Geometric Modification of the Tundish Impact Point

Abstract

:1. Introduction

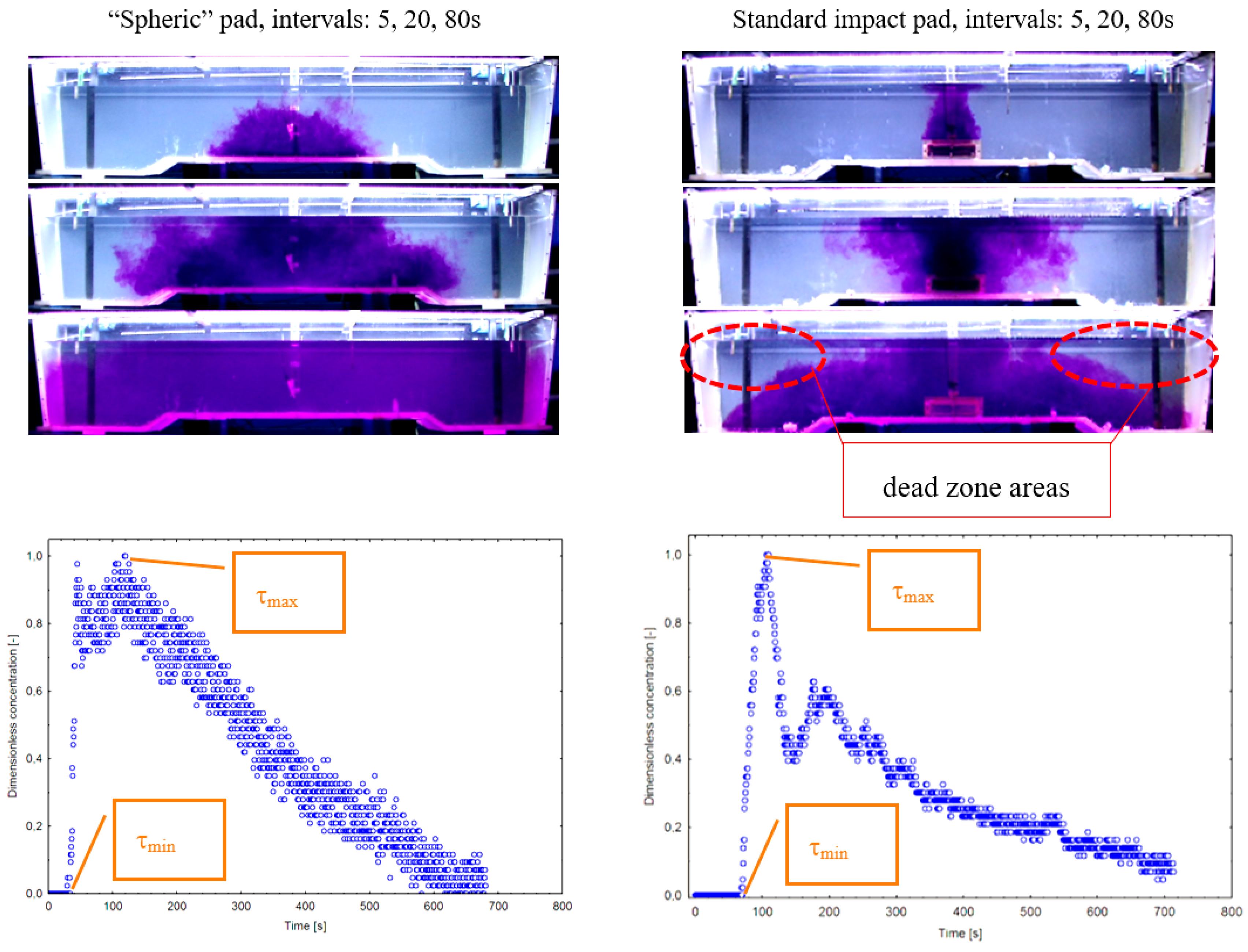

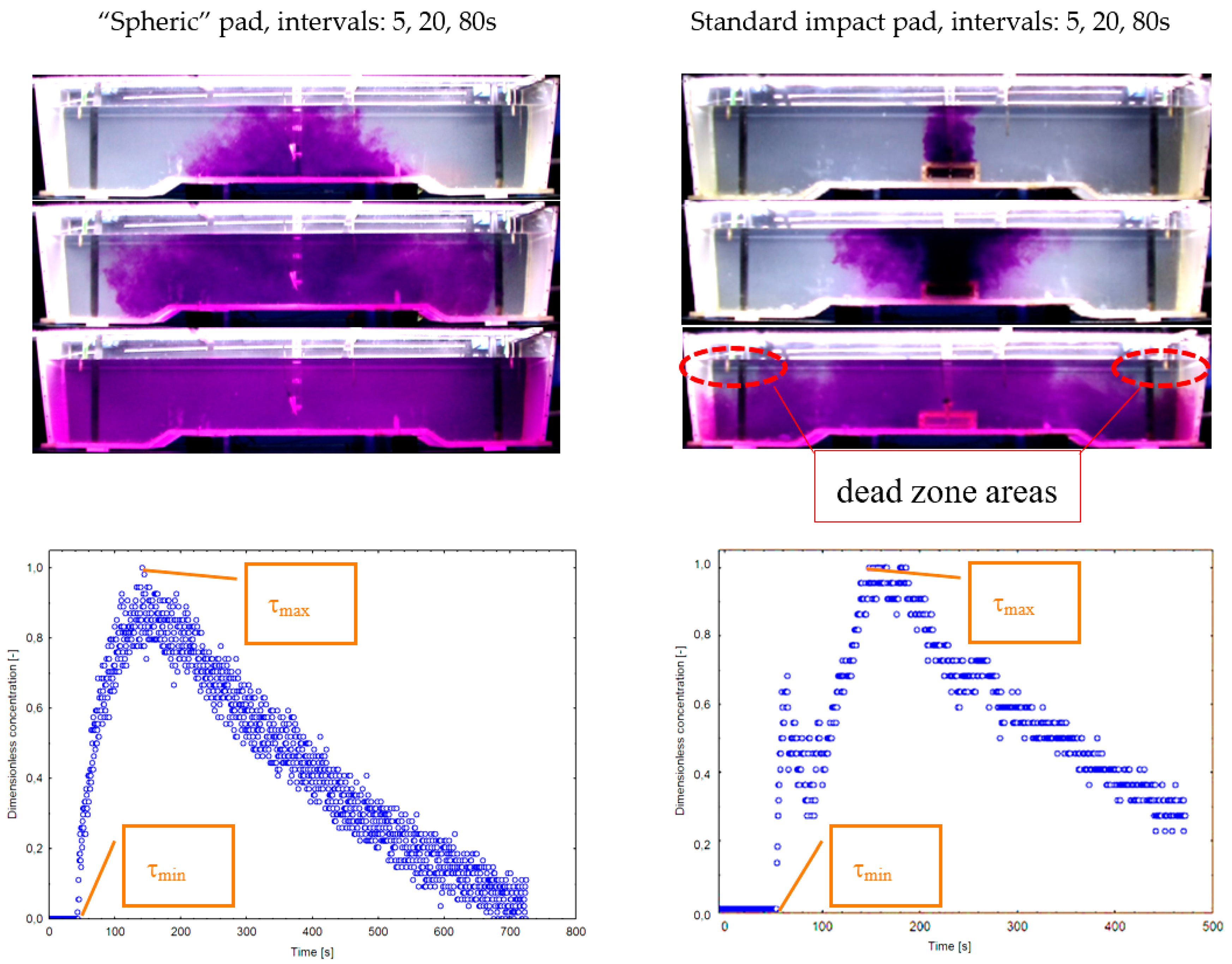

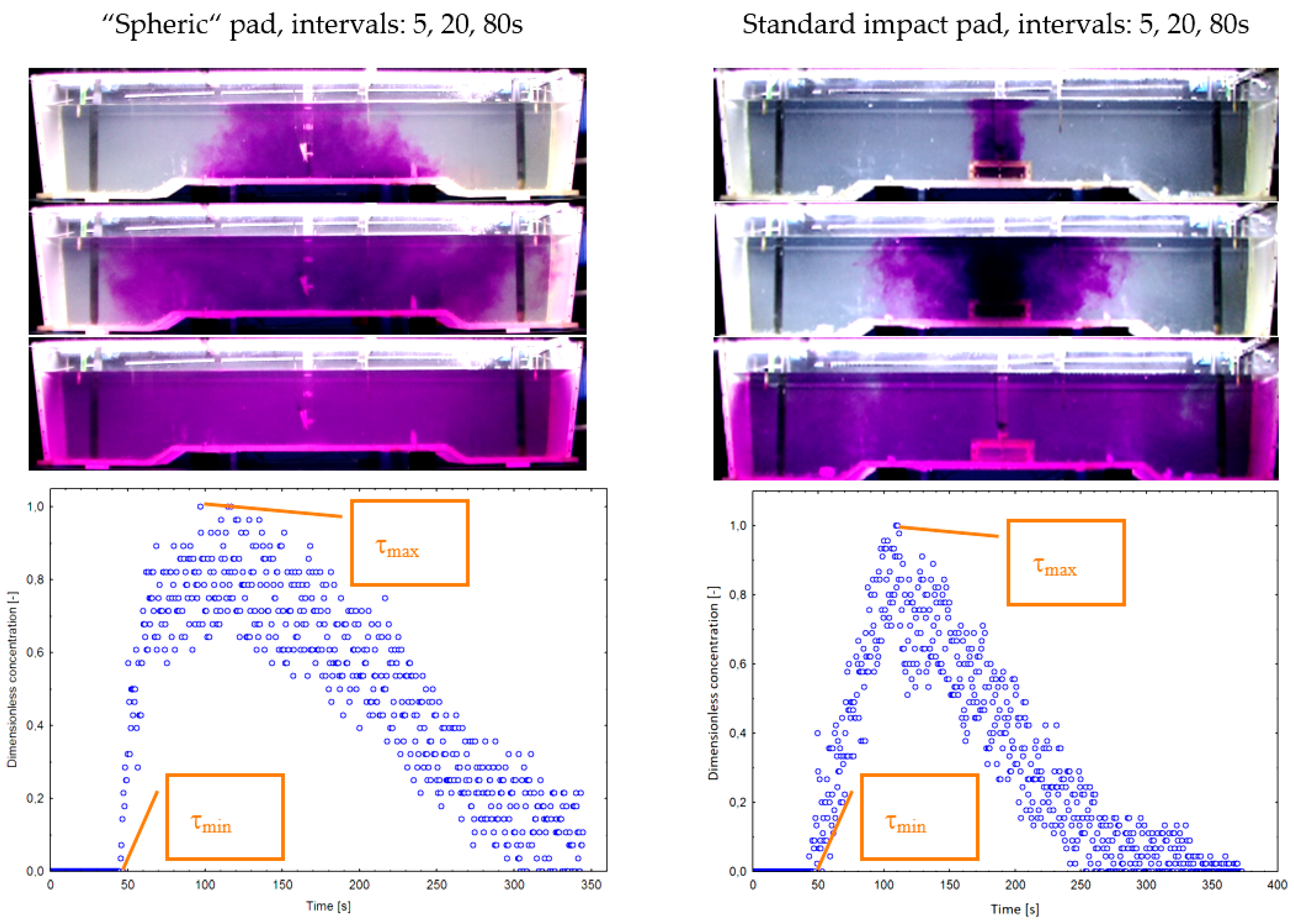

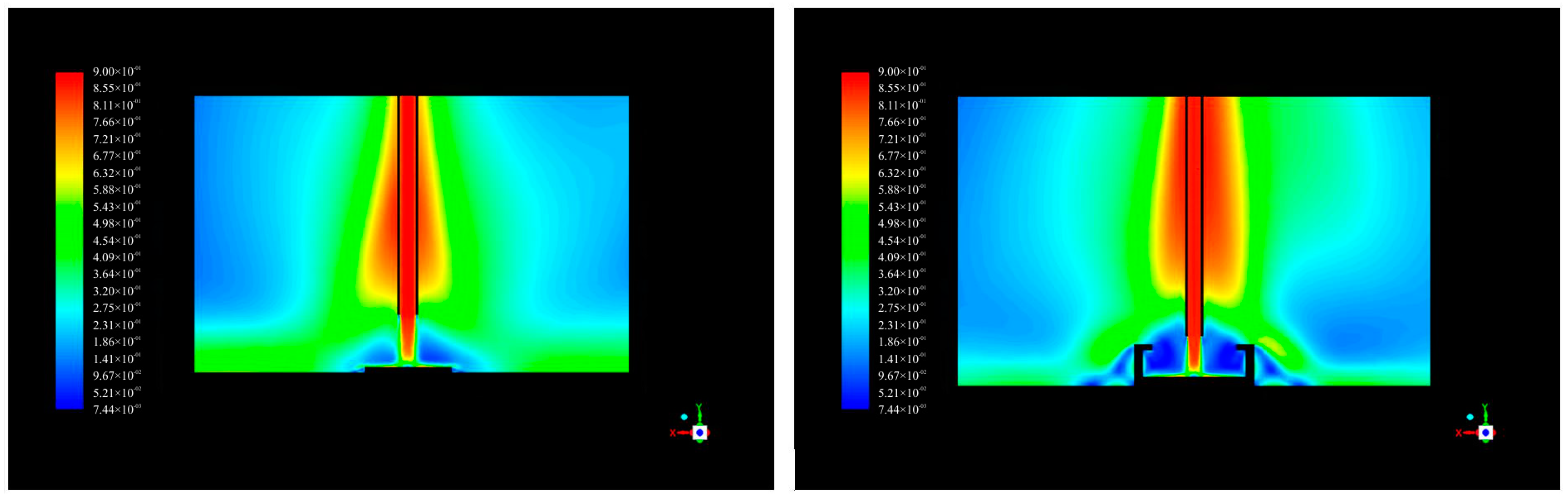

2. Experimental Materials and Methods

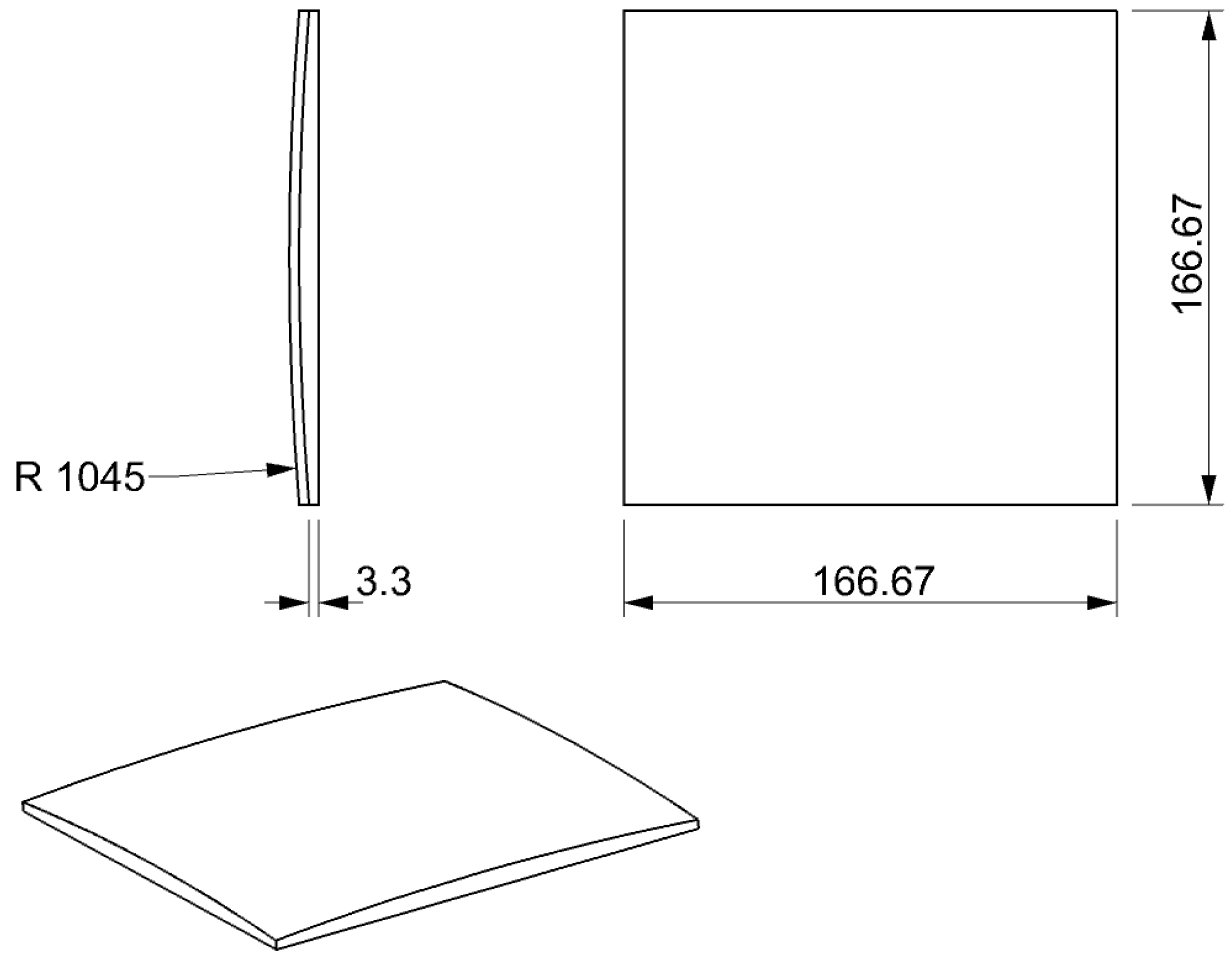

2.1. The “Spheric” Impact Pad

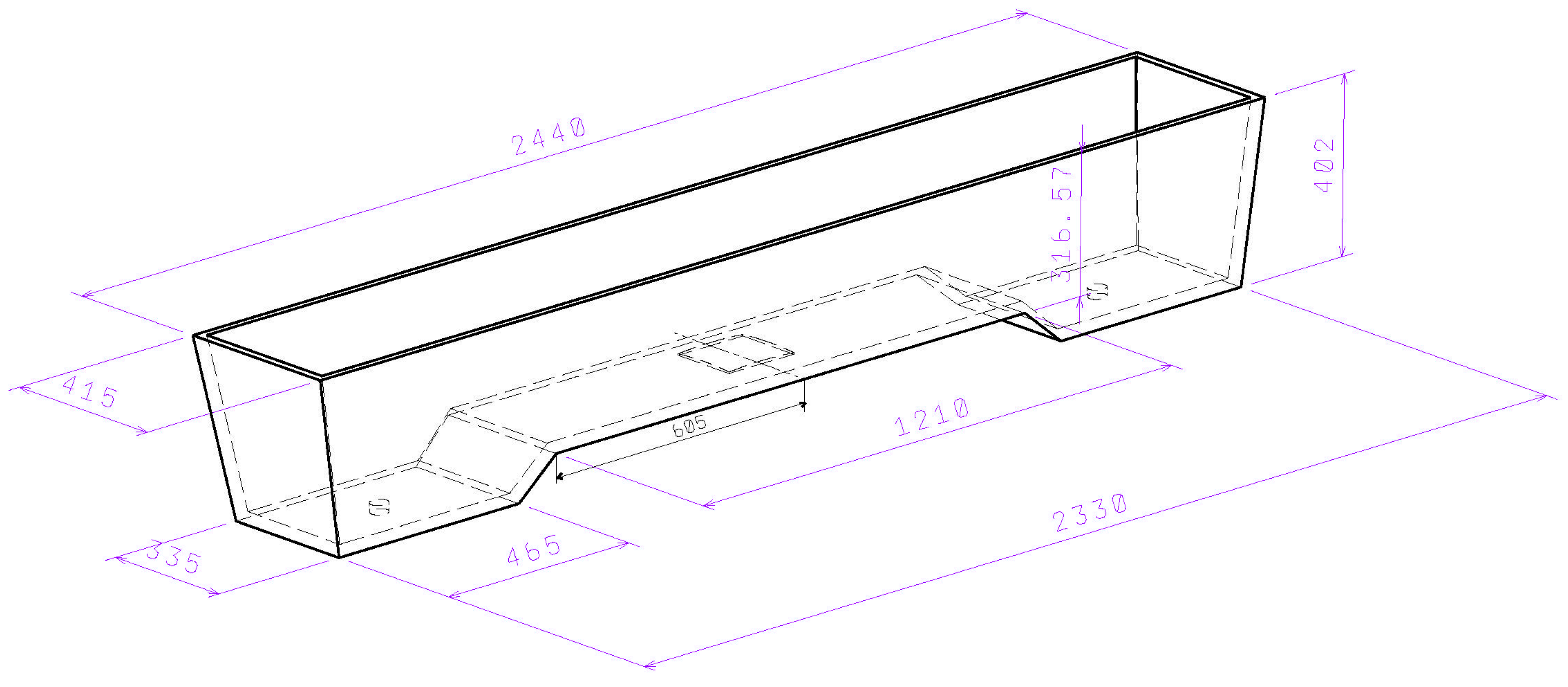

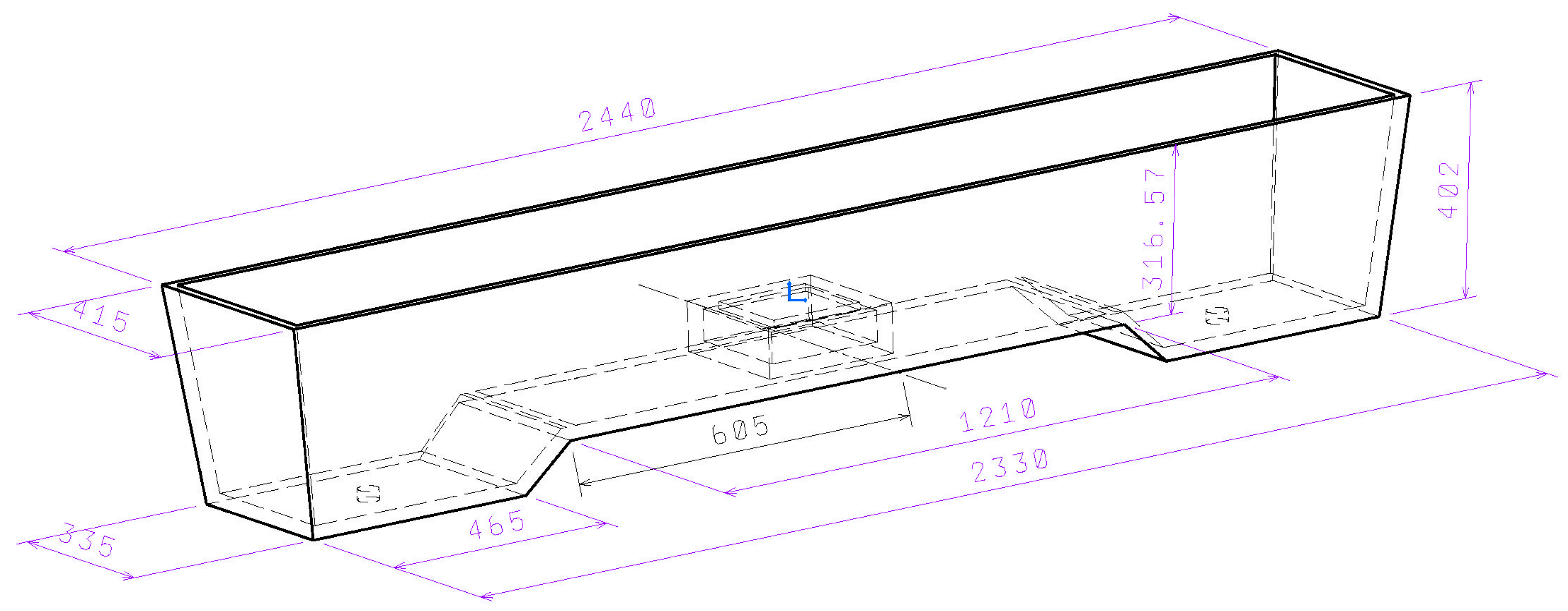

2.2. The Standard Impact Pad

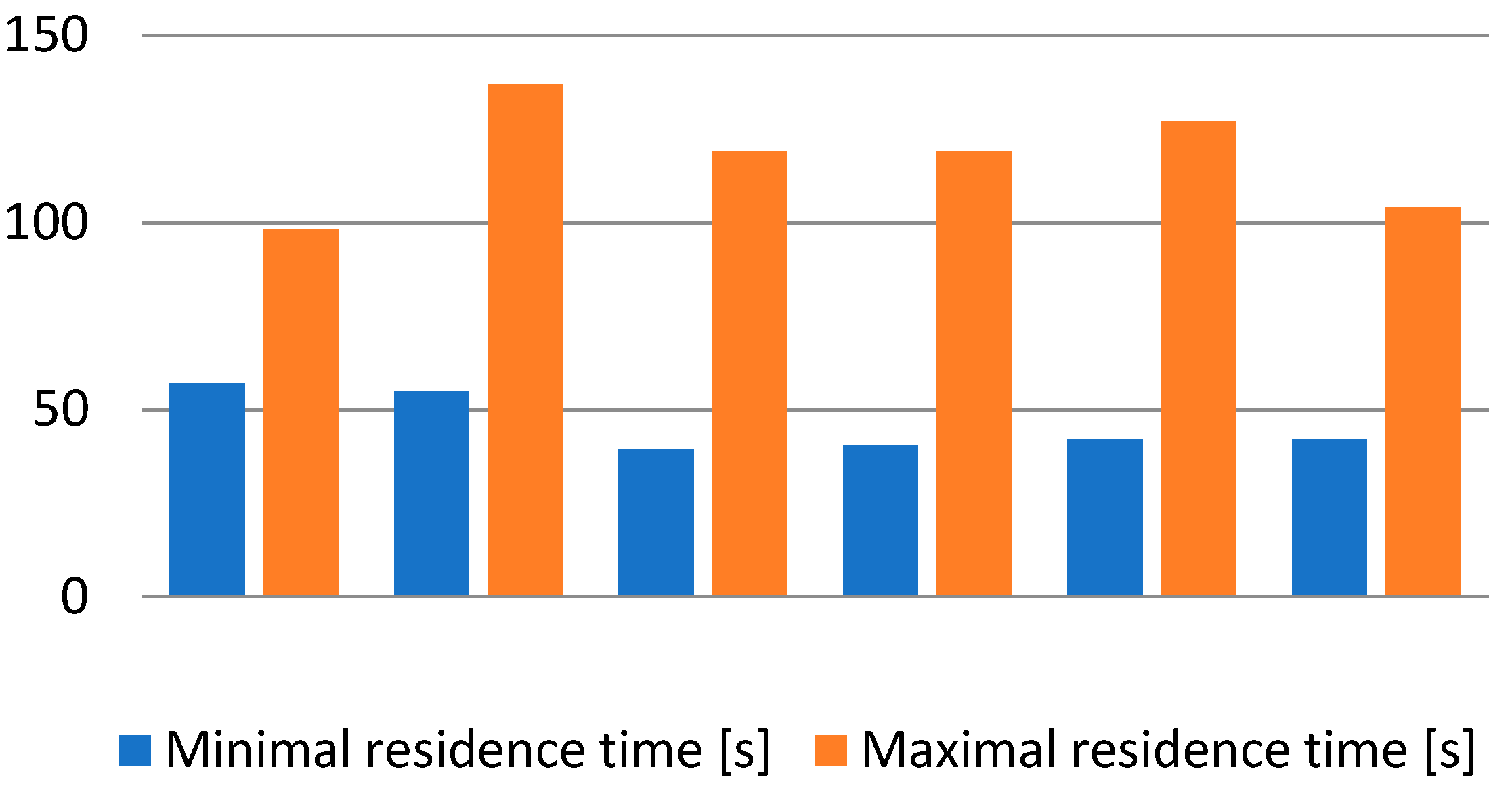

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Worldsteel Association. Steel Statistical Yearbook 2016. Available online: https://www.worldsteel.org/publications/bookshop/product-details.~Steel-Statistical-Yearbook-2016~PRODUCT~SSY2016~.html (accessed on 9 November 2018).

- Michalek, K.; Gryc, K.; Socha, L.; Tkadlečková, M.; Saternus, M.; Pieprzyca, J.; Merder, T.; Pindor, L. Physical modelling of tundish slag entrainment under various technological conditions. Arch. Metall. Mater. 2017, 62, 1467–1471. [Google Scholar] [CrossRef]

- Warzecha, M. Numerical Modelling of Non-Metallic Inclusion Separation in a Continuous Casting Tundish. Available online: https://www.researchgate.net/publication/221913237 (accessed on 9 November 2018).

- Braun, A.; Warzecha, M.; Pfeifer, H. Numerical and physical modeling of steel flow in a two-strand tundish for different casting conditions. Metall. Mater. Trans. B 2010, 41, 549–559. [Google Scholar] [CrossRef]

- Chattopadhyay, K.; Isac, M.; Guthrie, R.I.L. Physical and mathematical modelling of steelmaking tundish operations: A review of the last decade (1999–2009). ISIJ Int. 2010, 50, 331–348. [Google Scholar] [CrossRef]

- Kowitwarangkul, P.; Harnsihacacha, A. Tracer injection simulations and RTD analysis for the flow in a 3-strand steelmaking tundish. Key Eng. Mater. 2016, 728, 72–77. [Google Scholar] [CrossRef]

- Buľko, B.; Kijac, J. Optimization of tundish equipment. Acta Metall. Slovaca 2010, 16, 76–83. [Google Scholar]

- Buľko, B.; Molnár, M.; Demeter, P. Physical modeling of different configurations of a tundish for casting grades of steel that must satisfy stringent requirements on quality. Metallurgist 2014, 57, 976–980. [Google Scholar] [CrossRef]

- Chatterjee, D. Designing of a novel shroud for improving the quality of steel in tundish. Adv. Mater. Res. 2012, 585, 359–363. [Google Scholar] [CrossRef]

- Hoerner, S.F. Fluid Dynamic Drag: Practical Information on Aerodynamic Drag and Hydrodynamic Resistance; Hoerner Fluid Dynamics: Bakersfield, CA, USA, 1965. [Google Scholar]

- Laboratory of Simulation of Flow Processes. Available online: https://ohaz.umet.fmmr.tuke.sk/lspp/index_en.html (accessed on 17 September 2018).

- Priesol, I. A Method of Molten Metal Casting Utilizing an Impact Pad in the Tundish. International Patent Application No. PCT/IB2016/056207, 10 October 2016. [Google Scholar]

- Priesol, I. Spôsob Liatia Roztaveného Kovu s Využitím Dopadovej Dosky v Medzipanve. International Patent Classification: B22D 11/10 B22D 41/00, Application No. 109-2016, 11 October 2016; B22D 11/00 B22D 41/00, Application No. 89-2016, 10 October 2016. [Google Scholar]

- Michalek, K.; Gryc, K.; Socha, L.; Tkadlečková, M.; Saternus, M.; Pieprzyca, J.; Merder, T.; Pindor, L. Study of tundish slag entrainment using physical modeling. Arch. Metall. Mater. 2016, 61, 257–260. [Google Scholar] [CrossRef]

- Acta Metallurgica Slovaca. Available online: http://www.ams.tuke.sk/data/ams_online/2010/number2/mag01/mag01.pdf (accessed on 17 September 2018).

- Gryc, K.; Michalek, K.; Hudzieczek, Z.; Tkadlečková, M. Physical modelling of flow patterns in a 5-strand asymmetrical tundish with baffles. In Proceedings of the Metal 2010—19th International Conference on Metallurgy and Materials, Poruba, Czech Republic, 18–20 May 2010. [Google Scholar]

- Sahai, Y.; Emi, T. Melt flow characterization in continuous casting tundishes. ISIJ Int. 1996, 36, 667–672. [Google Scholar] [CrossRef]

- Väyrynen, P.; Wang, S.; Louhenkilpi, S.; Holappa, L. Modeling and removal of inclusions in continuous casting. In Proceedings of the Materials Science and Technology 2009—International Symposium on Inclusions and Clean Steel 2009, Pittsburgh, PA, USA, 25–29 October 2009. [Google Scholar]

- Michalek, K. Využití Fyzikálního a Numerického Modelování pro Optimalizaci Metalurgických Procesů; Vysoká škola Báňská—Technická Univerzita: Ostrava, Czech Republic, 2001; ISBN 80-7078-861-5. [Google Scholar]

- Falkus, J.; Lamut, J. Model testing of the bath flow through the Tundish of the continuous casting machine. Arch. Metall. Mater. 2005, 50, 709–718. [Google Scholar]

- Ansys Fluent 12.0 User’s Guide. 2009. Available online: http://users.ugent.be/~mvbelleg/flug-12-0.pdf (accessed on 22 August 2018).

- Nastac, L.; Zhang, L.; Thomas, B.G.; Zhu, M.; Ludwig, A.; Sabau, A.S.; Pericleous, K.; Combeau, H. CFD Modeling and Simulation in Materials Processing 2016; Springer International Publishing: New York, NY, USA, 2016. [Google Scholar]

- Gardin, P.; Brunet, M.; Domgin, J.F.; Pericleous, K. An experimental and numerical CFD study of turbulence in a tundish container. Appl. Math. Model. 2002, 26, 323–336. [Google Scholar] [CrossRef]

- Mazumdar, D.; Guthrie, R.I.L. The physical and mathematical modelling of continuous casting Tundish systems. ISIJ Int. 1999, 39, 524–547. [Google Scholar] [CrossRef]

- Liu, S.; Yang, X.; Du, L.; Li, L.; Liu, C. Hydrodynamic and mathematical simulations of flow field and temperature profile in an asymmetrical t-type single-strand continuous casting Tundish. ISIJ Int. 2008, 48, 1712–1721. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chattopadhyay, K. Formation of slag ‘eye’ in an inert gas shrouded Tundish. ISIJ Int. 2015, 55, 1416–1424. [Google Scholar] [CrossRef]

- Zhang, L.; Thomas, B.G. State of the art in evaluation and control of steel cleanliness. ISIJ Int. 2003, 43, 271–291. [Google Scholar] [CrossRef]

| Configuration | Casting Speed | Minimal Residence Time (s) | Maximal Residence Time (s) |

|---|---|---|---|

| Standard Impact Pad | 0.8 m·min−1 | 57 | 98 |

| 1.2 m·min−1 | 55 | 137 | |

| 1.6 m·min−1 | 39.5 | 119 | |

| Spheric Impact Pad | 0.8 m·min−1 | 40.5 (71%) | 119 |

| 1.2 m·min−1 | 42 (76%) | 127 | |

| 1.6 m·min−1 | 42 (106%) | 104 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buľko, B.; Priesol, I.; Demeter, P.; Gašparovič, P.; Baricová, D.; Hrubovčáková, M. Geometric Modification of the Tundish Impact Point. Metals 2018, 8, 944. https://doi.org/10.3390/met8110944

Buľko B, Priesol I, Demeter P, Gašparovič P, Baricová D, Hrubovčáková M. Geometric Modification of the Tundish Impact Point. Metals. 2018; 8(11):944. https://doi.org/10.3390/met8110944

Chicago/Turabian StyleBuľko, Branislav, Ivan Priesol, Peter Demeter, Peter Gašparovič, Dana Baricová, and Martina Hrubovčáková. 2018. "Geometric Modification of the Tundish Impact Point" Metals 8, no. 11: 944. https://doi.org/10.3390/met8110944

APA StyleBuľko, B., Priesol, I., Demeter, P., Gašparovič, P., Baricová, D., & Hrubovčáková, M. (2018). Geometric Modification of the Tundish Impact Point. Metals, 8(11), 944. https://doi.org/10.3390/met8110944