Optimization Study of Laser-Drilling Processes in Stainless Steel Under Two Scanning Path Strategies

Abstract

1. Introduction

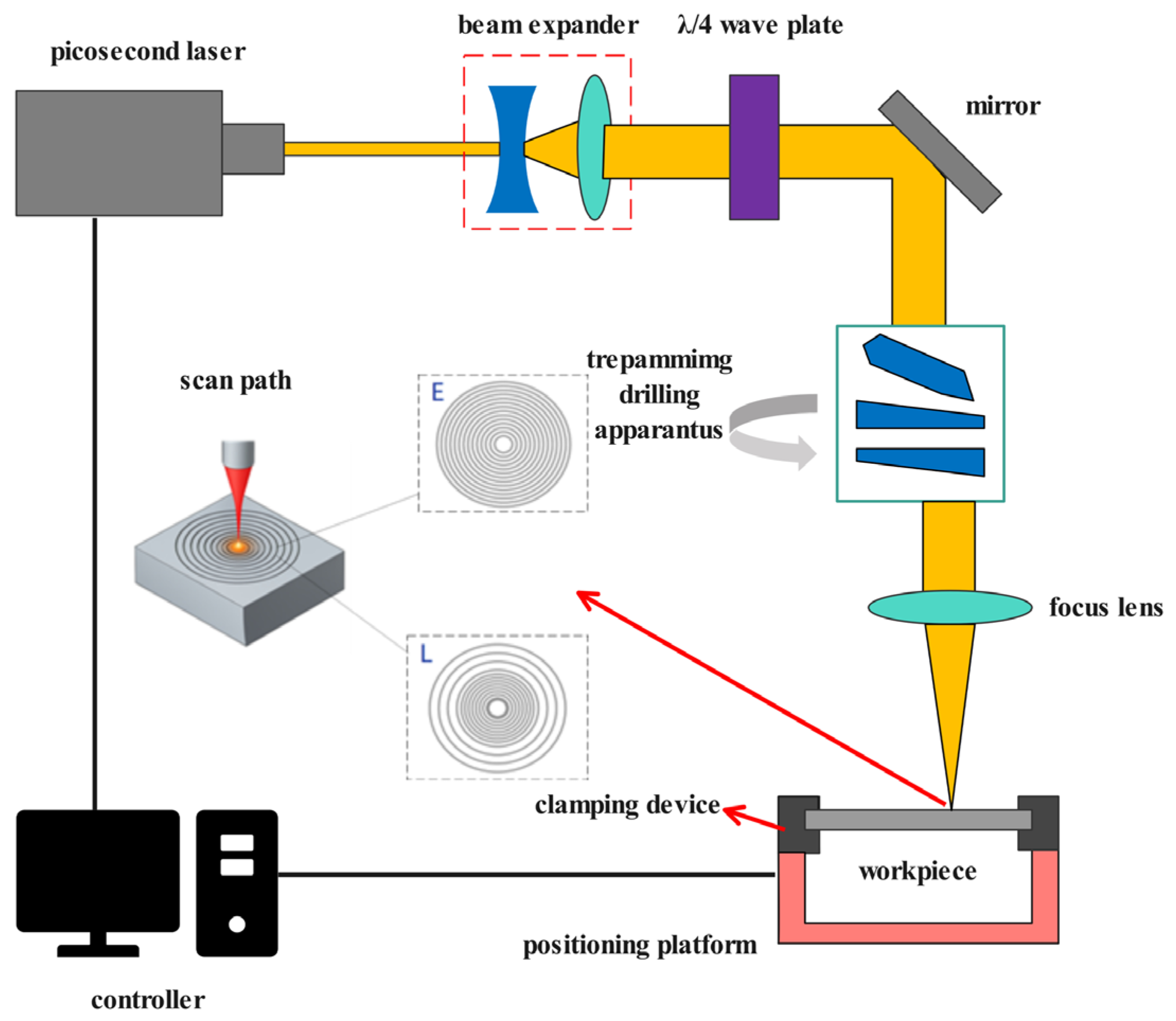

2. Experimental Details

2.1. Experimental Equipment and Materials

2.2. Experimental Design

3. Results and Discussion

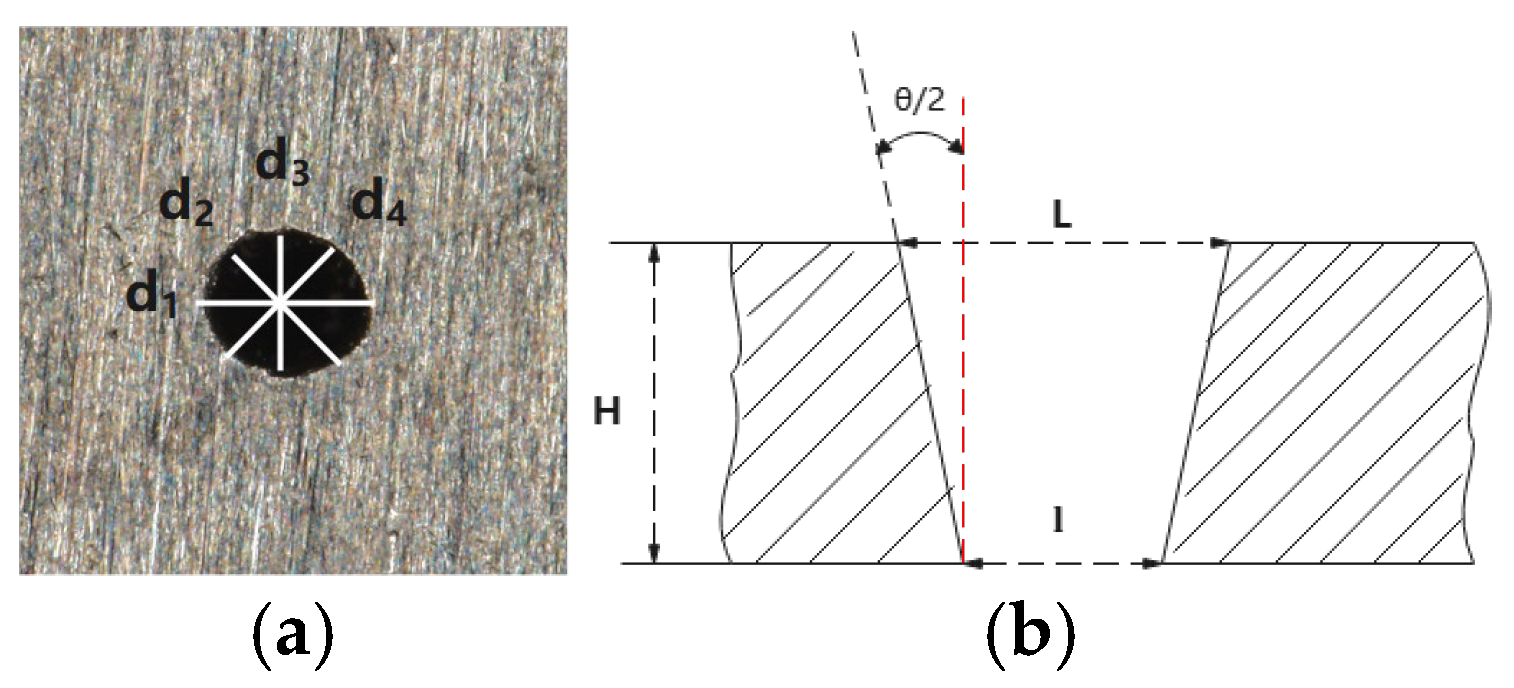

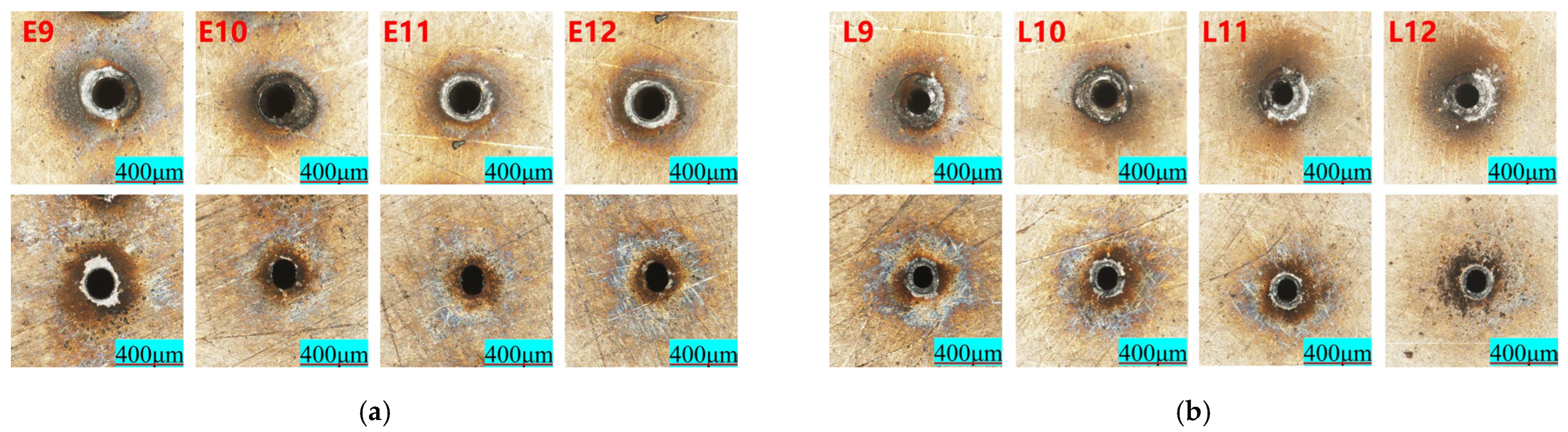

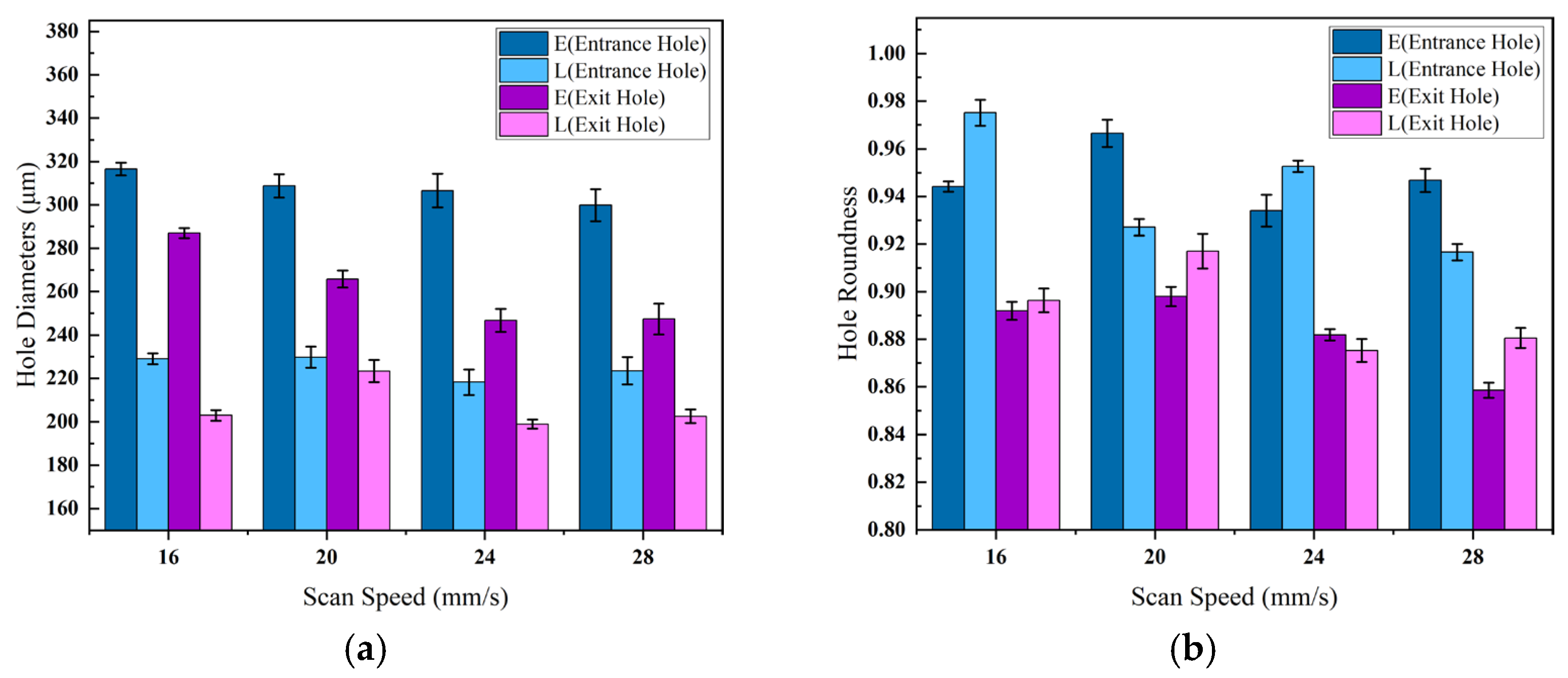

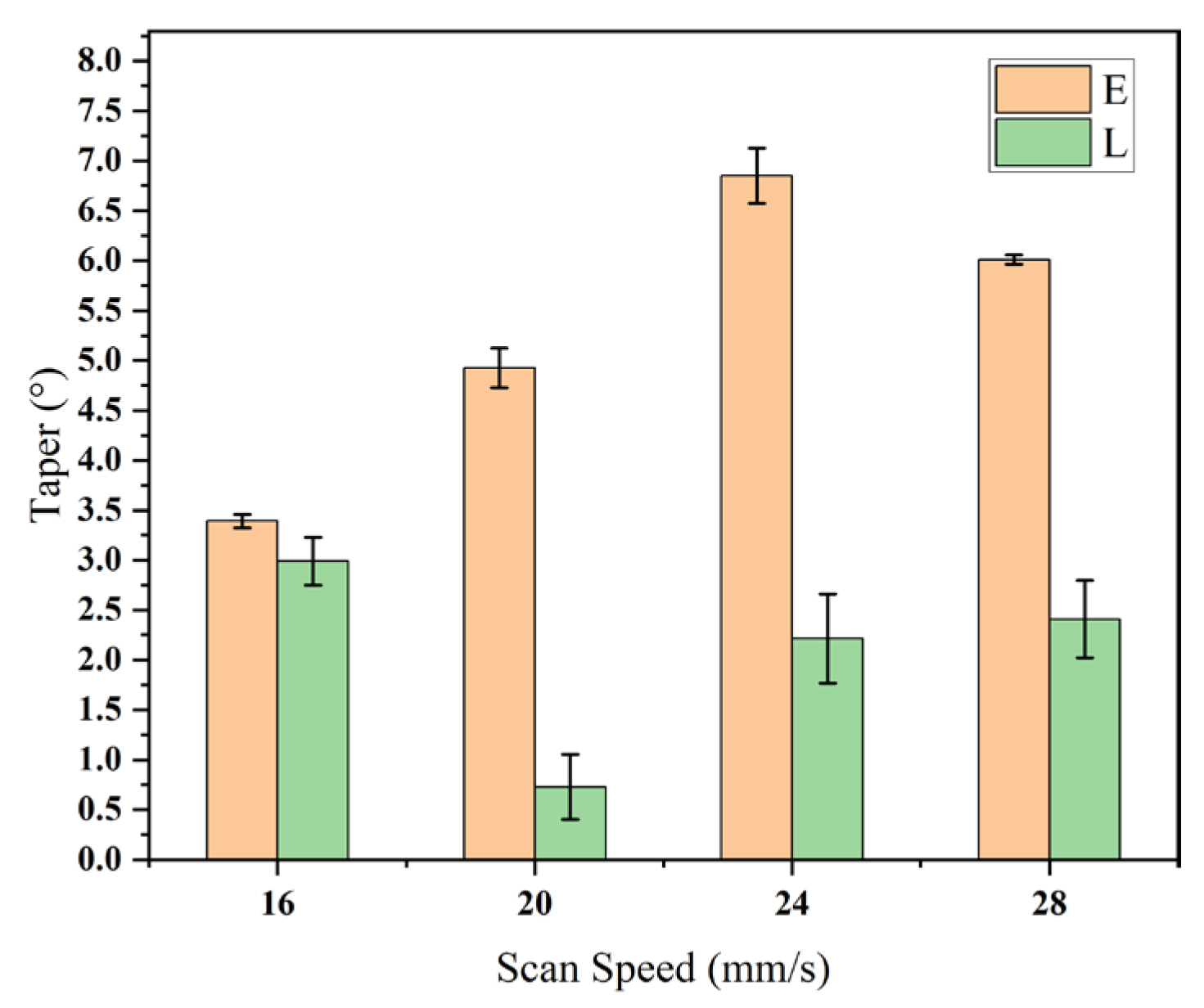

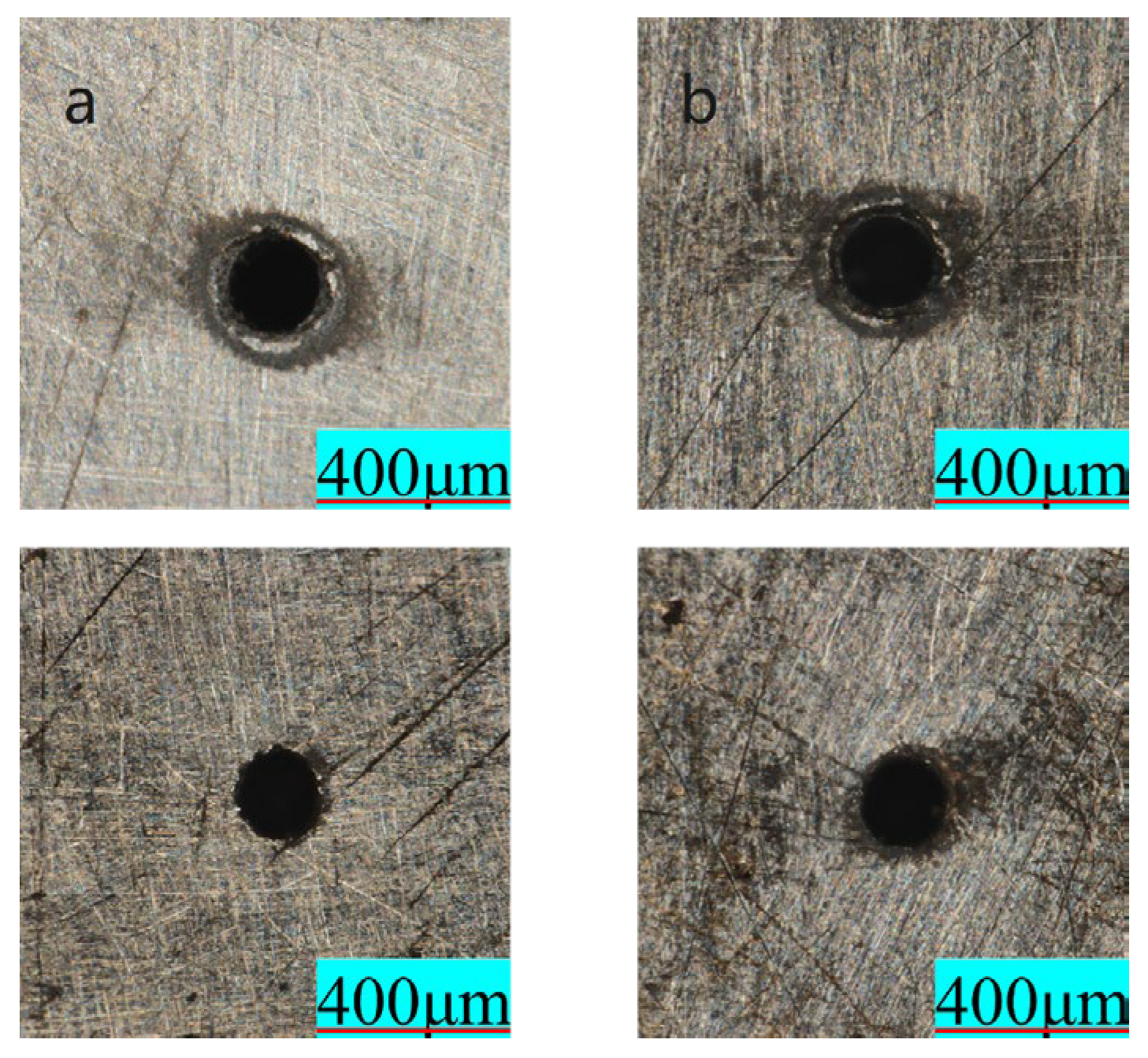

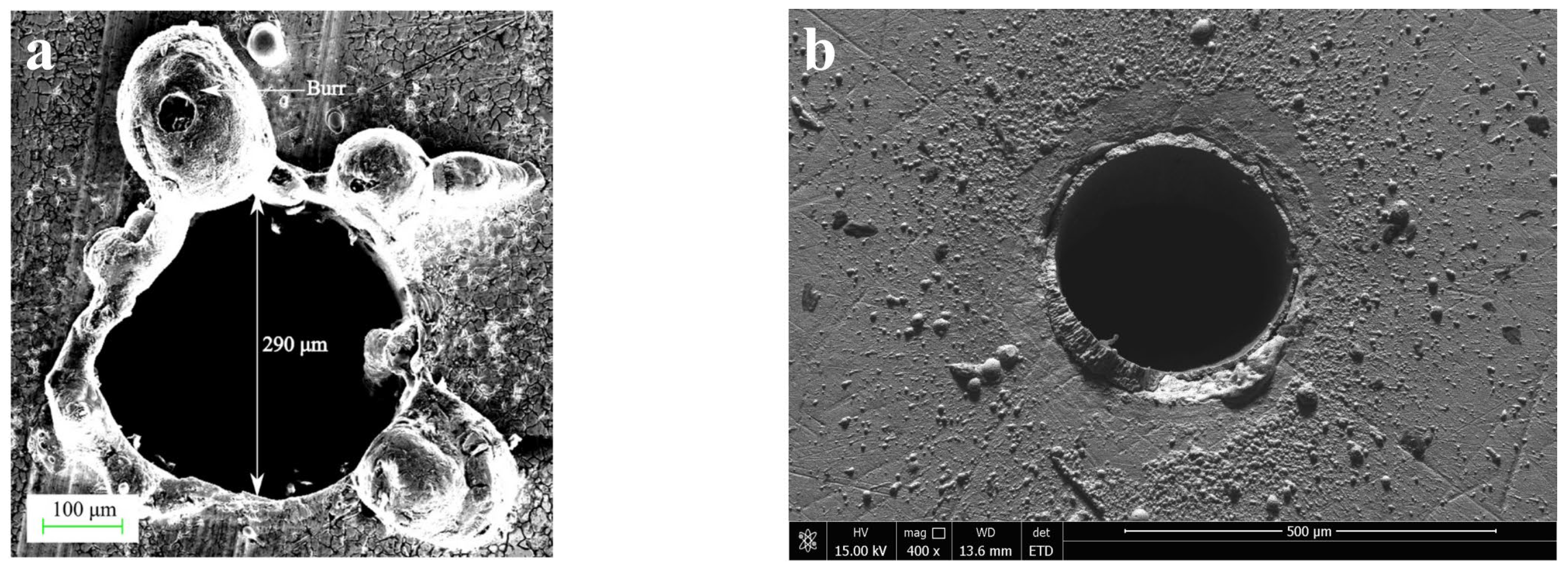

3.1. Comparison of Hole Quality Under Two Processing Paths

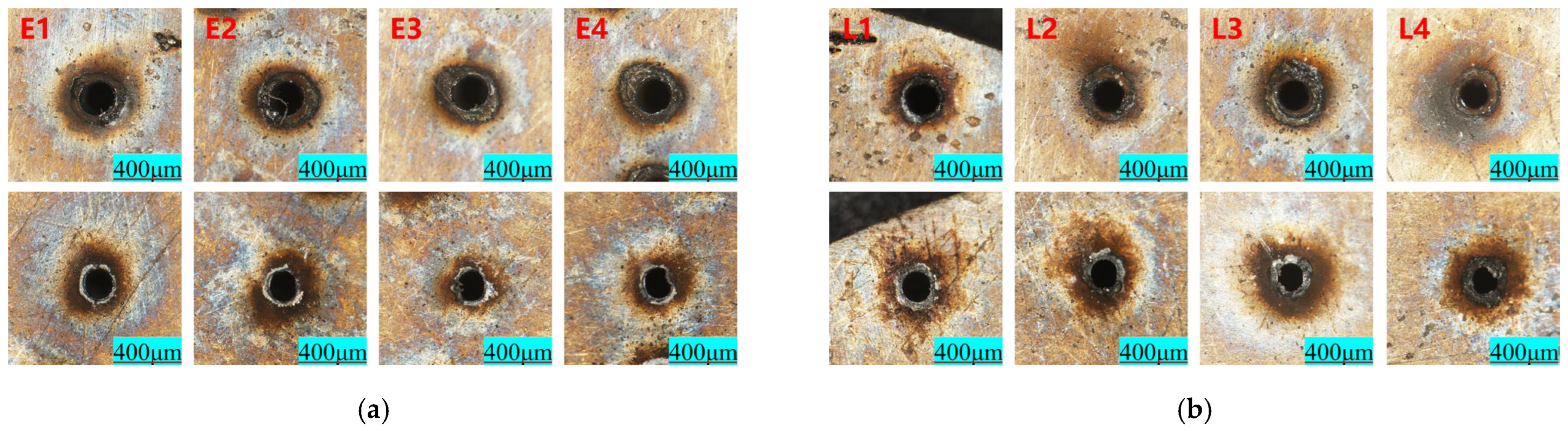

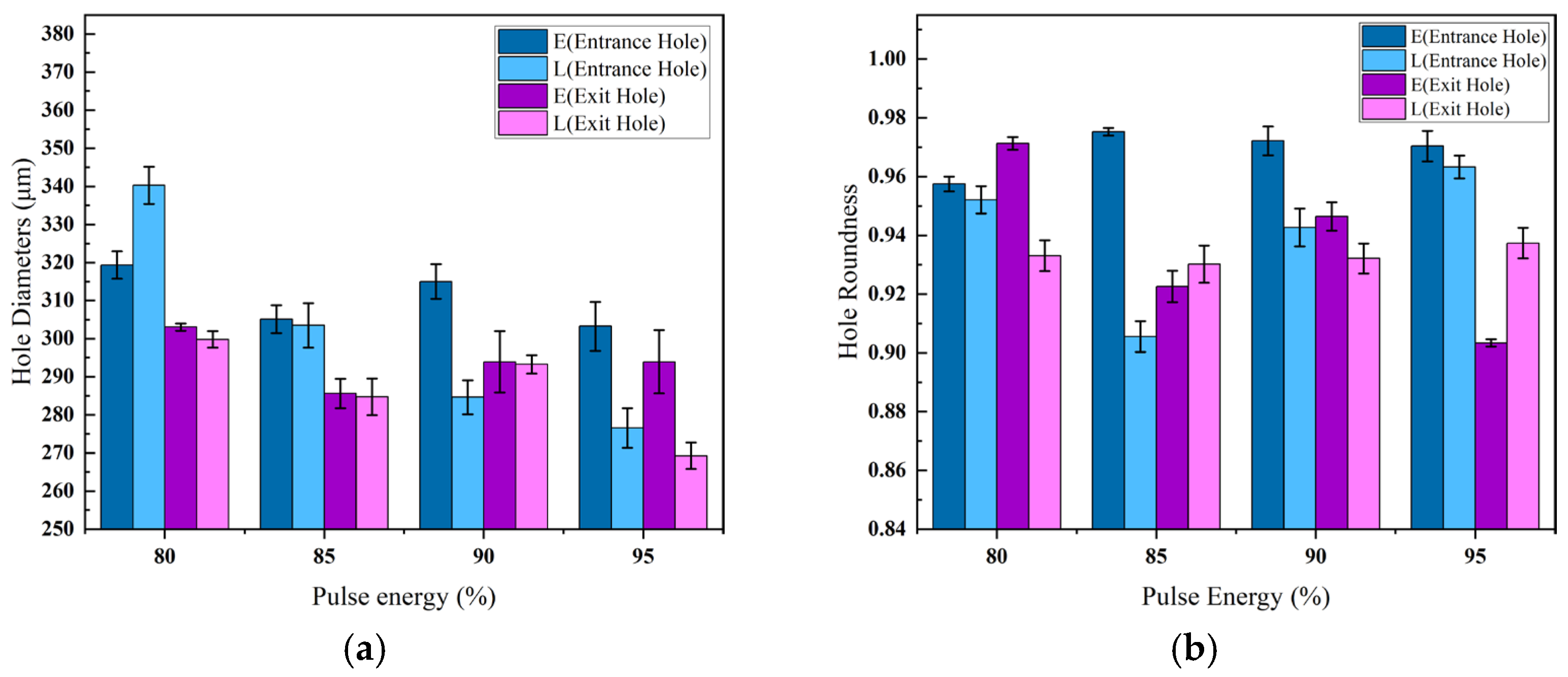

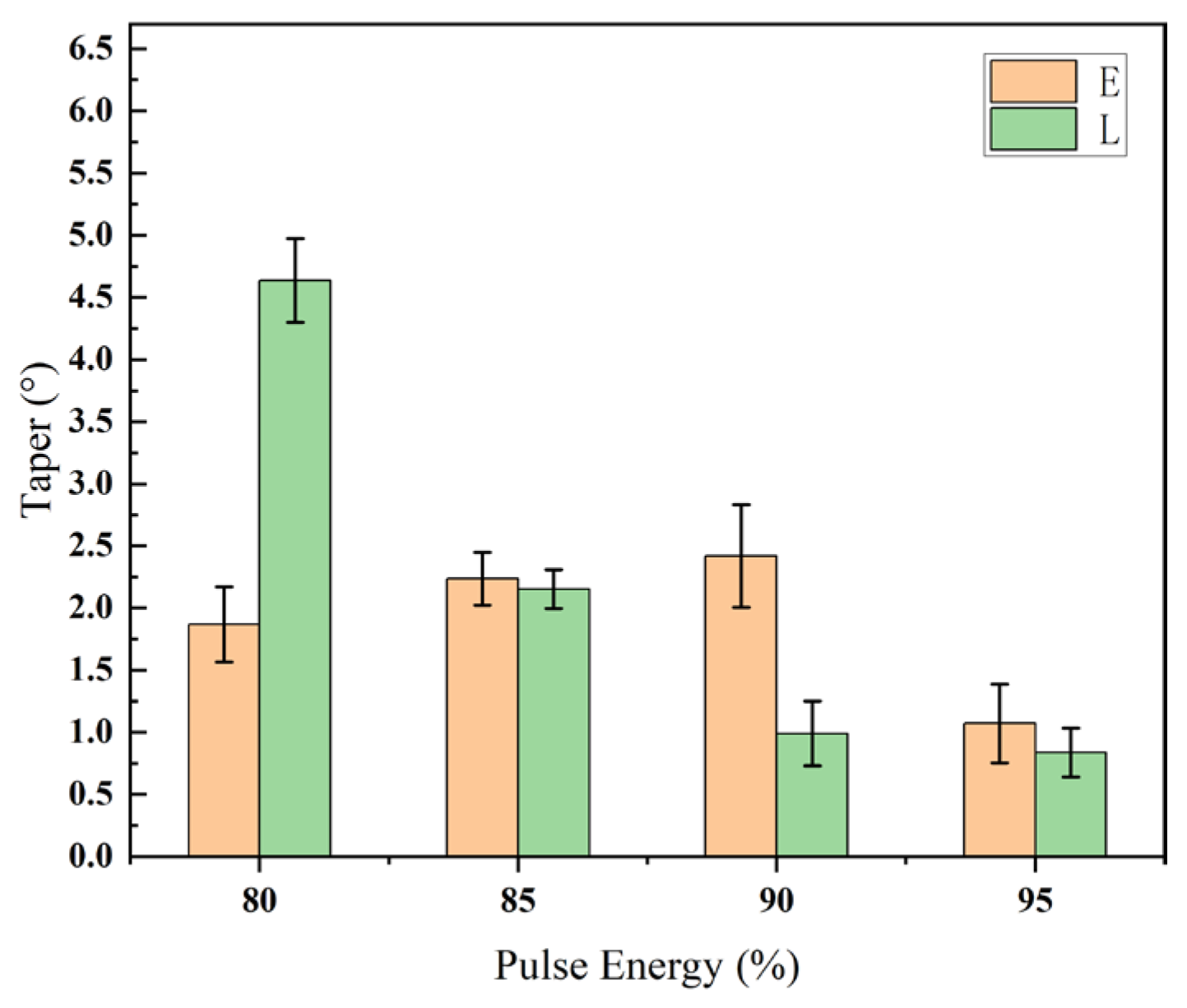

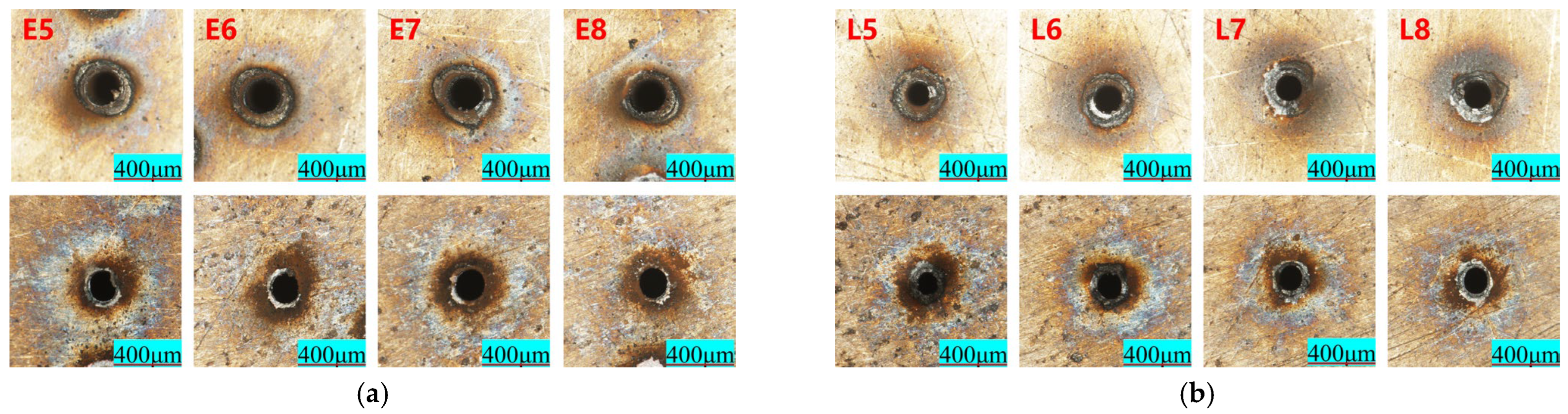

3.1.1. Effect of Pulse Energy on Drilling with Two Concentric Circle Processing Paths

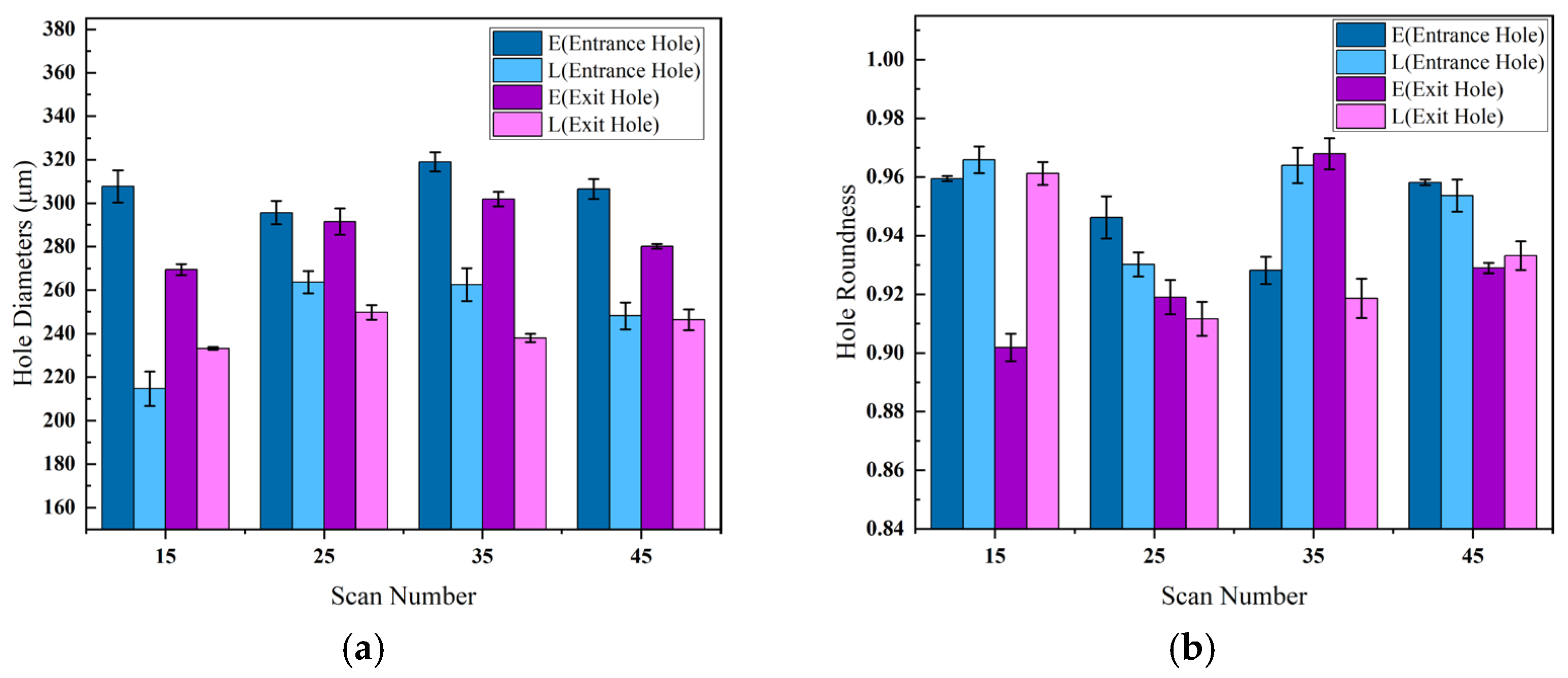

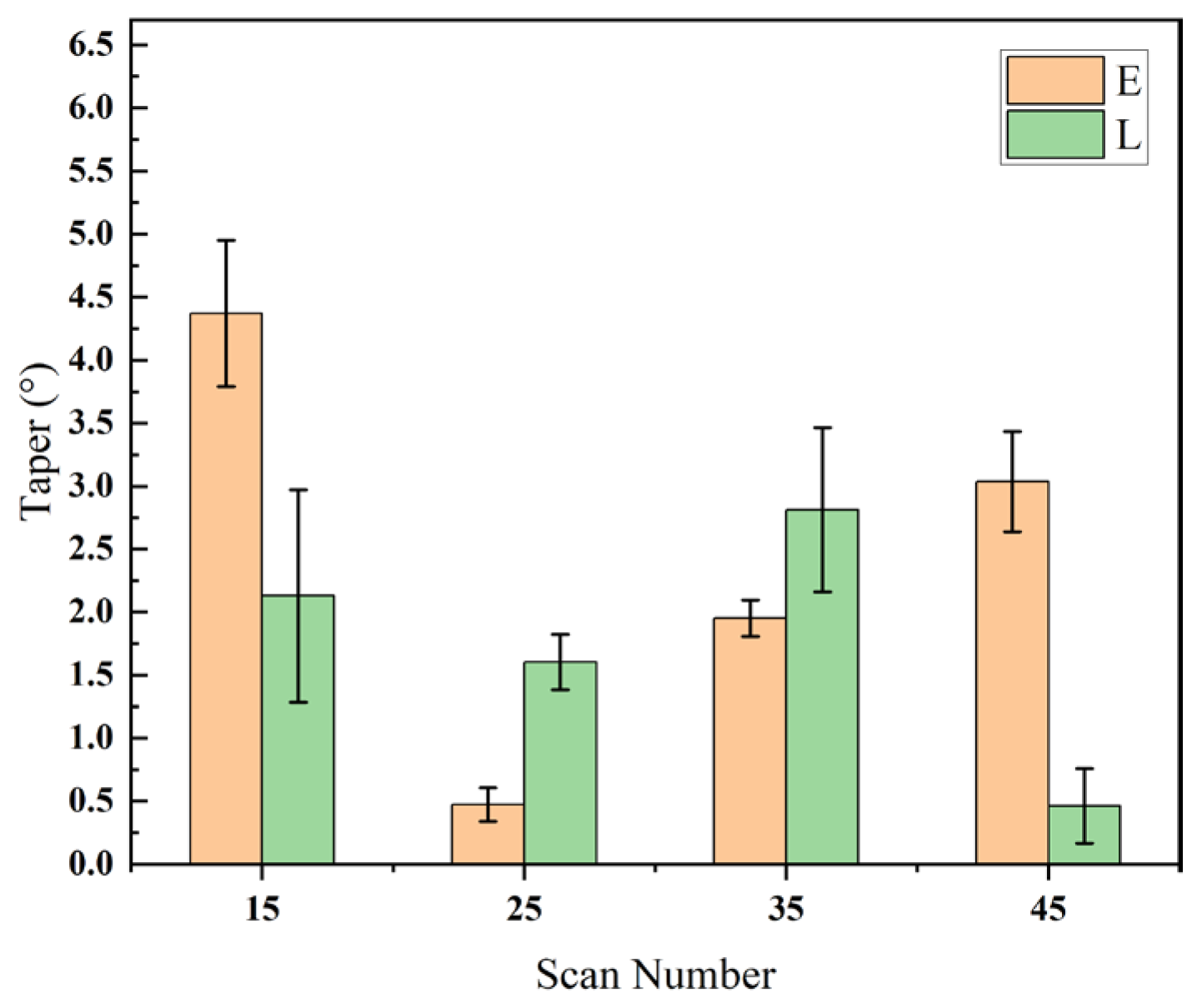

3.1.2. Effect of Number of Scans on Hole Drilling for Two Concentric Circle Processing Paths

3.1.3. Effect of Scan Speed on Hole Drilling for Two Concentric Circle Processing Paths

3.2. Selection of Processing Path

3.3. Parameter Optimization

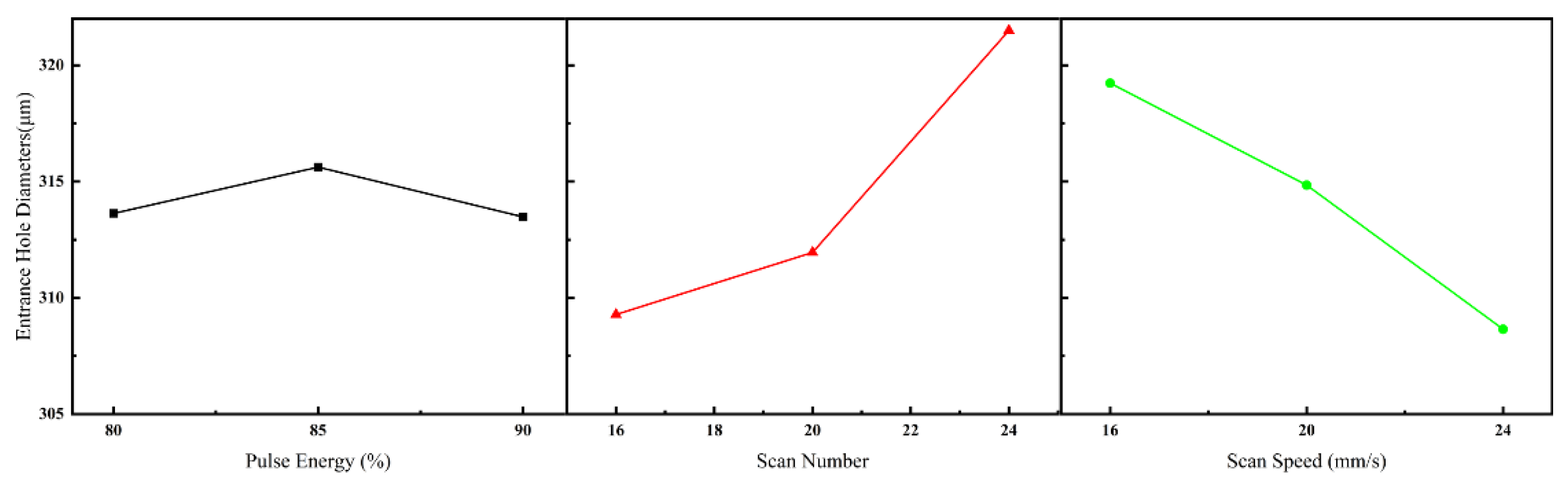

3.3.1. Hole Diameter

- Entrance Hole Diameter

- 2.

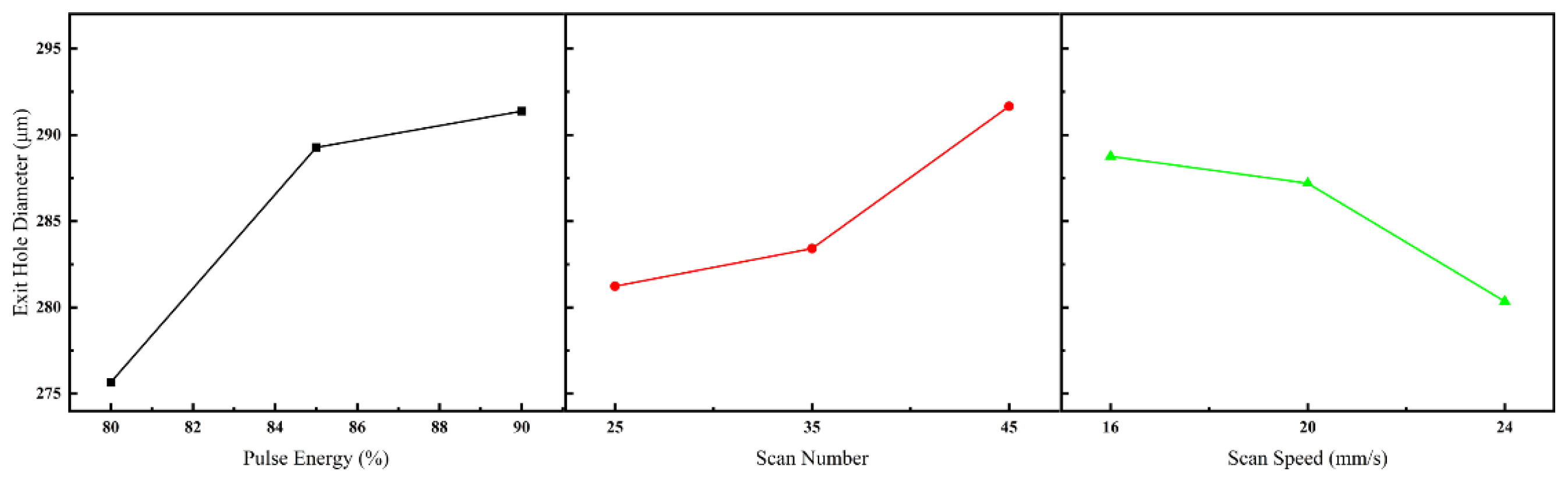

- Exit Hole Diameter

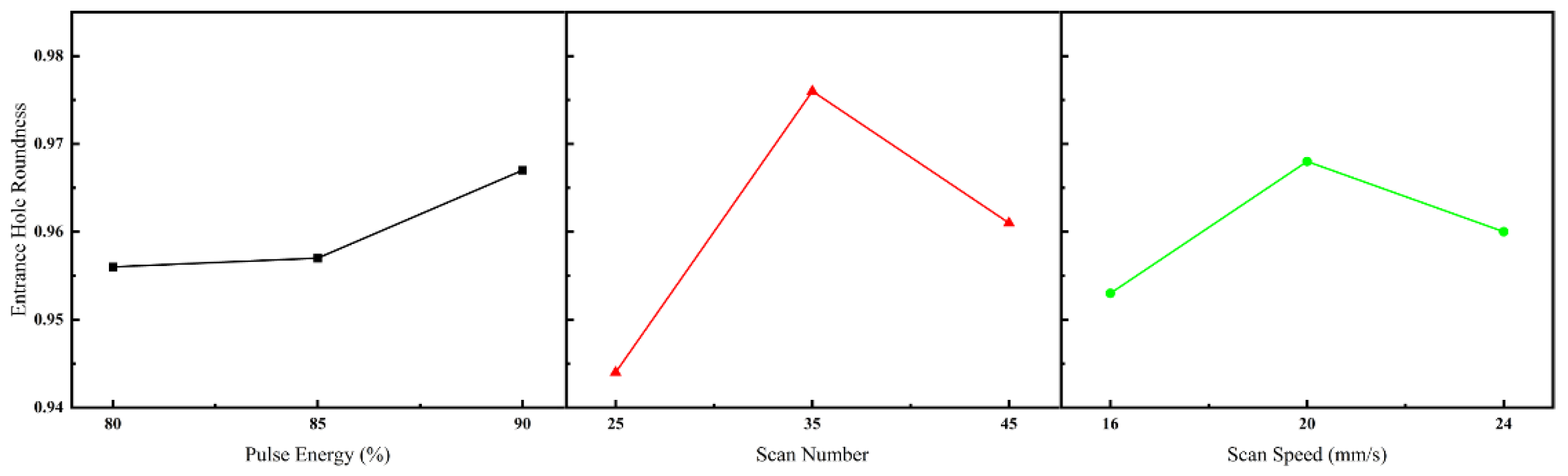

3.3.2. Roundness

- Entrance Hole Roundness

- 2.

- Exit Hole Roundness

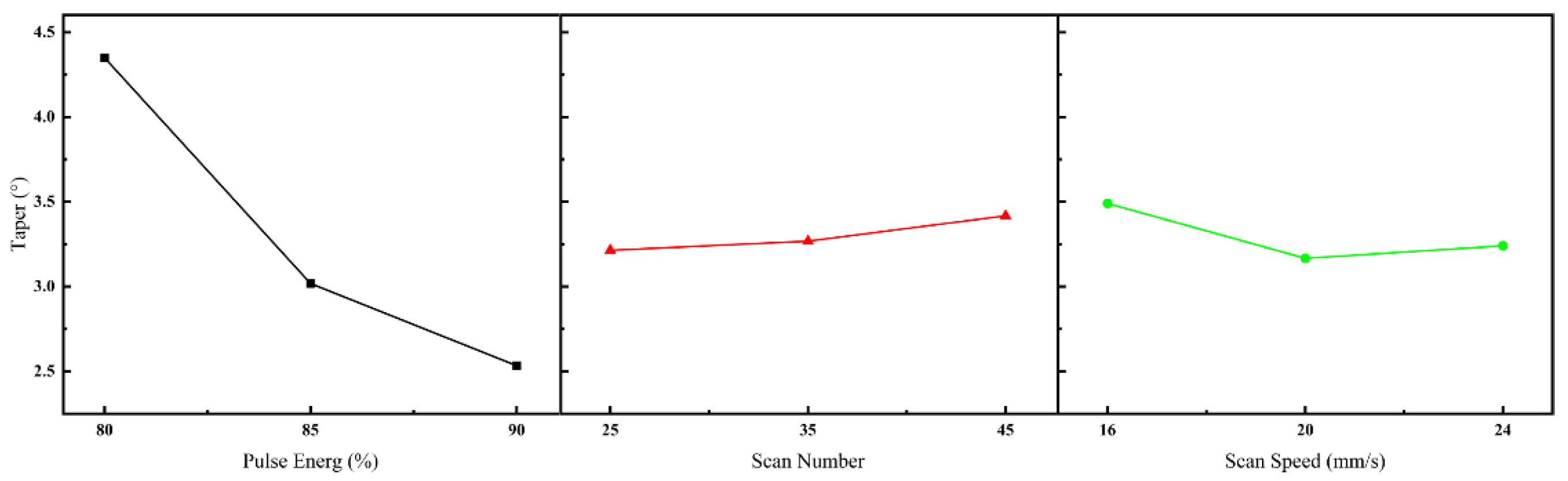

3.3.3. Taper

3.4. Parameter Optimization Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balakrishnan, T.S.; Sultan, M.T.H.; Shahar, F.S.; Saravanakumar, Y.N.; Chandran, N.K. Aerospace steel: Properties, processing, and applications. In Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2025; pp. 275–290. [Google Scholar]

- Gao, J.; Cao, Y.; Ma, Y.; Zheng, K.; Zhang, M.; Hei, H.; Gong, H.; Yu, S.; Kuai, P.; Liu, K. Wear, corrosion, and biocompatibility of 316L stainless steel modified by well-adhered Ta coatings. J. Mater. Eng. Perform. 2022, 31, 8784–8798. [Google Scholar] [CrossRef]

- Sharma, R.; Pradhan, S.; Bathe, R.N. A review of machinability aspects of difficult-to-cut materials using microtexture patterns. In Advanced Manufacturing and Processing Technology; CRC Press: Boca Raton, FL, USA, 2020; pp. 45–65. [Google Scholar]

- Lin, G.; Shi, H.; Liu, X.; Wang, Z.; Zhang, H.; Zhang, J. Tool wear on machining of difficult-to-machine materials: A review. Int. J. Adv. Manuf. Technol. 2024, 134, 989–1014. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Q.; Qian, Q.; Di, B. The development of laser drilling: A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 022067. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Żaba, K.; Trzepieciński, T. An Investigation of the Sequential Micro-Laser Drilling and Conventional Re-Drilling of Angled Holes in an Inconel 625 Ni-Based Alloy. Lubricants 2023, 11, 384. [Google Scholar] [CrossRef]

- Winter, J.; Spellauge, M.; Hermann, J.; Eulenkamp, C.; Huber, H.P.; Schmidt, M. Ultrashort single-pulse laser ablation of stainless steel, aluminium, copper and its dependence on the pulse duration. Opt. Express 2021, 29, 14561–14581. [Google Scholar] [CrossRef]

- Gu, Z.; He, Y.; Ji, J.; Wei, Y.; Fu, Y. Reducing the taper and heat-affected zone in nanosecond laser drilling of CFRP plate using backside sacrificial layer. Opt. Lasers Eng. 2025, 185, 108735. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, H.; Ke, R.; Wang, X. Fabrication of high aspect ratio and low taper angle micro-holes utilizing complex water-assisted femtosecond laser drilling. Opt. Laser Technol. 2025, 185, 112608. [Google Scholar] [CrossRef]

- Gu, Z.; He, Y.; Ji, J.; Fu, Y. Numerical simulation and experimental study of the shape variation influence on stainless steel drilling with picosecond laser. Opt. Laser Technol. 2025, 181, 112021. [Google Scholar] [CrossRef]

- Bara, A.; Sahoo, S.K.; Naik, S.S.; Sahu, A.K.; Mahapatra, S.S. Multi response optimization of Nd: YAG laser micro drilling characteristics of 304 stainless steel using desirability function approach. Mater. Today Proc. 2018, 5, 18975–18982. [Google Scholar] [CrossRef]

- Schneller, L.; Henn, M.; Spurk, C.; Olowinsky, A.; Beckmann, F.; Moosmann, J.; Holder, D.; Hagenlocher, C.; Graf, T. High-speed X-ray imaging of bulge formation during laser percussion drilling with various polarizations in stainless steel. Procedia CIRP 2024, 124, 644–648. [Google Scholar] [CrossRef]

- Zhang, H.; Mao, Y.; Kang, M.; Ma, C.; Li, H.; Zhang, Y.; Wang, X. Fabrication of High Aspect Ratio Micro-Holes on 304 Stainless Steel Via Backside-Water-assisted Laser Drilling. Opt. Lasers Eng. 2023, 162, 107426. [Google Scholar] [CrossRef]

- Gu, Z.; He, Y.; Yang, J.; Fu, Y.; Ji, J.; Zhang, Y.; Li, J.; Liu, G. Dual-path Micro-Holes Process for 0cr17ni7al Stainless Steel Thin Plate with Picosecond Laser. J. Manuf. Process. 2023, 101, 1224–1233. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Yu, G.; Li, S.; Tian, C.; Ning, W.; Zhang, Y. Dynamic Evolution of Keyhole During Multi-Pulse Drilling with a Millisecond Laser on 304 Stainless Steel. Opt. Laser Technol. 2022, 152, 108151. [Google Scholar] [CrossRef]

- Brinkmeier, D.; Holder, D.; Loescher, A.; Röcker, C.; Förster, D.J.; Onuseit, V.; Weber, R.; Abdou, A.M.; Graf, T. Process Limits for Percussion Drilling of Stainless Steel with Ultrashort Laser Pulses at High Average Powers. Appl. Phys. 2021, 128, 35. [Google Scholar] [CrossRef]

- Wang, L.; Rong, Y.; Xu, L.; Wu, C.; Xia, K. Process Optimization on Trepanning Drilling in Titanium Alloy Using a Picosecond Laser via an Orthogonal Experiment. Micromachines 2025, 16, 846. [Google Scholar] [CrossRef]

- Wang, L.; Wu, C.; Rong, Y.; Xu, L.; Xia, K. Experimental Study on Millisecond Laser Percussion Drilling of Heat-Resistant Steel. Materials 2025, 18, 3699. [Google Scholar] [CrossRef]

- Namdev, S.; Pandey, A.; Pandey, A.K.; Kumar, R. Modeling of hole geometrical features in laser drilling of AISI316L sheet. J. Eng. Res. 2022, 10, 194–204. [Google Scholar] [CrossRef]

- Li, Z.; Allegre, O.; Guo, W.; Gao, W.-Y.; Li, B.-H.; Feng, Q.-L.; Wu, X.-P.; Li, L. Ultrafast Laser Drilling of Crack-free, Debris-free and Heat Affected Zone (HAZ)-free Blind Holes in Al2O3 with Flat Bottom and Reduced Taper Angles. Lasers Eng. 2020, 46, 367–381. [Google Scholar]

- Liu, X.; Chen, L.; Wang, X.; Zhengjun, X. Micromilling blind holes in Al2O3 ceramics using UV laser. Laser Optoelectron. Prog. 2021, 58, 0514005. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Zheng, H.; Gao, J.; Jiang, C. Reducing plasma shielding effect for improved nanosecond laser drilling of copper with applied direct current. Opt. Laser Technol. 2023, 163, 109372. [Google Scholar] [CrossRef]

- Chen, L.; Deng, H.; Xiong, Z.; Guo, J.; Liu, Q.; Li, G.; Shang, L. Investigation of shielding effects on picosecond laser-induced copper plasma characteristics under different focusing distances. Photonics 2021, 8, 536. [Google Scholar] [CrossRef]

- Salama, A.; Yan, Y.; Li, L.; Mativenga, P.; Whitehead, D.; Sabli, A. Understanding the self-limiting effect in picosecond laser single and multiple parallel pass drilling/machining of CFRP composite and mild steel. Mater. Des. 2016, 107, 461–469. [Google Scholar] [CrossRef]

- Zhou, T.; Hong, Y.; Fang, Z.; Perrie, W.; Fei, Y.; Hu, Y.; Edwardson, S.; Dearden, G. Experimental and numerical study of multi-pulse picosecond laser ablation on 316 L stainless steel. Opt. Express 2023, 31, 38715–38727. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.J.; Wang, C.S.; Manikanta, G.; Hsiao, Y.H. Laser-induced Plasma Detection for Laser Percussion Drilling of Stainless Steel and CoCrMo Alloy. Sens. Mater. 2025, 37, 93–104. [Google Scholar] [CrossRef]

- Gupta, A.K.; Singh, R.; Marla, D. Millisecond Pulsed Laser Micro-drilling of Stainless Steel—Optimizing Hole Quality Using Response Surface Methodology. J. Laser Micro Nanoeng. 2023, 18, 187–195. [Google Scholar]

| Material Grade | Chemical Composition and Content (%) | |||

|---|---|---|---|---|

| SUS304 | C ≤ 0.08 | Mn ≤ 2.00 | Si ≤ 1.00 | P ≤ 0.045 |

| S ≤ 0.03 | Ni 8.00–10.50 | Cr 18.00–20.00 | Fe Balance | |

| Experiment No. | Repetition Frequency (Hz) | Pulse Energy (30 W) Proportion | Scanning Number | Scanning Speed (mm/s) |

|---|---|---|---|---|

| 1 | 1000 | 80% | 25 | 16 |

| 2 | 1000 | 85% | 25 | 16 |

| 3 | 1000 | 90% | 25 | 16 |

| 4 | 1000 | 95% | 25 | 16 |

| 5 | 1000 | 80% | 15 | 16 |

| 6 | 1000 | 80% | 25 | 16 |

| 7 | 1000 | 80% | 35 | 16 |

| 8 | 1000 | 80% | 45 | 16 |

| 9 | 1000 | 80% | 25 | 16 |

| 10 | 1000 | 80% | 25 | 20 |

| 11 | 1000 | 80% | 25 | 24 |

| 12 | 1000 | 80% | 25 | 28 |

| Experiment Number | Taper (E)/° | Taper (L)/° |

|---|---|---|

| 1 | 1.781 | 4.880 |

| 2 | 1.992 | 2.062 |

| 3 | 2.295 | −0.950 |

| 4 | 1.326 | 0.854 |

| 5 | 4.250 | −2.075 |

| 6 | 0.371 | 1.561 |

| 7 | 1.829 | 2.727 |

| 8 | 3.239 | 0.796 |

| 9 | 3.426 | 2.714 |

| 10 | 4.733 | 0.354 |

| 11 | 6.891 | 2.254 |

| 12 | 6.052 | 2.298 |

| Experiment Number | A Pulse Energy (30 W) Ratio | B Scan Number | C Scan Speed |

|---|---|---|---|

| 1 | 80% | 25 | 16 mm/s |

| 2 | 80% | 35 | 20 mm/s |

| 3 | 80% | 45 | 24 mm/s |

| 4 | 85% | 25 | 20 mm/s |

| 5 | 85% | 35 | 24 mm/s |

| 6 | 85% | 45 | 16 mm/s |

| 7 | 90% | 25 | 24 mm/s |

| 8 | 90% | 35 | 16 mm/s |

| 9 | 90% | 45 | 20 mm/s |

| Level | Entrance Hole Diameter (μm) | ||

| Pulse Energy (A) | Scan Number (B) | Scan Speed (C) | |

| 1 | 313.631 | 309.280 | 319.234 |

| 2 | 315.619 | 311.950 | 314.849 |

| 3 | 313.481 | 321.501 | 308.649 |

| Range Analysis | 2.138 | 12.221 | 10.585 |

| Level | Exit Hole Diameter (μm) | ||

|---|---|---|---|

| Pulse Energy (A) | Scan Number (B) | Scan Speed (C) | |

| 1 | 275.669 | 281.228 | 288.758 |

| 2 | 289.278 | 283.419 | 287.200 |

| 3 | 291.377 | 291.666 | 280.355 |

| Range Analysis | 15.718 | 10.438 | 8.404 |

| Level | Entrance Hole Roundness | ||

| Pulse Energy (A) | Scan Number (B) | Scan Speed (C) | |

| 1 | 0.956 | 0.944 | 0.953 |

| 2 | 0.957 | 0.976 | 0.968 |

| 3 | 0.967 | 0.961 | 0.960 |

| Range Analysis | 0.011 | 0.032 | 0.015 |

| Level | Exit Hole Roundness | ||

|---|---|---|---|

| Pulse Energy (A) | Scan Number (B) | Scan Speed (C) | |

| 1 | 0.926 | 0.939 | 0.950 |

| 2 | 0.930 | 0.926 | 0.925 |

| 3 | 0.955 | 0.946 | 0.935 |

| Range Analysis | 0.030 | 0.020 | 0.026 |

| Level | Taper/° | ||

|---|---|---|---|

| Pulse Energy (A) | Scan Number (B) | Scan Speed (C) | |

| 1 | 4.349 | 3.214 | 3.491 |

| 2 | 3.018 | 3.268 | 3.167 |

| 3 | 2.533 | 3.418 | 3.241 |

| Range Analysis | 1.817 | 0.204 | 0.324 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Wu, C.; Rong, Y.; Xu, L.; Xia, K. Optimization Study of Laser-Drilling Processes in Stainless Steel Under Two Scanning Path Strategies. Metals 2025, 15, 1024. https://doi.org/10.3390/met15091024

Wang L, Wu C, Rong Y, Xu L, Xia K. Optimization Study of Laser-Drilling Processes in Stainless Steel Under Two Scanning Path Strategies. Metals. 2025; 15(9):1024. https://doi.org/10.3390/met15091024

Chicago/Turabian StyleWang, Liang, Changjian Wu, Yefei Rong, Long Xu, and Kaibo Xia. 2025. "Optimization Study of Laser-Drilling Processes in Stainless Steel Under Two Scanning Path Strategies" Metals 15, no. 9: 1024. https://doi.org/10.3390/met15091024

APA StyleWang, L., Wu, C., Rong, Y., Xu, L., & Xia, K. (2025). Optimization Study of Laser-Drilling Processes in Stainless Steel Under Two Scanning Path Strategies. Metals, 15(9), 1024. https://doi.org/10.3390/met15091024