Abstract

This study presents a novel approach to understanding fatigue and crack growth phenomena by benchmarking experimental observations with numerical simulations. We introduced controlled residual stress fields away from notch-induced crack nucleation sites and analyzed their interaction with crack nucleation and growth. Surprisingly, our findings revealed that the introduction of generally beneficial compressive residual stresses had a counter-intuitive negative impact on product fatigue life. Despite daunting challenges in applying classical fatigue principles to describe crack nucleation and growth, our numerical simulations provided valuable insights, capturing the trend of observed crack paths, albeit not their velocity. This research sheds light on the complex interplay between residual stresses and crack propagation, offering important considerations for fatigue analysis and product design.

1. Introduction

We begin with a thought experiment. In engineering, one of the major design goals is to foresee and analyze the critical points in the structure. In fatigue analysis, this usually boils down to alleviating stress concentrators that promote the onset of fatigue cracks and therefore reduce the life of a product. One of the most effective solutions is to prescribe an additional manufacturing procedure of inducing beneficial residual stress fields on the surface of stress raisers, for example, peening procedures on notches or hole expansions on bolt and rivet locations. When performed properly, the added cost of these procedures results in extended product usability, increased safety, and ultimately peace of mind for all involved.

However, what if treating stress concentration areas results in the shifting of crack nucleation to a different location? As the crack begins to propagate, it encounters the influential area of the induced residual stress field and interacts with it. In this study, we delve into the potential outcomes of such scenarios.

Understanding the significance of residual stress under fatigue load is of utmost importance in accurately predicting the usable life of a product. James et al. [1] have distinguished two types of residual stress origins, thermal and mechanical deformations. Chen et al. [2] made recent discoveries that neglecting residual stress relaxation in welded joints can lead to overly conservative results. Here, we focus on the mechanical introduction of residual stresses commonly found in peening and cold-hole expansion processes. More specifically, we address the issue of residual stress relaxation under cyclic loading using the combined isotropic–kinematic material model discussed at length in [3].

The peening process represents a straightforward and uncomplicated technique for generating favorable compressive residual stresses on the product’s surface. This is accomplished by subjecting the material’s surface to plastic deformation using various means, such as shot beads, localized laser explosions, or mechanical actuators driven by ultrasound waves. The outcome is a surface with decreased roughness, enhanced hardness, and the presence of compressive residual stresses at both the surface and sub-surface levels. These combined factors contribute to an improved fatigue life of the material [4,5,6,7,8].

Hole expansion is another technique that introduces surface conditions beneficial to the fatigue life, similar to the peening process. In this method, a mandrel with a larger diameter than the hole is inserted forcefully through it. The diameter of the mandrel is carefully chosen to ensure that it plastically deforms the hole predominantly in the radial direction, resulting in circumferential normal residual stresses. To minimize plastic flow of the material in the axial direction of the hole, lubrication or a split sleeve is utilized to reduce friction between the mandrel and the hole wall. This technique finds common application in the aerospace industry, particularly for treating stress raisers such as holes in riveted or bolted connections. Additionally, in the railway industry, hole expansion is considered the most suitable approach to counteract the stress concentration effect in bolted rail segment connections [9,10,11,12].

Peening and cold-hole expansion are extensively studied and widely accepted techniques in the field of manufacturing and maintenance. However, this study deviates from the conventional focus on induced residual stresses and instead examines the direction of crack growth originating from untreated areas. If cracks initiate from the peened area or the cold-expanded hole, it indicates that the imposed barrier of introduced residual stress has been surpassed. With further crack propagation, the previously beneficial residual stress state is expected to have diminished effects due to fatigue load relaxation, and the stress state near the crack tip becomes more influential.

A study by Yasniy et al. [13] explores the impact of the cold-expanded hole procedure on a specimen with a pre-existing crack. The results demonstrate an improvement in fatigue life, as the crack growth rate is retarded to some extent. Another study by Ren et al. [14] reveals that the introduction of compressive residual stresses reduces the driving forces for crack propagation. Almer et al. [15] introduce a residual stress field by press-fitting two holes and subsequently cutting alongside them to create a double-edged specimen. The study demonstrates that if compressive residual stresses are present, cracks originating from these notches require more fatigue load cycles to propagate. Another study by Deschênes et al. [16] explores fatigue crack growth under the effect of nearby welding residual stresses. The authors conclude that the presence of residual stress had no effect on the rate of fatigue crack growth. Here, the objective was to introduce a symmetrical residual stress field under the assumptions of LEFM, which still provides a difficult framework in calculating the relaxation of residual stresses under the influence of plastic material flow.

A study conducted by Mahmoudi et al. [17] employs the side-punch technique to investigate the effect of the punching process on fracture initiation toughness. The results indicate that the force of crack growth significantly depends on the number and location of the punching dies used.

Overall, these studies contribute to the understanding of crack behavior and the influence of residual stress-inducing techniques in various manufacturing scenarios.

In this study, we conducted a unique test to explore the impact of residual stress on fatigue crack growth. We used a specialized specimen geometry similar to the Compact-Tension specimen. By employing the hole expansion process, we introduced residual stress into one of the drilled holes in the specimen. The experimental procedure details are presented in the next section. Additionally, we developed a novel numerical simulation method for fatigue and crack growth [18], which we parametrized and used to simulate the experimental observations. The results from both the experiments and numerical simulations are compared side by side in the final section before drawing conclusions.

2. Material and Methods

2.1. Specimens

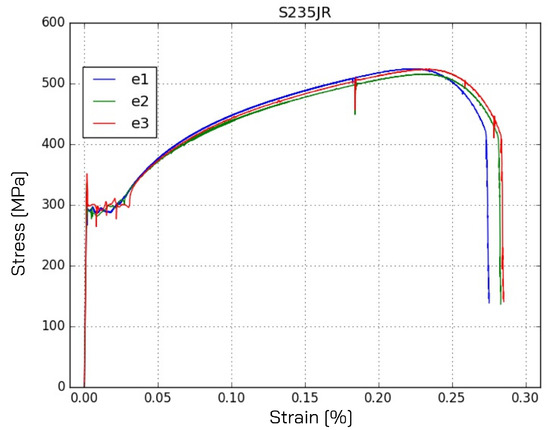

All the specimens were made from hot rolled sheets of S235JR steel, from Štore Steel d.o.o., Štore, Slovenia supplier. S235JR is a mild carbon steel with measured quasi-static stress–strain response, as shown in Figure 1, and a typical composition, as denoted in the standard [19]. What we can observe is a typical mild steel response. When the high yield stress is reached, the stress drops to the low yield stress which in this case corresponds to the yielding plateau. This plateau is a type of non-homogeneous plastic flow, where multiple bands of dislocations across the loaded cross section are activated. This nonlinearity is difficult to model in a numerical environment, but if we load the material beyond the plateau, under cyclic loading, it starts to behave as a material with gradual transition from elastic to plastic deformation. Previous studies [3] have shown that the most appropriate material model for S235JR is a combined isotropic–kinematic material model. If only the kinematic hardening is assumed, the calculation of stress relaxation is too great and unrealistic due to not taking into the account the growth of the yielding surface, which is modeled by the isotropic hardening.

Figure 1.

Stress–strain response of S235JR steel as measured from 3 experiments.

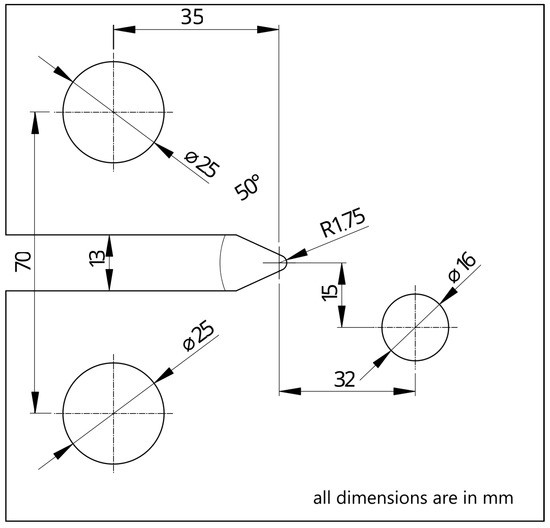

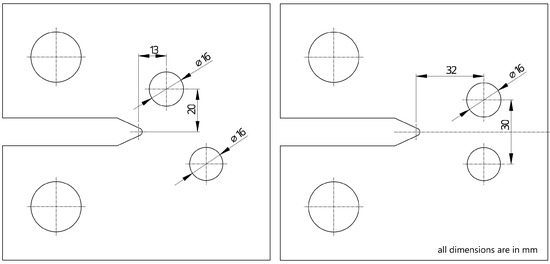

The base geometry of the reference specimen is illustrated in Figure 2. The specimens were cut from a 10 mm thick sheet of hot-rolled S235JR mild carbon steel using waterjet technology. To achieve the necessary clearance in the clamping pin holes (25 mm diameter) and the cold-hole-expanded hole (16 mm diameter), the rough contour was further machined. Derivations of the reference specimen were made by drilling an additional hole of the same dimensions as the cold-hole-expanded one. Figure 3 depicts the two derived configurations named A and B. Configuration C was obtained by introducing an additional notch to a B-type specimen, as shown in Figure 4.

Figure 2.

Geometry of the reference specimen. The specimens are cut from a hot-rolled S235JR steel sheet of 10 mm nominal thickness. The rolling direction relative to the figure orientation is bottom–up.

Figure 3.

Geometry of type A (left) and type B (right) specimens. They are a modification of the reference specimen by drilling an additional 16 mm diameter hole.

Figure 4.

Type C specimen is a further modification of a type B specimen by introducing a band saw-made notch.

The specimens were subjected to a fatigue load applied through the two pin holes in tension (with a load ratio ). Due to the specimen geometry, the crack nucleation site concentrated at the V-shaped notch. The motivation for the additional A configuration was that the added hole initially attracted the crack, diverting it from the cold-expanded bottom hole where crack-retarding compressive residual stresses were present. Configurations B and C had the additional hole positioned across the horizontal symmetrical plane of the specimen. In an ideal scenario, the crack should have propagated along this plane, as the symmetry effect of both holes canceled each other out. However, due to the material’s inhomogeneous lattice and imprecisions in drilling the symmetrical hole, the crack was redirected towards one hole or the other. We intentionally introduced an inhomogeneous stress state by cold-expanding one of the holes, which we anticipated would have the largest effect on the direction of crack growth.

In terms of differences between configurations B and C, the only variation was the presence of a sharp notch produced by a band saw in configuration C. This modification led to a decrease in the number of fatigue load cycles required for a macroscopic crack to appear, and it was employed at lower force amplitudes to expedite the experimental time. It is important to note that the emphasis was placed on the direction of fatigue crack growth rather than the number of cycles for macroscopic crack nucleation.

2.2. Cold-Hole Expansion

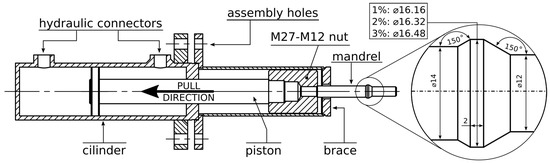

The introduction of residual stresses is achieved by the cold-hole expansion technique. We developed a prototype hydraulic mandrel pulling device, whose cross section is depicted in Figure 5.

Figure 5.

A cross-section view of the prototype mandrel pulling device for hole expansion.The largest diameter of the mandrel corresponds to the hole expansion.

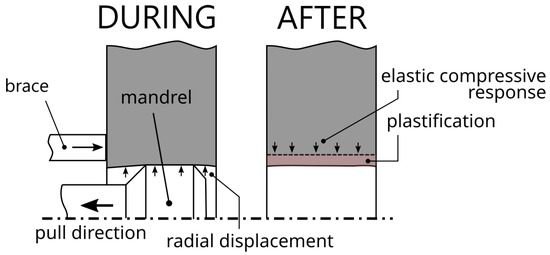

The principle of hole expansion is shown in Figure 6. The oversized mandrel is pulled through the hole, causing radial displacement of the specimen material. The oversize should be sufficient to induce material plastic flow. The material surrounding the hole is compressed, and an elastic tensile stress develops around the hole to maintain internal equilibrium.

Figure 6.

Principle of residual stress introduction by hole expansion.

The mandrel used is made of 42CrMo4 steel (according to ISO683-1:2016 [20]) and is additionally surface-hardened by nitration. The nominal diameter of the hole to be expanded is 16 mm, achieved by first drilling a hole with a 15.5 mm diameter drill and then reaming the hole with a 16 mm diameter reamer. All holes on the specimen, even those not cold-expanded, underwent the same treatment. The reaming process greatly reduces surface roughness and helps prevent crack nucleation on the hole’s surface.

Three mandrels with 1%, 2%, and 3% oversize were used. The calculation of the diameter oversize is presented in Equation (1), and the details of the mandrel’s expanding surface can be seen in Figure 5. Due to the high friction forces during the mandrel pulling process, additional graphene-based lubrication was used. Due to the significant difference in hardness between the mandrel and the specimen material, there was no observable wear on the mandrel, as confirmed by comparing the mandrel diameters before and after the experiment using a micrometer.

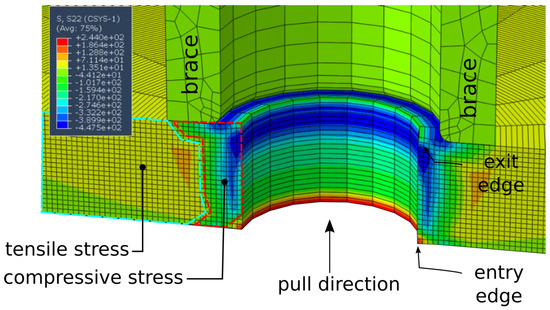

Figure 7 displays the results of a cold-hole expansion simulation conducted using the Abaqus 2017 finite-element solver. An axisymmetric model is employed to illustrate the stress state following the passage of the mandrel. The residual stress profile is influenced by the entry and exit conditions, which is also verified in previous studies [21,22]. In this simulation, CAX8 elements with a size of 0.5 mm were utilized to model the 10 mm thick specimen. The brace is represented as a rigid domain, and the friction coefficient between the mandrel and the specimen is assumed to be 0.1 (see [23] for solid graphene lubrication in a humid condition).

Figure 7.

S22-depicted stress is the stress in the direction of the natural cylindrical coordinate system of the hole. The inhomogeneous profile of induced compressive residual stress in the “z” direction is attributed to frictional effects and brace offset from the hole.The red dashed line marks the compressive and blue the tensile regions of residual stress.

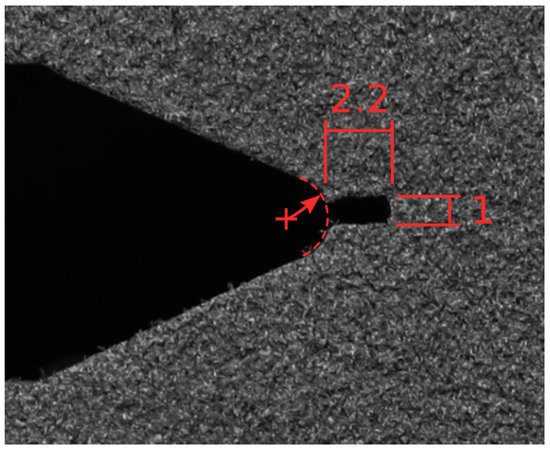

2.3. Digital Image Correlation for Crack Growth Tracking

For measuring fatigue crack growth, the digital image correlation method was employed. This method proved particularly advantageous in detecting short cracks that are challenging to observe. The Ncorr v1.2 software [24] was utilized for analysis, using a subset radius of 40 pixels and a spacing of 4 pixels. Subset truncation was activated when a crack propagated through a subset, as indicated by a reduction in correlation. Image acquisition was performed using a single camera, specifically the Canon EOS 40D, Canon, Tokyo, Japan, equipped with a Canon EFS 17–85 mm lens, from Canon as before, resulting in an average resolution of approximately 30 pixels per millimeter.

To generate a random surface pattern for deformation measurement, a spray paint technique was employed. Initially, a complete coat of matte white paint was applied, followed by the application of a speckle pattern using matte black spray paint. This approach allowed for the measurement of surface deformation throughout the entire process, including the initial cold expansion and subsequent fatigue loading, owing to its non-destructive nature. The detection and measurement of fatigue crack length followed the procedure outlined in [25].

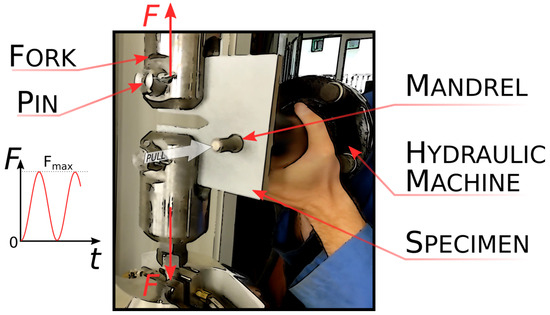

2.4. Experimental Procedure

To prepare the specimens for the digital image correlation (DIC) method, their surfaces are first made ready. Subsequently, the specimens are clamped using pin fork grips onto the MTS Landmark 100-kN servo-hydraulic tensile testing machine, MTS System Corporation, Eden Prairie, MN, USA. as shown in Figure 8. The machine is equipped with an MTS 634.11F-24 axial extensometer, supplied by MTS Systems Corporation as before. The orientation of the specimen, as seen from the camera’s perspective, is such that the crack grows from left to right, with the original hole of the reference specimen positioned below the horizontal symmetrical plane.

Figure 8.

Experimental setup showing the specimen before the cold hole expansion. The mandrel is pulled through the entire thickness of the specimen and is therefore not present during fatigue loading.

To remove the clearance between the grip pins and the specimen mounting holes, an initial force of 200 N in tension is applied. Prior to initiating fatigue loading, a residual stress is induced by cold-expanding one of the appropriate holes on the specimen. Than the pretension load is reduced from 200 N down to 0 N.

All specimens are subjected to a pulsating dynamic force with a load ratio . The maximum forces, the hole expansion (HE) ratios, and the frequency of the applied load are summarized in Table 1.

Table 1.

Experimental conditions overview.

2.5. Numerical Calculation

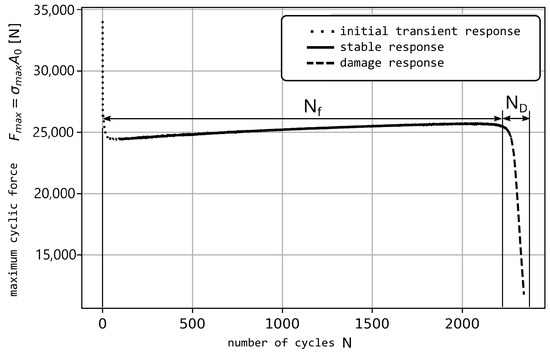

The idea behind the numerical simulation of fatigue and fatigue-governed crack growth is based on the observation of dog-bone test specimens subjected to constant amplitude fatigue load (see previous study [18]). Observing the maximum tensile force in the life of a uniaxially loaded specimen, it begins with an initial transient response, followed by material stabilization, and after a sufficient number of cycles , a crack appears, which reduces the stiffness and maximum force until an number of cycles are reached to complete the fracture. Such a response is shown in Figure 9. The goal of the used algorithm here is to use the domain of stable and fracture response to model the fatigue and fatigue crack growth respectfully. At the current state of the algorithm, only plain strain approximation with linear triangular elements can be used. We begin by first developing a strain-life model using the Coffin–Manson approach coupled with Morrow correction for mean stress, as shown in Equation (2). The Morrow correction is used to include the effect of residual stresses.

Figure 9.

Maximum force response of test specimen subjected to constant amplitude strain [18], with the permission from MDPI AG, 2025.

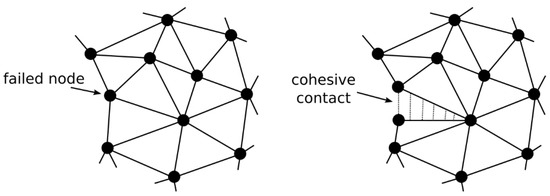

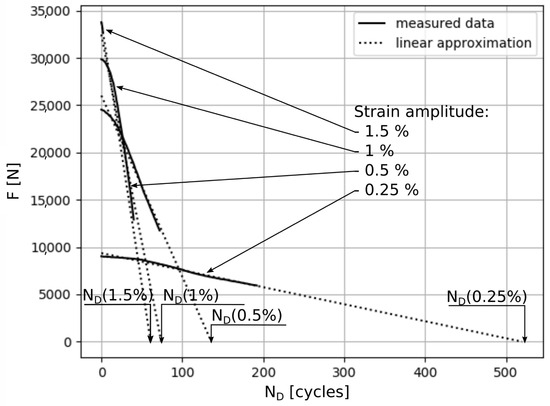

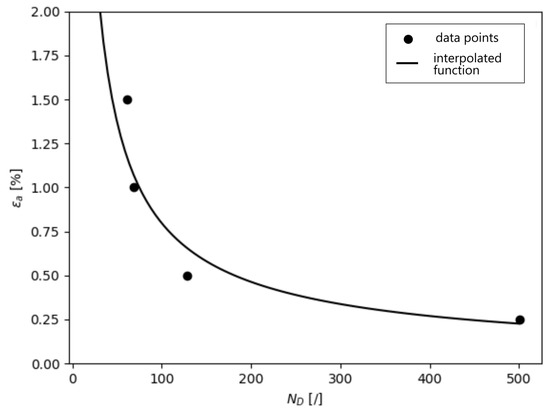

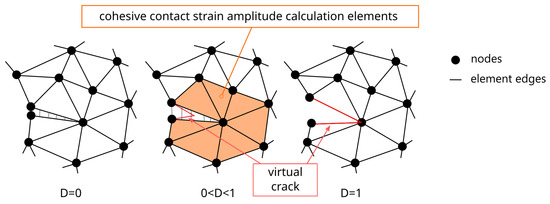

The specimens in this study are sufficiently loaded in order to focus on low-cycle-fatigue analysis. Still, the number of cycles is too large to model them directly using the finite element approach (FEM). A direct cyclic analysis (DCA) is employed to predict the stable stress–strain response of the domain. In each integration point of the FEM mesh, equivalent stress and strain are calculated. Equivalent stress is calculated on the premise of hydrostatically signed von Mises stress in each increment of the cyclic load. The analysis of this fluctuating equivalent stress is used to calculate the mean stress in every integration point in the FEM mesh. Similarly, the Tresca equivalent strain is calculated, and strain amplitude is derived. Using Equation (2), the number of cycles to crack nucleation is calculated in each integration point and extrapolated to the mesh nodes. In the first step of the calculation, a failing node with minimum is determined; other nodes receive this number of cycles as relative damage based on a linear accumulation rule of Palmgren–Miner. The algorithm then searches for a neighboring node with the highest , which translates to the highest probability for the crack growth direction. The failed node is duplicated, and together with the neighboring node, a new crack surface is introduced in the shape of a wedge. This node splittage method is suboptimal for crack modeling mainly because of high dependency on mesh size, and the instantaneous nature of growth is unrealistic. To partially address these two issues, a cohesive contact (CC), as shown in Figure 10, is introduced between the newly developed free edges with sufficient stiffness in order not to disrupt the stress state around it. CC is a linear elastic connection between the edges, and the idea of continuum damage mechanics is employed to simulate the macro scale effect of a crack growing inside the CC. Here, the fracturing damage D is derived from the observations of a number of cycles for crack growth under the influence of strain amplitude (see damage response in Figure 9). The prediction of the number of cycles for crack growth is based on a linear regression curve of the stiffness reduction part of the strain-life-tested specimens, as shown in Figure 11. A power function is derived connecting to , as shown in Figure 12 and Equation (3). Because this observation is valid only for the test specimens, a correlation is made to the scope of CC. A relative surface bearing ratio is calculated between specimen cross section and CC cross section , as shown in Equation (4).

Figure 10.

Principle of cohesive contact introduction.

Figure 11.

Test results that show the number of cycles of crack propagation at a given cyclic strain amplitude .

Figure 12.

An exponential law correlating the number of cycles of crack growth and applied strain amplitude .

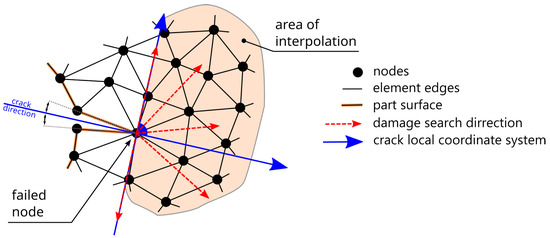

The strain amplitude inside the CC is calculated as an average of the strain in CC-connected elements, as shown in Figure 13. With this simple process, the number of cycles to complete crack growth through CC, termed , is derived. Fracturing damage D is a relative scalar that influences the components of the CC stiffness tensor. When a new CC is introduced, its initial damage is , and it acts under full rigidity. When the crack grows, the damage parameter increases and therefore the stiffness decreases. The crack propagates virtually inside the CC, as illustrated in Figure 13. As in the fatigue part of the calculation, here also, a stepwise approach in crack growth is introduced. The user of the algorithm specifies the permissible damage jump in each increment of the calculation. In this study, was used, whose results show that the crack grows the entire length of the CC in two increments. Smaller values result in a direct simulation of crack growth, and larger values result in more instantaneous growth. Here, a large was used in order to gain a coarse insight into the direction of crack growth. The global jump in the number of cycles is thus determined on the basis of , the corresponding current D in CC, and . As before, the damage parameter D accumulates linearly from 0 to 1, and is calculated on the same principle as in the crack initiation phase by the Palmgren–Miner approach. This results in a global step forward in the number of cycles, which increase in non-failed nodes and D in CCs. At any time, a new crack front can appear if a node fails before the complete rupture of CC. When the CC fails , the tip or the aforementioned neighboring node forms the crack front. A search algorithm is employed that determines the direction of maximum damage in several directions, as shown in Figure 14. When a neighboring node closest to the path of maximum damage is identified, this forms the direction of crack growth by again duplicating the current tip node and forming a new CC with the identified node. Further information on the material model used for the DCA analysis is available in [3] and an in-depth explanation of the novel algorithm in [18].

Figure 13.

Virtual crack growth in cohesive contact.

Figure 14.

The crack growth direction interpolator.

3. Results and Discussion

3.1. Reference Specimens

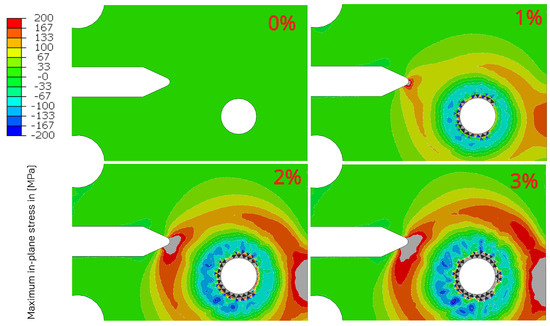

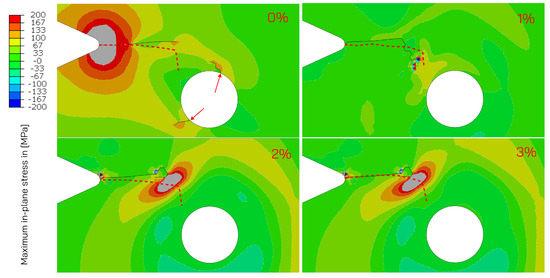

For insight into the magnitude of residual stresses, Figure 15 depicts fields of maximum in-plane principle stresses at different levels of hole expansion. As the material expands here as deformation hardening, the yield stress increases. There is a maximum of this hardening that we can achieve as the material can start to yield in the opposite direction as the mandrel is removed. This combination of isotropic–kinematic hardening was studied in great detail in [18]; here, only the effect is visible by comparing the results of 2% and 3% hole expansion, where no significant contribution of residual stresses is present at a higher expansion level.

Figure 15.

Results of initial residual stress field at different crack-hole expansions (number in %). The number in % corresponds to the imposed oversize for cold-hole expansion.

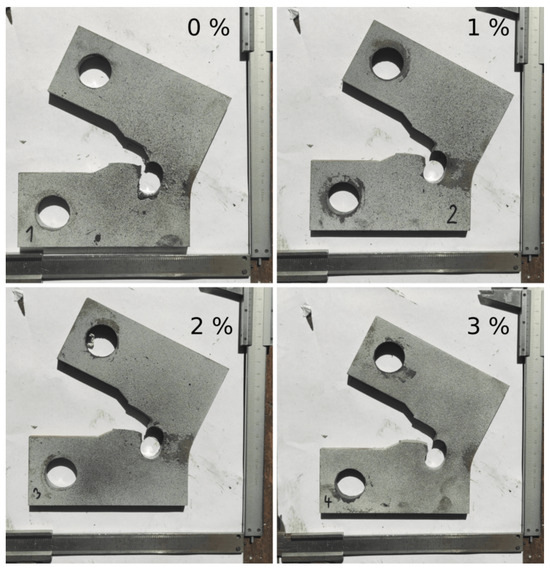

The experimental results depicted in Figure 16 illustrate that the fatigue crack initiates from the rounded notch and propagates towards the hole. The numerical analysis results are now focused on, shown in Figure 17, which display a consistent trend of fatigue crack growth. In all cases, the crack initially propagates horizontally and then sharply diverts towards the hole. In the case without the imposition of residual stresses (0% HE), a new crack appears first on the top part of the hole surface when the main notch crack has reached the length shown in Figure 17. We believe that this observation can be attributed to two phenomenons, the absence of crack-retarding compressive residual stresses near the hole and the fact that the combined effect of grown notch crack and hole has reduced the bearing surface, resulting in a new critical site for crack nucleation. This newly formed crack was not directly observed in the experiment due to the fact that this area undergoes large deformations as the load-bearing surface decreases due to the growing crack. In future, a displacement instead of force control would be more sensible. As the top crack, from the numerical simulation, grows toward the main notch crack, a new crack is nucleated on the bottom of the hole. The algorithm cannot connect two cracks; therefore, the region between the top and main notch crack is unable to propagate either crack; therefore, a new crack is nucleated on the bottom.

Figure 16.

Final state of reference specimens. The number in % corresponds to the oversize of the mandrel for cold-hole expansion applied prior to fatigue loading.

Figure 17.

Results of the fatigue crack growth algorithm at the last increment of crack growth for reference specimens.The red dotted line shows the overlaid experimental crack path for comparison. The two red arrow point to the crack that originate from the surface of the hole.

For the 1% HE, we observe initial horizontal crack growth, followed by a sharp turn towards the hole. However, the crack does not reach the hole due to limitations in the algorithm, where multiple nodes fail simultaneously in high-stress concentration areas. This indicates unstable crack growth. A similar behavior is observed in the 2% and 3% cases, where the crack concludes in a sharp turn or even a U-turn, which also indicates unstable crack growth.

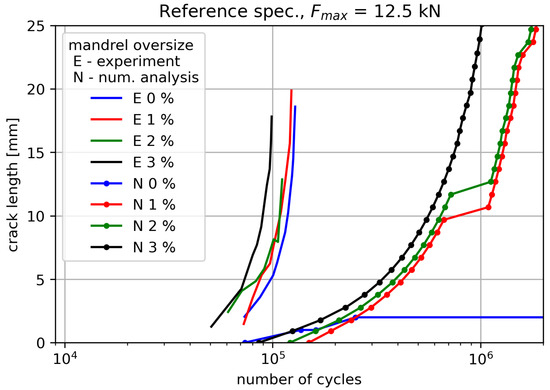

The results in Figure 18 compare the crack growth rate between the experimental and numerical analyses. Overall, the numerical analysis does not accurately capture the crack growth rate and provides non-conservative predictions in terms of cycle calculations. One of the main contributors is the averaging of specific deformation in and around the crack-governed cohesive contact (please see [18]) and the prescribed large damage step . However, the numerical analysis does capture the exponential rate trend typically observed in fatigue crack growth. Additionally, it confirms the experimental observation that increasing cold-hole expansion leads to a decrease in the number of cycles to crack nucleation.

Figure 18.

Experimental–numerical comparison of fatigue crack growth rate for the reference specimens.

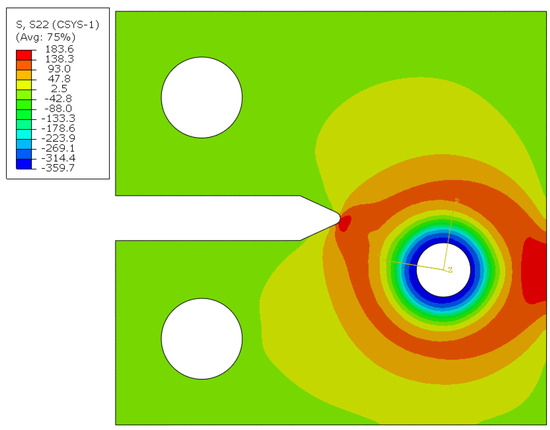

The key observation and reasoning of this study can be seen in Figure 19, which represents the initially imposed residual stress state in the direction (S22) of the cylindrical coordinate system placed at the center of the cold-expanded hole. The results demonstrate an area of compressive residual stresses near the vicinity of the hole, gradually transitioning to tensile or equilibrium stresses away from it. The tensile stresses, associated with a detrimental effect on fatigue life, concentrate in stress raisers, such as the free surface on the far-right side of the specimen and the left-hand-side notch. Within the range of cold-expansion oversize considered in this study (1%, 2%, and 3%), an increase in imposed compressive residual stresses near the cold-expanded hole is observed with increasing mandrel oversize. This correlates with the increase in tensile residual stresses near the specimen notch, which aligns with the observed decrease in the number of cycles to crack nucleation, as shown in Figure 19.

Figure 19.

Numerical results of stress state after the imposition of residual stresses by applying a displacement on the hole in the radial direction (3% hole expansion). Depicted stresses (S22) are transformed by the cylindrical coordinate system that is concentric to the cold-expanded hole and are shown in the principal direction of the r, , z directions.

3.2. Type A Specimens

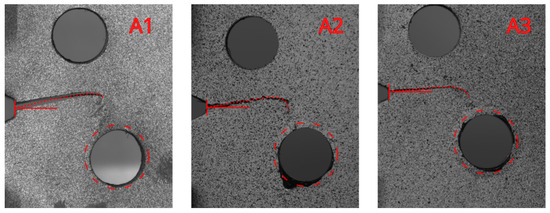

The reference specimens have shown that, despite the introduction of compressive residual stresses, the crack still propagates into the cold-expanded hole. The initial assumption was that the imposition of residual stresses would divert the crack away from the cold-expanded hole. Specimen A attempts to address this issue by drilling an additional hole above and closer to the notch. This additional hole acts as a stress raiser, attracting the growing crack and providing a higher chance for it to deviate from the cold-expanded hole. The influence of a hole on a growing fatigue crack is also discussed in references [26,27,28], but the basic idea is to tilt the angle of maximum principle stress. It is well known that crack propagates at an angle perpendicular to the maximum principle stress.

As depicted in Figure 20, the crack initially deviates from its horizontal growth direction but still ultimately propagates into the bottom cold-expanded hole. In all three cases, the maximum 3% oversize was applied, resulting in the introduction of the highest amount of compressive residual stresses. What is depicted in Figure 3 is the final geometry used in the experiment. A series of trials and errors were used beforehand in order to position the additional drilled hole in a way that attracts the growing crack from the notch as much as possible, giving the crack the best chance to overshoot the bottom cold-expanded hole. This would provide the framework to inspect the effect of cold expansion on the crack path. This experiment has shown that even at the greatest angle of approaching crack and the maximum imposition of residual stress, limited by the hole expansion tool, the crack still concludes in the hole. It appears that the combined effect of the additionally drilled hole and the reference hole diminishes the load-bearing capacity of the specimen in the region between the holes; therefore, the limit of this experiment has been reached. We therefore continue our efforts on type B specimens, discussed in the following chapters.

Figure 20.

Final stages of A1, A2 and A3 specimens. The crack (dotted line) initially diverts from the horizontal direction (solid line) toward the top hole but concludes in the bottom cold-expanded hole (split line).

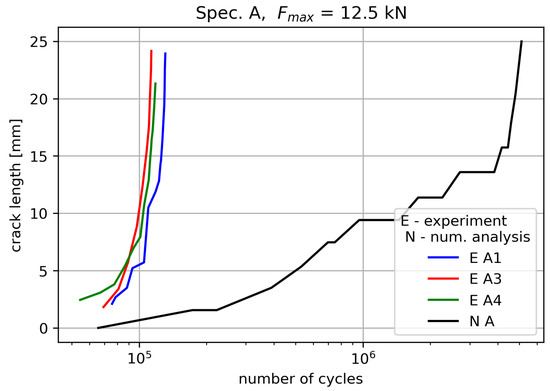

The comparison of crack growth rates, as shown in Figure 21, reveals that the numerical results underestimate the rate of crack growth compared with the experimental observations. However, the numerical simulation of fatigue crack growth depicted in Figure 22 roughly predicts the trend of crack growth. Initially, the crack propagates towards the top non-expanded hole and then diverts towards the bottom hole. The crack does not reach the bottom cold-expanded hole, which is attributed to the limitations of the algorithm in predicting the crack path when multiple nodes fail simultaneously.

Figure 21.

Experimental–numerical comparison of fatigue crack growth rate for the A specimens.

Figure 22.

Results of maximum in plane stress for the fatigue crack growth algorithm for specimen A. What is shown is the last increment of the crack growth algorithm. The red dotted line shows the overlaid experimental crack path.

3.3. Type B and C Specimens

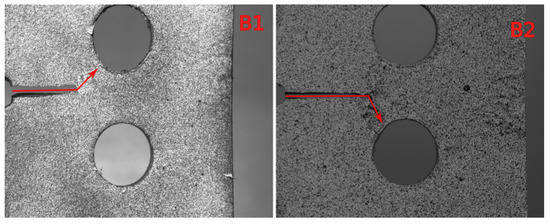

We began with type B geometry specimens without cold-expanding any holes in order to validate the symmetry of the geometry and loading conditions. Figure 23 displays an equal probability trend where the crack concludes in either hole. However, due to the limited number of specimens used without hole expansion, statistical significance cannot be attributed to this observation.

Figure 23.

Final stages of B1 and B2 specimens, subjected to kN load, without imposition of residual stresses. The crack initially grows in the horizontal direction and sharply turns toward one of the holes.

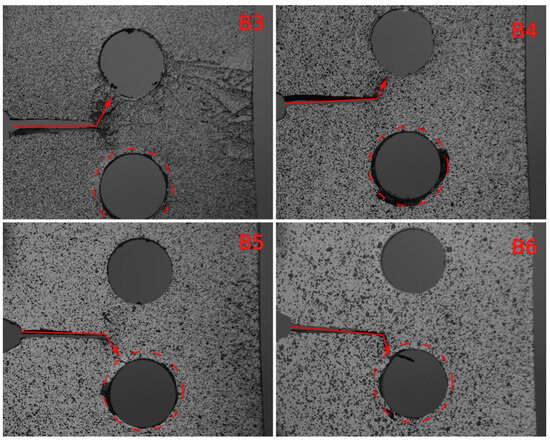

Further tests were conducted on type B specimens with cold expansion. As depicted in Figure 24, the red circle represents the bottom cold-expanded hole. The results once again demonstrate that cold expansion does not affect the location where the crack concludes. The images captured show the final stages of the test, just before the crack exponentially grows towards the hole.

Figure 24.

Final stages of B3 to B6 specimens, subjected to kN load. The red circle shows the cold-expanded hole with 3% mandrel oversize.

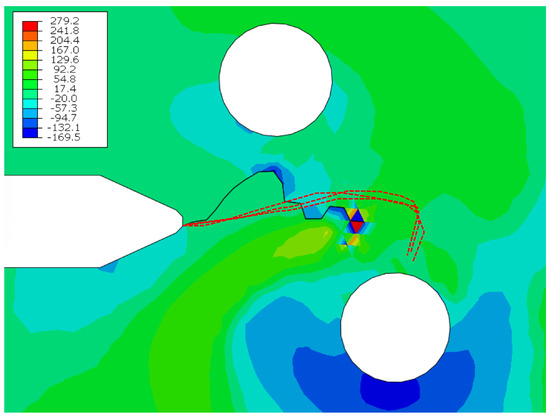

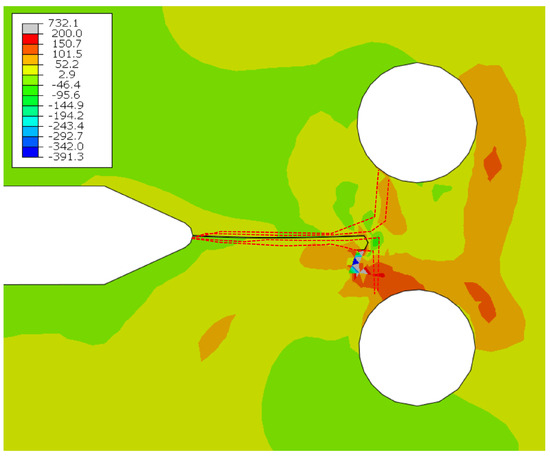

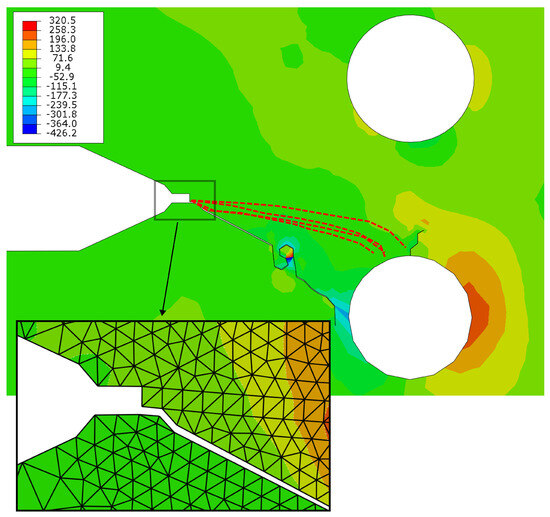

The numerical results shown in Figure 25 indicate that the crack initiates from the notch and proceeds horizontally. When it approaches the holes, it sharply turns towards the bottom cold-expanded hole. This observation aligns with the idea that the crack growth algorithm is attracted to the tensile stresses that result due to imposed compressive stresses.

Figure 25.

Results of maximum in-plane stress for the fatigue crack growth algorithm for specimen B at kN load, where the bottom hole is expanded. The red dotted line shows the overlaid experimental crack path.

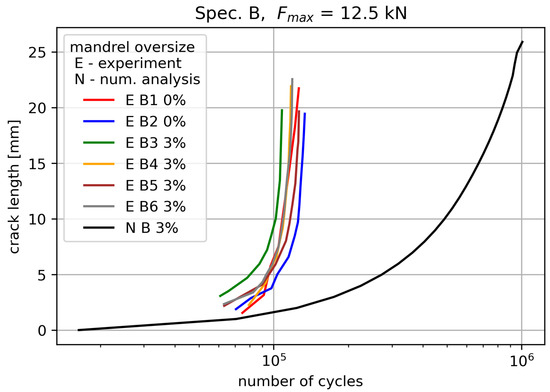

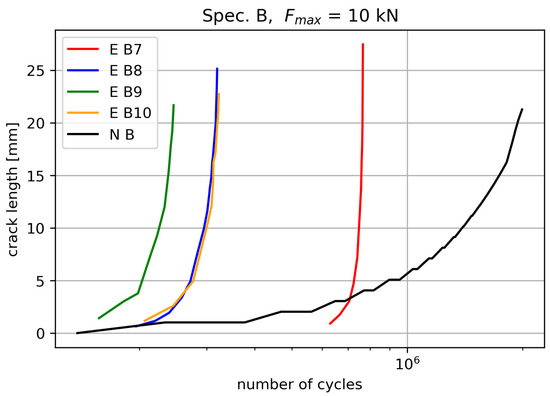

In the comparison of fatigue crack growth rates shown in Figure 26, it is evident that the numerical algorithm captures the exponential shape of crack growth. However, it underpredicts the rate of crack growth in terms of magnitude compared with the experimental observations.

Figure 26.

Experimental–numerical comparison of fatigue crack growth rate for the B1 to B6 specimens at kN.

Additionally, the results display the crack growth rates of both B1 and B2 specimens without cold expansion. It is noteworthy that both specimens exhibit the longest life until a noticeable crack, suggesting that cold expansion may have an effect on reducing the fatigue life.

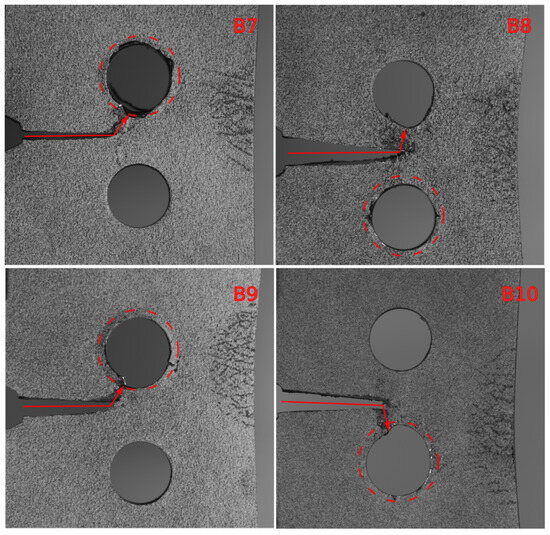

The four additional specimens, B7 to B10, were subjected to a reduced maximum fatigue load of in order to increase the influence of residual stresses. The location of the cold-expanded hole was alternated between the bottom and top hole, as shown in Figure 27. This alternation was performed to minimize the potential influence of loading pin friction on the crack growth direction.

Figure 27.

Final stages of B7 to B10 specimens, subjected to kN load. The red circle shows the cold-expanded hole with 3% mandrel oversize.

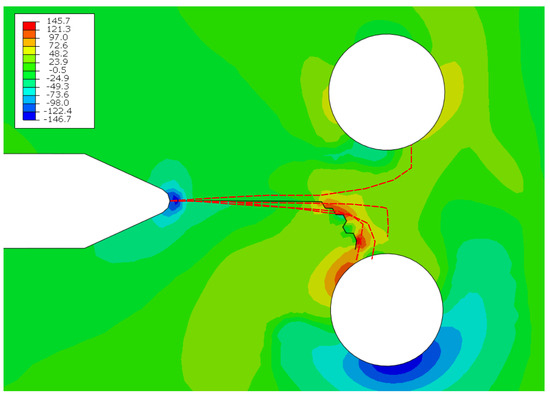

The results indicate that, in most cases, the growing crack is attracted to the cold-expanded hole. However, there is one exception where the crack does not conclude in the direction of the cold-expanded hole. The corresponding numerical simulation, presented in Figure 28, shows a similar response with the crack concluding in the direction of the cold-expanded hole.

Figure 28.

Results of maximum in-plane stress for the fatigue crack growth algorithm for specimen B at kN load. The red dotted line shows the overlaid experimental crack path. Here, the lines B7 and B9 are flipped to correspond to the location of the cold-expanded hole.

Comparing the experimental observations between the B specimens subjected to a 12.5 kN load (Figure 24) and a 10 kN load (Figure 27), it can be noted that, by reducing the maximum fatigue load, the crack progresses towards the hole in a more gradual manner. Similarly, the numerical results shown in Figure 25 and Figure 28 exhibit the same trend. This suggests that, by lowering the fatigue force amplitude, the effect of residual stress from the cold-expanded hole becomes more dominant, as the rate of residual stress relaxation is reduced.

Upon comparing the rates of crack growth shown in Figure 29, it can be observed that the experimental observations exhibit more scatter compared with the case with load. This increased scatter in the experimental results suggests greater variability in the crack growth behavior under the reduced fatigue load condition.

Figure 29.

Experimental–numerical comparison of fatigue crack growth rates for the B specimens at kN.

Additionally, the numerical results continue to indicate a non-conservative prediction of the crack growth rate. This implies that the numerical simulation underestimates the actual rate of crack propagation observed in the experiments.

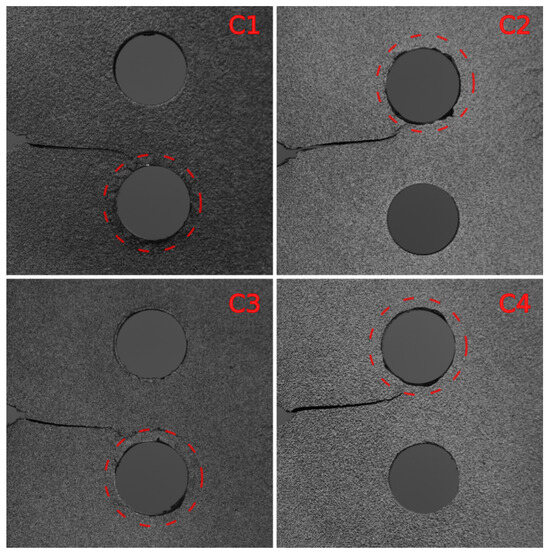

We continue our quest of lowering the maximum fatigue load (). Here, specimens C1 to C4 were used with a sharper initial notch to promote the early onset of fatigue crack. As depicted in Figure 30, the crack in all specimens concluded in the cold-expanded hole. Notably, the crack already showed a tendency towards the cold-expanded hole in the initial stages, deviating from the horizontal direction observed in previous B-type specimens.

Figure 30.

Final stages of C1 to C4 specimens, subjected to kN load. The red circle shows the cold-expanded hole with 3% mandrel oversize.

The numerical results presented in Figure 31 exhibit an oversensitive response to the effect of the cold-expanded hole or a strong mesh dependency. A balance was sought between the mesh density and time of calculation; remember that searching for the crack path is performed in the field of 180 degrees, therefore imposing possible difficulties in diverting the crack from the original path if the randomness of element edges is not sufficient. The results capture the trend observed in experiments, where the crack deviates towards the cold-expanded hole from the start. However, the angle of approach in the numerical simulation is more pronounced compared with the experimental observations.

Figure 31.

Results of maximum in-plane stress for the fatigue crack growth algorithm for specimen C at kN load. The red dotted line shows the overlaid experimental crack path. Here, the lines C2 and C4 are flipped to correspond to the location of the cold-expanded hole.

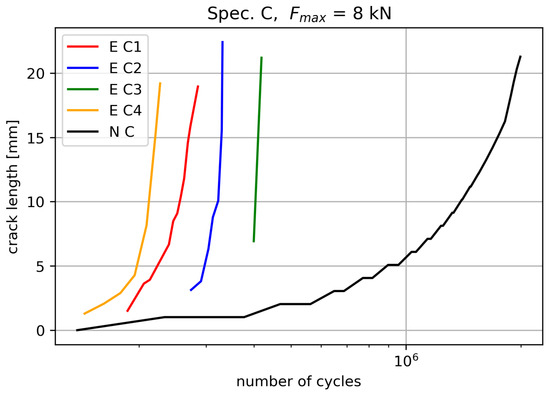

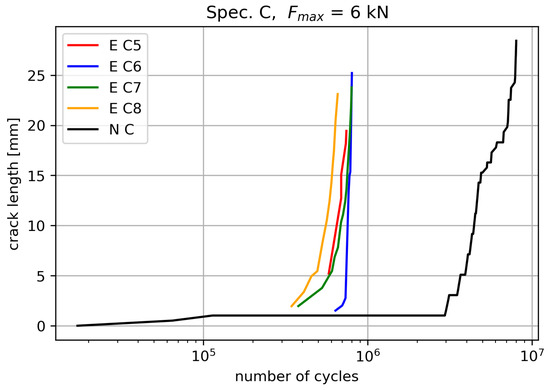

Upon comparing the numerical and experimental fatigue crack growth rates presented in Figure 32, we observe that the rates are similar to the observations made on B-type specimens subjected to . This similarity confirms that the sharper initial notch on the C-type specimens promotes an earlier onset of fatigue crack. However, it is important to note that the numerical rate remains non-conservative, meaning that it underestimates the actual crack growth rate observed in the experiments.

Figure 32.

Experimental–numerical comparison of fatigue crack growth rates for the C specimens at kN.

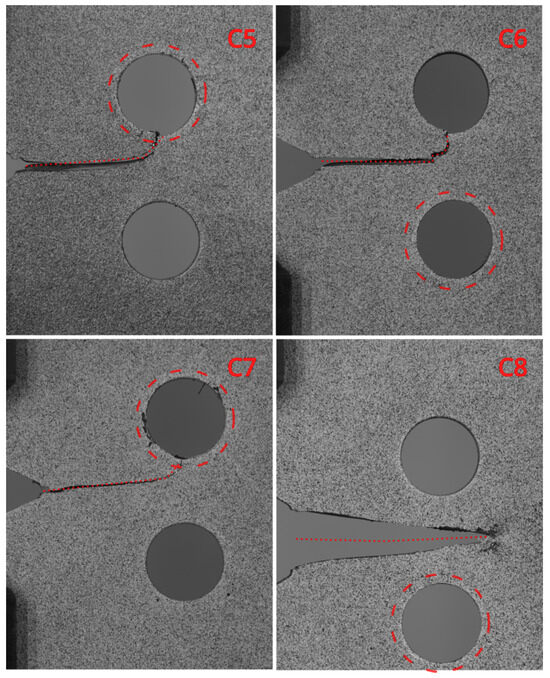

In the last set of experiments, C-type specimens were subjected to a reduced fatigue load of . The experimental observations shown in Figure 33 reveal that the crack concludes in the cold-expanded hole for specimens C5 and C7. However, on specimen C6, the crack initially grows horizontally and then abruptly jumps toward the non-expanded hole. On specimen C8, the crack completely disregards both holes and continues to grow horizontally past them.

Figure 33.

Final stages of C5 to C8 specimens, subjected to kN load. The red circle shows the cold-expanded hole with 3% mandrel oversize.

Reducing the amplitude of fatigue loading leads to an increase in the number of cycles needed for crack initiation and a decrease in the rate of crack propagation. Moreover, the prolonged cyclic loading affects the relaxation of residual stresses, diminishing its impact on the direction of crack growth. When the combined residual and applied stresses surpass the material’s current yield stress, plastic deformation occurs. The plastic flow of the material is considered the primary factor responsible for macro residual stress relaxation [3], particularly in cases involving prolonged higher load amplitudes.

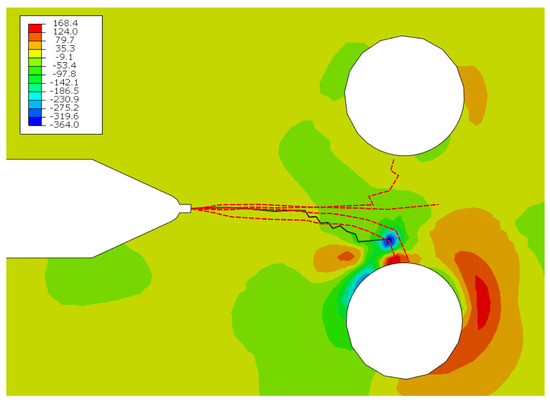

The numerical results presented in Figure 34 demonstrate an initial horizontal crack growth direction that gradually turns toward the bottom cold-expanded hole. The fatigue crack growth rate shown in Figure 35 indicates that the numerical simulation predicts an earlier crack nucleation compared with the previous test conducted at (Figure 31). However, it is important to note that the initial crack growth is severely hindered, and the exponential growth rate is observed at a larger number of cycles, which is expected.

Figure 34.

Results of maximum in-plane stress for the fatigue crack growth algorithm for specimen C at kN load. The red dotted line shows the overlaid experimental crack path. Here, the lines C5 and C7 are flipped to correspond to the location of the cold-expanded hole.

Figure 35.

Experimental–numerical comparison of fatigue crack growth rates for the C specimens at .

Overall, the numerical calculation once again underpredicts the rate of fatigue crack growth, indicating a non-conservative solution.

4. Conclusions

The present study investigates the interaction between a growing fatigue crack and induced residual stresses. The results challenge the initial hypothesis that the presence of compressive residual stresses would divert the crack. Instead, it is observed that the crack nucleates faster with increasing hole expansion ratio. The introduction of compressive residual stresses through cold-hole expansion leads to the generation of tensile residual stresses due to their self-equilibrating nature. The drilled hole for cold-hole expansion acts as a stress raiser, attracting the growing fatigue crack. This is evident in the A-type specimen, where the additional hole successfully diverts the crack initially. The positioning of the additional hole was determined through trial-and-error iterations to maximize the diversion of the crack from the bottom cold-expanded hole, thus allowing the compressive residual stress field a better chance to redirect the crack.

In the symmetrical B-type specimens, it is observed that the growing fatigue crack tends to ignore the induced residual stress field and concludes in an arbitrary hole, particularly at higher fatigue load amplitudes. However, there is an exception in the C1–C4 specimens, where the crack consistently concludes in the cold-expanded hole. This trend is partially observed in specimens C5–C8 as well, indicating that, by lowering the force amplitude, the effect of the residual stress field becomes more dominant. It is important to note that these experiments have a limited number of specimens, and statistical significance cannot be attributed to the observed phenomena.

This research also serves as an opportunity to test a novel numerical approach for simulating crack nucleation and growth. The algorithm, based on fatigue calculations, demonstrates reasonably accurate predictions for the onset of fatigue crack. However, the rate of fatigue crack growth is consistently slower in the numerical results compared with experimental observations. It is also evident that the cold-expanded hole attracts the growing fatigue crack due to the way it handles the mean stress effect. The numerical approach, although based on standard low cycle fatigue testing, shows promise for simulating fatigue crack growth.

Overall, this study provides valuable insights into the behavior of growing fatigue cracks in the presence of induced residual stresses and highlights the potential of the numerical approach in simulating crack nucleation and growth. Further work should address the calculation of field variables in the vicinity of the crack and incorporate the re-meshing technique.

Author Contributions

Conceptualization, P.Z. and J.K.; methodology, P.Z.; software, P.Z.; validation, P.Z.; formal analysis, P.Z.; investigation, P.Z.; resources, P.Z.; data curation, P.Z.; writing—original draft preparation, P.Z.; writing—review and editing, P.Z. and J.K.; visualization, P.Z.; supervision, J.K.; project administration, J.K.; funding acquisition, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received funding from the Slovenian Research Agency (research core funding no. P2-0182 entitled development evaluation).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest. Additionally, the funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| LEFM | linear elastic fracture mechanics |

| FEM | finite element analysis |

| DCA | direct cyclic analysis |

| CC | cohesive contact |

| DIC | digital image correlation |

| HE | hole expansion |

| S22 | stress in the direction of the cylindrical r, , z coordinate system |

References

- James, M. Relaxation of residual stresses an overview. Pergamon Press. Adv. Surf. Treat. Technol. Appl. Eff. 1987, 4, 349–365. [Google Scholar]

- Chen, F.; Liu, X.; Zhang, H.; Luo, Y.; Lu, N.; Liu, Y.; Xiao, X. Assessment of fatigue crack propagation and lifetime of double-sided U-rib welds considering welding residual stress relaxation. Ocean. Eng. 2025, 332, 121400. [Google Scholar] [CrossRef]

- Zobec, P.; Klemenc, J. Application of a nonlinear kinematic-isotropic material model for the prediction of residual stress relaxation under a cyclic load. Int. J. Fatigue 2021, 150, 106290. [Google Scholar] [CrossRef]

- Zhang, C.; Dong, Y.; Ye, C. Recent developments and novel applications of laser shock peening: A review. Adv. Eng. Mater. 2021, 23, 2001216. [Google Scholar] [CrossRef]

- Malaki, M.; Ding, H. A review of ultrasonic peening treatment. Mater. Des. 2015, 87, 1072–1086. [Google Scholar] [CrossRef]

- Gupta, R.K.; Pant, B.; Kain, V.; Kaul, R.; Bindra, K. Laser shock peening and its applications: A review. Lasers Manuf. Mater. Process. 2019, 6, 424–463. [Google Scholar] [CrossRef]

- Bikdeloo, R.; Farrahi, G.H.; Mehmanparast, A.; Mahdavi, S.M. Multiple laser shock peening effects on residual stress distribution and fatigue crack growth behaviour of 316L stainless steel. Theor. Appl. Fract. Mech. 2020, 105, 102429. [Google Scholar] [CrossRef]

- Ermakova, A.; Razavi, N.; Cabeza, S.; Gadalinska, E.; Reid, M.; Paradowska, A.; Ganguly, S.; Berto, F.; Mehmanparast, A. The effect of surface treatment and orientation on fatigue crack growth rate and residual stress distribution of wire arc additively manufactured low carbon steel components. J. Mater. Res. Technol. 2023, 24, 2988–3004. [Google Scholar] [CrossRef]

- Reid, L. Beneficial residual stresses at bolt holes by cold expansion. In Rail Quality and Maintenance for Modern Railway Operation; Springer: Berlin/Heidelberg, Germany, 1993; pp. 337–347. [Google Scholar] [CrossRef]

- Houghton, S.; Campbell, S. Identifying the residual stress field developed by hole cold expansion using finite element analysis. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 74–83. [Google Scholar] [CrossRef]

- Matvienko, Y.G.; Pisarev, V.; Eleonsky, S. The effect of low-cycle fatigue on evolution of fracture mechanics parameters in residual stress field caused by cold hole expansion. Str 2019, 13, 303–320. [Google Scholar] [CrossRef]

- Faghih, S.; Behravesh, S.B.; Shaha, S.K.; Jahed, H. Effect of split sleeve cold expansion on fatigue and fracture of rolled AZ31B magnesium alloy. Theor. Appl. Fract. Mech. 2023, 123, 103715. [Google Scholar] [CrossRef]

- Yasniy, P.; Okipnyi, I.; Dyvdyk, O.; Rudawska, A.; Senchyshyn, V. Residual lifetime of the plates with preexisting crack near cold expanded hole. Procedia Struct. Integr. 2022, 36, 197–202. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, Z.; Nyhus, B. Effect of residual stresses on ductile crack growth resistance. Eng. Fract. Mech. 2010, 77, 1325–1337. [Google Scholar] [CrossRef]

- Almer, J.; Cohen, J.; Moran, B. The effects of residual macrostresses and microstresses on fatigue crack initiation. Mater. Sci. Eng. A 2000, 284, 268–279. [Google Scholar] [CrossRef]

- Deschênes, P.A.; Lanteigne, J.; Verreman, Y.; Paquet, D.; Lévesque, J.B.; Brochu, M. A new experimental method to study the influence of welding residual stresses on fatigue crack propagation. Int. J. Fatigue 2017, 100, 444–452. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Truman, C.; Smith, D. Using local out-of-plane compression (LOPC) to study the effects of residual stress on apparent fracture toughness. Eng. Fract. Mech. 2008, 75, 1516–1534. [Google Scholar] [CrossRef]

- Zobec, P.; Klemenc, J. Yet another approach to fatigue crack growth simulation. Metals 2022, 12, 539. [Google Scholar] [CrossRef]

- DIN EN 10025-2; Hot Rolled Products of Structural Steels-Part, 2. DIN Standards Committee Iron and Steel (FES): Düsseldorf, Germany, 2011.

- ISO683-1:2016; Heat-Treatable Steels, Alloy Steels and Free-Cutting Steels—Part 1: Non-Alloy Steels for Quenching and Tempering. International Organization for Standardization: Geneva, Switzerland, 2016.

- Zheng, G.; Cao, Z.; Zuo, Y. A dynamic cold expansion method to improve fatigue performance of holed structures based on electromagnetic load. Int. J. Fatigue 2021, 148, 106253. [Google Scholar] [CrossRef]

- Pucillo, G.P.; Carrabs, A.; Cuomo, S.; Elliott, A.; Meo, M. Cold expansion of rail-end-bolt holes: Finite element predictions and experimental validation by DIC and strain gauges. Int. J. Fatigue 2021, 149, 106275. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-source 2D digital image correlation matlab software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Litrop, A.; Zobec, P.; Šeruga, D.; Nagode, M.; Klemenc, J. Experimental analysis of crack initiation and propagation in dynamically shear-loaded aluminium specimens using the digital image correlation method. Eng. Fail. Anal. 2022, 139, 106495. [Google Scholar] [CrossRef]

- Fageehi, Y.A. Two-and three-dimensional numerical investigation of the influence of holes on the fatigue crack growth path. Appl. Sci. 2021, 11, 7480. [Google Scholar] [CrossRef]

- Bashiri, A.H. 2D and 3D numerical simulation of fatigue crack growth path and life predictions of a linear elastic. Mater. Sci. Pol. 2021, 39, 285–297. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Fageehi, Y.A. Numerical analysis of fatigue crack growth path and life predictions for linear elastic material. Materials 2020, 13, 3380. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).