Microstructure and Mechanical Properties of Heat-Affected Zone of Repeated Welding AISI 304N Austenitic Stainless Steel by Gleeble Simulator

Abstract

:1. Introduction

2. Materials and Methods

3. Results

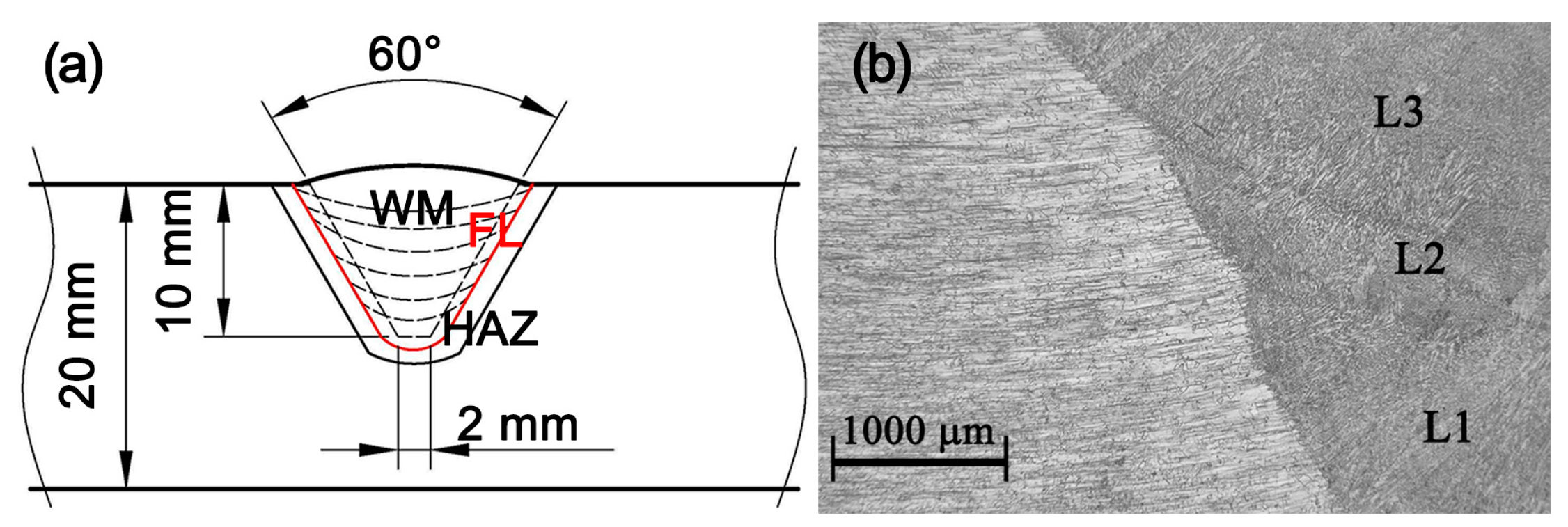

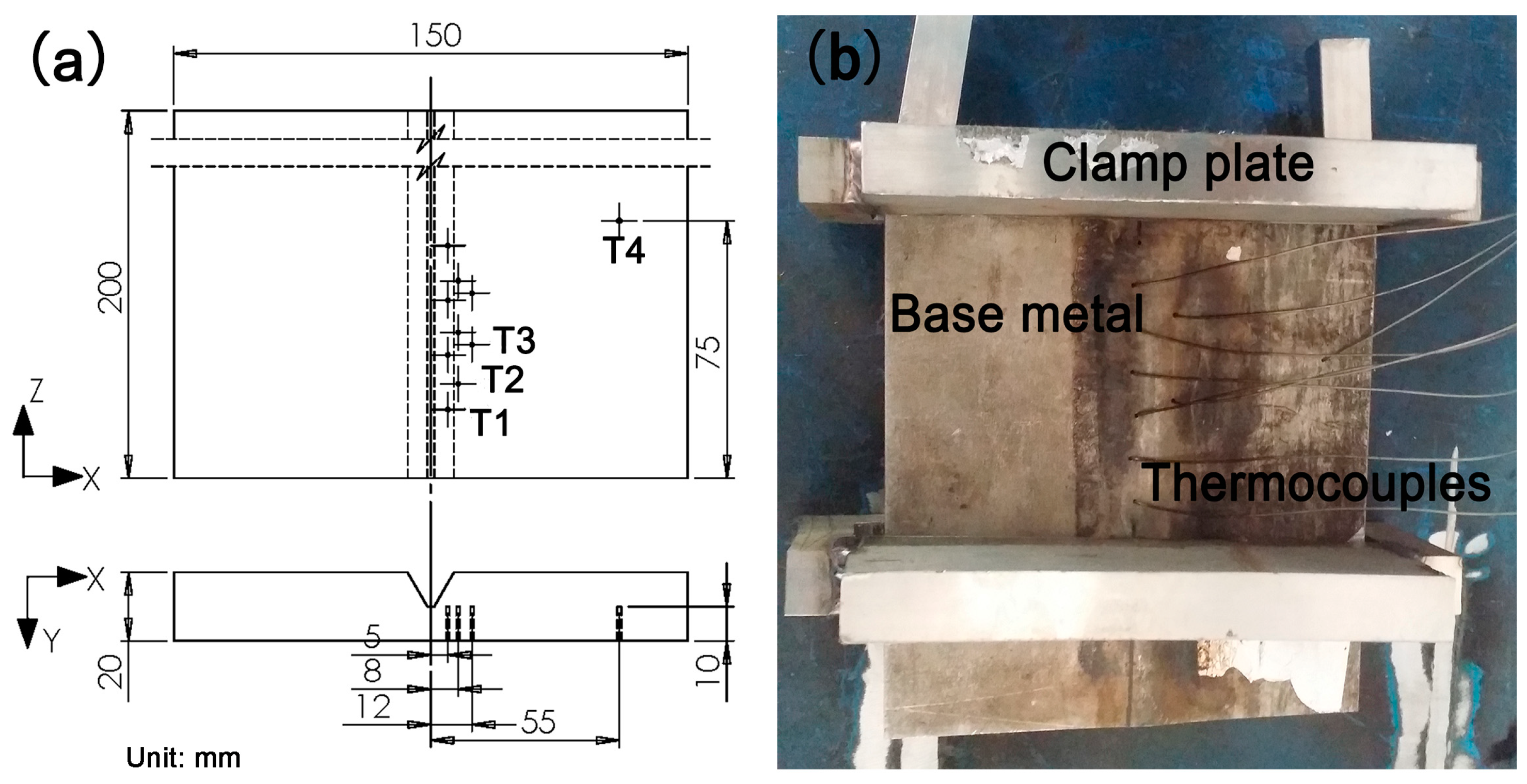

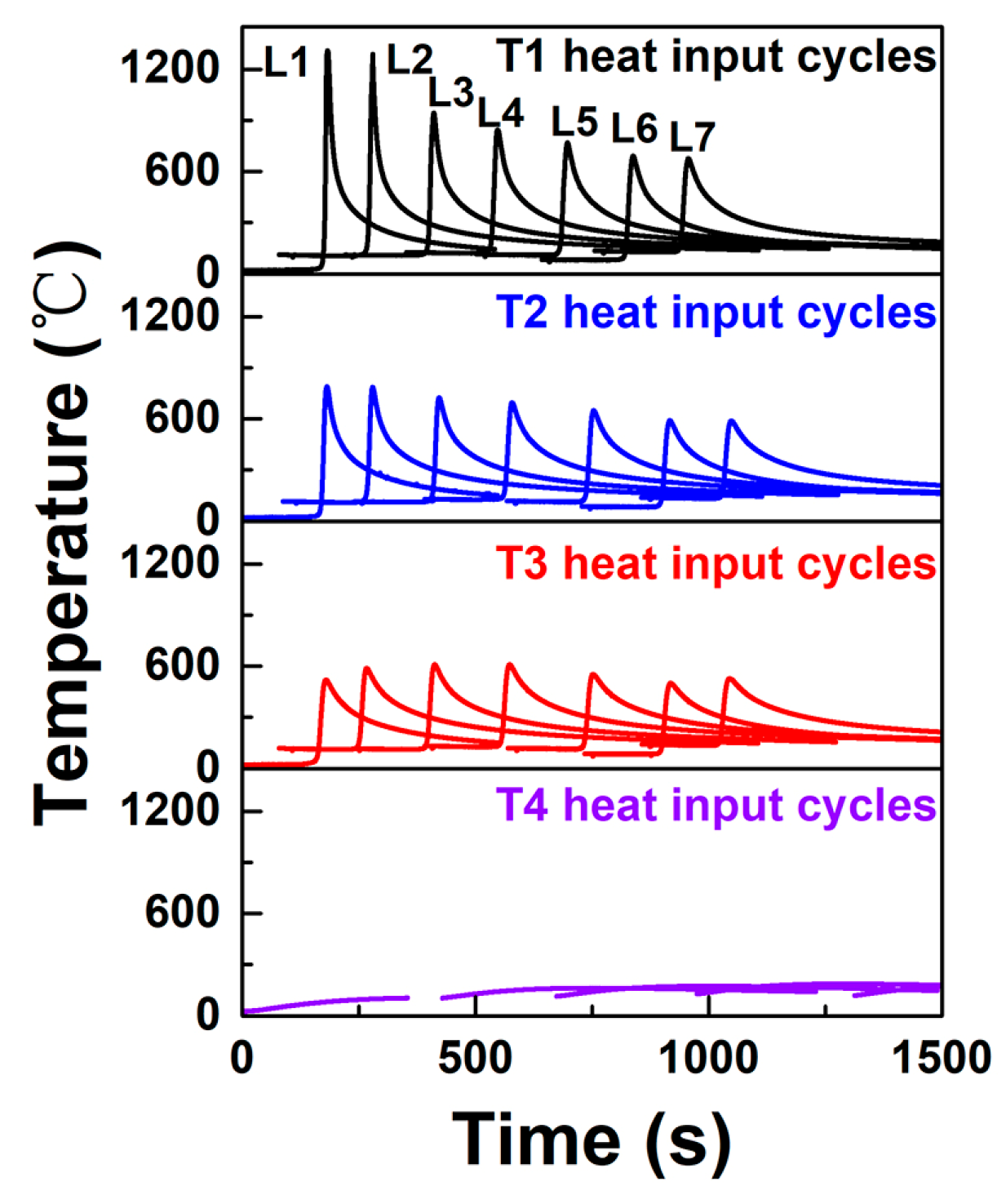

3.1. Heat Input of HAZ in the Multi-Bead Welding

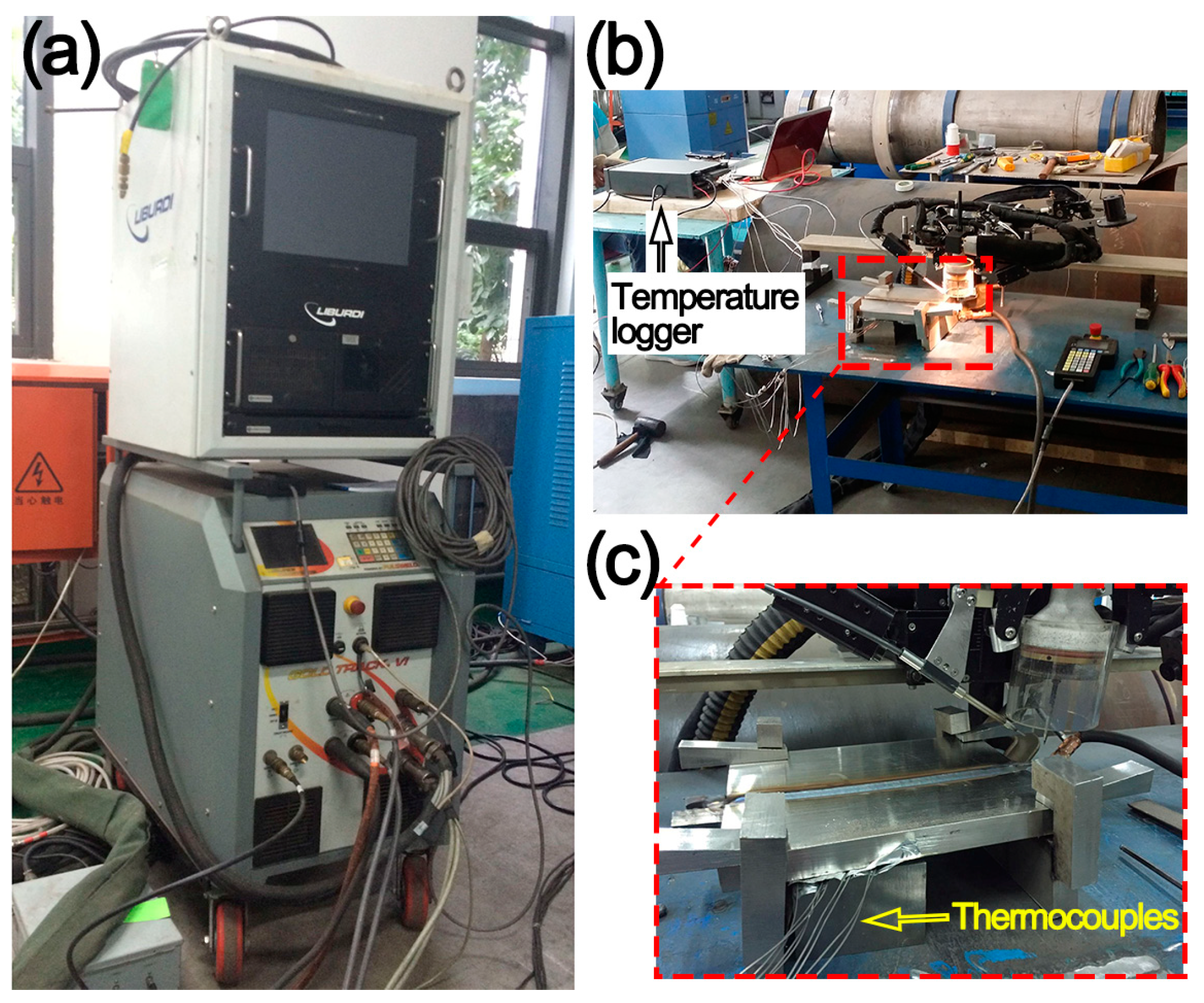

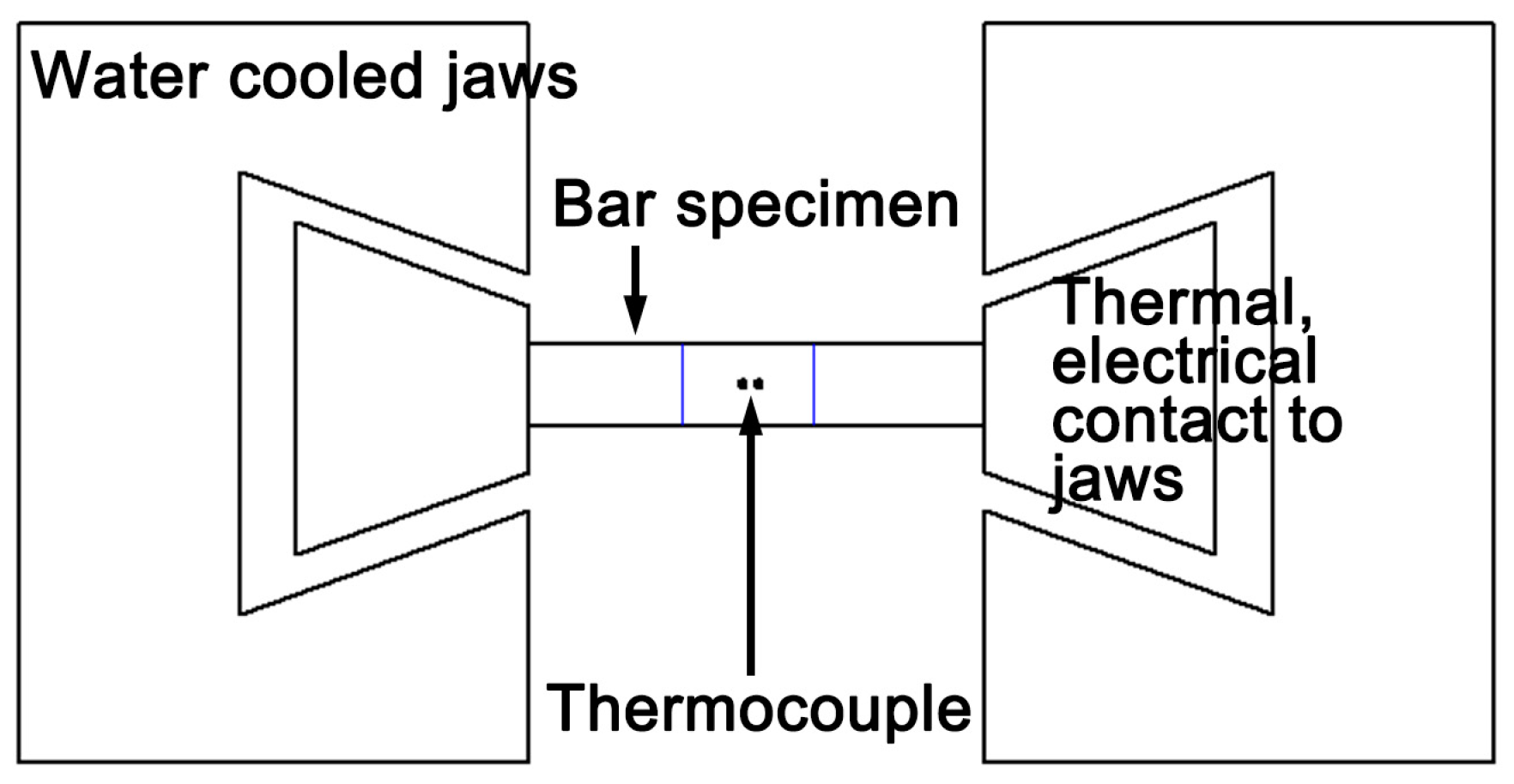

3.2. Gleeble Simulation of the Repeated Welding

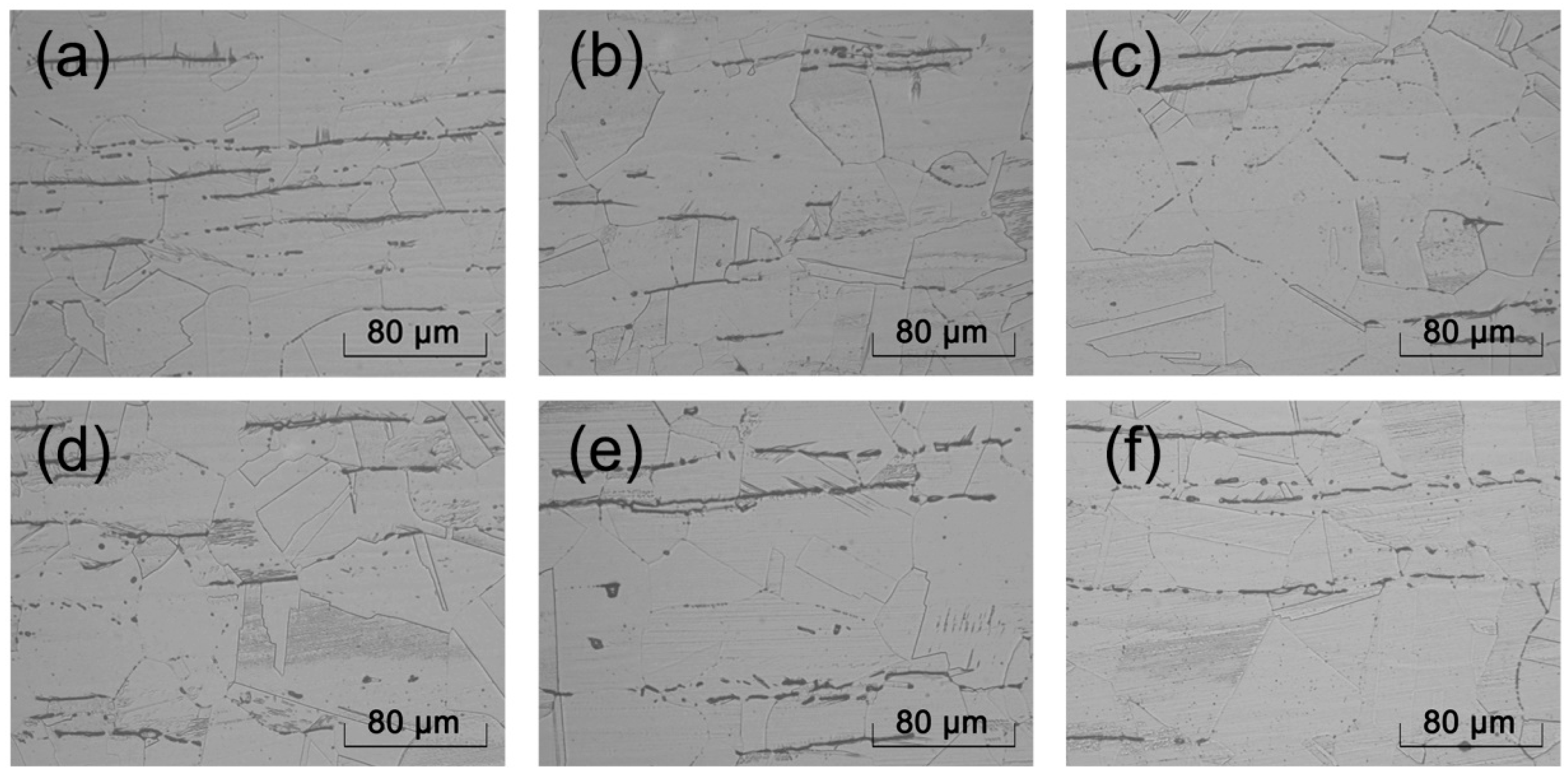

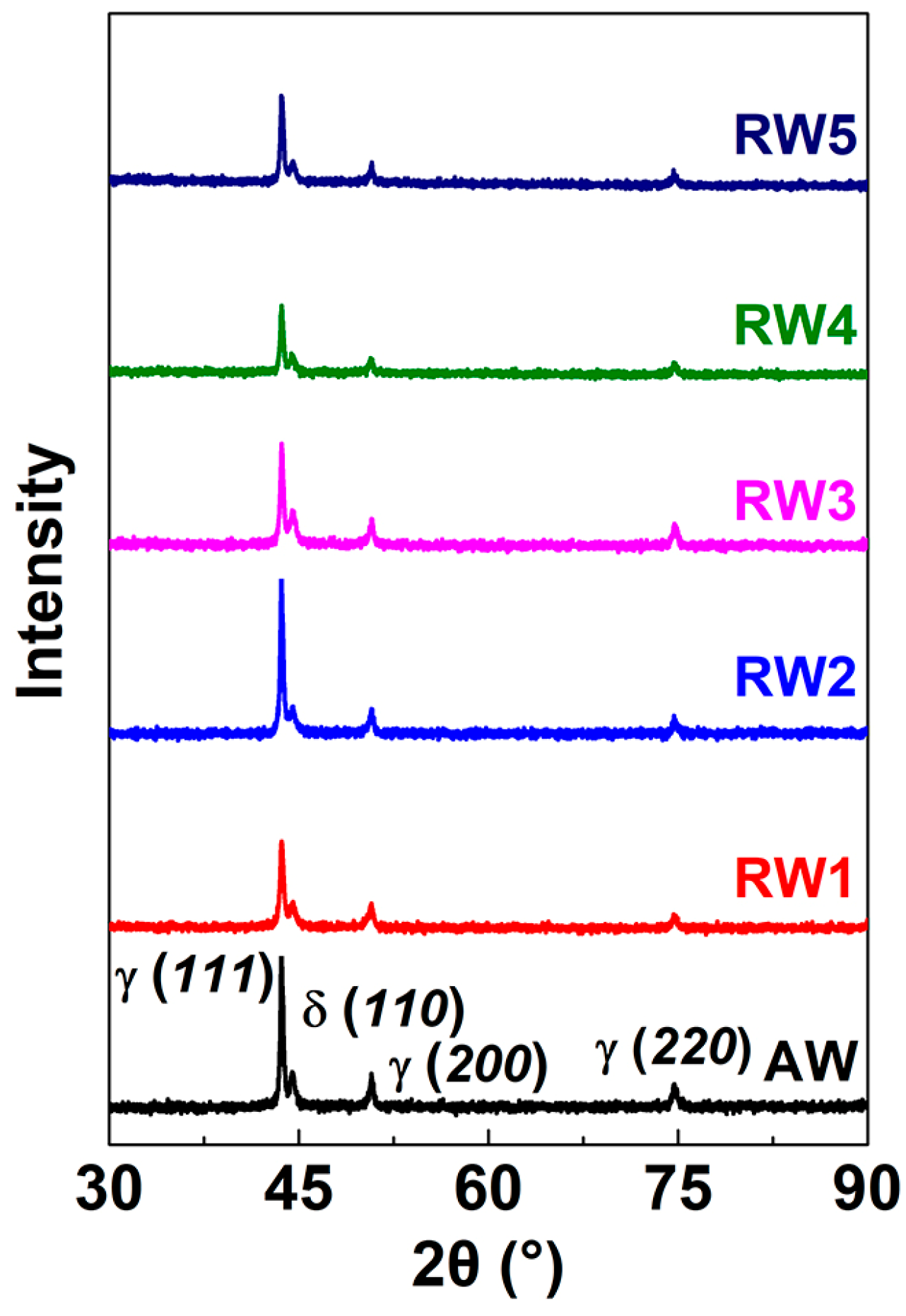

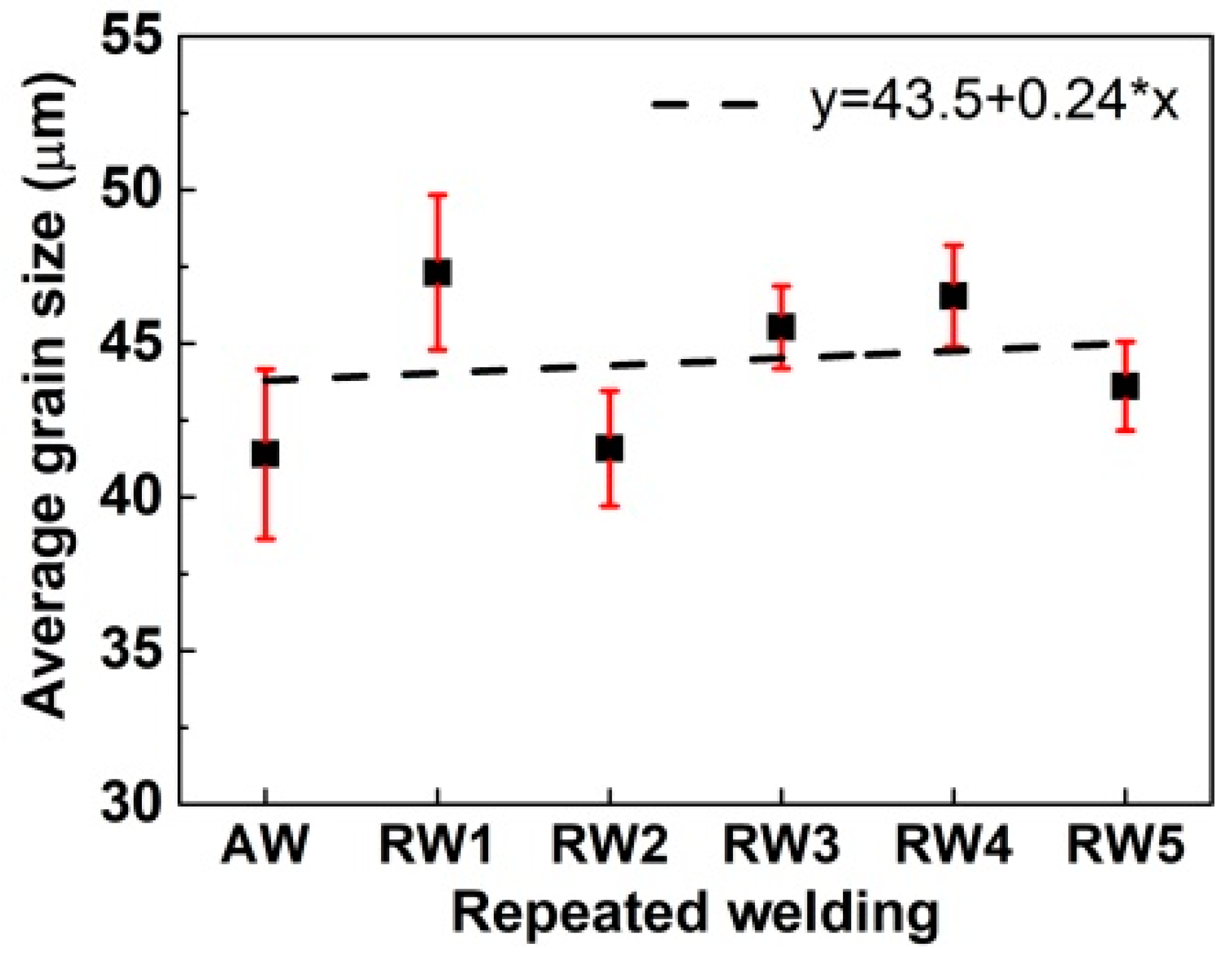

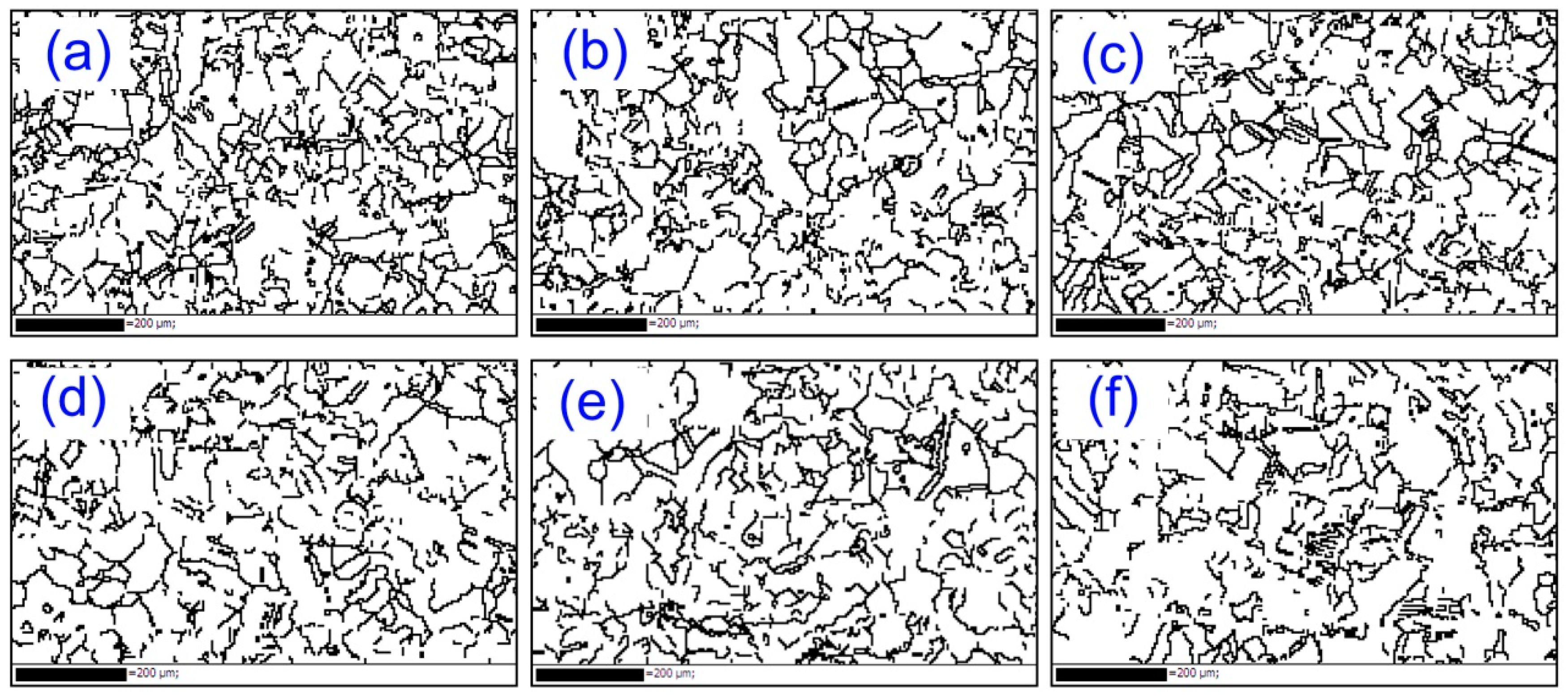

3.3. Microstructure of the Repeated Welding Specimens

3.4. Mechanical Properties of the Repeated Welding Specimens

4. Discussion

5. Conclusions

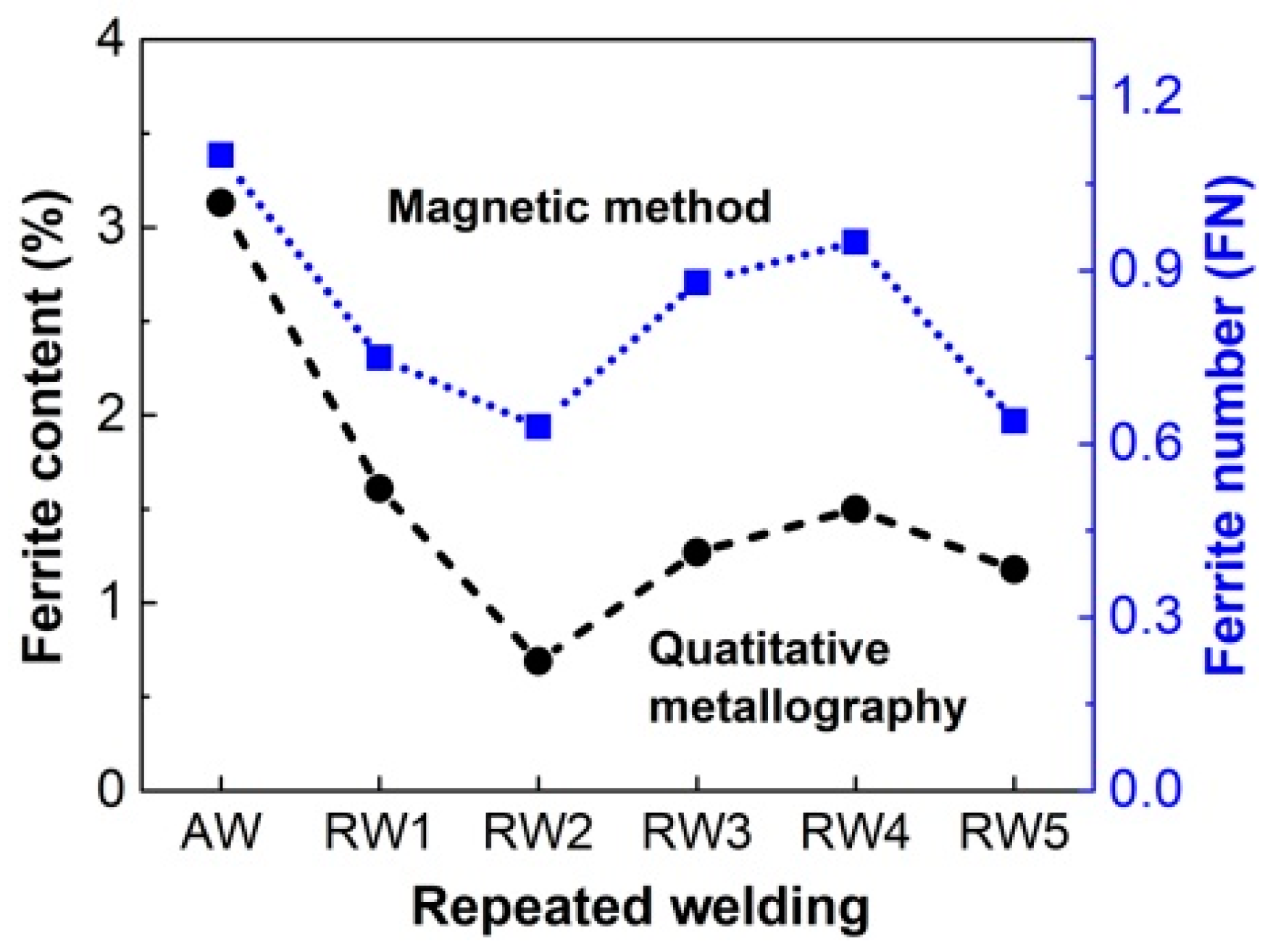

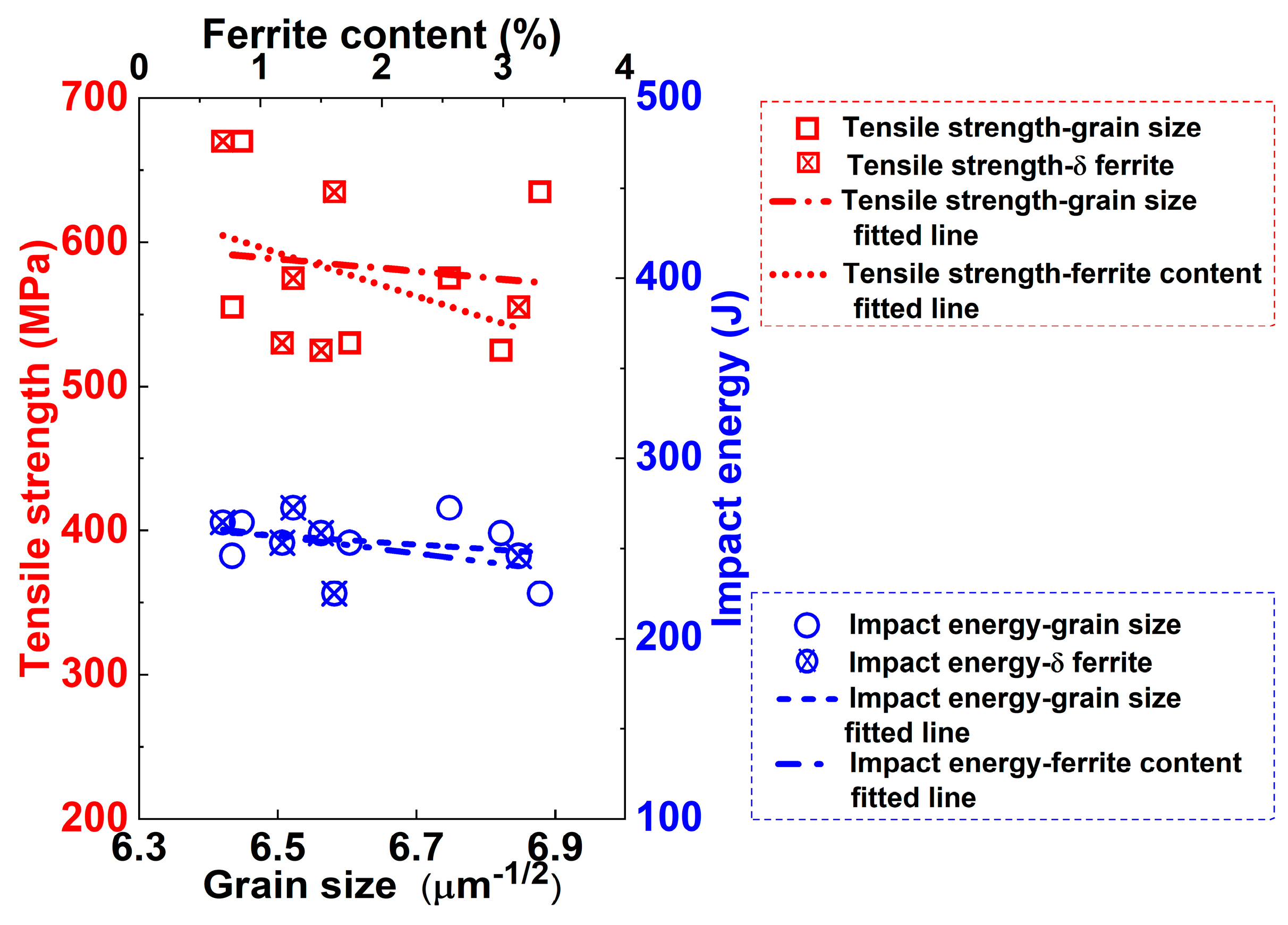

- Uniform HAZ specimens were prepared under the measured temperature field by the Gleeble weld-simulator to evaluate the microstructure of the repeated welding joints. With the increasing number of repeated welding, the average grain size of austenite fluctuated from 41.4 μm to 47.3 μm, and the content of δ-ferrite ranged from 0.69 vol.% to 3.13 vol.%.

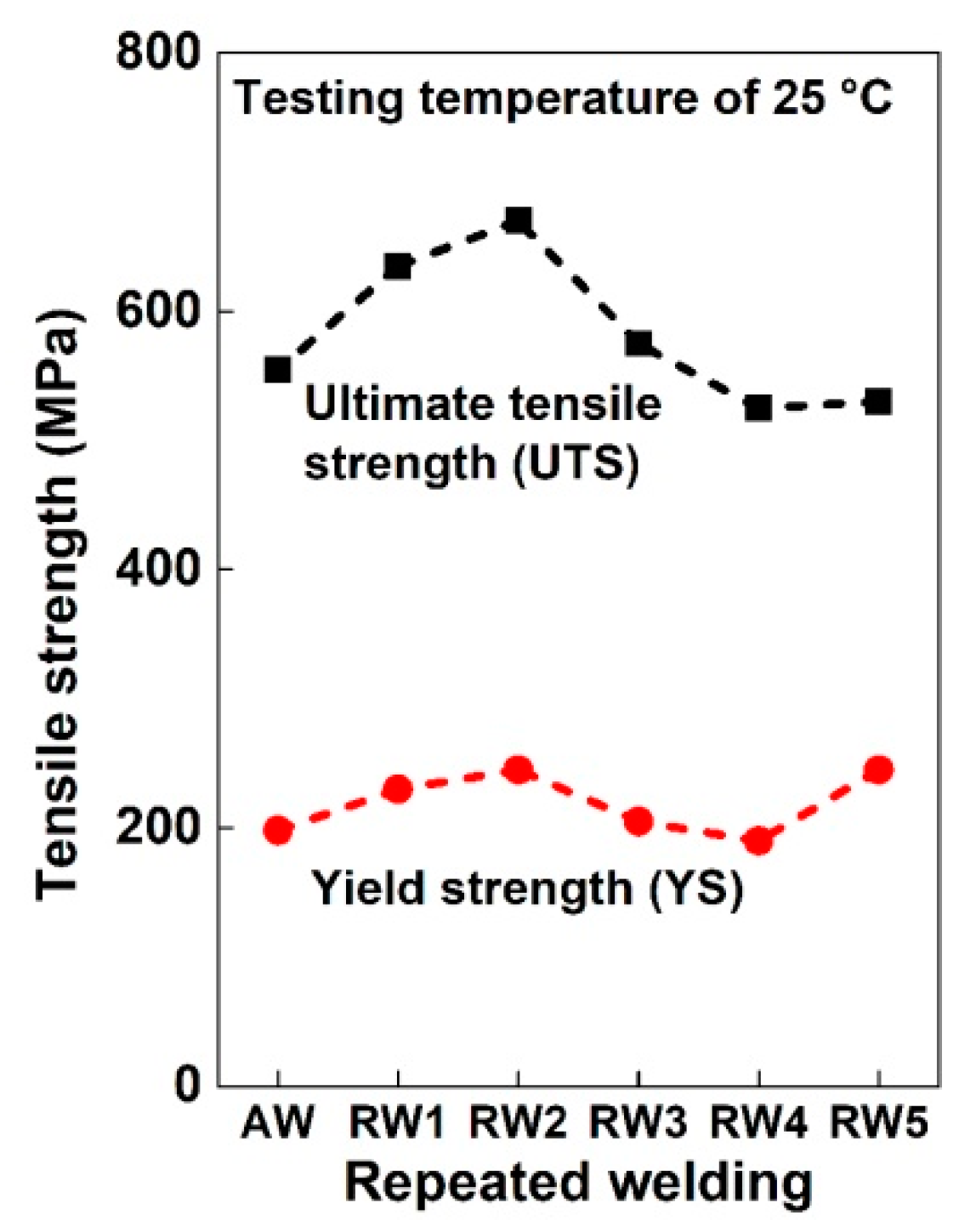

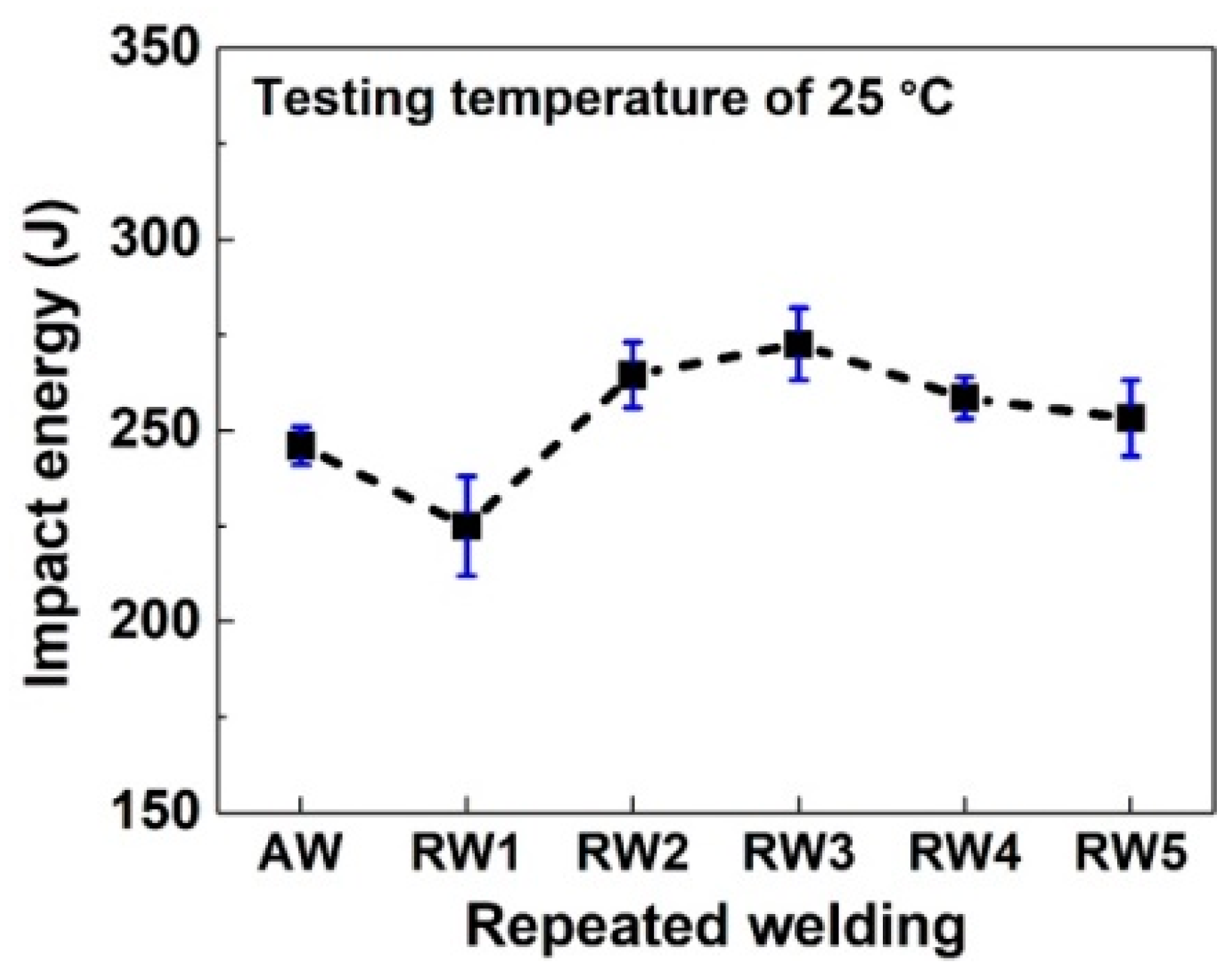

- The ultimate tensile strength and yield strength mainly depended on the δ-ferrite content and HAB frequency, and the impact energy mainly depended on both the austenitic grain size and the δ-ferrite content. The highest UTS and YS were obtained for the RW2 specimen with the minimum δ-ferrite content, and the lowest values were for the RW4 specimen with the maximum δ-ferrite content. A slight variation in the impact energy was observed for the RW1–RW5 specimens.

- The UTSs of the RW1–RW3 specimens were higher than those of the AW specimen, and all were above the UTS of the base austenitic stainless steel of 550 MPa to the ASME standard. The impact energy of all specimens was much higher than the ASME standard of 56 J. Repeated welding of up to three times met the requirements of construction, maintenance, and repair, considering the matching strength and toughness in industry.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Code for Construction of Field Equipment, Industrial Pipe Welding Engineering, GB Standard 50236-2011; China Planning Press: Beijing, China, 2011.

- Standard Construction Standard for Welding of Transportation Pipeline; IPS-C-PI-2070(2); Iranian Petroleum Standards: Tehran, Iran, 2001.

- RCC-M Design and Construction Rules for Mechanical Components of PWR Nuclear Island Section IX Welding; AFCEN: Pairs, France, 2002.

- Rules for Construction of Nuclear Facility Components Division 1-Subsection NB Class 1 Components; ASME Section III; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 3.

- Lant, T.; Robinson, D.L.; Spafford, B.; Storesund, J. Review of weld repair procedures for low alloy steels designed to minimize the risk of future cracking. Int. J. Press. Vessel. Pip. 2001, 78, 813–818. [Google Scholar] [CrossRef]

- AghaAli, I.; Farzam, M.; Golozar, M.A.; Danaee, I. The effect of repeated repair welding on mechanical and corrosion properties of stainless steel 316L. Mater. Des. 2014, 54, 331–341. [Google Scholar] [CrossRef]

- Lin, C.M.; Tsai, H.L.; Cheng, C.D.; Yang, C. Effect of repeated weld-repairs on microstructure, texture, impact properties and corrosion properties of AISI 304L stainless steel. Eng. Fail. Anal. 2012, 21, 9–20. [Google Scholar] [CrossRef]

- Vega, O.E.; Hallen, J.M.; Villagomez, A.; Contreras, A. Effect of multiple repairs in girth welds of pipelines on the mechanical properties. Mater. Charact. 2008, 59, 1498–1507. [Google Scholar] [CrossRef]

- Nascimento, M.P.; Voorwald, H.J.C.; Payão Filho, J.D.A.C. Effects of several TIG weld repairs on the axial fatigue strength of AISI 4130 aeronautical steel-welded joints. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 191–204. [Google Scholar] [CrossRef]

- Liu, W.; Lu, F.; Yang, R.; Tang, X.; Cui, H. Gleeble simulation of the HAZ in Inconel 617 welding. J. Mater. Process. Technol. 2015, 225, 221–228. [Google Scholar] [CrossRef]

- Kardoulaki, E.; Lin, J.; Balint, D.; Farrugia, D. Investigation of the effects of thermal gradients present in Gleeble high-temperature tensile tests on the strain state for free cutting steel. J. Strain Anal. Eng. Des. 2014, 49, 521–532. [Google Scholar] [CrossRef]

- Moeinifar, S.; Kokabi, A.H.; Hosseini, H.R.M. Effect of tandem submerged arc welding process and parameters of Gleeble simulator thermal cycles on properties of the intercritically reheated heat affected zone. Mater. Des. 2011, 32, 869–876. [Google Scholar] [CrossRef]

- Hsieh, R.-I.; Liou, H.-Y.; Pan, Y.-T. Effects of cooling time and alloying elements on the microstructure of the Gleeble-simulated heat-affected zone of 22% Cr duplex stainl ess steels. J. Mater. Eng. Perform. 2001, 10, 526–536. [Google Scholar] [CrossRef]

- Silwal, B.; Li, L.; Deceuster, A.; Griffiths, B. Effect of postweld heat treatment on the toughness of heat-affected zone for grade 91 steel. Weld. J. Res. Suppl. 2013, 92, 80–87. [Google Scholar]

- ГOCГ 6996 Welding Joints. Methods of Mechanical Properties Determination; Kaluga typography Standards Press: Moscow, Russia, 1966. [Google Scholar]

- Nakhodchi, S.; Shokuhfar, A.; Iraj, S.A.; Thomas, B.G. Evolution of temperature distribution and microstructure in multipass welded AISI 321 stainless steel plates with different thicknesses. J. Press. Vessel Technol. 2015, 137, 061405. [Google Scholar] [CrossRef]

- Li, M.-Y.; Kannatey-Asibu, E., Jr. Monte Carlo simulation of heat-affected zone microstructure in laser-beam-welded nickel sheet. Weld. J. Res. Suppl. 2002, 37–44. [Google Scholar]

- Winczek, J. Modeling of temperature field during multi-pass GMAW surfacing or rebuilding of steel elements taking into account the heat of the deposit metal. Appl. Sci. 2016, 7, 6. [Google Scholar] [CrossRef]

- Lippold, J.C.; Savage, W.F. Solidification of austenitic stainless steel weldments: Part I—A proposed mechanism. In AWS 60th Annual Meeting; American Welding Society: Detroit, USA, 1979; pp. 362–374. [Google Scholar]

- Moon, J.; Lee, J.; Lee, C. Prediction for the austenite grain size in the presence of growing particles in the weld HAZ of Ti-microalloyed steel. Mater. Sci. Eng. A 2007, 459, 40–46. [Google Scholar] [CrossRef]

- Gourgues, A.-F. Electron backscatter diffraction and cracking. Mater. Sci. Technol. 2002, 18, 119–133. [Google Scholar] [CrossRef]

- Kamiya, O.; Kumagai, K.; Kikuchi, Y. Effects of δ Ferrite morphology on low temperature fracture toughness of SUS304L steel weld metal. Trans. Jpn. Weld. Soc. 1990, 21, 57–62. [Google Scholar]

- Tseng, C.C.; Shen, Y.; Thompson, S.W.; Mataya, M.C.; Krauss, G. Fracture and the formation of Sigma Phase, M23C6, and Austenite from Delta-Ferrite in an AISI 304L stainless steel. Metall. Mater. Trans. A 1994, 25, 1147–1158. [Google Scholar] [CrossRef]

- Sinha, S.; Kim, D.-I.; Fleury, E.; Suwas, S. Effect of grain boundary engineering on the microstructure and mechanical properties of copper containing austenitic stainless steel. Mater. Sci. Eng. A 2015, 626, 175–185. [Google Scholar] [CrossRef]

- Harvey, D.P., II; Terrell, J.B.; Sudarshan, T.S.; Louthan, M.R., Jr. Participation of hydrogen in the impact behavior of 304L stainless steel. Eng. Fract. Mech. 1993, 46, 455–464. [Google Scholar] [CrossRef]

- Buirette, C.; Huez, J.; Gey, N.; Vassel, A.; Andrieu, E. Study of crack propagation mechanisms during Charpy impact toughness tests on both equiaxed and lamellar microstructures of Ti-6Al-4V titanium alloy. Mater. Sci. Eng. A 2014, 618, 546–557. [Google Scholar] [CrossRef]

- Lee, D.N.; Han, H.N. Orientation relationships between precipitates and their parent phases in steels at low transformation temperatures. J. Solid Mech. Mater. Eng. 2012, 6, 323–338. [Google Scholar] [CrossRef]

- Welding, Brazing and Fusing Qualifications, ASME Section IX; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume IX.

| Chemical Composition (wt.%) | Mechanical Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Ni | Mn | Si | P | S | N | UTS | YS |

| 0.050 | 18.545 | 8.211 | 1.600 | 0.500 | 0.034 | 0.001 | 0.120 | 550 MPa | 240 MPa |

| Bead No. | Current (A) | Volts (V) | Travel Speed (mm/s) | Feed Rate of Wire (mm/min) | Heat Input (kJ/mm) |

|---|---|---|---|---|---|

| 1 | 260 | 9.50 | 1.52 | 89 | 1.62 |

| 2 | 260 | 9.20 | 1.52 | 89 | 1.57 |

| 3–7 | 260 | 9.50 | 1.52 | 89 | 1.62 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.H.; Lin, L.; Zhang, D.; Liu, L.; Lei, M.K. Microstructure and Mechanical Properties of Heat-Affected Zone of Repeated Welding AISI 304N Austenitic Stainless Steel by Gleeble Simulator. Metals 2018, 8, 773. https://doi.org/10.3390/met8100773

Guo YH, Lin L, Zhang D, Liu L, Lei MK. Microstructure and Mechanical Properties of Heat-Affected Zone of Repeated Welding AISI 304N Austenitic Stainless Steel by Gleeble Simulator. Metals. 2018; 8(10):773. https://doi.org/10.3390/met8100773

Chicago/Turabian StyleGuo, Y.H., Li Lin, Donghui Zhang, Lili Liu, and M.K. Lei. 2018. "Microstructure and Mechanical Properties of Heat-Affected Zone of Repeated Welding AISI 304N Austenitic Stainless Steel by Gleeble Simulator" Metals 8, no. 10: 773. https://doi.org/10.3390/met8100773

APA StyleGuo, Y. H., Lin, L., Zhang, D., Liu, L., & Lei, M. K. (2018). Microstructure and Mechanical Properties of Heat-Affected Zone of Repeated Welding AISI 304N Austenitic Stainless Steel by Gleeble Simulator. Metals, 8(10), 773. https://doi.org/10.3390/met8100773