1. Introduction

Laser-directed energy deposition (L-DED) is an additive manufacturing technology that employs high-energy laser beams to melt metallic feedstock, forming metallurgical bonds with substrates [

1,

2]. This process achieves near-net shape forming of complex structures through layer-wise deposition, offering superior material utilization (exceeding 95%) [

3], enhanced design freedom (e.g., internal conformal channels) [

4], and rapid prototyping capabilities compared with subtractive manufacturing. These advantages enable widespread L-DED adoption for high-performance metal components in aerospace, energy, and biomedical sectors [

5,

6,

7]. However, complex coupling effects between process parameters and melt pool dynamics frequently cause geometric deviations, porosity, and microstructural inhomogeneity [

8], limiting L-DED’s application in critical load-bearing parts. Since single-bead deposition constitutes the fundamental unit determining final quality, investigating parameter–geometry relationships and establishing accurate bead dimension prediction models are essential for ensuring dimensional accuracy and process robustness.

The optimization of laser additive manufacturing processes is challenged by multi-parameter interactions, vast solution spaces, and complex physical-metallurgical phenomena, rendering trial-and-error approaches and numerical simulations prohibitively time-consuming and costly. Machine learning (ML) addresses these limitations by leveraging extensive process data to shorten experimental cycles, reduce computational expenses, and effectively predict/optimize process parameters. Veiga et al. [

9] have systematically analyzed how critical parameters (current, wire feed speed) govern bead geometry (width/height) in Invar alloy wire-arc additive manufacturing through real-time melt pool monitoring, establishing process-geometry correlations via linear regression models. Afshari et al. [

10] developed an integrated approach combining design of experiments, inverse analysis, and numerical simulation to evaluate bead geometry and cladding characteristics in Inconel 718 laser deposition, achieving precise prediction through multi-parameter optimization. Chigilipalli et al. [

11] optimized Incoloy 825 deposition parameters via neuro-fuzzy modeling, creating an intelligent prediction framework for nickel-based alloys. Shen et al. [

12] employed multiple ML algorithms (Random Forest, SVM, ANN) for dimension prediction in CoCrFeNiMo

0.

2 high-entropy alloy deposition. Li et al. [

13] proposed a novel differential evolution-optimized multi-output SVR (DE-MOSVR) model predicting bead morphology in 2319 aluminum wire-laser hybrid DED. Lee et al. [

14] utilized Gaussian process regression (GPR) to forecast layer height and porosity in Fe-Ni alloy laser metal deposition, with Shapley Additive Explanations (SHAP) quantifying parameter significance.

Although machine learning (ML) can accurately predict single-target outputs, it lacks the ability to autonomously reconcile conflicts between parameters such as bead width, depth and height. Multi-objective optimization is the key tool for resolving such challenges in engineering decision-making. Wang et al. [

15] developed an intelligent optimization method that integrates modified NSGA-II algorithms and multi-pass deposition profile prediction models to optimize parameters in aluminum alloy laser-arc hybrid additive manufacturing. Chen et al. [

16] proposed an innovative, multi-objective optimization framework that considers multiple objectives, such as energy efficiency, material utilization and environmental impact in order to optimize process parameters systematically. Using a titanium alloy as a case study, the study verified the effectiveness of this framework in balancing processing performance and environmental benefits. Aghaei et al. [

17] combined SVR prediction models with NSGA-II to map the relationship between different laser welding parameters and quality metrics (e.g., strength and penetration). This approach achieved multi-objective synergy through Pareto solutions, improving joint strength by 15% and reducing the width of the heat-affected zone by 20% compared with single-objective approaches. Panico et al. [

18] used Taguchi methods and neural networks to model correlations between fused deposition modeling (FDM) 3D printing parameters and quality, utilizing NSGA-II to resolve conflicts between printing speed, strength, and accuracy. Yu et al. [

19] created a hybrid framework that combines data augmentation, stacked ensemble learning, SHAP analysis and multi-objective optimization in order to design strong, tough, and ductile laser-melted titanium alloys. This framework simultaneously enhances the ultimate tensile strength (UTS) and elongation (EL) of LPBF Ti components. Together, these studies show that ML-multi-objective synergy is an innovative way to allocate weight precisely across competing objectives and identify optimal parameter sets in laser additive manufacturing.

Inconel 690 alloy, with its compatible filler ER NiCrFe-7A, has been shown to possess exceptionally high-temperature stability and corrosion resistance properties, thus making it a critical material for the manufacturing of components for nuclear power plants. The utilization of this alloy has been demonstrated to result in a substantial increase in service lifetimes. While the potential of additive manufacturing (AM) in the repair and fabrication of nuclear safety-critical components, including reactor penetration nozzles, large-curvature piping nozzles, and fuel assembly bottom grids (BG)/nozzles (BN), has been demonstrated [

20,

21,

22], current research on Inconel 690 AM remains considerably limited. Existing studies have primarily focused on mitigating high-temperature impregnation cracks and enhancing dissimilar-weld mechanical properties, with insufficient attention being paid to predicting and optimizing single-bead geometry. It is imperative to acknowledge that precise dimensional control of individual beads is of the essence in ensuring the quality and stability of fabricated components. Consequently, the advancement of predictive modelling and process optimization for Inconel 690 deposition assumes a pivotal role in nuclear safety assurance.

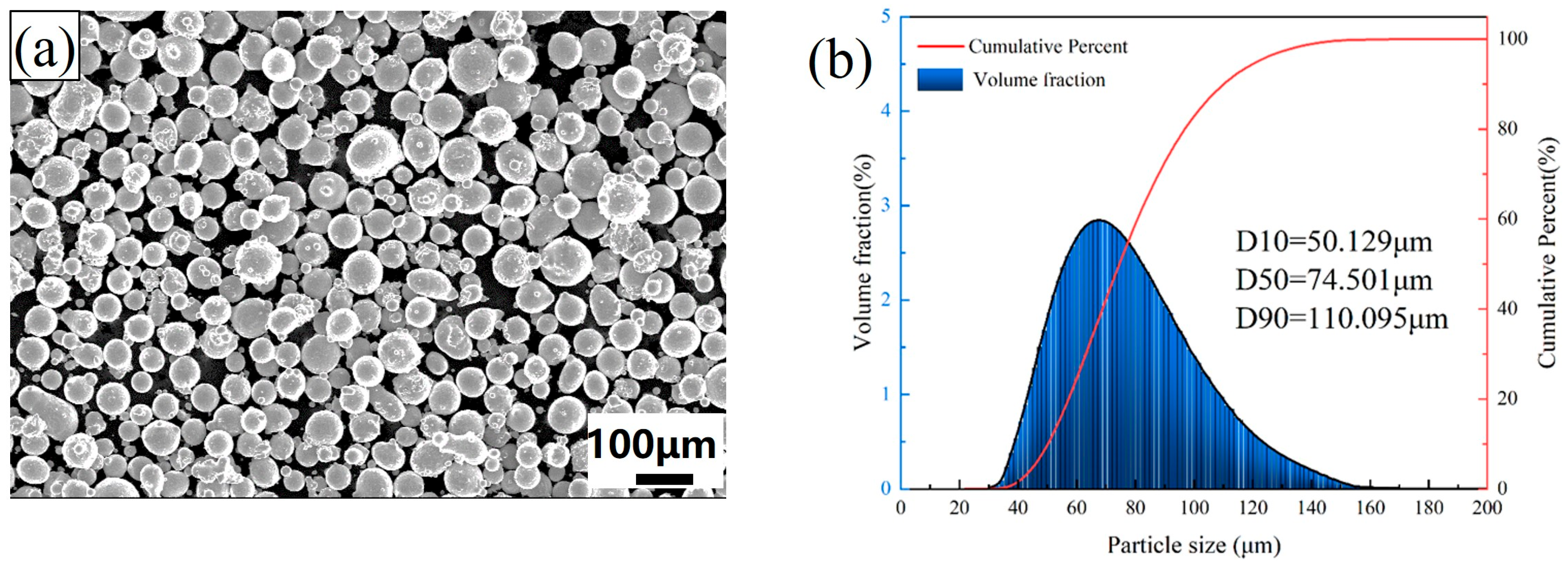

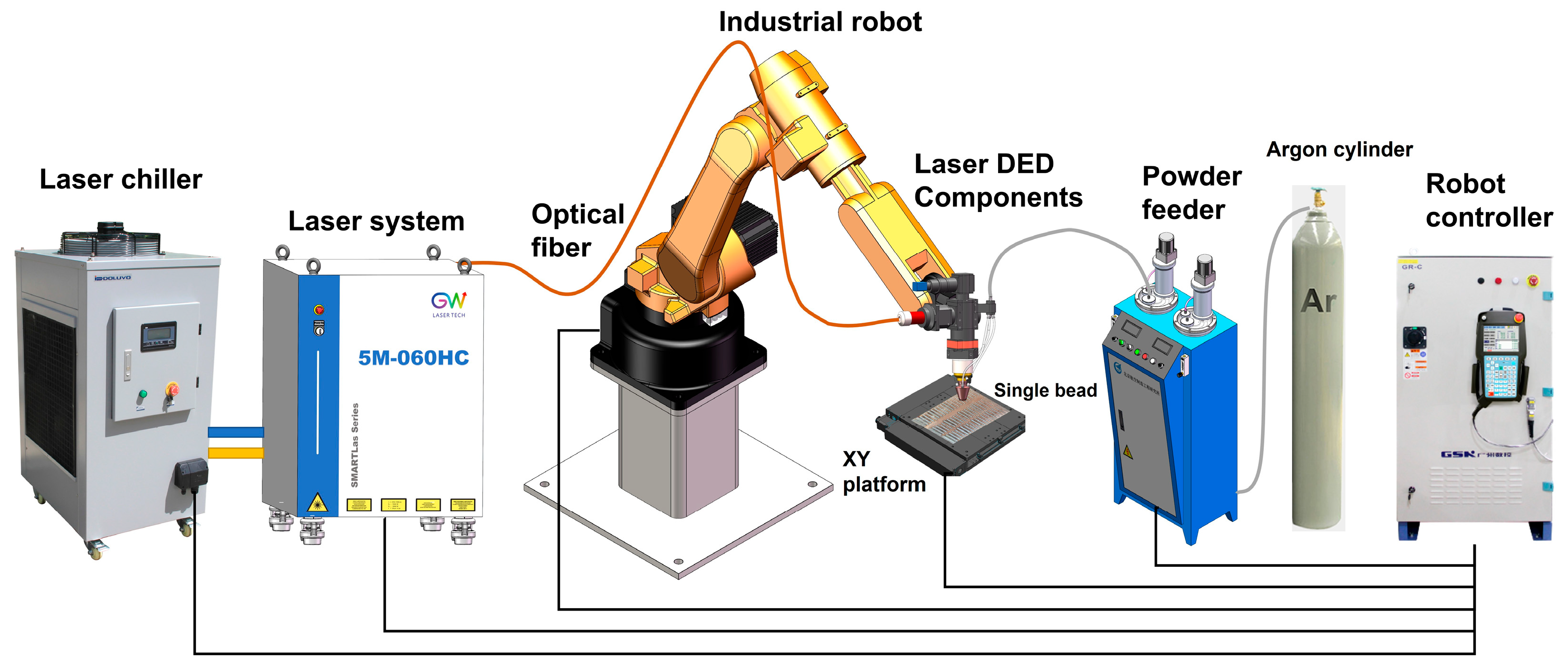

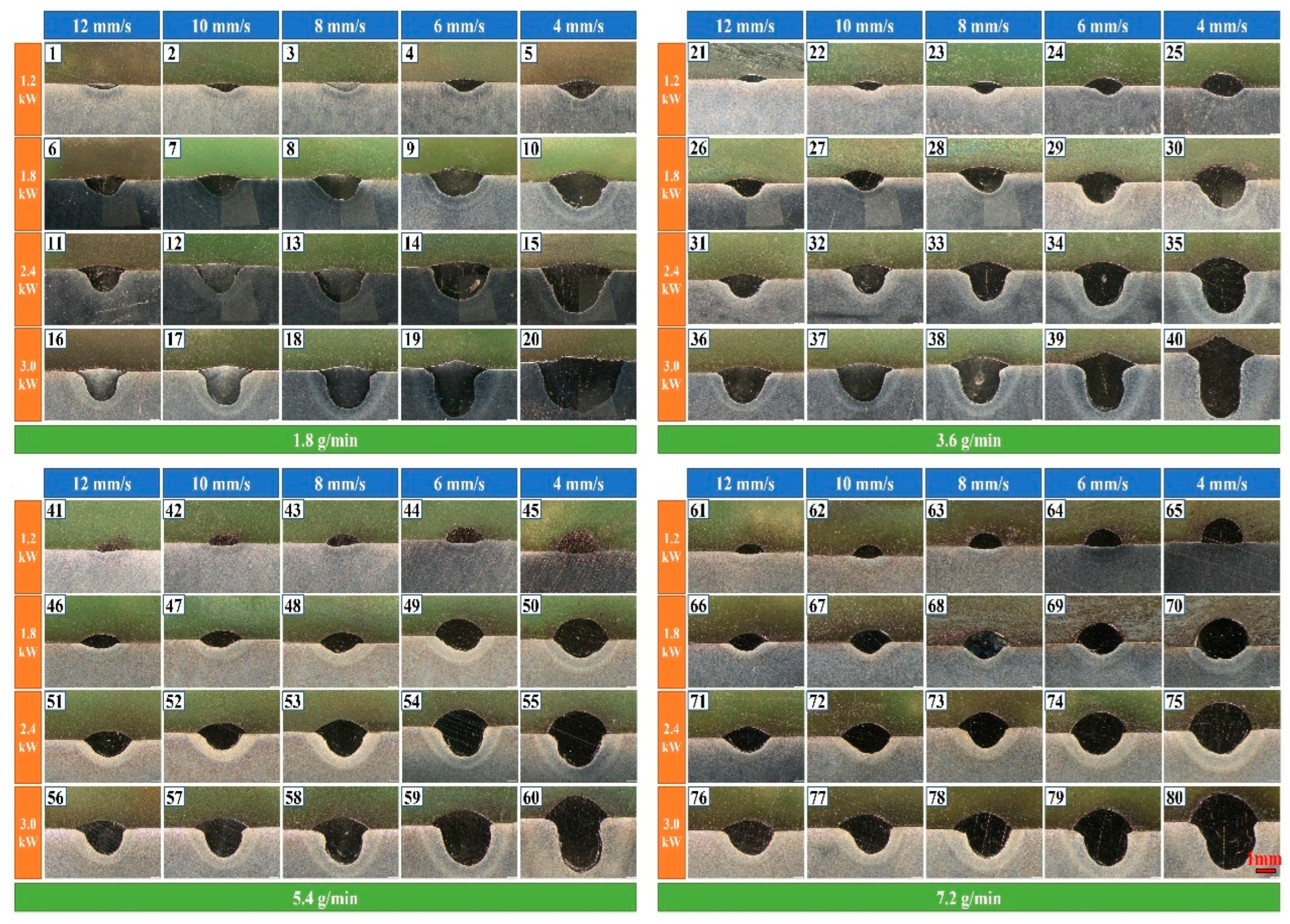

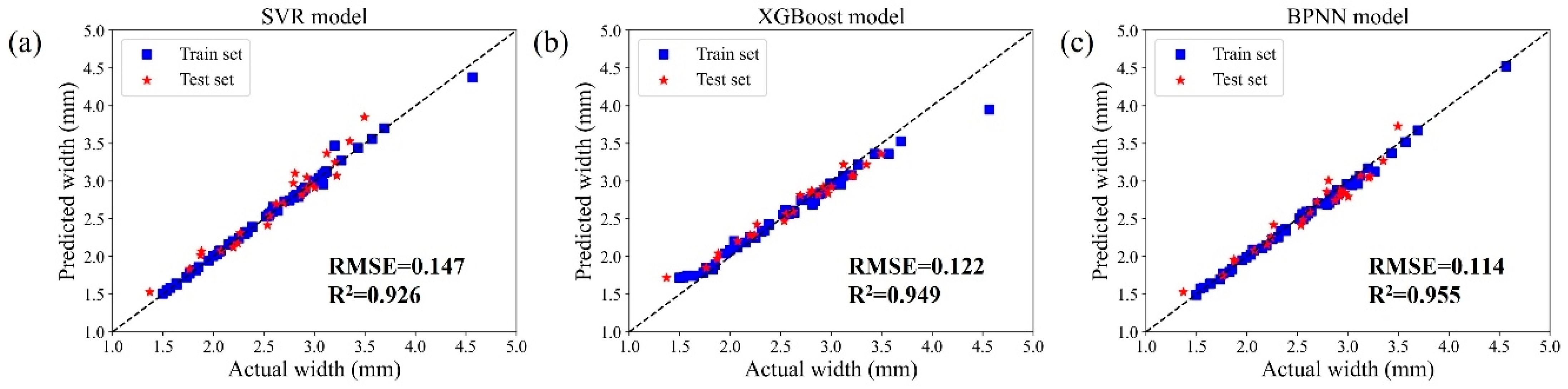

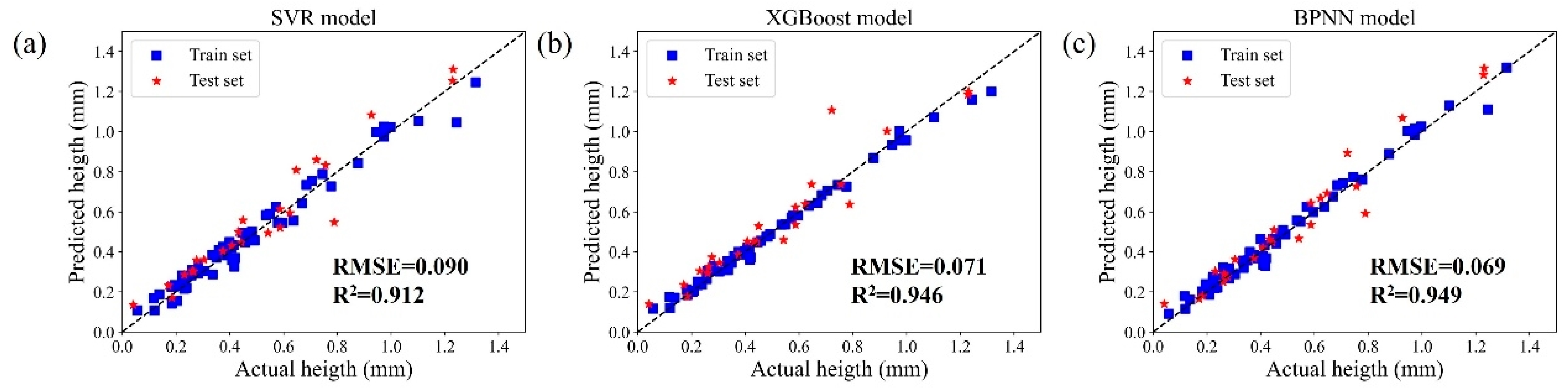

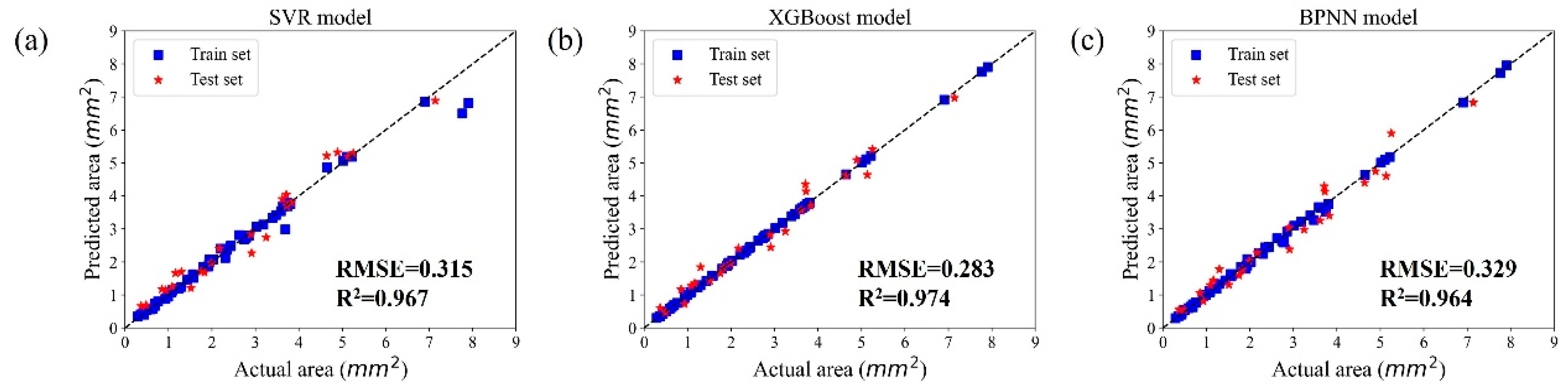

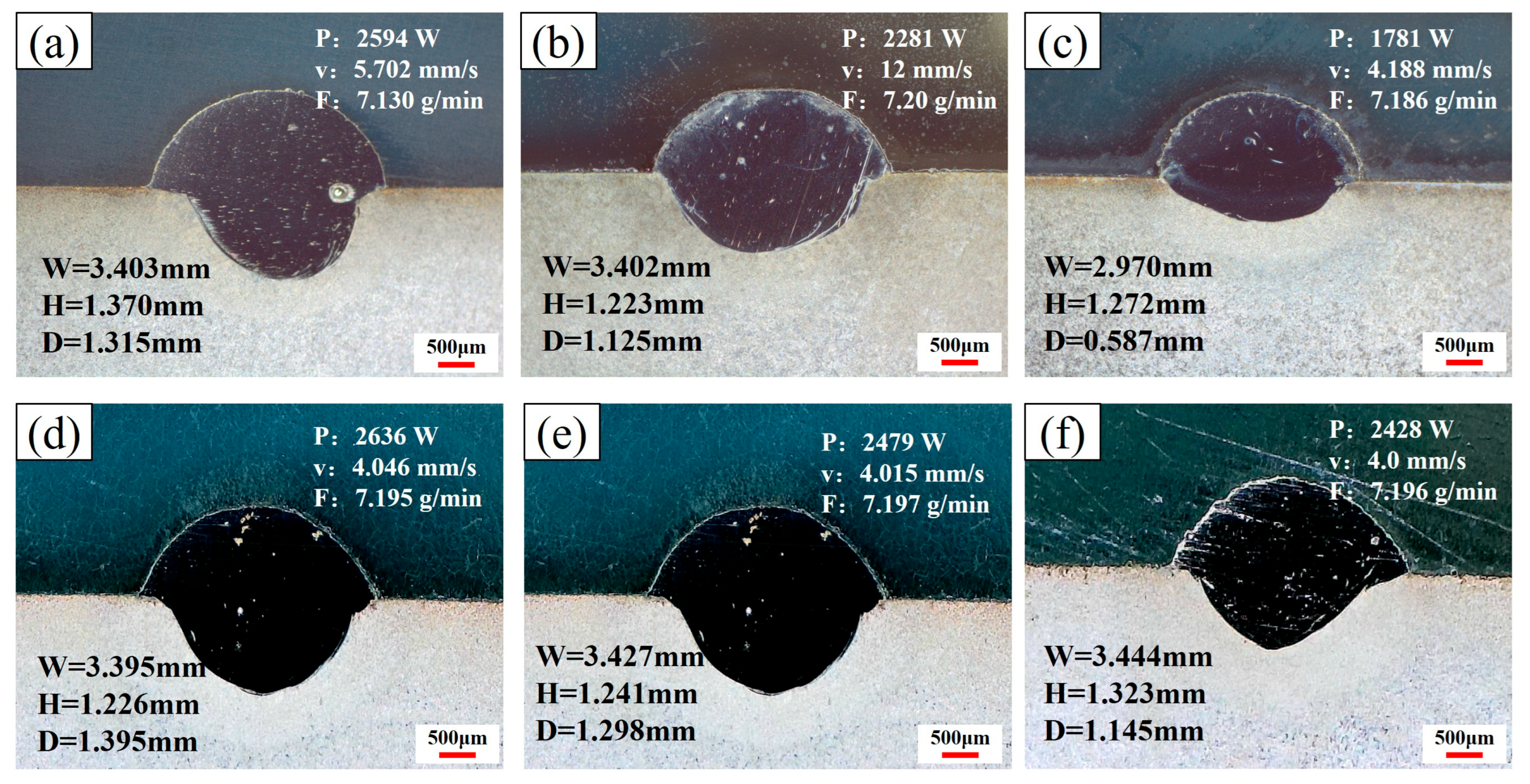

Therefore, this study combines machine learning and multi-objective optimization to create a predictive model for the geometry of beads in the laser-directed energy deposition (L-DED) of Inconel 690 alloy. A full-factorial experimental design was implemented, using laser power (P), travel speed (V), and powder feed rate (F) as the input variables and bead width (W), height (H), and depth (D) as the output targets. Three machine learning algorithms were used to develop geometric prediction models. The Non-dominated Sorting Genetic Algorithm II (NSGA-II) was then used to find Pareto-optimal combinations of process parameters, maximizing bead width and height while minimizing depth. Ultimately, experimental validation was performed using the optimal parameters predicted by the model.