1. Introduction

The steel industry is crucial to national economic development and national defense. Within this sector, bar products serve as key materials for machinery manufacturing and are extensively utilized. 20CrMnTi bars, renowned for their excellent hardness and wear resistance, are widely employed in the manufacturing of high-precision components. However, in engineering practice, a prevalent issue is straightness deviation exceeding tolerance limits. This problem arises from the coupling effect of uneven residual stresses induced by heat treatment and plastic deformation occurring during the forming process. The straightness of bars directly impacts the installation accuracy, service life, and overall performance of the final products, as well as the processing efficiency and cost of downstream operations. Consequently, the multi-roll straightening process constitutes an essential stage in bar production.

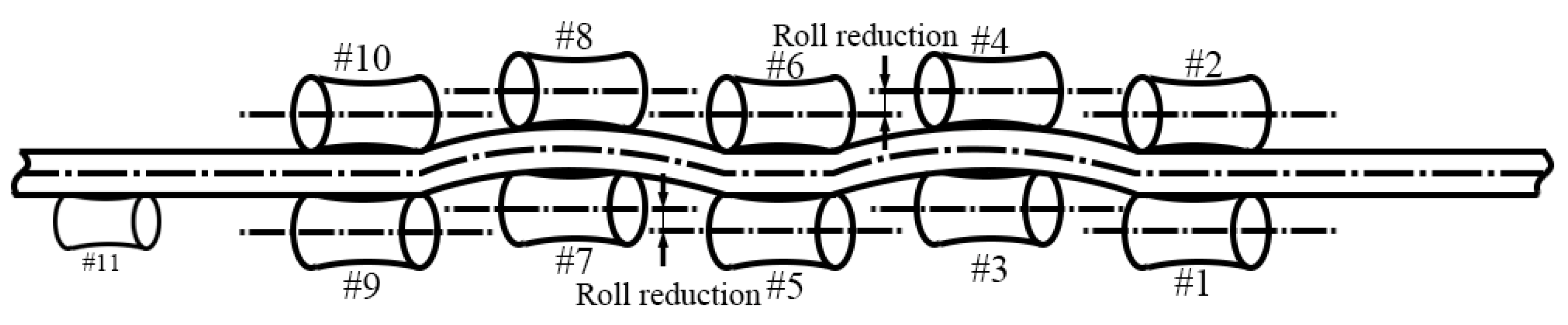

Multi-roll straightening employs various roll arrangement configurations. Common types include five-roll, six-roll, seven-roll, nine-roll, ten-roll, and eleven-roll straighteners. Specifically, the eleven-roll straightener incorporates an additional, smaller stabilizing tail roll compared to the ten-roll design. This tail roll serves to support the bar and restrict post-straightening whipping motion, thereby contributing to improved straightening accuracy. Although multi-roll straightening processes differ in form, their underlying principle remains consistent. By precisely controlling the reduction settings of each inclined roll, the bar is subjected to alternating reverse bending, inducing appropriate elasto-plastic deformation. The rotation of the rolls drives both the rotation and forward advancement of the workpiece. During the straightening process, the bar undergoes a variable-curvature rotary bending deformation. Material experiences multiple cycles of alternating tensile and compressive loading. Consequently, the influence of the Bauschinger effect must be accounted for in research on multi-roll straightening processes.

The Bauschinger effect refers to the phenomenon where, after a material undergoes plastic deformation in one direction, its yield stress upon subsequent reverse loading exhibits a significant reduction. The isotropic hardening model assumes that only the radius of the yield surface changes, while its central position remains fixed. Consequently, this model fails to capture the Bauschinger effect and significantly overestimates the yield strength during reverse loading. To describe the Bauschinger effect, Prager [

1] first proposed the linear kinematic hardening model. Subsequently, Ziegler [

2] modified Prager’s hardening model. The linear kinematic hardening model assumes that the yield surface translates linearly in the direction of the plastic strain. Thus, it can only describe linear hardening behavior and cannot account for nonlinear hardening phenomena. Nonlinear hardening is ubiquitous in materials, particularly when subjected to alternating tensile and compressive loading. Armstrong and Frederick [

3] introduced a dynamic recovery term into the linear kinematic hardening model, proposing the renowned A–F back stress evolution law, which can describe nonlinear hardening behavior. Chaboche et al. [

4,

5] decomposed the back stress into the sum of multiple back stress components, each following the A–F type evolution law. The Chaboche combined hardening model (combining the Chaboche back stress model with the isotropic hardening model) provides an accurate description of the response curves generated under cyclic loading. Its relatively simple formulation has led to its widespread embedding within numerous finite element software packages and broad application. Scholars subsequently made modifications to the Chaboche model [

6,

7,

8], which, to some extent, improved the fitting accuracy of the model, but at the same time increased the complexity of the model, making it difficult to apply these modified models. Okorokov et al. [

9,

10] proposed a novel form of kinematic hardening model; this model can accurately describe hysteresis loops under various loading conditions without requiring the superposition of multiple back stresses.

In the research on multi-roll straightening technology, Cui et al. [

11] proposed a unique method for designing the main parameters of straighteners, simplifying their design and manufacturing processes, thereby advancing straightening theory and technology. Liu et al. [

12] conducted a novel analysis of the roll shape curves for tube and bar straighteners and proposed a universal straightening principle applicable to different profiles using the same straightening roll. Song [

13], through research on adjusting the angles of straightening rolls, provided a theoretical basis for straightener setup. Zhu et al. [

14] applied the energy method to derive a calculation formula for the flattening reduction, revealing its variation patterns with diameter and wall thickness. Zhao et al. [

15] optimized the roll shape curve formula for inclined-roll straighteners, providing a theoretical basis for determining the installation angle and contact line length. Zheng [

16] conducted an in-depth study on the straightening process of a 2-2-2-type straightener based on elasto-plastic bending straightening theory. Zhang et al. [

17,

18] performed a detailed analysis of the flattening issues in tubes during multi-roll straightening. Current research on the cross-roll straightening process often simplifies the rotary bending process to multiple cycles of in-plane reverse bending, neglecting the strain path variation during rotation. Ma et al. [

19] derived the relationship between flattening force and flattening displacement using the energy method, enabling control of the ovality in straightened tubes. Ma et al. [

20] conducted a theoretical analysis of the eleven-roll inclined-roll straightening process and validated its effectiveness using field data. Li [

21] derived a formula for calculating straightening roll service life based on Miner’s damage criterion, verifying its rationality through finite element simulation and friction-wear experiments, and analyzed key factors affecting roll life. Yao et al. [

22] analyzed the influence of bite conditions, contact stress, and strength conditions on the roll diameter and roll pitch of roller straighteners, concluding that strength conditions are the key factor. Hu et al. [

23] addressed issues like traditional straightening processes relying on manual experience and low efficiency by optimizing a BP neural network using the Dung Beetle Optimizer (DBO) algorithm to establish a straightening process prediction model. Results showed this method effectively improves prediction accuracy. Gu et al. [

24] reviewed the current state of roller straightening technology, analyzed the influence of straightening strategies and key parameters on post-straightening flatness deviation and residual stress, providing theoretical support for the independent development of large-scale roller straightening equipment.

Mwita et al. [

25] conducted numerical predictions of the tensile yield strength and hardness properties of Ti6Al4V alloy subjected to Constrained Bending Straightening (CBS) and Severe Plastic Deformation (SPD) processes. Gruber et al. [

26] introduced a control scheme for a leveler employing different load triangles to eliminate straightening residual stresses. Petruska et al. [

27] addressed the modeling of round bar cross-roll straightening by proposing a novel finite element formulation. This method, based on an Eulerian description, simulates the flow of elasto-plastic material through a fixed spatial finite element mesh, coupled with a multi-roll straightening machine. Asakawa et al. [

28] performed a comprehensive analysis of the bar straightening process through simulation and experimental investigation. They proposed a method for predicting the deflection of bars after straightening. This method proves particularly effective for bars with large initial curvature, but further in-depth analysis and research are still required for bars with smaller initial curvature. Meng et al. [

29] conducted an in-depth study on the basic problem of rotational bending springback involved in the cross-roller straightening process and proposed a new analytical method for rotational bending springback considering the strain path. Domitner et al. [

30] proposed an experimental method to evaluate the wear of rollers in a multi-cross roller straightening process. Niu et al. [

31] proposed a new radial feed-in rotary straightening method to address the planetary roller screw deflection problem and verified the feasibility of the process using numerical simulation and experimental methods.

The main literature comparison results are shown in

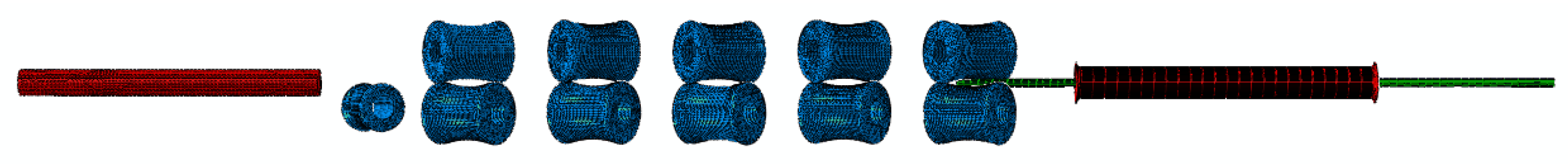

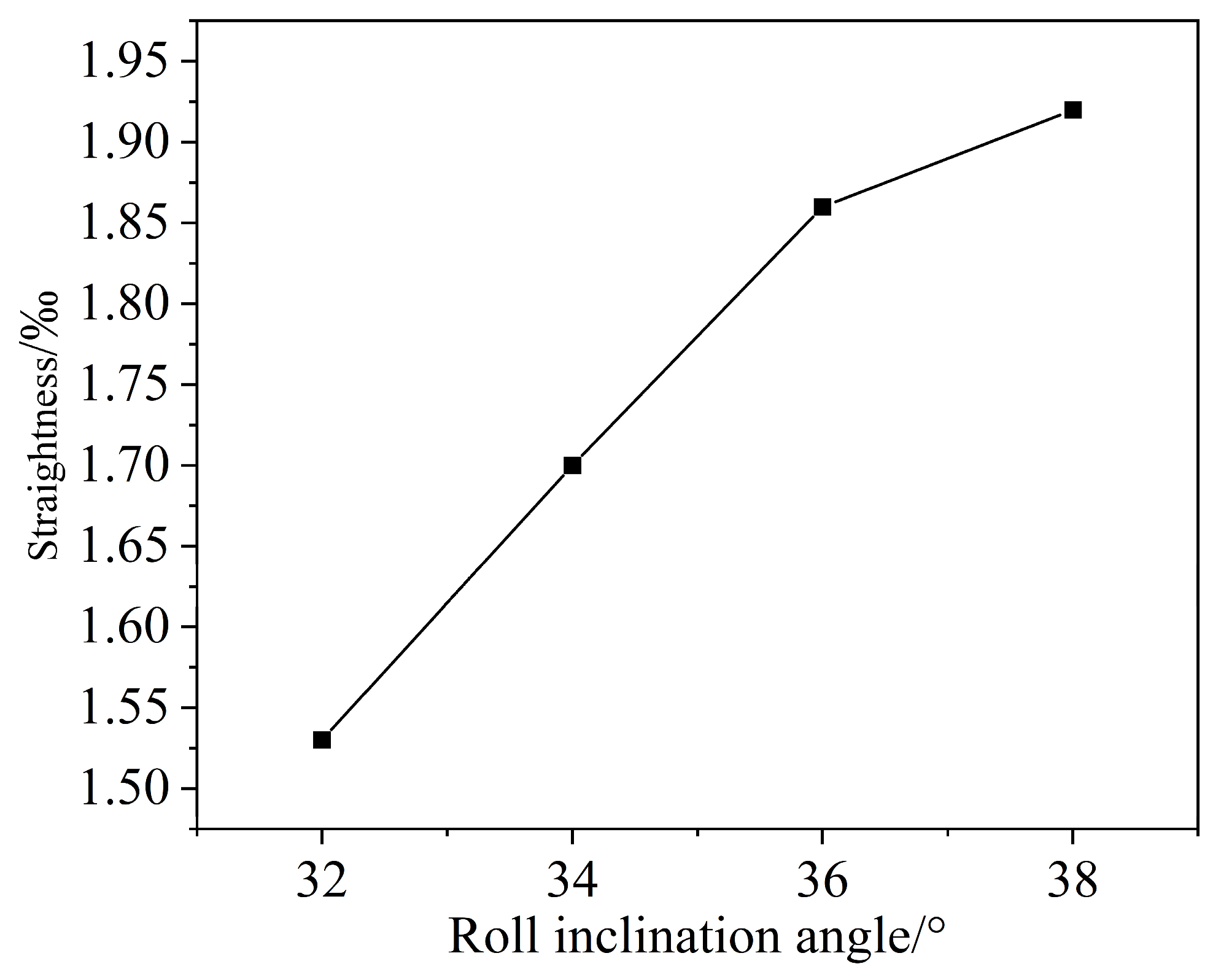

Table 1. In summary, existing research predominantly employs simplified material models, failing to accurately account for the influence of the Bauschinger effect. This limitation leads to insufficient prediction accuracy for the multi-roll straightening process. To address this, this study establishes an eleven-roll bar straightening finite element model based on a nonlinear combined hardening model. The orthogonal experimental design method is utilized to optimize the process parameters. Straightening experiments on 20CrMnTi bars using an eleven-roll straightener were conducted to validate the reliability of both the numerical simulation results and the optimized process parameters. Leveraging the established eleven-roll straightening FEM, the influence patterns of various process parameters on the straightening results were systematically investigated. The findings of this research can provide reliable theoretical support and technical reference for the optimization design of the eleven cross-roll straightening process for 20CrMnTi bars.

3. Constitutive Model

Considering the balance of accuracy, ease of use, and computational efficiency, the Chaboche combined hardening model with three back stresses was selected for this study.

Based on the von Mises isotropic yield criterion, the yield function for the kinematic hardening model can be expressed as follows:

where

F is the yield function,

is the deviatoric stress tensor,

is the back stress tensor (MPa),

are tensor indices, and

Y is the yield stress.

The evolution law for back stress is categorized into linear and nonlinear forms. The linear expression is as follows:

where

C is the parameter for the evolution of back stress.

Armstrong and Frederick [

3] introduced a dynamic recovery term into the linear evolution law, proposing the renowned A–F nonlinear back stress evolution law. Its mathematical expression is given by the following equation:

where

is the back stress evolution parameters. Compared to the linear kinematic hardening model, the A–F evolution law can accurately describe the nonlinear hardening behavior of materials.

Chaboche [

4] proposed an enhanced approach based on the A–F evolution law, representing the back stress as a superposition of multiple components. Each back stress component is assumed to independently follow the A–F evolution law, enabling a more precise description of the material’s nonlinear mechanical behavior:

where

N is the number of back stress components (in this study,

N = 3 is adopted), and

is the

m-th back stress component.

For the commonly used isotropic hardening model in the form of exponential functions, the expression is as follows:

where

is the initial yield stress (MPa),

is the isotropic hardening parameter, and

is the cumulative plastic strain.

Under uniaxial stress conditions, the back stress evolution law in Equation (3) can be integrated as follows:

where

is the initial value of the back stress at the start of the load cycle,

is the change in plastic strain during the loading cycle;

is the loading direction parameter, where

= ± 1 indicates the direction of loading. When

is positive, the value is positive, and when

is negative, the value is negative.

Then there is the following:

The stress expression for the unidirectional stress state is as follows:

The stress–strain relationship can be expressed using the linear elasticity assumption for the elastic deformation stage as follows:

where

E is the elastic modulus.