On the Stability of the Melt Jet Stream during Casting of Metallic Glass Wires

Abstract

:1. Introduction

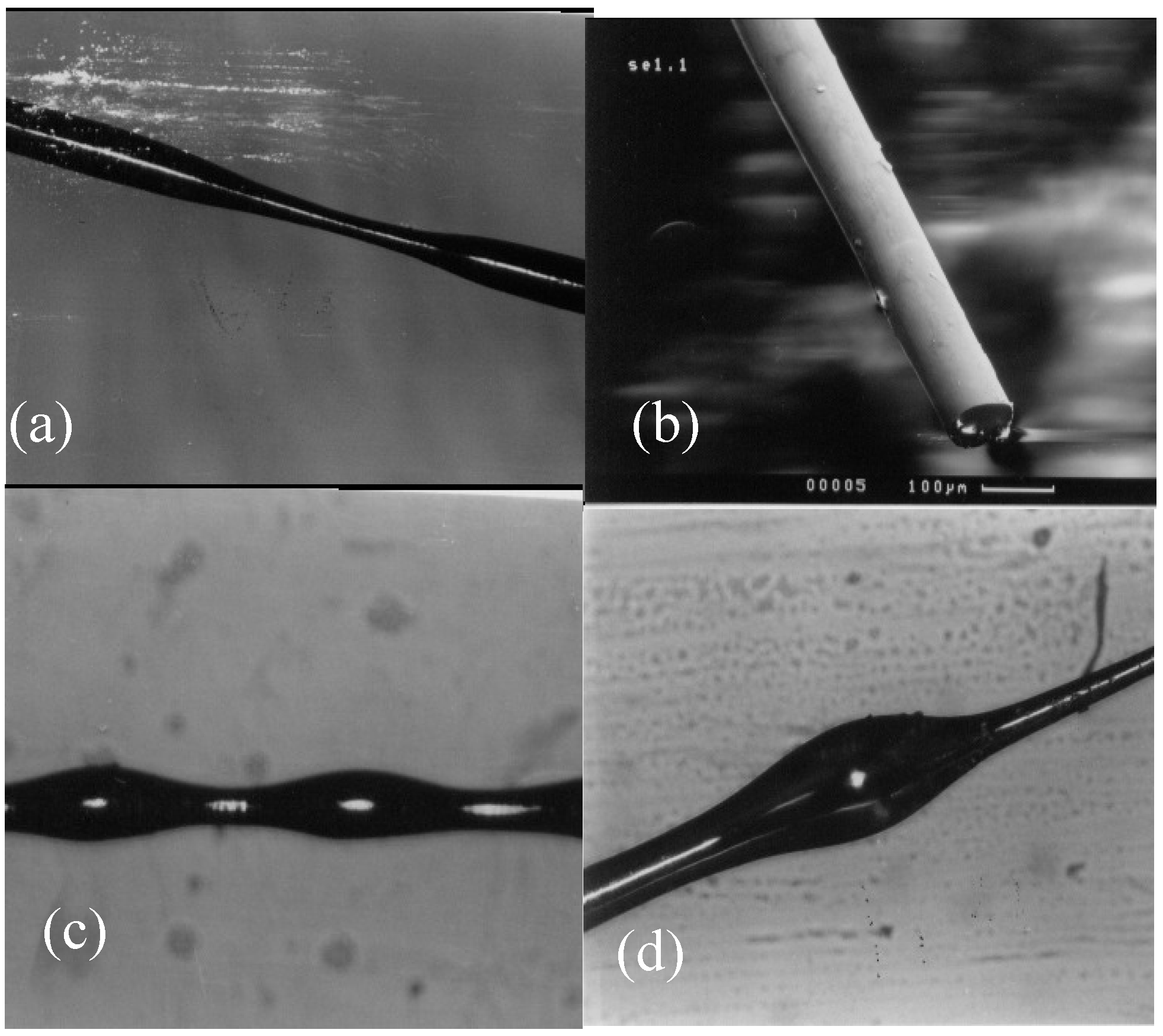

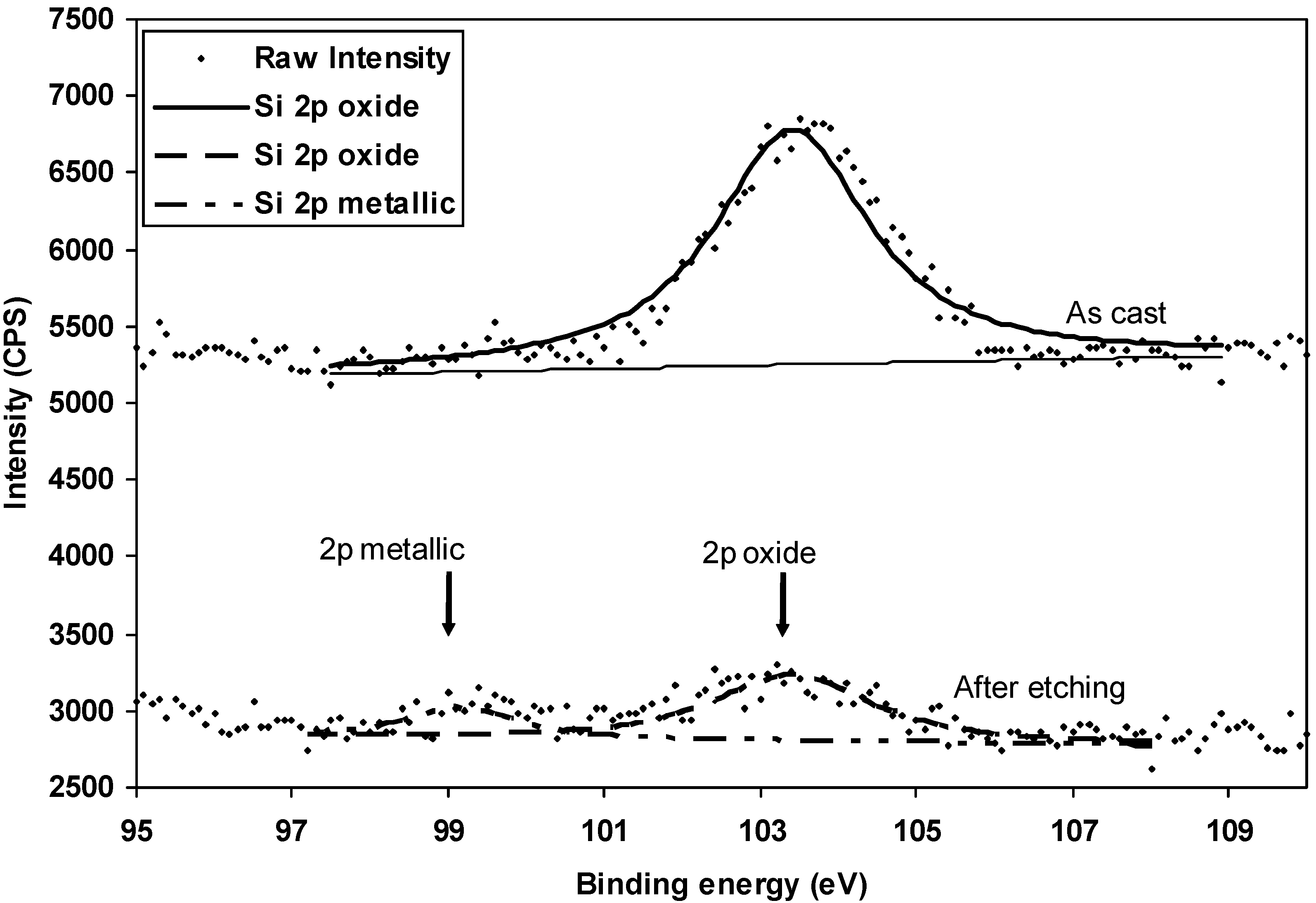

2. Experimental Section

2.1. Wire Casting

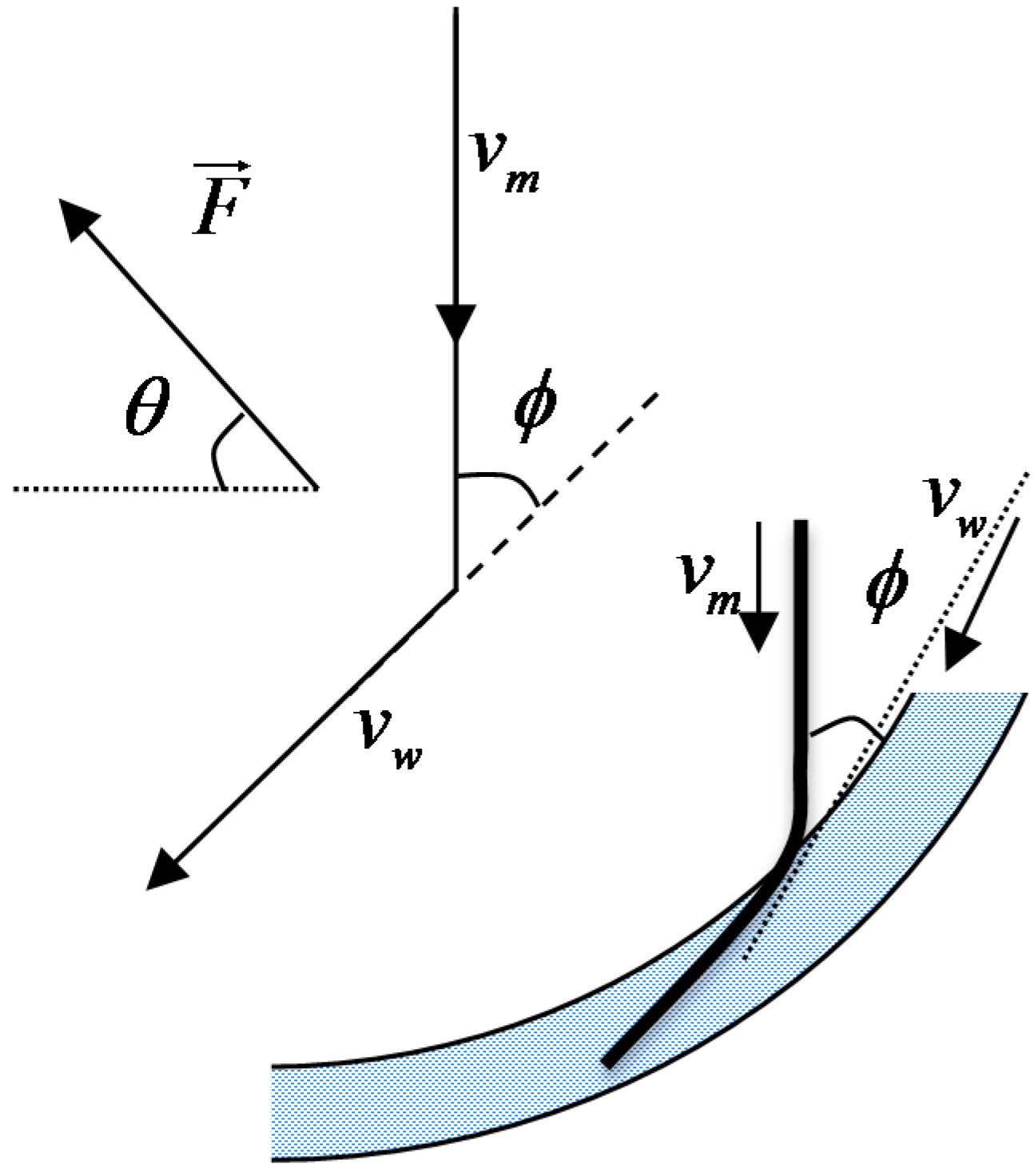

2.2. Determining Melt Stream Velocity

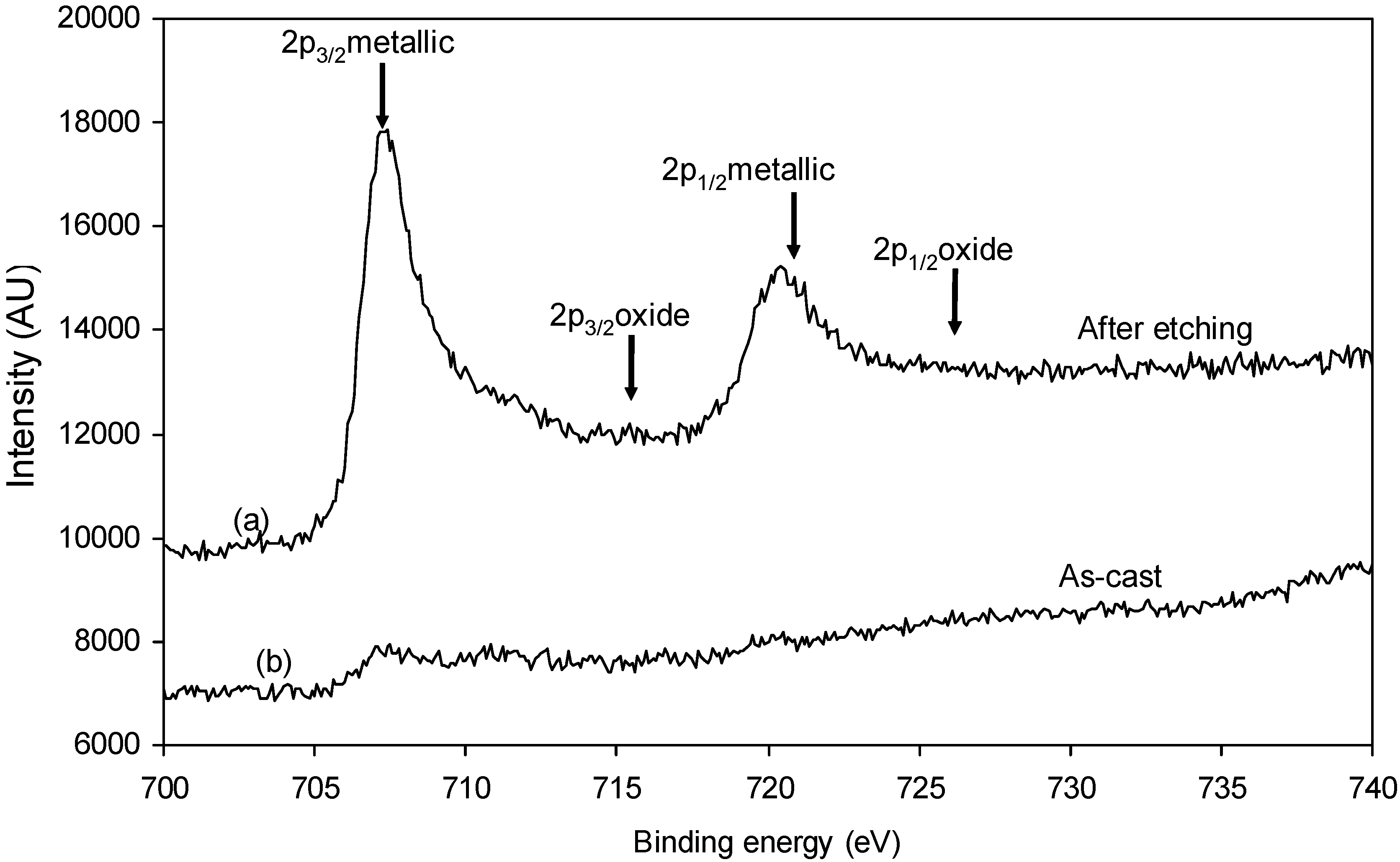

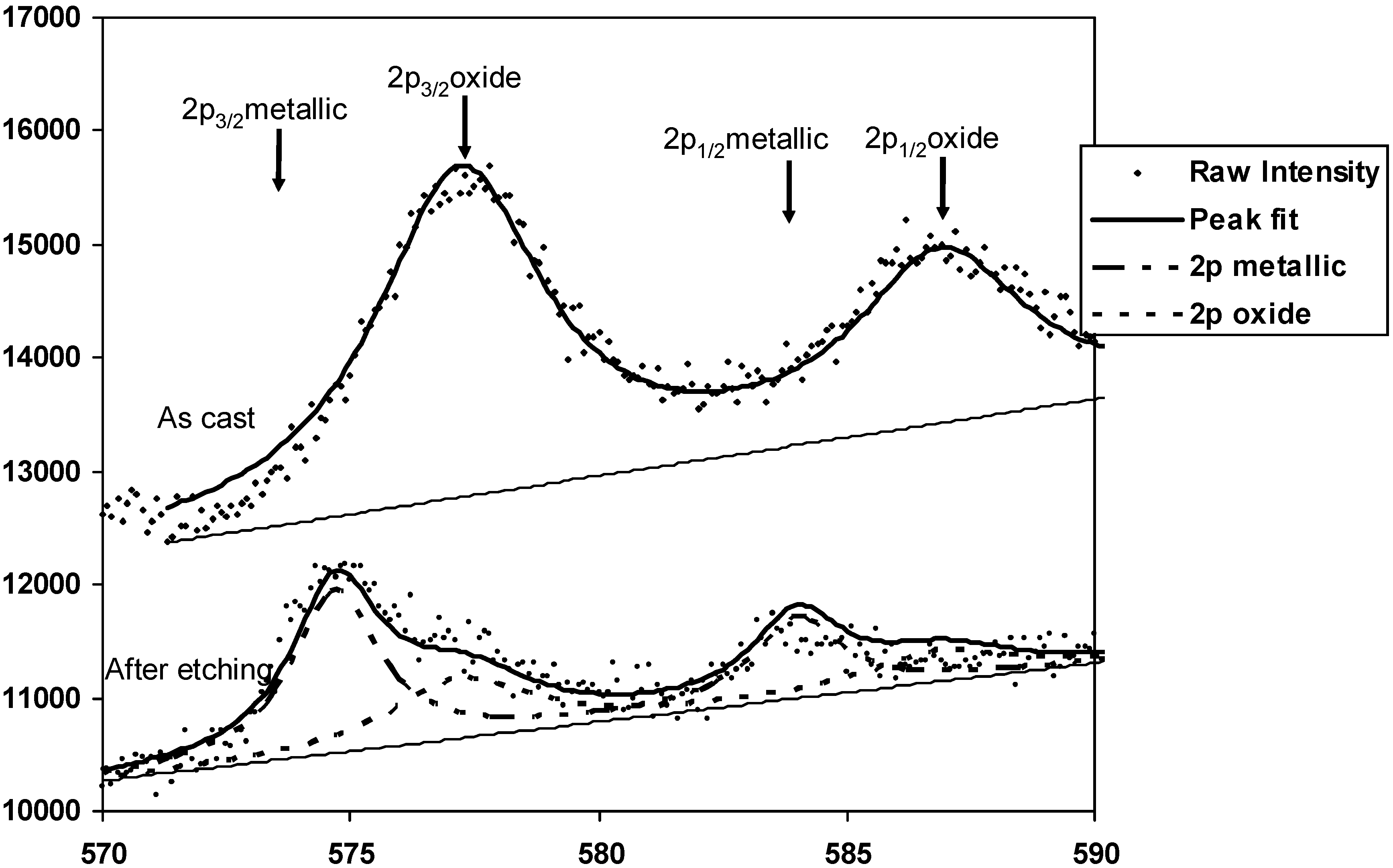

3. Results and Discussion

3.1. Factors Affecting Stability of Melt Jet

- Nozzle clearance distance from cooling liquid

- Nozzle/melt jet diameter

- Ratio of melt jet velocity to that of the cooling liquid

- Melt super heat

- Alloy composition

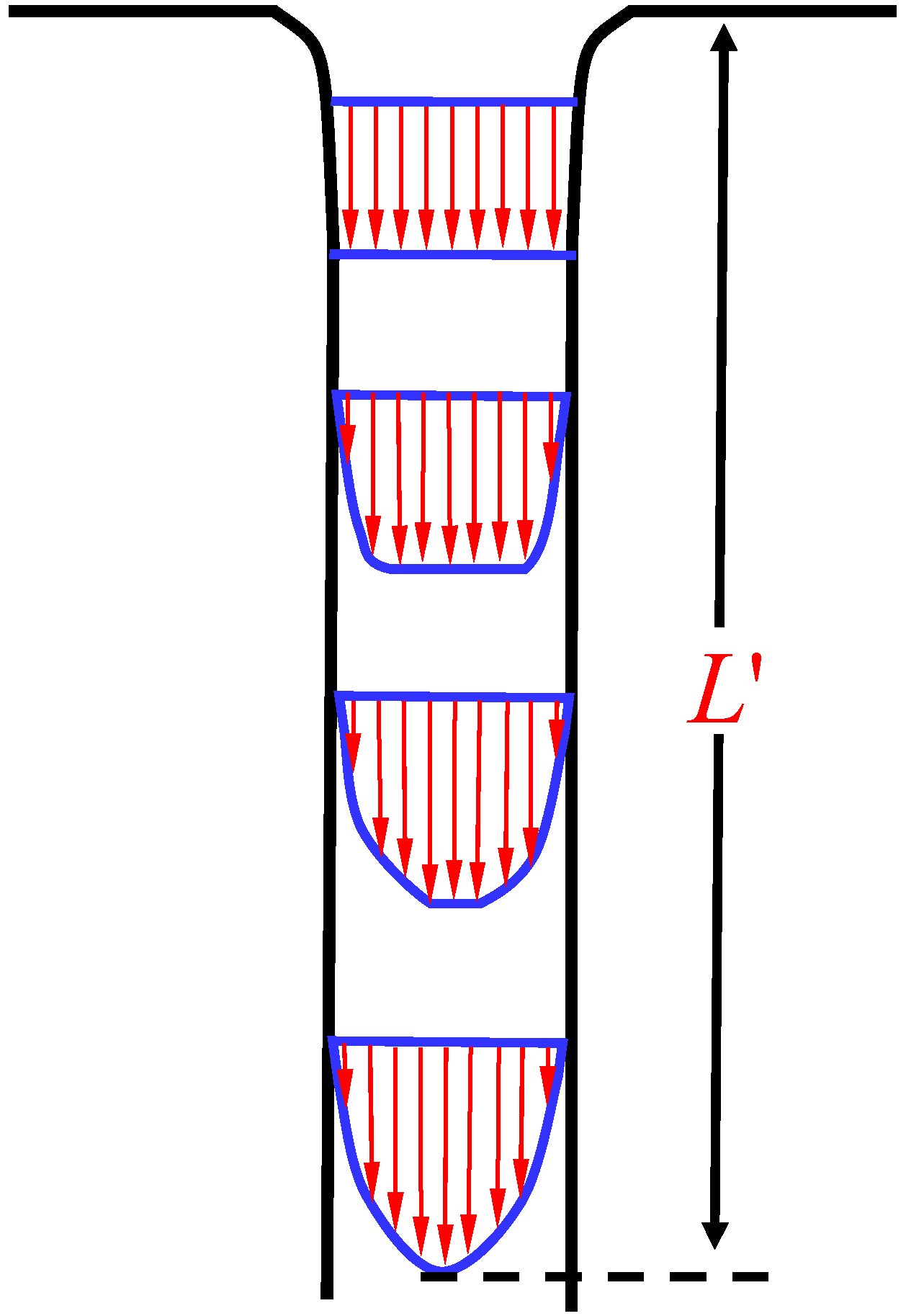

3.2. Nozzle Clearance Distance

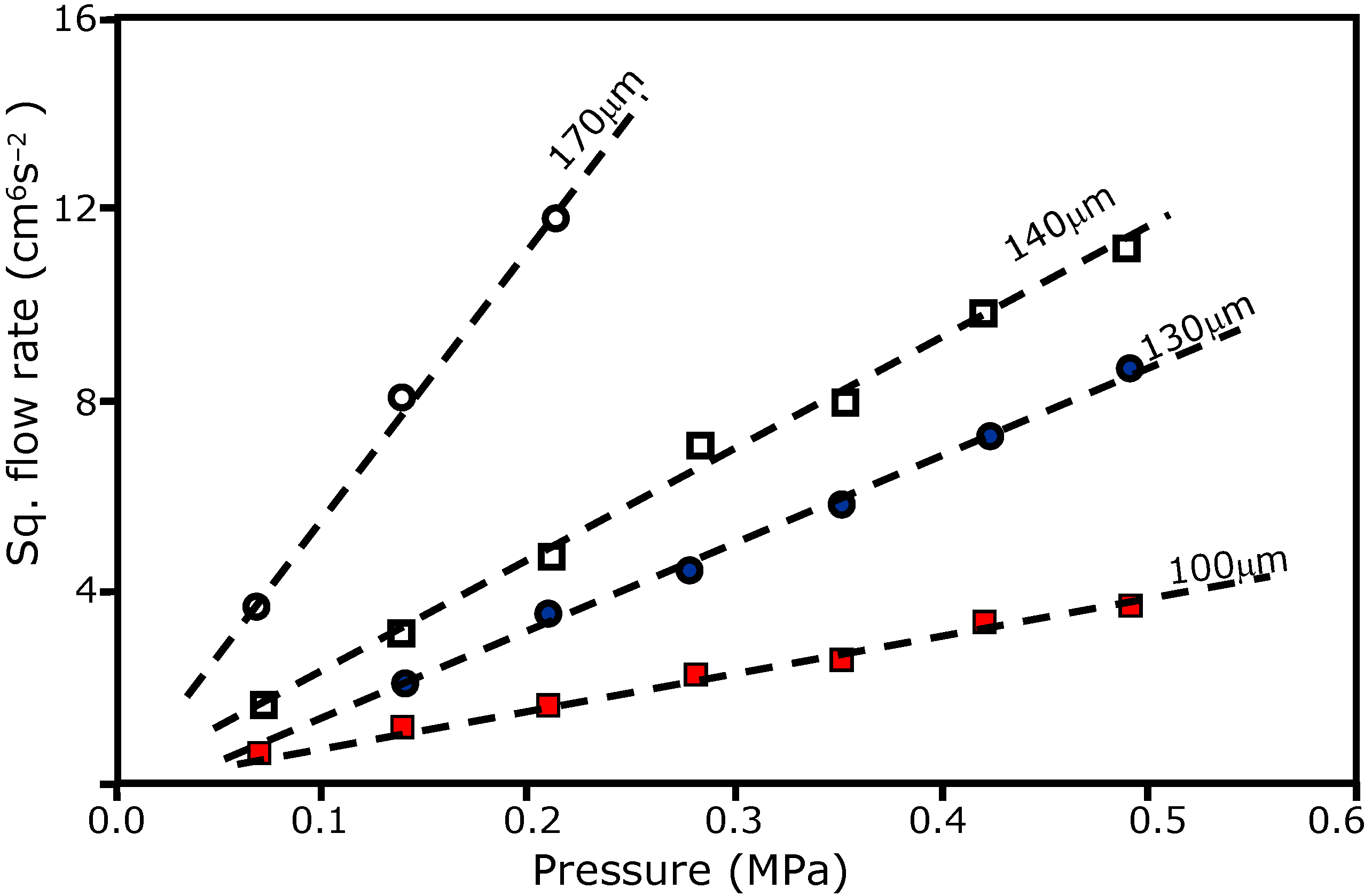

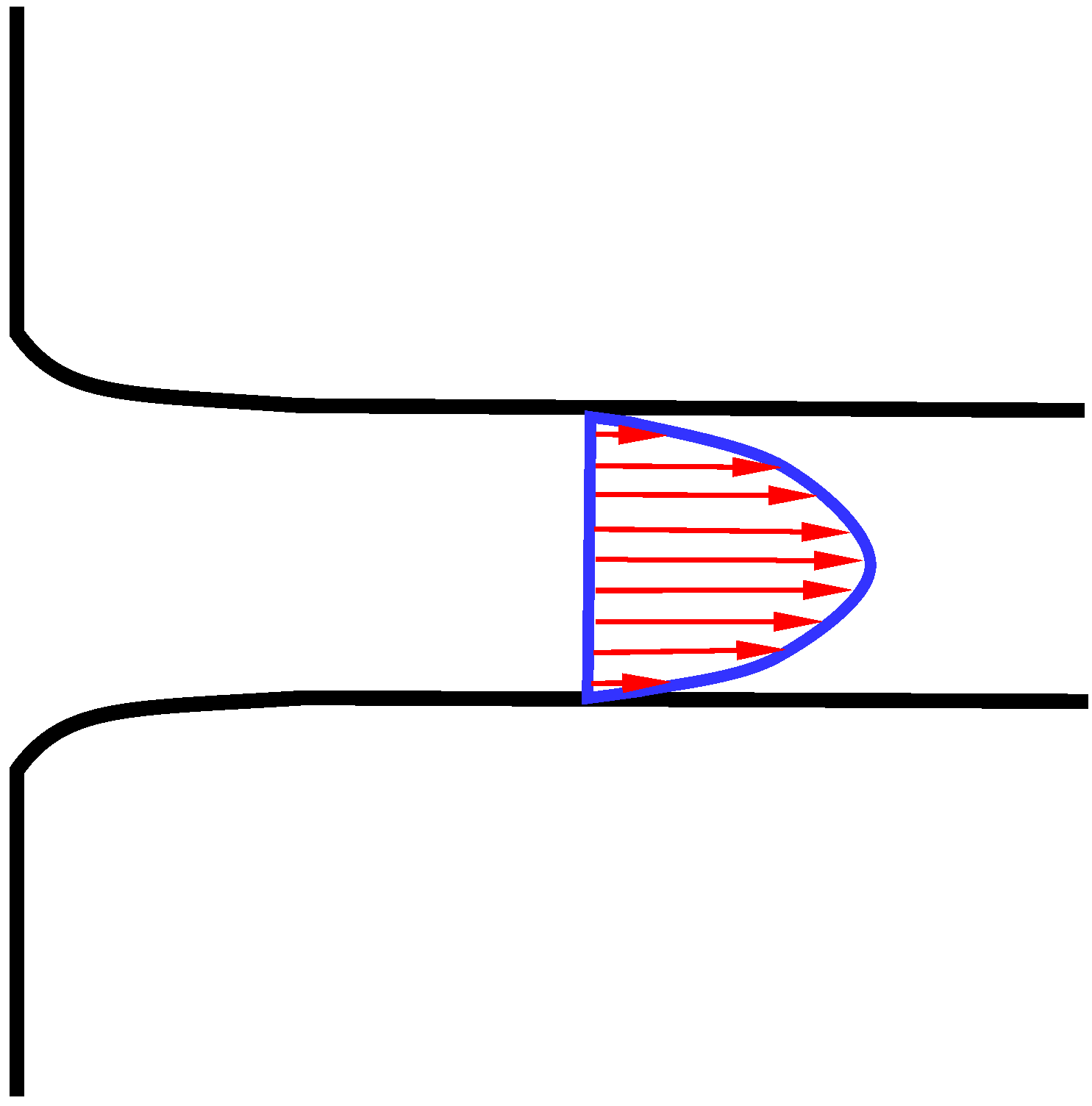

3.3. Nozzle Diameter and Jet Contraction

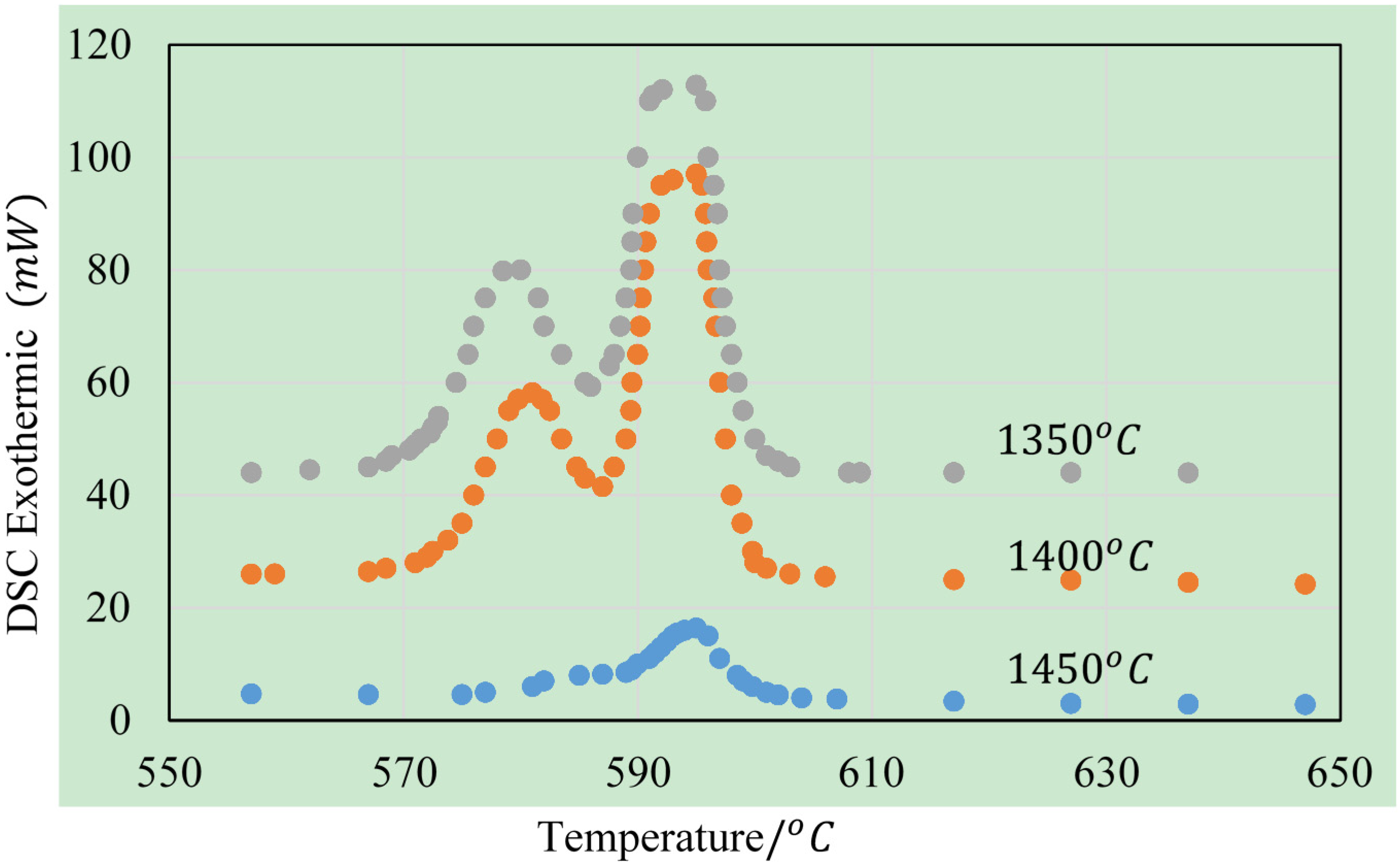

3.4. Melt Superheat

3.5. Effect of Water and Jet Velocity

3.6. Effect of Alloy Composition

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Small, E. Aparatus for Making Wire Solder. U.S. Patent 262625, 1882. [Google Scholar]

- Otstot, R.S.; Motern, J.W. Method and Apparatus for Improved Extrusion of Essentially Inviscid Jets. U.S. Patent 3,645,657, 1972. [Google Scholar]

- Privott, W.J.; Cunningham, R.E. Low Viscousity Melt Spinning Process. U.S. Patent 3,715,419, 1973. [Google Scholar]

- Kavesh, S. Apparatus for liquid quenching of free jet spun metal. U.S. Patent 3,845,805, 1976. [Google Scholar]

- Adler, R.P.I. Melt Spinning Process and Machine. U.S. Patent 4,020,891, 1977. [Google Scholar]

- Masumoto, T.; Hagiwara, M. Process for the Production of Fine Amorphous Metallic Wires. U.S. Patent 4,495,691, 1985. [Google Scholar]

- Masumoto, T.; Hamashima, T.; Hagiwara, M. Method of Manufacturing Thin Metal Wire. U.S. Patent 4,614,221, 1986. [Google Scholar]

- Hagiwara, M.; Menjiu, A.; Kohachi, N.; Masaru, K.; Yoshianao, Y.; Miyuri, S. Fine Amorphous Metal Wire. U.S. Patent 4,806,179, 1989. [Google Scholar]

- Larin, V.S.; Torcunov, A.V.; Zhukov, A.; Gonzalez, J.; Vazquez, M.; Panina, L. Preparation and properties of glass-coated microwires. J. Magn. Magn. Mater. 2002, 249, 39–45. [Google Scholar] [CrossRef]

- Inoue, A.; Krause, J.T.; Masumoto, T.; Hagiwara, M. Young’s modulus of Fe-, Co-, Pd- and Pt-based amorphous wires produced by the in-rotating-water spinning method. J. Mater. Sci. 1983, 18, 2743–2751. [Google Scholar] [CrossRef]

- Shalyginaa, E.E.; Umnova, N.V.; Umnov, P.P.; Molokanov, V.V.; Samsonova, V.V.; Shalygin, A.N.; Rozhnovskaya, A.A. Specific Features of Magnetic Properties of “Thick” Microwires Produced by the Ulitovsky–Taylor Method. Phys. Solid State 2012, 54, 287–292. [Google Scholar] [CrossRef]

- Frommeyer, G.; Frech, W. Continuous casting and rapid solidification of wires produced by a newly developed shape flow casting technique. Mater. Sci. Eng. A 1997, 226, 1019–1024. [Google Scholar] [CrossRef]

- Sarkar, P.; Roy, R.K.; Panda, A.K.; Mitra, A. Optimization of process parameters for developing FeCoSiB amorphous microwires through in-rotating-water quenching technique. Appl. Phys. A 2013, 111, 575–580. [Google Scholar] [CrossRef]

- Vazquez, M. Soft magnetic wires. Phys. B 2001, 299, 302–313. [Google Scholar] [CrossRef]

- Gavrilyuk, A.V.; Gavrilyuk, A.A.; Kovaleva, N.P.; Mokhovikov, A.Y.; Semenov, A.L.; Gavrilyuk, B.V. Magnetic properties of Fe75Si10B15 amorphous metallic wires. Phys. Metals Metallogr. 2006, 101, 434–439. [Google Scholar] [CrossRef]

- Sarkar, P.; Roy, R.K.; Mitra, A.; Panda, A.K.; Churyukanov, M.; Kaloshkin, S. Effect of Nb and Cr incorporation on the structural and magnetic properties of rapidly quenched FeCoSiB microwires. J. Magn. Magn. Mater. 2012, 324, 2543–2546. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, K.; Jia, X.; Wang, D.; Wang, S.; Luo, Y.; Ge, S. Bending fatigue behaviour of bearing ropes working around pulleys of different materials. Eng. Fail. Anal. 2013, 33, 37–47. [Google Scholar] [CrossRef]

- Vazquez, M.; Marin, P.; Olofinjana, A.O.; Davies, H.A. The magnetic properties of FeSiBCuNb wires during the first stages to the nanocrystallization process. Mater. Sci. Forum 1995, 179–181, 521–526. [Google Scholar] [CrossRef]

- Vazquez, M. Giant magneto-impedance in soft magnetic “wires”. J. Magn. Magn. Mater. 2001, 226, 693–699. [Google Scholar] [CrossRef]

- Mokhirev, I.I.; Chueva, T.R.; Zabolotnyi, V.T.; Umnov, P.P.; Umnova, N.V.; Molokanov, V.V. Strength and Plastic Properties of Amorphous Cobalt Alloy Wires Produced by Various Melt Quenching Methods. Russ. Metall. (Metally) 2010, 2011, 345–349. [Google Scholar] [CrossRef]

- Luo, Y.; Peng, H.X.; Qin, F.X.; Ipatov, M.; Zhukova, V.; Zhukov, A.; Gonzalez, J. Fe-based ferromagnetic microwires enabled meta-composites. Appl. Phys. Lett. 2013, 103, 251092. [Google Scholar] [CrossRef]

- Qin, F.; Peng, H.-X. Ferromagnetic microwires enabled multifunctional composite materials. Prog. Mater. Sci. 2013, 58, 183–259. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Li, H.; Hao, H.Y.; Li, M.; Zhang, Y.; Liaw, P.K. Microwires fabricated by glass-coated melt spinning. Rev. Sci. Instrum. 2013, 84, 075102. [Google Scholar] [CrossRef] [PubMed]

- Zhukov, A.; Chichay, K.; Talaat, A.; Rodionova, V.; Blanco, J.M.; Ipatov, M.; Zhukova, V. Manipulation of magnetic properties of glass-coated microwires by annealing. J. Magn. Magn. Mater. 2015, 383, 232–236. [Google Scholar] [CrossRef]

- Varga, R.; Ryba, T.; Vargova, Z.; Saksl, K.; Zhukova, V.; Zhukov, A. Magnetic and structural properties of Ni-Mn-Ga Heusler-type microwires. Scr. Mater. 2011, 65, 703–706. [Google Scholar] [CrossRef]

- Zhukov, A.; Rodionova, V.; Ilyn, M.; Aliev, A.M.; Varga, R.; Michalik, S.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Ipatov, M.; Zhukova, V. Magnetic properties and magnetocaloric effect in Heusler-type glass-coated NiMnGa microwires. J. Alloys Compd. 2013, 575, 73–79. [Google Scholar] [CrossRef]

- Zhukova, V.; Aliev, A.M.; Varga, R.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Zhukov, A. Magnetic Properties and MCE in Heusler-Type Glass-Coated Microwires. J. Supercond. Novel Magn. 2013, 26, 1415–1419. [Google Scholar] [CrossRef]

- Zhukova, V.; Ipatov, M.; Granovsky, A.; Zhukov, A. Magnetic properties of Ni-Mn-In-Co Heusler-type glass-coated microwires. J. Appl. Phys. 2014, 115, 17A939. [Google Scholar] [CrossRef]

- Zhukova, V.; Rodionova, V.; Fetisov, L.; Grunin, A.; Goikhman, A.; Torcunov, A.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Perov, N.; et al. Magnetic Properties of Heusler-Type Microwires and Thin Films. IEEE Trans. Magn. 2014, 50. [Google Scholar] [CrossRef]

- Zhukov, A.; Gonzalez, J.; Blanco, J.M.; Vazquez, M.; Larin, V. Microwires coated by glass: A new family of soft and hard magnetic materials. J. Mater. Res. 2000, 15, 2107–2113. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukov, A.; Gonzalez, J. Magnetic properties of sub-micrometric Fe-rich wires. Thin Solid Films 2013, 543, 130–132. [Google Scholar] [CrossRef]

- Varga, R.; Zhukov, A.; Ipatov, M.; Blanco, J.M.; Gonzalez, J.; Zhukova, V.; Vojtanik, P. The influence of glass coating on the single domain wall potential in amorphous glass-coated Fe-based microwires. J. Magn. Magn. Mater. 2006, 304, E519–E521. [Google Scholar] [CrossRef]

- Qin, F.; Peng, H.X.; Tang, J.; Qin, L.C. Ferromagnetic microwires enabled polymer composites for sensing applications. Composites Part A 2010, 41, 1823–1828. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeno, A.F.; Zhukov, A.; Blanco, J.M.; Puerta, S.; Gonzalez, J.; Vazquez, M. Tailoring of magnetic properties of glass-coated microwires by current annealing. J. Non-Cryst. Solids 2001, 287, 31–36. [Google Scholar] [CrossRef]

- Olofinjana, A.O.; Kern, J.H.; Daves, H.A. Effects of process variables on the multi-strand casting of high strength sub-millimetre metallic glass wire. J. Mater. Process. Technol. 2004, 155, 1344–1349. [Google Scholar] [CrossRef]

- Olofinjana, A.O.; Kern, J.H.; Davies, H.A. Multistrand casting of amorphous alloy wire. Mater. Lett. 1995, 23, 55–57. [Google Scholar] [CrossRef]

- Finnmore, E.; Franzini, J. Fluid Mechanics with Engineering Applications; McGraw-Hill Education: New York, NY, USA, 2001. [Google Scholar]

- Zeller, S.; Gnauk, J. Shape memory behaviour of Cu-Al wires produced by horizontal in-rotating-liquid-spinning. Mater. Sci. Eng. A 2008, 481, 562–566. [Google Scholar] [CrossRef]

- Castrejon-Pita, A.A.; Castrejon-Pita, J.R.; Hutchings, I.M. Breakup of Liquid Filaments. Phys. Rev. Lett. 2012, 108, 074506. [Google Scholar] [CrossRef] [PubMed]

- Richards, J.R.; Lenhoff, A.M.; Beris, A.N. Dynamic breakup of liquid jets. Phys. Fluids 1994, 6, 2640–2655. [Google Scholar] [CrossRef]

- Liu, J.; Arnberg, N.; Backstrom, S.; Savage, S. Fundamental Parameters in the direct wire casting process. Mater. Sci. Eng. A 1988, 98, 21–24. [Google Scholar] [CrossRef]

- Darken, L.S. Physical Chemistry of Metals; McGraw-Hill: New York, NY, USA, 1953. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olofinjana, A.; Voo, N.Y. On the Stability of the Melt Jet Stream during Casting of Metallic Glass Wires. Metals 2015, 5, 1029-1044. https://doi.org/10.3390/met5021029

Olofinjana A, Voo NY. On the Stability of the Melt Jet Stream during Casting of Metallic Glass Wires. Metals. 2015; 5(2):1029-1044. https://doi.org/10.3390/met5021029

Chicago/Turabian StyleOlofinjana, Ayo, and Nyuk Yoong Voo. 2015. "On the Stability of the Melt Jet Stream during Casting of Metallic Glass Wires" Metals 5, no. 2: 1029-1044. https://doi.org/10.3390/met5021029

APA StyleOlofinjana, A., & Voo, N. Y. (2015). On the Stability of the Melt Jet Stream during Casting of Metallic Glass Wires. Metals, 5(2), 1029-1044. https://doi.org/10.3390/met5021029