Arc Quenching Effects on the Groove Shapes of Carbon Steel Tubes

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussion

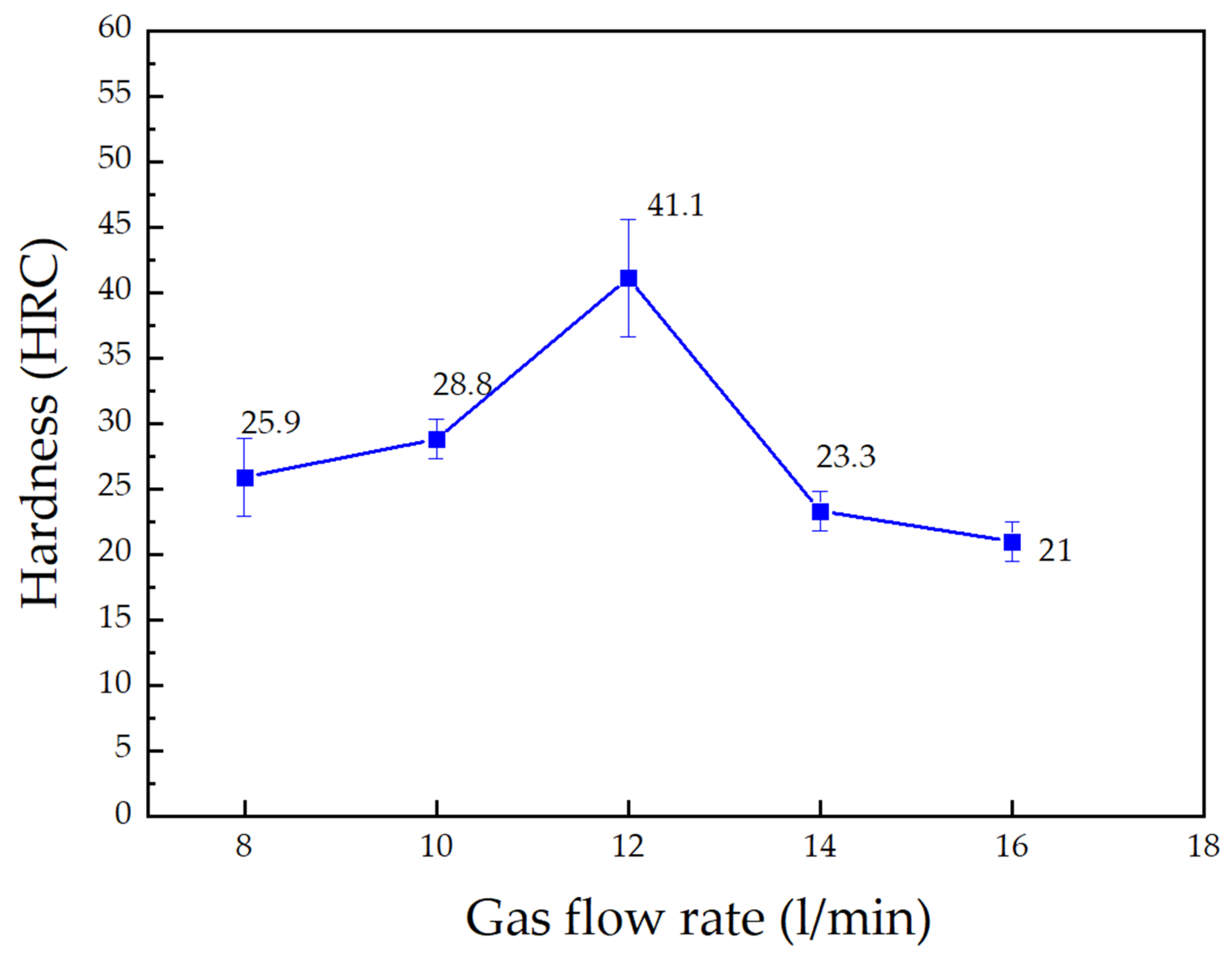

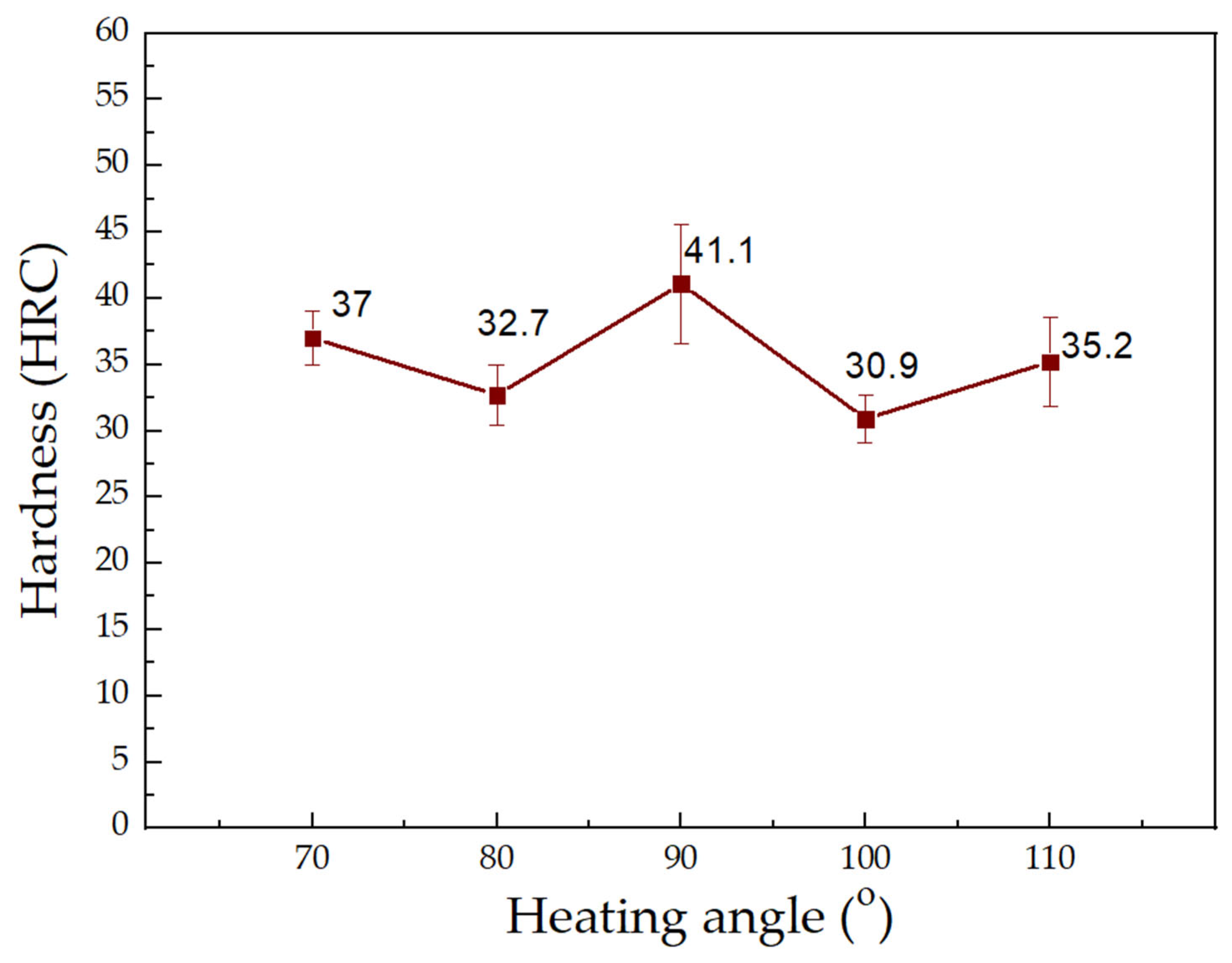

3.1. Effects of Arc Hardening Parameters on the Surface Hardness

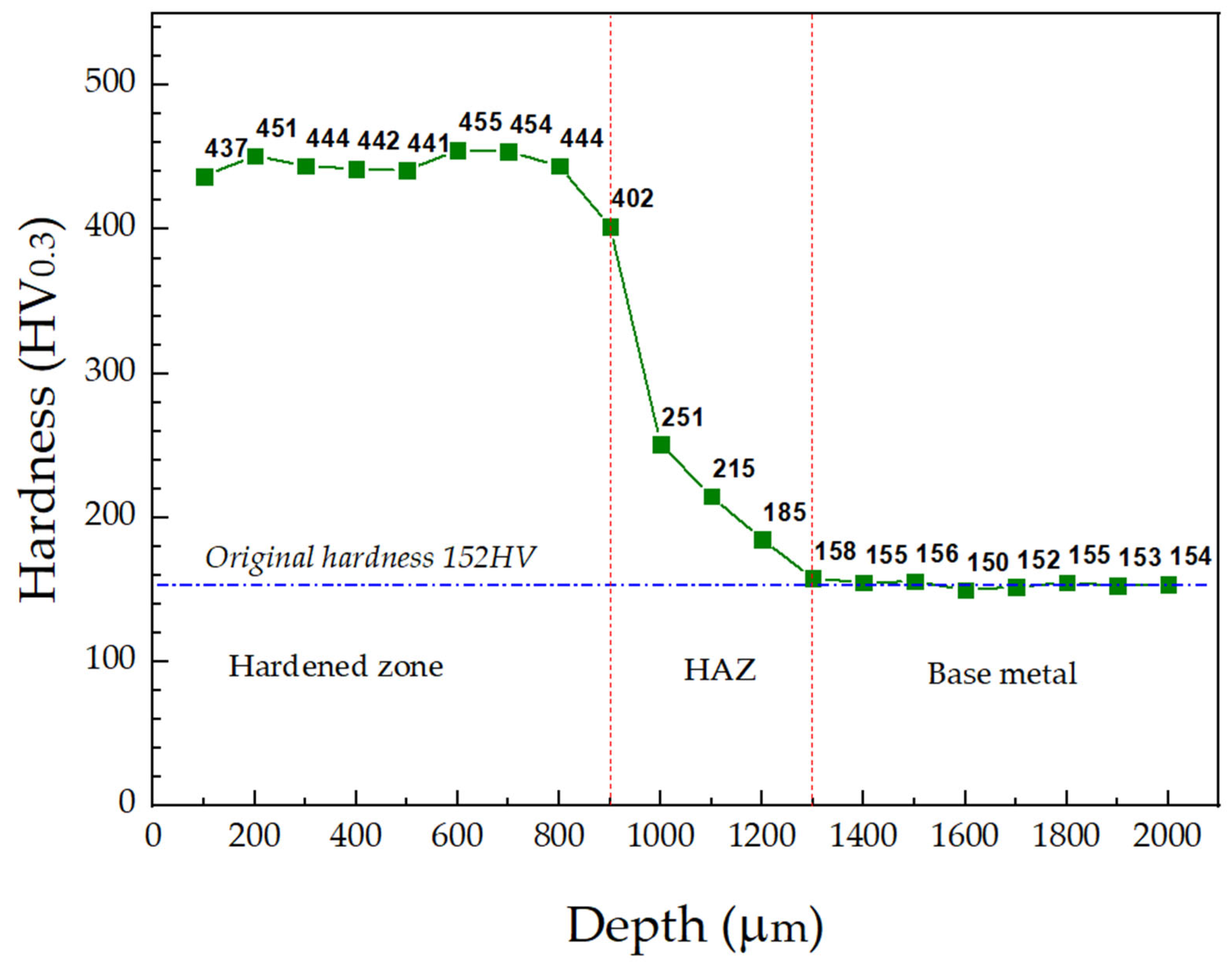

3.2. Hardness with Load and Microstructure of the Hardened Sample

4. Conclusions

- -

- Compared to the original hardness of the tube, the surface hardness increases dramatically when applying arc quenching. The surface hardness can rise to 50.3 HRC, which is 3.4 times higher than the untreated surface. Changing the arc quenching parameters, such as current intensity, gas flow, arc length, scanning speed, heating angle, and cooling angle, leads to fluctuations in surface hardness because these parameters directly affect the surface heating and rapid cooling of S45C steel.

- -

- The hardness with load distribution contains three zones: the hardened zone with a high hardness value, the heat-affected zone (HAZ) with rapidly falling hardness, and the base metal with a low hardness value. The hardened zone has a hardness with a load of 0.3 N of around 440 HV and a case depth of approximately 900 μm. The next zone is the HAZ, where the hardness with a load of 0.3 N decreases drastically. In the base metal zone, the hardness constantly returns to its initial value of 152 HV.

- -

- The microstructure, consistent with the hardness distribution, reveals the relationship between the hardness value and its phases. The hardened zone consists of martensite and residual austenite phases, which correspond to a high hardness value. The bainite phase makes up the HAZ, which corresponds to the zone of rapid hardness decline. Finally, the base metal zone has ferrite and pearlite microstructures, which correspond to the softest zone. The results of the study may help us better understand the arc-hardening method and increase its applicability in the industry. Further investigations should focus on the distortion effects caused by the arc hardening method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schneider, M.J.; Chatterjee, M.S. Introduction to surface hardening of steels. In Steel Heat Treating Fundamentals and Processes; ASM International: Almere, The Netherlands, 2013; pp. 389–398. [Google Scholar]

- Dinesh Babu, P.; Balasubramanian, K.R.; Buvanashekaran, G. Laser surface hardening: A review. Int. J. Surf. Sci. Eng. 2011, 5, 131–151. [Google Scholar] [CrossRef]

- Kim, C.K.; Kim, Y.C.; Park, J.I.; Lee, S.; Kim, N.J.; Yang, J.S. Effects of alloying elements on microstructure, hardness, and fracture toughness of centrifugally cast high-speed steel rolls. Metall. Mater. Trans. A 2005, 36, 87–97. [Google Scholar] [CrossRef]

- Aswad, M.F.; Mohammed, A.J.; Faraj, S.R. Induction surface hardening: A review. J. Phys. Conf. Ser. 2021, 1973, 012087. [Google Scholar] [CrossRef]

- Grum, J. Comparison of different techniques of laser surface hardening. J. Achiev. Mater. Manuf. Eng. 2007, 24, 17–25. [Google Scholar]

- Zenker, R.; Buchwalder, A. Electron beam surface hardening. In Steel Heat Treating Fundamentals and Processes; ASM International: Almere, The Netherlands, 2013; pp. 462–475. [Google Scholar]

- Lee, M.K.; Kim, G.H.; Kim, K.H.; Kim, W.W. Control of surface hardnesses, hardening depths, and residual stresses of low carbon 12Cr steel by flame hardening. Surf. Coat. Technol. 2004, 184, 239–246. [Google Scholar] [CrossRef]

- Ion, J.C. Laser transformation hardening. Surf. Eng. 2002, 18, 14–31. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.; Zhang, S.; Ren, Y.; Cheng, H.; Tian, G. Multi-response assessment for carbon emission and hardening effect in laser surface quenching. Environ. Sci. Pollut. Res. 2023, 30, 1–17. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, Q.; Wang, J.; Yun, X.; He, B.; Luo, J. Behaviors of 40Cr steel treated by laser quenching on impact abrasive wear. Opt. Laser Technol. 2018, 103, 118–125. [Google Scholar] [CrossRef]

- Schüßler, P.; Damon, J.; Mühl, F.; Dietrich, S.; Schulze, V. Laser surface hardening: A simulative study of tempering mechanisms on hardness and residual stress. Comput. Mater. Sci. 2023, 221, 112079. [Google Scholar] [CrossRef]

- Xu, Z.; Leong, K.H.; Reed, C.B. Nondestructive evaluation and real-time monitoring of laser surface hardening. J. Mater. Process. Technol. 2008, 206, 120–125. [Google Scholar] [CrossRef]

- Yu, Z.K.; Zong, Q.Y.; Tam, Z.T. A preliminary investigation of surface hardening of steel and iron by solar energy. J. Heat Treat. 1982, 2, 344–350. [Google Scholar] [CrossRef]

- Safonov, E.N.; Zhuravlev, V.I. Surface hardening of iron-carbon alloys by arc quenching. Weld. Int. 1998, 12, 326–328. [Google Scholar] [CrossRef]

- Dombrovskii, Y.M.; Brover, A.V. Treatment of steel by an air-plasma arc with scanning. Met. Sci. Heat Treat. 1999, 41, 12. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Minh, P.S.; Dang, H.S.; Ho, N. Optimization of arc quenching parameters for enhancing surface hardness and line width in S45C steel using Taguchi method. PLoS ONE 2024, 19, e0314648. [Google Scholar] [CrossRef] [PubMed]

- Arai, Y.; Sugimoto, M.; Kimura, M.; Sugiyama, S.; Takeda, K. Medium Carbon Steel Surface Hardening by Vacuum Arc Cleaning of Oxide Layers. ISIJ Int. 2008, 48, 1438–1442. [Google Scholar] [CrossRef]

- Safonov, E.N.; Mironova, M.V. Surface Electric Arc Hardening of Low-Carbon Steels. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2020; Volume 989, pp. 318–323. [Google Scholar] [CrossRef]

- Nikolaou, J.; Bourithis, L.; Papadimitriou, G. Selective case hardening of plain steel by carbon alloying with a plasma transferred arc (PTA) technique. J. Mater. Sci. 2003, 38, 2883–2891. [Google Scholar] [CrossRef]

- Mikheev, A.E.; Ivasev, S.S.; Girn, A.V.; Terekhin, N.A.; Statsura, V.V. Surface hardening of steel components with a constricted electric arc. Weld. Int. 2003, 17, 570–572. [Google Scholar] [CrossRef]

- Dewangan, S.; Nemade, V.V.; Nemade, K.H. Critical Analysis of Material Behaviour in Welded Plates of Aisi 0.2%-C Steel Under As-Welded, Quenched and Annealed Conditions. Acta Metall. Slovaca 2023, 29, 26–33. [Google Scholar] [CrossRef]

- Kumar, R.; Ghosh, P.K.; Kumar, S. Thermal and metallurgical characteristics of surface modification of AISI 8620 steel produced by TIG arcing process. J. Mater. Process. Technol. 2017, 240, 420–431. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Ohta, A.; Matsuoka, K.; Suzuki, N.; Maeda, Y. Analytical solutions for transient temperature of semi-infinite body subjected to 3-D moving heat sources. Weld. J. N. Y. 1999, 78, 265s–274s. [Google Scholar]

- Patel, N.S.; Patel, R.B. A review on parametric optimization of TIG welding. Int. J. Comput. Eng. Res. 2014, 4, 27–31. [Google Scholar]

- Jeyaprakash, N.; Haile, A.; Arunprasath, M. The parameters and equipments used in TIG welding: A review. Int. J. Eng. Sci. (IJES) 2015, 4, 11–20. [Google Scholar]

- Zhang, G.; Xiong, J.; Gao, H.; Wu, L. Effect of process parameters on temperature distribution in twin-electrode TIG coupling arc. J. Quant. Spectrosc. Radiat. Transf. 2012, 113, 1938–1945. [Google Scholar] [CrossRef]

| Weight % | C | Si | Mn | P | S | Ni | Cr |

|---|---|---|---|---|---|---|---|

| S45C | 0.42–0.50 | 0.17–0.37 | 0.5–0.8 | 0.035 max | 0.035 max | 0.25 max | 0.25 max |

| Samples | V (mm/min) | L (mm) | I (A) | Q (L/min) | α (°) | β (°) |

|---|---|---|---|---|---|---|

| 1 | 500 | 1.5 | 130 | 12 | 90 | 90 |

| 2 | 490 | |||||

| 3 | 480 | |||||

| 4 | 470 | |||||

| 5 | 460 | |||||

| 6 | 480 | 1.9 | ||||

| 7 | 1.7 | |||||

| 3 | 1.5 | |||||

| 8 | 1.3 | |||||

| 9 | 1.1 | |||||

| 10 | 1.5 | 140 | ||||

| 11 | 135 | |||||

| 3 | 130 | |||||

| 12 | 125 | |||||

| 14 | 120 | |||||

| 15 | 130 | 16 | ||||

| 16 | 14 | |||||

| 3 | 12 | |||||

| 17 | 10 | |||||

| 18 | 8 | |||||

| 19 | 12 | 110 | ||||

| 20 | 100 | |||||

| 3 | 90 | |||||

| 21 | 80 | |||||

| 22 | 70 | |||||

| 23 | 90 | 110 | ||||

| 24 | 100 | |||||

| 3 | 90 | |||||

| 25 | 80 | |||||

| 26 | 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uyen, T.M.T.; Nguyen, V.-T.; Anh, P.Q.; Minh, P.S.; Ho, N. Arc Quenching Effects on the Groove Shapes of Carbon Steel Tubes. Metals 2025, 15, 928. https://doi.org/10.3390/met15090928

Uyen TMT, Nguyen V-T, Anh PQ, Minh PS, Ho N. Arc Quenching Effects on the Groove Shapes of Carbon Steel Tubes. Metals. 2025; 15(9):928. https://doi.org/10.3390/met15090928

Chicago/Turabian StyleUyen, Tran Minh The, Van-Thuc Nguyen, Pham Quan Anh, Pham Son Minh, and Nguyen Ho. 2025. "Arc Quenching Effects on the Groove Shapes of Carbon Steel Tubes" Metals 15, no. 9: 928. https://doi.org/10.3390/met15090928

APA StyleUyen, T. M. T., Nguyen, V.-T., Anh, P. Q., Minh, P. S., & Ho, N. (2025). Arc Quenching Effects on the Groove Shapes of Carbon Steel Tubes. Metals, 15(9), 928. https://doi.org/10.3390/met15090928