3.1. Results of FE Model

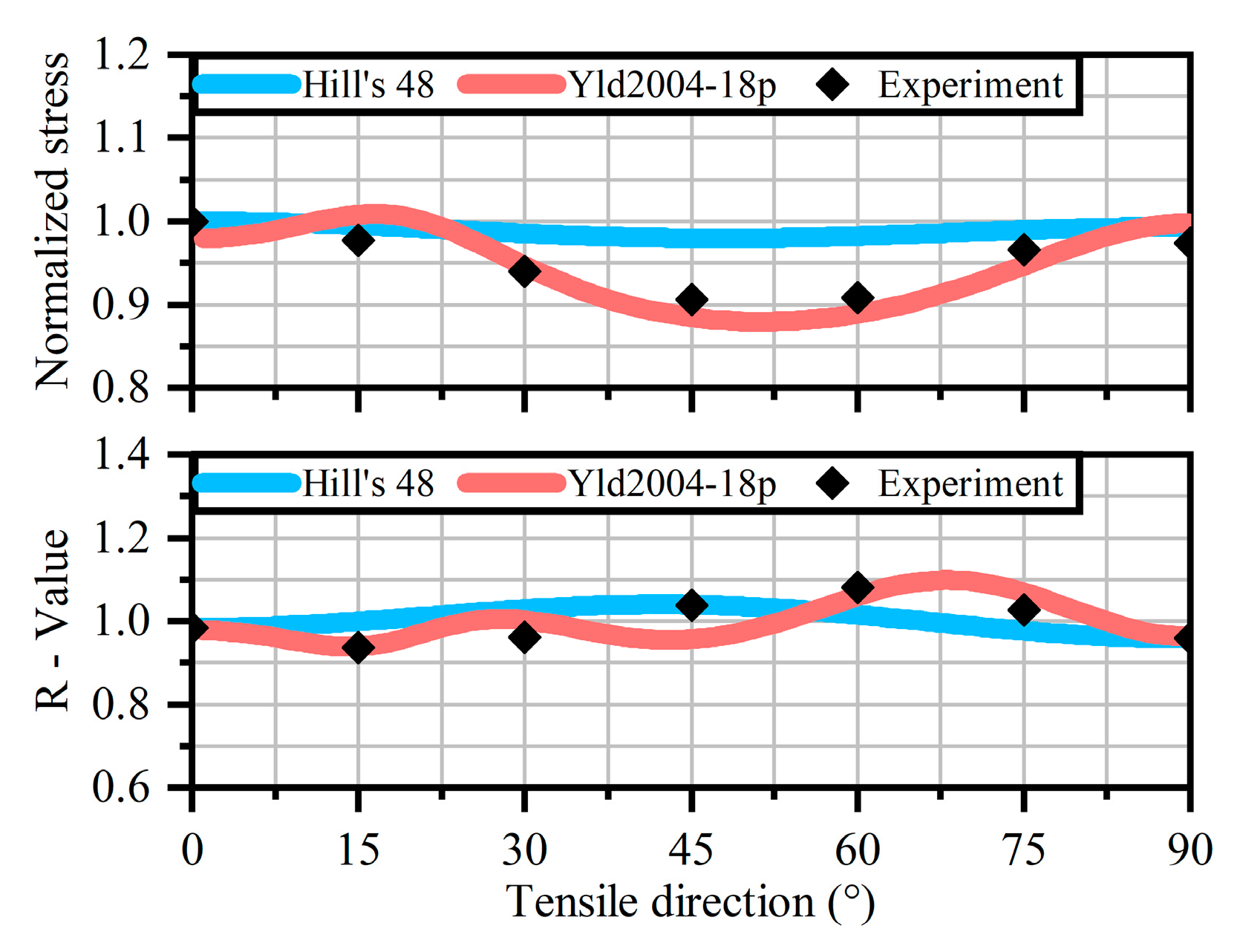

Based on the FE model established earlier, simulations were first conducted using the built-in Von Mises yield model in the software.

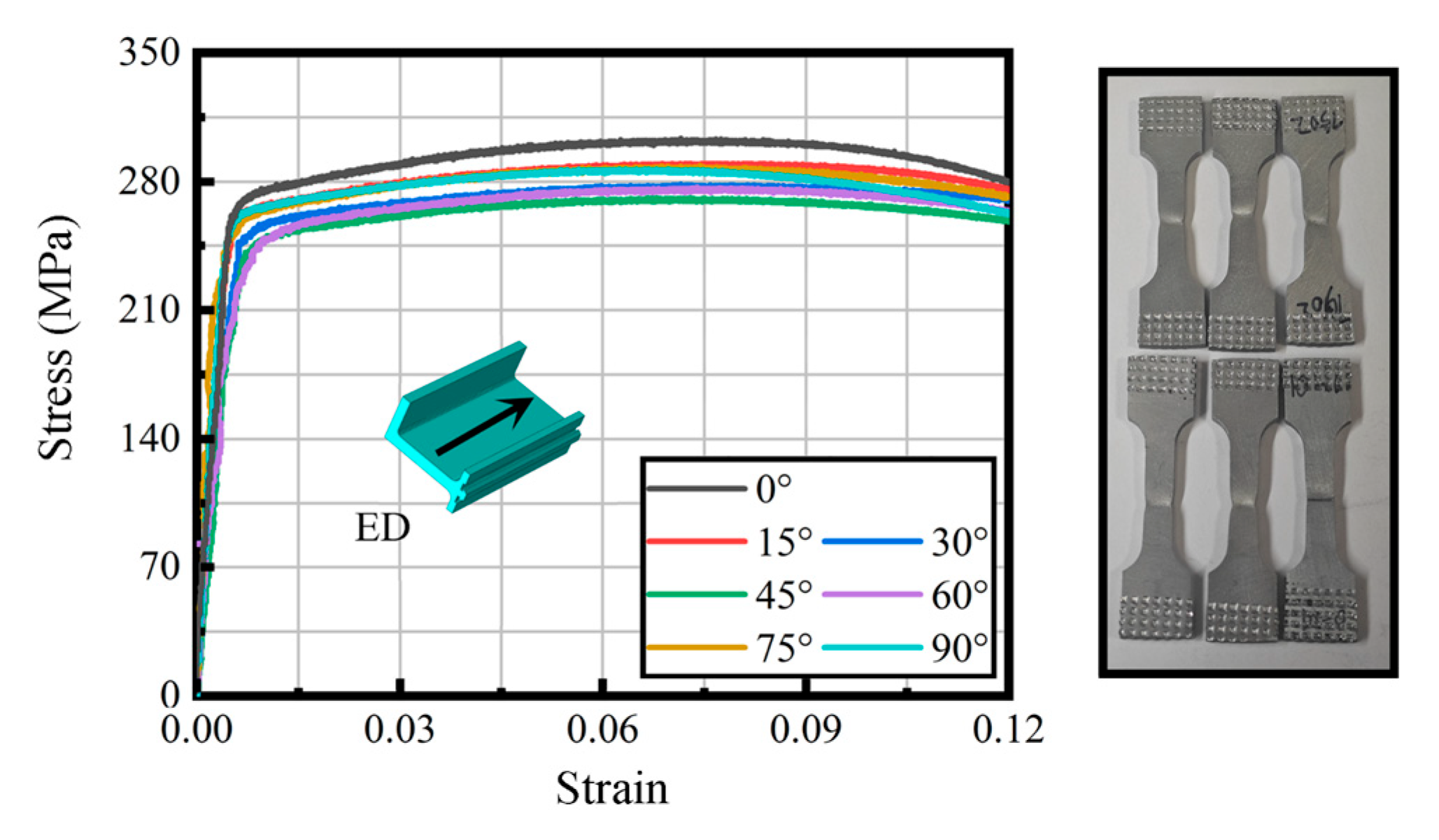

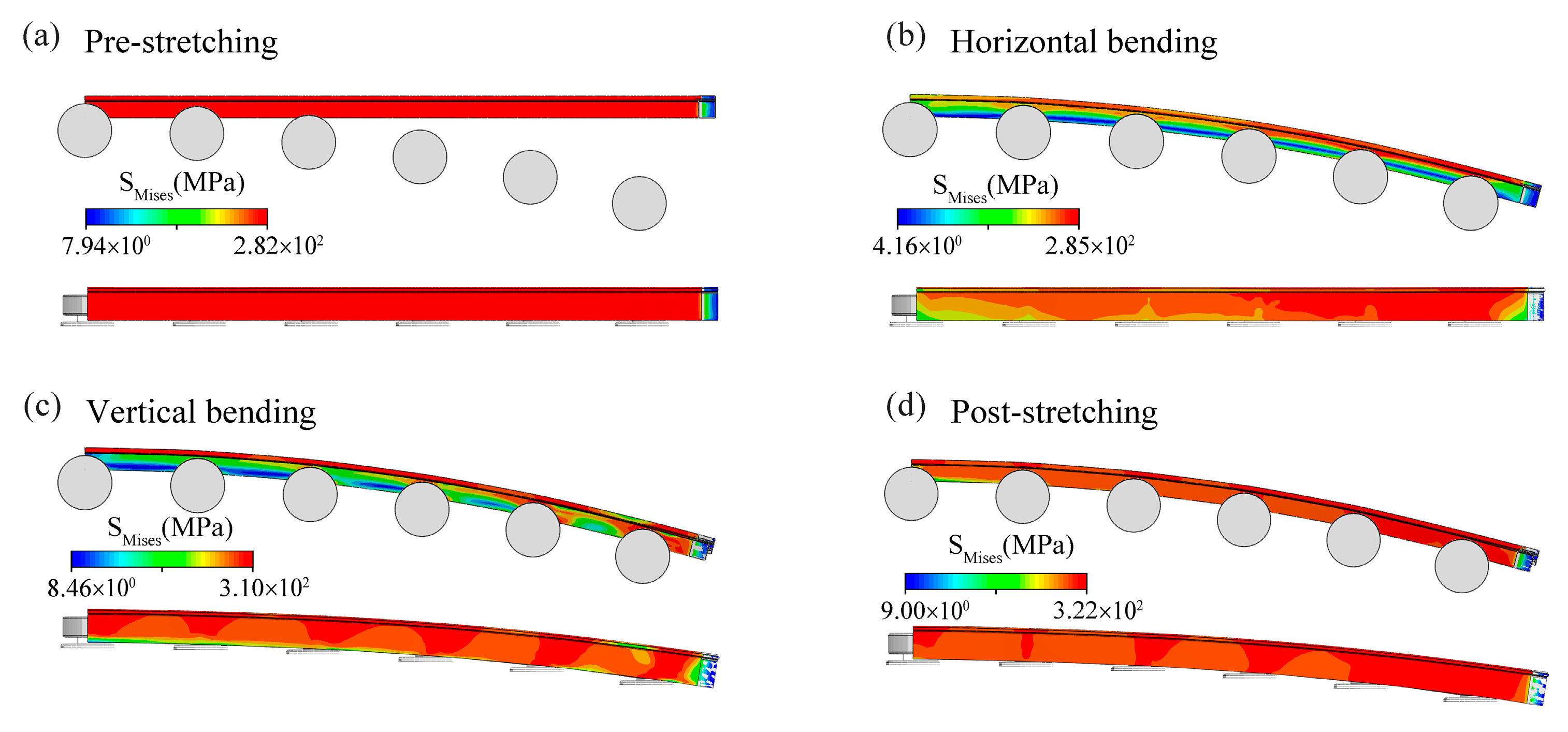

Figure 6 shows the deformation results at different analysis steps for a 30° horizontal bend and a 15° vertical bend, with both pre-stretching and post-stretching strain rates set at 1%. As observed in the figure, after the bending process, the stress distribution in the blank becomes highly uneven, with significant local stress concentration near the roller contact area. Comparing

Figure 6c,d, the maximum equivalent stress increases from 3.10 × 10

2 MPa to 3.22 × 10

2 MPa, yet the overall internal stress distribution becomes more uniform, with no obvious stress concentration. This indicates that the introduction of post-stretching can effectively improve the uniformity of the stress distribution within the blank without significantly increasing the maximum stress.

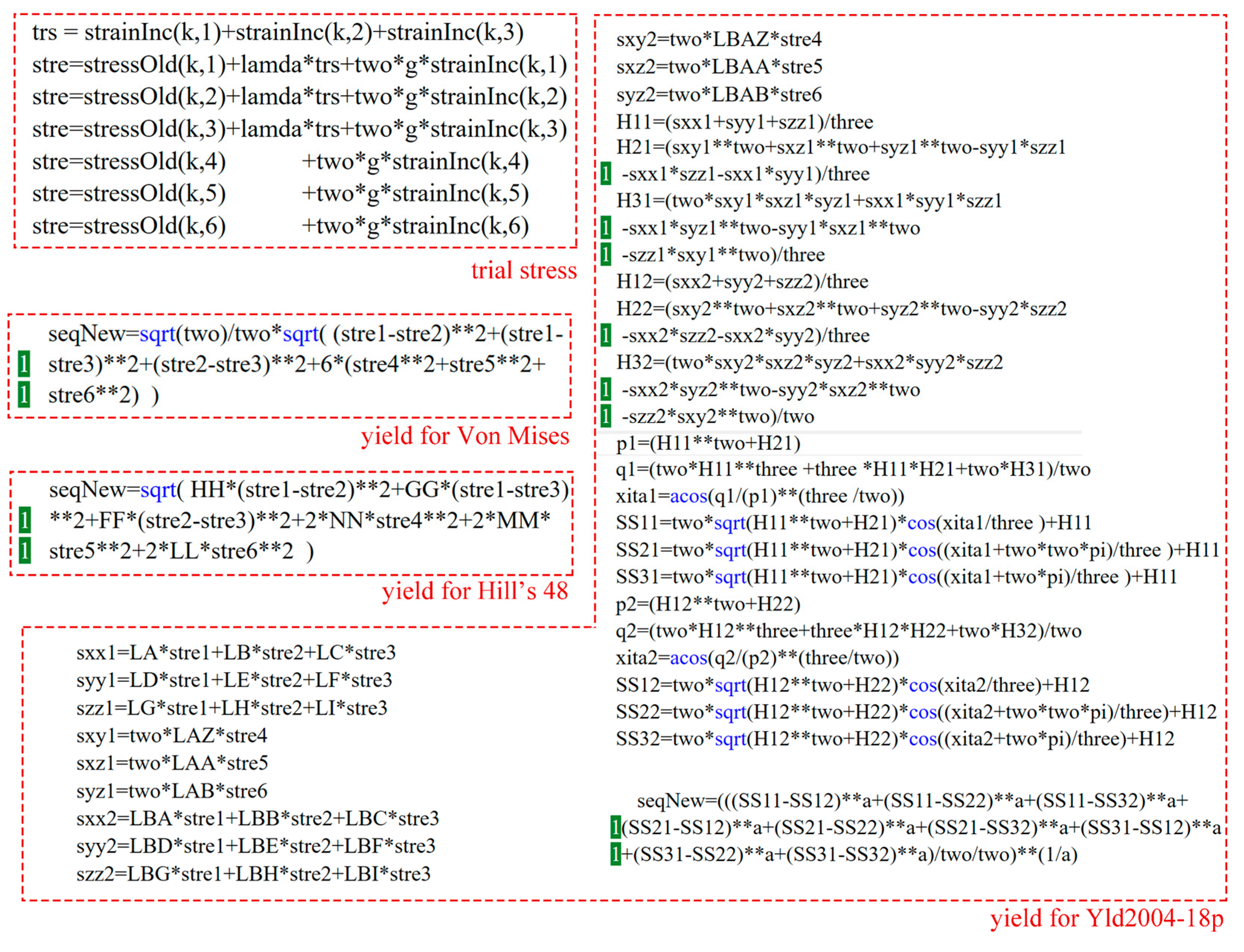

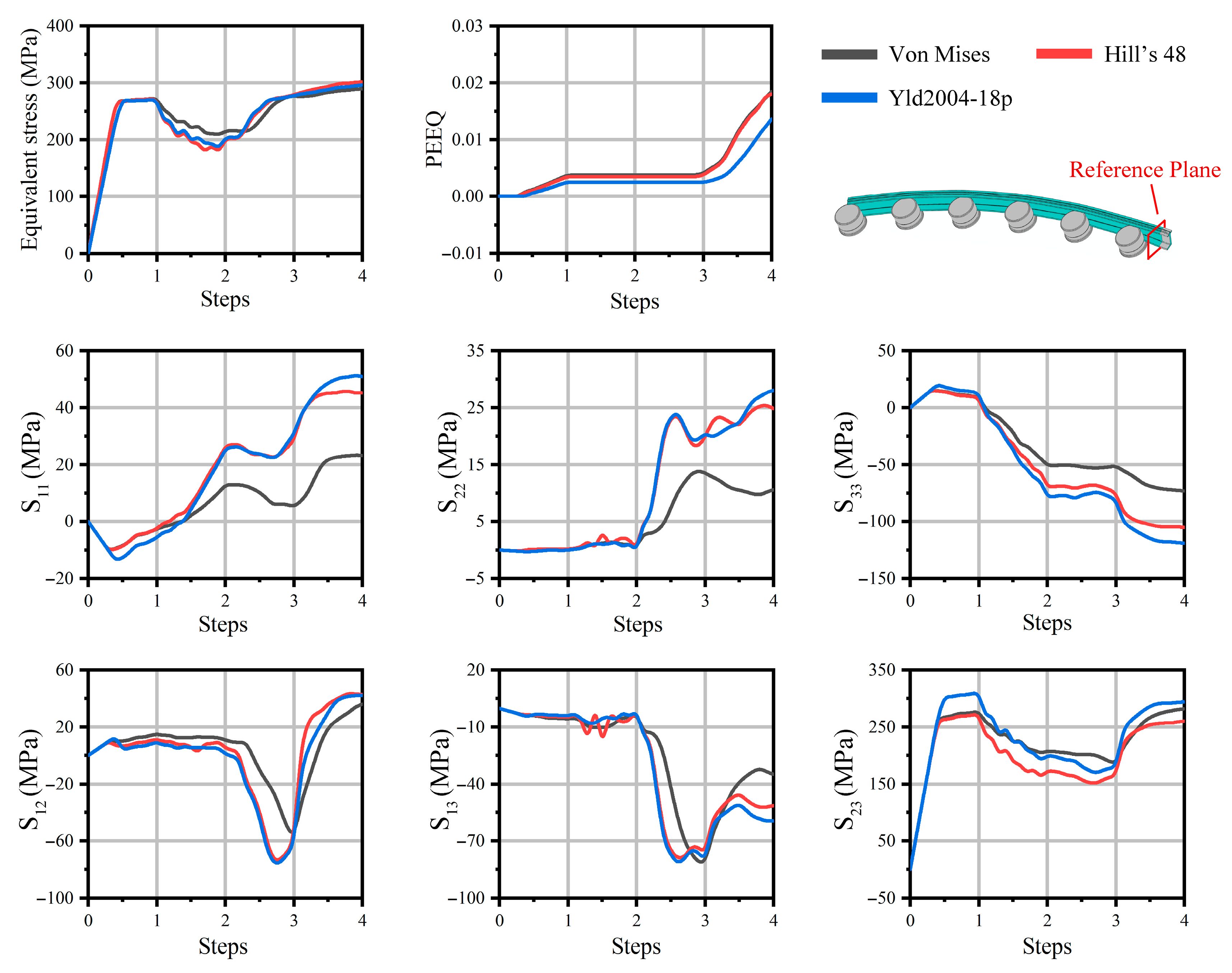

Based on the analysis of the bending forming model under the aforementioned process parameters, this study further conducts FE analysis using Hill’s 48 and Yld2004-18p yield models and compares them with the Von Mises isotropic yield model. The plane near the clamps is selected as the reference plane, and the stress–strain behavior at the center of the cross-section is compared. The results are shown in

Figure 7. The horizontal axis of the curve represents the analysis step time, with analysis steps 1 to 4 corresponding to the pre-stretching, horizontal bending, vertical bending, and post-stretching stages, respectively. By observing the equivalent stress curves, it can be seen that in the first half of analysis step 1, the equivalent stresses under different yield models are approximately equal. This is because the reference point is in the elastic stage, and the changes brought by the yield models only affect the yielding and subsequent plastic flow process. Therefore, the equivalent plastic strain curve remains zero, and in the data for different stress components, the curves during the initial elastic stage overlap nearly completely. The minor discrepancies in the figure are due to the iterative analysis process and can be neglected.

As shown in

Figure 6a, in the first analysis step (pre-stretching stage), the maximum equivalent stress in the blank is approximately 282.2 MPa, which is greater than the initial yield stress of 272 MPa. The corresponding contour region includes the reference plane area in

Figure 7. Therefore, it can be concluded that after the first analysis step, plastic yielding has occurred at the center of the reference cross-section, which is also reflected in

Figure 7, where the equivalent plastic strain starts to deviate from zero. However, the equivalent stress curves of different models coincide at this point. This is because the initial stresses near the yield surface are small, and the differences introduced by the anisotropic models in the calculation of equivalent stress are also minimal. Comparing the different stress components at this stage reveals that their behaviors vary. Among them, S

11, S

22, and S

33 shown in

Figure 7 represent the three normal stress components, corresponding to the directions of the global coordinate system in

Figure 1. S

12, S

13, and S

23 represent the corresponding shear stress components. For example, the S

22 component shows similar curves for all models, while the S

11 component exhibits considerable differences. This is due to the differences in stress variations along different directions introduced by the anisotropic models. These differences will lead to variations in the final simulation results, which is the key focus of this study.

After entering the second analysis step, due to the horizontal bending process, the pre-stretched blank is brought closer to the die, and the volume change in the reference point unit is minimal, with only a shape change occurring. As a result, the PEEQ (the equivalent plastic strain) value changes only slightly, and a plateau appears in the curve graph. However, corresponding differences in the equivalent stress and different stress components are observed at this point. This is because the direction of concentrated stress changes as a result of the shape alteration. Under the same level of deformation, stresses in different directions exhibit significant differences due to the material’s plastic anisotropy. Additionally, the anomalous sawtooth fluctuations observed in the S13 stress component in Hill’s 48 model are caused by computational errors during the iterative calculation of partial derivatives. The corresponding curve in the figure shows fluctuations when entering the second analysis step, and no similar changes occur thereafter. Since the fluctuations do not cause any deviations in the final data, the subsequent curve changes follow a similar pattern. Therefore, it is concluded that this error does not affect the final results. Upon entering the vertical bending analysis step, the stress components under different models show significant differences, especially the normal stresses S11, S22, and S33. However, the calculated equivalent stress differences remain small. This is due to the stress distribution differences introduced by the anisotropic models, but the equivalent stress, which represents the overall stress state, does not change significantly. Based on the differences in yield functions, the PEEQ value gradually accumulates as the equivalent strain changes minimally, and thus increases as the deformation progresses. Consequently, after the post-stretching analysis step, this difference is further amplified. At the final analysis step, when the simulation ends, the PEEQ difference between different material models becomes apparent. The PEEQ for the Von Mises model is 1.85 × 10−2, while for Hill’s 48 model, it is 1.81 × 10−2, and for Yld2004-18p, it is 1.36 × 10−2. The error values of the two anisotropic models are 2% and 26.5%, showing significant differences when isotropic simplification is applied. However, the corresponding equivalent stress values are 289.64 MPa, 301.61 MPa, and 295.67 MPa, and the error values are 4.1% and 2.1%, with only minor differences.

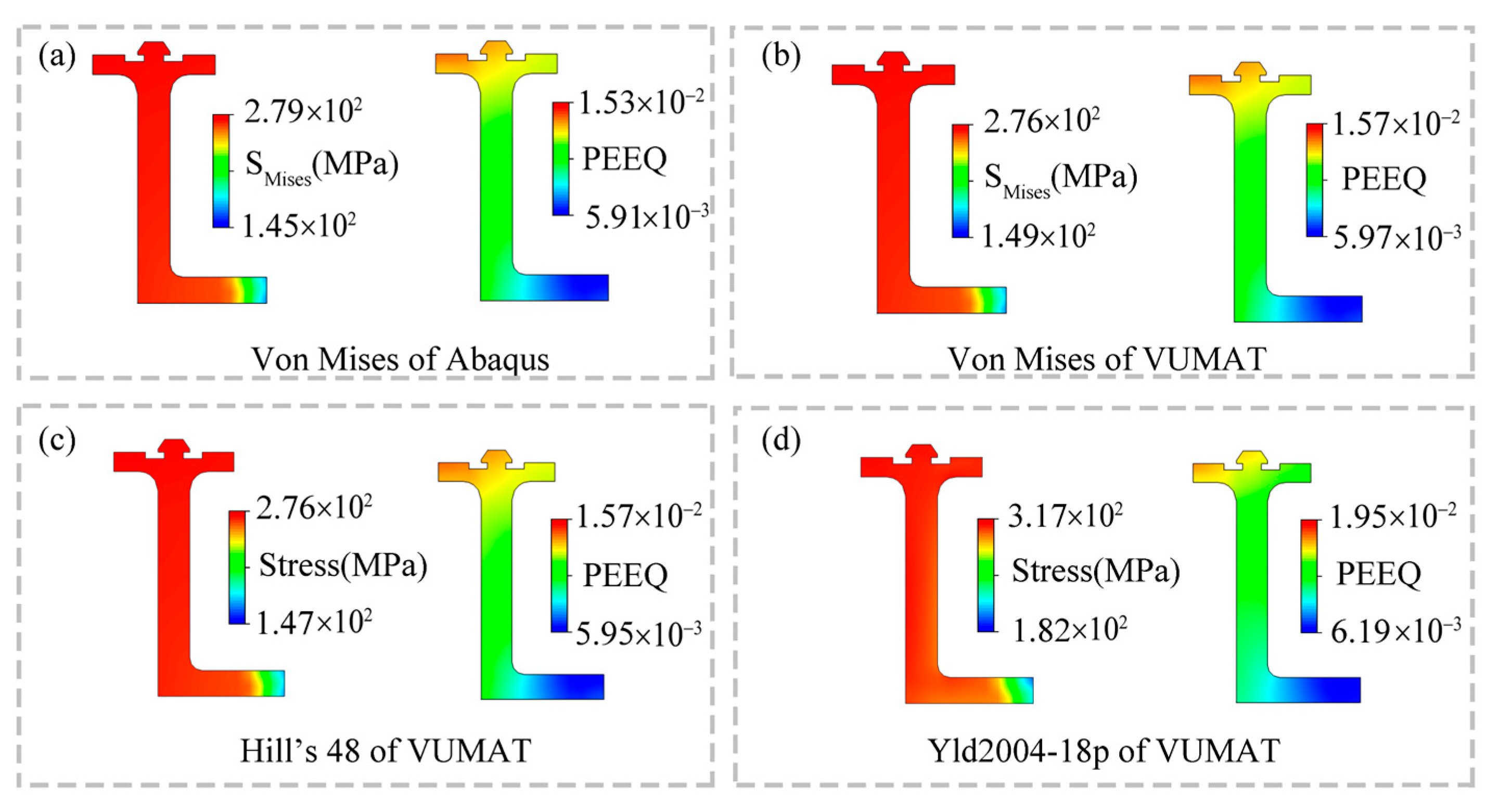

Figure 8 compares and analyzes the cross-sectional deformation result contours at 200 mm, including equivalent stress and equivalent strain. By comparing the corresponding indicators in

Figure 8a,b, it can be seen that the indicators obtained using the subroutine solution show little difference from those obtained by the software’s built-in solver. The maximum equivalent stresses are 279.2 MPa and 276.2 MPa, respectively, with a negligible error of about 1%. Correspondingly, the error in the maximum equivalent strain is also very small, at approximately 2.6%.

Figure 8c,d employ the Hill’s 48 and Yld2004-18p models for the solution, respectively. Different yield models introduce certain errors in equivalent stress and equivalent strain, reaching up to 13% and 27%, respectively. However, there is no intuitive difference in the contour distribution in the corresponding images. This is because, during the deformation process, the differences caused by different yield models only significantly affect local deformation values and have a relatively minor impact on the overall deformation results. After entering the yield state, the growth rate of equivalent stress significantly slows down with the accumulation of deformation (as shown in the stress–strain curve in

Figure 3). Therefore, in the equivalent stress contour plot shown in

Figure 8, there are large areas of red, while the PEEQ contour plot is evenly distributed.

3.2. Influence of Material Models on Deformation Results

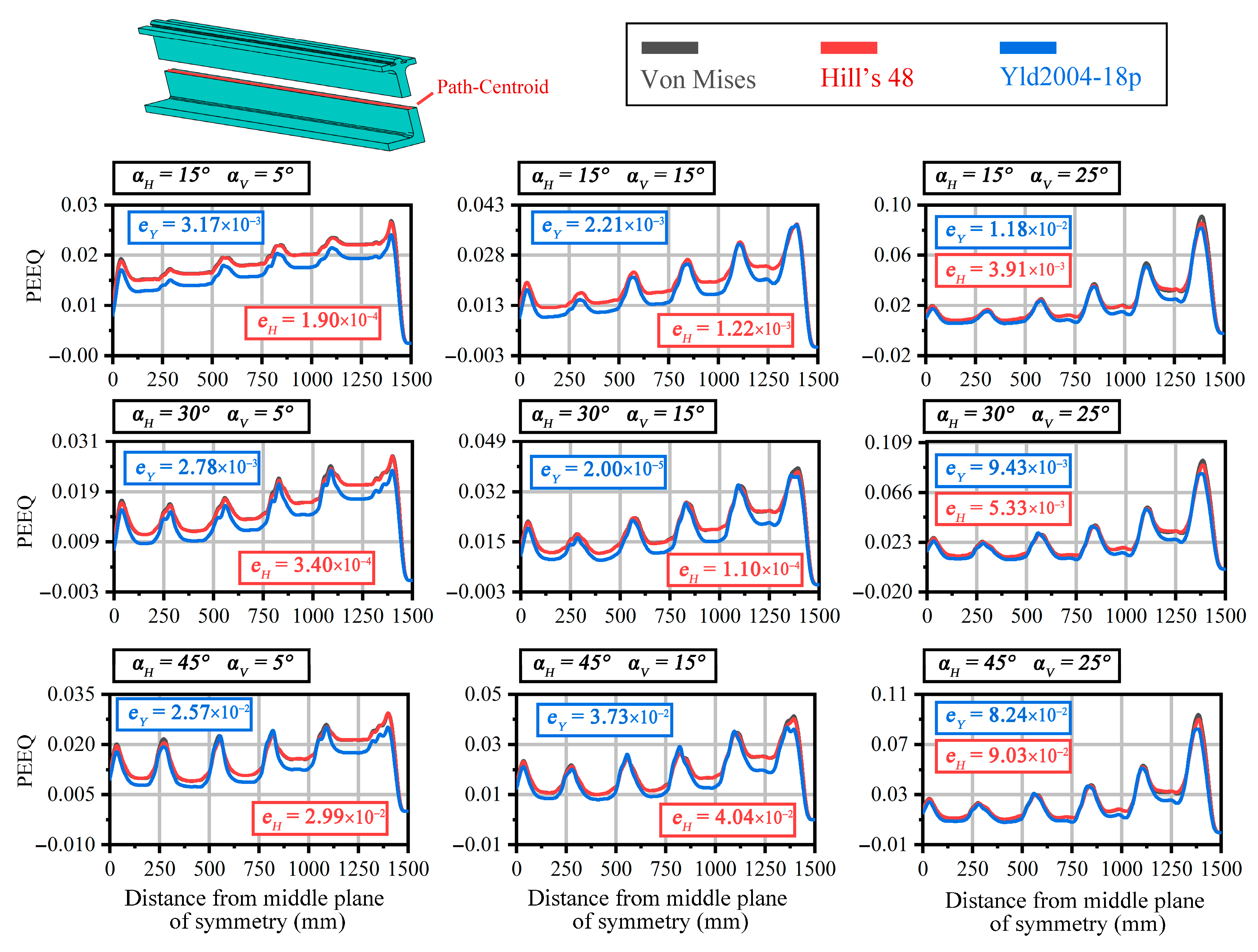

Based on the above analysis, this study conducted FE simulations of the forming process under different bending angle process parameters. During the deformation result analysis, the PEEQ indicator is typically used to represent the local deformation degree and potential shape errors in the blank. The centerline path of the section is chosen to represent the overall deformation results, as shown in

Figure 9. The horizontal axis of the curve represents the distance from the middle of the symmetry plane. From the figure, it is observed that the curves for different material models under different process parameters exhibit local peaks. These peaks are due to differences caused by the discrete die contacting the local areas of the blank. Comparing the different material models, the peak positions correspond well and are located at the blank-die contact area. Additionally, it can be seen that the horizontal bending process has a smaller effect on the PEEQ, whereas the vertical bending process has a larger effect on the PEEQ. This is because, during the horizontal bending process, the blank tends to undergo shape changes with minimal volume change. In contrast, during the vertical bending process, the blank experiences significant volume changes due to tangential forces from the clamps, leading to larger changes in equivalent plastic strain.

The comparison of different material model curves under various process parameters shows that the Hill’s 48 model aligns closely with the isotropic Von Mises model, exhibiting only minor deviations at peak values. In contrast, the Yld2004-18p model displays notable differences across various positions. To quantify the degree of variation, the peak errors eH and eY between the Hill’s 48 and Yld2004-18p models and the isotropic model were calculated. Across the same process parameters, eH values were slightly lower than eY, in line with the curves shown. However, the differences in eH and eY across different parameters are minimal, and the values for eY are also small, less than 10%. This suggests that an isotropic simplification can effectively capture the overall shape error defects in the deformation process analyzed in this study.

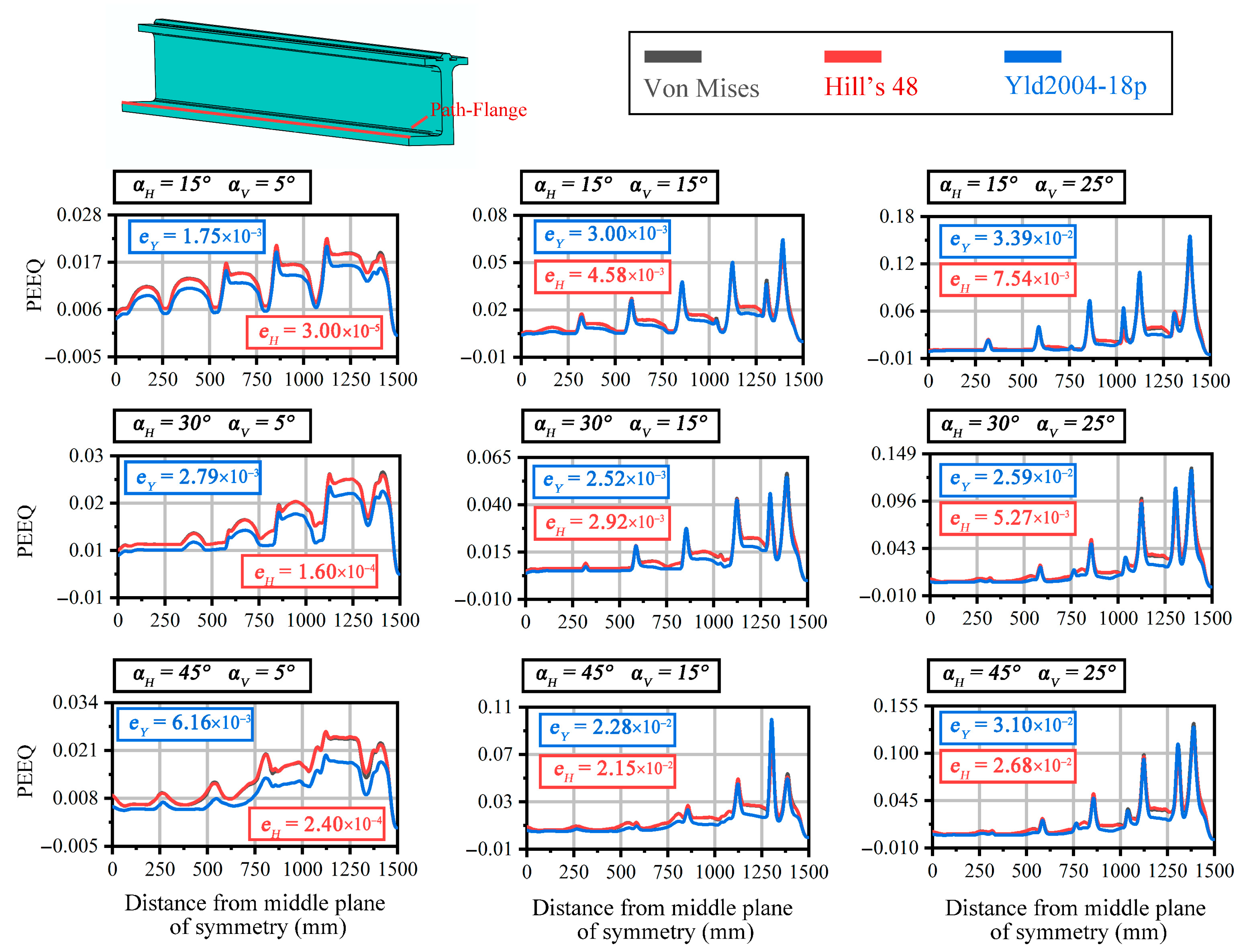

Furthermore, as depicted in

Figure 1, during the FSBRD process, significant contact occurs between the flange of the L-shaped profile and the roller dies. This contact results in stress concentrations in the contact area of the flange, as illustrated in

Figure 6. Due to the resistance to horizontal and vertical bending provided by the roller dies, maximum deformation typically occurs in the flange area. Thus, PEEQ analysis on the flange is often used to represent deformation due to contact.

Figure 10 illustrates the PEEQ variation along the flange path under different bending angle parameters, along with the error values for each material model. Here, errors e

H and e

Y are defined as in the previous sections. Comparing these results with those in

Figure 9 for Path-Centroid, it is evident that the PEEQ peak along Path-Flange is significantly higher than that along Path-Centroid, while PEEQ values in non-peak areas remain comparable. This finding confirms that localized contact on the flange induces substantial localized deformation, which macroscopically manifests as local indentations. In non-contact areas, the PEEQ distribution across the cross-section remains uniform.

For different material models, unlike the Path-Centroid case, the error of the curve is no longer less than 10%, and non-negligible errors emerge. When αH = 15° and αV = 25°, there is an error eY of 3.39 × 10−2 between the Yld2004-18p material model and the Von Mises isotropic model. The corresponding error rate is as high as 22.6%, which is significantly greater than 10%. Therefore, it is concluded that using the isotropic simplification for the model under these conditions would result in a relatively large error. This is due to the relatively large process parameters and high degree of deformation. As a result, the differences caused by material anisotropy are significant and cannot be ignored. Correspondingly, when αV = 25°, the values of eY under different αH parameters are all relatively large, being 3.39 × 10−2, 2.59 × 10−2, and 3.10 × 10−2, respectively. The corresponding error rates are 22.6%, 19.9%, and 23.2%, all of which are significantly greater than 10%. Similarly, when αH = 45°, the values of eY corresponding to different αV are also relatively large. This indicates that the isotropic simplification cannot be used when the process parameters are relatively large.

In addition, as can be seen from the figure, when αH = 45°, the indicators eY and eH show a significant degree of closeness. For example, when αH = 45° and αV = 15°, the two indicators are 2.28 × 10−2 and 2.15 × 10−2, respectively, corresponding to error rates of 22.8% and 21.5%, indicating that the errors are close. Therefore, both the Yld2004-18p material model and the Hill’s 48 material model can describe the process deformation results relatively well. However, when αH = 30° and αV = 25°, the difference between the two indicators becomes larger, being 2.59 × 10−2 and 5.27 × 10−2, respectively, with corresponding error rates of 19.9% and 4.1%. This is because, in the process applied in this study, vertical bending induces greater contact deformation. Therefore, compared to horizontal bending deformation, an increase in vertical bending deformation is more likely to reveal differences in anisotropy. As a result, the corresponding eY is larger, and the Yld2004-18p material model provides a more accurate description of the deformation results. An analysis of the computational time for the corresponding finite element simulations reveals significant differences among the material models. The average simulation time using the Von Mises model is approximately 24.49 h. In contrast, the Hill’s 48 model requires about 31.12 h, indicating a notable increase in computational time. The most computationally intensive model is the Yld2004-18p model, which takes as long as 71.86 h. Therefore, when selecting a material model, simplification should be made as much as possible within an acceptable error range to reduce computational costs.

In summary, when the deformation degree is relatively large, an anisotropic material model should be selected for a more accurate description of the process. In other cases, the Von Mises model can be used for simplification. When the vertical bending angle αV is large, there is a significant difference between the Yld2004-18p material model and the Hill’s 48 model. Therefore, the Yld2004-18p material model should be chosen to reduce simulation errors. When the horizontal bending angle αH is large, the difference between the Yld2004-18p and Hill’s 48 models is relatively small. Thus, the Hill’s 48 material model can be selected to reduce both errors and computational time costs.

The difference in results is caused by localized contact.

Figure 11 compares the PEEQ results in the localized contact zone of the material models under different deformation levels. As shown in

Figure 11a, when the deformation level is small (

αH = 15°), the results from the different material models are similar. The maximum abrupt values of local PEEQ for the three models are 4.24 × 10

−2, 4.32 × 10

−2, and 4.63 × 10

−2, respectively, indicating small differences. Compared with the isotropic model, the differences introduced by the two anisotropic models are 1.9% and 9.2%, both less than 10%. Therefore, when the deformation level is small, the error caused by using the isotropic simplification is relatively minor.

In

Figure 11c, when the deformation degree is relatively large, with

αH = 45°, the corresponding PEEQ also shows a significant abrupt change, with local maximum values of 6.72 × 10

−2, 8.02 × 10

−2, and 8.74 × 10

−2, respectively. At this point, noticeable differences appear among the indicators corresponding to different material models. The difference introduced by the Hill’s 48 model is 19.3%, and that by the Yld2004-18p model is 29.6%, both exceeding 15%. Therefore, it is concluded that isotropic simplification of the material model at this stage would introduce significant errors.

3.3. Results of Experimental Analysis

To validate the applicability of the simplified FE model through practical experiments, this paper uses springback as the reference metric. This is because springback is relatively easy to measure in both actual experiments and FE simulations. As previously mentioned, the differences introduced by various material models are mainly manifested at local contact areas with significant deformation.

Figure 12a shows that the cross-sectional strain distribution in the non-contact area is uniform, while obvious localized strain jumps occur in the cross-section of the contact area.

Figure 12b illustrates how springback is represented in the FE simulation process. The principle of solving springback in bent profiles is based on determining the stress–strain state of the cross-section [

21]. Therefore, altering the cross-sectional strain distribution will directly affect the final calculation of springback. This leads to differences in the springback results obtained from simulations using different material models.

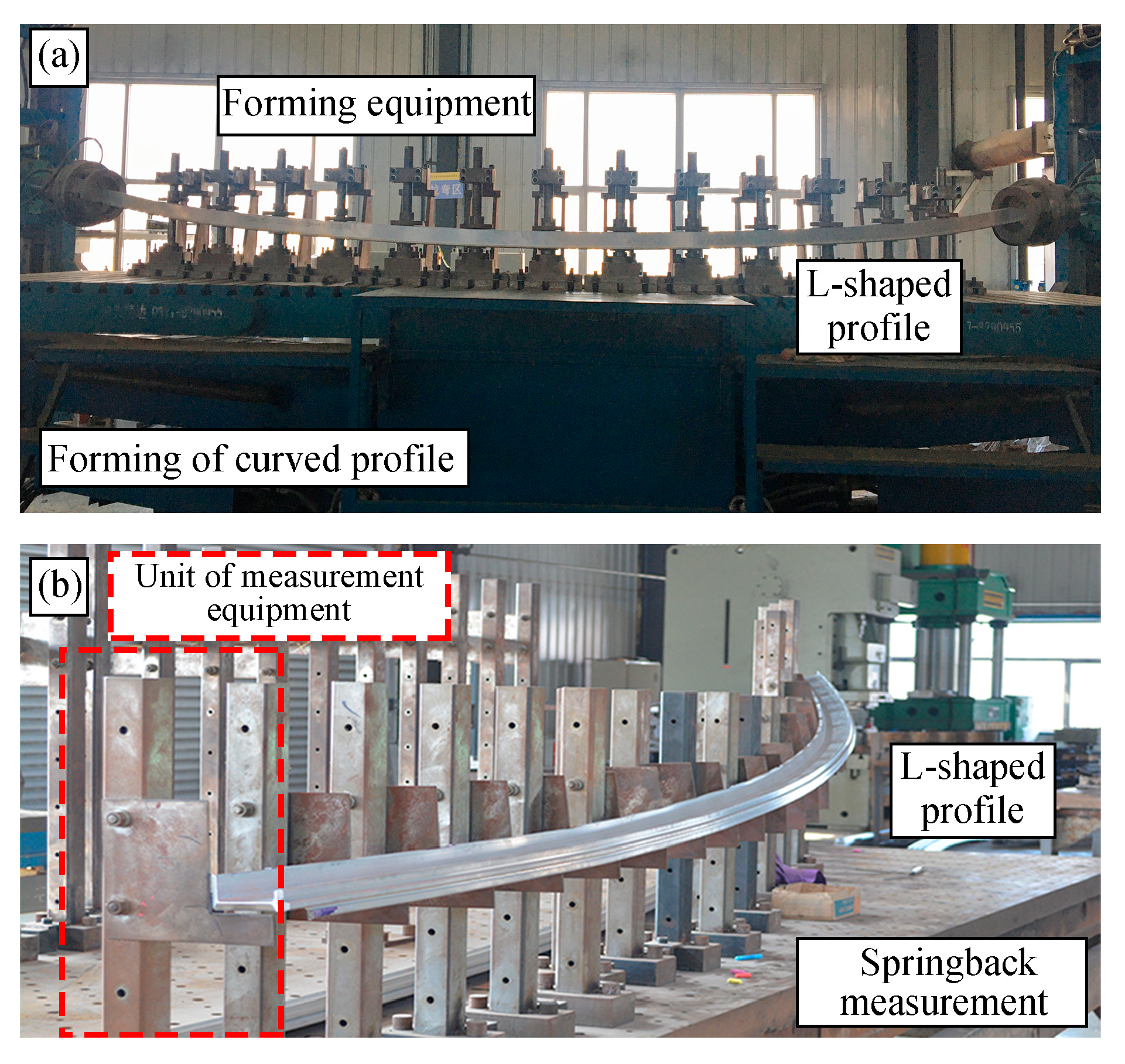

Simulations and experimental tests were conducted for various horizontal bending angles to validate the FE model and the related theoretical analyses. The forming process and springback measurement process are shown in

Figure 13 below.

Figure 13b illustrates the process of measuring the springback of L-shaped section profile. During the measurement, the unloaded experimental piece is placed on the equipment. And the bracket and detection point positions of the detection unit are adjusted to match the position of the unloaded formed piece. By comparing it with the position of the forming mold, the required springback amount can be obtained.

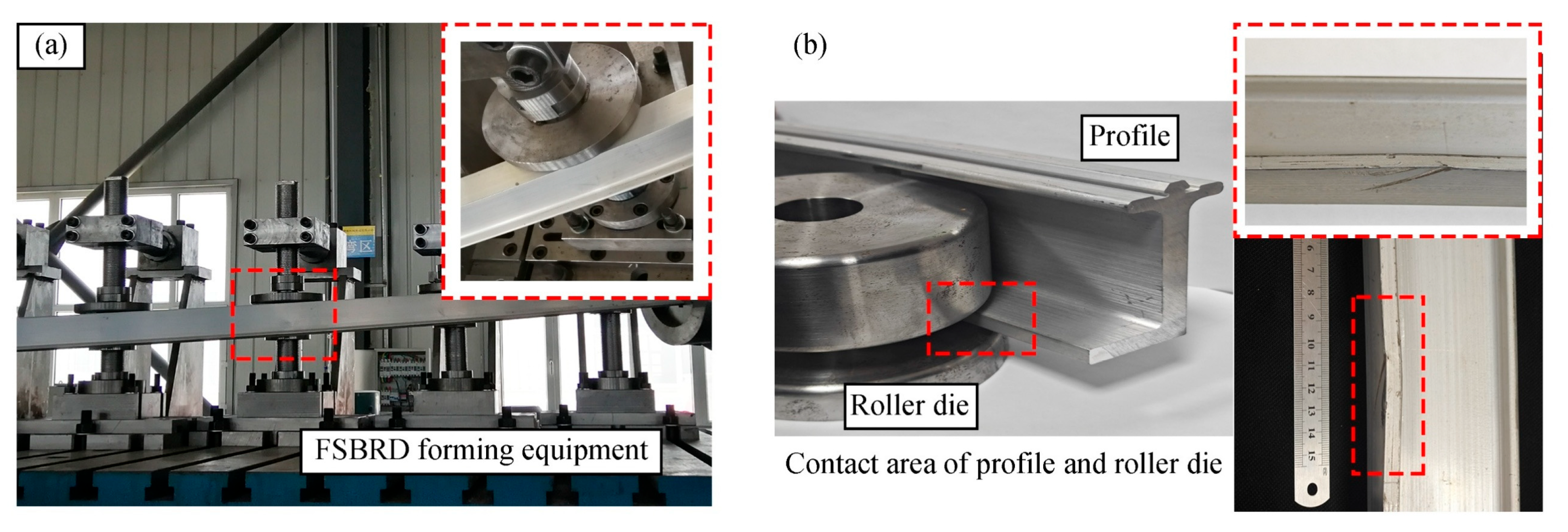

As shown in

Figure 14, during the FSBRD forming process, the profile blank will exhibit localized indentations due to contact with the discretized roller die. These indentations appear near the contact zones corresponding to the edges of the die, as illustrated in

Figure 14b. This matches the FE simulation results shown in

Figure 11. The contact between the profile and the roller die alters the stress–strain state of the profile’s cross-section, which in turn affects the springback results. Additionally, since the deformation caused by localized contact is relatively large, it is more significantly influenced by the anisotropic properties of the material. Moreover, as the degree of deformation increases, the constraint exerted by the roller die on the profile blank also increases, leading to a greater influence of the anisotropic properties. This aligns with the variation patterns summarized earlier.

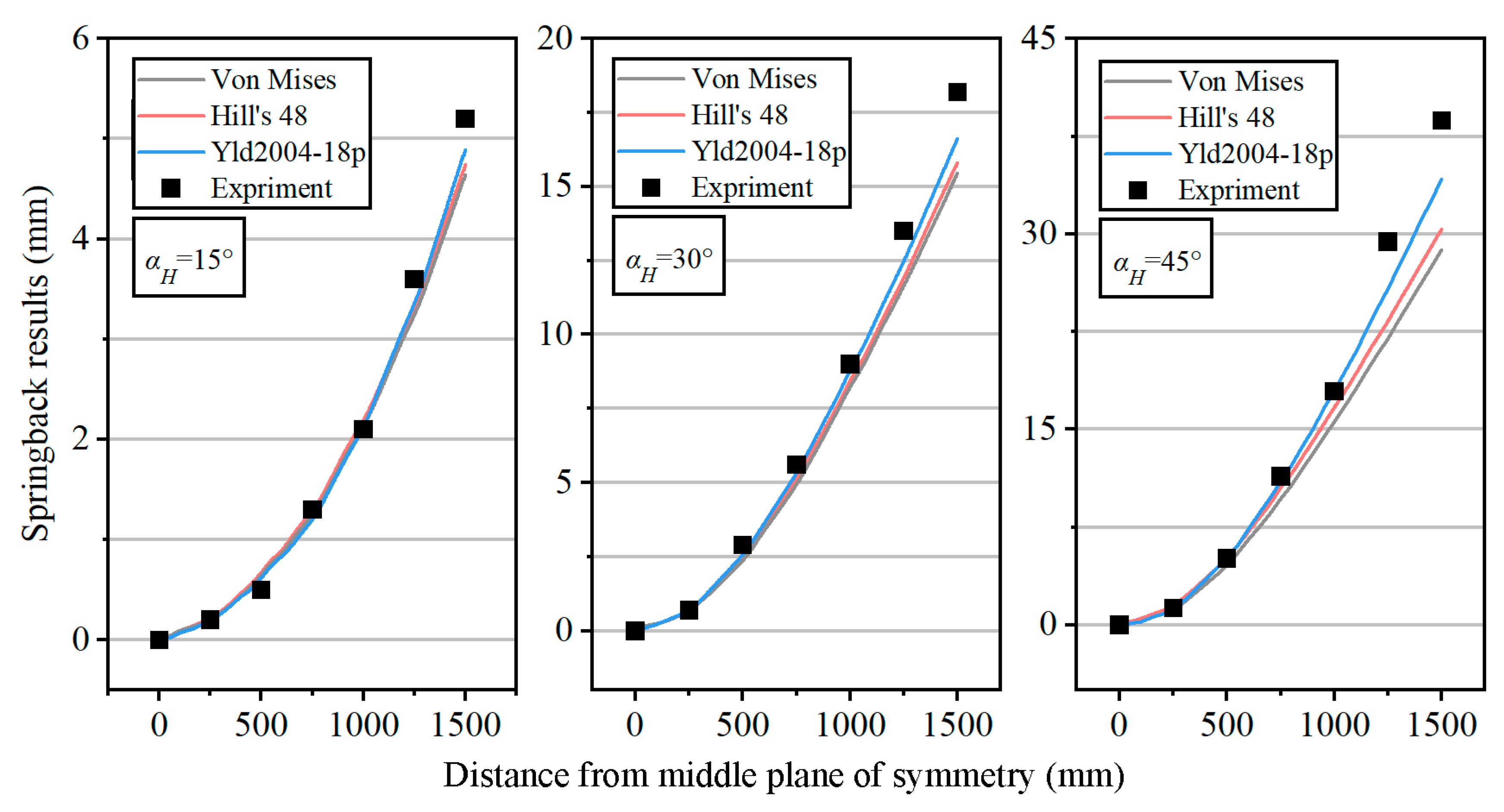

The springback results are measured as shown in

Figure 15. It is clear that different material models significantly impact the numerical values of springback. The Yld2004-18p anisotropic model provides results that are closer to the experimental values, thus offering higher accuracy. By comparing the springback values across different process parameters, it can be seen that, at smaller bending angles, the differences between the FE models and experimental results are minimal. This makes the error introduced by the isotropic simplification negligible.

As shown in the figure, when the horizontal bending angle αH = 15°, the simulation results of different material models are close to the experimental results, with relatively small differences. The springback value increases as the reference point moves away from the middle plane of symmetry. At a distance of 1500 mm from the middle plane, the experimental springback is about 5.2 mm. The simulation results from the different material models are 4.67 mm, 4.75 mm, and 4.89 mm, with errors of 10.2%, 8.7%, and 5.9%, respectively, all less than 15%. Since these differences are considered small, it is concluded that the isotropic simplified model can be used for relatively accurate simulation and analysis. However, when αH = 45°, the differences among the different material models become more significant. The errors in the simulation results from the different material models are 25.6%, 21.5%, and 11.6%, respectively. Among them, the Yld2004-18p anisotropic model yields the smallest error, less than 15%. Therefore, this material model should be selected for the analysis, consistent with earlier findings.

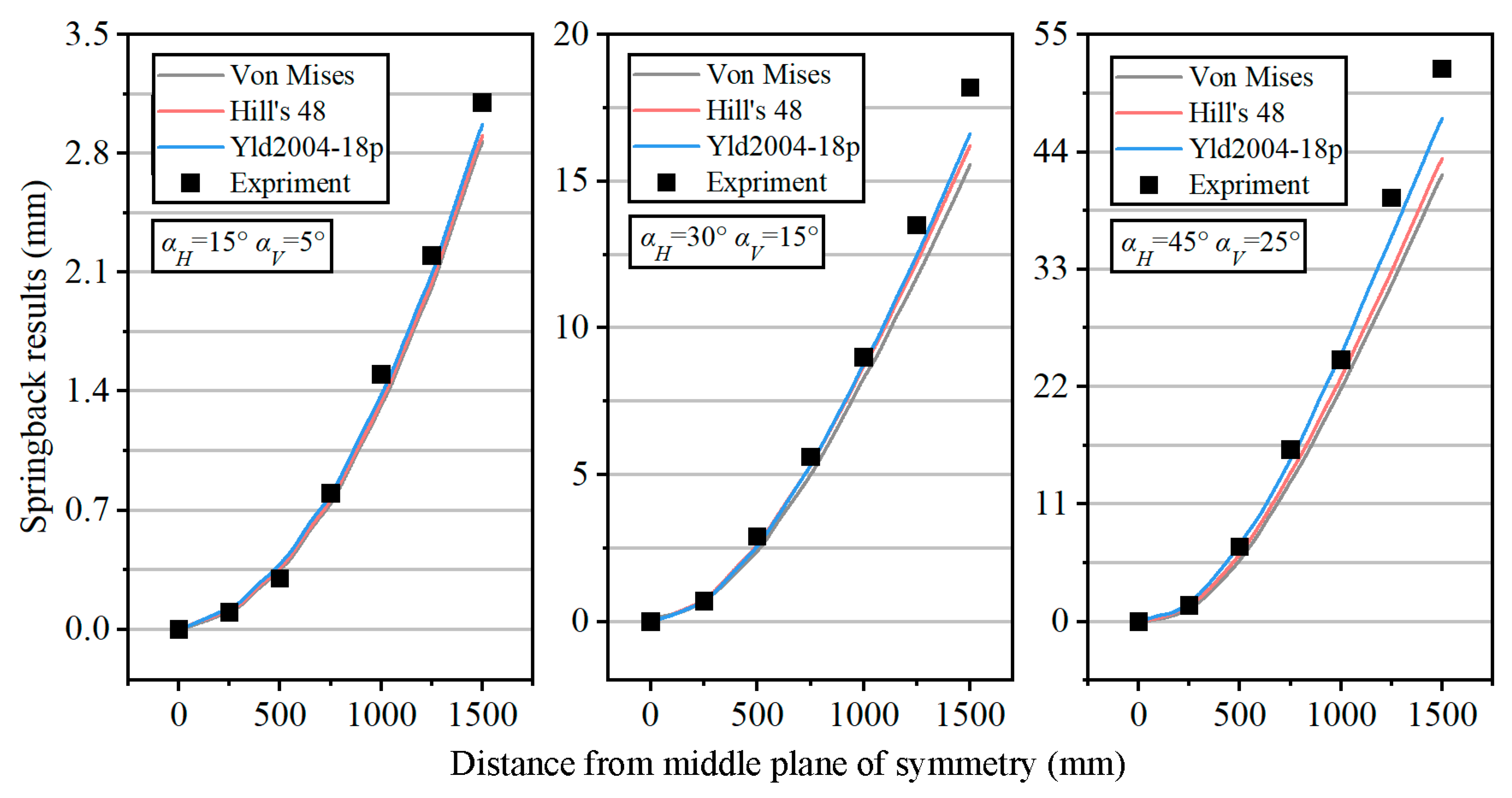

Figure 16 compares the springback results under three different deformation levels. When

αH = 15° and

αV = 5°, the overall deformation during the forming process is relatively small. In this case, the springback curves of the deformation results from the different material models overlap well. Compared with the experimental results, the errors are relatively small, being 7.4%, 6.2%, and 4.1%, respectively. Therefore, under these process parameters, an isotropic model can be used for simulation to improve computational efficiency. When

αH = 45° and

αV = 25°, the deformation level is higher. By comparing the differences between the three material models and the experimental results, the errors are found to be 19.2%, 16.2%, and 8.9%, respectively. Due to the relatively large errors introduced by the isotropic simplification, the Yld2004-18p material model should be selected for simulation.

In summary, as the process parameters change, the differences in simulation results among different material models increase with the rise in deformation degree. When conducting related research, model selection should be based on the actual error tolerance requirements. In this study, an error value of 15% is taken as the permissible error threshold. Therefore, when the horizontal bending angle (αH) exceeds 30° and the vertical bending angle (αV) exceeds 15°, the anisotropic Yld2004-18p and Hill’s 48 model should be selected. Otherwise, the isotropic Von Mises model can be used for simplification to improve computational efficiency. Furthermore, when choosing the anisotropic model, the Hill’s 48 model should be prioritized within the allowable error range to enhance computational efficiency.