Design Optimisation of the Feeding System of a Novel Counter-Gravity Casting Process

Abstract

1. Introduction

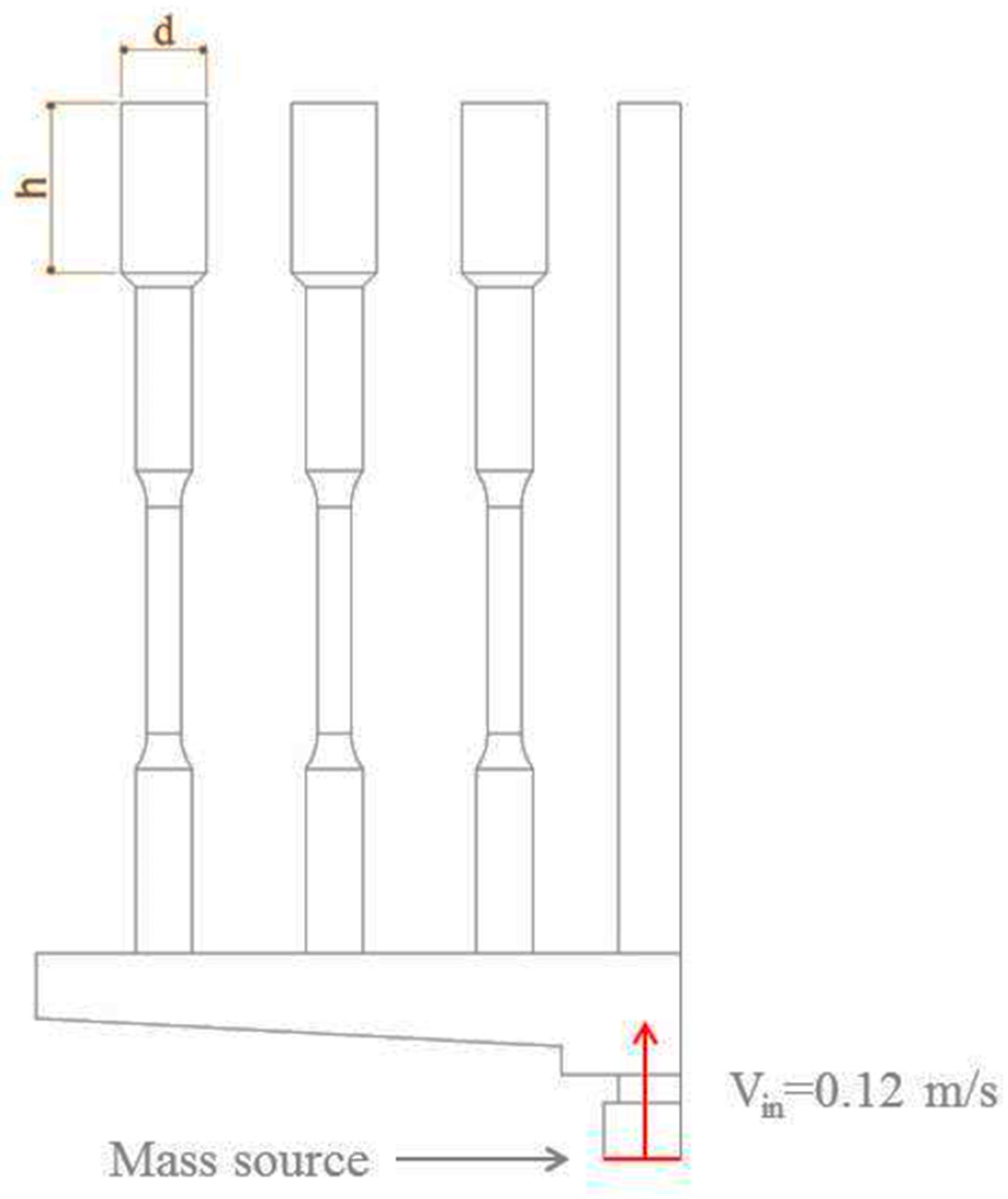

2. Simulation Methodology

2.1. CRIMSON

2.2. Optimisation

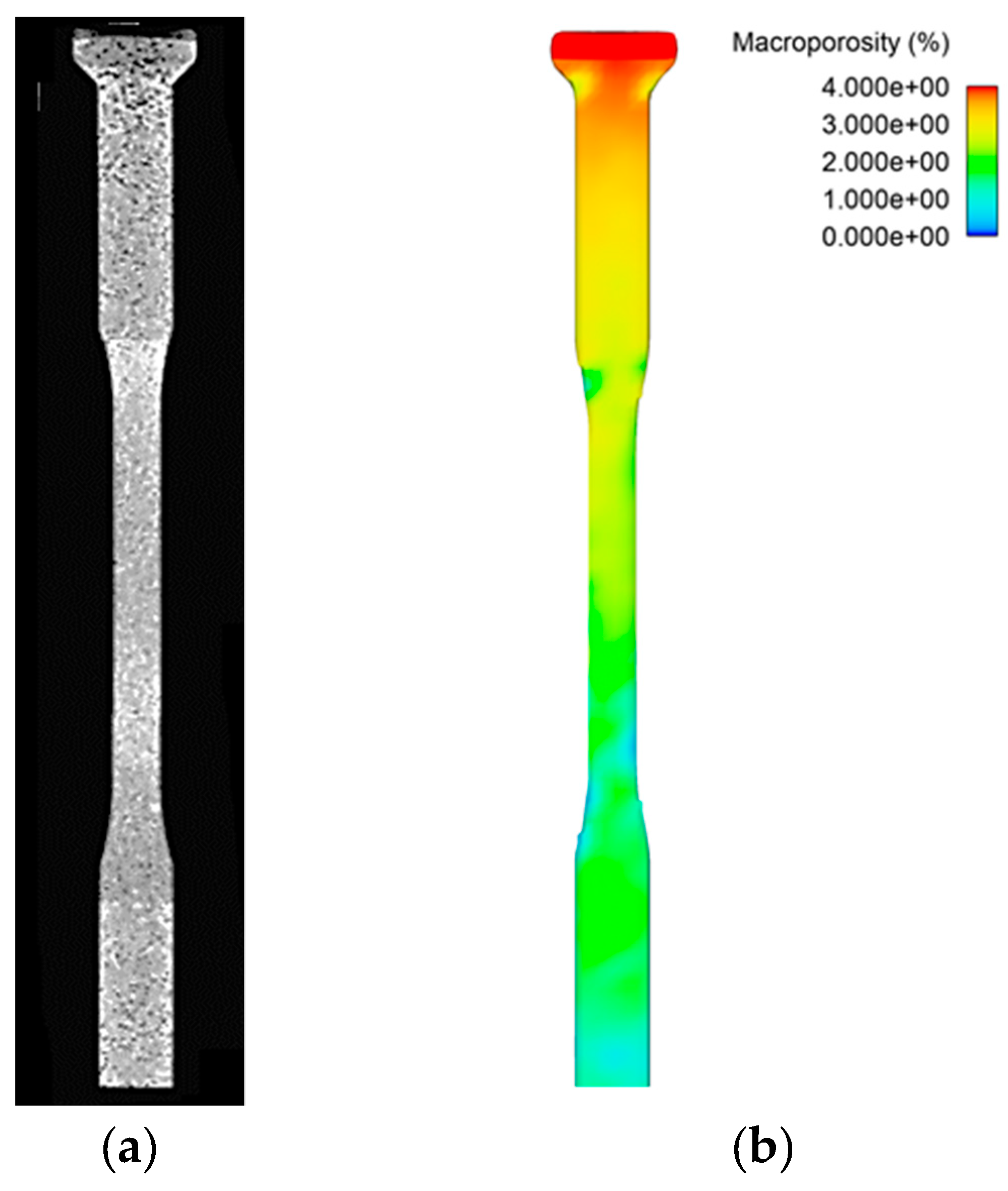

2.3. Validation of Numerical Modelling

3. Results and Discussion

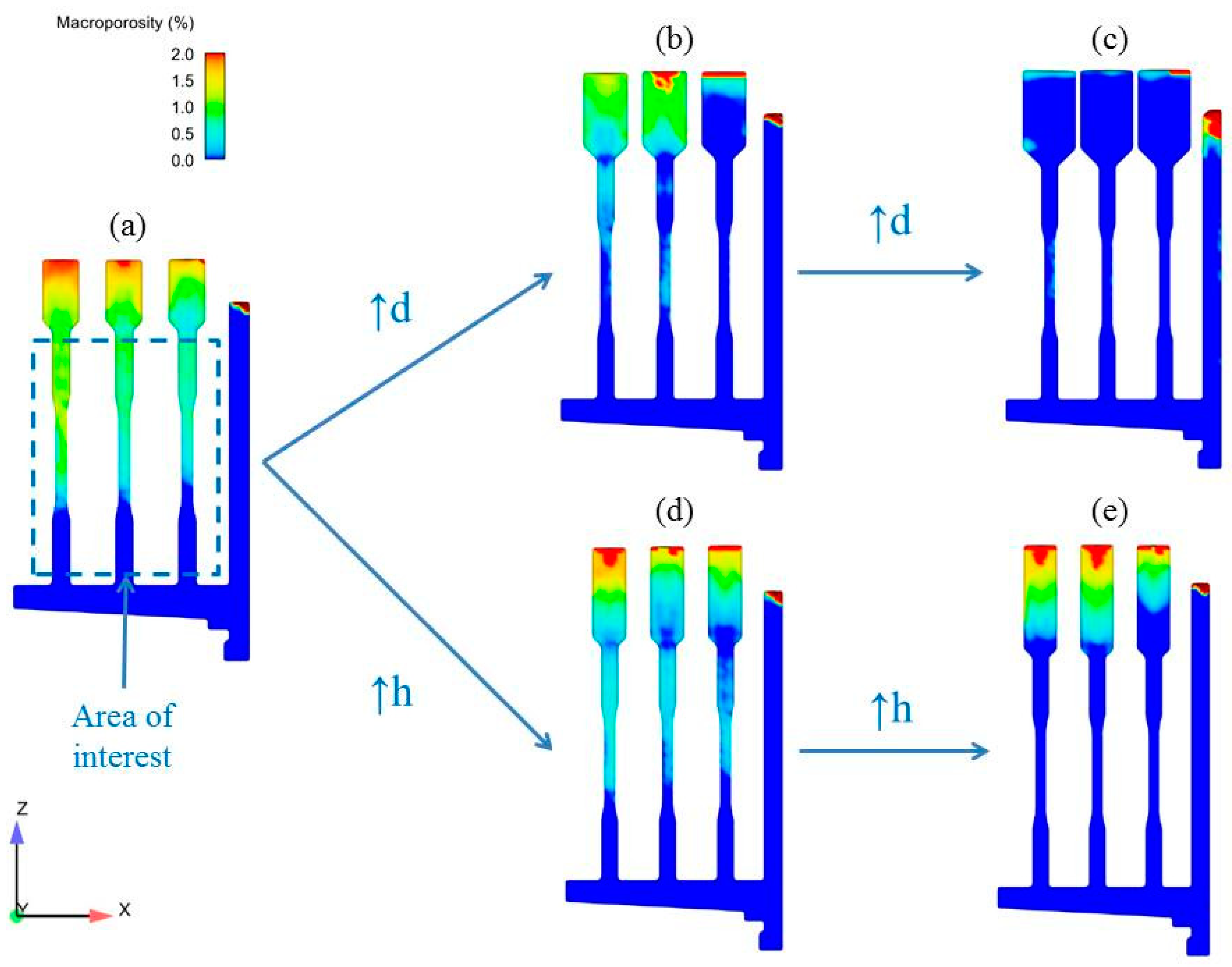

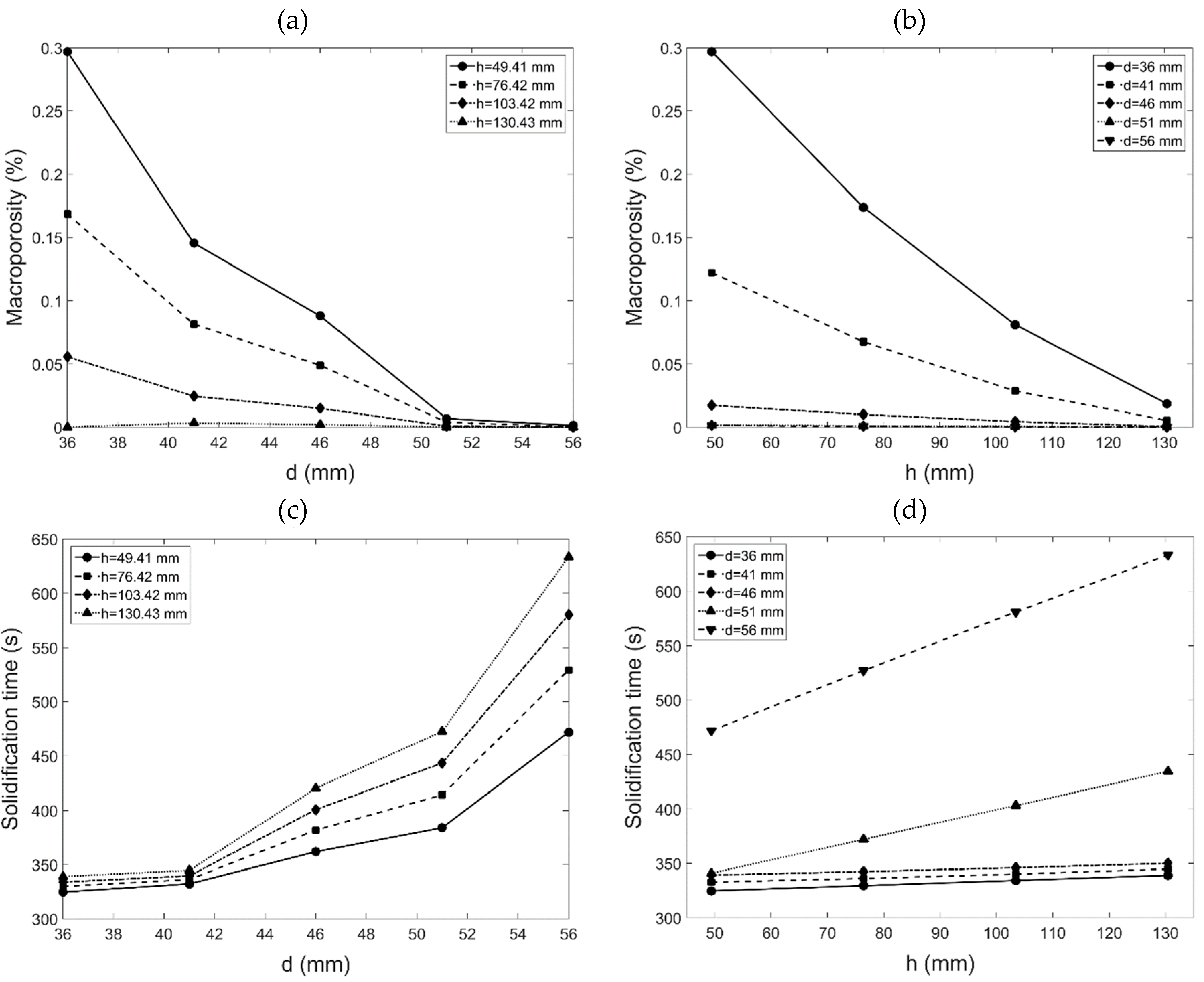

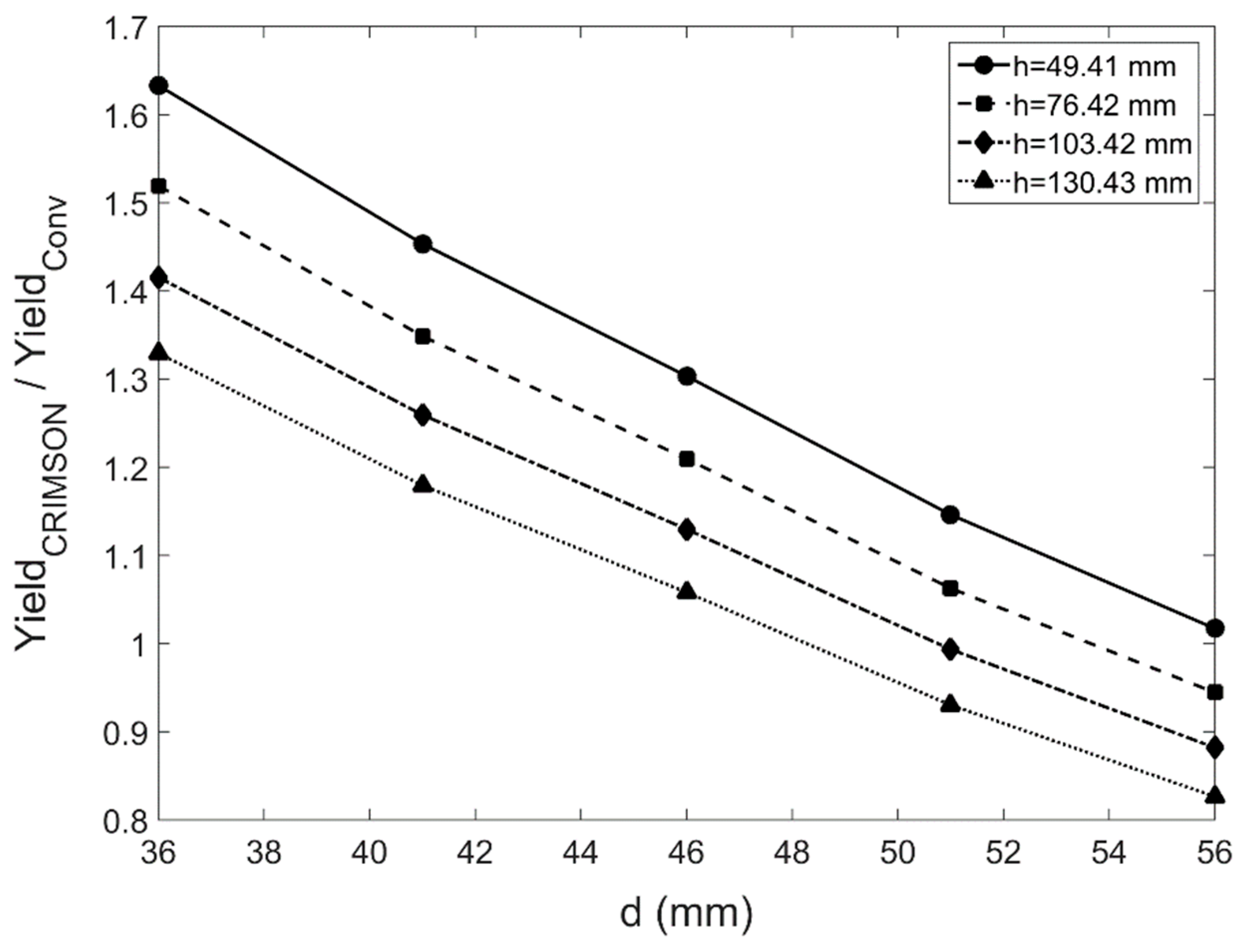

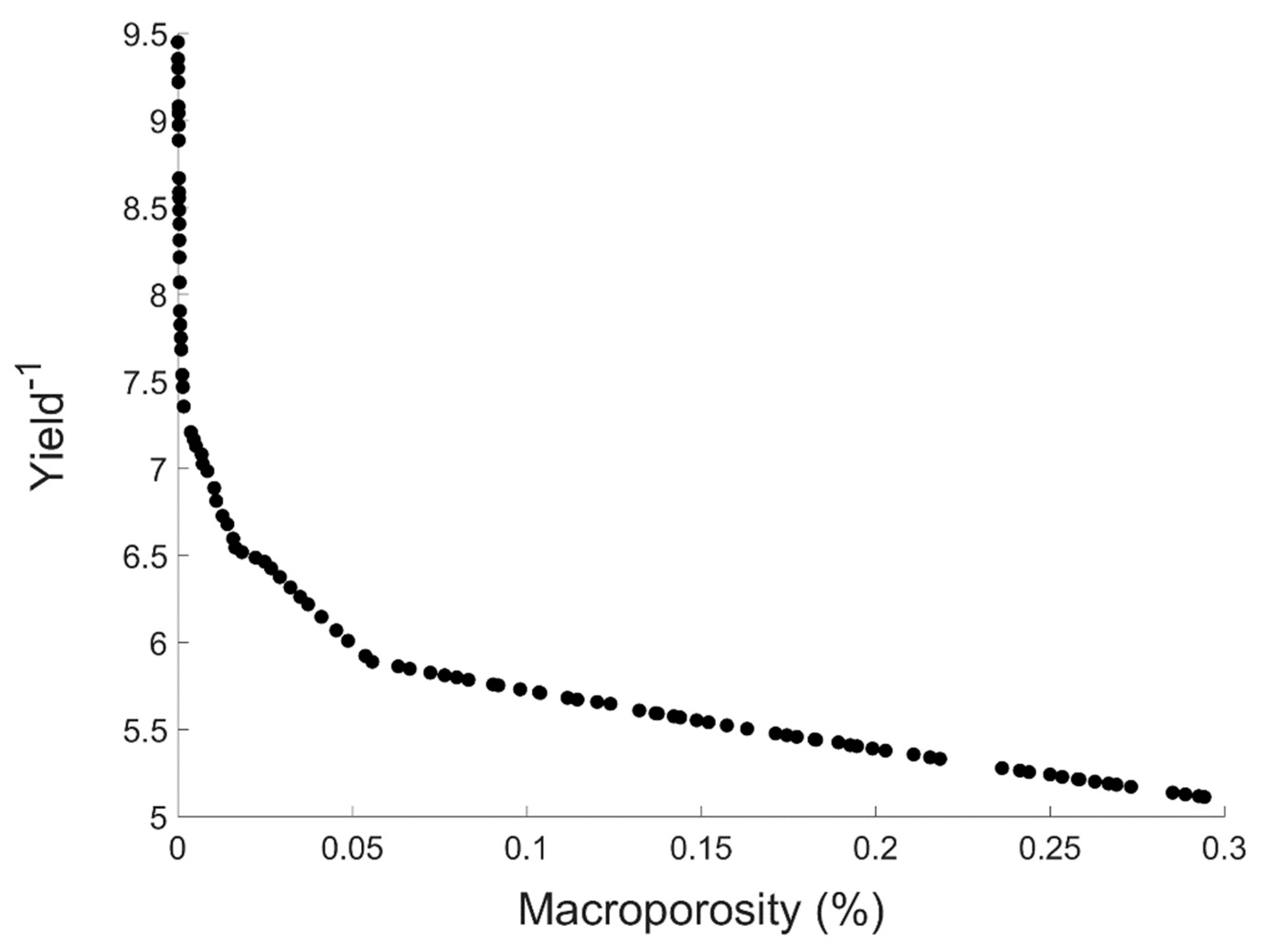

3.1. Feeder Design Effects on Macroporosity and Yield

3.2. Optimisation

4. Conclusions

- Weighted sum methods can be used to minimise the macroporosity and maximise the yield if there is a priori knowledge of the process characteristics and the weights that should be assigned to each of the objective function components. The optimisation result in this case is a set of riser dimensions which corresponds to a global minimum of the objective function for a specified set of weights.

- When there is no a priori knowledge of the process characteristics, the estimation of a Pareto front is highly suggested. The Pareto fronts of the macroporosity versus the yield/solidification time, drawn using the NSGA-II evolutionary algorithm, illustrate the trade-off between the aforementioned objective functions. It is evident that enhanced quality is offset by lower yield. Moreover, it has been shown that there is no need for increasing the riser dimensions beyond certain values as the final cast product macroporosity remains constant and equal to zero.

- The proposed optimisation framework contributes towards significant time savings as the total number of simulation runs is reduced by performing linear or cubic interpolation between an existing set of data points. Additional time savings can possibly be achieved by applying the Design of Experiments (DoE) method to estimate the minimum number of data points required to derive mathematical formulas accurately describing the dependence of the output variables on the independent ones.

- The multi-objective optimisation framework presented in this investigation has the potential to be applied on a wide span of casting processes and mould geometries. One of the reasons is that the adopted methodology allows for constrained independent variables which is the case in almost every engineering problem. Moreover, both the cases of a priori knowledge of the casting process characteristics and ab initio design are being covered. In the case where the objective function is a non-convex function, the NSGA-II algorithm can provide decision makers with a set of accurate solutions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Salonitis, K.; Zeng, B.; Mehrabi, H.A.; Jolly, M. The Challenges for Energy Efficient Casting Processes. Proced. CIRP 2016, 40, 24–29. [Google Scholar] [CrossRef]

- Campbell, J. Complete Casting Handbook: Metal. Casting Processes, Techniques and Design, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 978-0-444-63509-9. [Google Scholar]

- BCS, Inc. Advanced Melting Technologies: Energy Saving Concepts and Opportunities for the Metal Casting Industry; BCS, Incorporated: Columbia, MD, USA, 2005. [Google Scholar]

- Jolly, M.R. High integrity single shot casting process with reduced energy consumption. Mater. Technol. 2009, 24, 143. [Google Scholar]

- Salonitis, K.; Jolly, M.R.; Zeng, B.; Mehrabi, H. Improvements in energy consumption and environmental impact by novel single shot melting process for casting. J. Clean. Prod. 2016, 137, 1532–1542. [Google Scholar] [CrossRef]

- Couper, M.J.; Neeson, A.E.; Griffiths, J.R. Casting Defects and the Fatigue Behaviour of an Aluminium Casting Alloy. Fatigue Fract. Eng. Mater. Struct. 1990, 13, 213–227. [Google Scholar] [CrossRef]

- Barkhudarov, M.R.; Hirt, C.W. Casting Simulation: Mold Filling and Solidification—Benchmark Calculations Using FLOW-3D®; U.S. Department of Energy: Washington, DC, USA, 1995.

- Hirt, C.W. Modeling Shrinkage Induced Micro-Porosity; Flow Science, Inc.: Santa Fe, NM, USA, 2004. [Google Scholar]

- Reilly, C.; Green, N.R.; Jolly, M.R.; Gebelin, J.-C. The modelling of oxide film entrainment in casting systems using computational modelling. Appl. Math. Model. 2013, 37, 8451–8466. [Google Scholar] [CrossRef]

- Hirt, C.W. Modeling Turbulent Entrainment of Air at a Free Surface; Flow Science, Inc.: Santa Fe, NM, USA, 2012. [Google Scholar]

- Kwon, H.-J.; Kwon, H.-K. Computer aided engineering (CAE) simulation for the design optimization of gate system on high pressure die casting (HPDC) process. Rob. Comput. Integr. Manuf. 2018. [Google Scholar] [CrossRef]

- Keste, A.A.; Gawande, S.H.; Sarkar, C. Design optimization of precision casting for residual stress reduction. J. Comput. Des. Eng. 2016, 3, 140–150. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, H.; Chen, X. Numerical optimization of gating system parameters for a magnesium alloy casting with multiple performance characteristics. J. Mater. Process. Technol. 2008, 199, 256–264. [Google Scholar] [CrossRef]

- Roy, R.K. A Primer on the Taguchi Method; Society of Manufacturing Engineers: Dearborn, MI, USA, 2010; ISBN 0872638642. [Google Scholar]

- Dabade, U.A.; Bhedasgaonkar, R.C. Casting Defect Analysis using Design of Experiments (DoE) and Computer Aided Casting Simulation Technique. Proced. CIRP 2013, 7, 616–621. [Google Scholar] [CrossRef]

- Krimpenis, A.; Benardos, P.G.; Vosniakos, G.-C.; Koukouvitaki, A. Simulation-based selection of optimum pressure die-casting process parameters using neural nets and genetic algorithms. Int. J. Adv. Manuf. Technol. 2006, 27, 509–517. [Google Scholar] [CrossRef]

- Taha, T.; Cui, Z.F. CFD modelling of slug flow in vertical tubes. Chem. Eng. Sci. 2006, 61, 676–687. [Google Scholar] [CrossRef]

- FLOW-3D CFD Software, Multiphysics Modeling, Numerical Simulation. Available online: https://www.flow3d.com/ (accessed on 10 October 2018).

- Campbell, J. Castings; Butterworth-Heinemann: Oxford, UK, 2003; ISBN 0080488447. [Google Scholar]

- Buhmann, M.D.; Fletcher, R.; Barrodale, I.; Zala, C.; de Boor, C.; Micchelli, C.A.; Ron, A.; Conn, A.R.; Scheinberg, K.; Toint, P.L.; et al. Approximation Theory and Optimization: Tributes to M.J.D. Powell; Cambridge University Press: Cambridge, UK, 1997; ISBN 0521581907. [Google Scholar]

- Minimize(method=’SLSQP’)—SciPy v1.1.0 Reference Guide. Available online: https://docs.scipy.org/doc/scipy/reference/optimize.minimize-slsqp.html (accessed on 10 October 2018).

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Platypus—Multiobjective Optimization in Python—Platypus Documentation. Available online: http://platypus.readthedocs.io/en/latest/ (accessed on 10 October 2018).

- Gebelin, J. Simulation of Tensile Test Bars: Does the Filling Method Matter. In Simulation of Aluminum Shape Casting Processing: From Alloy Design to Mechanical Properties; Wiley: Hoboken, NJ, USA, 2006; pp. 299–310. [Google Scholar]

- Zeng, B.; Salonitis, K.; Jolly, M.R. Comparison of the environmental impact of the CRIMSON process with normal sand casting process. In Proceedings of the 11th International Conference on Manufacturing Research: Advances in Manufacturing Technology XXVII, Cranfield, Bedfordshire, UK, 19–20 September 2013; pp. 281–286. [Google Scholar]

- Grodzevich, O.; Romanko, O. Normalization and other topics in multi-objective optimization. In Proceedings of the Fields–MITACS Industrial Problems Workshop, Toronto, ON, Canada, 14–18 August 2006. [Google Scholar]

- Strongin, R.G. Global Optimization with Non-Convex Constraints: Sequential and Parallel Algorithms; Springer: Berlin, Germany, 2000; ISBN 146154677X. [Google Scholar]

| Parameters | Values |

|---|---|

| Mould surface temperature (°C) | 25 |

| Pouring Temperature (°C) | 700 |

| Air temperature (°C) | 25 |

| Filling velocity (m/s) | 0.12 |

| Metal/mould heat transfer coefficient (W/(m2∙K)) | 1000 |

| Metal/air heat transfer coefficient (W/(m2∙K)) | 30 |

| Sand thermal conductivity (W/(m∙K)) | 0.7 |

| Surface tension coefficient (kg/s2) | 0.87 |

| # | Solution | |||||||

|---|---|---|---|---|---|---|---|---|

| h (mm) | d (mm) | Average Riser Volume (m3) | OF1 | OF2 | ||||

| 0.25 | 0.75 | 1 | 49.42 | 48.16 | 5.07 × 10−4 | 5.73 × 10−3 | 8.74 × 10−2 | 9.3 × 10−2 |

| 2 | 128.18 | 38.32 | 2.28 × 10−2 | 7.11 × 10−2 | 9.4 × 10−2 | |||

| 3 | 118.84 | 39.03 | 2.04 × 10−2 | 7.45 × 10−2 | 9.5 × 10−2 | |||

| 0.5 | 0.5 | 1 | 121.15 | 36 | 4.68 × 10−4 | 3.18 × 10−2 | 1.05 × 10−1 | 1.36 × 10−1 |

| 2 | 109.19 | 36.37 | 6.07 × 10−2 | 9.28 × 10−2 | 1.54 × 10−1 | |||

| 3 | 108.28 | 36.63 | 6.06 × 10−2 | 9.52 × 10-2 | 1.56×10−1 | |||

| 0.75 | 0.25 | 1 | 108.12 | 36 | 3.98 × 10−4 | 3.54 × 10−2 | 1.28 × 10−1 | 1.64 × 10−1 |

| 2 | 92.95 | 36 | 7.88 × 10−2 | 9.46 × 10−2 | 1.73 × 10−1 | |||

| 3 | 92.5 | 36 | 8.04 × 10−2 | 9.36 × 10−2 | 1.74 × 10−1 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papanikolaou, M.; Pagone, E.; Georgarakis, K.; Rogers, K.; Jolly, M.; Salonitis, K. Design Optimisation of the Feeding System of a Novel Counter-Gravity Casting Process. Metals 2018, 8, 817. https://doi.org/10.3390/met8100817

Papanikolaou M, Pagone E, Georgarakis K, Rogers K, Jolly M, Salonitis K. Design Optimisation of the Feeding System of a Novel Counter-Gravity Casting Process. Metals. 2018; 8(10):817. https://doi.org/10.3390/met8100817

Chicago/Turabian StylePapanikolaou, Michail, Emanuele Pagone, Konstantinos Georgarakis, Keith Rogers, Mark Jolly, and Konstantinos Salonitis. 2018. "Design Optimisation of the Feeding System of a Novel Counter-Gravity Casting Process" Metals 8, no. 10: 817. https://doi.org/10.3390/met8100817

APA StylePapanikolaou, M., Pagone, E., Georgarakis, K., Rogers, K., Jolly, M., & Salonitis, K. (2018). Design Optimisation of the Feeding System of a Novel Counter-Gravity Casting Process. Metals, 8(10), 817. https://doi.org/10.3390/met8100817