The Corrosion Behavior of Ti-Based Metallic Glass Matrix Composites in the H2SO4 Solution

Abstract

:1. Introduction

2. Materials and Methods

3. Results

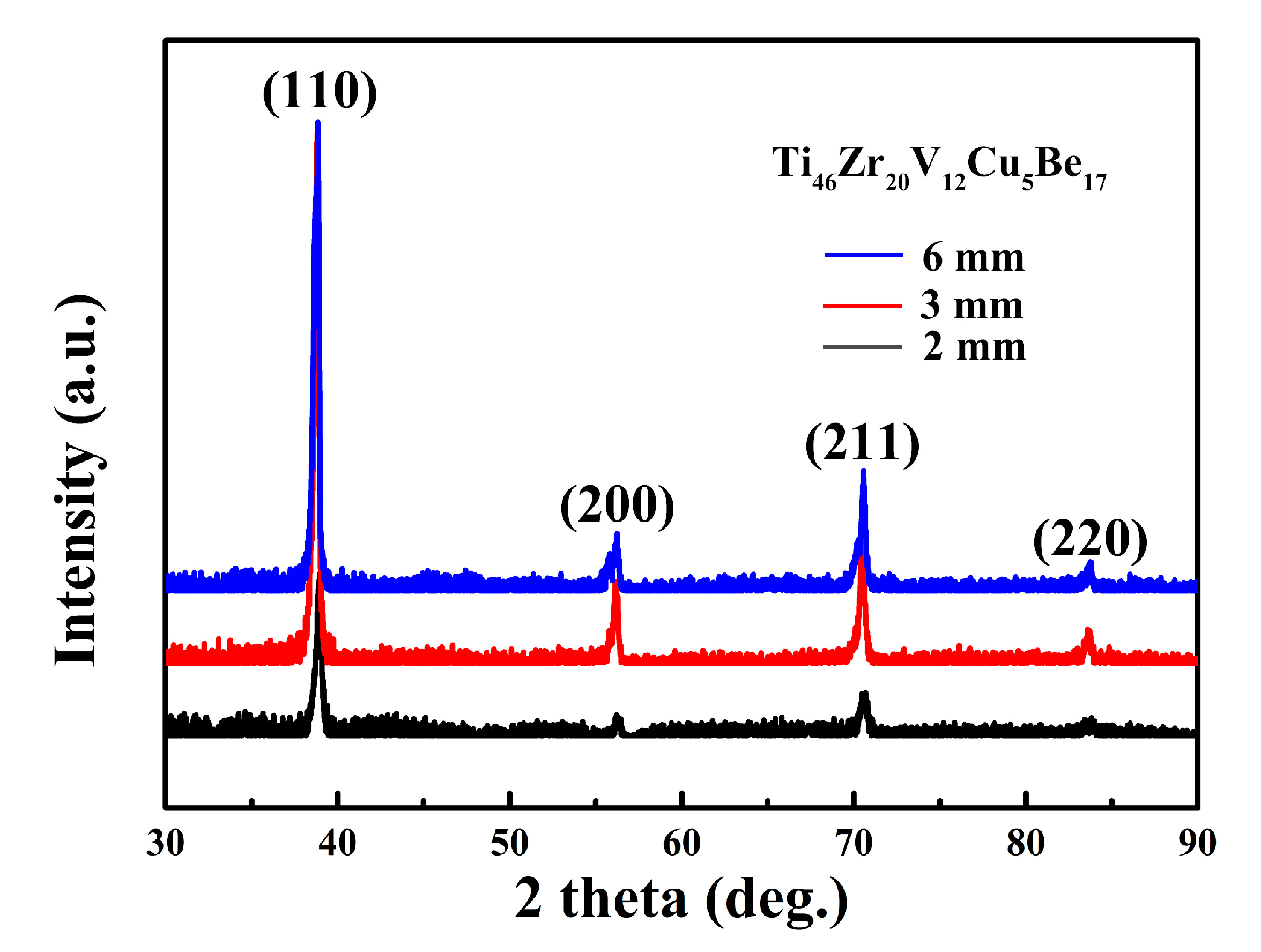

3.1. Structure Characterization

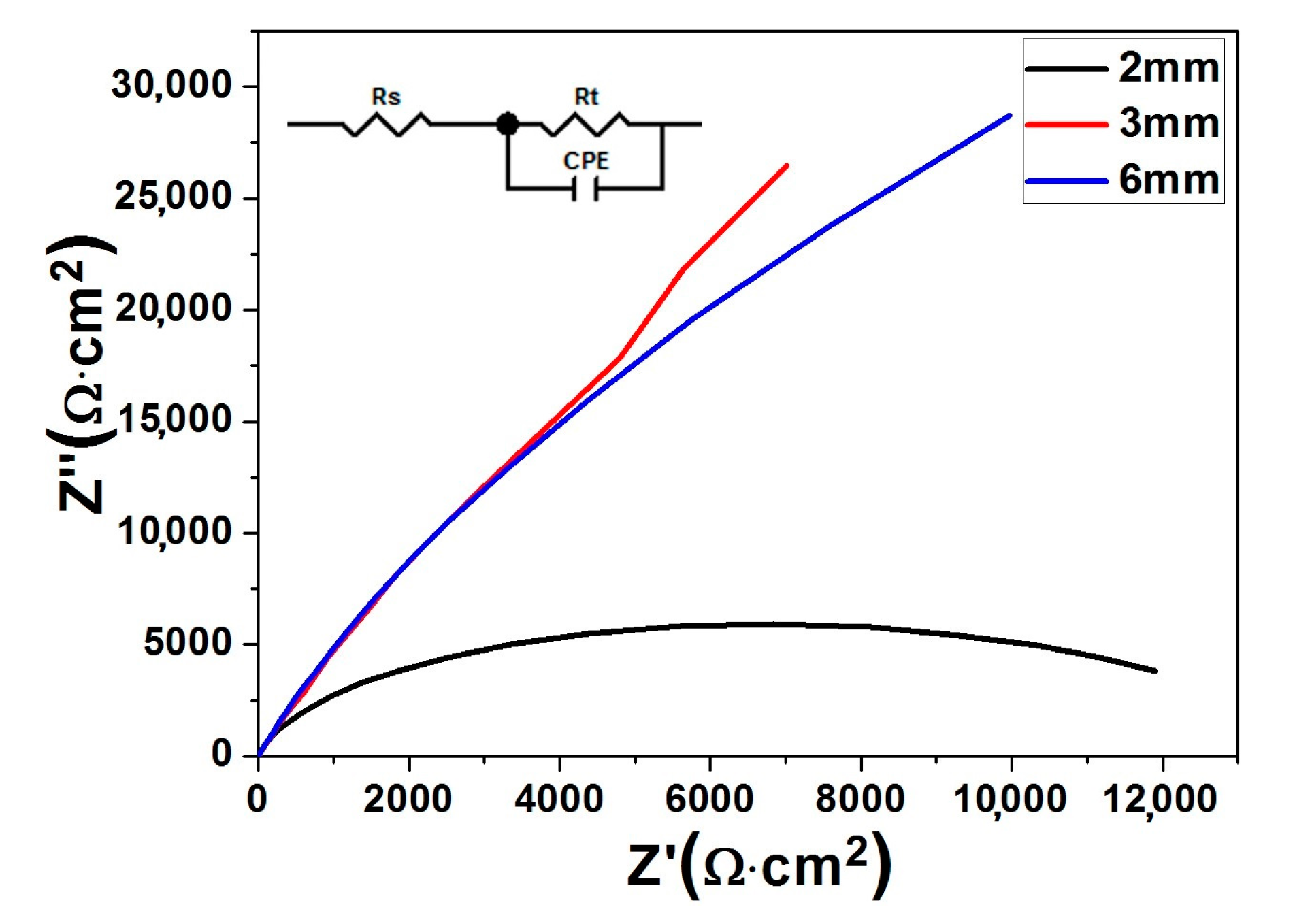

3.2. Electrochemical Corrosion Measurements

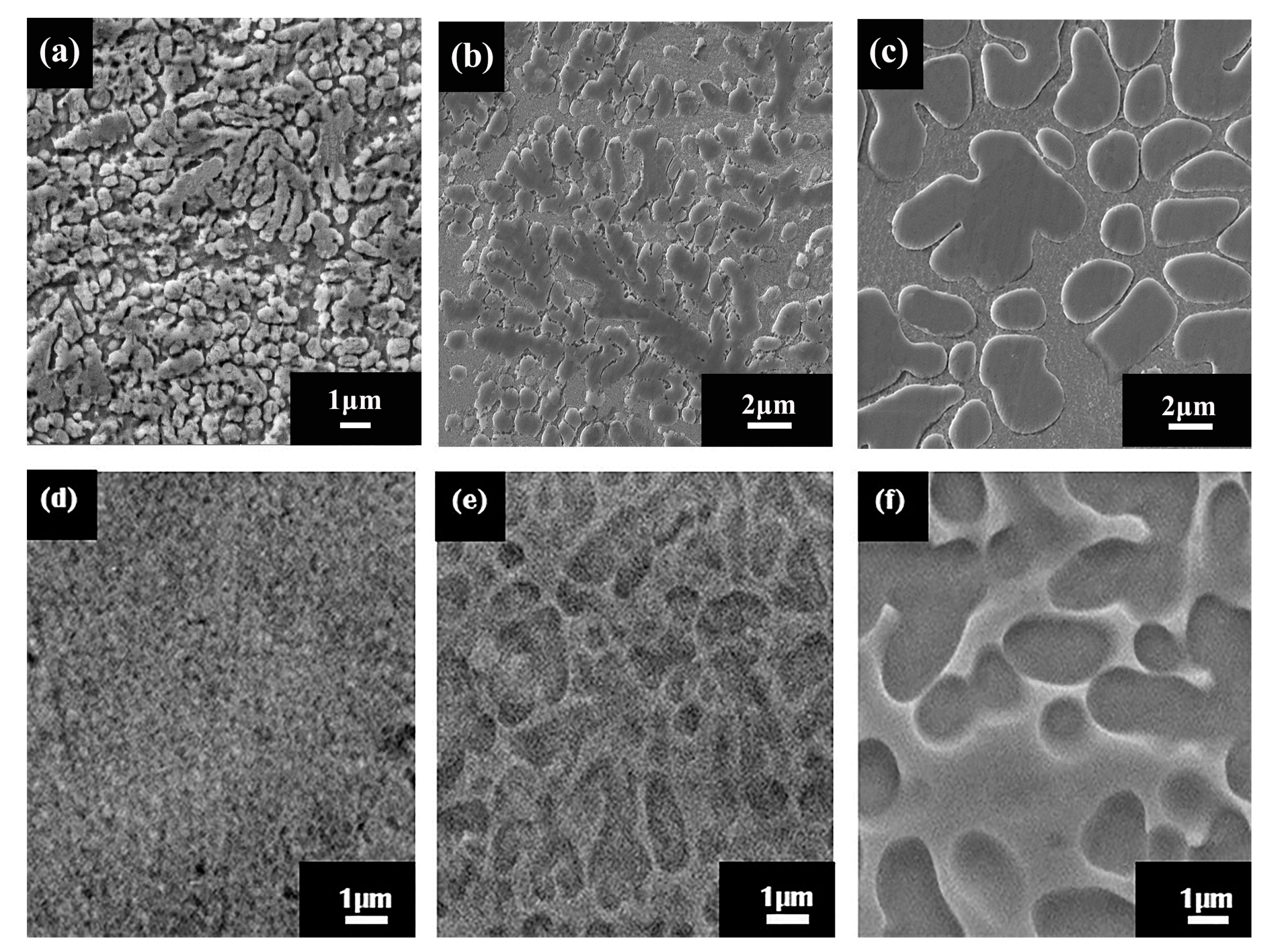

3.3. Chemical Corrosion Measurements

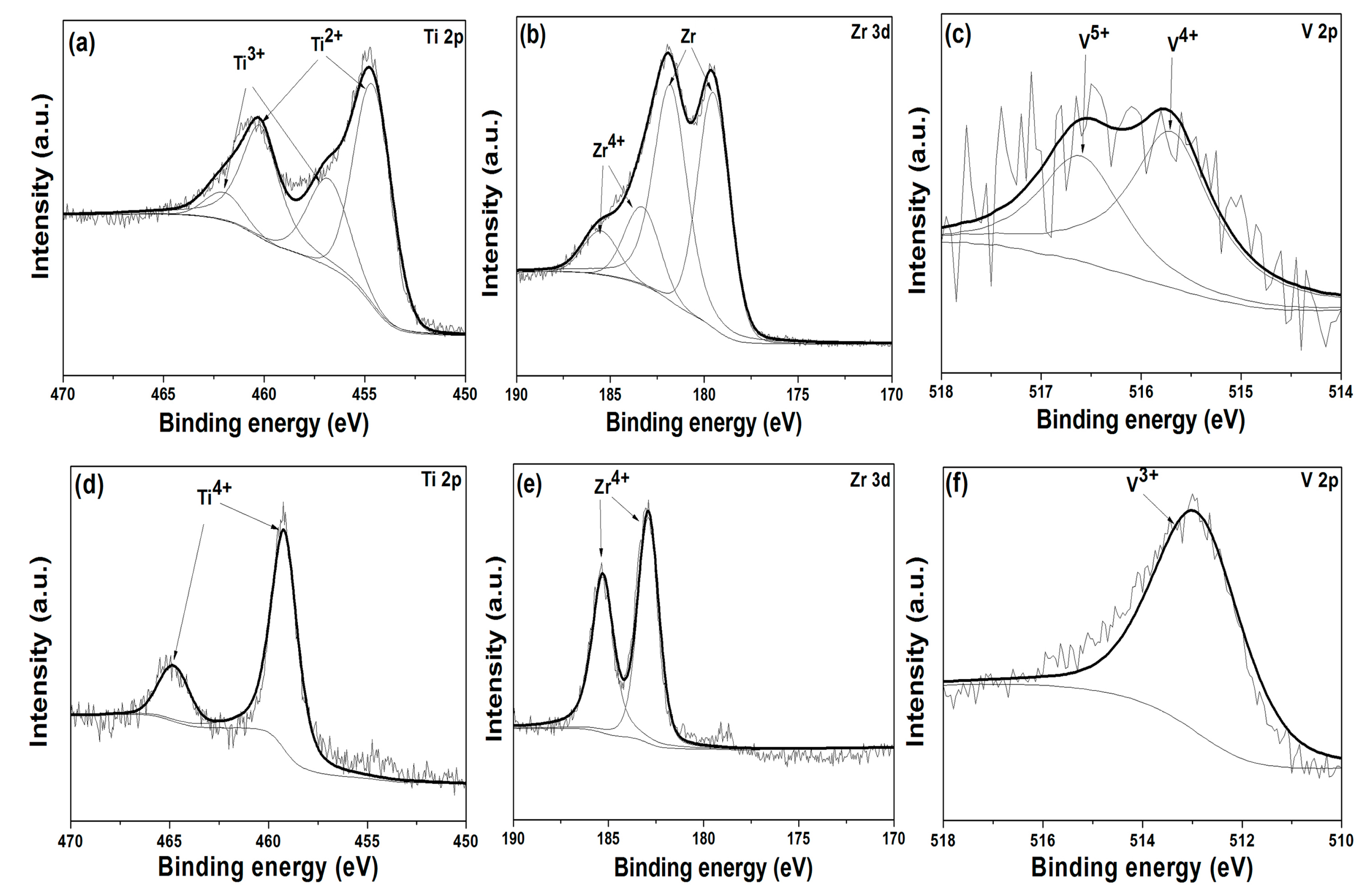

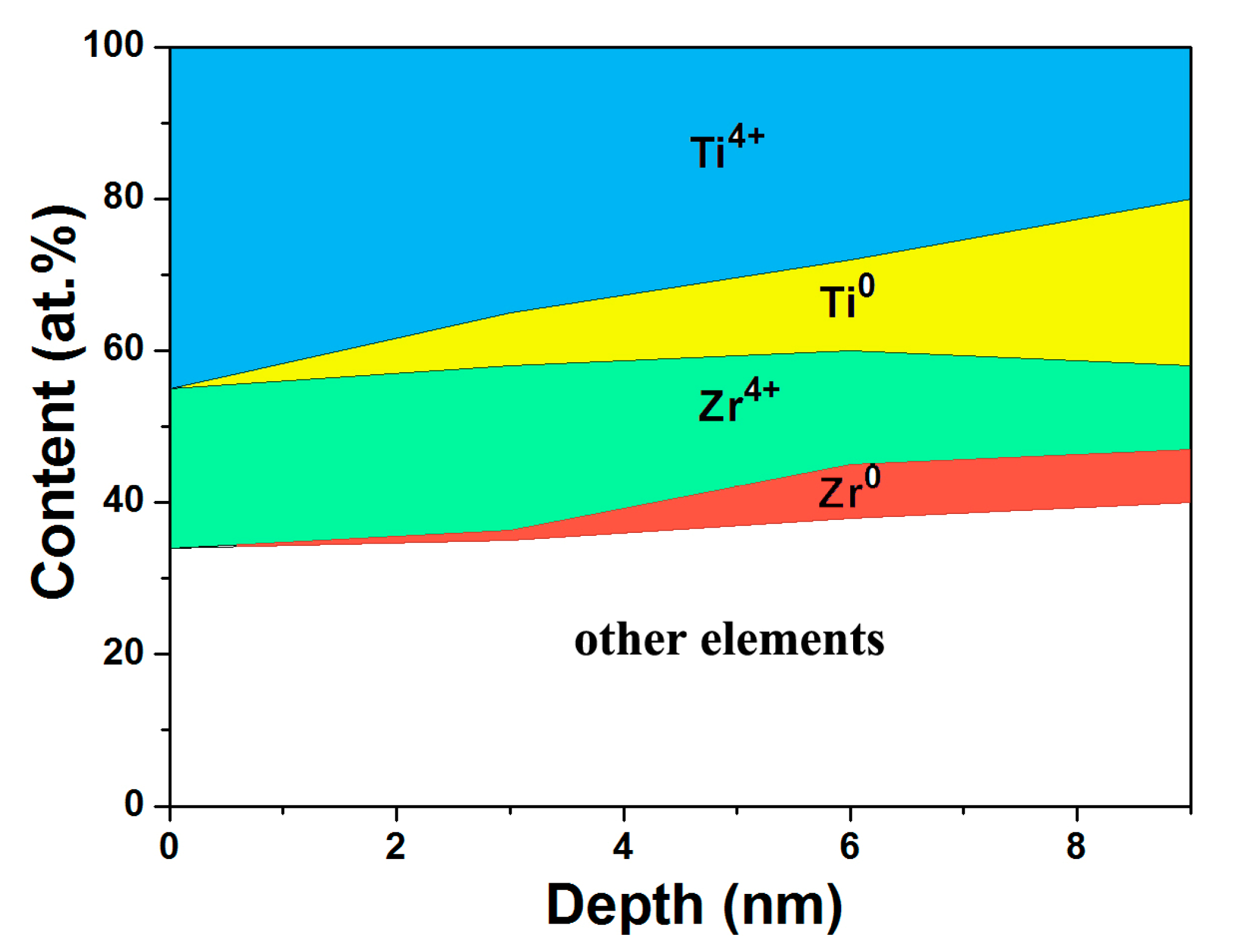

3.4. XPS Results

4. Discussion

4.1. The Effect of the Composition of the Passive Film on Corrosion Properties

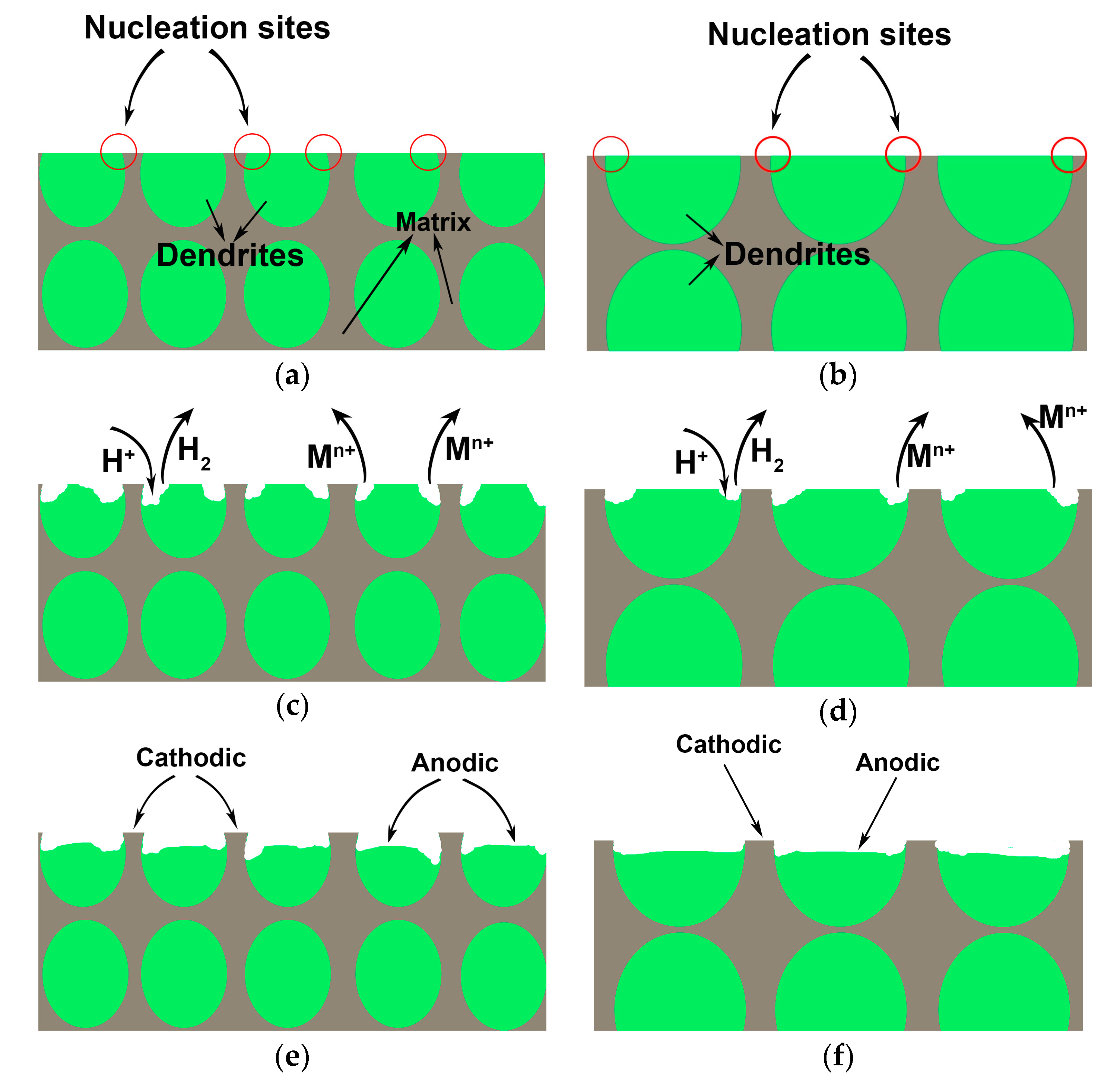

4.2. Possible Corrosion Mechanisms

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Hays, C.C.; Kim, C.P.; Johnson, W.L. Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in-situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 2000, 84, 2901–2904. [Google Scholar] [CrossRef] [PubMed]

- Peker, A.; Johnson, W.L. A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 1993, 63, 2342–2344. [Google Scholar] [CrossRef]

- Fan, C.; Louzguine, D.V.; Li, C.; Inoue, A. Nanocrystalline composites with high strength obtained in Zr–Ti–Ni–Cu–Al bulk amorphous alloys. Appl. Phys. Lett. 1999, 75, 340–342. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A.; Duan, G.; Lind, M.L.; Demetriou, M.D.; Johnson, W.L. Development of tough, lowdensity titanium-based bulk metallic glass matrix composites with tensile ductility. Proc. Natl. Acad. Sci. USA 2008, 105, 20136–20140. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A.; Duan, G.; Lind, M.L.; Demetriou, M.D.; Johnson, W.L. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.W.; Wang, S.; Zhang, Y.; Liaw, P.K.; Chen, G.L. Large plasticity and tensile necking of Zr-based bulk-metallic-glass-matrix composites synthesized by the bridgman solidification. Appl. Phys. Lett. 2009, 94, 151905. [Google Scholar] [CrossRef]

- Qiao, J.W.; Sun, A.C.; Huang, E.W.; Zhang, Y.; Liaw, P.K.; Chuang, C.P. Tensile deformation micromechanisms for bulk metallic glass matrix composites: From work-hardening to softening. Acta Mater. 2011, 59, 4126–4137. [Google Scholar] [CrossRef]

- Wang, Z.M.; Ma, Y.T.; Zhang, J.; Hou, W.L.; Chang, X.C.; Wang, J.Q. Influence of yttrium as a minority alloying element on the corrosion behavior in fe-based bulk metallic glasses. Electrochim. Acta 2008, 54, 261–269. [Google Scholar] [CrossRef]

- Wang, Z.; Scudino, S.; Prashanth, K.G.; Eckert, J. Corrosion properties of high-strength nanocrystalline Al84Ni7Gd6Co3 alloy produced by hot pressing of metallic glass. J. Alloys Compd. 2017, 707, 63–67. [Google Scholar] [CrossRef]

- Zhang, H.J.; Zhang, D.F.; Ma, C.H.; Guo, S.F. Improving mechanical properties and corrosion resistance of Mg6ZnMn magnesium alloy by rapid solidification. Mater. Lett. 2013, 92, 45–48. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, W.; Tan, H.; Li, Y. Microstructure control and ductility improvement of La–Al–(Cu,Ni) composites by bridgman solidification. Acta Mater. 2005, 53, 2607–2616. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Qiao, J.W.; Ma, S.G.; Gao, M.C.; Yang, H.J.; Chen, M.W.; Zhang, Y. A hexagonal close-packed high-entropy alloy: The effect of entropy. Mater. Des. 2016, 96, 10–15. [Google Scholar] [CrossRef]

- Debnath, M.R.; Kim, D.-H.; Fleury, E. Dependency of the corrosion properties of in-situ Ti-based BMG matrix composites with the volume fraction of crystalline phase. Intermetallics 2012, 22, 255–259. [Google Scholar] [CrossRef]

- Debnath, M.R.; Chang, H.-J.; Fleury, E. Effect of group 5 elements on the formation and corrosion behavior of Ti-based BMG matrix composites reinforced by icosahedral quasicrystalline phase. J. Alloys Compd. 2014, 612, 134–142. [Google Scholar] [CrossRef]

- Qiao, J.W.; Zhang, T.; Yang, F.Q.; Liaw, P.K.; Pauly, S.; Xu, B.S. A tensile deformation model for in-situ dendrite/metallic glass matrix composites. Sci. Rep. 2013, 3, 2816. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Tian, H.F.; Lan, A.D.; Zhou, H.F.; Wang, B.C.; Yang, H.J.; Qiao, J.W. Corrosion behavior of Ti-based in situ dendrite-reinforced metallic glass matrix composites in various solutions. Metall. Mater. Trans. A 2015, 46, 2399–2403. [Google Scholar] [CrossRef]

- Wang, Z.M.; Chang, X.C.; Hou, W.L.; Wang, J.Q. Selective dissolution sensitive to minor alloying in CuZr-based metallic glasses. Corros. Sci. 2013, 76, 465–473. [Google Scholar] [CrossRef]

- Hourani, M.; Wedian, F. The effect of adatoms on the corrosion rate of copper. Corros. Sci. 2000, 42, 2131–2144. [Google Scholar] [CrossRef]

- Jeon, C.; Lee, H.; Kim, C.P.; Joo, S.-H.; Kim, H.S.; Lee, S. Effects of effective dendrite size on tensile deformation behavior in ti-based dendrite-containing amorphous matrix composites modified from Ti-6Al-4V alloy. Metall. Mater. Trans. A 2014, 46, 235–250. [Google Scholar] [CrossRef]

- Sun, X.H.; Wang, Y.S.; Fan, J.; Yang, H.J.; Ma, S.G.; Wang, Z.H.; Qiao, J.W. Plasticity improvement for dendrite/metallic glass matrix composites by pre-deformation. Mater. Des. 2015, 86, 266–271. [Google Scholar] [CrossRef]

- Qin, C.L.; Oak, J.J.; Ohtsu, N.; Asami, K.; Inoue, A. XPS study on the surface films of a newly designed Ni-free Ti-based bulk metallic glass. Acta Mater. 2007, 55, 2057–2063. [Google Scholar] [CrossRef]

- Wang, D.P.; Wang, S.L.; Wang, J.Q. Relationship between amorphous structure and corrosion behaviour in a Zr–Ni metallic glass. Corros. Sci. 2012, 59, 88–95. [Google Scholar] [CrossRef]

- Sobolev, V.I.; Koltunov, K.Y. MoVNbTe mixed oxides as efficient catalyst for selective oxidation of ethanol to acetic acid. ChemCatChem 2011, 3, 1143–1145. [Google Scholar] [CrossRef]

- Szewieczek, D.; Held, J.T.; Paszenda, Z. Corrosion investigations of nanocrystalline iron based alloy. J. Mater. Process. Technol. 1998, 78, 171–176. [Google Scholar] [CrossRef]

- Jayaraj, J.; Sordelet, D.J.; Kim, D.H.; Kim, Y.C.; Fleury, E. Corrosion behaviour of Ni–Zr–Ti–Si–Sn amorphous plasma spray coating. Corros. Sci. 2006, 48, 950–964. [Google Scholar] [CrossRef]

| Samples | Ecorr (mV) | icorr (μA/cm2) | ipass (at 0.5 V) |

|---|---|---|---|

| Φ2 mm rod | −760 ± 22 | 1.76 ± 0.35 | 100 ± 15 |

| Φ3 mm rod | −758 ± 15 | 0.17 ± 0.22 | 12.6 ± 1.35 |

| Φ6 mm rod | −740 ± 26 | 0.11 ± 0.04 | 9.46 ± 1.15 |

| Alloys | Rs (Ω·cm2) | Rp (Ω·cm2) | Q (μF·cm−2) |

|---|---|---|---|

| Φ2 mm rod | 1.02 ± 0.11 | 1761 ± 106 | 52.9 ± 4.3 |

| Φ3 mm rod | 0.68 ± 0.15 | 3500 ± 125 | 1.99 ± 0.41 |

| Φ6 mm rod | 1.23 ± 0.26 | 3600 ± 163 | 23 ± 2.5 |

| Diameter of Samples | Atomic Percentage | |||||||

|---|---|---|---|---|---|---|---|---|

| Matrices | Crystalline Dendrites | |||||||

| Ti | Zr | V | Cu | Ti | Zr | V | Cu | |

| Φ2 mm | 45.5 | 27.6 | 10.0 | 16.9 | 58.8 | 20.8 | 13.9 | 6.5 |

| Φ3 mm | 42.9 | 32.4 | 8.7 | 16.0 | 61.6 | 18.6 | 14.6 | 5.2 |

| Φ6 mm | 48.4 | 28.4 | 10.0 | 13.2 | 57.6 | 20.6 | 14.6 | 7.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, J.; Fan, J.; Yang, F.; Shi, X.; Yang, H.; Lan, A. The Corrosion Behavior of Ti-Based Metallic Glass Matrix Composites in the H2SO4 Solution. Metals 2018, 8, 52. https://doi.org/10.3390/met8010052

Qiao J, Fan J, Yang F, Shi X, Yang H, Lan A. The Corrosion Behavior of Ti-Based Metallic Glass Matrix Composites in the H2SO4 Solution. Metals. 2018; 8(1):52. https://doi.org/10.3390/met8010052

Chicago/Turabian StyleQiao, Junwei, Jing Fan, Fan Yang, Xiaohui Shi, Huijun Yang, and Aidong Lan. 2018. "The Corrosion Behavior of Ti-Based Metallic Glass Matrix Composites in the H2SO4 Solution" Metals 8, no. 1: 52. https://doi.org/10.3390/met8010052

APA StyleQiao, J., Fan, J., Yang, F., Shi, X., Yang, H., & Lan, A. (2018). The Corrosion Behavior of Ti-Based Metallic Glass Matrix Composites in the H2SO4 Solution. Metals, 8(1), 52. https://doi.org/10.3390/met8010052