Abstract

This study investigates on Zn-Al alloy microstructural characteristics and mechanical properties of a Zn-Al alloy with calcium (Ca) additions ranging from 0.5 to 1.5 wt.%. The base alloy composition is 94.95 wt.% Zn, 4.0 wt.% Al, 1.0 wt.% Cu, and 0.05 wt.% Mg, and it is utilized in various engineering applications, including domestic and automotive. The alloys were fabricated under controlled atmospheric conditions using the traditional squeeze casting technique. The squeeze-cast Zn-Al alloys with varying Ca content were characterized through chemical analysis, optical microscopy (OM), scanning electron microscopy (SEM), Energy Dispersive Spectroscopy (EDS), and X-ray diffraction (XRD) analysis. The microstructure of the Zn-Al alloy with Ca reinforcement comprises the intermetallic phase CaZn13, which is distributed within the Zn-Al solid solution. The CaZn13 phase within the Zn matrix exhibited a synergistic effect on grain refinement, resulting in a 96% reduction in grain size, as confirmed by SEM analysis. The mechanical properties of the Zn-Al alloy reinforced with calcium significantly enhanced microhardness and tensile strength. The results indicated that calcium additions up to 1.5 wt.% increased both microhardness and tensile strength, with the 1.0 wt.% calcium addition yielding the highest hardness value of 141 HV0.1 and a tensile strength of 359 MPa compared to the base alloy. These findings suggest that adding calcium enhances the grain refinement and mechanical properties of Zn-Al alloys.

1. Introduction

Zinc-based alloys, particularly those containing aluminum, copper, and magnesium (Zn-Al-Cu-Mg systems), have garnered considerable interest for structural and automotive applications due to their favorable strength-to-weight ratio, excellent castability, low density, ease in energy-efficient shaping, cost effectiveness, moderate strength, and low cost [1]. These alloys have promising potential for parts subjected to mechanical and environmental stresses because of their reputation for combining mechanical strength with corrosion resistance and wear performance [2].

Recent advancements in alloy processing have highlighted the role of squeeze casting, a technique that combines the advantages of conventional casting and forging by applying pressure during solidification. This process leads to enhanced densification, reduced porosity, and refined microstructures, improving cast components’ overall mechanical performance [3,4]. As such, squeeze casting has emerged as a key method for producing high-integrity, defect-free parts that meet the rigorous standards of modern engineering applications. Researchers have explored various strategies to achieve these improvements, including alloying with elements like copper and aluminum and reinforcing the alloys with particulates or fibers. Increasing aluminum content in Zn-Al alloys significantly enhances strength, hardness, and wear resistance, though at the expense of reduced ductility [5]. Aluminum, a key alloying element, improves the fluidity of the alloy melt, refines grain structure, and strengthens the alloy, especially at elevated temperatures [6]. Copper further enhances the strength of zinc–aluminum systems, as demonstrated in commercial alloys, where high-purity zinc has overcome early issues of poor mechanical performance [7,8]. Alloys with hypoeutectic compositions are widely used in engineering due to their reliable mechanical properties and wear resistance [5,9,10].

One promising approach to further improve the properties of Zn-based alloys is microalloying—the addition of trace elements to tailor the microstructure and enhance specific properties. Among these, calcium (Ca) has shown potential due to its ability to refine grain structure, form beneficial intermetallic phases, and improve corrosion resistance [8,9,10,11,12]. Adding calcium to Zn-Al-based alloys often causes the formation of secondary intermetallic phases such as CaZn13, Al2Ca1Zn, and other calcium-rich compounds. The literature reports suggest that certain intermetallic phases, such as fine, uniformly distributed CaZn13, AlZn, or Zn-rich eutectic phases, can enhance mechanical properties by acting as barriers to dislocation motion and refining grain boundaries [13,14,15]. Conversely, excessive or clustered coarse or brittle intermetallic compounds such as Al2Ca1Zn may serve as sites for crack initiation, negatively impacting ductility and toughness. However, excessive Ca may result in brittle phase formation and a consequent reduction in ductility and toughness [16,17,18]. Controlling the volume fraction, morphology, and distribution of intermetallics phases is crucial for achieving a balance between strength and ductility in Zn-based alloys. The role of calcium in modifying aluminum and magnesium-based alloys has been studied [19].

Recent research on Zn and Mg-based alloys has highlighted the role of Ca additions in enhancing mechanical strength and microstructural refinement. For instance, Fu et al. reported that Ca additions in Zn-Mg alloys refine grain size and improve tensile properties by forming Ca2Mg6Zn3 intermetallics [20]. Additionally, Chen et al. observed UTS values exceeding 300 Mpa and elongation above 30% in Zn-0.1Mg-0.02Ca alloys processed via ECAP and cold rolling [21]. In Mg-Zn-Ca systems, Zhang et al. noted similar trade-offs, where Ca2Mg6Zn3 phases improved corrosion and strength but compromised elongation [15]. Doroshenko et al. studied Al-6%Mg-2%Ca-2%Zn alloys and linked phase formation to casting parameters and mechanical response [22]. There is a lack of comprehensive research on its effects on Zn-Al-Cu-Mg alloys, mainly when processed using squeeze casting. Understanding the influence of calcium on the microstructure and mechanical response of these alloys is essential for optimizing their performance under demanding service conditions.

The present study aims to evaluate the effects of varying calcium content (0.5–1.5 wt.%) on the microstructure and mechanical properties of Zn-Al-Cu-Mg alloys fabricated by squeeze casting. Experimental techniques such as tensile and hardness testing, SEM/EDS microstructural examination, and phase identification via X-ray diffraction (XRD), were employed to establish correlations between calcium content and alloy performance. The findings will help to determine the optimal Ca addition level to maximize strength while minimizing the formation of detrimental brittle phases.

2. Materials and Methods

2.1. Development of Alloy and Precursors

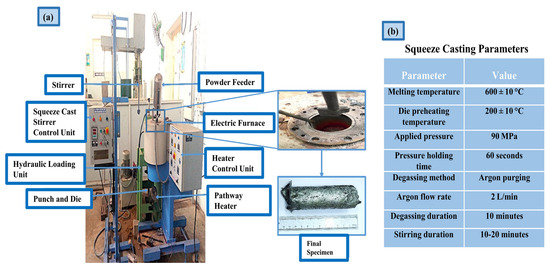

Figure 1a illustrates the schematic diagram of the squeeze casting setup used in the present study. Commercial grade zinc–aluminum alloy consisting of 94.95 wt.% Zn, 4.0 wt.% Al, 1.0 wt.% Cu, and 0.05 wt.% Mg was used as a base alloy. Pure metallic calcium was added in increments of 0.5 wt.%, reaching a maximum of 1.5 wt.%. Squeeze casting was then employed to produce a Zn-Al-Cu-Mg alloy with varying weight percentages of Ca (0.5 wt.%, 1.0 wt.%, and 1.5 wt.%). The squeeze casting process parameters are summarized in Figure 1b for clarity. The Zn-Al-Cu-Mg alloy ingot was cut into four pieces using an abrasive cutting machine, weighed to predetermined amounts, and placed in a graphene paste-coated crucible with a capacity of 10 kg inside the furnace.

Figure 1.

(a) Schematic representation of the squeeze casting setup and (b) Squeeze casting parameters.

The melt was directly prepared by melting the base metals, and pure metallic Ca was weighed precisely and thoroughly mixed with the base alloy to achieve the target compositions, followed by thorough stirring to ensure homogeneity and maintain the intended composition. The coated crucible and cast iron metal mold were preheated to a temperature range of 180–215 °C. The casting charge was melted in a graphite-coated crucible within an electric furnace designed for bottom pouring in an Ar environment at 600 ± 10 °C. Manual stirring was performed for 1–3 min after each addition to promote uniform element distribution. To minimize gas porosity and oxide inclusions, the molten alloy was degassed using high-purity argon (99.995%) at a flow rate of 2 L/min for 10 min, before pouring. Argon gas was delivered through a rotating lance submerged just below the molten surface. This process helped remove dissolved hydrogen and floating dross, which reduced the micro-porosity in the castings. The preheated reinforcement was introduced into the melt at 550 °C while the melt was continuously stirred at 250 rpm to ensure uniform distribution. After maintaining this setup for a holding time of 20 min, with ongoing stirring through the bottom pouring mechanism, the slag was carefully skimmed off the surface before transferring the melt to the preheated squeeze die. The molten alloy was poured into a preheated cylindrical die (inner diameter 40 mm, height 150 mm) that was maintained at 200 °C. The melt was then squeeze cast under a uniaxial pressure of 90 MPa using a vertical hydraulic press immediately after the pouring process. The pressure was maintained for 60 s to ensure complete filling and solidification. The alloy was allowed to cool under pressure inside the die to avoid porosity and thermal cracking. The solidified billets were subsequently extracted and allowed to cool to room temperature under ambient conditions. The squeeze-cast specimens were sectioned into standard test specimens for metallurgical and mechanical properties analyses. The final compositions of each alloy were machined into square-shaped samples measuring (20 mm × 20 mm × 5 mm) for spectroanalysis, and the chemical composition results are presented in Table 1.

Table 1.

Chemical composition of Zn-Al-Cu-Mg alloy reinforcement with Ca.

2.2. Characterization of Squeeze Cast Zn-Al-Cu-Mg Alloy with Reinforced Ca

The actual density of each cylindrical specimen was determined using a METTLER TOLEDO (New Classic MF) densitometer (Zurich, Switzerland) based on its measured mass and volume. The theoretical density was calculated using mixture rules based on elemental composition, while porosity was assessed by comparing theoretical and actual densities. The microstructural examination was carried out on four specimens of Zn-Al-Cu-Mg alloy without additions and with additions of 0.5 wt.%, 1.0 wt.%, and 1.5 wt.% Ca by cutting samples from the cast pieces. The Leica DM2500M optical microscope (Wetzlar, Germany) was utilized to capture microscopic images of the prepared samples. The samples were sectioned into square-shaped samples (10 mm × 10 mm × 5 mm) and cleaned with acetone. It is mounted in a sample holder by hot mounting. The mounted samples were first ground using silicon carbide (SiC) emery papers of progressively finer grades (240 to 1200 grit), followed by polishing with a 1 µm alumina slurry and final buffing using a 1 µm polycrystalline diamond paste to reveal the microstructure features. The samples were etched using a 2% Nital solution for 5 s. After etching, they underwent an examination under an optical microscope to assess the continuity and discontinuity of the grain boundaries, as well as to evaluate the abundance of second-phase particles at those boundaries. Scanning electron microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDS) were used for detailed morphological and compositional analysis of the fracture surfaces and intermetallic phases.

XRD analysis involved exposing specimens to Co-K radiation with a wavelength of 0.154 nm. The characteristics of the crystalline phase and the influence of secondary phase particles on textural modifications are evident through peak shifts, analyzed using a Pan-Analytical X-ray diffractometer. The diffracted rays were recorded as peak intensities and subsequently compared with the ICDD standard diffraction pattern. Scans occurred in the two ranges of 20–80 degrees at a scan rate of 2 degrees per minute. The microhardness of the experimental alloys was measured using the Matsuzawa Vickers microhardness tester (Model No: MMT-X7, Matsuzawa, Akita-shi, Japan), by the ASTM E92 standard [23]. A test load of 0.9807 N with a dwell of 15 s was applied to the specimen. Five replicas of readings were carried out for microhardness, and an average was reported. For the micro-tensile test, three specimens were prepared and tested for each alloy composition to ensure repeatability and statistical reliability. The specimens were machined according to ASTM E8/E8M [24] sub-size standards using wire EDM, and had a gauge length of 6.0 mm, a thickness of 1.0 mm, and a width of 4 mm. Tinius Olsen, Model No: H25KT (Horsham, PA, USA) was used to conduct testing on a micro-universal testing machine at a test speed of 0.2 mm/min. The reported tensile strength values represent the average of three measurements. Error bars indicating ±1 standard deviation are included in the tensile plot to reflect the variability.

3. Results and Discussion

3.1. Alloy Integrity

The porosity contents and density of the as-cast Zn-Al-Cu-Mg alloy with different wt.% of Ca is shown in Table 2. The results show that porosity percentages are highest for 1.5 wt.% of Ca and lowest for 0.5 wt.% Ca with Zn-Al-Cu-Mg alloy; incorporating 1.5 wt.% calcium in the Zn-Al-Cu-Mg alloy increases porosity due to several factors, including intermetallic phase formation, reduced density, and altered solidification behavior. Calcium combines with zinc and aluminum to produce intermetallic compounds that damage the alloy microstructure, resulting in voids during solidification. While a small addition of calcium (0.5 wt.%) appears to slightly reduce porosity due to improved grain refinement and better feeding characteristics, higher calcium levels (≥1.0 wt.%) tend to increase porosity. This issue arises from calcium’s low density and poor wettability, which at higher concentrations can decrease alloy fluidity and hinder mold filling, resulting in air entrapment and increased shrinkage porosity. Calcium modifies the alloy solidification characteristics by acting as a nucleation agent, promoting grain refinement and influencing cooling rates due to changes in thermal conductivity and latent heat evolution [15,25].

Table 2.

Porosity and density readings of various wt.% of Ca with Zn-Al-Cu-Mg alloy.

The study analyzed the porosity of alloys with varying amounts of calcium. Excessive calcium addition was observed to increase porosity, while a small addition (0.5 wt.% Ca) resulted in slightly reduced porosity. Alloys with 0.5 wt.% Ca and 1.0 wt.% Ca exhibited a relatively sound matrix with minimal porosity, suggesting the effectiveness of the argon degassing process. However, the 1.5 wt.% Ca alloy displayed increased interdendritic and shrinkage porosity resulting from reduced melt fluidity and premature nucleation of coarse intermetallics such as CaZn13 and Al2Ca1Zn. During solidification, these stages might prevent feeding, resulting in the formation of porosity. Although argon degassing reduced hydrogen-induced porosity, Ca-induced changes in melt behavior played a dominant role at higher concentrations. The study also highlighted the importance of controlling Ca content and optimizing degassing parameters to balance microstructural integrity and mechanical performance. At higher Ca contents, the formation of Ca-rich intermetallics may disrupt flow and lead to localized shrinkage porosity. The cooling rate of porosity in simple, non-directionally solidified castings controls the amount of micro-porosity that forms. The observed porosity at higher calcium content may be due to incomplete dissolution or segregation during the melting and casting processes. All measured densities of alloy compositions were found to be within 5% of the theoretical values, indicating minimal porosity and confirming that proper melting and casting procedures were followed.

3.2. Microstructural Examination and SEM with EDS Analysis

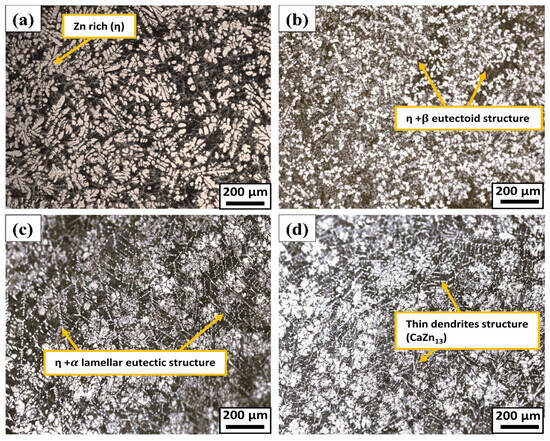

Figure 2 displays the microstructures of the squeeze-cast Zn-Al-Cu-Mg alloy with calcium additions. Optical images showed a transition from coarse dendritic structures in the unreinforced alloy to a more uniform and fine-grained morphology in Ca-reinforced samples. Zn-Al alloys consist of Al and Zn-rich solid solutions arranged based on calcium content, as shown in Figure 2a. The microstructure features coarse Zn-rich dendrites and eutectoid colonies (Figure 2a). In the squeeze-cast Zn-3.5Al-0.9Cu-0.04Mg alloy with 1.5% calcium (Figure 2d), there is a compound phase structure of CaZn13 and Ca1Mg2, with a new Zn-Al phase [10,12]. CaZn13 shows dendritic or blocky morphology, with less bright contrast than Al1Cu + Cu6Zn, as calcium is 13% lighter than aluminum. Al-Zn particles attach to CaZn13 particles, forming a compound structure confirmed by XRD analysis [4]. Figure 3 displays a typical dendritic CaZn13 structure. On comparing the microstructures with and without 1.5 wt.% calcium (Figure 2d), it is observed that calcium addition alters the dendritic morphology. Although the length of the Zn-rich dendrites appears to increase slightly, the secondary dendrite arm spacing becomes finer and the overall grain structure becomes more uniform. This microstructural refinement improves mechanical properties up to an optimal Ca content.

Figure 2.

OM images of Zn-Al-Cu-Mg alloys, both with and without Ca addition. (a) Base alloy; (b) 0.5 wt.% Ca; (c) 1.0 wt.% Ca; (d) 1.5 wt.% Ca.

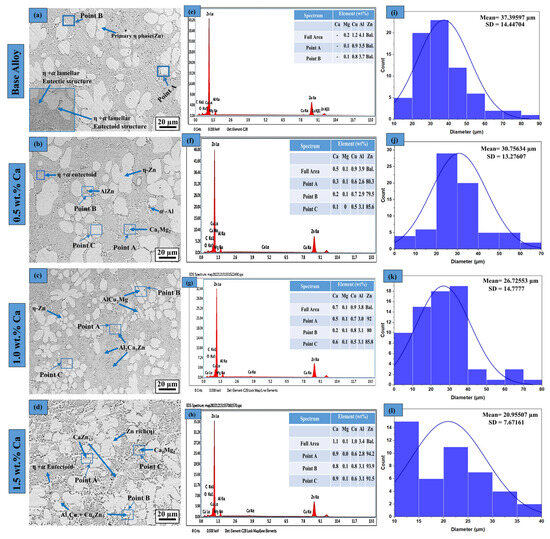

Figure 3.

(a–d) SEM morphology of the Zn-Al-Cu-Mg alloy without and with Ca addition, (e–h) showing EDS spot analysis locations (full area and points A–C) and (i–l) average grain size measurement of the Zn-Al-Cu-Mg alloy without and with Ca addition.

Figure 3 displays the FESEM and EDS analyses that show the distribution of components and phases in the middle region of Zn-Al-Cu-Mg alloy with reinforced Ca samples. Figure 3a shows the microstructure of the Zn-Al-Cu-Mg alloy without Ca, consisting of bright white globular grains, including fine lamellar and coarse cellular structures. The microstructure of the Zn-Al-Cu-Mg alloy with 1.5 wt.% Ca, shown in Figure 3d, solidified at a slower cooling rate, resulting in larger dendritic phase, lamellar eutectic structure, and darker areas at dendrite boundaries with fine lamellar eutectoid structure. According to the Zn-Al phase diagram, in hypoeutectic Zn-Al alloys, the primary phase is α-Zn, and as the temperature decreases, a eutectic reaction occurs, resulting in a mixture of α-Zn and α-Al phases. At Point A (Figure 3a), the EDS spectrum revealed high concentrations of Zn-rich and Al, which corresponded well with the known composition range of the η-Zn region. Point B also exhibited high levels of aluminum and zinc, which corresponded to the AlZn phase typically observed in these systems. Figure 3b shows the EDS points A-C. Point A corresponds to the Ca1Mg2 phase, whereas Point C corresponds to the η-Zn and AlZn regions. Meanwhile, Point B, located in a lighter dendritic region, shows a predominantly Zn-rich composition with minor Al and Cu, suggesting that it corresponds to the η-phase (Zn). In Figure 3c, EDS Point A indicates elevated levels of Ca and Al, along with trace amounts of Mg and Cu. This composition suggests the presence of Al2Ca1Zn intermetallic, consistent with previous reports [16,17,18]. Similarly, Point B shows elevated Al, Mg, and Cu contents, which align with the AlCu2Mg phase. Meanwhile, Point C, located in a moderate dendritic region, exhibited a predominantly Zn-rich composition with a Ca content matching the CaZn13 phase, whereas the brighter zones were Zn-rich. Similar results were observed at 1.5 wt.% Ca (Figure 3d), where regions with detectable Ca, Al, and Cu likely correspond to complex Al1Cu, Cu6Zn7, and CaZn13 phases. In the 1.5 wt.% Ca sample (Figure 3d), point analysis in the darker regions indicated a high Ca content, matching the CaZn13 phase, whereas the brighter zones were Zn-rich. The interpretations are supported by the morphology observed in SEM and are further confirmed by the XRD peaks at 2θ values corresponding to CaZn13, Ca1Mg2, and Al2Ca1Zn [26]. The results for the 0.5 wt.% Ca and 1 wt.% Ca alloys were identical to those of the 1.5 wt.% Ca alloy. The analysis shows that coarse dendrites without Ca alloys and larger dendrites in 1.5 wt.% Ca alloys contain the CaZn13 phase. The precipitates in 1.0 wt.% Ca and 1.5 wt.% Ca alloys are identified as CaZn13 and Ca1Mg2. Figure 3d shows the CaZn13 phase embedded between primary Zn and eutectoid Zn + Al phases. The addition of Ca refined the eutectic structure, which was attributed to the retarded eutectic and eutectoid transformation kinetics. The smallest eutectoid lamellar spacing was observed in the 1 wt.% Ca alloy. The larger dendrites and eutectoid lamellar spacing in the 1.5 wt.% Ca alloy might be due to retarded diffusion of Zn and Al from the higher Ca addition, causing an increased growth rate of eutectoid lamellae instead of new lamellae nucleation [17]. Whereas it is recognized that EDS alone cannot definitively determine phase structure, compositional trends combined with SEM morphology and XRD data provide sufficient evidence for phase identification.

3.3. Phase Identification (XRD Analysis)

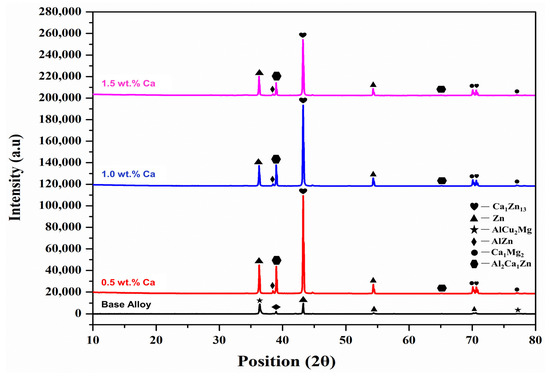

X-ray diffraction (XRD) patterns shown in Figure 4 demonstrate the effects of different calcium additions, ranging from 0.5 wt.% to 1.5 wt.%, on the base alloys. XRD patterns (Figure 4) show prominent peaks corresponding to Zn. Minor peaks at 2θ ≈ 36°, 39°, and 71° are suggestive of CaZn13, Al2Ca1Zn, and Ca1Mg2 phases, respectively, though these peaks are relatively weak and may overlap with Zn (Table 3). The presence of intermetallic compounds was confirmed and cross-verified with standard ICDD data and complementary EDS observations to avoid misinterpretation caused by peak overlap. The variation in average grain size with different Ca contents indicates that grain refinement of the base alloy occurs with Ca additions up to 1.5 wt.%.

Figure 4.

XRD patterns of squeeze cast Zn-Al-Cu-Mg alloy without and with different wt.% of Ca.

Table 3.

Key phases identified by XRD and their associated effects.

As shown in Figure 4, all samples exhibit dominant peaks corresponding to the η-Zn matrix phase. With increasing Ca content, additional peaks begin to emerge, which are tentatively attributed to intermetallic compounds such as CaZn13 and Al2Ca1Zn. However, due to overlapping peak positions with Zn-rich phases, reliable identification of these minor phases based on XRD alone is limited. It may state that Ca addition facilitates grain refinement due to two primary mechanisms: the inhibition of grain growth during solidification by the formation of Zn-Ca precipitates, notably the CaZn13 dendritic structure, and the formation of Zn-Al phases, namely Al2Ca1Zn and AlCu2Mg. These phases prevent the formation of the Zn-Ca lamellar phase and the ZnCa1Al granular phase, thereby enhancing the strength of the squeeze-cast alloy [26]. However, Ca additions exceeding 1.5 wt.% result in the consumption of a greater number of Al atoms in Zn-Ca precipitates, which diminishes the grain-refining effect of Zn-Al in the base alloy.

3.4. Mechanical Properties

Figure 5a illustrates the microhardness of the base alloy, both unreinforced and reinforced with 0.5 wt.%, 1.0 wt.%, and 1.5 wt.% Ca under squeeze casting processes. The base alloy exhibited a microhardness of 113 ± 5 HV0.1. Upon adding 0.5 wt.% Ca, a slight increase to 122 ± 3 HV0.1 was observed, indicating an initial strengthening effect attributed to the dispersed complex intermetallic compounds within the zinc matrix. The most pronounced enhancement was observed at 1.0 wt.% Ca, where the reinforced alloy attained a microhardness of 141 ± 6 HV0.1. This increase in microhardness from the 1.0 wt.% Ca-reinforced base alloy illustrates the uniform distribution and robust interfacial bonding of Ca within the Zn matrix, contributing to superior hardness properties [17,27]. The alloy containing 1.5 wt.% Ca exhibited a microhardness of 130 ± 3 HV0.1. While this indicates potential increased strength, possibly due to the formation of intermetallic compounds, it is important to note that the lowest elongation was observed in the sample with 1.0 wt.% Ca, indicating that the optimal Ca content may reduce ductility not only because of intermetallic brittleness but also due to microstructural refinement. Figure 5b illustrates the various reinforced Ca levels, with the base alloy containing 1.0 wt.% Ca exhibiting the highest tensile strength of 359 ± 10 MPa. In contrast, the base alloy without Ca exhibited the lowest tensile strength value of 287 ± 4 MPa compared to the Ca-containing alloys, which showed improved strength with increasing up to 1.0 wt.% Ca. The calculated 0.2% offset yield strength (YS) values exhibited a trend similar to that of the tensile strength. The YS of the base alloy without Ca was 182 MPa, which decreased to 158 MPa with 0.5 wt.% Ca addition, possibly due to slight softening or structural modification. A significant increase in the YS was observed at 1.0 wt.% Ca (303 MPa), followed by a slight decline at 1.5 wt.% Ca (175 MPa), likely due to increased porosity and the formation of brittle intermetallic phases. The results for the base alloy without Ca revealed an elongation of 9.37%, whereas a maximum elongation of 15.6% was observed for the alloy with 0.5 wt.% Ca, as represented in Figure 5b. The tensile results indicated that the ductility decreased in the Ca-containing alloys compared to that in the base alloy, with the lowest elongation observed at 1.0 wt.% Ca, as evidenced by the decrease in elongation percentage. The elongation diminished by more than half of the value observed without Ca addition. The base alloy with up to 1.0 wt.% Ca acts as a grain refiner, facilitating the formation of fine intermetallic compounds (CaZn13 or CaAl2), which prevent dislocation motion. Although higher Ca content may contribute to the formation of brittle intermetallic phases that promote crack initiation, the tensile results indicate that the lowest elongation occurred at 1.0 wt.% Ca, suggesting that ductility does not decrease linearly with increasing Ca content and may be influenced by complex microstructural interactions. As shown in Figure 5b, the tensile strength improved with Ca addition up to 1.0 wt.%, which can be attributed to grain refinement and dispersion strengthening from the formation of fine intermetallic phases such as CaZn13 or CaAl2. However, despite the observed grain refinement at 1.0 wt.% Ca, a noticeable reduction in ductility was recorded. This apparent contradiction can be explained by the increased formation and agglomeration of coarse or brittle intermetallics at higher Ca levels, which may act as stress concentrators and initiate micro cracks under load.

Figure 5.

(a) Hardness value. (b) Tensile test results of squeeze cast without and with different wt.% Ca of Zn-Al-Cu-Mg alloy.

3.5. Fracture Surfaces Analysis

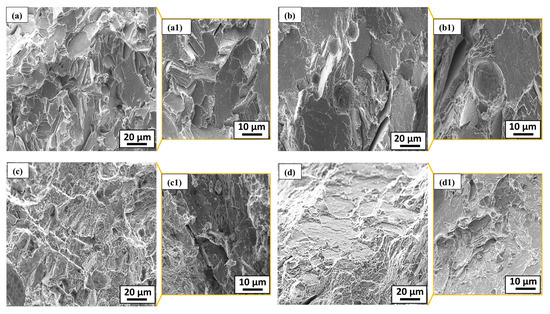

Figure 6 presents the fracture surfaces of the tensile specimens of the base and Ca-reinforced alloys, highlighting the influence of the Ca content on the fracture behavior. The base alloy (Figure 6a) exhibits cleavage planes and river patterns characteristic of brittle fracture, accompanied by mild tearing along the facets. At 0.5 wt.% Ca (Figure 6b), the fracture surface displays the development of voids and a predominantly brittle morphology, with a limited presence of ductile dimples. Interestingly, this alloy demonstrated a relatively higher elongation than the others, indicating that the fracture morphology may be influenced by localized features such as intermetallic distribution, porosity, or crack propagation paths, and not solely by global ductility. Figure 6c (1.0 wt.% Ca) displays a transitional fracture mode, characterized by a mix of shallow dimples and faceted cleavage surfaces, indicating partial ductile behavior. However, the presence of challenging intermetallic phases likely restricted plastic deformation, leading to reduced elongation despite grain refinement. At 1.5 wt.% Ca (Figure 6d), the fracture surface is dominated by pronounced cleavage features, intergranular cracking, and sparse small dimples, indicative of a shift toward brittle failure.

Figure 6.

SEM images of fracture surfaces of tensile-tested samples showing the effect of Ca addition on fracture morphology: (a) base alloy, (b) 0.5 wt.% Ca, (c) 1.0 wt.% Ca, and (d) 1.5 wt.% Ca. Corresponding higher-magnification insets (a1–d1) reveal finer morphological details.

To improve morphological clarity, higher-magnification images (Figure 6(a1–d1)) were captured, revealing micro-dimples, void coalescence, and cleavage steps that correspond to the underlying fracture mechanisms. The evolution of the fracture characteristics correlates with the formation and coarsening of Ca-rich intermetallics, such as CaZn13 and Al2Ca1Zn, which act as stress concentrators and promote premature crack initiation.

Overall, the microstructural evolution resulting from Ca addition, including grain refinement and the formation of intermetallic compounds such as CaZn13 and Al2Ca1Zn, directly influenced the observed fracture behavior. Finer grains at 1.0 wt.% Ca promote strength, yet the associated intermetallics act as stress concentrators, reducing ductility. Fracture surface analysis (Figure 6) links the observed structural changes to the mechanical response, demonstrating how the optimal Ca content achieves a balance between strength and toughness. This highlights the importance of controlled intermetallic morphologies and uniform phase distributions in enhancing the fracture resistance of Zn-Al-based alloys [3,28].

4. Conclusions

The present study investigated the effects of calcium (Ca) reinforcement on the microstructure and mechanical properties of squeeze-cast Zn-Al-Cu-Mg alloys. The findings led to the following conclusions:

Microstructural evaluation revealed that moderate Ca additions, particularly at 1.0 wt.%, contributed to grain refinement and facilitated the formation of intermetallic phases such as CaZn13 and Al2Ca1Zn. These microstructural modifications resulted in an enhancement of tensile strength and hardness. However, further increases in Ca content beyond 1.0 wt.% resulted in the coarsening of intermetallic compounds and an uneven distribution, which adversely affected ductility and structural homogeneity.

X-ray diffraction (XRD) patterns confirmed the presence of Zn as the primary matrix phase, while CaZn13 and Al2Ca1Zn emerged as dominant secondary phases. Their influence on the alloy’s properties varied with their morphology and distribution, strengthening the alloy at moderate levels, but contributing to brittleness when present in excessive amounts.

Mechanical testing confirmed that the alloy containing 1.0 wt.% Ca achieved the optimal combination of high tensile strength and moderate ductility, reflecting a well-balanced microstructure. Fracture surface analysis via SEM showed a transition from mixed ductile–brittle fracture modes at lower Ca content (0.5–1.0 wt.%) to predominantly brittle cleavage and intergranular cracking at higher Ca levels (1.5–2.0 wt.%). The fracture mechanisms were strongly affected by the size and distribution of Ca-rich intermetallics, as well as porosity and localized stress concentration effects. High-magnification insets of fracture surfaces revealed characteristics such as micro void coalescence and cleavage planes, providing deep insights into the failure mechanisms influenced by Ca concentration.

These findings demonstrate that while calcium serves as an effective microalloying element to strengthen Zn-based alloys, its content must be carefully controlled to avoid embrittlement. The presence and morphology of intermetallic phases, rather than grain size alone, play a critical role in governing mechanical performance. A Ca addition of 1.0 wt.% is identified as optimal, balancing the trade-off between strength and ductility. To expand upon this work, future studies should focus on the corrosion performance, thermal stability, and fatigue resistance of Ca-reinforced Zn-Al-Cu-Mg alloys. Advanced characterization techniques, such as Rietveld refinement for phase quantification and 3D tomography for porosity evaluation, are recommended to deepen the understanding of microstructure–property relationships in these alloys.

Author Contributions

Conceptualization, T.G. and S.P.K.B.; methodology, T.G.; software, T.G.; validation T.G., S.P.K.B. and S.R.S.; formal analysis, T.G.; investigation, S.P.K.B. and S.R.S.; resources, S.P.K.B.; data curation, S.P.K.B. and S.R.S.; writing—original draft preparation, T.G.; writing—review and editing, S.R.S. and S.P.K.B.; visualization, S.P.K.B.; supervision, S.R.S. and S.P.K.B.; project administration, S.P.K.B.; funding acquisition, S.R.S. and S.P.K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank the Surface Engineering Laboratory, Department of Metallurgical and Materials Engineering, NIT Trichy, for providing the necessary facilities to conduct the present investigation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wu, Z.; Sandlöbes, S.; Wu, L.; Hu, W.; Gottstein, G.; Korte-Kerzel, S. Mechanical Behaviour of Zn–Al–Cu–Mg Alloys: Deformation Mechanisms of as-Cast Microstructures. Mater. Sci. Eng. A 2016, 651, 675–687. [Google Scholar] [CrossRef]

- Neres da Silva, N.A.; Pereira, P.H.R.; Siqueira Corrêa, E.C.; Paulino Aguilar, M.T.; Cetlin, P.R. Microstructural Evolution and Mechanical Properties in a Zn–Al–Cu–Mg Hypoeutectic Alloy Processed by Multi-Directional Forging at Room Temperature. Mater. Sci. Eng. A 2021, 801, 140420. [Google Scholar] [CrossRef]

- Xiao, Y.; Cai, Y.; Yao, W.; Zhuang, D.; Chen, F.; Li, T.; Zhong, Y.; Luo, C.; Chen, W.; Lyu, Z.; et al. Developing High Elongation of Ca-Containing Zn Alloys with Superior Osteogenic and Antibacterial Properties. J. Alloys Compd. 2025, 1010, 176988. [Google Scholar] [CrossRef]

- Luqman, M.; Ali, Y.; Zaghloul, M.M.Y.; Sheikh, F.A.; Chan, V.; Abdal-hay, A. Grain Refinement Mechanism and Its Effect on Mechanical Properties and Biodegradation Behaviors of Zn Alloys—A Review. J. Mater. Res. Technol. 2023, 24, 7338–7365. [Google Scholar] [CrossRef]

- Abou El-khair, M.T.; Daoud, A.; Ismail, A. Effect of Different Al Contents on the Microstructure, Tensile and Wear Properties of Zn-Based Alloy. Mater. Lett. 2004, 58, 1754–1760. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Wang, C.; Cao, S.; Bai, W.; Wu, C.; Qian, J. Effect of Al Content on Microstructure and Properties of Zn-Cu-Al Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 746, 012018. [Google Scholar] [CrossRef]

- Sun, S.; Yu, J.; Wang, C. Effect of Al or Cu Content on Microstructure and Mechanical Properties of Zn Alloys Fabricated Using Continuous Casting and Extrusion. Metals 2024, 14, 888. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, G.; Liu, W.; Zhang, L.; Pang, S.; Wang, Y.; Ding, W. Effects of Processing Parameters and Ca Content on Microstructure and Mechanical Properties of Squeeze Casting AZ91–Ca Alloys. Mater. Sci. Eng. A 2014, 595, 109–117. [Google Scholar] [CrossRef]

- Liu, Y.; Geng, C.; Zhu, Y.; Chen, X. Effect of Sr Addition on Microstructure Evolution and Mechanical Properties of Zn 4%Al Hypoeutectic Alloy. J. Alloys Compd. 2017, 695, 443–451. [Google Scholar] [CrossRef]

- Pola, A.; Tocci, M.; Goodwin, F.E. Review of Microstructures and Properties of Zinc Alloys. Metals 2020, 10, 253. [Google Scholar] [CrossRef]

- Nie, K.; Zhu, Z.; Munroe, P.; Deng, K.; Han, J. The Effect of Zn/Ca Ratio on the Microstructure, Texture and Mechanical Properties of Dilute Mg–Zn–Ca–Mn Alloys That Exhibit Superior Strength. J. Mater. Sci. 2020, 55, 3588–3604. [Google Scholar] [CrossRef]

- Zou, Y.; Chen, X.; Chen, B. Effects of Ca Concentration on Degradation Behavior of Zn-x Ca Alloys in Hank’s Solution. Mater. Lett. 2018, 218, 193–196. [Google Scholar] [CrossRef]

- Kong, J.; An, L.; Zheng, J.; Du, X. Effect of Zn Addition on Microstructure and Mechanical Properties of a Hypoeutectic Al–7Si-Based Alloy. Int. J. Met. 2025. [Google Scholar] [CrossRef]

- Ritapure, P.P.; Yadav, R.G.; Rasal, V.T.; Damale, A.V.; Kharde, Y.R. Comparative Review and Experimental Validation of Tribological and Mechanical Properties of Zinc Aluminium Alloy (ZA27) and Aluminium Zinc Alloy (Al-25Zn). J. Alloys Metall. Syst. 2024, 7, 100099. [Google Scholar] [CrossRef]

- Zhang, Z.; Hou, H.; Zhang, Y.; Sayed, M.E.E.; Murshed, M.N.; Samir, A.; Wu, P.; Gong, C.; Yong, H.; Song, G.; et al. Effect of Calcium Addition on the Microstructure, Mechanical Properties, and Corrosion Behavior of AZ61-Nd Alloy. Adv. Compos. Hybrid Mater. 2023, 6, 50. [Google Scholar] [CrossRef]

- Hou, C.; Qi, F.; Wang, L.; Lu, L.; Zhao, N.; She, J.; Zhou, Y.; Ouyang, X. Effects of Ca Addition on the Microstructure and Mechanical Properties of Mg–Zn–Sn–Mn Alloys. J. Mater. Res. Technol. 2023, 25, 3884–3900. [Google Scholar] [CrossRef]

- Belov, N.A.; Naumova, E.A.; Akopyan, T.K. Effect of Calcium on Structure, Phase Composition and Hardening of Al-Zn-Mg Alloys Containing up to 12wt.%Zn. Mater. Res. 2015, 18, 1384–1391. [Google Scholar] [CrossRef]

- Mondal, D.P.; Jha, N.; Badkul, A.; Das, S.; Yadav, M.S.; Jain, P. Effect of Calcium Addition on the Microstructure and Compressive Deformation Behaviour of 7178 Aluminium Alloy. Mater. Des. 2011, 32, 2803–2812. [Google Scholar] [CrossRef]

- Mo, W.; Zhang, L.; Wu, G.; Zhang, Y.; Liu, W.; Wang, C. Effects of Processing Parameters on Microstructure and Mechanical Properties of Squeeze-Cast Mg–12Zn–4Al–0.5Ca Alloy. Mater. Des. 2014, 63, 729–737. [Google Scholar] [CrossRef]

- Fu, T.; Ma, L.; Lu, K.; Wang, G.; Shen, H.; Guan, T. Composition Design and Performance Analysis of Zn–0.4Mg–nCa Biodegradable Alloys. J. Mater. Res. 2024, 39, 2589–2600. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, H.; Wu, Y.; Yan, K.; Ju, J.; Teng, H.; Song, D.; Jiang, J.; Bai, J. Comparative Study of the Microstructure Evolution and Mechanical Properties of Zn-0.1Mg-0.02Ca Alloy under Cold Rolling and ECAP. Mater. Sci. Eng. A 2024, 908, 146765. [Google Scholar] [CrossRef]

- Doroshenko, V.; Shurkin, P.; Sviridova, T.; Fortuna, A.; Shkaley, I. Phase Composition and Microstructure of Cast Al-6%Mg-2%Ca-2%Zn Alloy with Fe and Si Additions. Metals 2023, 13, 1584. [Google Scholar] [CrossRef]

- ASTM E92; Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- Qian, X.; Gao, Y.; Dong, Z.; Jiang, B.; He, C.; Wang, C.; Zhang, A.; Yang, B.; Zheng, C.; Pan, F. The Enhanced Zn and Ca Co-Segregation and Mechanical Properties of Mg–Zn–Ce Alloy with Micro Ca Addition. Mater. Sci. Eng. A 2023, 867, 144712. [Google Scholar] [CrossRef]

- Shi, Z.-Z.; Yu, J.; Liu, X.-F.; Zhang, H.-J.; Zhang, D.-W.; Yin, Y.-X.; Wang, L.-N. Effects of Ag, Cu or Ca Addition on Microstructure and Comprehensive Properties of Biodegradable Zn-0.8Mn Alloy. Mater. Sci. Eng. C 2019, 99, 969–978. [Google Scholar] [CrossRef]

- Liu, Z.; Qiu, D.; Wang, F.; Taylor, J.A.; Zhang, M. Effect of Grain Refinement on Tensile Properties of Cast Zinc Alloys. Metall. Mater. Trans. A 2016, 47, 830–841. [Google Scholar] [CrossRef]

- Liu, J.H.; Huang, C.X.; Wu, S.D.; Zhang, Z.F. Tensile Deformation and Fracture Behaviors of High Purity Polycrystalline Zinc. Mater. Sci. Eng. A 2008, 490, 117–125. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).