Effects of Sintering Pressure and Co Content on the Microstructure and Mechanical Performance of WC–Co Cemented Carbides

Abstract

1. Introduction

2. Materials and Methods

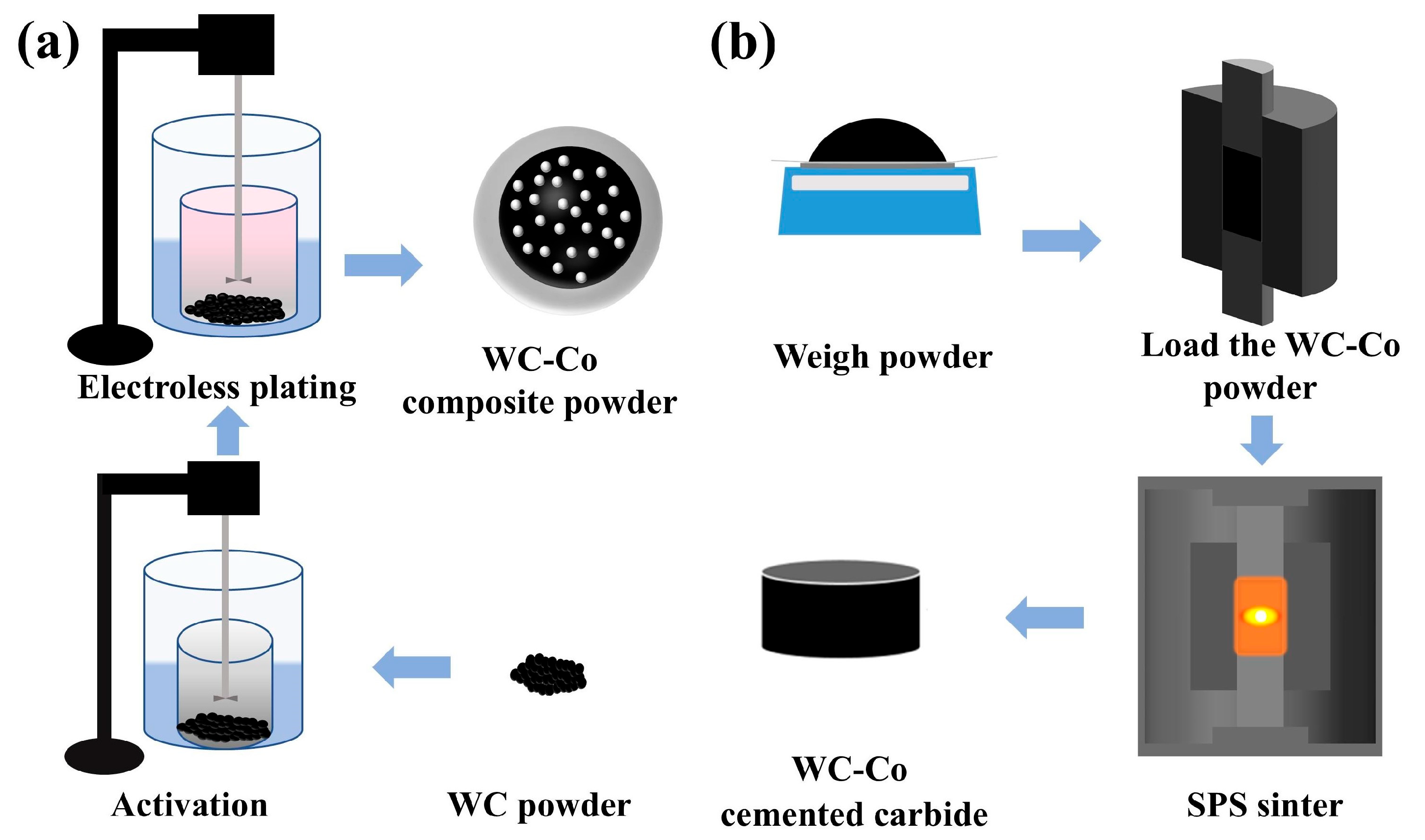

2.1. Preparation of WC–Co Composite Powders

2.2. Spark Plasma Sintering

2.3. Microstructural Characterization

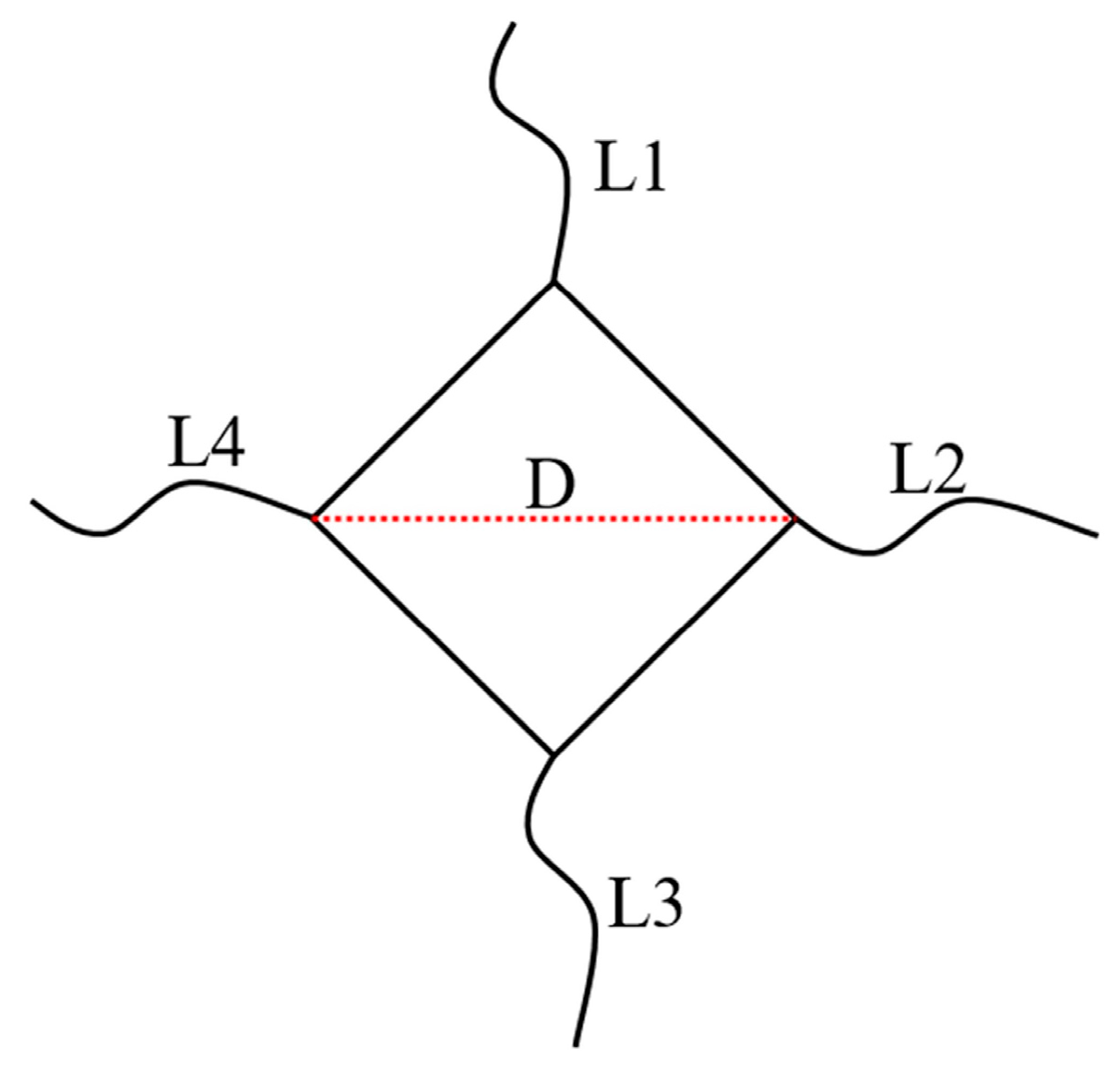

2.4. Mechanical Characterization

3. Results and Discussion

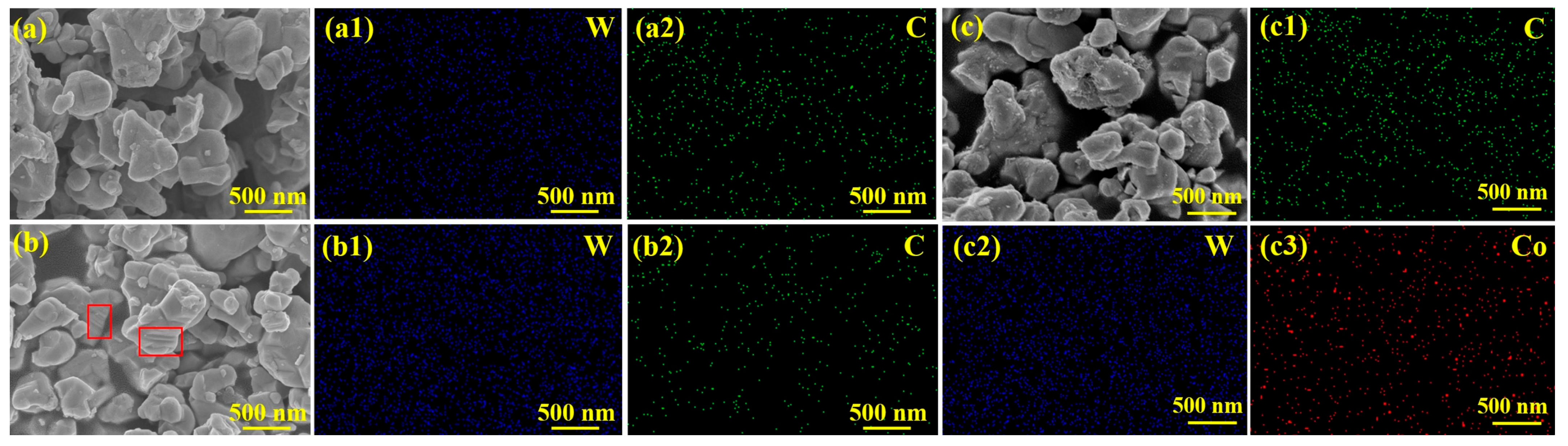

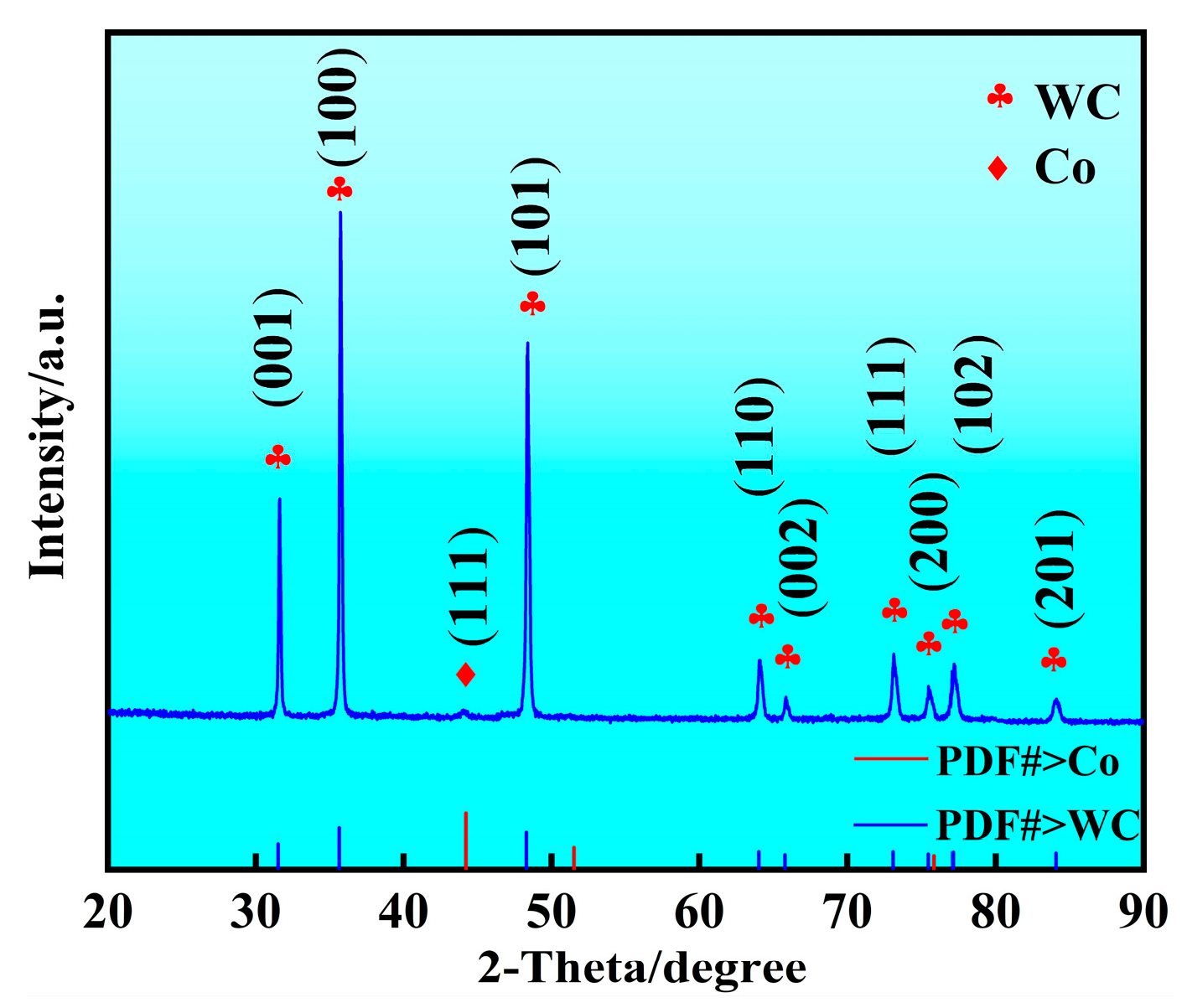

3.1. Microstructural Analysis of Coated WC–Co Composite Powders

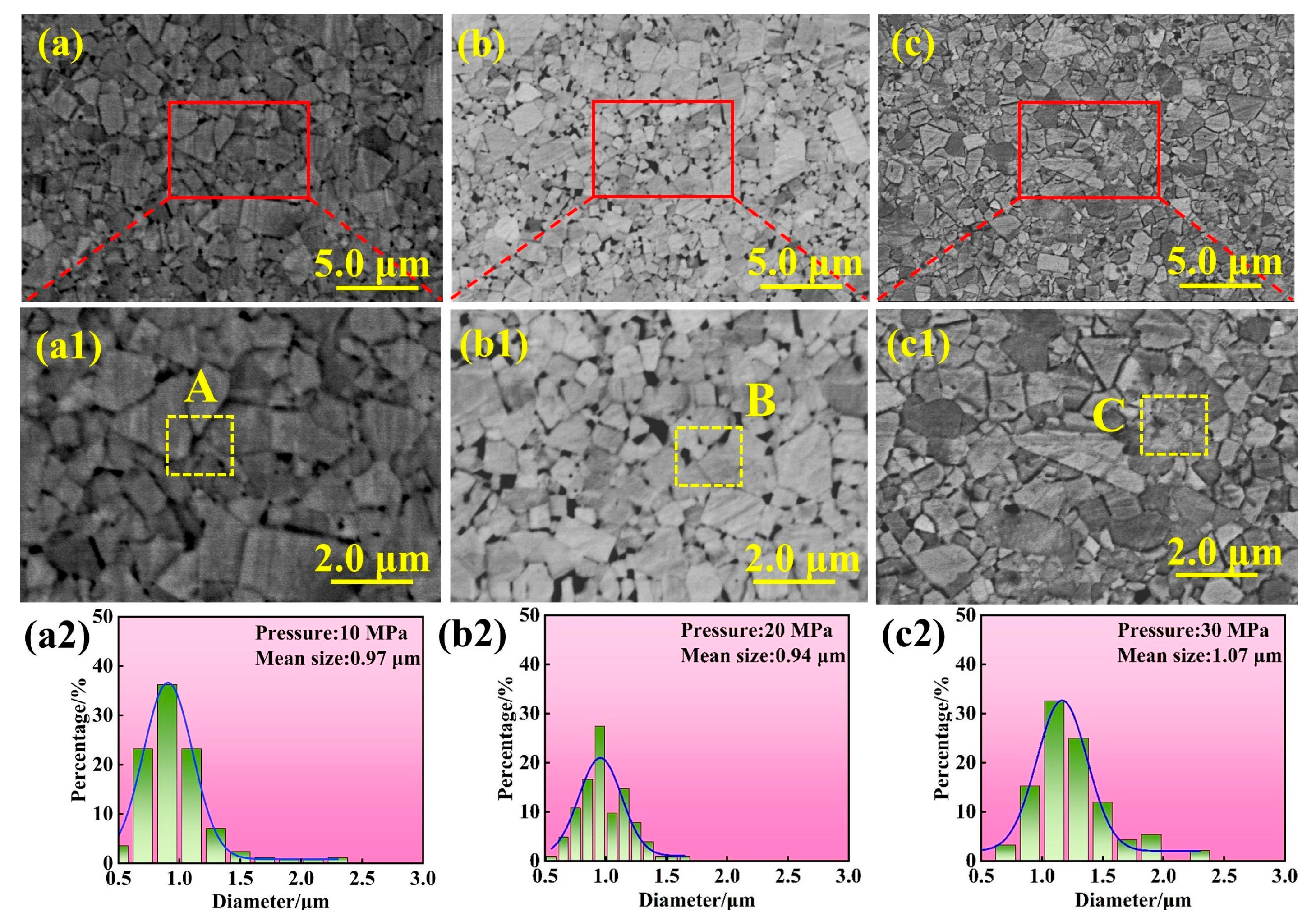

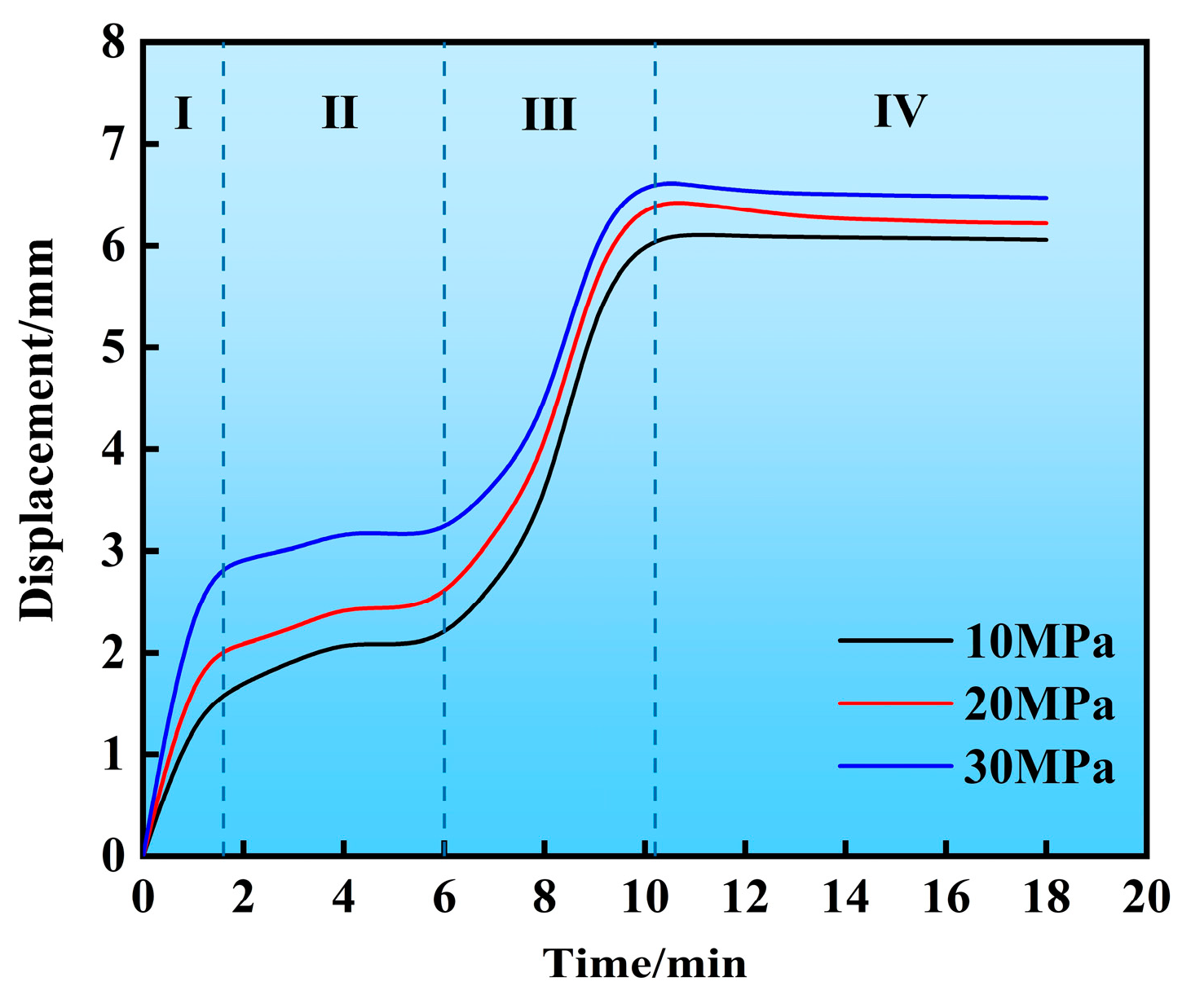

3.2. Effects of Sintering Pressure on the Microstructure of Cemented Carbides

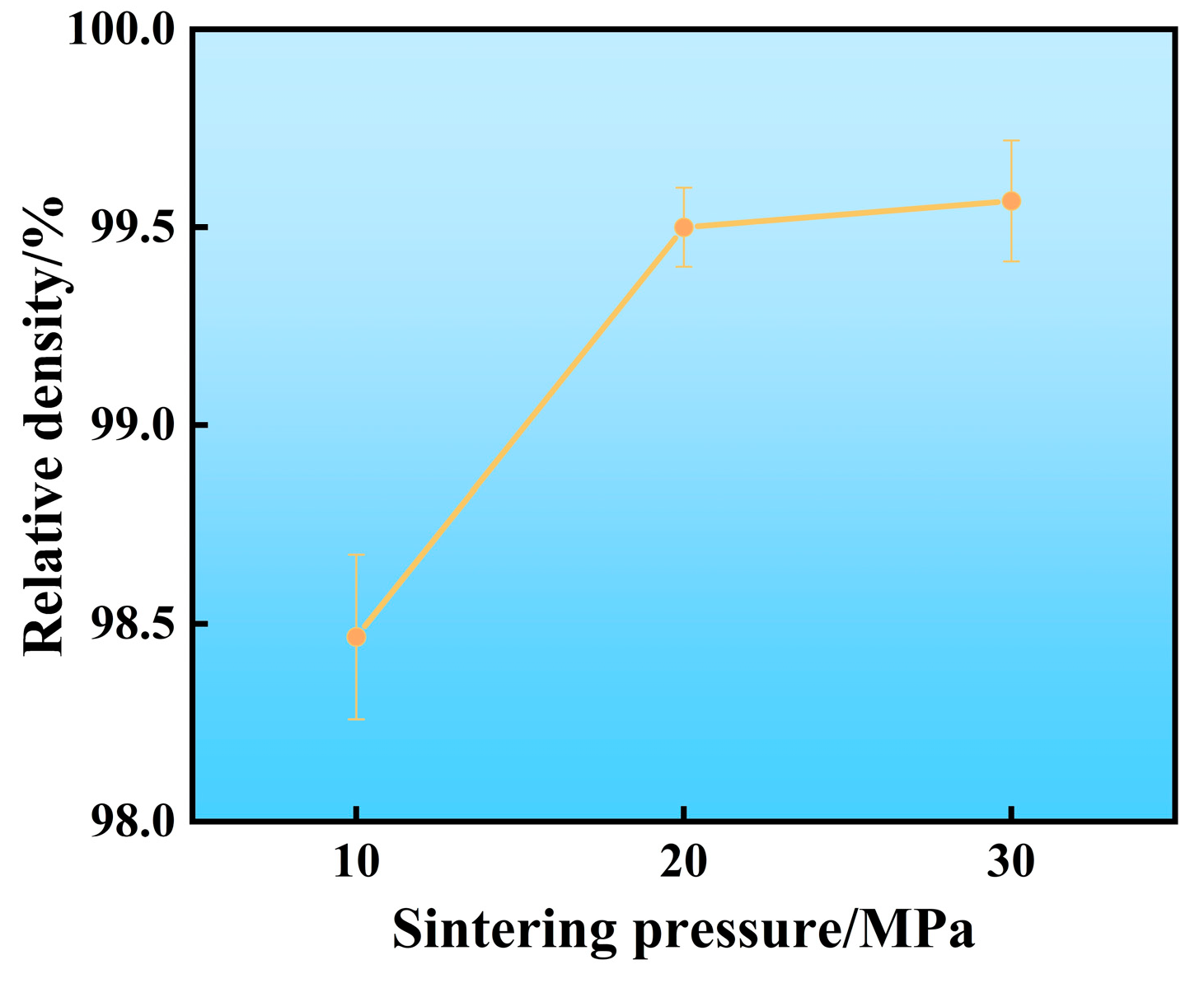

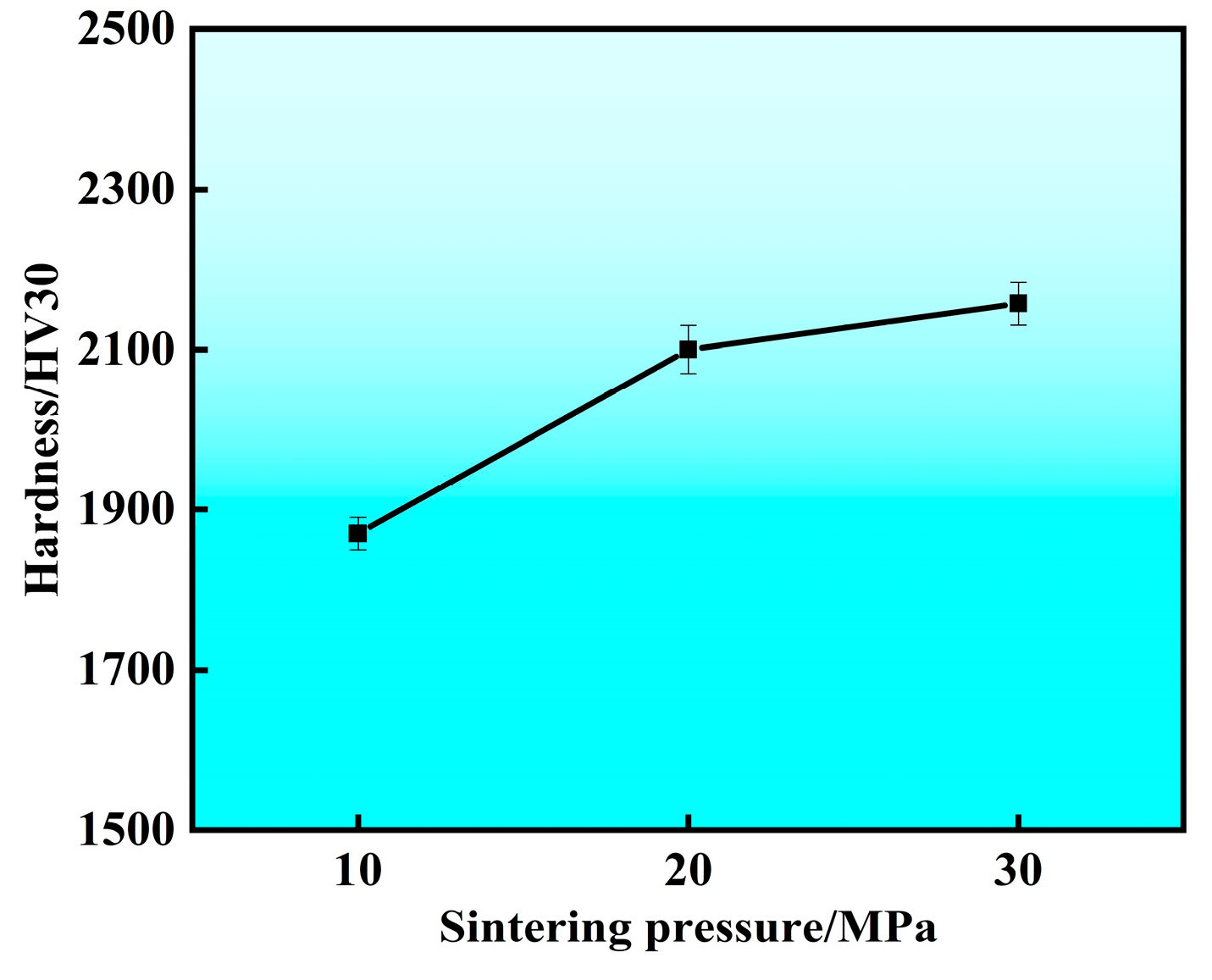

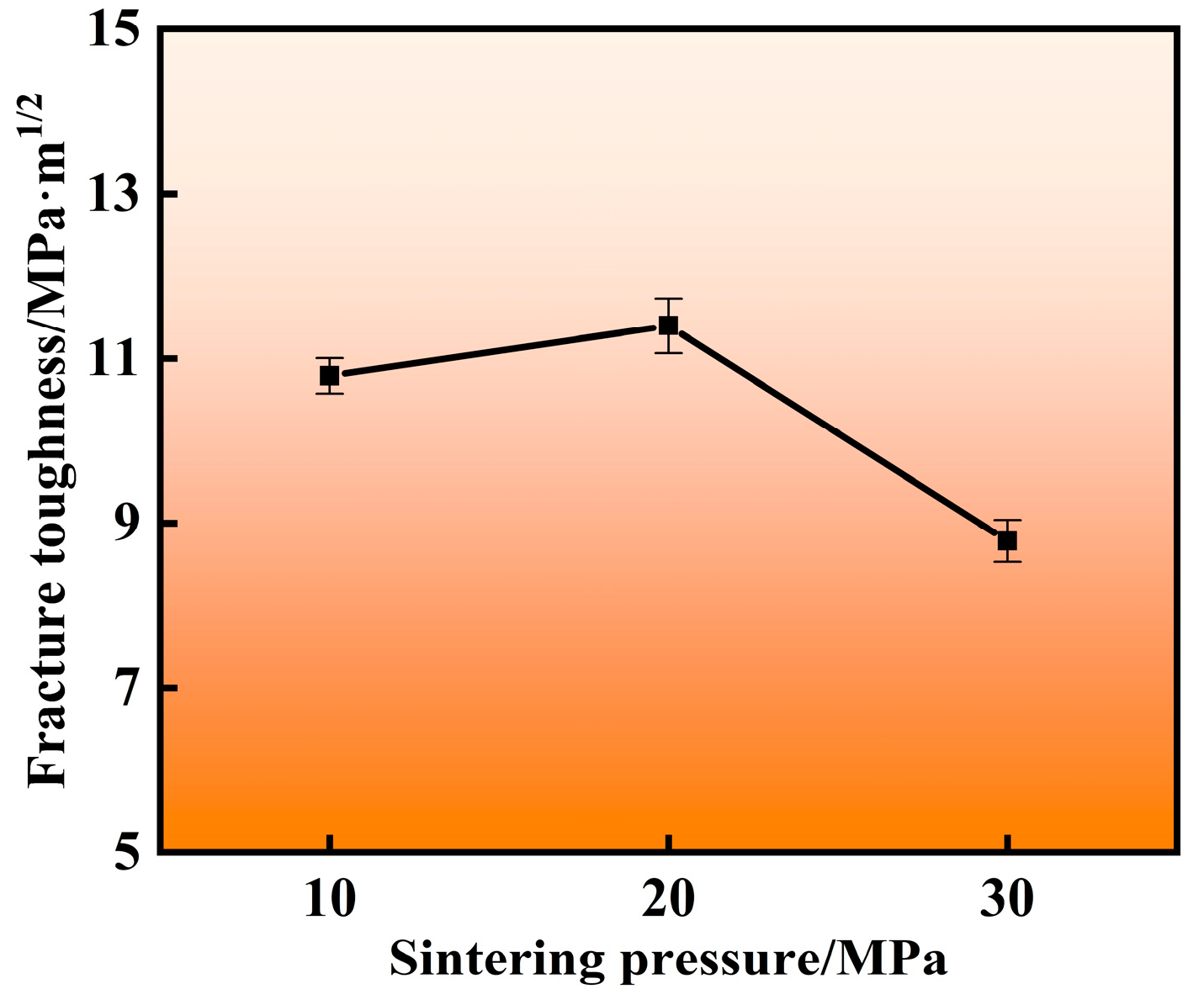

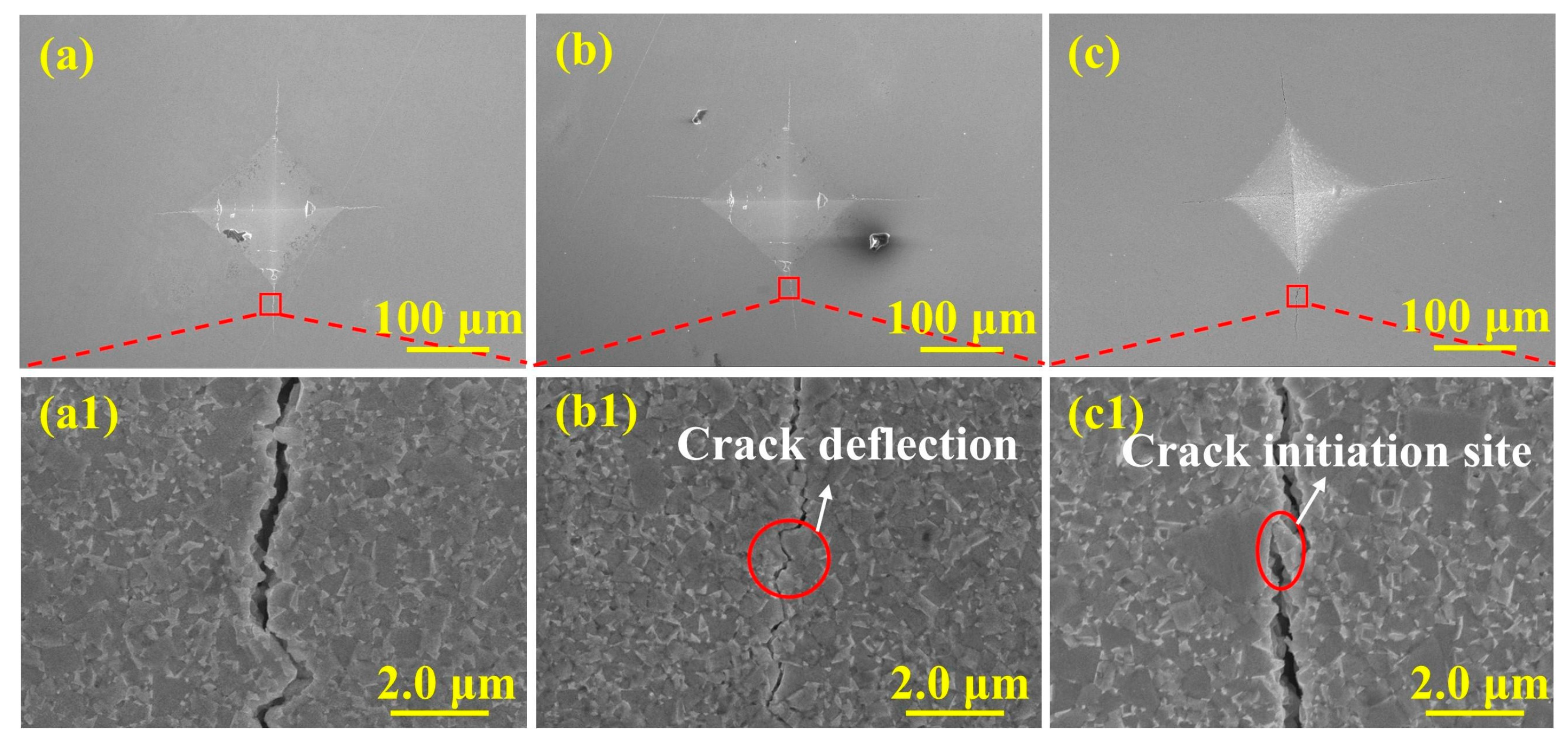

3.3. Effects of Sintering Pressure on the Mechanical Properties of the Cemented Carbides

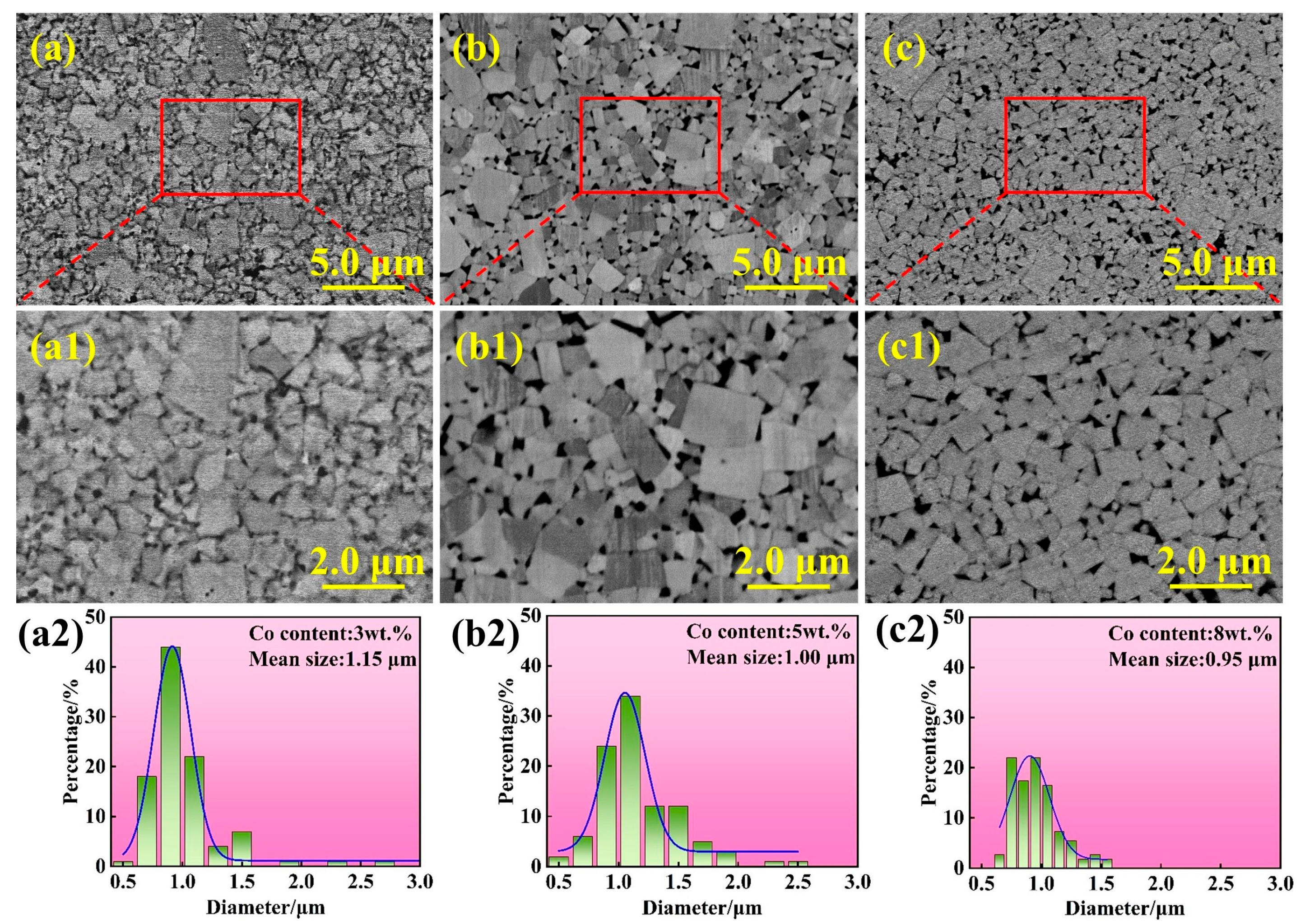

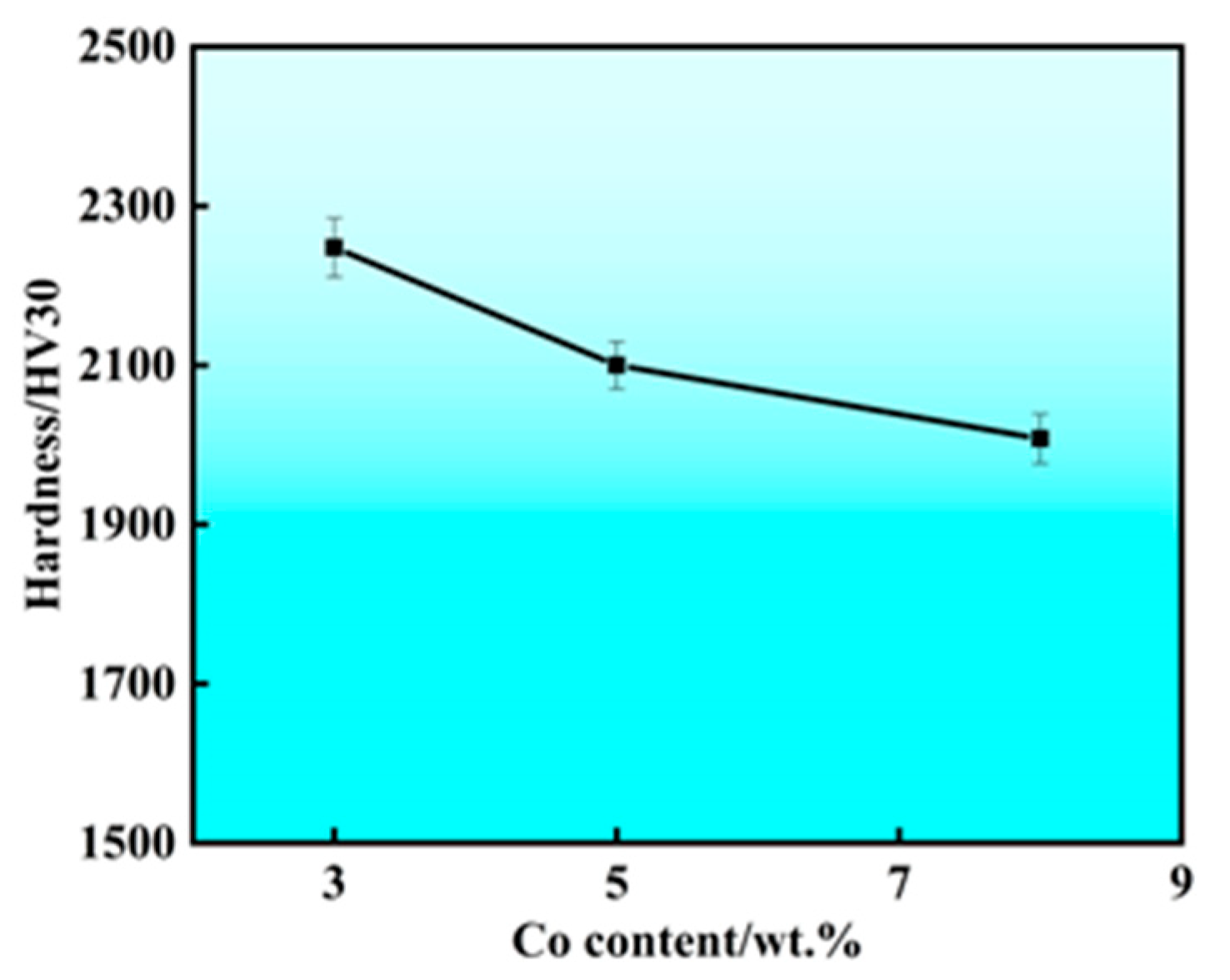

3.4. Effects of Cobalt Content Variation on the Mechanical Properties of WC–Co Cemented Carbides

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Spalden, M.V.; Pötschke, J.; Michaelis, A. Novel Route for Preparing Diamond-Enhanced Cemented Carbides via Reactive Sintering. Metals 2023, 13, 1908. [Google Scholar] [CrossRef]

- Premjarunan, S.; Tuchinda, K.; Worasaen, K. Study on the Effects of Cryogenic Treatment on WC-Co Cemented Carbide at Different Scales Using an Indentation Technique. Metals 2025, 15, 297. [Google Scholar] [CrossRef]

- Yu, S.B.; Min, F.; Li, D.; Noudem, G.J.; Zhang, H.L.; Ma, J.C.; Zhao, K.; Yao, Z.; Zhang, J. Comparative Study on Microstructure and Mechanical Properties of Coarse-Grained WC-Based Cemented Carbides Sintered with Ultrafine WC or (W+C) as Additives. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 2024, 39, 399–409. [Google Scholar] [CrossRef]

- Li, C.; Li, T.L.; Zhang, X.H.; He, T.Z.S.; Su, L.Z.; Wen, D.D.; Shao, S.Z.; Cai, X.; Cao, Q.Z. Investigating the Influence of Laser-Etched Straight and Wavy Textures on Grinding Efficiency and Tool Quality of WC-Co Carbide Cutting Tools. Materials 2025, 18, 528. [Google Scholar] [CrossRef]

- Fan, Y.; Li, Z.; Hao, Z. Study on Interface Characteristics of WC-Co Doped Y Rare Earth Element Cemented Carbide Cutting Tool and Its Influence on Material Properties. Mater. Sci. Technol. 2025, 41, 962–974. [Google Scholar] [CrossRef]

- Tang, X.; Mao, R.; Zhang, F.; Jin, Y.; Zhou, W.; Su, W.; Jiang, W.; Wang, J. Optimizing WC-10Co Cemented Carbides with High-Entropy (Ti, Cr, V, Nb, Mo)(C, N) Inhibitor: Microstructure, Mechanics, and Wear Resistance. J. Alloy Compd. 2025, 1037, 182148. [Google Scholar] [CrossRef]

- Muraliraja, R.; Selvan, R.A.S.; Selvakumar, A.; Franco, M.; Tamilarasan, T.R.; Sanjith, U.; Sha, W.; Sudagar, J. A Review of Electroless Coatings on Non-Metals: Bath Conditions, Properties and Applications. J. Alloy Compd. 2023, 960, 170723. [Google Scholar] [CrossRef]

- Yang, X.H.; Wang, K.F.; Chou, K.C.; Zhang, G.H. Preparation of Low Binder WC-Co-Ni Cemented Carbides with Fine WC Grains and Homogeneous Distribution of Co/Ni. Mater. Today Commun. 2022, 30, 103081. [Google Scholar] [CrossRef]

- Buravleva, A.A.; Fedorets, A.N.; Vornovskikh, A.A.; Ognev, A.V.; Nepomnyushchaya, V.A.; Sakhnevich, V.N.; Lembikov, A.O.; Kornakova, Z.E.; Kapustina, O.V.; Tarabanova, A.E.; et al. Spark Plasma Sintering of WC-Based 10wt.%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes. Materials 2022, 15, 1091. [Google Scholar] [CrossRef]

- Wang, Y.; Xiang, F.M.; Yuan, X.B.; Yang, B.B.; Wang, F.L.; Li, Y.P. Effects of Processing Parameters on the Microstructure and Mechanical Properties of Nanoscaled WC-10Co Cemented Carbide. Materials 2022, 15, 4472. [Google Scholar] [CrossRef]

- Sun, X.G.; Wang, Y.; Li, D.Y. Mechanical Properties and Erosion Resistance of Ceria Nano-Particle-Doped Ultrafine WC–12Co Composite Prepared by Spark Plasma Sintering. Wear 2013, 301, 406–414. [Google Scholar] [CrossRef]

- Yang, Q.M.; Yang, J.A.; Wen, Y.; Zhang, Q.Y.; Chen, L.Y.; Chen, H. A Novel Route for the Synthesis of Ultrafine WC-15 wt. %Co Cemented Carbides. J. Alloy Compd. 2018, 748, 577–582. [Google Scholar] [CrossRef]

- Su, W.; Luo, W.; Lu, J.H.; Zeng, S.J.; Zhou, W.X. Coarse-Grained WC–6Co Hardmetals with Dual-Scale and Plate-like WC Structures Fabricated by Convention Powder Metallurgy Process. Int. J. Refract. Met. Hard Mater. 2024, 125, 106886. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, J.F.; Tu, Z.B.; Xue, N.; Li, W.W. Effects of Powder Microscopic Defects on Densification and Mechanical Properties of WC via Spark Plasma Sintering. Mater. Sci. Forum. 2021, 5994, 1770–1777. [Google Scholar] [CrossRef]

- Wang, J.F.; Zuo, D.W.; Zhu, L.; Tu, Z.B.; Dai, S. Preparation of low Co-coated WC composite powder by electroless plating and its sintering by spark plasma sintering process. T. Mater. Heat Treat. 2016, 37, 12–17. [Google Scholar] [CrossRef]

- Guo, L.; Xiao, L.R.; Zhao, X.J.; Song, Y.F.; Cai, Z.Y.; Wang, H.J.; Liu, C.B. Preparation of WC/Co Composite Powders by Electroless Plating. Ceram. Int. 2017, 43, 4076–4082. [Google Scholar] [CrossRef]

- Tong, J.; Zhang, J.F.; Wang, Y.; Min, F.L.; Wang, X.Y.; Zhang, H.L.; Ma, J.C. Preparation of Co-Plated WC Powders by a Non-Precious-Co-Activation Triggered Electroless Plating Strategy. Adv. Powder Technol. 2019, 30, 2311–2319. [Google Scholar] [CrossRef]

- He, R.G.; Li, B.; Ou, P.H.; Yang, C.H.; Yang, H.L.; Ruan, J.M. Effects of Ultrafine WC on the Densification Behavior and Microstructural Evolution of Coarse-Grained WC-5Co Cemented Carbides. Ceram. Int. 2020, 46, 12852–12860. [Google Scholar] [CrossRef]

- Voorhees, P.W. The Theory of Ostwald Ripening. J. Stat. Phys. 1985, 38, 231–252. [Google Scholar] [CrossRef]

- Wu, Z.C.; Ye, N.; Zhuo, H.O.; Mao, J.; Zhu, W.T.; Gong, Z.Y.; Chen, X.L.; Tang, J.C. High-Pressure and High-Temperature Synthesis of Binder less Nanocrystalline WC Cemented Carbide: Microstructure and Mechanical Properties. Ceram. Int. 2025, 51, 7756–7765. [Google Scholar] [CrossRef]

- Fan, X.Q.; He, D.W.; Wang, P.; Li, D.; Liu, Y.J.; Ma, D.J.; Du, Y.C.; Gao, S.P.; Kou, Z.L. High Pressure Infiltration Sintering Behavior of WC-Co Alloys. High Press. Res. 2016, 36, 585–594. [Google Scholar] [CrossRef]

- Bonache, V.; Salvador, M.D.; Fernández, A.; Borrell, A. Fabrication of Full Density Near-Nanostructured Cemented Carbides by Combination of VC/Cr3C2 Addition and Consolidation by SPS and HIP Technologies. Int. J. Refract. Met. Hard Mater. 2011, 29, 202–208. [Google Scholar] [CrossRef]

- Lu, Z.C.; Wang, W.; Zeng, M.Q.; Zhu, M. Breaking the Hardness-Toughness Trade-off in WC-Co Hard metals: Introduction of Dual-Scale Plate-like WC and Modification of Prediction Models. Int. J. Refract. Met. Hard Mater. 2022, 108, 105910. [Google Scholar] [CrossRef]

- Cha, S.I.; Hong, S.H.; Kim, B.K. Spark Plasma Sintering Behavior of Nanocrystalline WC-10Co Cemented Carbide Powders. Mater. Sci. Eng. A 2003, 351, 31–38. [Google Scholar] [CrossRef]

- Siwak, P.; Garbiec, D. WC-5Co Cemented Carbides Fabricated by SPS. Arch. Metall. Mater. 2018, 63, 2031–2037. [Google Scholar] [CrossRef]

- Müller, D.; Konyashin, I.; Farag, S.; Ries, B.; Zaitsev, A.A.; Loginov, P.A. WC Coarsening in Cemented Carbides during Sintering. Part I: The Influence of WC Grain Size and Grain Size Distribution. Int. J. Refract. Met. Hard Mater. 2022, 102, 105714. [Google Scholar] [CrossRef]

- Yadav, S.; Zhang, Q.F.; Behera, A.; Haridas, R.S.; Agrawal, P.; Gong, J.D.; Mishra, R.S. Role of Binder Phase on the Microstructure and Mechanical Properties of a Mechanically Alloyed and Spark Plasma Sintered WC-FCC HEA Composites. J. Alloy Compd. 2021, 877, 160265. [Google Scholar] [CrossRef]

- Chen, W.Y.; Yin, Z.B.; Li, X.L.; Yuan, J.T. Effect of Co-Doped Additives on Microstructure and Mechanical Properties of Microwave-Sintered WC-10Co Cemented Carbide Tool Materials. J. Alloy Compd. 2023, 962, 171148. [Google Scholar] [CrossRef]

- Ye, Y.; Xia, H.; Lin, Y.; Chen, F.; Shen, Q. Refined WC Grain Size and Improved Mechanical Properties in a Hardmetal WC-8Co Processed via Short-Time Semi-Solid Hot Pressing. J. Alloy Compd. 2021, 889, 161560. [Google Scholar] [CrossRef]

- Chermant, J.L.; Osterstock, F. Fracture Toughness and Fracture of WC-Co Composites. J. Mater. Sci. 1976, 11, 1939–1951. [Google Scholar] [CrossRef]

- Garcia, J.; Cipres, V.C.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Saito, H.; Iwabuchi, A.; Shimizu, T. Effects of Co Content and WC Grain Size on Wear of WC Cemented Carbide. Wear 2006, 261, 126–132. [Google Scholar] [CrossRef]

- Tian, X.; Liang, Y.; He, G.; Zeng, L. Reduced Graphene Oxide and Alumina Synergistically Enhance the Mechanical and Wear Properties of WC-8Co Cemented Carbide. Int. J. Refract. Met. Hard Mater. 2023, 113, 106184. [Google Scholar] [CrossRef]

- Yin, C.; Ruan, J.M.; Du, Y.; Long, J.Z.; Peng, Y.B.; Li, K. Effects of Cr3C2, VC, and TaC on Microstructure, WC Morphology and Mechanical Properties of Ultrafine WC-10 Wt.% Co Cemented Carbides. Metals 2020, 10, 1211. [Google Scholar] [CrossRef]

| Reagent | Concentration |

|---|---|

| 65% HNO3 | 20~60 mL/L |

| 40% HF | 30~50 mL/L |

| NH4F | 2~4 g/L |

| Reagent | Concentration |

|---|---|

| CoSO4·7H2O | 20~30 g/L |

| NaH2PO2·H2O | 20~30 g/L |

| Na3C5H5O7·2H2O | 40~50 g/L |

| H3BO3 | 20~30 g/L |

| NaOH | For adjusting the pH within 10~11 |

| Area | Compositions (wt.%) | ||

|---|---|---|---|

| W | C | Co | |

| A | 84.56 | 10.13 | 5.31 |

| B | 84.62 | 9.35 | 6.03 |

| C | 84.28 | 10.88 | 4.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, J.; Huang, D.; Xu, H.; Dong, D.; Lou, J.; Xu, Y.; Shi, J.; Zhu, L. Effects of Sintering Pressure and Co Content on the Microstructure and Mechanical Performance of WC–Co Cemented Carbides. Metals 2025, 15, 930. https://doi.org/10.3390/met15090930

Ju J, Huang D, Xu H, Dong D, Lou J, Xu Y, Shi J, Zhu L. Effects of Sintering Pressure and Co Content on the Microstructure and Mechanical Performance of WC–Co Cemented Carbides. Metals. 2025; 15(9):930. https://doi.org/10.3390/met15090930

Chicago/Turabian StyleJu, Jinhu, Dan Huang, Haitao Xu, Duo Dong, Jiangpeng Lou, Yuan Xu, Jiao Shi, and Liu Zhu. 2025. "Effects of Sintering Pressure and Co Content on the Microstructure and Mechanical Performance of WC–Co Cemented Carbides" Metals 15, no. 9: 930. https://doi.org/10.3390/met15090930

APA StyleJu, J., Huang, D., Xu, H., Dong, D., Lou, J., Xu, Y., Shi, J., & Zhu, L. (2025). Effects of Sintering Pressure and Co Content on the Microstructure and Mechanical Performance of WC–Co Cemented Carbides. Metals, 15(9), 930. https://doi.org/10.3390/met15090930