape memory alloys for actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Guo, W.; Kato, H. Development of a high-damping NiTi shape-memory-alloy-based composite. Mater. Lett. 2015, 158, 1–4. [Google Scholar] [CrossRef]

- Školáková, A.; Novák, P.; Salvetr, P.; Moravec, H.; Šefl, V.; Deduytsche, D.; Detavernier, C. Investigation of the effect of magnesium on the microstructure and mechanical properties of niti shape memory alloy prepared by self-propagating high-temperature synthesis. Metall. Mater. Trans. A 2017, 48, 3559–3569. [Google Scholar] [CrossRef]

- Karamooz-Ravari, M.R.; Taheri Andani, M.; Kadkhodaei, M.; Saedi, S.; Karaca, H.; Elahinia, M. Modeling the cyclic shape memory and superelasticity of selective laser melting fabricated NiTi. Int. J. Mech. Sci. 2018, 138–139, 54–61. [Google Scholar] [CrossRef]

- Taylor, S.L.; Ibeh, A.J.; Jakus, A.E.; Shah, R.N.; Dunand, D.C. NiTi-Nb micro-trusses fabricated via extrusion-based 3D-printing of powders and transient-liquid-phase sintering. Acta Biomater. 2018, 76, 359–370. [Google Scholar] [CrossRef]

- Hao, S.; Cui, L.; Jiang, J.; Guo, F.; Xiao, X.; Jiang, D.; Yu, C.; Chen, Z.; Zhou, H.; Wang, Y. A novel multifunctional NiTi/Ag hierarchical composite. Sci. Rep. 2014, 4, 5267. [Google Scholar] [CrossRef]

- Yuan, B.; Zhu, M.; Chung, C.Y. Biomedical porous shape memory alloys for hard-tissue replacement materials. Materials 2018, 11, 1716. [Google Scholar] [CrossRef]

- Andani, M.T.; Moghaddam, N.S.; Haberland, C.; Dean, D.; Miller, M.J.; Elahinia, M. Metals for bone implants. Part 1. Powder metallurgy and implant rendering. Acta Biomater. 2014, 10, 4058–4070. [Google Scholar] [CrossRef] [PubMed]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Progr. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Reed-Hill, R.E.; Abbaschian, R.; Abbaschian, R. Physical Metallurgy Principles; Cengage Learning: Stamford, CT, USA, 1973. [Google Scholar]

- Robson, J.D.; Henry, D.T.; Davis, B. Particle effects on recrystallization in magnesium–manganese alloys: Particle-stimulated nucleation. Acta Mater. 2009, 57, 2739–2747. [Google Scholar] [CrossRef]

- Salvetr, P.; Školáková, A.; Novak, P. Effect of magnesium addition on the structural homogeneity of NiTi alloy produced by self-propagating high-temperature synthesis. Kovove Mater.-Metall. Mater. 2017, 55, 379–383. [Google Scholar] [CrossRef]

- Turner, P.S. The Problem of Thermal-Expansion Stresses in Reinforced Plastics; NACA: Washingtion, DC, USA, 1942. [Google Scholar]

- Stanford, M.K. Thermophysical Properties of 60-Nitinol for Mechanical Component Applications; NASA: Cleveland, OH, USA, 2012.

- Stanford, M.K. Hardness and Microstructure of Binary and Ternary Nitinol Compounds; NASA: Cleveland, OH, USA, 2016.

- Aboudzadeh, N.; Dehghanian, C.; Shokrgozar, M. Synthesis, microstructure and mechanical properties of Mg. 5Zn. 0.3 Ca/nHa nanocomposites. Iran. J. Mater. Sci. Eng. 2017, 14. [Google Scholar] [CrossRef]

- Száraz, Z.; Trojanová, Z.; Cabbibo, M.; Evangelista, E. Strengthening in a WE54 magnesium alloy containing SiC particles. Mater. Sci. Eng. A 2007, 462, 225–229. [Google Scholar] [CrossRef]

- Choi, S.-M.; Awaji, H. Nanocomposites—A new material design concept. Sci. Technol. Adv. Mater. 2005, 6, 2. [Google Scholar] [CrossRef]

- Yuan, Q.; Zeng, X.; Wang, Y.; Luo, L.; Ding, Y.; Li, D.; Liu, Y. Microstructure and mechanical properties of Mg-4.0Zn alloy reinforced by NiO-coated CNTs. J. Mater. Sci. Technol. 2017, 33, 452–460. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of hall–petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Nayak, U.P.; Sabat, R.; Suwas, S.; Almajid, A.; Gupta, M. Nano-zno particle addition to monolithic magnesium for enhanced tensile and compressive response. J. Alloys Compd. 2014, 615, 211–219. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Sabat, R.; Jayalakshmi, S.; Suwas, S.; Gupta, M. Effect of nanoscale boron carbide particle addition on the microstructural evolution and mechanical response of pure magnesium. Mater. Design 2014, 56, 428–436. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Meenashisundaram, G.K.; Gupta, M. Enhancing the hardness/compression/damping response of magnesium by reinforcing with biocompatible silica nanoparticulates. Int. J. Mater. Res. 2016, 107, 1091–1099. [Google Scholar] [CrossRef]

| Material | Theoretical Density (g/cc) | Experimental Density (g/cc) | Porosity (%) |

|---|---|---|---|

| Pure Mg | 1.73 | 1.72 ± 0.025 | 0.85 |

| Mg0.5NiTi | 1.74 | 1.73 ± 0.008 | 0.48 |

| Mg1NiTi | 1.75 | 1.74 ± 0.002 | 0.51 |

| Mg1.5NiTi | 1.75 | 1.75 ± 0.003 | 0.50 |

| Mg3NiTi | 1.78 | 1.76 ± 0.008 | 0.67 |

| Material | Grain Size (µm) | CTE (×10−6/K) | Microhardness (Hv) |

|---|---|---|---|

| Pure Mg | 40 ± 9.4 | 27.1 | 57 ± 4.6 |

| Mg0.5NiTi | 17 ± 2.2 (60%↓) | 26.4 (3%↓) | 59 ± 3.3 (4%↑) |

| Mg1NiTi | 13 ± 1 (67%↓) | 25.9 (4%↓) | 72 ± 2.5 (26%↑) |

| Mg1.5NiTi | 10 ± 3.3 (75%↓) | 25.6 (5%↓) | 73 ± 3.9 (28%↑) |

| Mg3NiTi | 9 ± 1.8 (76%↓) | 24.3 (10%↓) | 75 ± 2.6 (31%↑) |

| Material | 0.2% TYS (MPa) | UTS (MPa) | Fracture Strain (%) | Energy Absorbed (MJ/m3) |

|---|---|---|---|---|

| Pure Mg | 84 ± 6 | 148 ± 6 | 13 ± 0.9 | 17 ± 1.5 |

| Mg0.5NiTi | 106 ± 12 (26%↑) | 167 ± 14 (13%↑) | 9 ± 0.8 | 24 ± 1.8 (41%↑) |

| Mg1NiTi | 123 ± 2 (47%↑) | 176 ± 9 (19%↑) | 9 ± 4.2 | 14 ± 1.6 |

| Mg1.5NiTi | 163 ± 9 (94%↑) | 187 ± 8 (26%↑) | 9 ± 0.4 | 14 ± 2.1 |

| Mg3NiTi | 193 ± 17 (129%↑) | 217 ± 16 (46%↑) | 11 ± 0.2 | 23 ± 2.4 (35%↑) |

| Material | 0.2% CYS (MPa) | UCS (MPa) | Fracture Strain (%) | Energy Absorbed (MJ/m3) |

|---|---|---|---|---|

| Pure Mg | 46 ± 2 | 274 ± 4 | 23 ± 0.9 | 39 ± 2.7 |

| Mg0.5NiTi | 42 ± 4 (9%↓) | 265 ± 15 (3%↓) | 23 ± 0.3 | 36 ± 2.4 |

| Mg1NiTi | 52 ± 6 (13%↑) | 290 ± 4 (6%↑) | 23 ± 0.7 | 40 ± 1.5 |

| Mg1.5NiTi | 78 ± 5 (70%↑) | 337 ± 4 (23%↑) | 18 ± 0.4 | 35 ± 2.1 |

| Mg3NiTi | 94 ± 3 (104%↑) | 345 ± 5 (26%↑) | 18 ± 0.9 | 35 ± 2.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parande, G.; Manakari, V.; Wakeel, S.; Kujur, M.S.; Gupta, M. Enhancing Mechanical Response of Monolithic Magnesium Using Nano-NiTi (Nitinol) Particles. Metals 2018, 8, 1014. https://doi.org/10.3390/met8121014

Parande G, Manakari V, Wakeel S, Kujur MS, Gupta M. Enhancing Mechanical Response of Monolithic Magnesium Using Nano-NiTi (Nitinol) Particles. Metals. 2018; 8(12):1014. https://doi.org/10.3390/met8121014

Chicago/Turabian StyleParande, Gururaj, Vyasaraj Manakari, Saif Wakeel, Milli Suchita Kujur, and Manoj Gupta. 2018. "Enhancing Mechanical Response of Monolithic Magnesium Using Nano-NiTi (Nitinol) Particles" Metals 8, no. 12: 1014. https://doi.org/10.3390/met8121014

APA StyleParande, G., Manakari, V., Wakeel, S., Kujur, M. S., & Gupta, M. (2018). Enhancing Mechanical Response of Monolithic Magnesium Using Nano-NiTi (Nitinol) Particles. Metals, 8(12), 1014. https://doi.org/10.3390/met8121014