Effect of Heat Treatment Temperature on the Microstructure and Mechanical Properties of Fe-18Mn-0.6C-xAl

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Room Temperature Tensile and Cryogenic Impact Tests

2.3. Microstructure Characterizations

3. Results and Discussion

3.1. Tensile and Cryogenic Impact Properties

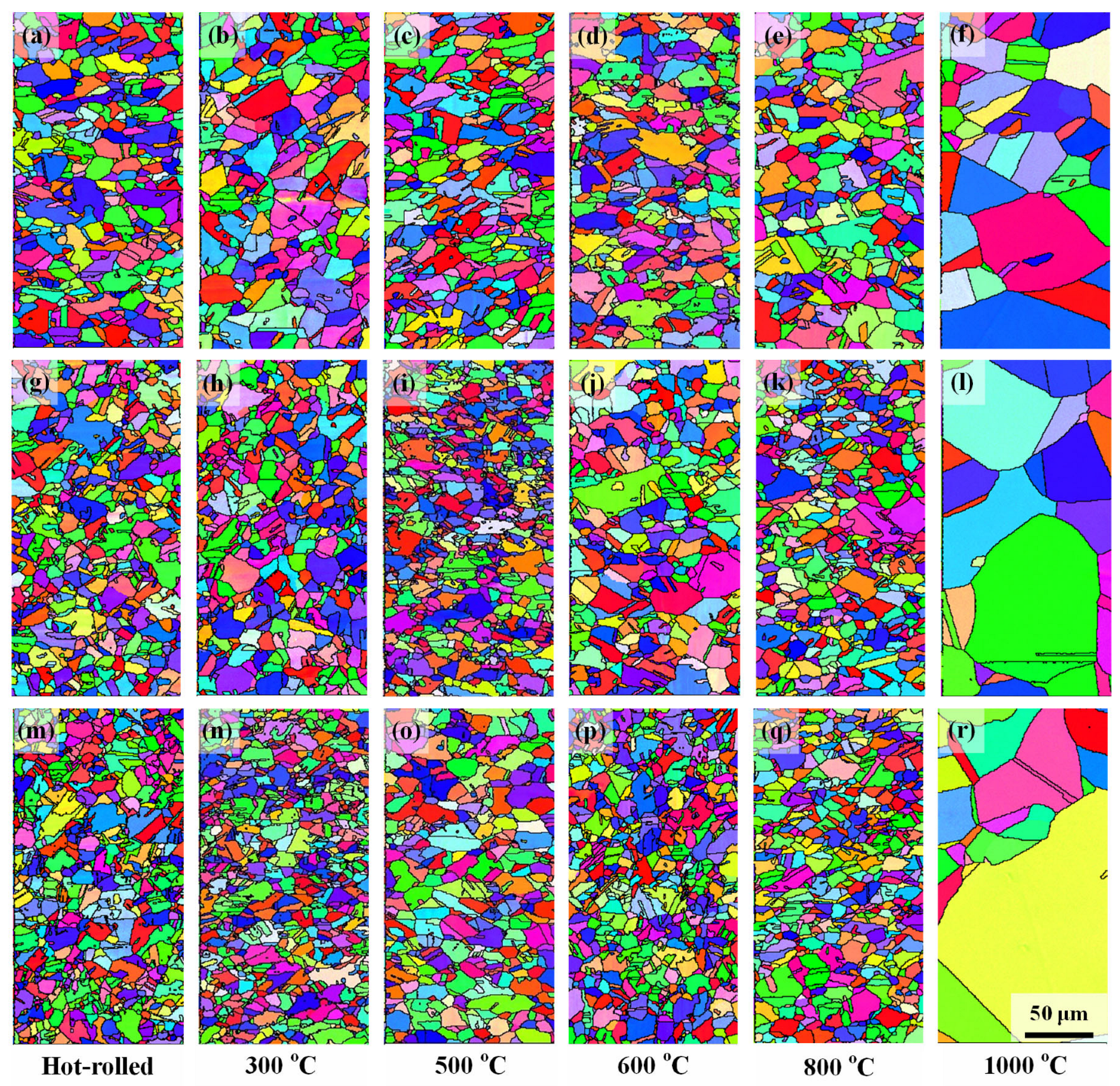

3.2. Microstructure Characteristics Before Deformation

3.3. Microstructure Characteristics After Cryogenic Impact Deformation

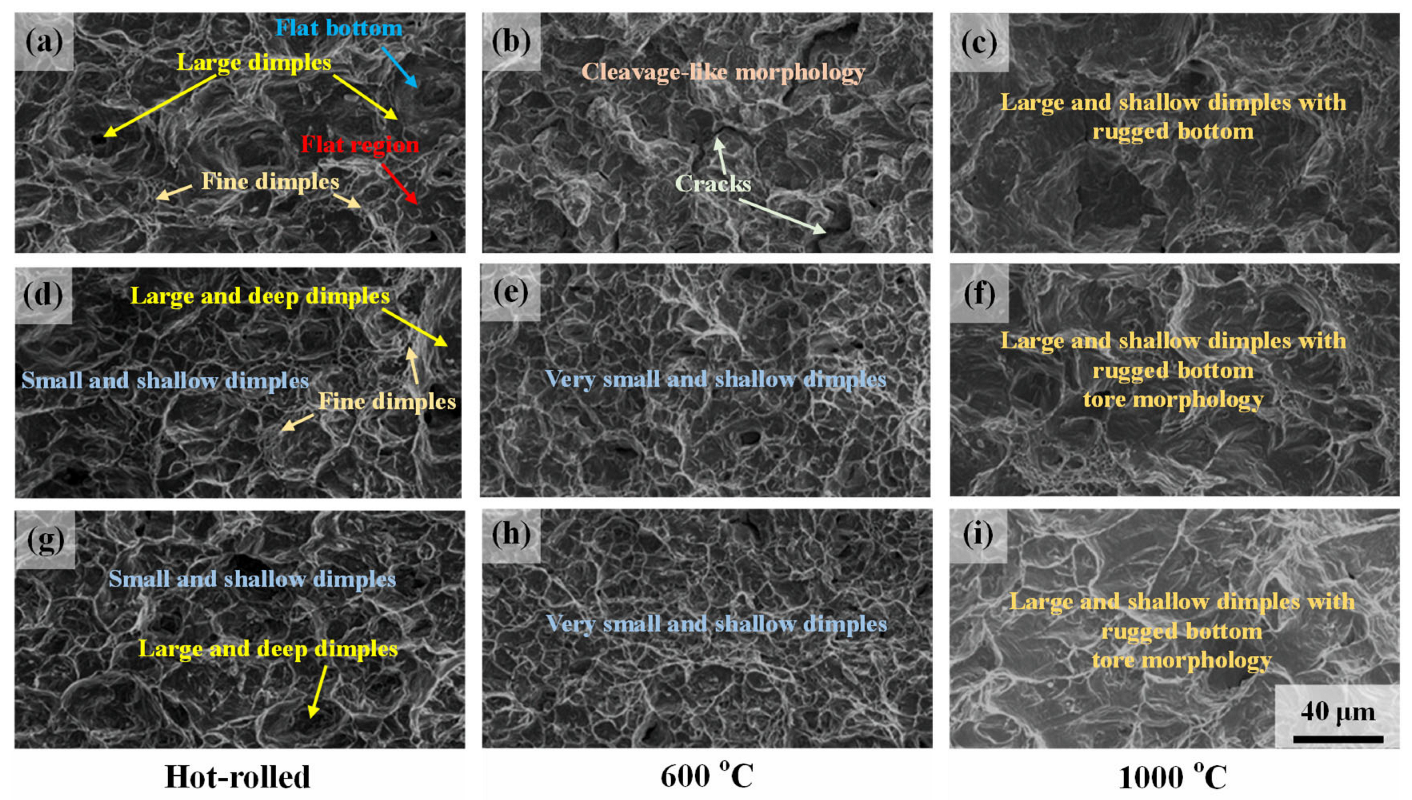

3.3.1. Impact Fracture Morphology

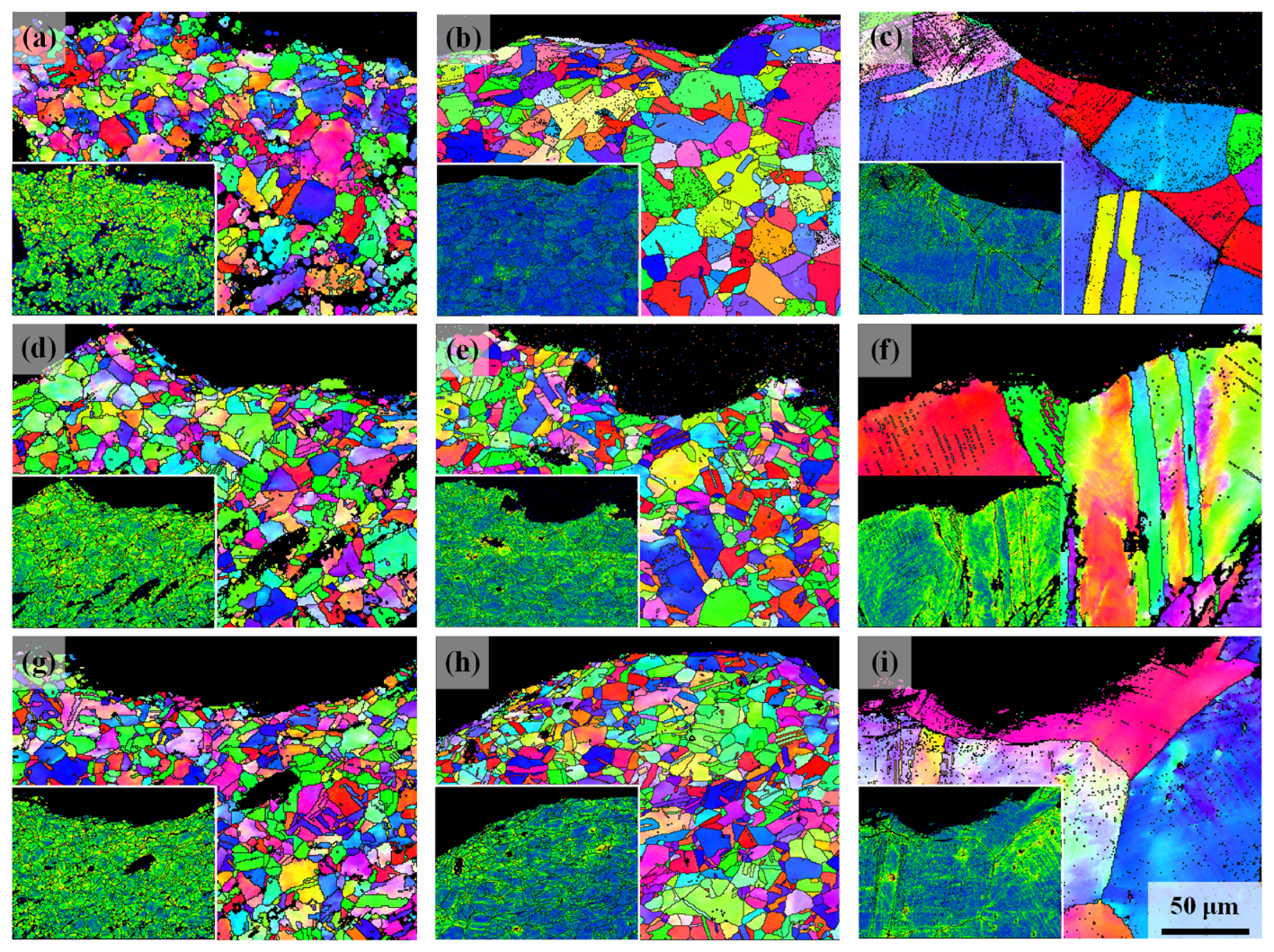

3.3.2. EBSD Observations of Cross-Sectional Regions Close to Fracture Surfaces

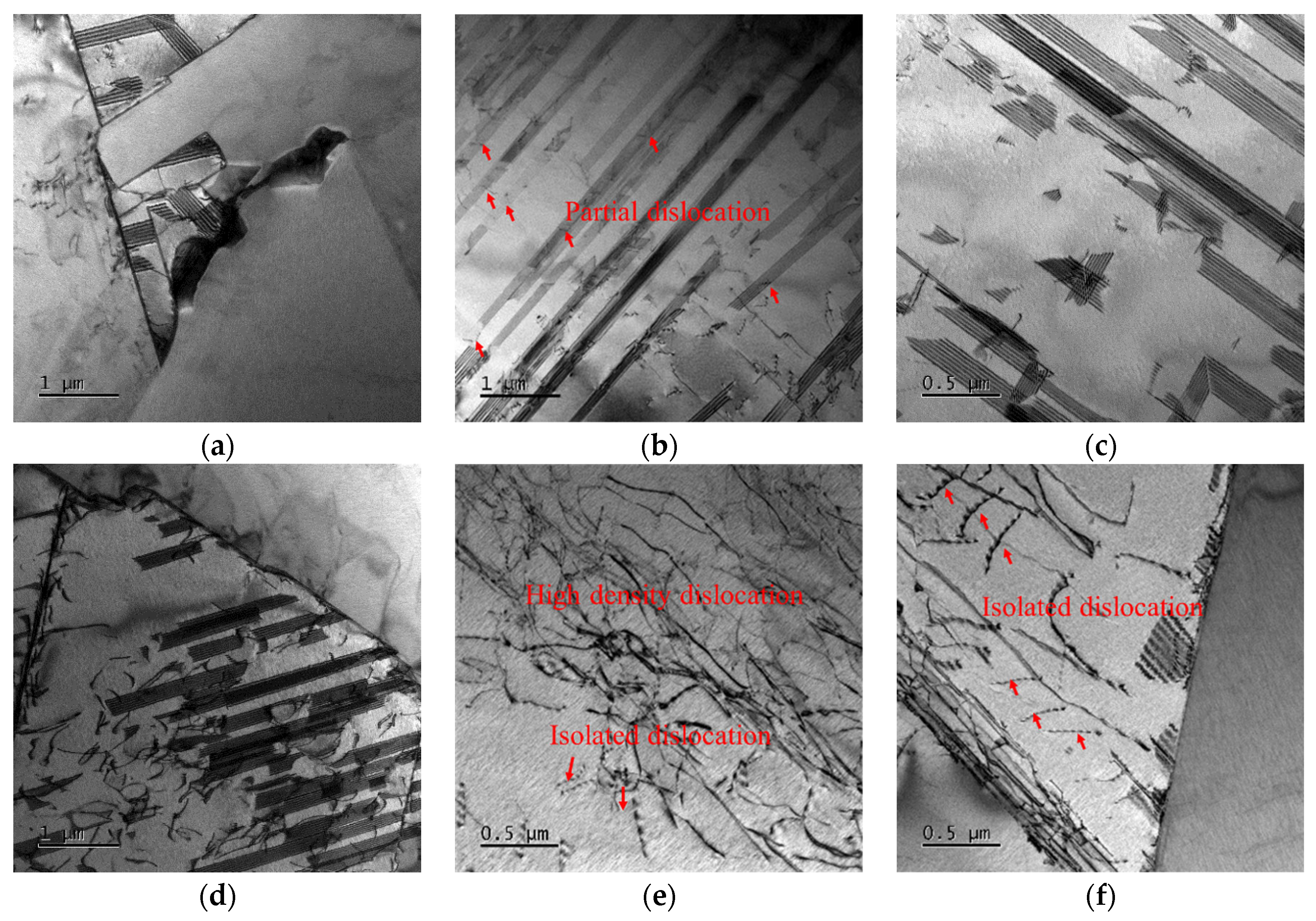

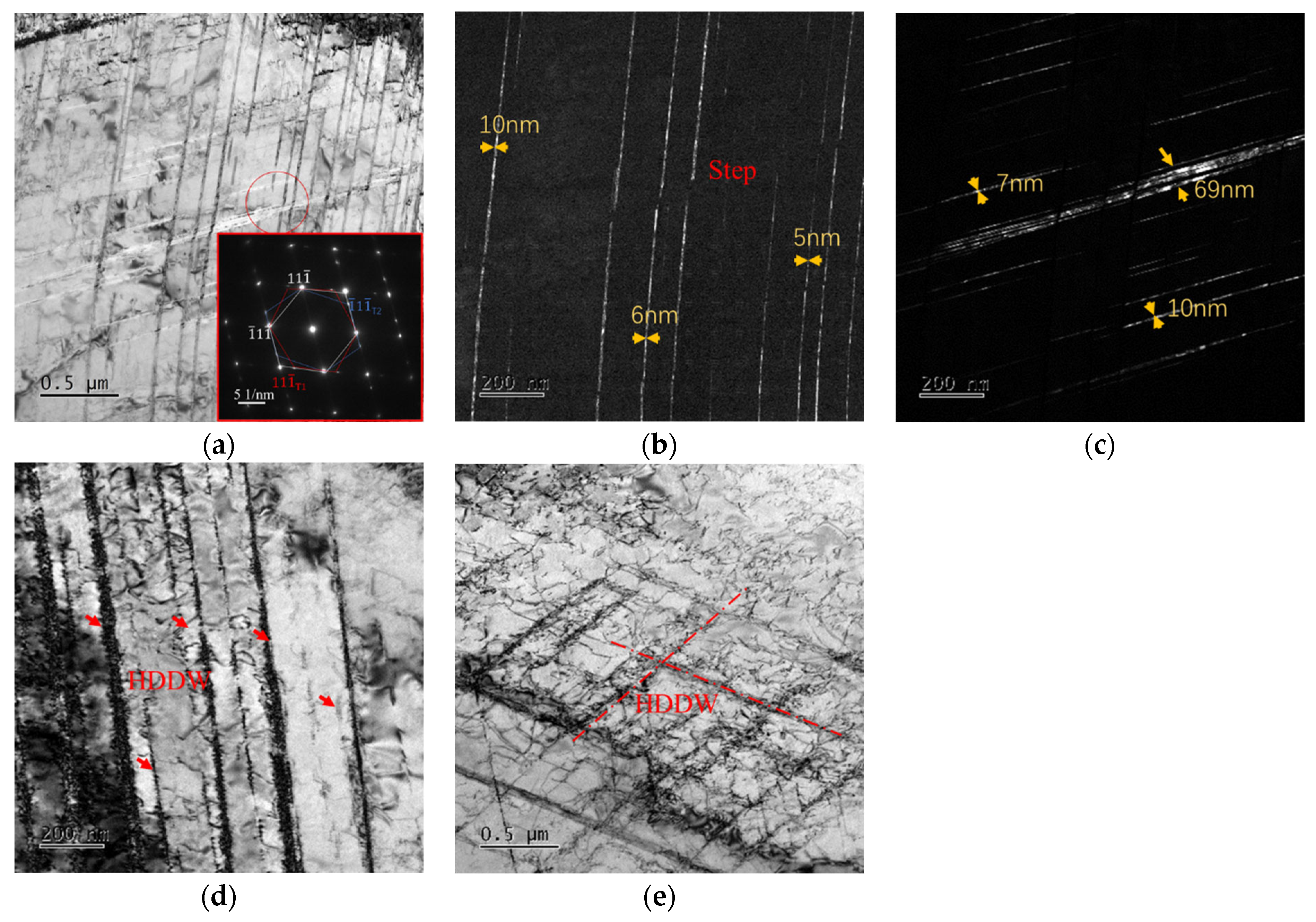

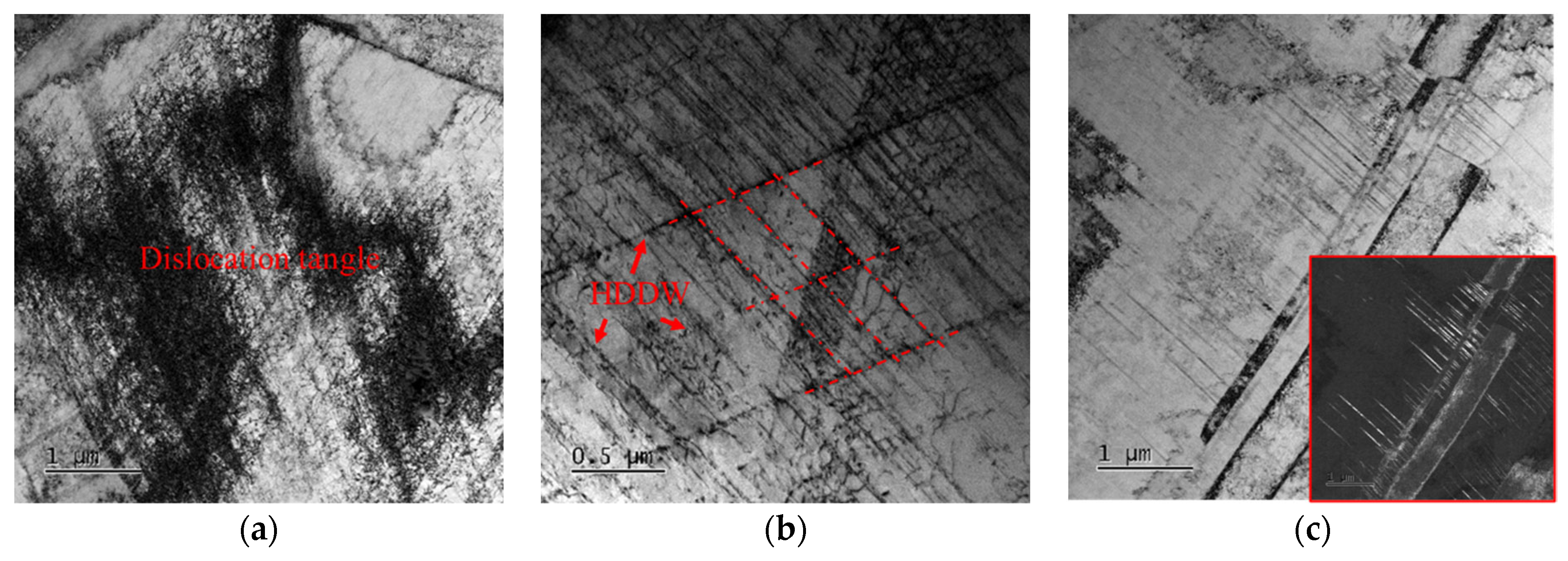

3.3.3. TEM Observations of Cross-Sectional Regions Close to Fracture Surfaces

4. Conclusions

- (1)

- There is a cryogenic impact brittle zone (400–800 °C) in the three steels, and a very small amount of absorbed energy is usually observed at around 600 °C. The addition of Al can shift the onset of the brittle zone from 400 to 500 °C, thus narrowing the brittle zone. In addition, the absorbed energy can be lowered by around 89%, 48%, and 40% for the 0Al, 3Al, and 5Al steels after heat treatment at 600 °C compared to their hot-rolled counterparts, respectively. However, there is no tensile ductility brittle zone in the three steels, and the tensile properties are virtually unaffected by heat treatment at a temperature range of 150–800 °C.

- (2)

- It is found that grain morphology and size are not greatly affected by heat treatment at 300–800 °C, and the average grain size ranges of the 0Al, 3Al, and 5Al steels are 8.0–9.3, 6.3–7.3, and 6.0–6.6 μm, respectively. However, their grain sizes sharply increase to 32.6, 38.6, and 43.1 μm after heat treatment at 1000 °C.

- (3)

- The degree of plastic deformation is greatly lowered after heat treatment at 600 °C, exhibiting cleavage-like fracture in the 0Al steel as well as ductile fracture with small and shallow dimples in the 3Al and 5Al steels; this implies that the addition of Al can enhance the degree of plastic deformation. The main deformation mechanism of the 0Al steel is partial dislocation slip, which forms numerous stacking faults, while those of the 3Al and 5Al steels are twining and strong planar slip.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Kwon, O.; Chin, K.-G. State-of-the-knowledge on TWIP steel. Mater. Sci. Technol. 2012, 28, 513–527. [Google Scholar] [CrossRef]

- Kim, Y.G.; Park, Y.S.; Han, J.K. Low temperature mechanical behavior of microalloyed and controlled-rolled Fe-Mn-Al-C-X alloys. Metall. Trans. A 1985, 16, 1689. [Google Scholar] [CrossRef]

- Choi, J.K.; Lee, S.G.; Park, Y.H.; Han, I.W.; Morris, J.W., Jr. High Manganese Austenitic Steel For Cryogenic Applications Available to Purchase. In Proceedings of the Twenty-Second International Offshore and Polar Engineering Conference, Rhodes, Greece, 17–22 June 2012; pp. 29–35. [Google Scholar]

- Kim, H.; Ha, Y.; Kwon, K.H.; Kang, M.; Kim, N.J.; Lee, S. Interpretation of cryogenic-temperature Charpy impact toughness by microstructural evolution of dynamically compressed specimens in austenitic 0.4C–(22–26)Mn steels. Acta Mater. 2015, 87, 332–343. [Google Scholar] [CrossRef]

- Chen, J.; Liu, N.; Liu, Z.Y.; Wang, G.D. Alloying design as well as strength and toughness of high Mn steels for LNG tank building. China Metall. 2023, 33, 73–80. [Google Scholar] [CrossRef]

- Sohn, S.S.; Hong, S.; Lee, J.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn and Al contents on cryogenic-temperature tensile and Charpy impact properties in four austenitic high-Mn steels. Acta Mater. 2015, 100, 39–52. [Google Scholar] [CrossRef]

- Wang, X.; Sun, X.; Song, C.; Chen, H.; Han, W.; Pan, F. Enhancement of yield strength by chromium/nitrogen alloying in high-manganese cryogenic steel. Mater. Sci. Eng. A 2017, 698, 110–116. [Google Scholar] [CrossRef]

- Chen, J.; Lu, S.; Hou, Z.-Y.; Song, W.-W.; Liu, Z.-Y.; Wang, G.-D.; Furuhara, T. Atomic-scale understanding of twin intersection rotation and ε-martensite transformation in a high Mn twinning-induced plasticity steel. Acta Mater. 2024, 271, 119832. [Google Scholar] [CrossRef]

- A1106/A1106M: 2017; Standard Specification for Pressure Vessel Plate, Alloy Steel, Austenitic High Manganese for Cryogenic Application. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Chen, J.; Ren, J.-K.; Liu, Z.-Y.; Wang, G.-D. Interpretation of significant decrease in cryogenic-temperature Charpy impact toughness in a high manganese steel. Mater. Sci. Eng. A 2018, 737, 158–165. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, A.-M.; Mi, Z.-L.; Jing, H.-T.; Li, W.-Y.; Hui, Y.-J. Formability of Fe-Mn-C Twinning Induced Plasticity Steel. J. Iron Steel Res. Int. 2013, 20, 111–117. [Google Scholar] [CrossRef]

- Lee, D.; Yoon, G.-Y.; Park, S.-J.; Lee, J.S.; Heo, Y.-U. M23C6-assisted formation mechanism of grain boundary cellular structure and its role on the brittle fracture in an austenitic Fe-Mn-Al-C lightweight alloy. J. Alloys Compd. 2024, 972, 172865. [Google Scholar] [CrossRef]

- Lee, D.; Trang, T.; Kim, D.-H.; Yoon, G.-Y.; Park, S.-J.; Lee, J.S.; Heo, Y.-U. Boron-induced unique precipitation behavior at the grain boundary and its effect on the brittle fracture in a Fe-Mn-Al-C-based austenitic lightweight alloy. Scr. Mater. 2025, 259, 116574. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Jo, Y.H.; Jung, S.; Choi, W.M.; Sohn, S.S.; Kim, H.S.; Lee, B.J.; Kim, N.J.; Lee, S. Cryogenic strength improvement by utilizing room-temperature deformation twinning in a partially recrystallized VCrMnFeCoNi high-entropy alloy. Nat. Commun. 2017, 8, 15719. [Google Scholar] [CrossRef]

- Yang, H.-S.; Jang, J.; Bhadeshia, H.; Suh, D. Critical assessment: Martensite-start temperature for the γ→ε transformation. Calphad 2012, 36, 16–22. [Google Scholar] [CrossRef]

- Dastur, Y.N.; Leslie, W.C. Mechanism of work hardening in Hadfield manganese steel. Metall. Trans. A 1981, 12, 749–759. [Google Scholar] [CrossRef]

- Hwang, J.-K. Deformation behaviors of various Fe–Mn–C twinning-induced plasticity steels: Effect of stacking fault energy and chemical composition. J. Mater. Sci. 2020, 55, 1779–1795. [Google Scholar] [CrossRef]

- Tobler, R.L.; Meyn, D. Cleavage-like fracture along slip planes in Fe-18Cr-3Ni-13Mn-0.37N austenitic stainless steel at liquid helium temperature. Metall. Trans. A 1988, 19, 1626–1631. [Google Scholar] [CrossRef]

- Tomota, Y.; Xia, Y.; Inoue, K. Mechanism of low temperature brittle fracture in high nitrogen bearing austenitic steels. Acta Mater. 1998, 46, 1577–1587. [Google Scholar] [CrossRef]

- Liu, S.; Liu, D.; Liu, S. Transgranular fracture in low temperature brittle fracture of high nitrogen austenitic steel. J. Mater. Sci. 2007, 42, 7514–7519. [Google Scholar] [CrossRef]

- Lee, J.; Sohn, S.S.; Hong, S.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn Addition on Tensile and Charpy Impact Properties in Austenitic Fe-Mn-C-Al-Based Steels for Cryogenic Applications. Met. Mater. Trans. A 2014, 45, 5419–5430. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.-T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Wang, L.; Guan, P.; Teng, J.; Liu, P.; Chen, D.; Xie, W.; Kong, D.; Zhang, S.; Zhu, T.; Zhang, Z.; et al. New twinning route in face-centered cubic nanocrystalline metals. Nat. Commun. 2017, 8, 2142. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 2012, 60, 5791–5802. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Al | P | S | N | O | Fe | SFE (25 °C), mJ/m2 | SFE (−196 °C), mJ/m2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Al | 0.60 | 0.61 | 18.04 | 0.04 | 0.0021 | 0.0110 | 0.030 | 0.0006 | Bal. | 24.40 | 10.74 |

| 3Al | 0.58 | 0.47 | 17.87 | 3.01 | 0.0063 | 0.0056 | 0.031 | 0.0006 | Bal. | 44.66 | 20.54 |

| 5Al | 0.62 | 0.49 | 18.37 | 5.16 | 0.0024 | 0.0071 | 0.029 | 0.0007 | Bal. | 61.62 | 29.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, L.; Zhang, Y.; Huang, H.; Zhang, B.; Ji, N.; Li, S.; Chen, J. Effect of Heat Treatment Temperature on the Microstructure and Mechanical Properties of Fe-18Mn-0.6C-xAl. Metals 2025, 15, 927. https://doi.org/10.3390/met15080927

Xiao L, Zhang Y, Huang H, Zhang B, Ji N, Li S, Chen J. Effect of Heat Treatment Temperature on the Microstructure and Mechanical Properties of Fe-18Mn-0.6C-xAl. Metals. 2025; 15(8):927. https://doi.org/10.3390/met15080927

Chicago/Turabian StyleXiao, Li, Yuqi Zhang, Huan Huang, Bochao Zhang, Ningning Ji, Shuang Li, and Jun Chen. 2025. "Effect of Heat Treatment Temperature on the Microstructure and Mechanical Properties of Fe-18Mn-0.6C-xAl" Metals 15, no. 8: 927. https://doi.org/10.3390/met15080927

APA StyleXiao, L., Zhang, Y., Huang, H., Zhang, B., Ji, N., Li, S., & Chen, J. (2025). Effect of Heat Treatment Temperature on the Microstructure and Mechanical Properties of Fe-18Mn-0.6C-xAl. Metals, 15(8), 927. https://doi.org/10.3390/met15080927