The Effect of Mo on the Microstructure and Mechanical Properties of High-Manganese Railway Frog Steel Produced with the Thermal Mechanical Control Process

Abstract

1. Introduction

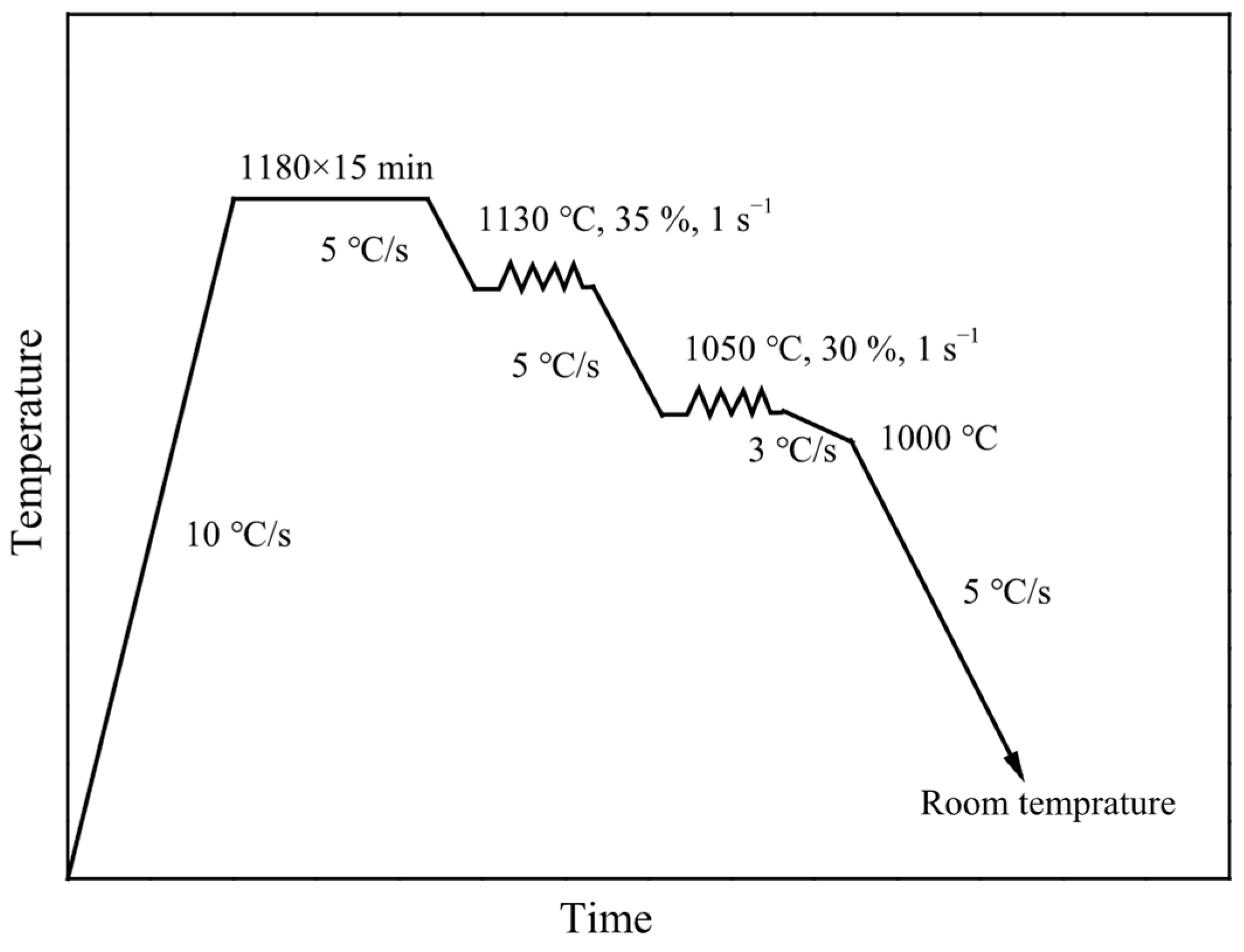

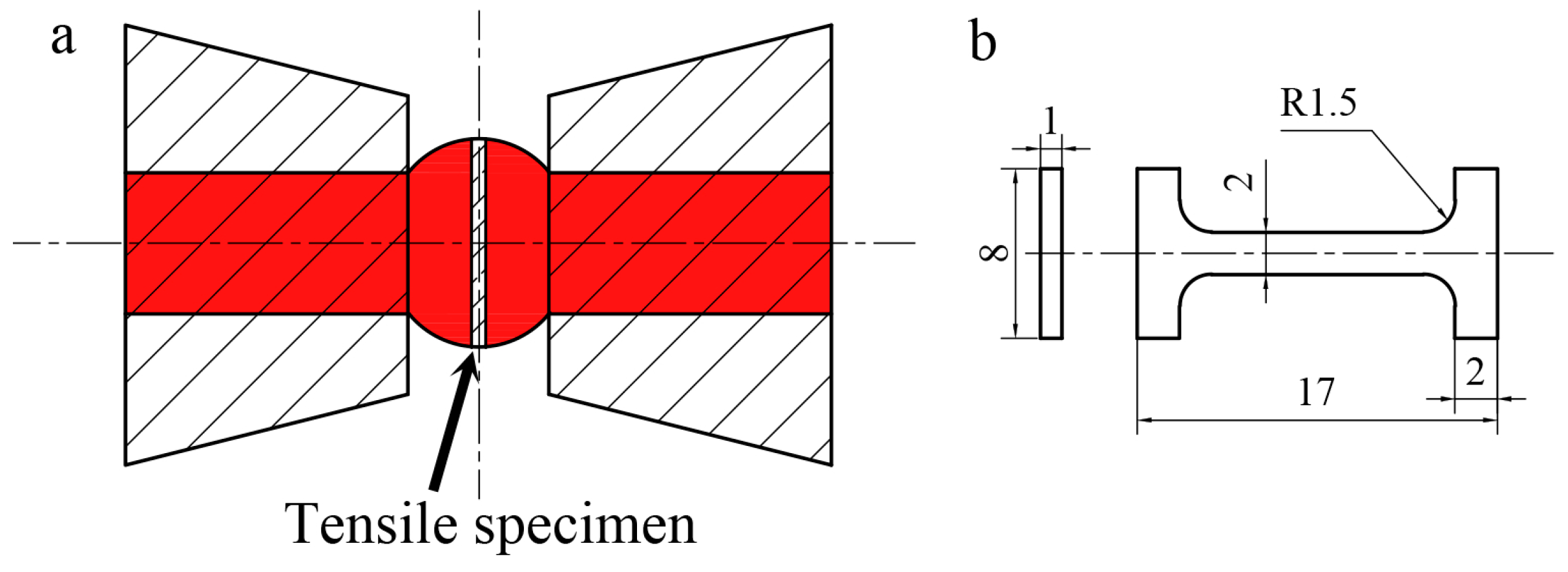

2. Materials and Methods

3. Results

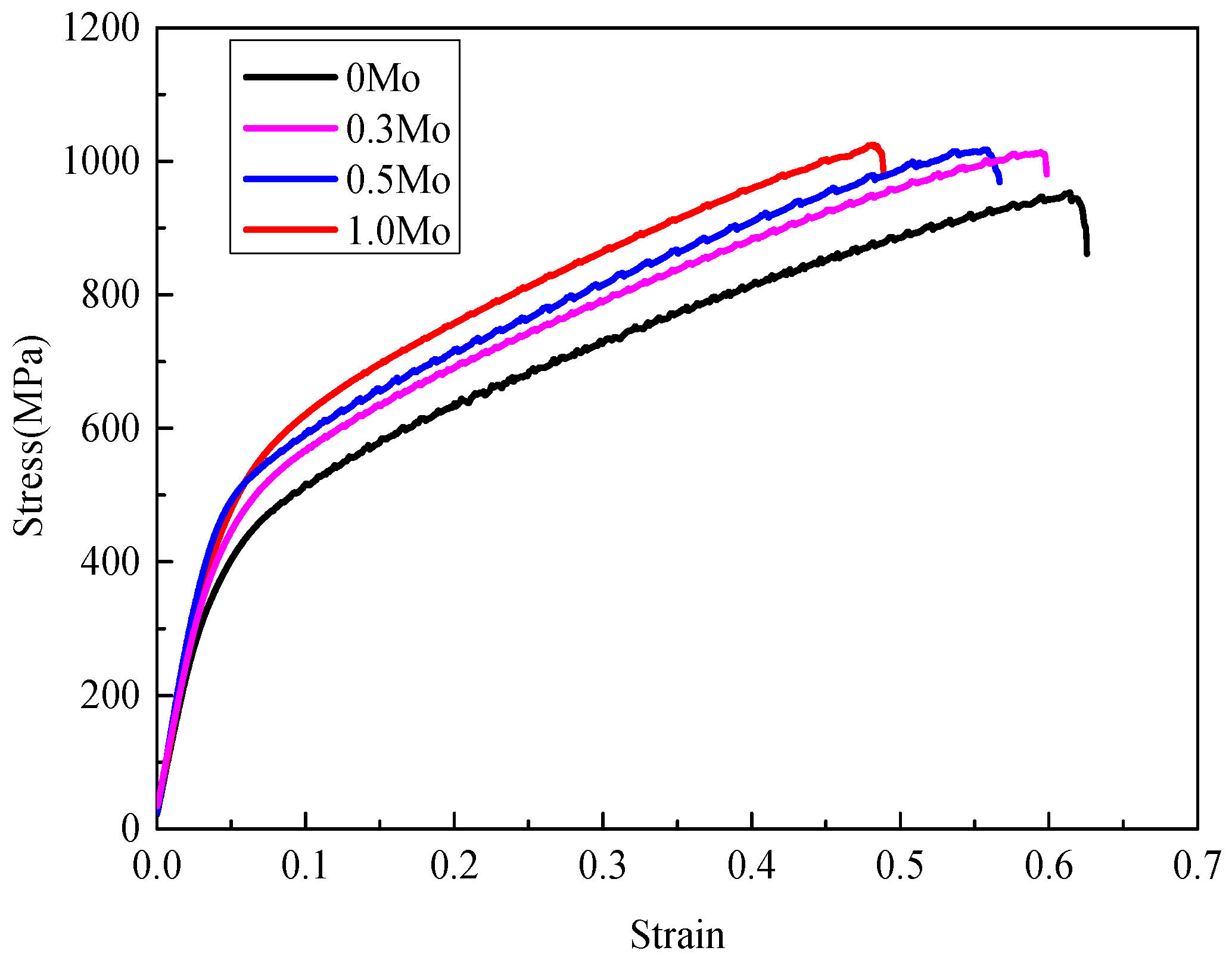

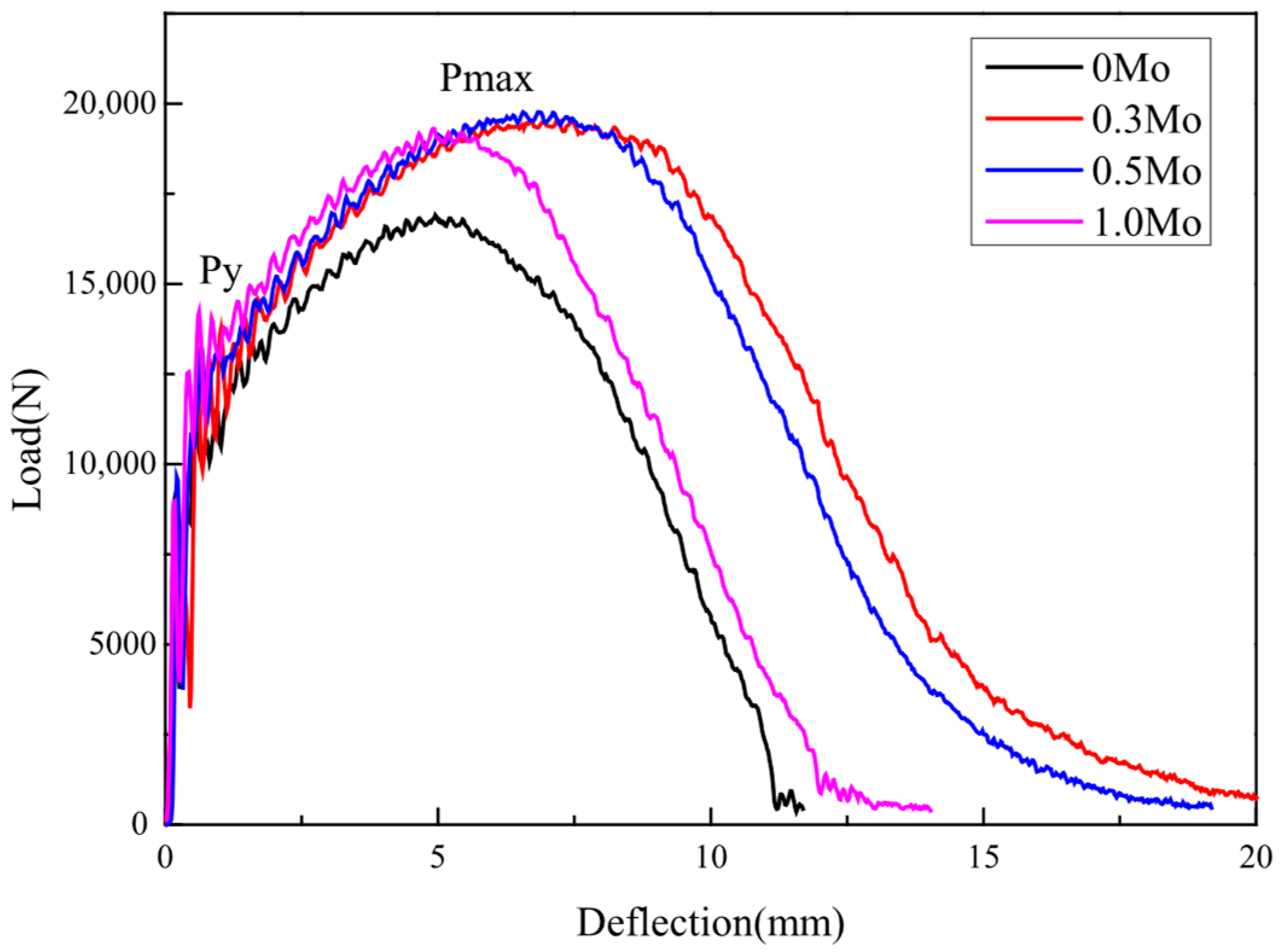

3.1. Mechanical Properties

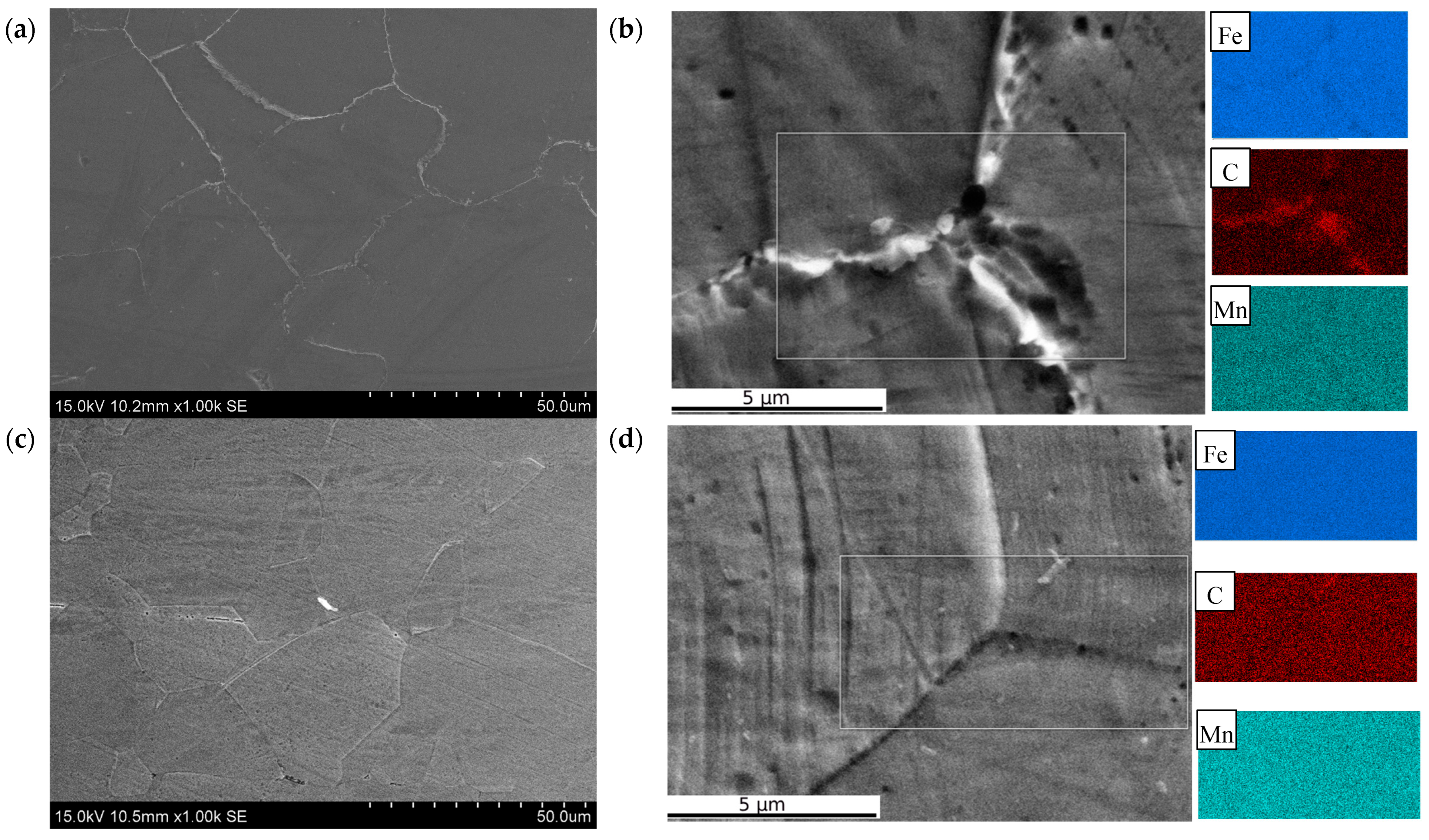

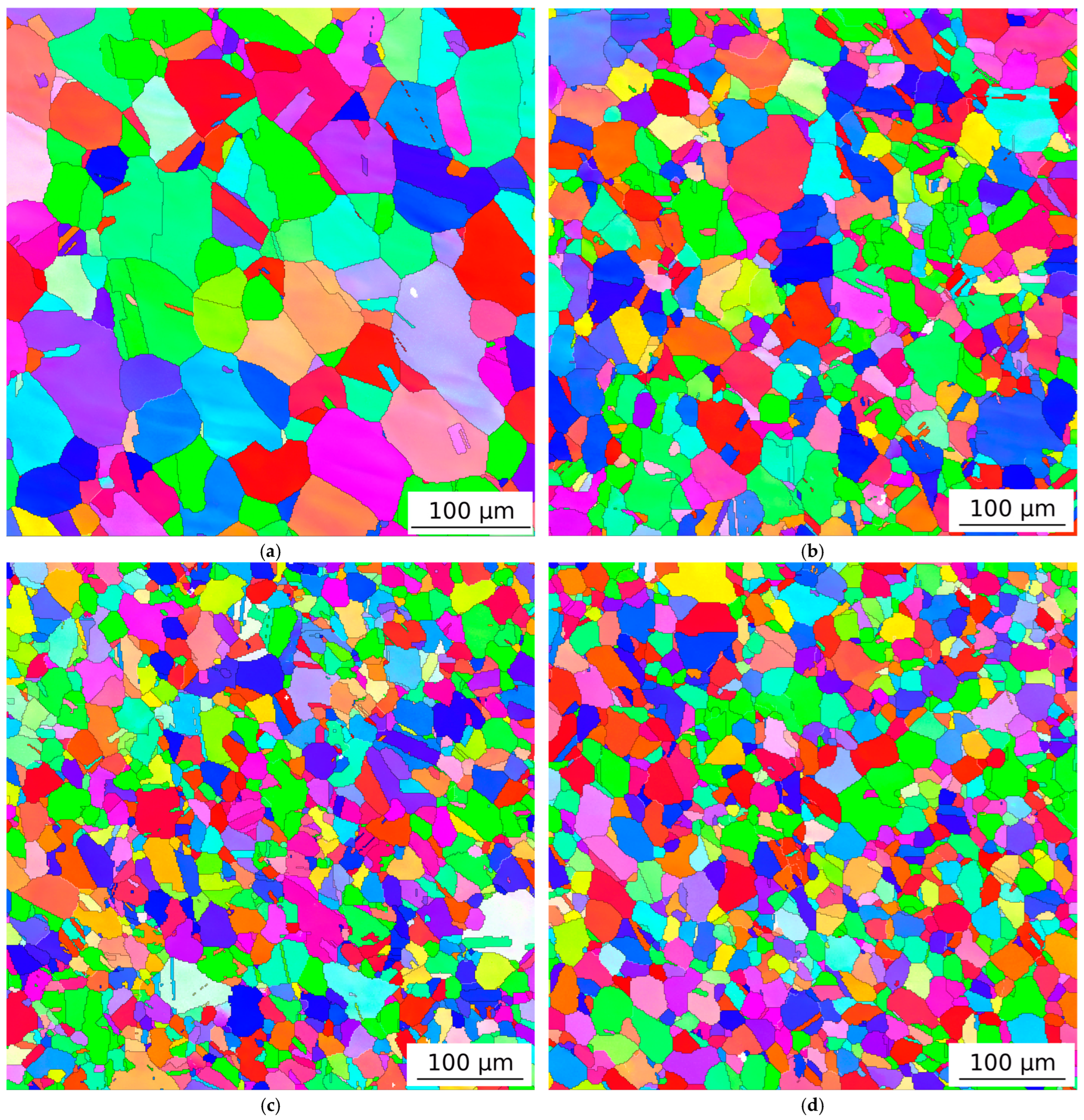

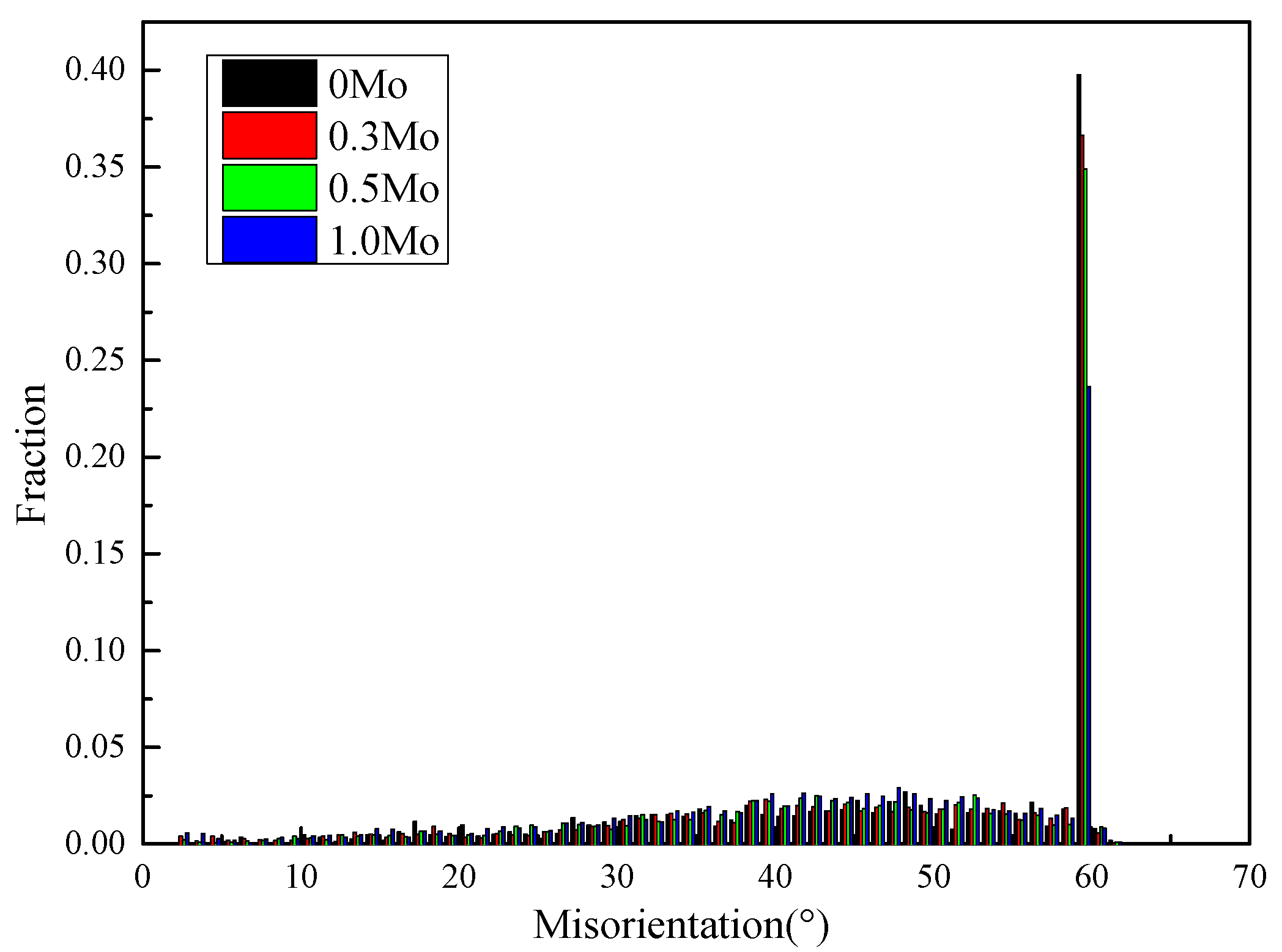

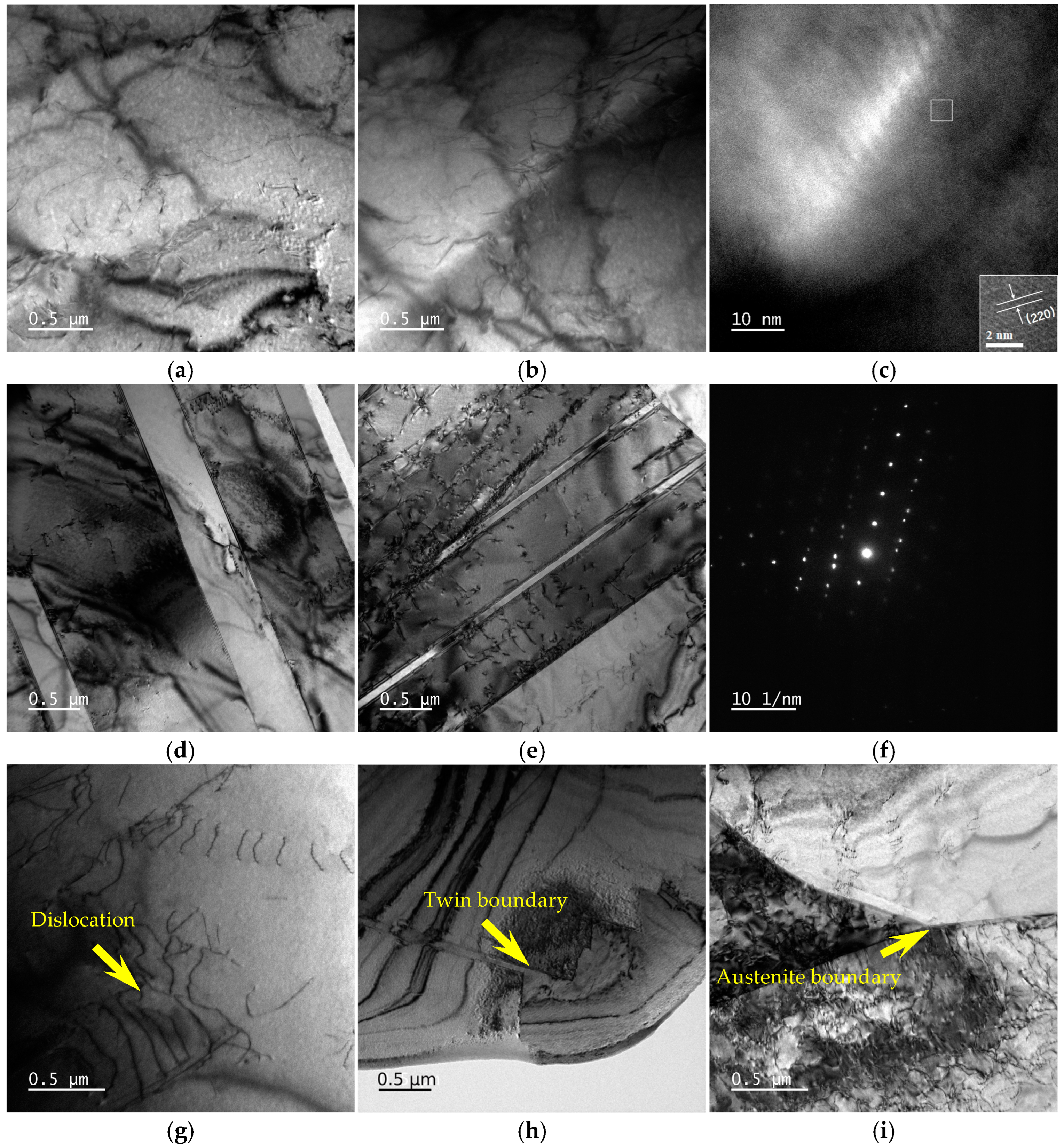

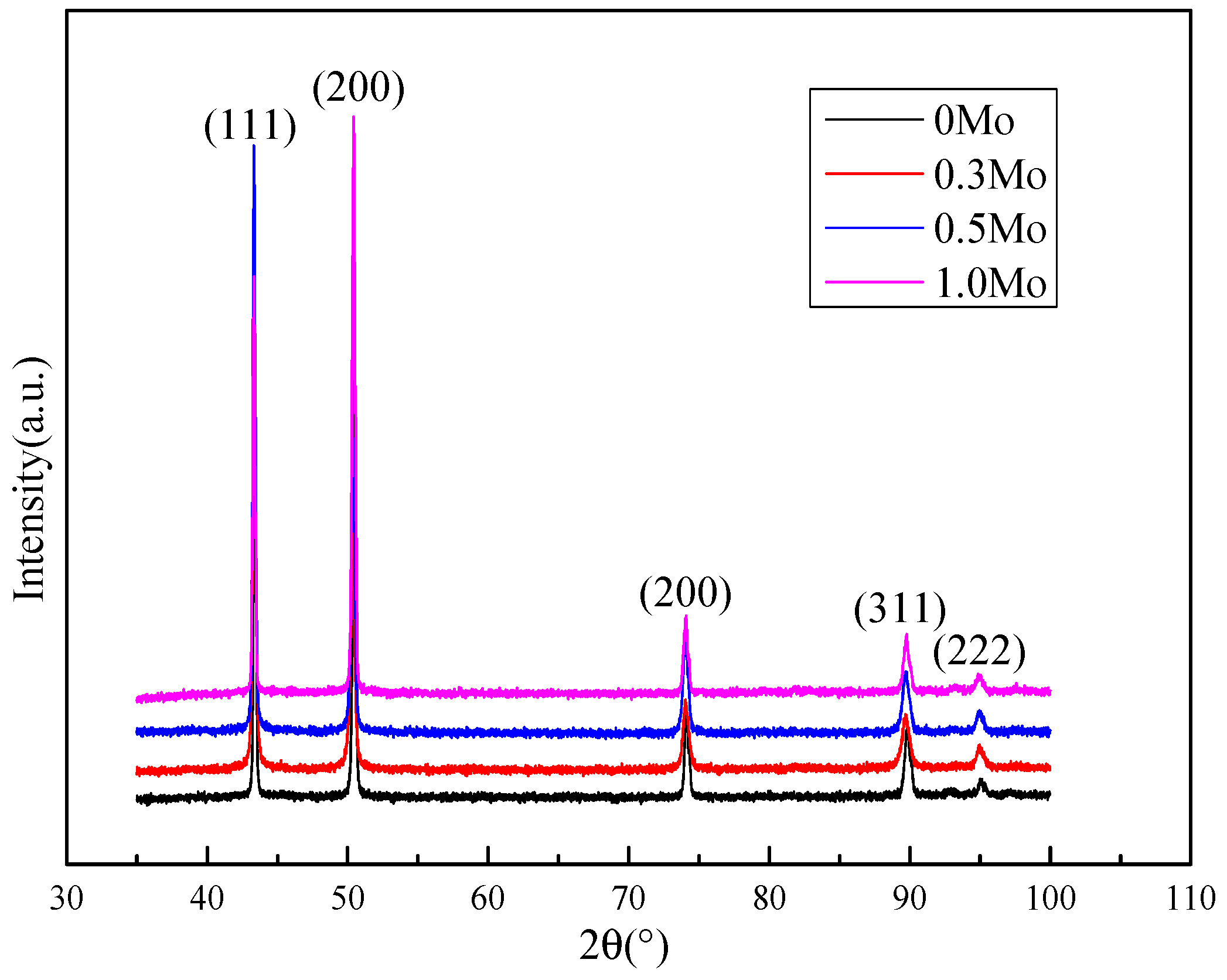

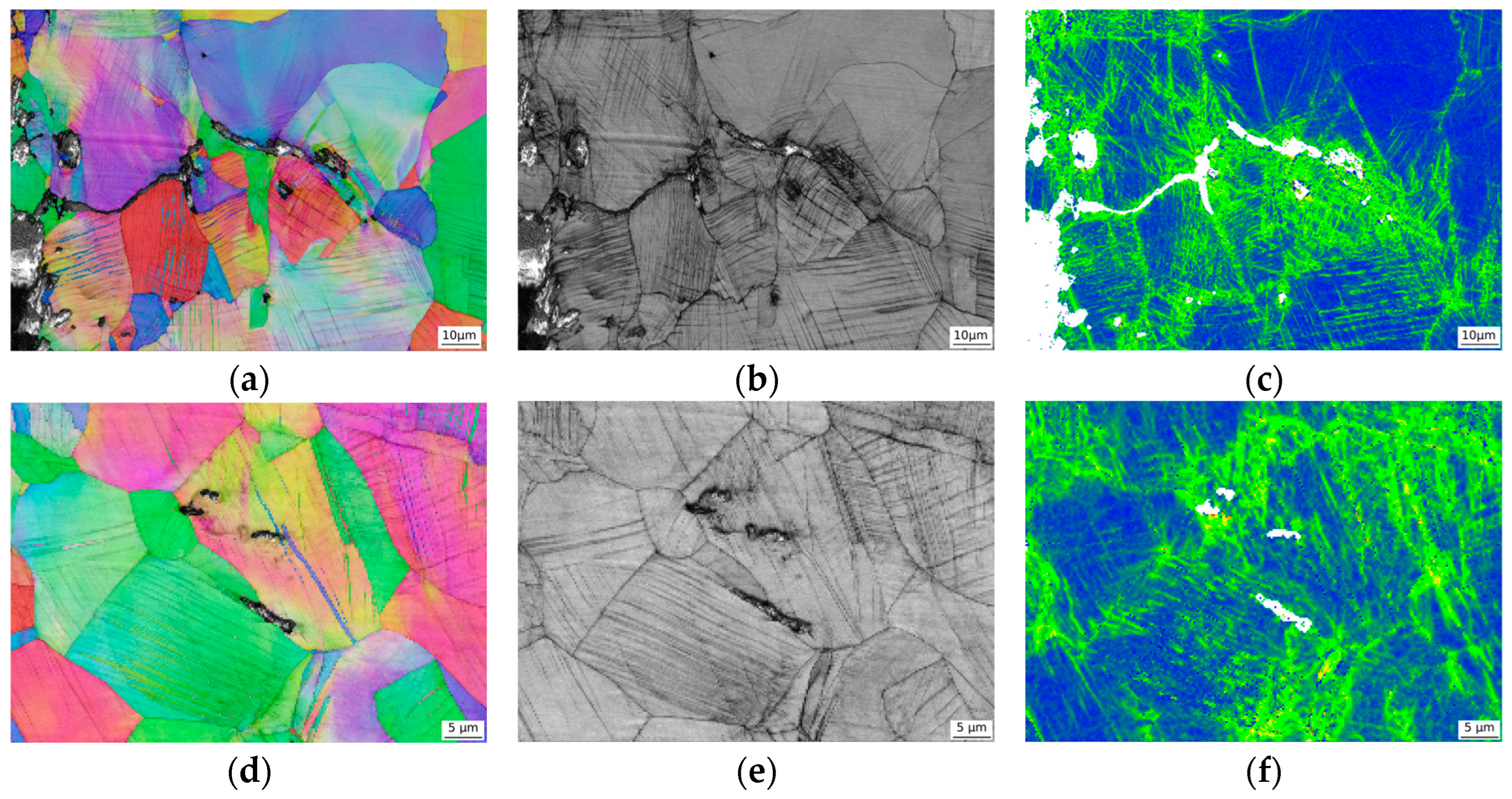

3.2. Microstructure

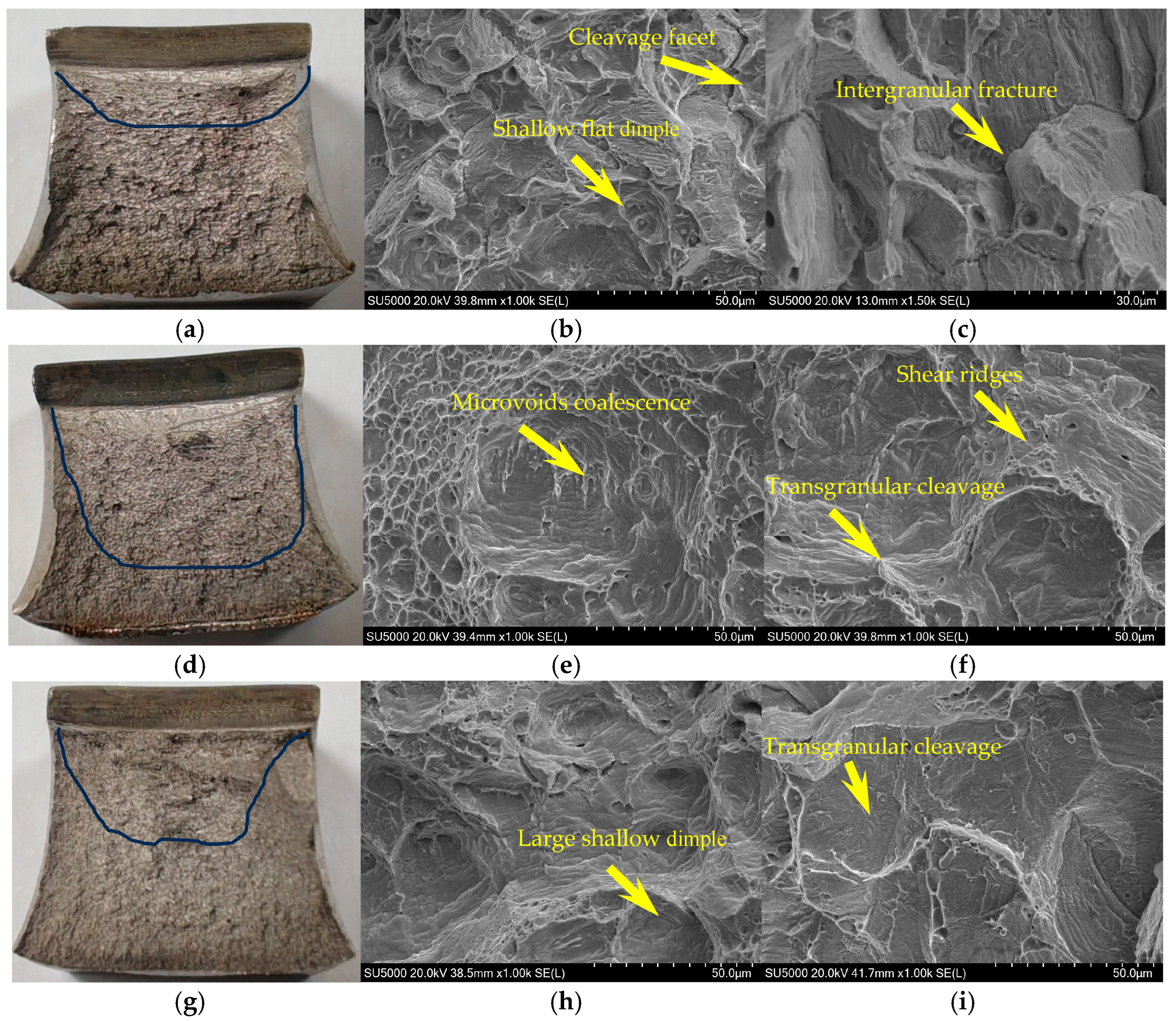

3.3. Impact Fracture Characteristics

4. Discussion

4.1. Effect of Mo Content on Microstructures

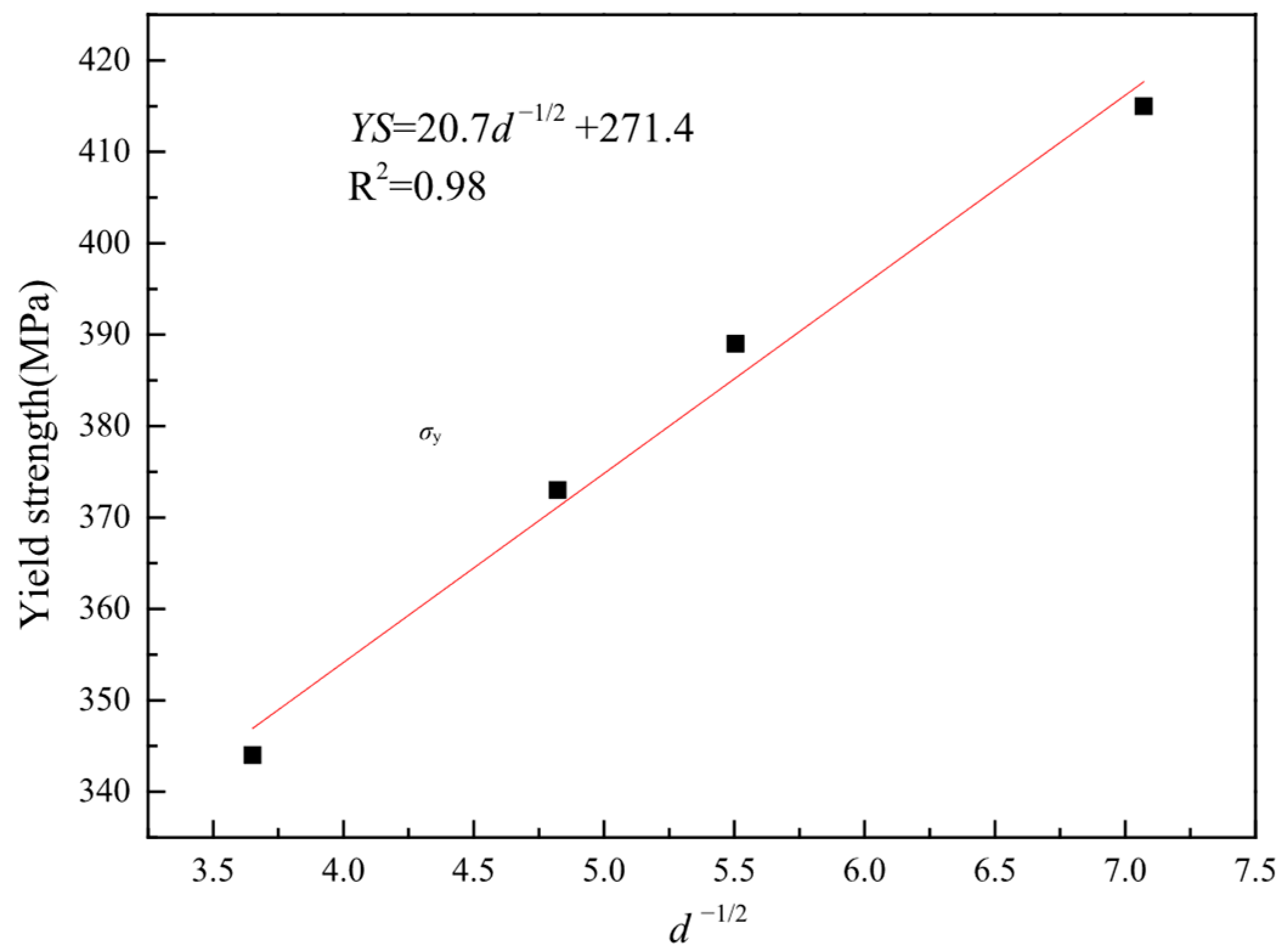

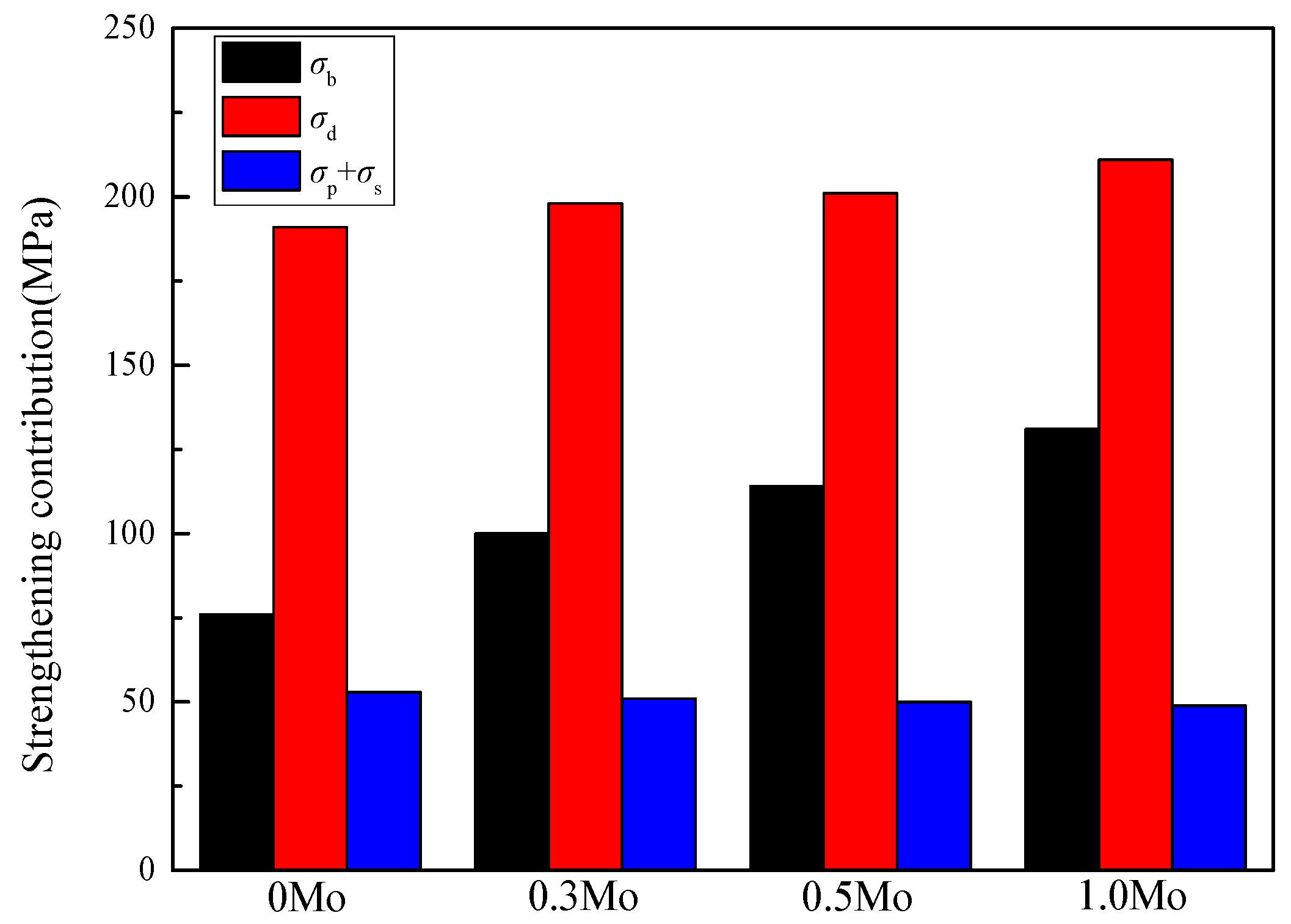

4.2. Effect of Mo Content on Tensile Properties

4.3. Effect of Mo Content on Impact Properties

5. Conclusions

- (1)

- A single austenite formed in each Mo-containing steel. With an increased Mo content, the grain boundary carbides decreased due to the formation of carbides within the grains, and the austenite and twin sizes were refined due to the dragging effect of the solute atoms of Mo and the pinning effect of the precipitates.

- (2)

- With an increase in Mo content, grain boundary strengthening and dislocation strengthening increased, while solid solution strengthening and precipitation strengthening had little effect, leading to an increase in the final yield strength. The contribution of dislocation strengthening to the yield strength was 51~56%, indicating that dislocation strengthening was the most significant strengthening method in the high-manganese steel.

- (3)

- The impact energy showed a trend of first increasing and then decreasing, and the impact energy reached the highest point when the Mo content was 0.30 wt.%. This was caused by the combined regulation of the grain boundary carbides, austenite, and twin boundaries.

- (4)

- From the perspective of the results and analysis of the microstructure and properties, considering the requirement of a low alloy cost, for the hot-rolled high-manganese austenitic steel, the optimal control target for the Mo content is 0.30 wt.%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schilke, M.; Ahlström, J.; Karlsson, B. Low Cycle Fatigue and Deformation Behaviour of Austenitic Manganese Steel in Rolled and in As-Cast Conditions. Procedia Eng. 2010, 2, 623–628. [Google Scholar] [CrossRef]

- Wu, T.-Y.; Ieong, H.I.; Hsu, W.-L.; Chang, C.-M.; Lai, Y.-C. Assessment of Fatigue Crack Growth in Metro Cast Manganese Steel Frogs and Inspection Strategy. Eng. Fail. Anal. 2024, 163, 108512. [Google Scholar] [CrossRef]

- Falodun, O.E.; Oke, S.R.; Okoro, A.M.; Olubambi, P.A. Characterization of Cast Manganese Steels Containing Varying Manganese and Chromium Additions. Mater. Today Proc. 2020, 28, 730–733. [Google Scholar] [CrossRef]

- Qian, L.; Cui, X.; Li, D.; Liu, S.; Meng, J.; Zhang, F.; Xie, H. Cyclic Deformation Fields Interactions between Pores in Cast High Manganese Steel. Int. J. Plast. 2019, 112, 18–35. [Google Scholar] [CrossRef]

- Sabzi, M.; Farzam, M. Hadfield Manganese Austenitic Steel: A Review of Manufacturing Processes and Properties. Mater. Res. Express 2019, 6, 1065c2. [Google Scholar] [CrossRef]

- Han, J.; Luo, S.; Liu, N.; Chen, K.; Xie, S.; Wang, W.; Zhu, M. Experimental Investigation on Effect of Cooling Rate on Carbide Precipitation during Solidification of High Manganese Steel. J. Mater. Res. Technol. 2024, 33, 1075–1086. [Google Scholar] [CrossRef]

- Liu, E.; Wu, W.; Zhao, Y.; Tan, X.; Nie, S.; Yan, Q.; Xia, M.; Guo, H.; He, M.; Ge, C. Tailoring Precipitation Behavior of Carbonitrides in High Manganese-Aluminum Steels via Microalloying Elements. J. Mater. Res. Technol. 2025, 36, 6050–6061. [Google Scholar] [CrossRef]

- Yang, H.; Fang, C.; Zhao, E.; Liu, H.; Liu, H.; Hao, J.; Peng, Y.; Yi, H. Wear-Resistant High Manganese Steel/WC Composite Coatings with Twinning-Induced Hardening Ability Prepared by Laser Cladding. Wear 2025, 580–581, 206250. [Google Scholar] [CrossRef]

- Sui, F.; Wang, X.; Zhao, J.; Ma, B.; Li, C. Analysis on Shear Deformation for High Manganese Austenite Steel during Hot Asymmetrical Rolling Process Using Finite Element Method. J. Iron Steel Res. Int. 2015, 22, 990–995. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, D.; Yang, G.; Wang, Q.; Bao, S.; Zhao, G. Effect of Quenching Temperature on the Austenite Stability and Mechanical Properties of High-Strength Air-Cooled TRIP Steel Prepared with Hot-Rolled C–Si–Mn Sheets. J. Mater. Res. Technol. 2024, 31, 420–433. [Google Scholar] [CrossRef]

- Mishra, G.; Chandan, A.K.; Kundu, S. Hot Rolled and Cold Rolled Medium Manganese Steel: Mechanical Properties and Microstructure. Mater. Sci. Eng. A 2017, 701, 319–327. [Google Scholar] [CrossRef]

- Cazac, A.-M.; Chelariu, R.G.; Cimpoesu, R.; Bernevig, M.A.; Benchea, M.; Jurca, A.M.; Radu, A.M.; Vasilescu, G.D.; Garaliu-Busoi, B.; Lupu, F.C.; et al. Investigation of CuTi Alloy for Applications as Non-Sparking Material. Appl. Sci. 2024, 14, 11574. [Google Scholar] [CrossRef]

- Lupu, F.C.; Munteanu, C.; Istrate, B. Improvement of the Mechanical and Microstructural Properties of the Materials Used for Armour by Surface Deposition Using the Cold Spray Method. INCAS Bull. 2024, 16, 73–80. [Google Scholar] [CrossRef]

- Hu, Q.; Du, H.; Sun, X.; Hou, L.; Wang, Q.; Guo, Z.; Li, H.; Fan, J.; Wei, Y.; Liu, X.; et al. Effect of Mo on the σ-Phase Precipitation Behavior of Super-Austenitic Stainless Steel. Emerg. Mater. Res. 2024, 13, 141–151. [Google Scholar] [CrossRef]

- Liu, C.; Sun, J.; Lu, S. Precipitation Behavior and Mechanical Properties of 16Cr–25Ni Austenitic Stainless Steel Weld Metals with Different Mo Content during Aging. J. Mater. Sci. Technol. 2026, 241, 1–17. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, H.; Cao, Y.; Liu, H.; Zhao, Z.; Chen, X.; Li, D. Revisiting the Effect of Localized Alloying Elements on Stacking Fault Energy in Austenitic Steel. Mater. Sci. Eng. A 2025, 929, 148074. [Google Scholar] [CrossRef]

- Hua, M.; Chen, C.; Lin, W.; Ming, X.; Guoji, C.; Fucheng, Z. Effect of Mo Alloying on Wear Behavior of Hadfield Steel. J. Mech. Eng. 2020, 56, 81. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, Y.; Yang, B.; Xiong, Z.; Cheng, X. Multiphase Precipitation Behavior and Tensile Properties of a Fe-Mn-Al-Mo-C Austenitic Lightweight Steel. Mater. Sci. Eng. A 2023, 885, 145654. [Google Scholar] [CrossRef]

- Zhao, Y.; Cao, Y.; Wen, W.; Lu, Z.; Zhang, J.; Liu, Y.; Chen, P. Effects of Mn Content on Austenite Stability and Mechanical Properties of Low Ni Alumina-Forming Austenitic Heat-Resistant Steel: A First-Principles Study. Sci. Rep. 2023, 13, 5769. [Google Scholar] [CrossRef]

- Moon, J.; Kim, S.-D.; Lee, C.-H.; Jo, H.-H.; Hong, H.-U.; Chung, J.-H.; Lee, B.H. Strengthening Mechanisms of Solid Solution and Precipitation at Elevated Temperature in Fire-Resistant Steels and the Effects of Mo and Nb Addition. J. Mater. Res. Technol. 2021, 15, 5095–5105. [Google Scholar] [CrossRef]

- Huang, J.; Bahador, A.; Kondoh, K. Microstructure Development and Strengthening Behaviour in Hot-Extruded Ti-Mo Alloys with Exceptional Strength-Ductility Balance. J. Alloys Compd. 2025, 1010, 177195. [Google Scholar] [CrossRef]

- Liu, C.; Xiong, F.; Wang, Y.; Cao, Y.; Liu, X.; Xue, Z.; Peng, Q.; Peng, L. Strengthening Mechanism and Carbide Precipitation Behavior of Nb-Mo Microalloy Medium Mn Steel. Materials 2021, 14, 7461. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.; Park, S.-J.; Moon, J.; Han, H.N. Correlation between Macroscale Tensile Properties and Small-Scale Intrinsic Mechanical Behavior of Mo-Added Fe–Mn–Al–C Lightweight Steels. Mater. Sci. Eng. A 2019, 768, 138460. [Google Scholar] [CrossRef]

- Han, R.; Yang, G.; Xu, D.; Jiang, L.; Fu, Z.; Zhao, G. Effect of V on the Precipitation Behavior of Ti−Mo Microalloyed High-Strength Steel. Materials 2022, 15, 5965. [Google Scholar] [CrossRef]

- Cui, G.; Liu, H.; Li, S.; Gao, G.; Hassani, M.; Kou, Z. Effect of Ni, W and Mo on the Microstructure, Phases and High-Temperature Sliding Wear Performance of CoCr Matrix Alloys. Sci. Technol. Adv. Mater. 2020, 21, 229–241. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.; Park, S.-J.; Jang, J.H.; Lee, T.-H.; Lee, C.-H.; Hong, H.-U.; Han, H.N.; Lee, J.; Lee, B.H.; Lee, C. Investigations of the Microstructure Evolution and Tensile Deformation Behavior of Austenitic Fe-Mn-Al-C Lightweight Steels and the Effect of Mo Addition. Acta Mater. 2018, 147, 226–235. [Google Scholar] [CrossRef]

- Moon, J.; Ha, H.-Y.; Park, S.-J.; Lee, T.-H.; Jang, J.H.; Lee, C.-H.; Han, H.N.; Hong, H.-U. Effect of Mo and Cr Additions on the Microstructure, Mechanical Properties and Pitting Corrosion Resistance of Austenitic Fe-30Mn-10.5Al-1.1C Lightweight Steels. J. Alloys Compd. 2019, 775, 1136–1146. [Google Scholar] [CrossRef]

- Sairam, K.; Phaniraj, M.P.; Rajesh, K. Effect of Molybdenum on Recrystallization Behavior of Fe30Mn5Al1C- x Mo Lightweight Austenitic Steels. Scr. Mater. 2023, 230, 115399. [Google Scholar] [CrossRef]

- Shi, Y.B.; Zhou, G.Y.; Cao, G.H.; Zhang, H.; Liu, C.S.; Dong, X.M.; Zhang, Z.H. Effect of Nb and Mo Microalloying on Sulfide Stress Cracking Resistance and Hydrogen Permeation Behavior of Advanced Casing Steel. Int. J. Hydrogen Energy 2025, 161, 150583. [Google Scholar] [CrossRef]

- ASTM A128/A128M-21; Standard Specification for Steel Castings, Austenitic Manganese. ASTM International: West Conshohocken, PA, USA, 2021.

- Chen, Z.; Miao, S.; Kong, L.; Wei, X.; Zhang, F.; Yu, H. Effect of Mo Concentration on the Microstructure Evolution and Properties of High Boron Cast Steel. Materials 2020, 13, 975. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, M.; Li, J.; Wang, R.; Yuan, Z.; Tan, Z.; Yu, W. Precipitation Mechanisms and Crystallographic Study of Co-Precipitation Carbides in Super Austenitic Stainless Steel. J. Alloys Compd. 2025, 1036, 181942. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, B.; Liang, X.; Peng, H.; Zhou, J.; Lin, F. Strengthened Microstructure and Mechanical Properties of Austenitic 316L Stainless Steels by Grain Refinement and Solute Segregation. J. Mater. Res. Technol. 2025, 34, 552–565. [Google Scholar] [CrossRef]

- Kusakin, P.; Belyakov, A.; Molodov, D.A.; Kaibyshev, R. On the Effect of Chemical Composition on Yield Strength of TWIP Steels. Mater. Sci. Eng. A 2017, 687, 82–84. [Google Scholar] [CrossRef]

- Croft, S. Kaye and Laby—Tables of Physical and Chemical Constants (15th Edn). Phys. Bull. 1987, 38, 149. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch Relation and Boundary Strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Li, Y.Z.; Huang, M.X. The Respective Hardening Contributions of Dislocations and Twins to the Flow Stress of a Twinning-Induced Plasticity Steel. Scr. Mater. 2016, 112, 28–31. [Google Scholar] [CrossRef]

- Bouaziz, O.; Guelton, N. Modelling of TWIP Effect on Work-Hardening. Mater. Sci. Eng. A 2001, 319–321, 246–249. [Google Scholar] [CrossRef]

- Liu, J.; Li, L.; Yang, S.; Ding, C.; Wang, E.; Yu, X.; Wu, H.; Niu, G. Effect of Intragranular κ Carbides and Intergranular Precipitates on the Hot Deformation Mechanism and Dynamic Recrystallization Mechanism of Fe–28Mn–11Al–1.5C–5Cr Lightweight Steel. J. Mater. Res. Technol. 2023, 27, 2346–2362. [Google Scholar] [CrossRef]

- Elkot, M.N.; Sun, B.; Zhou, X.; Ponge, D.; Raabe, D. Hydrogen-Assisted Decohesion Associated with Nanosized Grain Boundary κ-Carbides in a High-Mn Lightweight Steel. Acta Mater. 2022, 241, 118392. [Google Scholar] [CrossRef]

- Hong, S.; Lee, J.; Lee, B.-J.; Kim, H.S.; Kim, S.-K.; Chin, K.-G.; Lee, S. Effects of Intergranular Carbide Precipitation on Delayed Fracture Behavior in Three TWinning Induced Plasticity (TWIP) Steels. Mater. Sci. Eng. A 2013, 587, 85–99. [Google Scholar] [CrossRef]

- Du, H.; Hu, Q.; Yue, X.; Jia, J.; Wei, Y.; Hou, L.; Luo, H.; Wang, Q.; He, H.; Wei, H.; et al. Effect of Mo on Intergranular Corrosion Behavior in Super-Austenitic Stainless Steel. Corros. Sci. 2024, 231, 111986. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Mo | Fe |

|---|---|---|---|---|---|

| 0Mo | 1.08 | 0.33 | 13.3 | 0.02 | Balance |

| 0.3Mo | 1.08 | 0.33 | 13.3 | 0.30 | Balance |

| 0.5Mo | 1.11 | 0.38 | 13.2 | 0.48 | Balance |

| 1.0Mo | 1.09 | 0.35 | 13.3 | 1.01 | Balance |

| Steel | YS (MPa) | TS (MPa) | TE (%) | Wi | Wp | Wt (J) |

|---|---|---|---|---|---|---|

| 0Mo | 344 ± 7 | 946 ± 10 | 62 ± 4 | 68 ± 7 | 70 ± 5 | 138 ± 12 |

| 0.3Mo | 373 ± 7 | 1013 ± 11 | 60 ± 3 | 105 ± 10 | 122 ± 10 | 227 ± 20 |

| 0.5Mo | 389 ± 8 | 1016 ± 11 | 56 ± 3 | 102 ± 9 | 113 ± 11 | 215 ± 20 |

| 1.0Mo | 415 ± 8 | 1023 ± 13 | 48 ± 3 | 78 ± 7 | 88 ± 6 | 166 ± 13 |

| Steel | Mean Diameter (μm) | fAB (%) | fTB (%) | Dislocation Density (×1014 m−2) |

|---|---|---|---|---|

| 0Mo | 75 | 58.05 | 39.75 | 7.07 |

| 0.3Mo | 43 | 59.07 | 36.64 | 7.59 |

| 0.5Mo | 33 | 61.71 | 34.88 | 7.86 |

| 1.0Mo | 25 | 71.51 | 23.66 | 8.61 |

| Steel | Austenite Boundaries | Twin Boundaries |

|---|---|---|

| 0Mo | 29.56° <-1-2-4> | 59.11° <-1-1-1> |

| 34.58° <0-1-4> | 59.68° <-1-1-1> | |

| 45.34° <-1-2-4> | 59.45° <-1-1-1> | |

| 33.87° <-2-3-4> | 59.10° <-1-1-1> | |

| 0.3Mo | 35.05° <0-3-4> | 59.38° <-1-1-1> |

| 39.16° <-1-4-4> | 59.79° <-1-1-1> | |

| 27.03° <-1-1-4> | 58.93° <-1-1-1> | |

| 36.01° <-2-3-4> | 59.28° <-1-1-1> | |

| 0.5Mo | 31.56° <-1-1-3> | 59.65° <-1-1-1> |

| 38.97° <-1-1-2> | 59.83° <-1-1-1> | |

| 23.83° <-1-1-4> | 59.29° <-1-1-1> | |

| 38.21° <-1-4-4> | 59.98° <-1-1-1> | |

| 1.0Mo | 26.47° <-1-3-4> | 59.85° <-1-1-1> |

| 52.38° <-1-2-4> | 59.49° <-1-1-1> | |

| 35.00° <-1-3-4> | 59.99° <-1-1-1> | |

| 32.01° <-1-1-3> | 59.45° <-1-1-1> |

| Steel | YS (MPa) | σ0 (MPa) | σb (MPa) | σd (MPa) | (σs + σp) (MPa) |

|---|---|---|---|---|---|

| 0Mo | 344 | 24 | 76 | 191 | 53 |

| 0.3Mo | 373 | 24 | 100 | 198 | 51 |

| 0.5Mo | 389 | 24 | 114 | 201 | 50 |

| 1.0Mo | 415 | 24 | 131 | 211 | 49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Shi, G.; Fu, X.; Tang, T.; Wang, Q.; Wang, P. The Effect of Mo on the Microstructure and Mechanical Properties of High-Manganese Railway Frog Steel Produced with the Thermal Mechanical Control Process. Metals 2025, 15, 1025. https://doi.org/10.3390/met15091025

Lin J, Shi G, Fu X, Tang T, Wang Q, Wang P. The Effect of Mo on the Microstructure and Mechanical Properties of High-Manganese Railway Frog Steel Produced with the Thermal Mechanical Control Process. Metals. 2025; 15(9):1025. https://doi.org/10.3390/met15091025

Chicago/Turabian StyleLin, Junke, Genhao Shi, Xiangyao Fu, Tiebing Tang, Qingfeng Wang, and Ping Wang. 2025. "The Effect of Mo on the Microstructure and Mechanical Properties of High-Manganese Railway Frog Steel Produced with the Thermal Mechanical Control Process" Metals 15, no. 9: 1025. https://doi.org/10.3390/met15091025

APA StyleLin, J., Shi, G., Fu, X., Tang, T., Wang, Q., & Wang, P. (2025). The Effect of Mo on the Microstructure and Mechanical Properties of High-Manganese Railway Frog Steel Produced with the Thermal Mechanical Control Process. Metals, 15(9), 1025. https://doi.org/10.3390/met15091025