1. Introduction

Due to their superior high-temperature strength, corrosion resistance, and mechanical properties, superalloys are indispensable for critical components such as the hot-section parts of aero-engines and gas turbine blades. However, the manufacturing of numerous precision cooling holes, which are essential for ensuring operational integrity and extending service life, presents significant machining challenges [

1,

2,

3]. Consequently, non-contact advanced machining technologies are preferred, although even viable options such as electrochemical machining (ECM) and electrical discharge machining (EDM) often face limitations in processing efficiency and cost [

4,

5,

6]. For instance, although EDM can achieve excellent machining quality, its inherently slow processing speed presents a bottleneck for high-volume production compared to laser drilling [

1,

7,

8,

9]. Consequently, laser drilling has emerged as a key technology to overcome these bottlenecks, leveraging its unique advantages, including non-contact processing, high energy density, and a minimal heat-affected zone (HAZ) [

10,

11,

12].

Nevertheless, conventional long-pulse lasers induce a series of defects in the vicinity of the hole during processing, primarily due to the heat accumulation effect. In recent years, ultrafast laser technology, particularly picosecond lasers, has offered a novel solution to these challenges [

13,

14]. The key lies in the ultrashort pulse duration, which is shorter than the material’s characteristic time for thermal diffusion. This allows energy to be deposited and material to be removed via direct ablation before significant heat can transfer to the surrounding lattice. This mechanism drastically reduces the heat-affected zone (HAZ) and associated defects [

15,

16,

17]. For instance, H. Zhu et al. investigated the drilling of film cooling holes on DD6 single crystal superalloy using a hybrid process that combined a picosecond laser with assisted waterjet and electrochemical post-processing, revealing the influence of key parameters on hole taper and demonstrating the effectiveness of the combined process in eliminating thermal damage and improving hole quality [

18]. Q. Tang et al. employed a combination of numerical simulation and experiments to study the influence of plasma on picosecond laser drilling [

19]. H. Wang et al. developed a hybrid technique combining picosecond laser layered trepanning with cooperative airflow and E-field modulation to machine deep high-aspect-ratio micro holes in titanium alloy TC4, demonstrating its ability to significantly increase the achievable hole depth and aspect ratio while effectively suppressing residual stress [

20]. C. Liu et al. proposed a two-dimensional transient numerical model to simulate the hole shape evolution and thermal effects in picosecond laser drilling of 2.5D C/SiC composites and validated the model’s accuracy in predicting hole profiles and thermal damage through experimental results [

21]. S. Zhang et al. proposed a back-water-assisted picosecond laser drilling technique for the mass fabrication of micro holes in aviation filters, demonstrating that this method can significantly reduce hole taper and thermal defects while increasing processing efficiency by 40–60% compared to direct laser drilling [

22]. Currently, there is insufficient research on the picosecond laser trepanning of superalloys, specifically concerning the systematic influence of parameters like laser power, scanning speed, number of scans, and defocusing distance on hole quality, and on methods to improve orifice quality and surface cleanliness.

Accordingly, this paper focuses on the nickel-based superalloy GH4169. First, from an experimental analysis perspective, picosecond laser trepanning experiments were conducted. A single-factor method was systematically employed to investigate the effects of laser power, number of scans, scanning speed, and defocusing distance on hole quality. Second, in terms of defect control research, we conducted an in-depth analysis of the morphology and causes of microdefects. By elucidating the defect mechanisms, this method guides the optimization of process parameters, providing a more reliable and scientifically rigorous solution for achieving high-quality, defect-free holes in GH4169 material, surpassing the limitations of trial-and-error optimization.

4. Conclusions

This study systematically investigated the influence of key parameters—namely laser power, scanning speed, defocus, and scan count—on the geometrical quality of micro-holes trepanned in GH4169 superalloy using a picosecond laser. Based on the findings, an effective defect control strategy is proposed. The main conclusions are as follows:

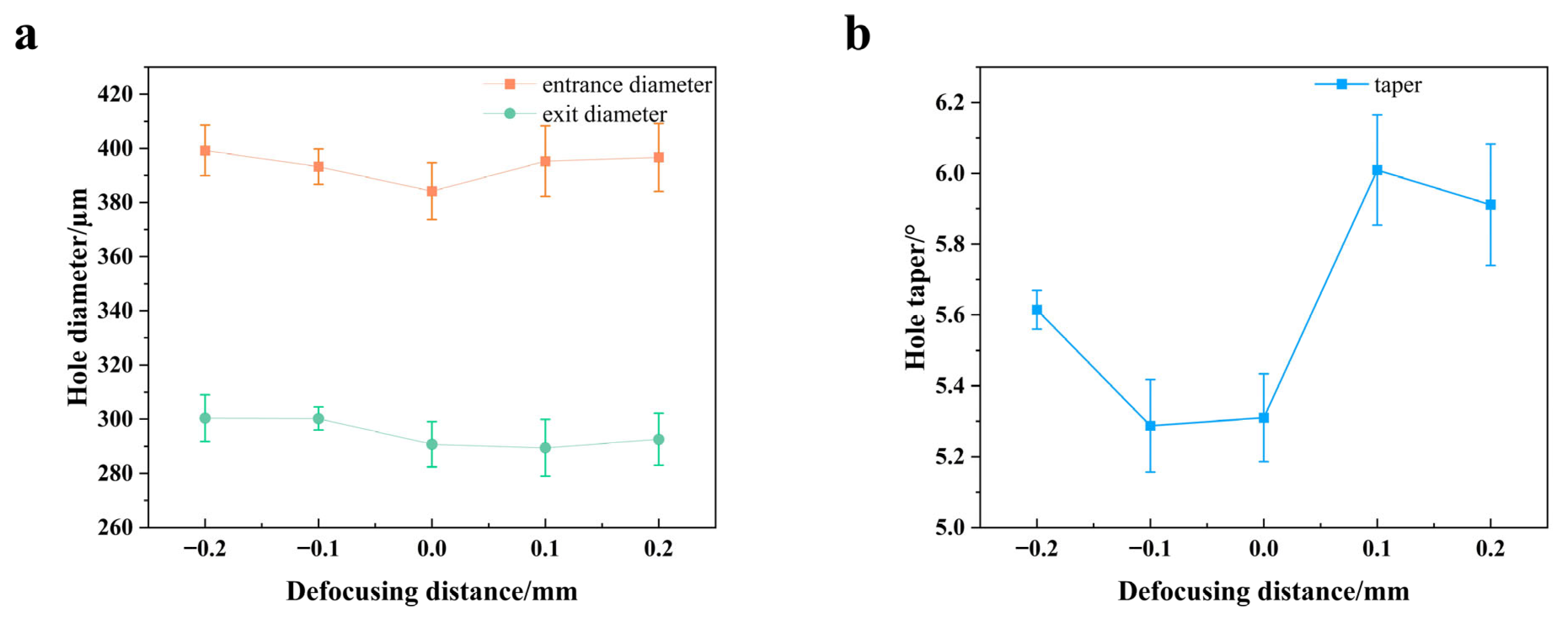

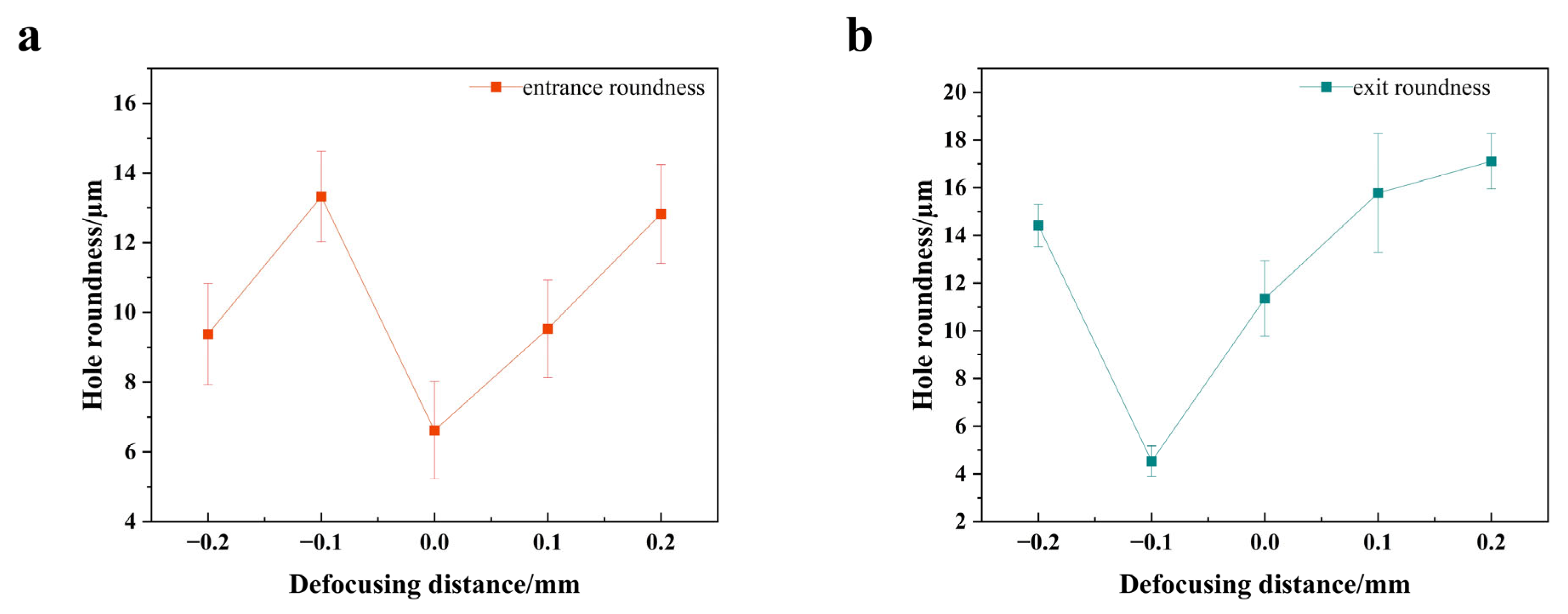

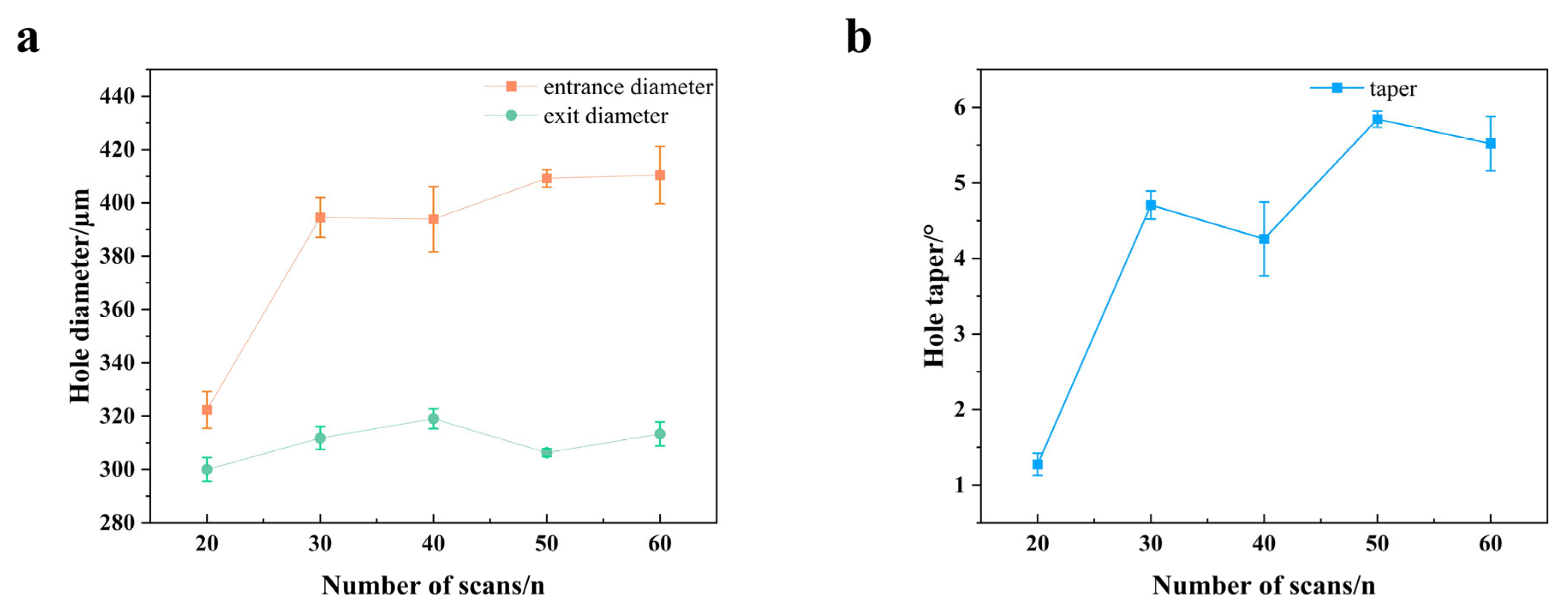

1. The quality of laser-drilled holes is governed by a complex interplay of process parameters. Laser power and defocusing distance are the dominant factors for modulating hole taper; an optimal energy distribution, achieved within the 80–90% power range and at a defocusing distance of zero, is conducive to minimizing taper. However, a trade-off exists for roundness optimization: while a zero defocusing distance benefits the entrance, a slight negative defocusing distance is more effective for the exit. The influence of scanning speed is more intricate, as both excessively high and low speeds are detrimental to roundness, with the highest processing instability observed around 22 mm/s. Furthermore, the number of scans plays a pivotal role. Increasing the number of scans can rectify poor exit roundness caused by insufficient energy input, but an excessive number of scans leads to significant thermal accumulation. This in turn causes a sharp increase in the entrance diameter and taper, thereby degrading the entrance roundness.

2. A key finding of this study is that the optimal process parameters are highly dependent on the specific quality metric being prioritized, highlighting the critical trade-offs in the laser drilling process. For instance, to minimize hole taper, the ideal combination is an 85% laser power, a scanning speed of 26 mm/s, a defocusing distance of 0.0 mm, and a number of scans of 20. In contrast, achieving the minimum hole diameter requires a lower power (75%) and speed (14 mm/s) while keeping the same defocusing distance and number of scans. Furthermore, for applications demanding the highest exit roundness, the process must be tailored again, utilizing 80% power, a high speed of 30 mm/s, a negative defocusing distance of −0.1 mm, and a moderate number of scans (30–50).

3. A positive correlation was confirmed between the scan count and both the height of the recast layer and the extent of dross and spatter. High scan counts result in excessive recast material at the hole orifice. Accordingly, this study proposes a defect control strategy: utilizing the minimum scan count necessary to achieve workpiece breakthrough. This approach prioritizes the integrity of the substrate material by fundamentally reducing the total heat input, thus minimizing recast layer and spatter defects to the lowest possible level.

From an industrial perspective, these findings directly address the limitations of conventional machining, namely tool wear and thermal damage. Although the initial capital cost of picosecond laser systems is significant, their value proposition in manufacturing critical components like turbine blade cooling holes is undeniable. The proposed defect control strategy (using a minimal scan count) enhances both processing quality and efficiency, leading to tangible economic benefits through reduced scrap rates and the elimination of tool-related costs. Ultimately, this work establishes a practical manufacturing framework that effectively bridges the gap between advanced laser technology and its high-quality industrial application.

Author Contributions

Conceptualization, L.W. and K.X.; Methodology, Y.R.; Software, C.W.; Validation, L.X. and C.W.; Formal Analysis, L.X.; Writing—original draft, Y.R.; Writing—review and editing, L.W., K.X., L.X. and C.W.; Supervision, L.W.; Project administration, L.W.; Funding acquisition, L.W. and K.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (grant numbers 52375434 and 52205469), and Major Research Projects of the Natural Science Research Foundation of Jiangsu Higher Education Institutions (grant number 23KJA460003), and the Postgraduate Research and Practice Innovation Program of Huaiyin Institute of Technology (grant number HGYK202508).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, C.; Wang, Q.; Qian, Q.; Di, B. The development of laser drilling: A review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Qingdao, China, 28–29 December 2020; p. 022067. [Google Scholar]

- Wang, S.; Xie, W.; Ding, Y.; Liu, H.; Zhang, X.; Yang, L.; Chen, X.; Chen, M.; Zhang, W.; Lu, Y. Investigations on the Water-Jet Guided Laser drilling film cooling holes on the 8.5 mm-thick TBC superalloy. J. Manuf. Process. 2024, 125, 374–388. [Google Scholar] [CrossRef]

- Xia, K.; Ren, N.; Lin, Q.; Yang, H. Femtosecond laser drilling in superalloy with water-based magnetic assistance. Opt. Commun. 2023, 527, 128902. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C.; Wen, Z.; Yue, Z. Surface integrity and low cycle fatigue behavior of Ni-based single-crystal film with cooling holes processed by ECM, EDM and PLM. Eng. Fract. Mech. 2025, 326, 111378. [Google Scholar] [CrossRef]

- Liu, G.; Li, Y.; Kong, Q.; Tong, H. Research on ECM process of micro holes with internal features. Precis. Eng. 2017, 47, 508–515. [Google Scholar] [CrossRef]

- Tamang, S.; Natarajan, N.; Chandrasekaran, M. Optimization of EDM process in machining micro holes for improvement of hole quality. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 1277–1287. [Google Scholar] [CrossRef]

- Sarfraz, S.; Shehab, E.; Salonitis, K. A review of technical challenges of laser drilling manufacturing process. In Advances in Manufacturing Technology XXXI, Proceedings of the 15th International Conference on Manufacturing Research, London, UK, 5–7 September 2017; Sage: Thousand Oaks, CA, USA; pp. 51–56.

- Antar, M.; Chantzis, D.; Marimuthu, S.; Hayward, P. High speed EDM and laser drilling of aerospace alloys. Procedia Cirp 2016, 42, 526–531. [Google Scholar] [CrossRef]

- Karim, M.A.; Jahan, M.P. Effectiveness of Electrode Design Methodologies for Fast EDM Slotting of Thick Silicon Wafers. Appl. Sci. 2025, 15, 6374. [Google Scholar] [CrossRef]

- Fan, R.; Mei, X.; Cui, J. Process in laser drilling of deep microholes without taper on metal materials. Sci. China Technol. Sci. 2024, 67, 37–59. [Google Scholar] [CrossRef]

- Jia, X.; Chen, Y.; Liu, L.; Wang, C.; Duan, J.a. Advances in laser drilling of structural ceramics. Nanomaterials 2022, 12, 230. [Google Scholar] [CrossRef]

- Tang, Z.-Q.; Li, Y.-F.; Wang, G.; Yu, Y.; Cao, H.; Li, L.-F.; Jin, Z.-S.; Wang, Y.-L.; Lu, Z. Research advances of femtosecond laser drilling microholes in hard and brittle materials. Opt. Laser Technol. 2025, 185, 112572. [Google Scholar] [CrossRef]

- Sahoo, N.; Carvalho, O.; Özcan, M.; Silva, F.; Souza, J.C.; Lasagni, A.-F.; Henriques, B. Ultrashort pulse laser patterning of zirconia (3Y-TZP) for enhanced adhesion to resin-matrix cements used in dentistry: An integrative review. J. Mech. Behav. Biomed. Mater. 2023, 143, 105943. [Google Scholar] [CrossRef] [PubMed]

- Ebenezer, G.; Adam Khan, M.; Winowlin Jappes, J. Influence of short-pulsed laser and its thermal effect on micromachining of NiTi alloy. Sādhanā 2022, 47, 201. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Y.; Li, C.; Xu, B. Numerical simulation and experimental study on picosecond laser ablation of stainless steel. Opt. Laser Technol. 2020, 127, 106150. [Google Scholar] [CrossRef]

- Deepu, P.; Jagadesh, T. A review on short and ultrashort pulsed laser microdrilling: Materials, mechanism, methods, and applications. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 408. [Google Scholar] [CrossRef]

- Račiukaitis, G. Ultra-short pulse lasers for microfabrication: A review. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–12. [Google Scholar] [CrossRef]

- Zhu, H.; Xie, W.; Du, W.; Zhang, Q.; Yuan, H.; Xu, K.; Liu, Y.; Wang, J.; Saetang, V.; Zhang, Z. Fabrication and quality improvement of film cooling holes via picosecond laser drilling assisted by waterjet and post-electrochemical machining. Opt. Laser Technol. 2025, 182, 112162. [Google Scholar] [CrossRef]

- Tang, Q.; Wu, C.; Wu, T. Defocusing effect and energy absorption of plasma in picosecond laser drilling. Opt. Commun. 2021, 478, 126410. [Google Scholar] [CrossRef]

- Wang, H.; Yu, G.; Xin, W.; Wang, Y.; Kong, X. New solution for machining deep high-aspect-ratio micro holes based upon picosecond laser layered trepanning. Opt. Laser Technol. 2025, 189, 113107. [Google Scholar] [CrossRef]

- Liu, C.; Li, C.; Gao, L.; Shen, R. Micro-hole drilling of 2.5 DC/SiC composite with picosecond laser: Numerical modeling and experimental validation on hole shape evolution. J. Manuf. Process. 2022, 81, 852–864. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Zhu, H.; Li, S.; Wang, Y.; Xu, K.; Chu, S.; Huang, J. Mass Fabrication of Microholes in Aviation Kerosene Filters Using the Back-water-assisted Picosecond Laser Drilling Technique. Lasers Eng. 2022, 52, 37. [Google Scholar]

- Kannatey-Asibu, E. Laser Cutting and Drilling. In Principles of Laser Materials Processing: Developments and Applications; Wiley: Hoboken, NJ, USA, 2023; pp. 279–334. [Google Scholar]

- Zhang, H.; Di, J.; Zhou, M.; Yan, Y.; Wang, R. An investigation on the hole quality during picosecond laser helical drilling of stainless steel 304. Appl. Phys. A 2015, 119, 745–752. [Google Scholar] [CrossRef]

- Zhang, H.; Di, J.; Zhou, M.; Yan, Y. A comparison in laser precision drilling of stainless steel 304 with nanosecond and picosecond laser pulses. Chin. J. Mech. Eng. 2014, 27, 972–977. [Google Scholar] [CrossRef]

- Yu, Z.; Hu, J.; Li, K. Investigating the multiple-pulse drilling on titanium alloy in picosecond laser. J. Mater. Process. Technol. 2019, 268, 10–17. [Google Scholar] [CrossRef]

- Sun, X.; Dong, X.; Wang, K.; Wang, R.; Fan, Z.; Duan, W. Experimental investigation on thermal effects in picosecond laser drilling of thermal barrier coated In718. Opt. Laser Technol. 2019, 113, 150–158. [Google Scholar] [CrossRef]

- Weck, A.; Crawford, T.; Wilkinson, D.; Haugen, H.; Preston, J. Laser drilling of high aspect ratio holes in copper with femtosecond, picosecond and nanosecond pulses. Appl. Phys. A 2008, 90, 537–543. [Google Scholar] [CrossRef]

- Tuennermann, A.; Nolte, S.; Limpert, J. Femtosecond vs. picosecond laser material processing: Challenges in ultrafast precision laser micromachining of metals at high repetition rates. Laser Tech. J. 2010, 7, 34–38. [Google Scholar] [CrossRef]

- Spiro, A.; Lowe, M.; Pasmanik, G. Drilling rate of five metals with picosecond laser pulses at 355, 532, and 1064 nm. Appl. Phys. A 2012, 107, 801–808. [Google Scholar] [CrossRef]

- Li, W.; Zhang, R.; Liu, Y.; Wang, C.; Wang, J.; Yang, X.; Cheng, L. Effect of different parameters on machining of SiC/SiC composites via pico-second laser. Appl. Surf. Sci. 2016, 364, 378–387. [Google Scholar] [CrossRef]

- Zheng, Z.; Ma, Y.; Wang, Z.; Liu, S.; Wu, C. Dual-method characterization and optimization of drilling parameters for picosecond laser drilling quality in CFRP. Polymers 2024, 16, 2603. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Z.; Xu, J.; Xu, K.; Ren, Y. An experimental study of micro-machining of hydroxyapatite using an ultrashort picosecond laser. Precis. Eng. 2018, 54, 154–162. [Google Scholar] [CrossRef]

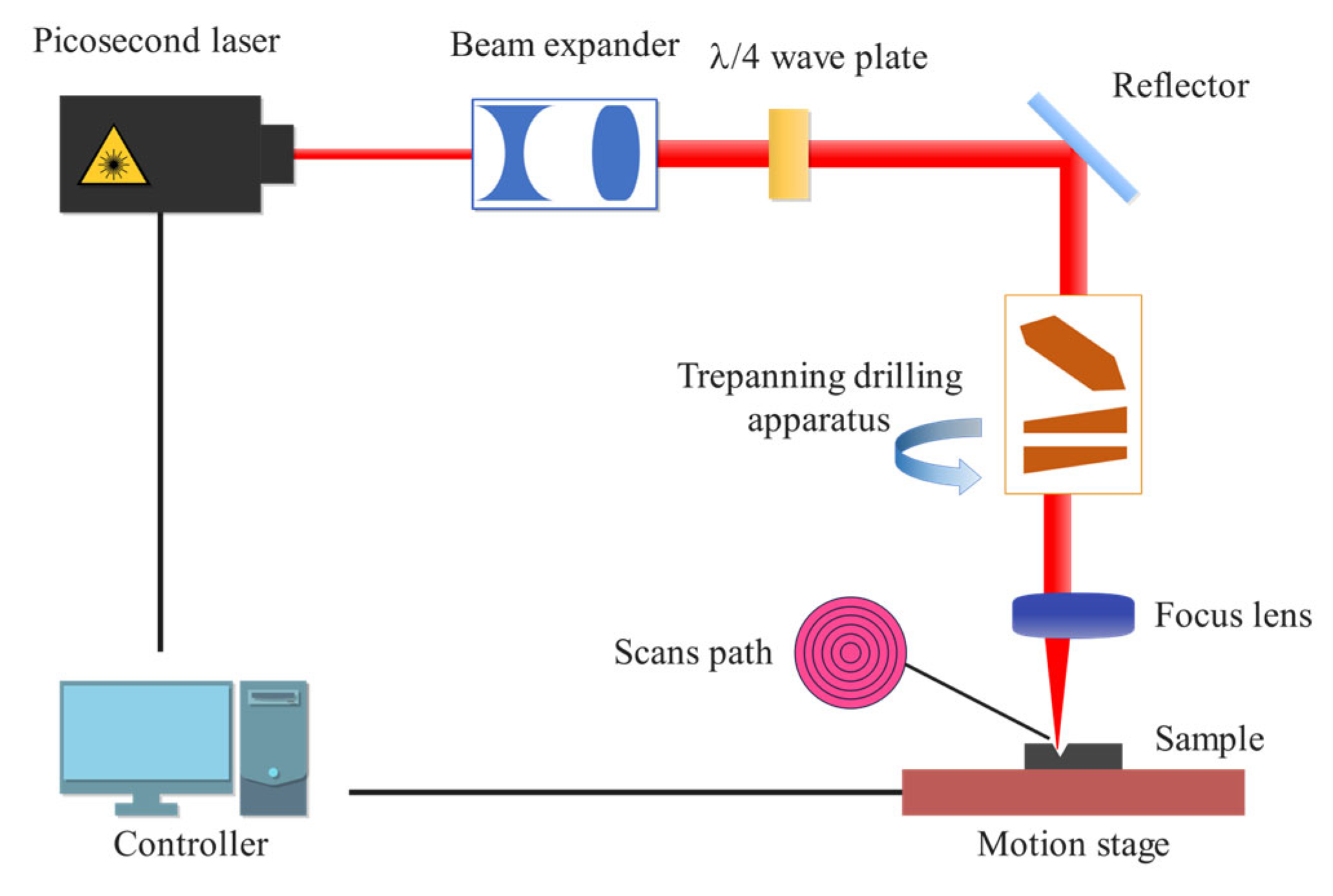

Figure 1.

Laser drilling device.

Figure 2.

Schematic diagram of laser drilling hole. (a) Single-pulse drilling. (b) Multi-pulse percussion drilling. (c) Trepan drilling.

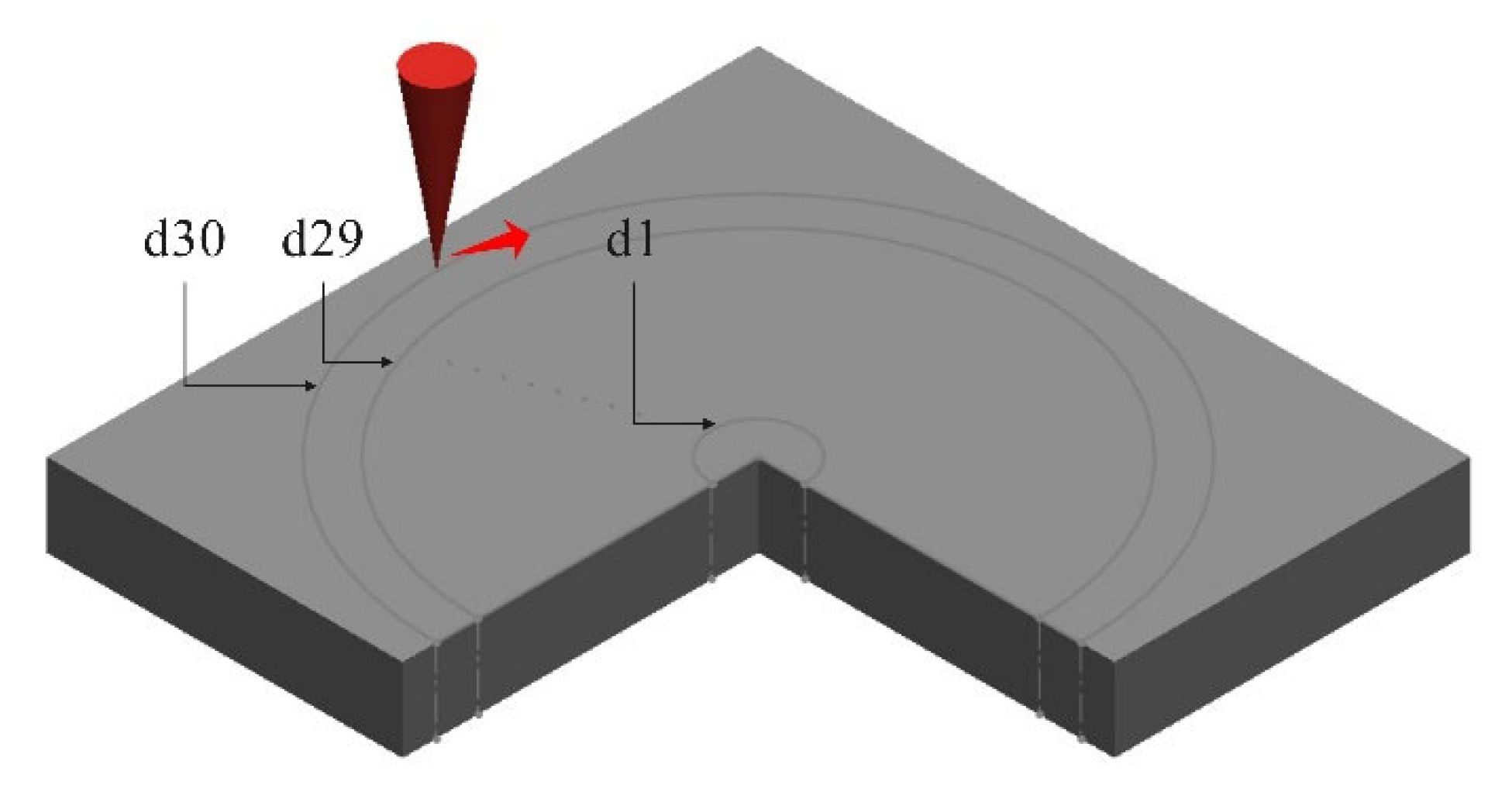

Figure 3.

Scanning path diagram.

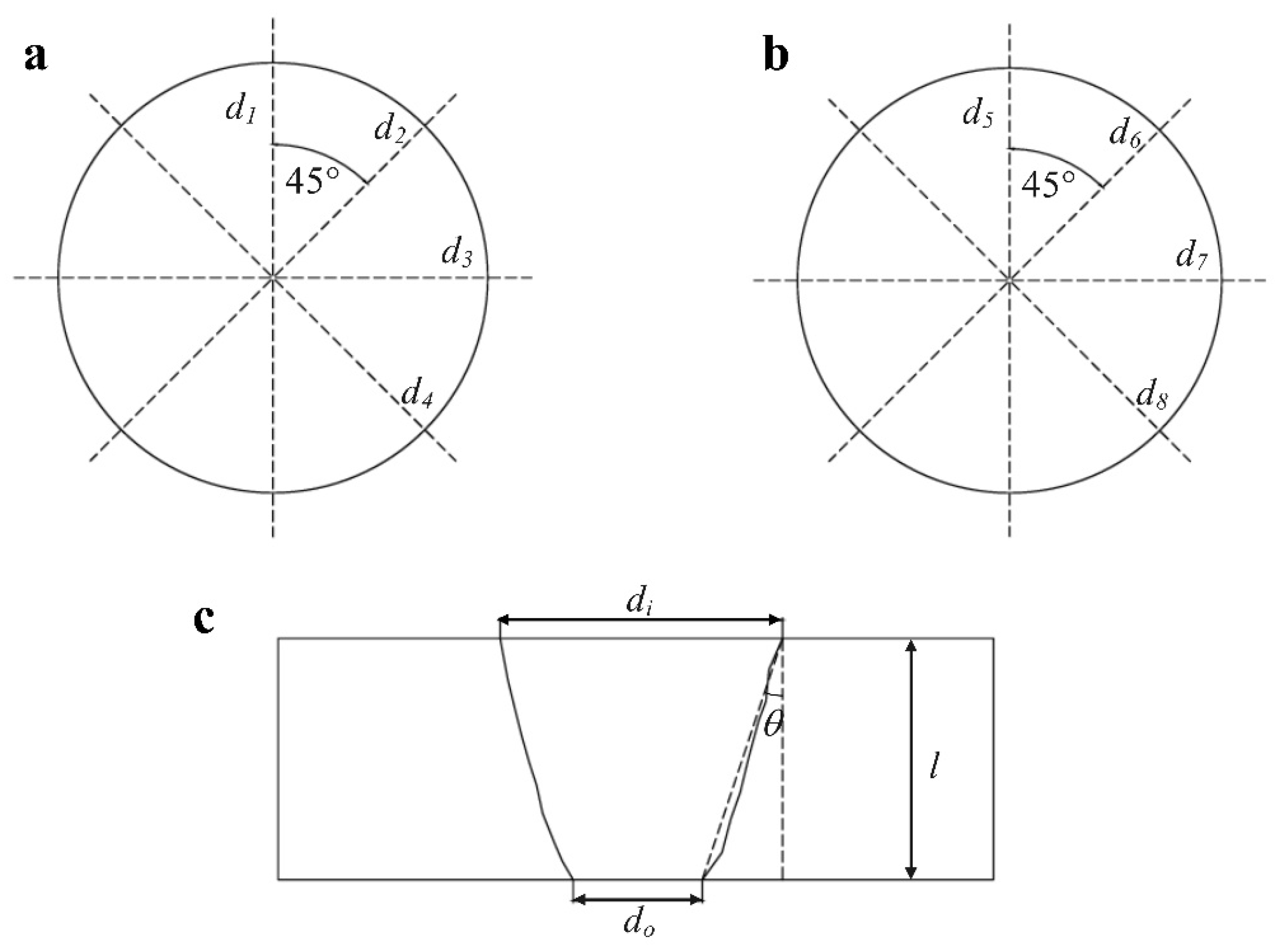

Figure 4.

Micro-hole feature characterization: (a) Entrance diameter, (b) Exit diameter; (c) Taper.

Figure 5.

Effect of laser power on micro-hole morphology. (a) Micro-hole entrance before polishing. (b) Micro-hole exit before polishing. (c) Micro-hole entrance after polishing. (d) Micro-hole exit after polishing.

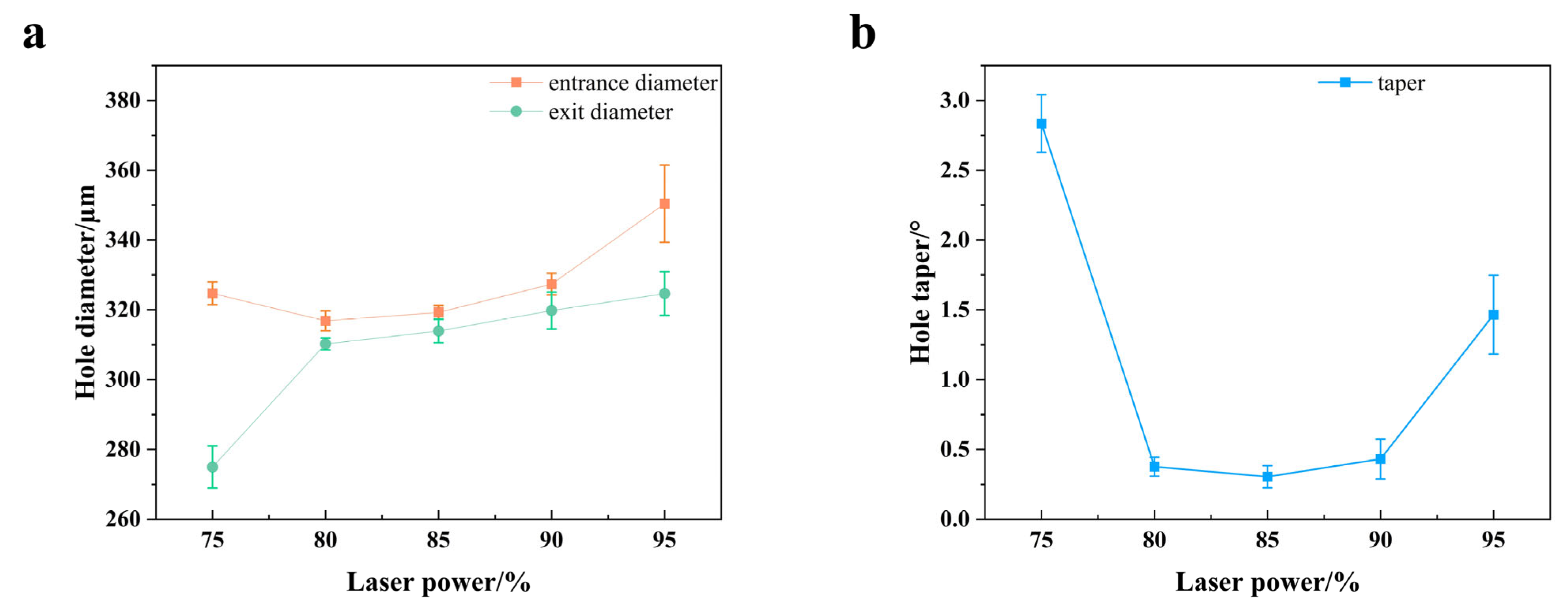

Figure 6.

Effect of laser power on hole diameter and taper. (a) Hole diameter. (b) Hole taper.

Figure 7.

Effect of laser power on hole roundness: (a) entrance; (b) exit.

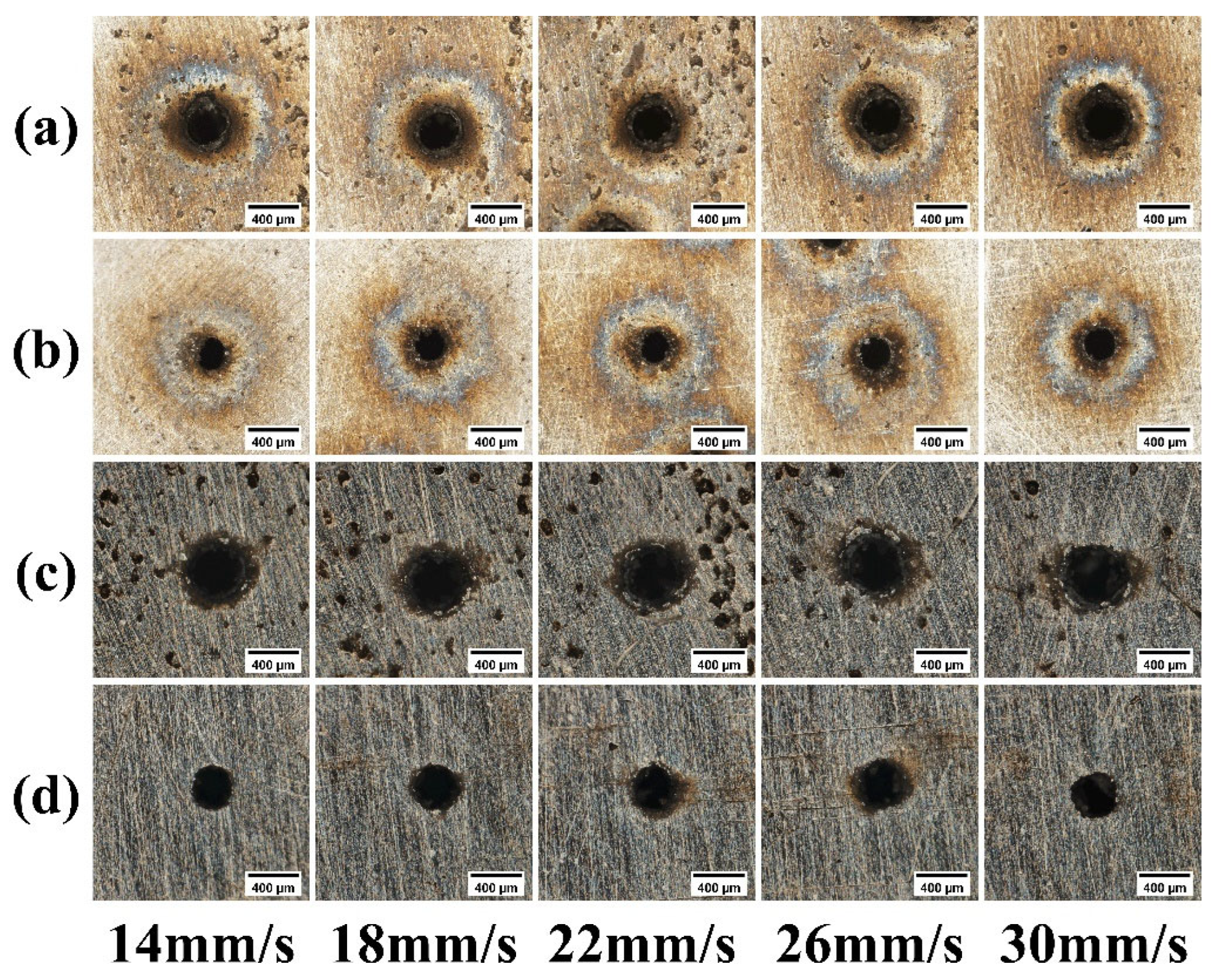

Figure 8.

Effect of scanning speed on hole morphology (a) Hole entrance before polishing. (b) Hole exit before polishing. (c) Hole entrance after polishing. (d) Hole exit after polishing.

Figure 9.

Effect of scanning speed on hole diameter and taper (a) Hole diameter. (b) Hole taper.

Figure 10.

Effect of scanning speed on hole roundness: (a) entrance; (b) exit.

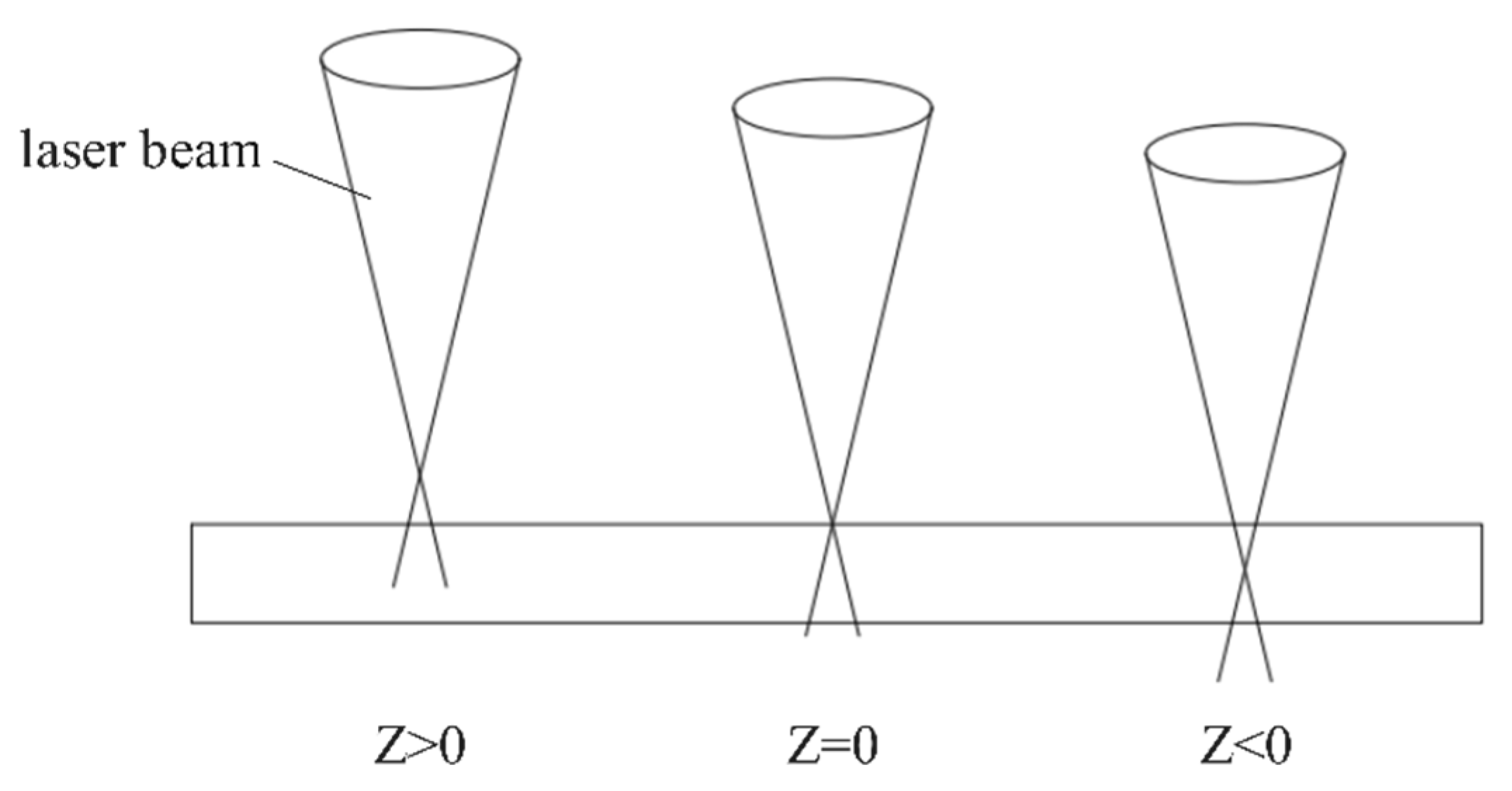

Figure 11.

Schematic diagram of defocusing distance.

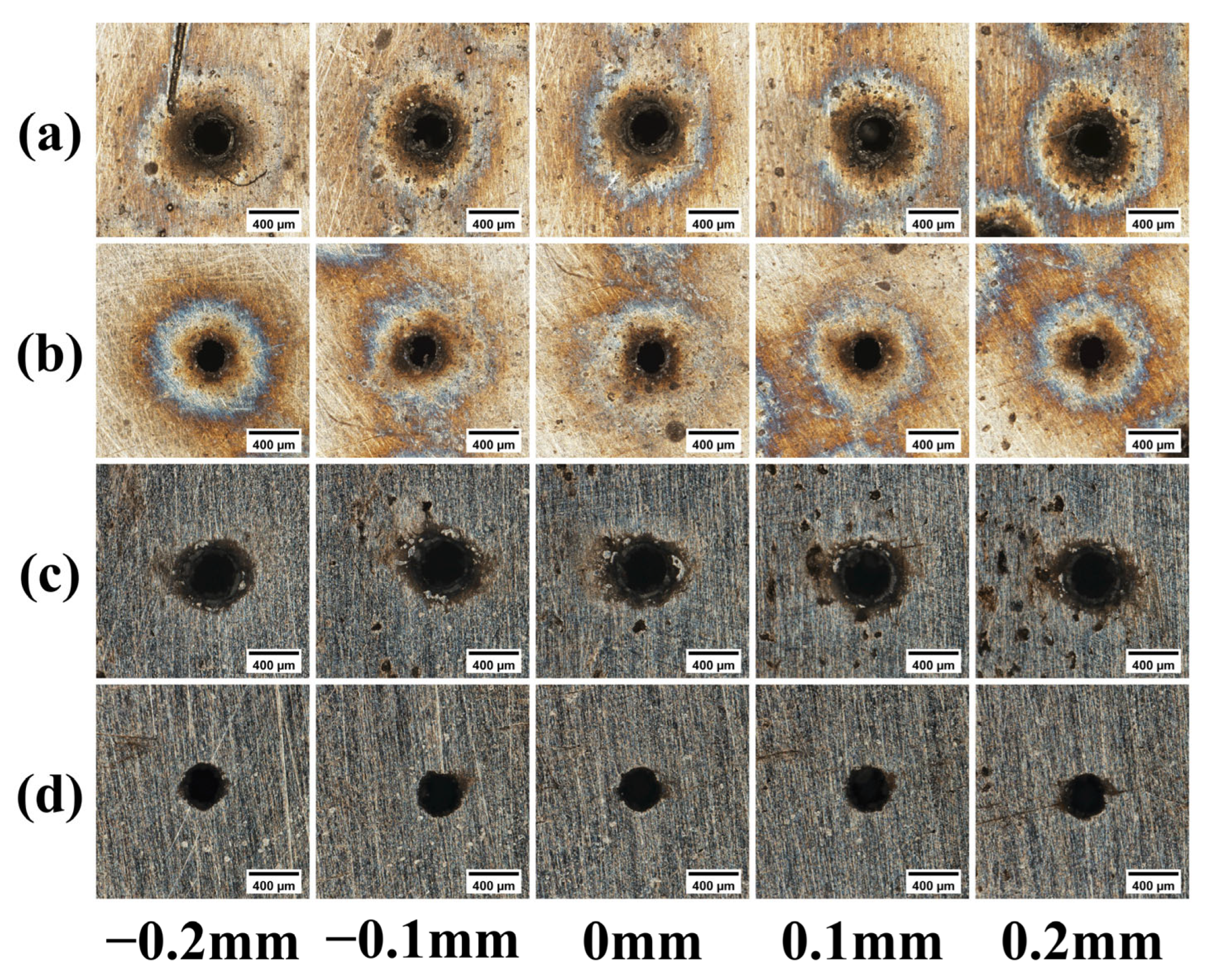

Figure 12.

Effect of defocusing distance on hole morphology (a) Hole entrance before polishing. (b) Hole exit before polishing. (c) Hole entrance after polishing. (d) Hole exit after polishing.

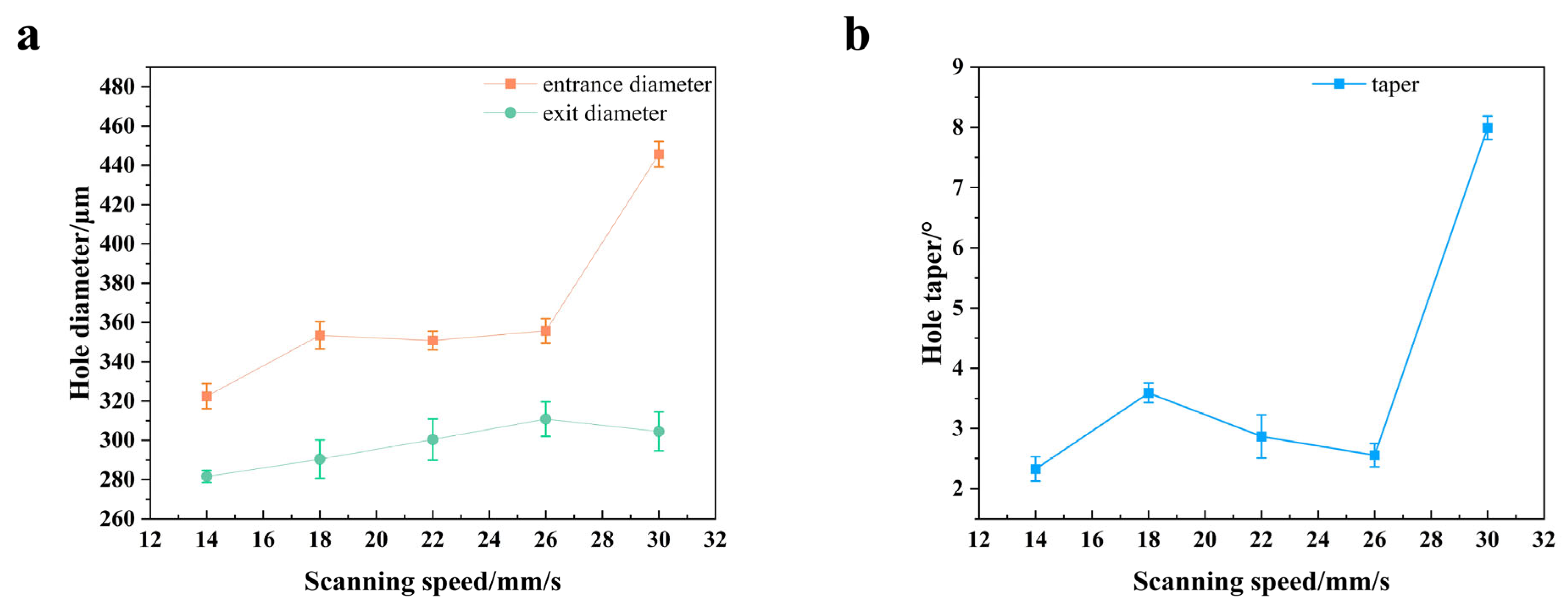

Figure 13.

Effect of defocusing distance on hole diameter and taper (a) Hole diameter. (b) Hole taper.

Figure 14.

Effect of defocusing distance on hole roundness: (a) entrance; (b) exit.

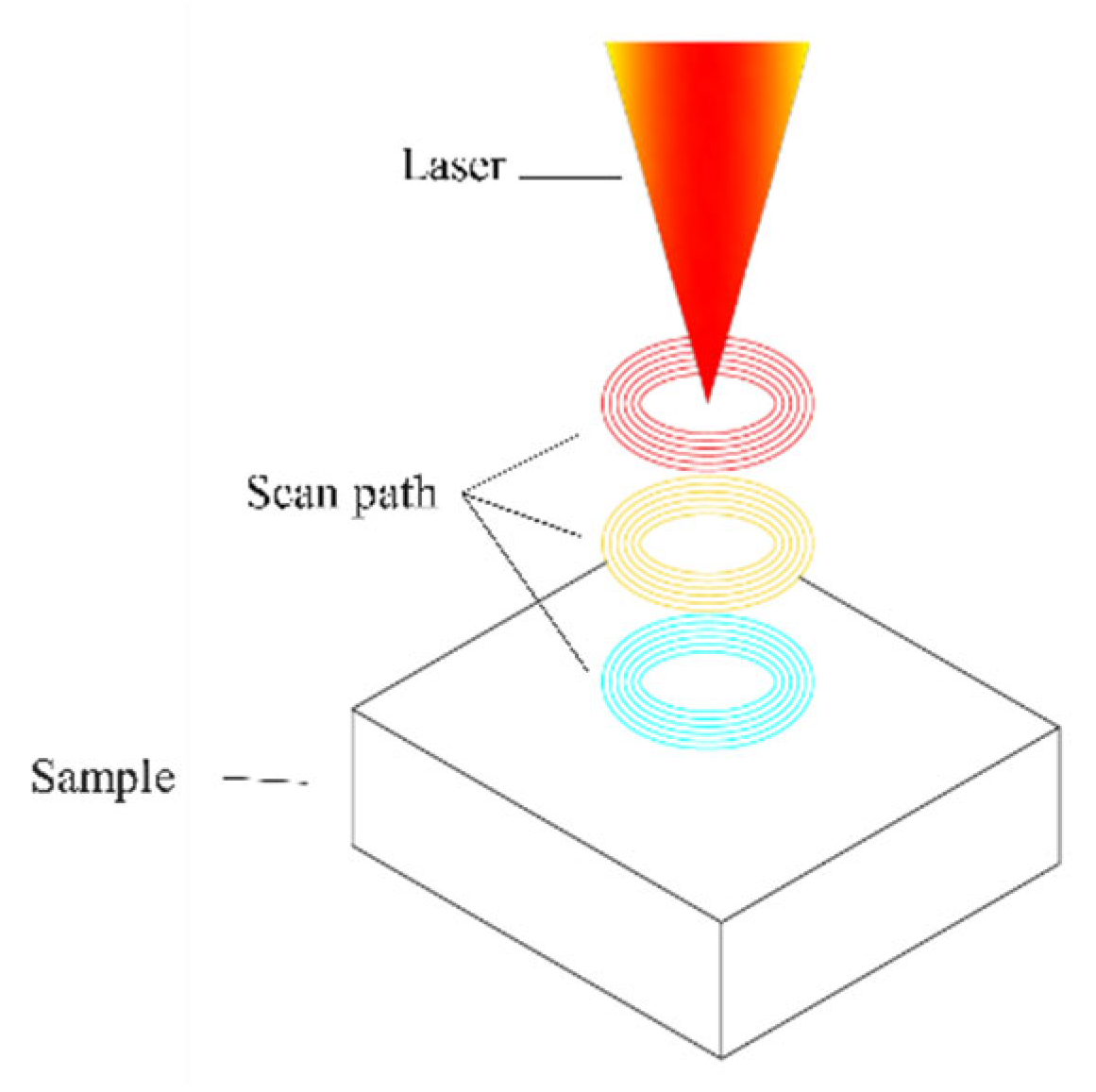

Figure 15.

Schematic diagram of number of scans.

Figure 16.

Effect of number of scans on hole morphology (a) Hole entrance before polishing. (b) Hole exit before polishing. (c) Hole entrance after polishing. (d) Hole exit after polishing.

Figure 17.

Effect of number of scans on hole diameter and taper: (a) Hole diameter; (b) Hole taper.

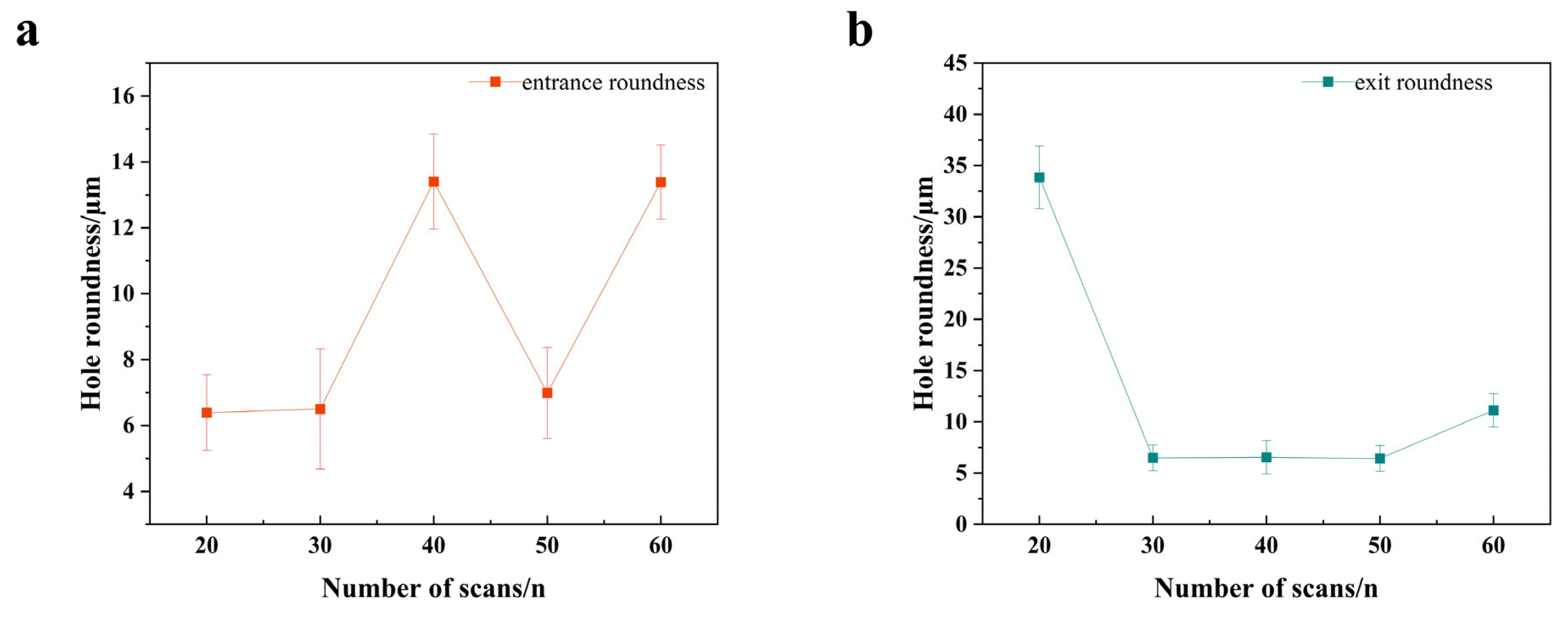

Figure 18.

Effect of number of scans on hole roundness (a) entrance. (b) exit.

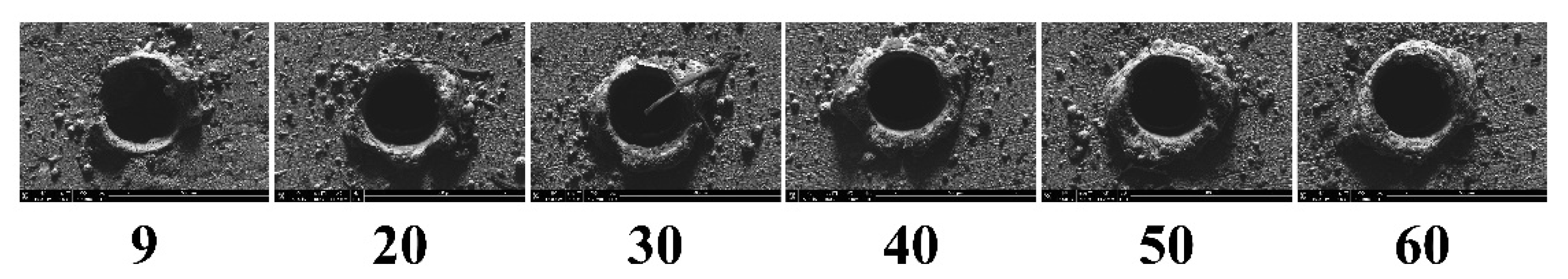

Figure 19.

SEM micrographs of hole entrance morphology under different numbers of scans.

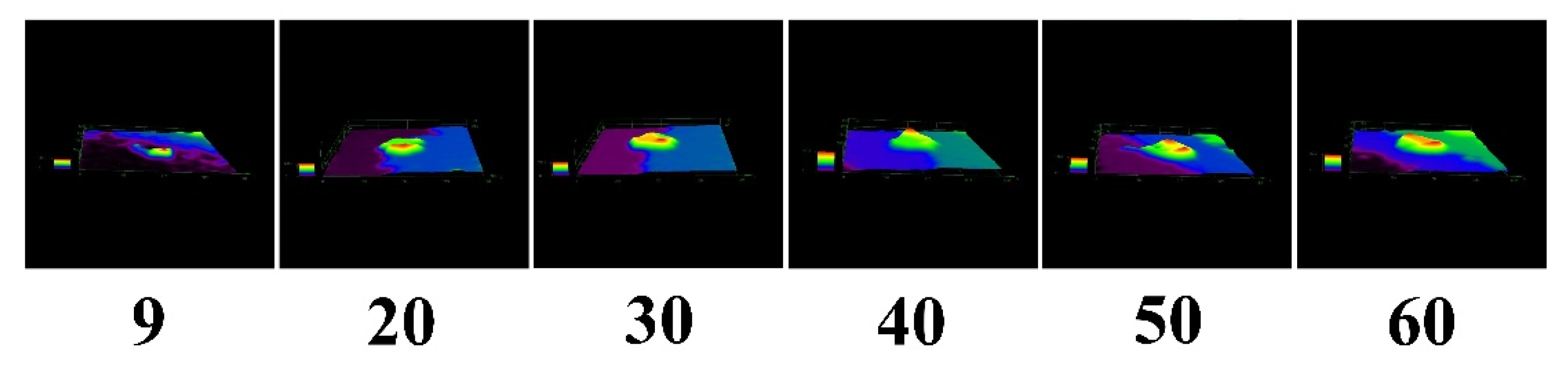

Figure 20.

Resolidification height at hole entrance under different numbers of scans.

Table 1.

Chemical composition of superalloy GH4169.

| Composition | Ni | Cr | Si | Mn | C | Mo | S | P | Fe | Al | Ti | Nb | Co | Cu |

|---|

| Mass Fraction/% | 51.8 | 18.3 | 0.33 | 0.14 | 0.046 | 2.97 | 0.002 | 0.009 | Allowance | 0.58 | 0.95 | 5.15 | 0.34 | 0.07 |

Table 2.

Laser power parameters.

| Laser Power/(%) | Number of Scans/(n) | Scanning Speed/(mm/s) | Defocusing Distance/(mm) |

|---|

| 75/80/85/90/95 | 25 | 25 | 0 |

Table 3.

Scanning speed parameters.

| Laser Power/(%) | Number of Scans/(n) | Scanning Speed/(mm/s) | Defocusing Distance/(mm) |

|---|

| 80 | 25 | 14/18/22/26/30 | 0 |

Table 4.

Defocusing distance parameters.

| Laser Power/(%) | Number of Scans/(n) | Scanning Speed/(mm/s) | Defocusing Distance/(mm) |

|---|

| 80 | 25 | 25 | −0.2/−0.1/0/0.1/0.2 |

Table 5.

Number of scans parameters.

| Laser Power/(%) | Number of Scans/(n) | Scanning Speed/(mm/s) | Defocusing Distance/(mm) |

|---|

| 80 | 20/30/40/50/60 | 25 | 0 |

Table 6.

Resolidification height data.

| Number of Scans/(n). | Recast Layer Height/(μm) * |

|---|

| 9 | 90.1 |

| 20 | 131.6 |

| 30 | 181.2 |

| 40 | 143.5 |

| 50 | 152.2 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).