Comprehensive Investigation of Coverage Rates of Shot Peening on the Tribological Properties of 6061-T6 Alloy

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

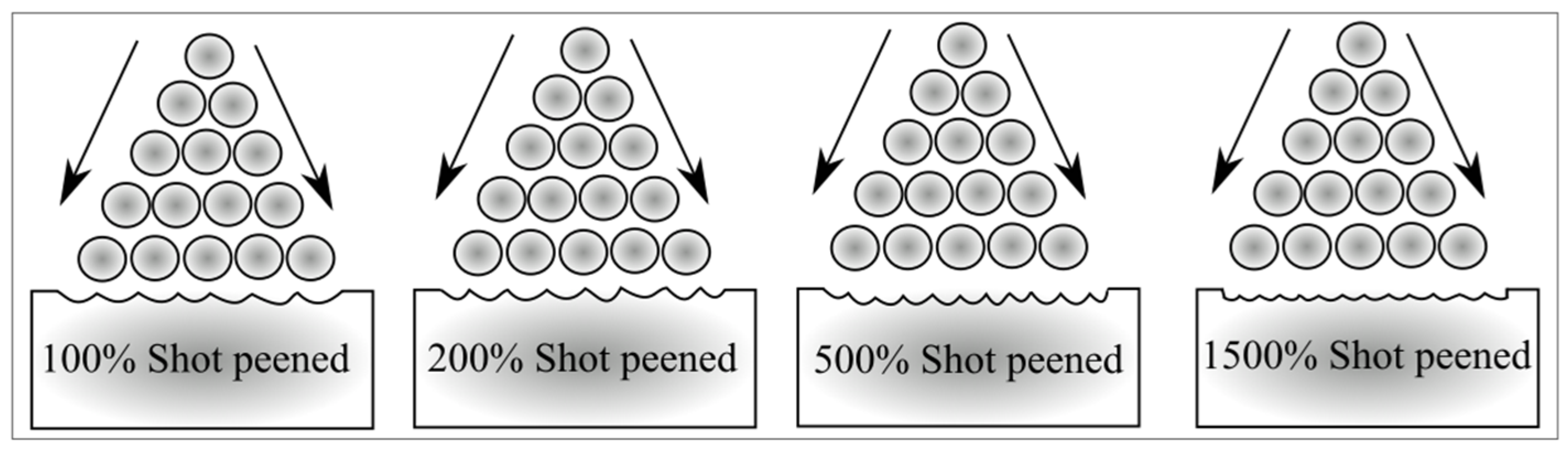

2.2. Shot Peening Process

2.3. Roughness Measurements

2.4. Microstructural Examinations

2.5. Microhardness Measurements

2.6. Residual Stress Evaluation

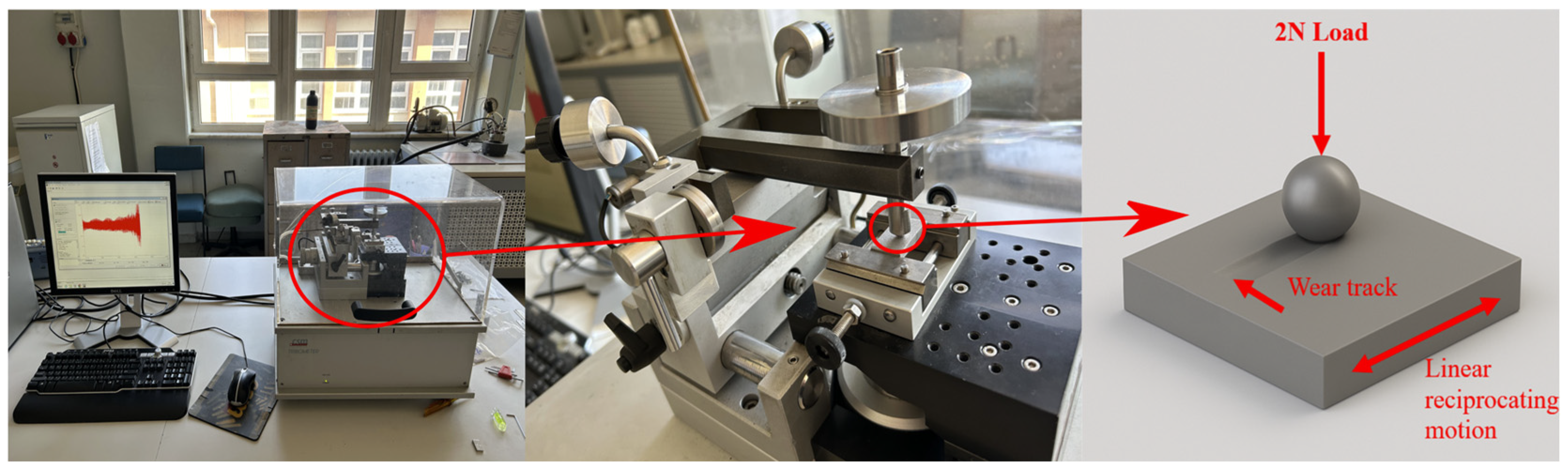

2.7. Wear Tests

2.8. SEM Analysis

3. Results and Discussion

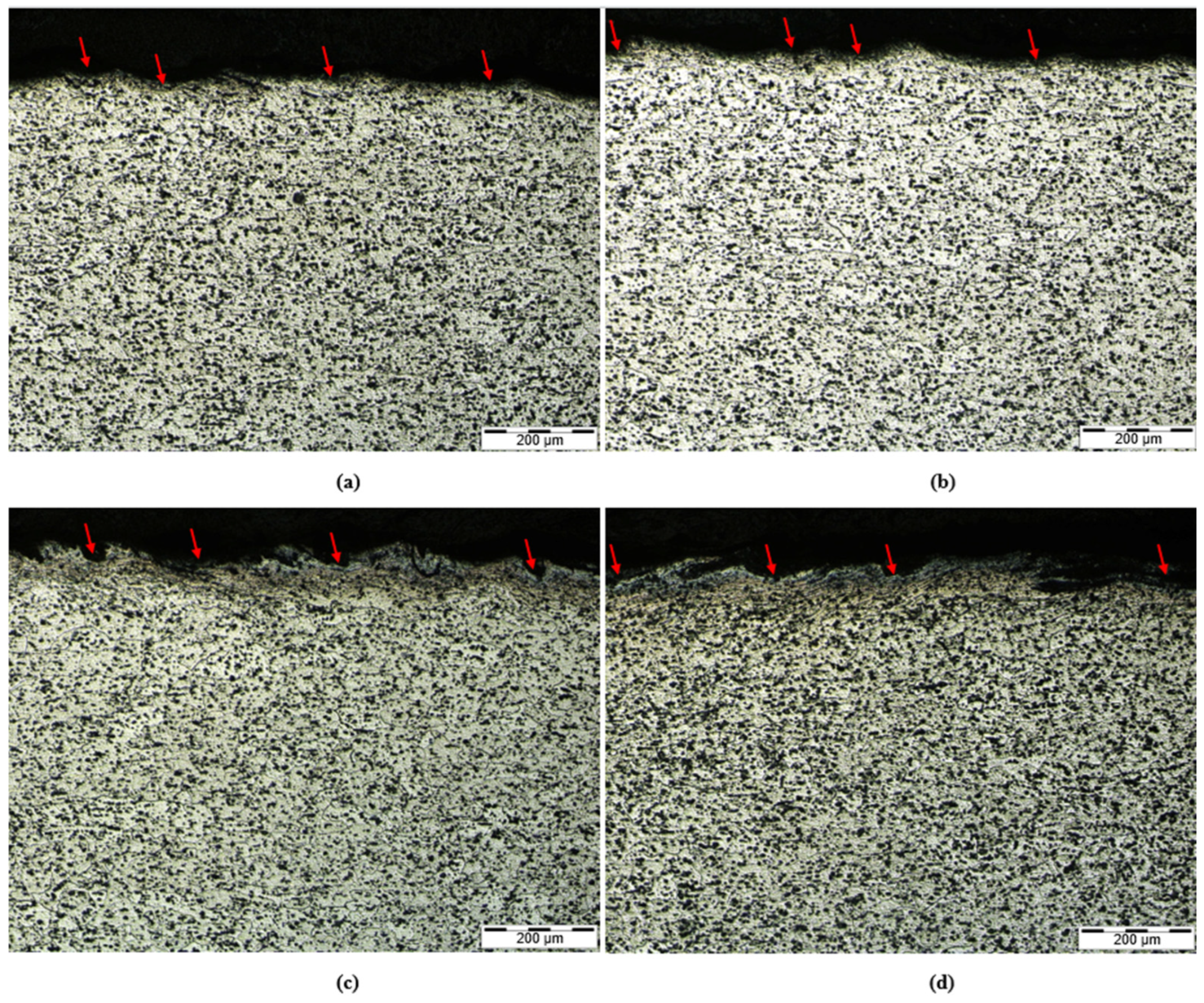

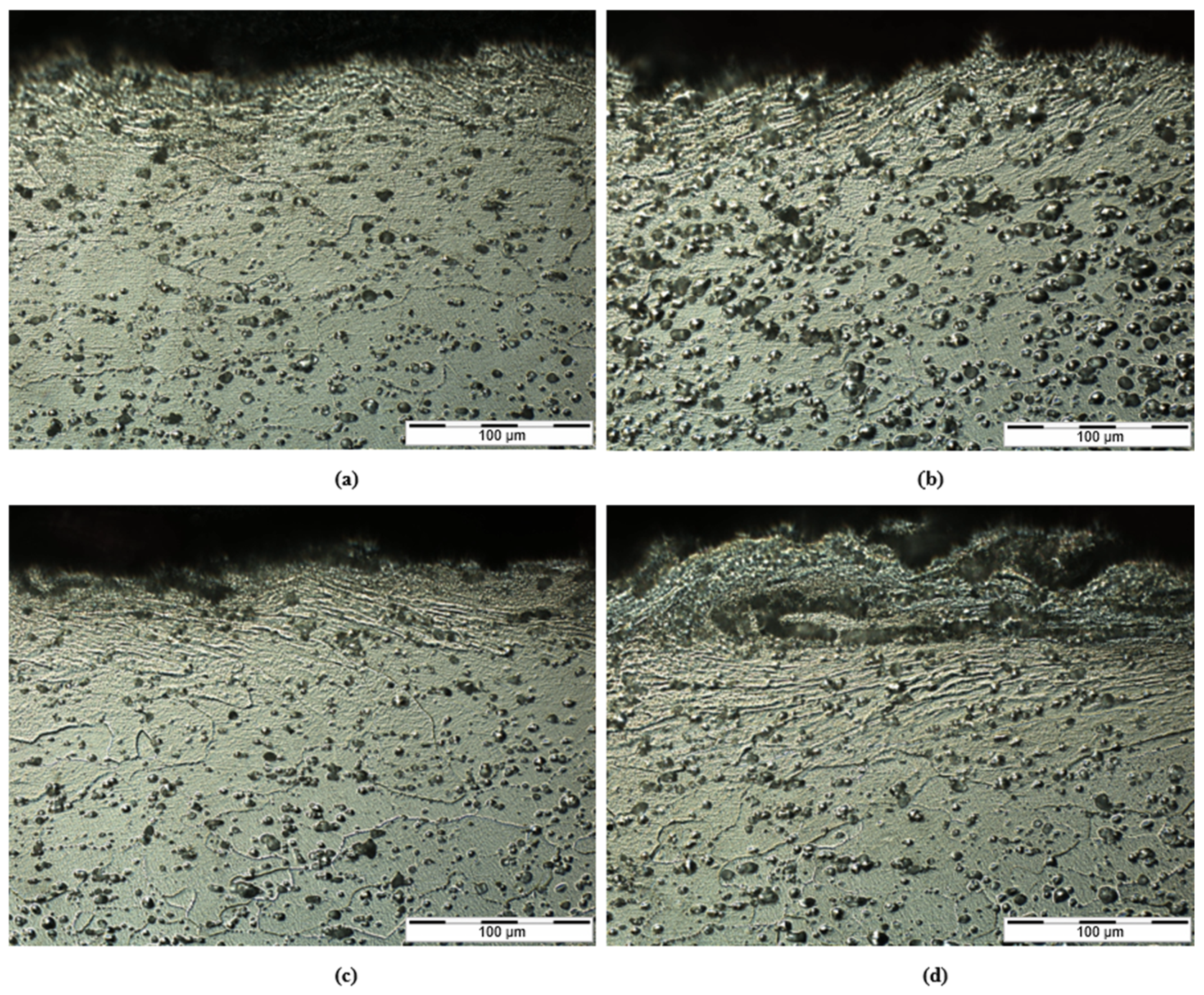

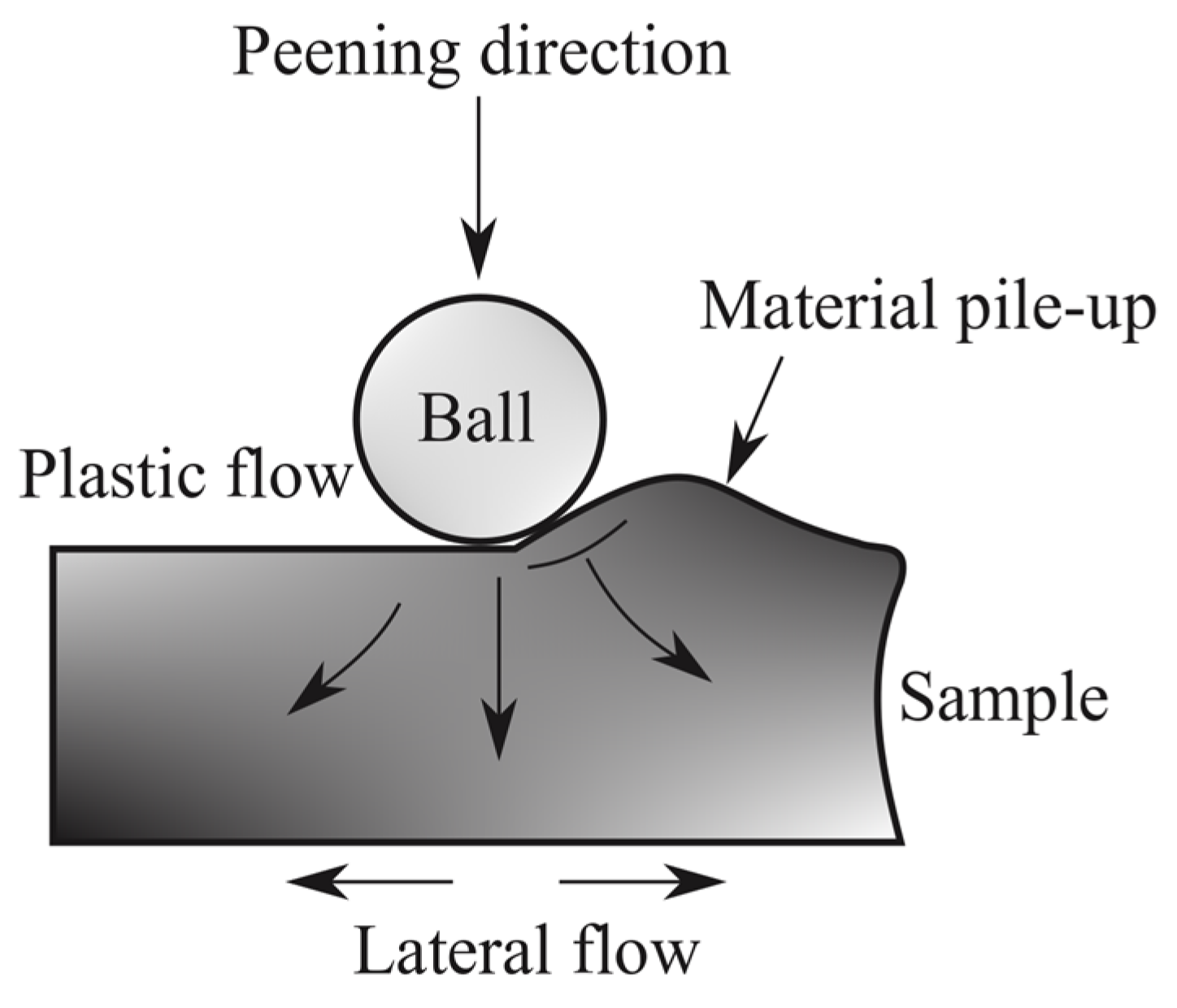

3.1. Microstructural and Surface Analysis

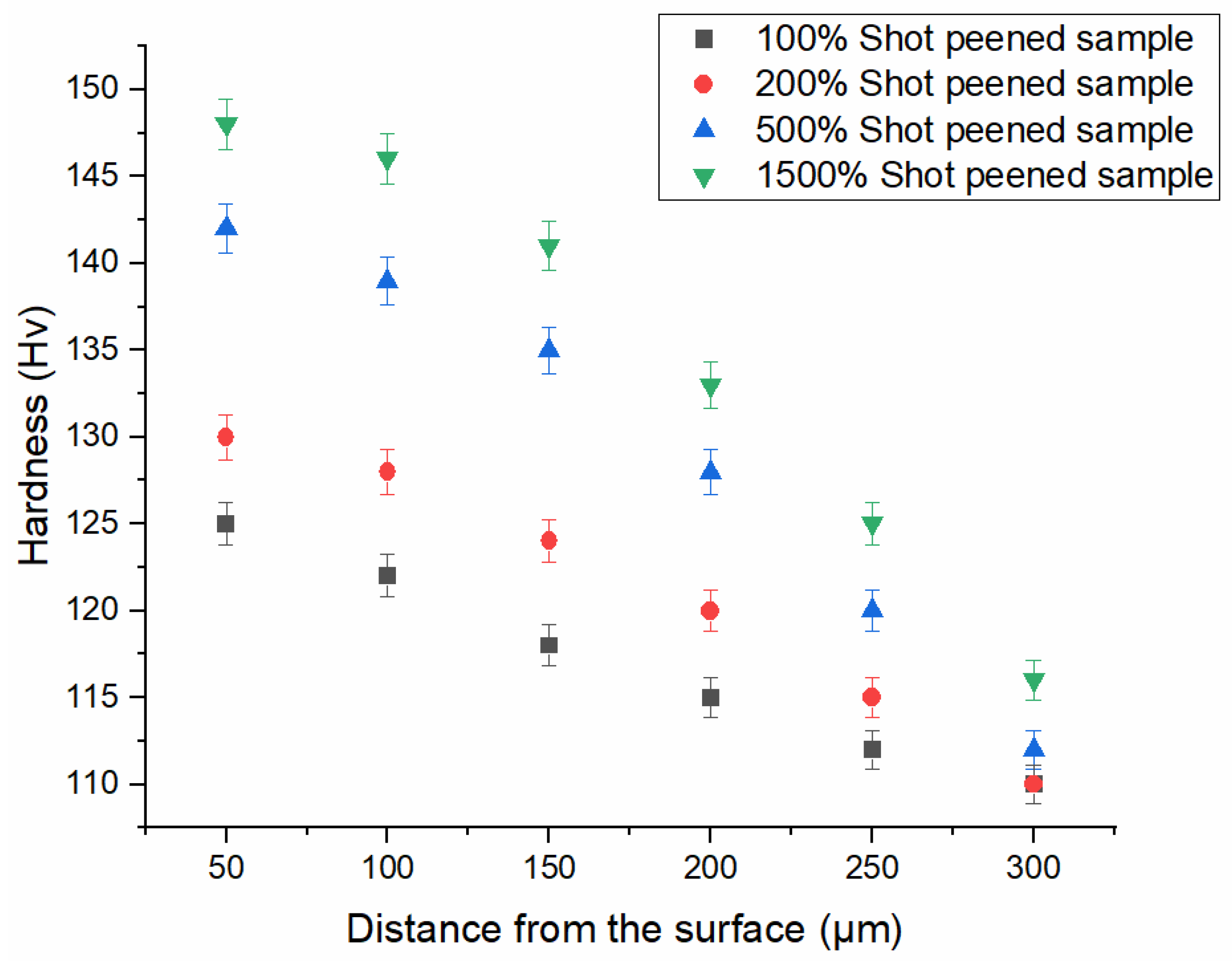

3.2. Hardness Results

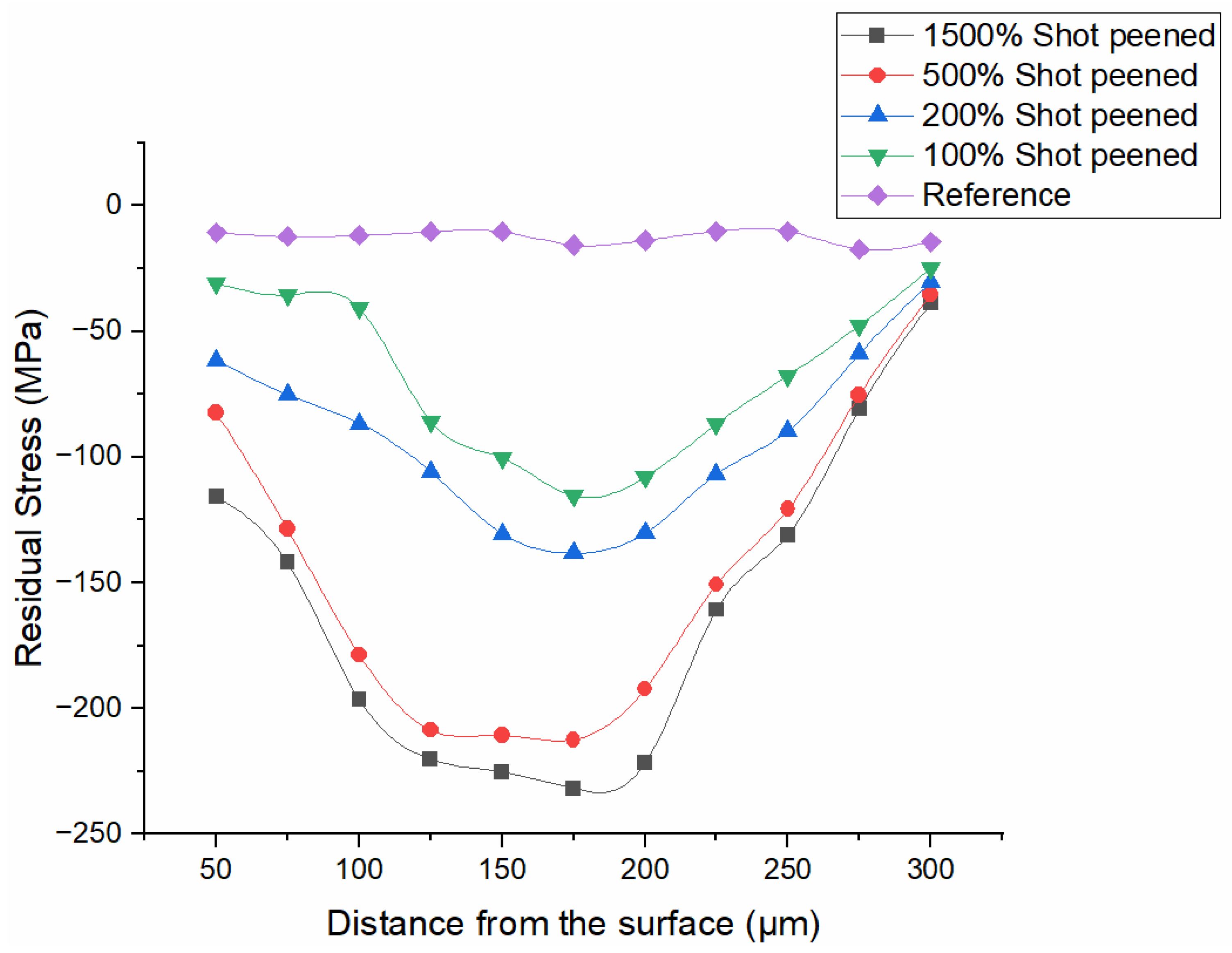

3.3. Residual Stress Analysis

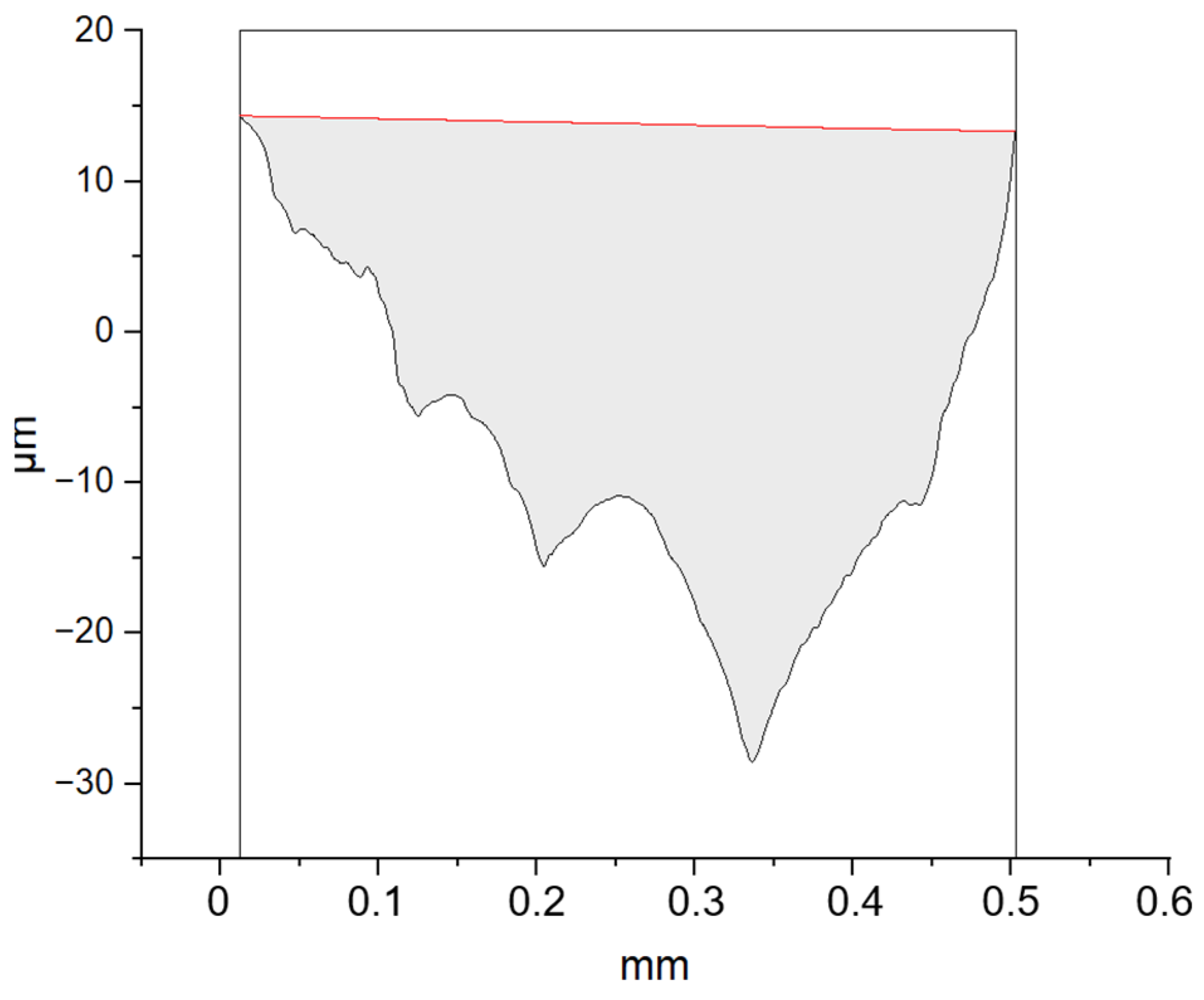

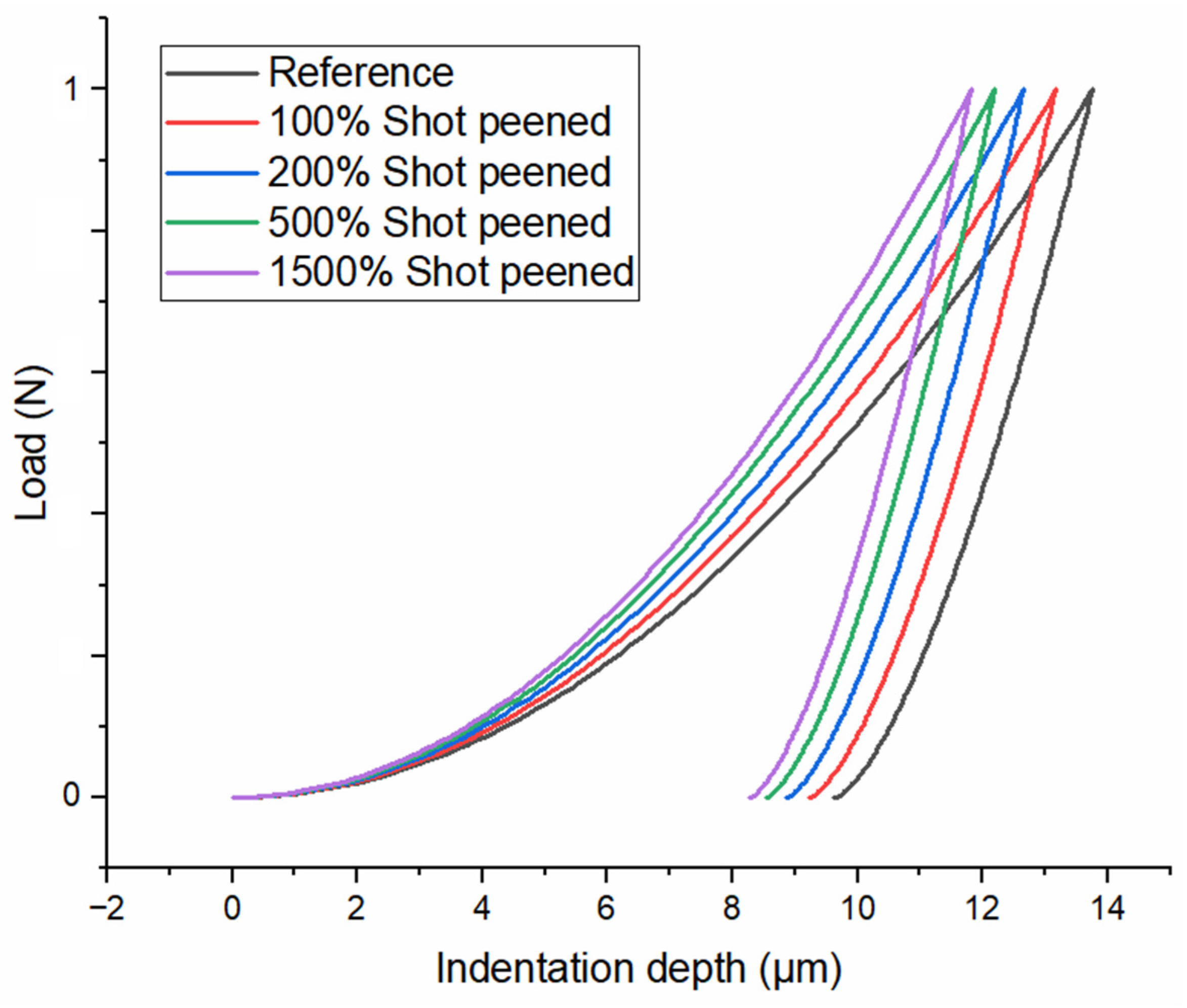

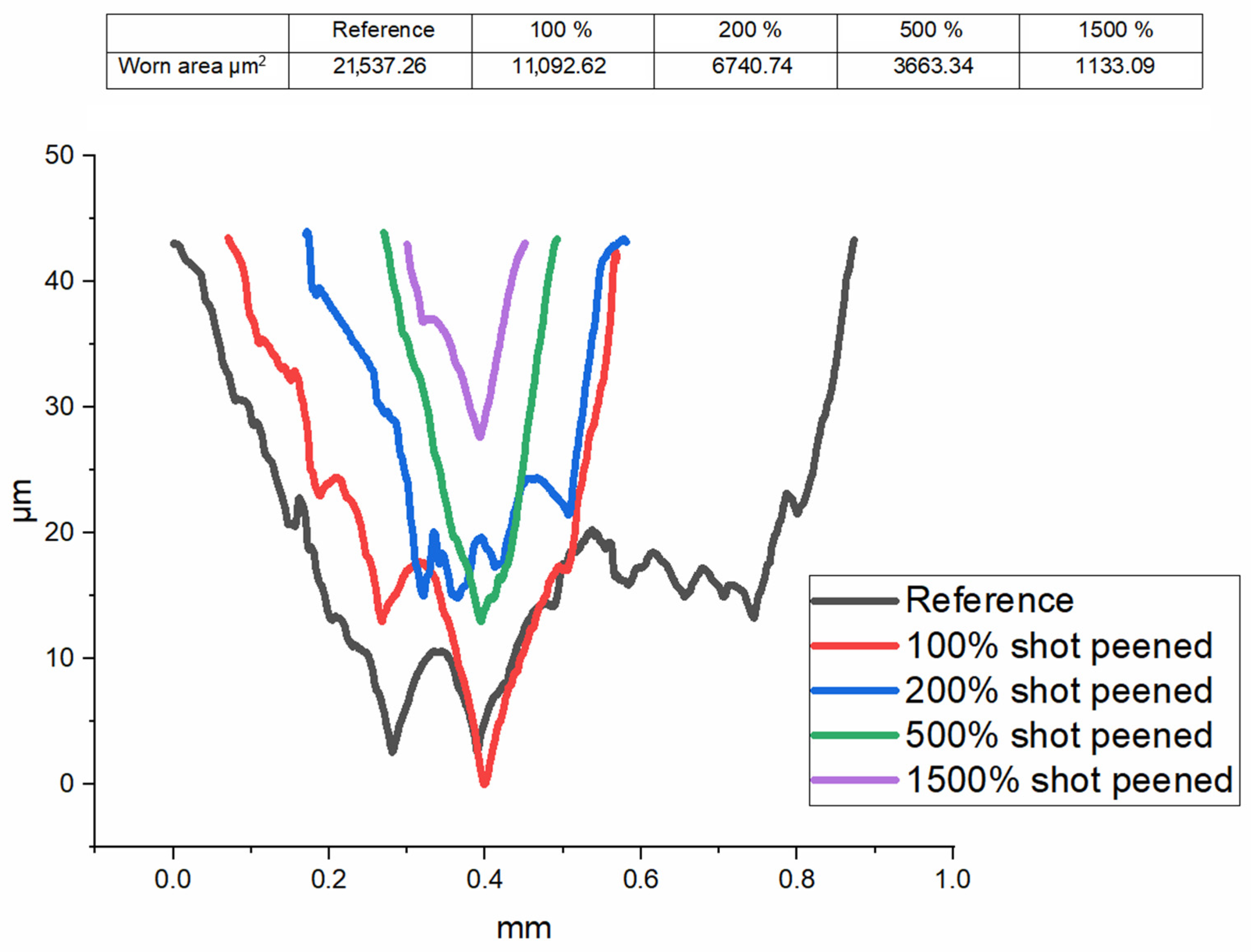

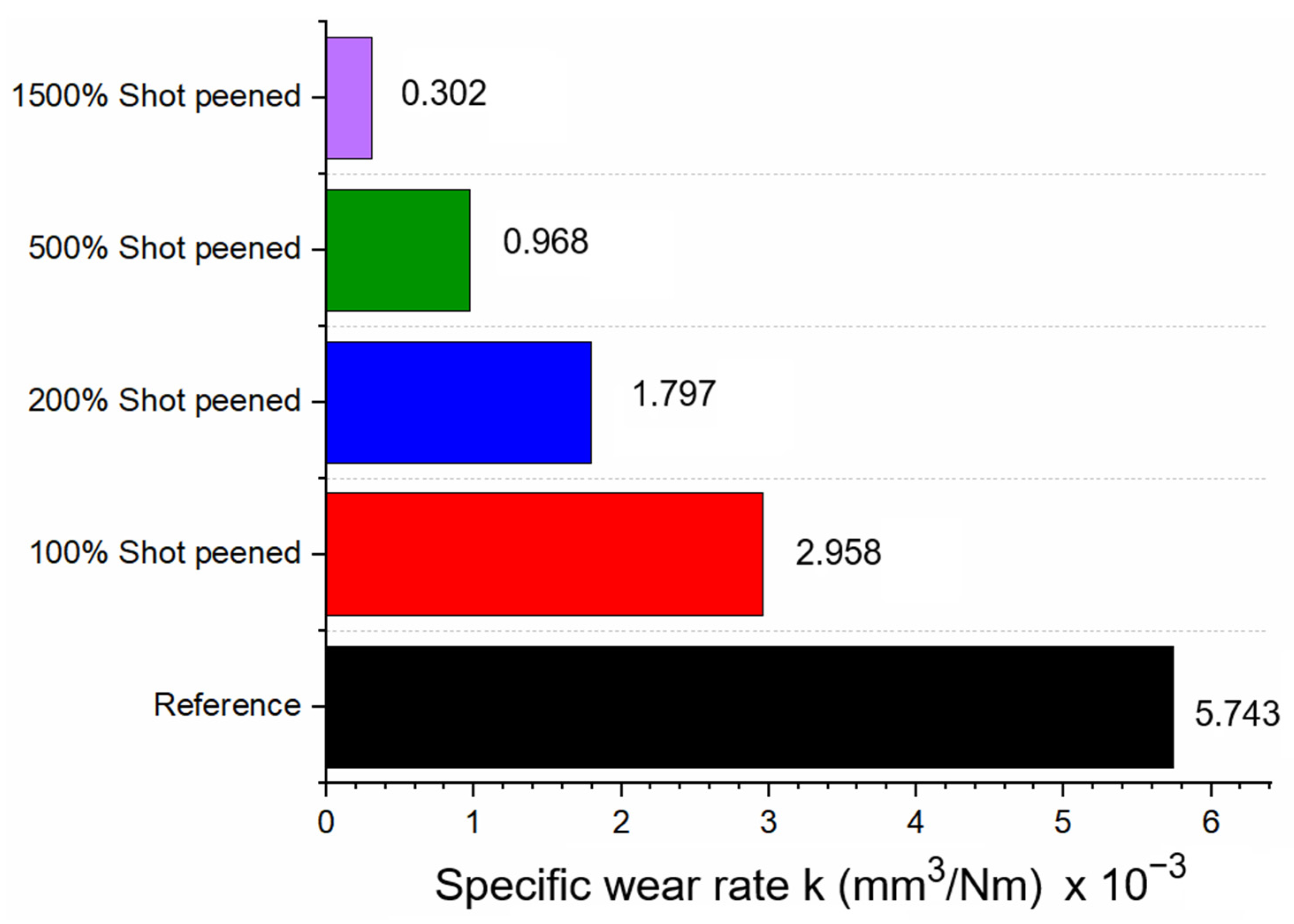

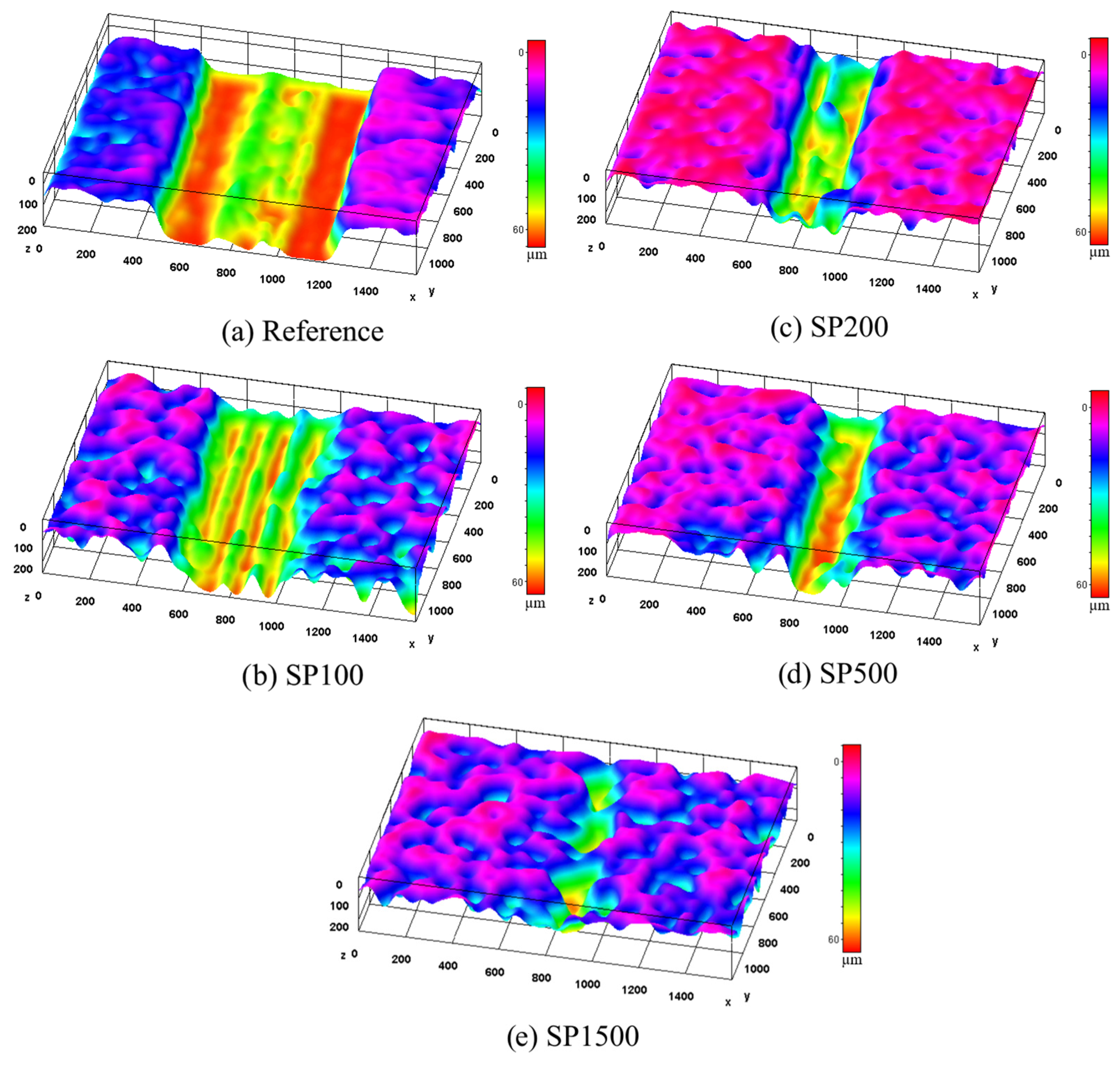

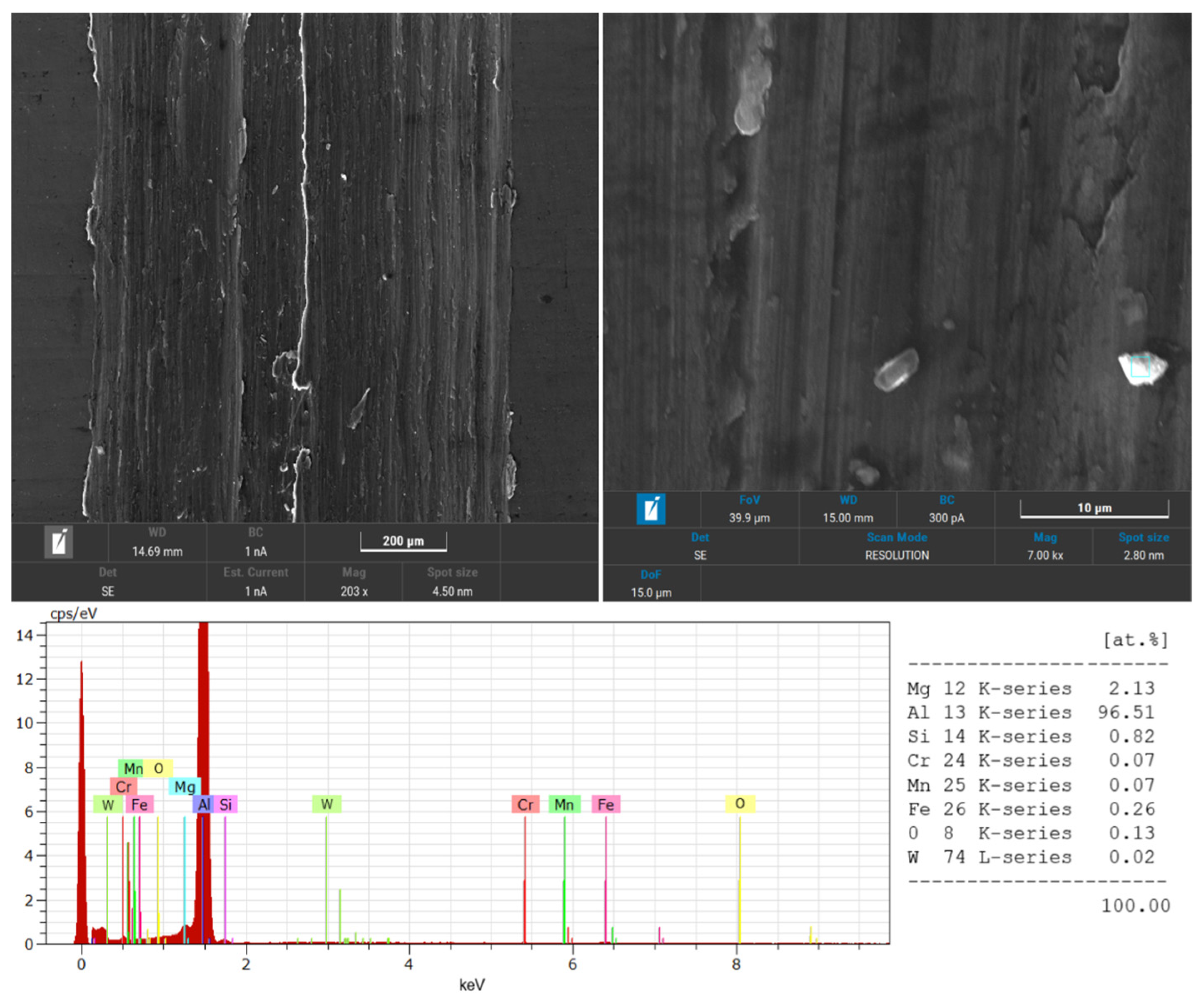

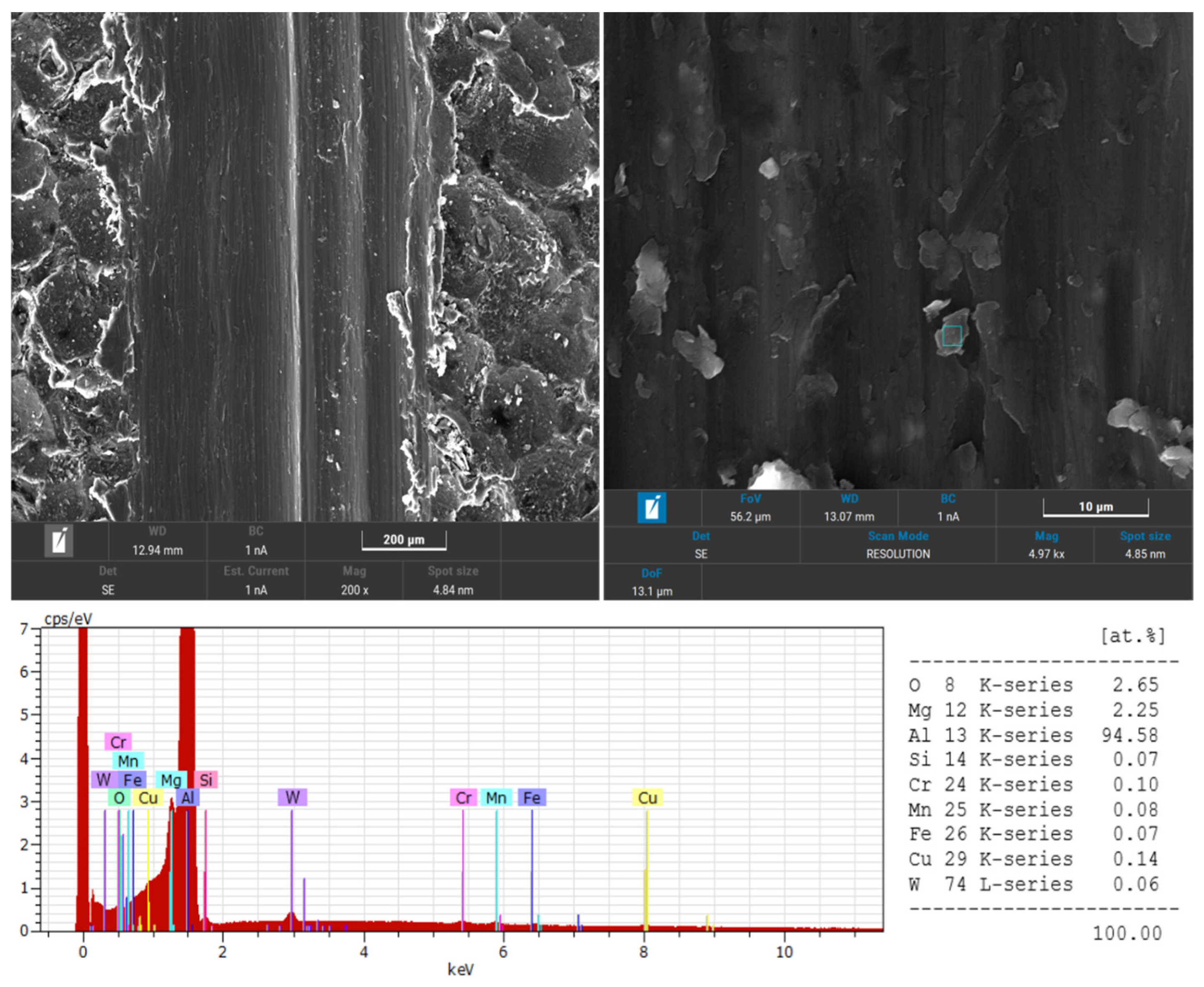

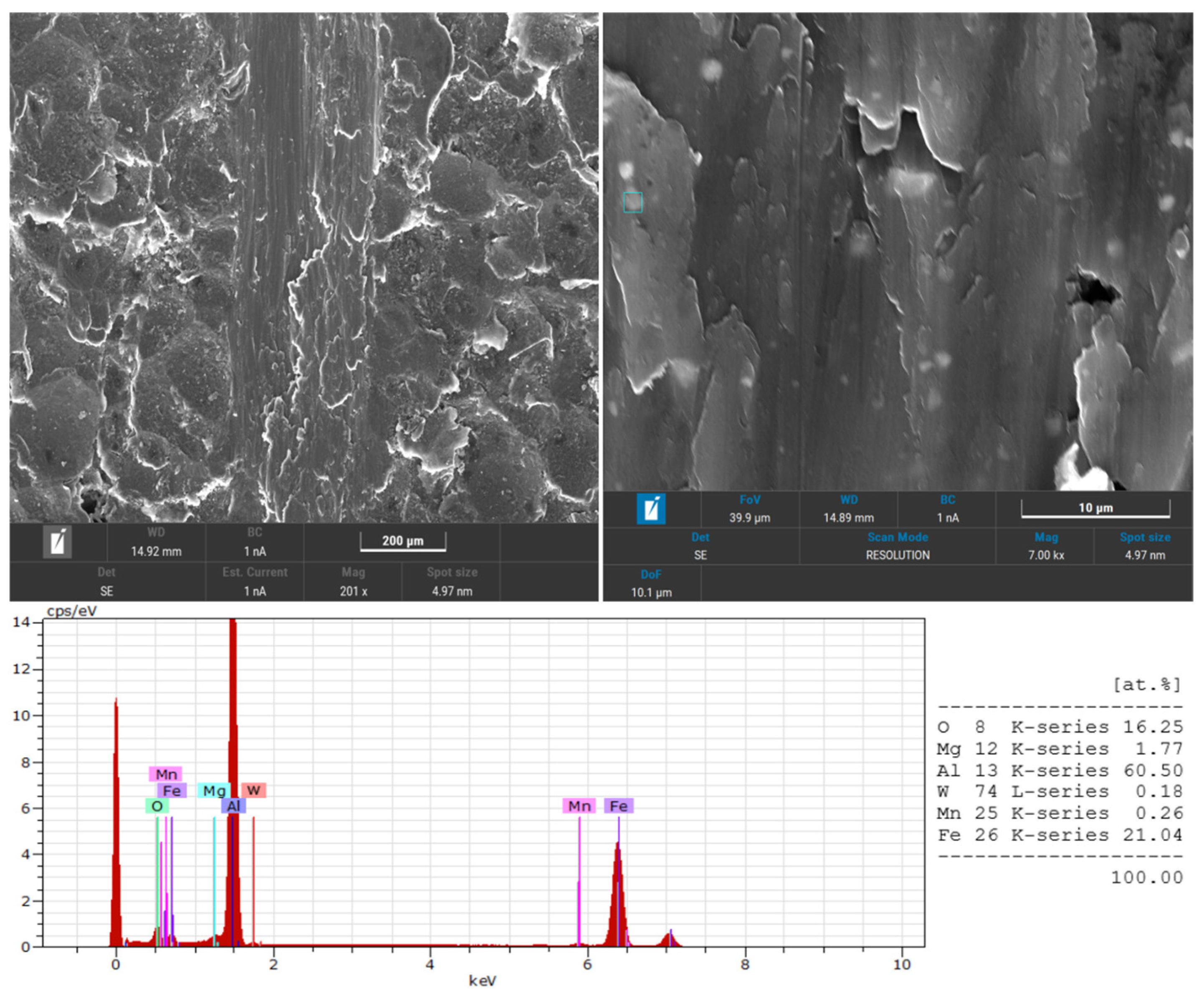

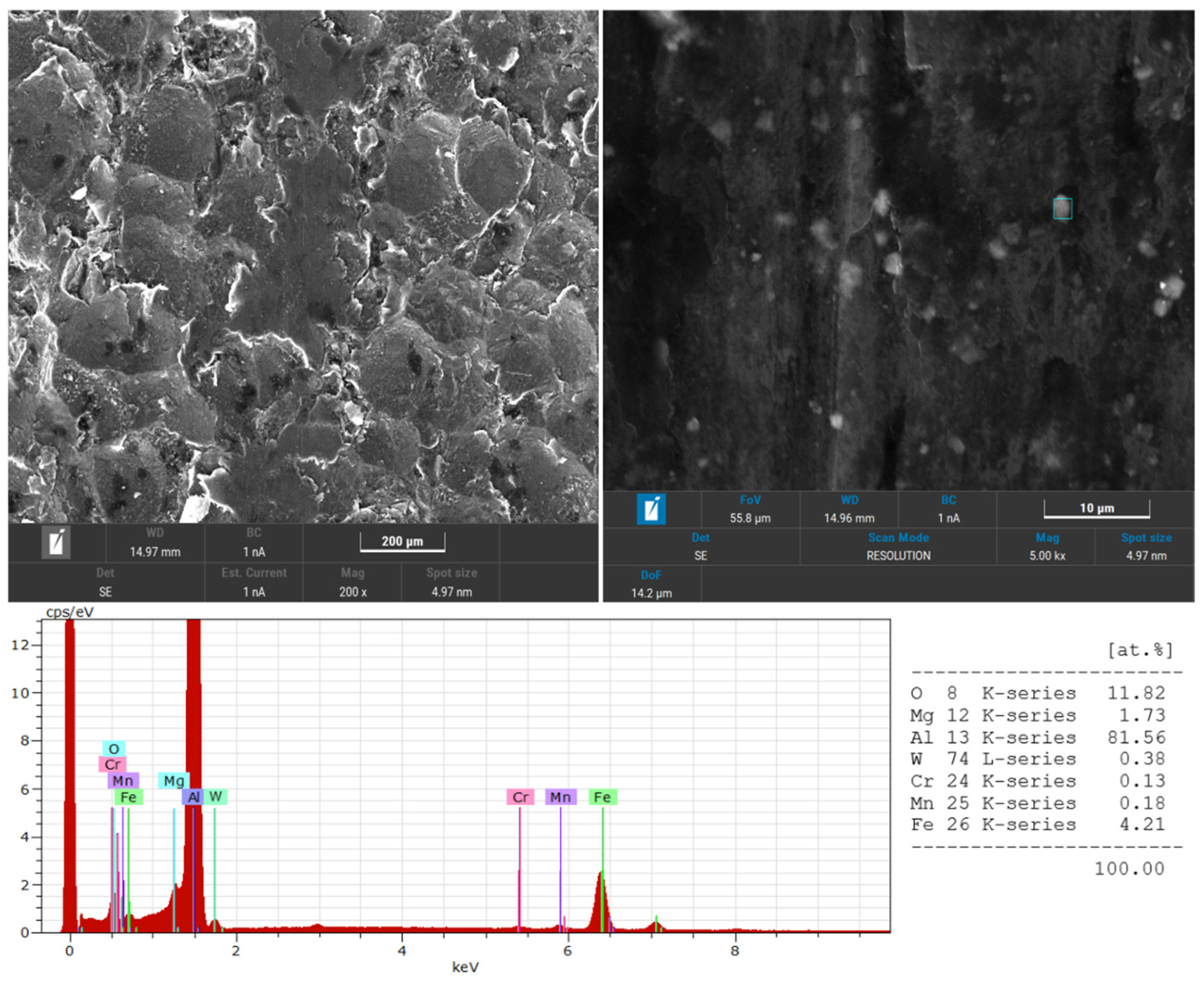

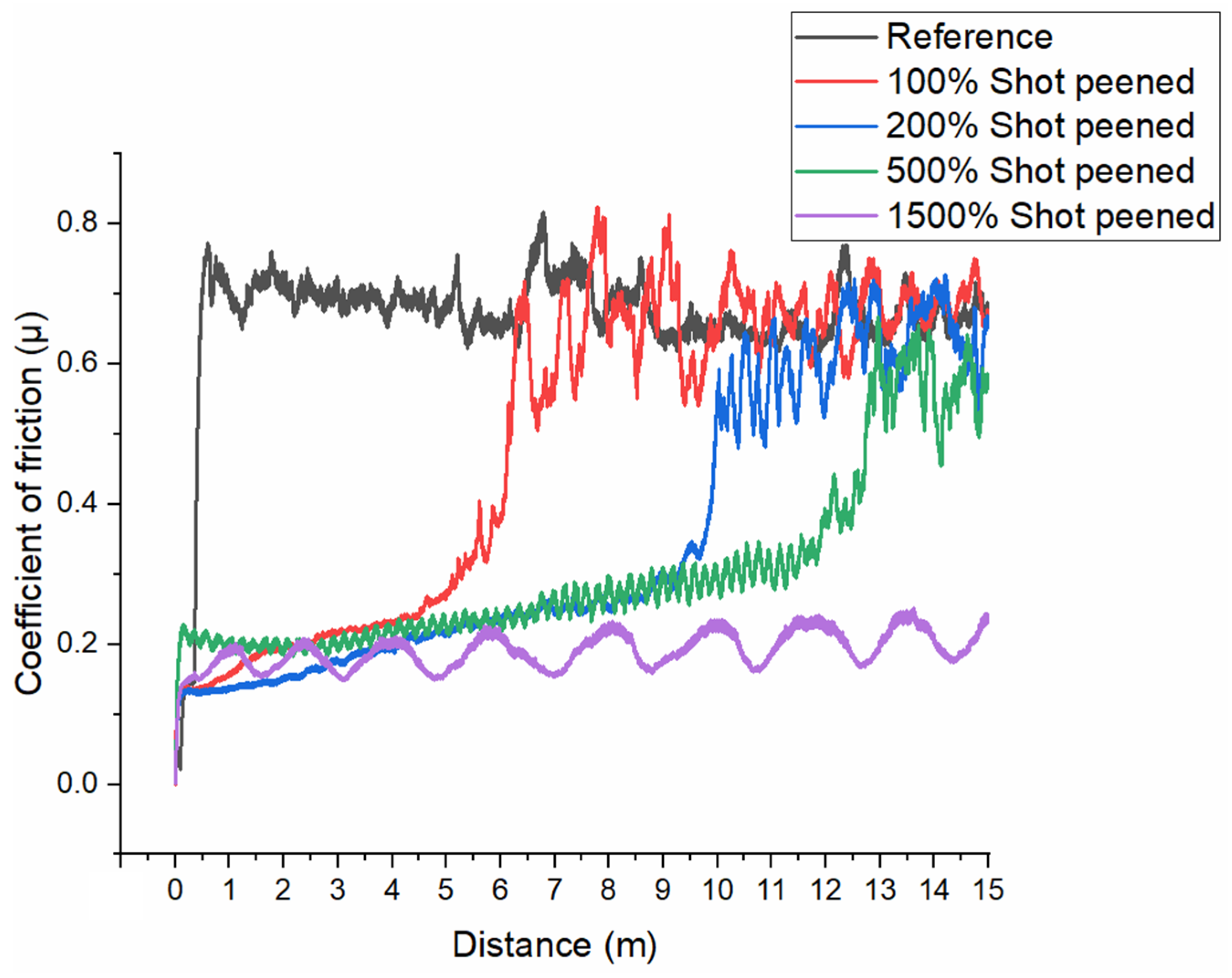

3.4. Wear Test Results

4. Conclusions

- (1)

- As the coverage rates increased, the thickness of the severely plastically deformed surface layer gradually increased.

- (2)

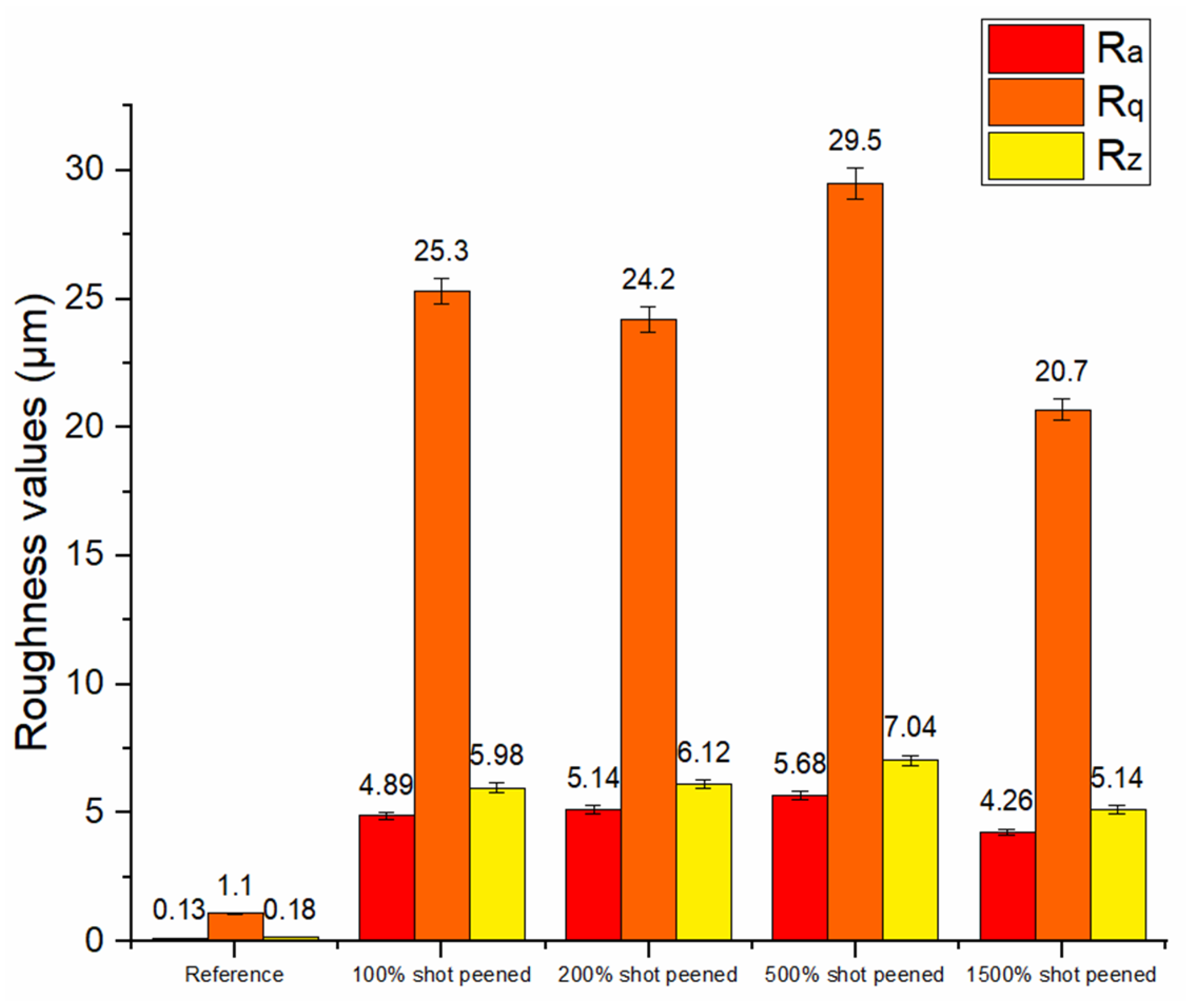

- The mean surface roughness value increased progressively from 100% to 500% coverage but decreased at 1500% coverage because of the repeated shot peening process.

- (3)

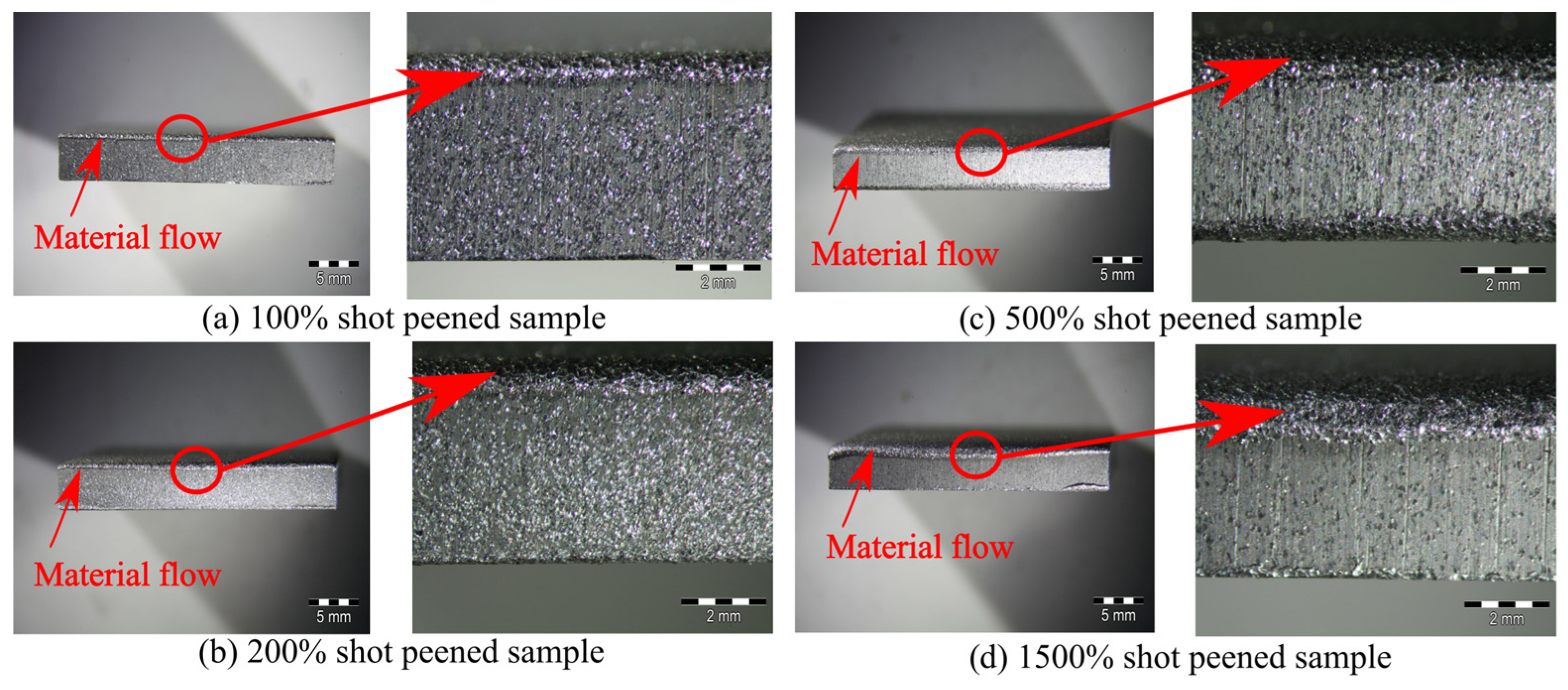

- The material flow along the top edge of the sample increased as the coverage rates increased.

- (4)

- The highest hardness value was obtained for the SP1500 sample, but it did not exhibit a significant increase in comparison to the SP500 sample. The same behavior was also observed for residual stress profiles.

- (5)

- According to the results of the specific wear rates, the sample with the highest wear resistance was SP1500.

- (6)

- During the ball-on-plate wear tests in dry sliding conditions, the main wear mechanisms were adhesive and abrasive and their combinations.

- (7)

- The obtained COF values showed that shot peening effectively enhanced tribological performance by altering surface characteristics, although its benefits were highly dependent on the coverage rate of the shot peening process. The mean COF values for the Sref, SP100, SP200, SP500, and SP1500 samples were obtained as 0.67, 0.66, 0.62, 0.57, and 0.19, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, H.; Dong, P.; Wei, Z. Microstructure and Properties of 6061 Aluminum Alloy by Additive Friction Stir Deposition. Metals 2025, 15, 539. [Google Scholar] [CrossRef]

- Al-Qutub, A.; Al-Hamed, A.A.S.; Mohammed, A.S. Elevated Temperature Tribological Performance of Submicron Alumina Particle-Reinforced 6061 Aluminum Alloy Under Dry Conditions. Arab. J. Sci. Eng. 2024, 49, 1597–1610. [Google Scholar] [CrossRef]

- Anand, S.H.; Venkateswaran, N.; Sathishkumar, B.; Rajeshkumar, L. Microstructural, Mechanical and Tribological Analysis of TiB2 Ceramic-Reinforced Al6061 Aluminum Alloy Composites. Arab. J. Sci. Eng. 2024, 49, 1827–1842. [Google Scholar] [CrossRef]

- Qu, L.; Ma, N.; Xiao, X.; Zhang, K.; Li, H. Microstructure and Properties of Nonlinear Lap Joint of 6061 Aluminum Alloy by Friction Stir Welding. Metals 2023, 13, 1494. [Google Scholar] [CrossRef]

- Rajeshshyam, R.; Venkatraman, R.; Raghuraman, S. Process Optimisation and Tribological Behaviour Studies on Surface Modified Al 6061-T6 Alloy Deposited with WS2 Solid Lubricant Layer Through Electrical Discharge Approach. Arab. J. Sci. Eng. 2022, 47, 8009–8030. [Google Scholar] [CrossRef]

- Oberreiter, M.; Horvath, M.; Stoschka, M.; Fladischer, S. Effect of Surface Finishing State on Fatigue Strength of Cast Aluminum and Steel Alloys. Materials 2023, 16, 4755. [Google Scholar] [CrossRef] [PubMed]

- Žagar, S.; Mrvar, P.; Grum, J.; Šturm, R. The Influence of Shot Peening and Artificially Ageing Aluminum Alloy 7075 on Corrosion Behaviour. Materials 2022, 15, 3094. [Google Scholar] [CrossRef] [PubMed]

- Žagar, S.; Markoli, B.; Naglič, I.; Šturm, R. The Influence of Age Hardening and Shot Peening on the Surface Properties of 7075 Aluminum Alloy. Materials 2021, 14, 2220. [Google Scholar] [CrossRef] [PubMed]

- Tekkalmaz, M.; Er, Ü.; Çakir, F.H.; Bozkurt, F. A New Approach to Monitoring the Operational Success of Shot Peening with Electromechanical Impedance Technique. Int. J. Adv. Manuf. Technol. 2021, 117, 3503–3513. [Google Scholar] [CrossRef]

- Çakir, F.H.; Öteyaka, M.Ö.; Er, Ü.; Bozkurt, F. Enhancing Wear Resistance of AISI 304 Alloy with Shot Peening and Investigation of Corrosion Behaviour in Marine Water. Trans. IMF 2021, 99, 194–202. [Google Scholar] [CrossRef]

- Wang, T.; Wang, J.B.; Zhang, X.J.; Liu, C. A Study on Prediction of Process Parameters of Shot Peen Forming Using Artificial Neural Network Optimized by Genetic Algorithm. Arab. J. Sci. Eng. 2021, 46, 7349–7361. [Google Scholar] [CrossRef]

- Chen, B.; Huang, B.; Liu, H.; Li, X.; Ni, M.; Lu, C. Surface Nanocrystallization Induced by Shot Peening and Its Effect on Corrosion Resistance of 6061 Aluminum Alloy. J. Mater. Res. 2014, 29, 3002–3010. [Google Scholar] [CrossRef]

- Mohammadi, S.; Irani, M.; Taheri, A.K. The Effects of Combination of Severe Plastic Deformation and Shot Peening Surface Treatment on Fatigue Behavior of 6082 Aluminum Alloy. Russ. J. Non-Ferr. Met. 2015, 56, 206–211. [Google Scholar] [CrossRef]

- Sun, Q.; Han, Q.; Wang, S.; Xu, R. Microstructure, Corrosion Behaviour and Thermal Stability of AA 7150 after Ultrasonic Shot Peening. Surf. Coat. Technol. 2020, 398, 126127. [Google Scholar] [CrossRef]

- Ravnikar, D.; Šturm, R.; Žagar, S. Effect of Shot Peening on the Strength and Corrosion Properties of 6082-T651 Aluminum Alloy. Materials 2023, 16, 4976. [Google Scholar] [CrossRef] [PubMed]

- Mathi, P.; Prasad, C.R.; Chembuly, V.V.M.J.S.; Sai, A.N.; Chekuri, R.B.R.; Penmetsa, R.V.; Gudaru, K.R. Effect of Shot Peening-Induced Microstructure and Precipitate Evolutions on the Surface Residual Stresses, Hardness, and Wear Behavior of Al 6061 Alloy. J. Inst. Eng. India Ser. D 2025. [Google Scholar] [CrossRef]

- Park, S.J.; Heogh, W.; Yang, J.; Kang, S.; Jeong, W.; Lee, H.; Jang, T.-S.; Jung, H.-D.; Jahazi, M.; Han, S.C.; et al. Meta-Structure of Amorphous-Inspired 65.1Co28.2Cr5.3Mo Lattices Augmented by Artificial Intelligence. Adv. Compos. Hybrid Mater. 2024, 7, 224. [Google Scholar] [CrossRef] [PubMed]

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Wang, Q.; Ozaki, K.; Ishikawa, H.; Nakano, S.; Ogiso, H. Indentation Method to Measure the Residual Stress Induced by Ion Implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Interact. 2006, 242, 88–92. [Google Scholar] [CrossRef]

- ASTM G133-22; Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM International: West Conshohocken, PA, USA, 2022.

- Ji, H.; Hu, Y.; Yu, R.; Liu, S.; Pei, W.; Wang, B. Experimental Study on TIG Full Welding and Single Pass Welding Quality of 6061-T6 Aluminum Alloy Sheet. J. Mater. Res. Technol. 2023, 27, 5965–5976. [Google Scholar] [CrossRef]

- Jiang, Y.; Qiu, X.; Song, Z.; Dai, S.; Chen, Z.; Wang, X.; Wu, C.; Ren, X.; Meng, C. New Insights into Enhancing the Mechanical Properties of 6061-T6 Aluminum Alloy MIG Welded Joints by Constructing Bionic Heterostructure. Mater. Sci. Eng. A 2024, 912, 147009. [Google Scholar] [CrossRef]

- Bao, L.; Li, K.; Zheng, J.; Zhang, Y.; Zhan, K.; Yang, Z.; Zhao, B.; Ji, V. Surface Characteristics and Stress Corrosion Behavior of AA 7075-T6 Aluminum Alloys after Different Shot Peening Processes. Surf. Coat. Technol. 2022, 440, 128481. [Google Scholar] [CrossRef]

- Su, C.-H.; Chen, T.-C.; Ding, Y.-S.; Lu, G.-X.; Tsay, L.-W. Effects of Micro-Shot Peening on the Fatigue Strength of Anodized 7075-T6 Alloy. Materials 2023, 16, 1160. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, L.; Zhang, Q.; Ali, R.A.; Chen, W.; Zhou, L. Surface Layer Strengthening Mechanism of 2060 Aluminum–Lithium Alloy after Shot-Peening. J. Mater. Res. Technol. 2023, 23, 4615–4633. [Google Scholar] [CrossRef]

- Si, C.; Sun, W.; Tian, Y.; Cai, J. Cavitation Erosion Resistance Enhancement of the Surface Modified 2024T351 Al Alloy by Ultrasonic Shot Peening. Surf. Coat. Technol. 2023, 452, 129122. [Google Scholar] [CrossRef]

- John, M.; Ralls, A.M.; Misra, M.; Menezes, P.L. Effect of Ultrasonic Impact Peening on Stress Corrosion Cracking Resistance of Austenitic Stainless-Steel Welds for Nuclear Canister Applications. J. Nucl. Mater. 2023, 584, 154590. [Google Scholar] [CrossRef]

- Er, Ü.; Bozkurt, F. Investigation of the Effects of Cryogenic Treatment on the Friction and Wear Properties of 36CrB4 Boron Steel. Arab. J. Sci. Eng. 2022, 47, 16209–16221. [Google Scholar] [CrossRef]

- Liu, X.; Yang, M.; Zhou, D.; Zhao, Y. Microstructure and Wear Resistance of Mg2Si–Al Composites Fabricated Using Semi-Solid Extrusion. Metals 2020, 10, 596. [Google Scholar] [CrossRef]

- Tebib, M.; Samuel, A.M.; Ajersch, F.; Chen, X.-G. Effect of P and Sr Additions on the Microstructure of Hypereutectic Al–15Si–14Mg–4Cu Alloy. Mater. Charact. 2014, 89, 112–123. [Google Scholar] [CrossRef]

- Bozkurt, F. The Effect of Anodizing Time on the Tribological Properties of 6061-T6 Aluminum Alloy. In Proceedings of the 33rd International Conference on Metallurgy and Materials, Brno, Czech Republic, 22–24 May 2024; pp. 373–379. [Google Scholar]

- Amanov, A.; Sasaki, S.; Kim, D.; Penkov, O.V.; Pyun, Y. Improvement of the Tribological Properties of Al6061–T6 Alloy under Dry Sliding Conditions. Tribol. Int. 2013, 64, 24–32. [Google Scholar] [CrossRef]

- Chang, Y.-P.; Liu, C.-T.; Chu, L.-M.; Chou, H.-M. Wear Mechanisms of Aluminum 5083/6061/7075 with and without T6 Treatment. Adv. Mech. Eng. 2023, 15, 16878132231201000. [Google Scholar] [CrossRef]

| Fe | Si | Mn | Cr | Ti | Cu | Mg | Zn | Al |

| 0.41 | 0.70 | 0.14 | 0.17 | 0.04 | 0.24 | 0.86 | 0.05 | Balance |

| Counter Body | Load | Distance | Stroke | Speed | Temperature | Condition |

|---|---|---|---|---|---|---|

| Ø3 mm, WC-%6 Co | 2 N | 15 m | 8 mm | 2.5 cm/s | 21 °C | Dry |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canbulat, O.; Bozkurt, F. Comprehensive Investigation of Coverage Rates of Shot Peening on the Tribological Properties of 6061-T6 Alloy. Metals 2025, 15, 964. https://doi.org/10.3390/met15090964

Canbulat O, Bozkurt F. Comprehensive Investigation of Coverage Rates of Shot Peening on the Tribological Properties of 6061-T6 Alloy. Metals. 2025; 15(9):964. https://doi.org/10.3390/met15090964

Chicago/Turabian StyleCanbulat, Orçun, and Fatih Bozkurt. 2025. "Comprehensive Investigation of Coverage Rates of Shot Peening on the Tribological Properties of 6061-T6 Alloy" Metals 15, no. 9: 964. https://doi.org/10.3390/met15090964

APA StyleCanbulat, O., & Bozkurt, F. (2025). Comprehensive Investigation of Coverage Rates of Shot Peening on the Tribological Properties of 6061-T6 Alloy. Metals, 15(9), 964. https://doi.org/10.3390/met15090964