Abstract

In the process of producing ferroalloys, a large amount of secondary raw materials is formed, including slag, aspiration dusts and sludge. The recycling of secondary raw materials can create resources and bring environmental and economic benefits. Wet secondary raw materials (WSRMs) are characterized by a high chromium oxide content (averaging 24%), but due to their high moisture levels, they cannot be directly used in arc furnaces. As a strategic approach, mixing WSRMs with drier, more chromium-rich dusts (up to 45% Cr2O3) has been proposed. This not only reduces the overall moisture content of the mixture but also enhances the metallurgical value of the charge material. This paper presents the results of laboratory studies on the agglomeration of secondary wet raw materials using briquetting, extrusion and pelletizing methods. The main factors influencing the quality of the resulting product were analyzed, including the method of agglomeration, the composition of the mixture, as well as the type and dosage of the binder component. The strength characteristics of the finished agglomerated samples were evaluated in terms of resistance to splitting, impact loads and falling. Notably, the selected binders are organic and polymer substances capable of complete combustion under metallurgical smelting conditions.

1. Introduction

The production of high-carbon ferrochrome is an energy-intensive metallurgical process in which chrome ore is reduced with carbon-containing materials in alternating current (SAF) or DC electric arc furnaces [1,2,3,4,5]. At the same time, along with the target product—ferrochrome—a significant amount of secondary raw materials is formed in the form of slag, aspiration dust and sludge [6,7,8]. Slag is a valuable raw material for use in the road and construction sectors [9,10,11]. Crushed slag is 1.5–2 times cheaper than natural crushed stone; slag pumice is three times cheaper than expanded clay and requires lower unit costs [12]. Slag utilization is carried out by crushing it and separating the metal component. The resulting crushed material is used as construction crushed stone, while the extracted metal (ferrochrome concentrate) is used to obtain marketable products or concentrate.

The processing of dust generated during the production of ferroalloys can simultaneously solve a number of important problems: it reduces or completely eliminates the negative impact of man-made waste on the atmosphere and water resources, ensures the return of valuable components to the main technological process, helps to reduce the cost of production due to the reuse of raw materials, and also opens up opportunities for the production of new types of products based on industrial waste [13,14].

In the process of ferrochrome production, significant volumes of dust are captured using dry and wet gas cleaning systems installed on electric furnaces. A wet dust collection system is more efficient than dry gas cleaning, but more expensive. In addition, instead of dry dust, secondary raw materials with a moisture content of 15–25% are formed. While the dusts from dry gas cleaning can be returned to the main processing stage and pre-agglomerated if necessary [15,16,17,18,19,20,21], wet secondary raw materials (hereinafter referred to as WSRMs) require forced drying and, in some cases, grinding before agglomeration.

Aspirated dust generated during ferrochrome smelting contains significant amounts of valuable components—primarily oxides of chromium and iron, as well as residual carbon. Due to the presence of Cr and Fe in its composition, such dust fractions are considered potential secondary raw materials for reuse in the metallurgical cycle. However, processing this dust presents a number of technological challenges, including high particle dispersion, hygroscopicity, the presence of oxides in hard-to-reduce forms, and unstable chemical composition. Sludge waste from wet aspiration is particularly difficult to process, as it contains a high proportion of moisture, organic impurities, and poorly filterable fractions.

In line with the concept of sustainable development and closed-loop production cycles, current research focuses on developing effective approaches to the agglomeration of aspirated dust and sludge for their reuse in smelting units [22].

In recent years, increasing attention has been given to dust briquetting and agglomeration methods aimed at returning the material to the main smelting process. One approach to utilizing fine-grained materials is the briquetting of aspirated dust using polymeric binders [23]. In study [24], a method of vibro-briquetting ferrochrome crushing dust followed by remelting was proposed, which demonstrated high briquette strength and a high chromium recovery rate. The authors of [25] demonstrated the effectiveness of agglomeration methods for aspirated waste using both organic and inorganic binders, resulting in durable shaped products resistant to transportation and thermal impact.

Thus, the development of effective methods for processing aspirated dust is a relevant task that contributes to reducing environmental impact, improving resource efficiency in production, and ensuring comprehensive utilization of mineral raw materials.

WSRMs, with an average chromium oxide content of 24%, are considered unsuitable for direct metallurgical processing. One possible solution to this problem is the introduction of dry dusts rich in Cr2O3 into the WSRM. This addition not only reduces the overall moisture content of the resulting mixture, but also increases the concentration of chromium oxide in it. Then, the only unresolved issue is the choice of the most effective method for agglomeration of the mixture of dry and wet gas cleaning dust. According to research data [26], WSRMs have more than twice the developed specific surface area compared to dry gas cleaning dusts. The developed surface of the WSRM contributes to the increased adhesion of the material, which improves its suitability for the agglomeration process.

Thus, the purpose of this work is to select the optimal method and technological parameters for cold agglomeration of a mixture of wet secondary materials and dry dusts, with the selection of appropriate binders (M400-grade cement, bentonite clay powder, polyacrylamide-based binder, epoxy resin-based polymer binder and modified lignosulfonate-based binder).

2. Materials and Methods

In order to carry out laboratory studies on the development of the WSRM cold agglomeration technology in a mixture with rich aspiration dust during the smelting of high-carbon ferrochrome in an open-type ore-thermal furnace (hereinafter referred to as dust No.1) and aspiration dust after drying chrome ore (hereinafter referred to as dust No.2) in the laboratory, the following conditions were adopted: the ratio of materials in the agglomeration mixture to dry weight: WSRM: 48%; dust No.1: 8%; dust No.2: 44%. The ratio of materials is related to the volume of education in real production. The chemical composition of the materials used is given in Table 1.

Table 1.

Chemical composition of agglomeration materials.

Before starting work, the wet secondary material was dried to a residual moisture content of 0.5% and ground in a rod mill to a fraction of less than 0.5 mm.

The following materials were used as binders:

- M 400 cement.

- Bentonite clay powder.

- Polyacrylamide binder (PAA).

- Polymer binder based on epoxy resins (PB).

- Binder based on modified lignosulfonate (LM).

2.1. Method of Briquetting on a Laboratory Press

The dosage of dust and binder was carried out by weight. The initial mixing of the components was carried out in a dry state for 5 min with a KENWOOD KVC51 laboratory mixer (Kenwood Limited, Havant, UK). Then water was added, and the wet mixture was stirred until the water was completely distributed throughout. A cylindrical mold with a diameter of 30 mm was used for briquetting. The finished mixture was poured into the mold in portions, and briquetted on a hydraulic press IP-1000 (LLC ZIM Tochmashpribor, Armavir, Krasnodar Region, Russia) with a pressing force of 2.9 kN/cm2. The specified pressing force was selected based on the characteristics of industrial hydraulic presses. The appearance of the manufactured briquettes is shown in Figure 1.

Figure 1.

Appearance of finished briquettes.

Some of the finished briquettes were subjected to forced drying at a temperature of 120 °C for 3 h to a residual moisture content of less than 0.5%. The rest of the briquettes were dried under natural conditions (20–25 °C, air humidity 50–75%) for 3 days.

2.2. Vibrobriquetting Technique

The vibrocompression method is considered as one of the promising areas of agglomeration [27], since molding is carried out due to the simultaneous impact of vibration and pressure on the initial mixture. In the process of vibration, the material particles spontaneously occupy an optimal position, which excludes the appearance of internal stresses and elastic deformations. At the same time, the specific pressure on the mixture remains low—no more than 2 MPa. From an energy point of view, this technology is highly economical. Its main advantages include high productivity (up to 50 t/h), no waste, environmental safety, low energy consumption, full automation of the production process and minimal time spent on production.

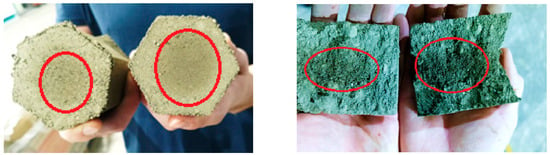

The materials for vibrobriquetting were weighed separately, then loaded into a BP-1G-100 single-screw mixer (JSC Schneider Electric, Moscow, Russia), and dry stirring was carried out for 7 min. Next, water was added, and wet mixing was continued until the water was evenly distributed over the entire volume of the mixture (about 7 min). After that, the press itself was turned on, and briquettes were made. The diameter of the briquettes at the vertices of the hexagon was 80 mm; the height of the briquette was also 80 mm. As in the above work, the briquettes were subjected to forced drying at a temperature of 120 °C for 5 h and under natural conditions for 3 days. It is important to note that the increase in forced drying time to 5 h was due to the presence of an insufficiently dried area in the center of the briquettes after 3 h of drying (highlighted in red in Figure 2).

Figure 2.

Appearance and middle of finished briquettes.

2.3. Extrusion Technique

The method of dust extrusion in ferroalloy production consists of the creation of extrusion briquettes (hereinafter referred to as brax) by compacting the mixture with a screw and removing air and excess moisture between the particles of the material by pressing through a spinneret with round holesshape and size of the die holes. This contributes to denser packaging and the production of strong braxes [28,29,30]. The length of the braxes is determined by their density and ductility and the shape and size of the die openings. As a result of the increase in bending moment, which occurs under the influence of the increasing weight of the braxes as their length grows when leaving the die, the braxes break off. For extrusion, a mixture was prepared, identical to that used for briquetting on a hydraulic press. The finished mixture was passed through a screw granulator of the FSh-004RK02 brand (hereinafter referred to as the extruder) with a spinneret channel diameter of 16 mm. After forming, some of the braxes were subjected to forced drying at a temperature of 120 °C for 3 h. The other part of the braxes was dried under natural conditions for 1 and 3 days. The appearance of the braxes is shown in Figure 3.

Figure 3.

Appearance of braxes.

2.4. Pelletizing Method on a Disk Granulator

Before the start of work, a separate weighing of dry materials was carried out. The total weight of the dry mixture was 5 kg.

The mixture preparation process consisted of two stages. In the first stage, the mixture of dry raw materials with a binder was mixed for 5 min on a BP-1G-100 single-screw mixer (JSC Schneider Electric, Moscow, Russia). In the second stage, a small amount of water was added to the mixture (the amount was selected separately for each type of binder), after which the already moistened mixture was passed through a sieve with a mesh size of 1 × 1 mm to destroy the formed lumps and obtain a homogeneous consistency.

At the end of the preparatory work, the pelletizing process was carried out. The angle of inclination of the tray of the granulator GT-06 (LLC RKF Proterm, Rybinsk, Russia) was 45° and the rotation speed 25–30 rpm. If necessary, during the granulation process, it was allowed to wet the mixture with a spray bottle. The volume of additional moisture was taken into account at the end of the experiment.

The resulting pellet fractions were sieved through sieves with mesh sizes of 12 × 12 mm and 14 × 14 mm (Figure 4). The pellets were unloaded and laid out in metal pallets in a single layer. One part of the finished pellets was dried in a drying oven at a temperature of 120 °C until the moisture was completely removed, followed by the determination of their fracture strength. The other half of the finished pellets was dried under natural conditions with the determination of fracture strength measurements after 1 and 3 days. Laboratory presses RB-1000 and IPG-1M depending on the strength of pellets.

Figure 4.

Finished pellets fraction 12–14 mm.

2.5. Methods for Determining Strength Characteristics

The splitting strength of finished briquettes, braxes and pellets was determined in accordance with State Standard 24765-81 using the RB-1000 automatic press with a maximum load capacity of 1000 kgf, which applies a continuously increasing load until destruction occurs [31]. To determine compressive strength, 10 samples of each type of agglomerated material were selected. Each sample was placed in the press, and the maximum load at the point of destruction was recorded.

The drop strength was assessed according to State Standard 25471-82 [32]. A 10 kg sample of each agglomerated material was taken, placed in a container at a height of 2 m, and subjected to three consecutive drops onto a metal surface. After the third drop, the sample was sieved through screens with openings of +5 mm and −0.5 mm. The drop strength index was calculated based on the percentage distribution of the material retained on each sieve.

Impact and abrasion strength were determined in accordance with State Standard 15137-77 [33]. This method is based on mechanical treatment in a rotating steel drum, followed by sieve analysis to evaluate changes in the particle size distribution, which characterizes the ability of the agglomerated products to resist impact and abrasion. A 10 kg sample was loaded into a steel drum with a diameter of 1000 mm rotating at 25 rpm. After a specified rotation period, the sample was discharged and sieved through +5 mm, 0.5–5 mm, and −0.5 mm screens. Each fraction was weighed separately, and the strength index was calculated using the following formula

where

- I—strength index, %

- M+5—mass of the fraction greater than 5 mm

- Mtotal—initial mass.

The +5 mm fraction indicates impact resistance, while the −0.5 mm fraction indicates the abrasion resistance of the samples.

3. Test Results

The results of measuring strength indicators, compositions and briquetting parameters are presented in Table 2. Measurement of the strength of briquettes with a diameter of 30 mm obtained on a hydraulic press for splitting is shown in Figure 5.

Table 2.

Briquetting parameters and splitting strength of briquettes.

Figure 5.

Splitting strength test of briquettes.

According to the results obtained, the highest fracture strength was achieved using a binder based on polyacrylamide (PAA) (option No.4).

Based on the results of Table 2, the option with the highest strength indicators (No.4) was chosen for the production of a batch of briquettes on a vibropress in the amount of 60–80 kg with subsequent forced and natural drying.

The measurements of the strength characteristics of the developed briquettes, regardless of the method of drying, showed extremely unsatisfactory results. The fracture strength, as well as impact and abrasion strength, were below the limit of the determination of the devices. One of the possible reasons for the results obtained may be insufficient plasticity of the mixture.

Taking into account this fact, it was decided to replace the polymer binder (PAA) with an organic binder (LM) and repeat the vibrobriquetting tests.

The results of measuring the strength indicators and the composition of briquettes are presented in Table 3.

Table 3.

Results of strength characteristics of briquettes.

This type of briquetting showed higher strength indicators compared to the previous one. In general, according to the results of laboratory experiments, it was revealed that regardless of the types of binders used and the parameters of briquetting equipment, it was not possible to achieve the target indicators for the strength characteristics of briquettes. This is because, firstly, vibrocompression works better with coarser materials than pulverized mixtures. In fine materials, vibration can cause them to “float” rather than compact. Secondly, as mentioned above, in vibropresses, the pressure is insufficient to compact the particles of the mixture. As a result of the low molding pressure, air is not fully removed from the briquette, leading to a loose fit between the particles of raw materials and binders.

After drying the braxes, their fracture strength was measured (Figure 6). The results of measuring strength indicators, compositions and extrusion parameters are presented in Table 4.

Figure 6.

Splitting strength test of braxes.

Table 4.

Extrusion parameters and splitting strength of braxes.

According to the results obtained, high fracture strength was achieved with the use of binders such as PAA and PS (versions No.3 and 5), regardless of the drying method.

In other mixtures, certain drying conditions or an increase in the consumption of binder material are required to achieve acceptable splitting strength. For example, when using bentonite, an increase in its consumption and only forced drying are required. The same conditions are required when combining bentonite and polymer binders.

After assessing the results of the split strength, a batch of braxes was produced according to options No.3 and 5 (using PAA and PS binders at a consumption of 1%). Some of the braxes were dried under natural conditions, some through forced drying. At the end of the drying operations, the discharge, impact and abrasion strength were measured. The extrusion parameters and strength indicators are presented in Table 5 below.

Table 5.

Results of the strength characteristics of braxes.

From the data obtained (Table 4 and Table 5) it can be seen that the use of polymer binders of the PAA and PB types makes it possible to obtain braces with high strength characteristics.

To determine the strength characteristics of pellets, 10 samples of pellets of 12–14 mm fraction were taken from each series of the experiment. Images of the obtained pellets are shown in Figure 7. The results of the strength characteristics of pellets are presented in Table 6.

Figure 7.

Appearance of raw pellets.

Table 6.

Pelletizing parameters and splitting strength of pellet.

Based on the results of Table 6, it can be concluded that the highest splitting strength is achieved with the use of LM binder material with a flow rate of 2% and 3%. The strength of dried pellets under natural conditions for 3 days and forcibly dried pellets in a drying oven reaches 45–50 kgf/pellet. Pellets using all other types of binders turned out to be less durable, and were destroyed by a force that did not reach ~10 kgf/pellet on average. In addition to the high strength of the resulting pellets using lm, the use of this type of binder differs from other binders by a high degree of clumpability, which is one of the main indicators characterizing the pelletizing process.

It should be noted that despite the same granulation conditions for all types of binders (the disk pelletizer tilt angle was 45°, with a rotation speed of 25–30 rpm.), the pelletizing process was not always stable. When using PAA and PB type binders, the mixture granulation process did not take place at all. The charge stuck to the surface of the pellet tray, thereby disrupting the process of pellet formation. The reduction in binder consumption and mixture moisture did not lead to the stabilization of the pelletizing process.

A series of experiments using binders such as Bentonite, PS, as well as a combination of binders Bentonite/LM, PAA/Bentonite and PB/Bentonite, despite the stable pelletizing regime, have a lower yield of suitable pellets, and the strength is several times lower than the strength of pellets using LM.

Based on the results of a series of tests, LM with an addition of 3% of the dry charge weight was chosen as the main binder. Next, a batch of pellets in the amount of 20 kg was produced with subsequent forced and natural drying. During the pelletizing process, additional moisture was introduced as required for the formation of strong granules. The total moisture content values are presented in the “Moisture” column of Table 7 and Table 8: value “6” corresponds to the moisture added during the initial mixing of the charge, while value “3” refers to the additional moisture introduced during the pelletizing stage. After working out a batch of pellets using LM, their strength characteristics were measured. In addition to the listed strength indicators, the splitting strength of raw pellets was also determined after drying in natural conditions for 1 and 3 days, as well as after the complete removal of moisture in a drying oven. Figure 8 shows photos of pellets after discharge tests, impact and abrasion. The parameters and results of determining the strength characteristics of the pilot batch are presented in Table 7 and Table 8.

Table 7.

Splitting strength of raw and dried pellets.

Table 8.

Drop resistance, impact strength, and abrasion resistance of pellets dried at 120 °C.

Figure 8.

Appearance of pellets after tested drop, impact and abrasion.

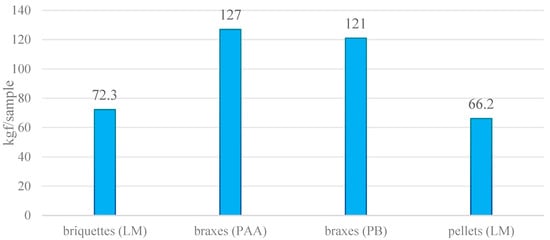

According to the data in Table 7, the green pellets have a splitting strength of 6.51 kgf/pellet, while the dried ones range from 53.0 to 66.2 kgf/pellet. Considering these results, the pellets dried by forced convection at 120 °C were selected for testing drop resistance, impact strength, and abrasion resistance (Table 8), since the pellets dried under ambient conditions exhibited low splitting strength. The resulting pellets have 100% drop strength and 96.9% impact strength.

The resulting pellets have 100% drop strength and 96.9% impact strength.

4. Results and Discussion

In this work, the following methods of agglomeration were investigated—briquetting, extrusion and pelletizing using different types of binders in different ratios.

Laboratory studies show that WSRMs can be returned back to the metallurgical processing for ferrochrome smelting after drying the raw materials and agglomerating them. In the course of laboratory experiments, it was found that extrusion and granulation are acceptable technologies for agglomerating WSRMs.

The best results were obtained with the use of polymer binders (PAA, PB) and organic binders of vegetable origin (LM). The use of these types of binders provides higher mechanical strength for splitting, impact and abrasion resistance. The use of binders in the form of bentonite and cement did not lead to the required strength characteristics of the resulting agglomerated products.

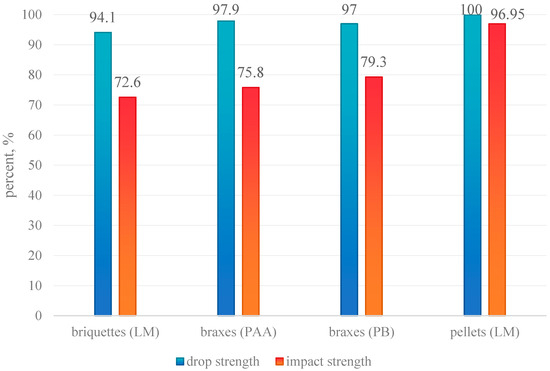

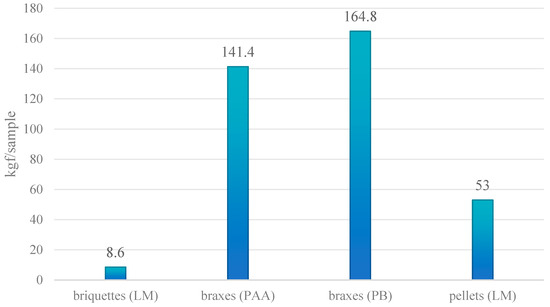

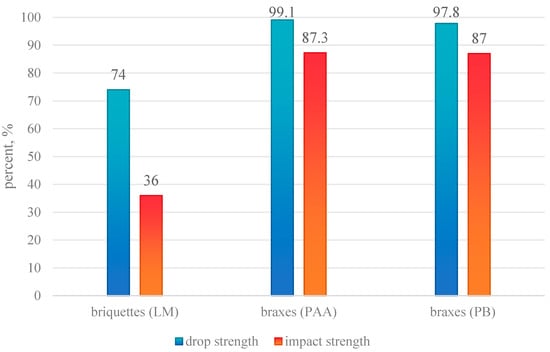

A comparative assessment of mechanical properties shows that agglomerated products exhibit higher strength indicators after forced drying at 120 °C (Figure 9 and Figure 10). An exception is extrusion agglomeration, in which briquettes gain strength more effectively in natural conditions (Figure 11 and Figure 12), characterized by high splitting strength values—141.4 kgf/briquette (PAA briquettes) and 164.8 kgf/briquette (PB briquettes). This phenomenon is explained by the gradual removal of moisture, which helps avoid temperature gradients and microcracks. This, in turn, indicates the ability of the briquettes to maintain integrity under destructive loads occurring during transferring or movement of the layer in the furnace. Briquettes require 30 to 36 h to fully gain strength exceeding the levels necessary for transportation and charging into a submerged electric arc furnace. The resulting pellets demonstrate 100% strength in drop tests and possess impact strength at the level of 96.9%. According to the results of the study, the briquettes and pellets adequately withstand impact loads and maintain integrity during testing. The high strength characteristics of the braxes may be attributed to the fact that polymer binders possess adhesive and film-forming properties, which, in a moist environment, are evenly distributed over the particle surfaces, forming viscoelastic films. During the extrusion process, polymer binders (PAA, PS) are further activated by shear stress and friction, enhancing interparticle adhesion. They also impart viscoplastic properties to the mixture, which are essential for passing through the die and ensuring uniform density throughout the material. Braxes based on polymer binders do not crack due to internal stresses.

Figure 9.

Results of splitting test after forced drying at 120 °C.

Figure 10.

Results of drop and impact strength tests after forced drying at 120 °C.

Figure 11.

Results of splitting test during natural drying (3 days).

Figure 12.

Results of drop and impact strength tests during natural drying (3 days).

As for the pellets, the LM organic binder increases the pelletizing ability of the mixture, facilitating the formation of pellets with a dense core and porous shell. In addition, LM improves the wettability and plasticity of the granulated mixture, which is particularly important for maintaining process stability on a disk pelletizer.

5. Conclusions

Thus, the results of the conducted agglomeration tests of ferrochrome production waste (WSRM) show the following:

- -

- Agglomeration of WSRMs mixed with rich dusts using the vibro-pressing method, regardless of the amount of binder used, does not make it possible to obtain briquettes with the required strength characteristics for further metallurgical processing;

- -

- The use of extrusion and granulation methods makes it possible to obtain agglomerated products in the form of briquettes and pellets, whose strength indicators fully meet the requirements for agglomerated materials used in ferrochrome production;

- -

- The use of polymer (PB) and organic (LM) binders, which possess burnout properties at high temperatures, does not dilute the chromium-containing raw materials, allowing for the production of agglomerated material with a chromium oxide (Cr2O3) content of no less than 35%. The light hydrocarbon fractions of the organic and polymer binders combust at temperatures of 500–650 °C, while the remaining carbon framework contributes to the formation of a porous structure in the material and provides a reducing potential during metallurgical smelting.

The extrusion and granulation methods for WSRMs combined with enriched dusts using organic and polymer binders, as proposed in this study, offer several significant advantages over traditional high-temperature agglomeration methods:

- -

- These methods enable efficient processing of fine-grained wastes of varying particle sizes and moisture content, including WSRM, without requiring complete pre-drying;

- -

- Agglomeration is carried out at low temperatures, which significantly reduces energy consumption during the preparation of secondary raw materials compared to the firing of pellets and sinters;

- -

- The absence of high-temperature processing minimizes the formation of toxic gases and reduces atmospheric emissions;

- -

- The resulting braxes and pellets exhibit high mechanical strength, are resistant to transport, and do not disintegrate when fed into the furnace melting zone.

From a practical perspective, the proposed solutions not only reduce the volume of metallurgical waste generated during ferrochrome production but also allow valuable elements (Cr, Fe, C) contained in WSRMs and aspirated dust to be reintroduced into the production cycle.

Author Contributions

Conceptualization, N.U. (Nursultan Ulmaganbetov), S.L. and A.A.; methodology, M.J., S.L. and A.J.; software, M.J., N.U. (Nurbala Ubaidulayeva) and R.A.; validation, N.U. (Nurbala Ubaidulayeva) and R.A.; formal analysis, M.A. and A.A.; investigation, M.A., N.U. (Nursultan Ulmaganbetov) and S.L.; resources, A.J.; data curation, Y.S. and R.A.; writing—original draft preparation, M.J.; writing—review and editing, Y.Z., Y.S. and A.A.; visualization, N.U. (Nursultan Ulmaganbetov), A.J. and N.U. (Nurbala Ubaidulayeva); supervision, Y.Z. and M.A.; project administration, Y.S.; funding acquisition, Y.Z. and Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. BR24992882).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Maral Almagambetov, Maulen Jundibaev, Nursultan Ulmaganbetov and Salamat Laikhan were employed by the ERG Research and Engineering Center. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationship that could be construed as a potential conflict of interest.

References

- Oterdoom, H.; Reuter, M.; Zietsman, J. DC Ferrochrome Smelting: The Arcing Zone and Its Influence on Energy Transport and Exergy Dissipation. Metall. Mater. Trans. B 2025, 56, 890–912. [Google Scholar] [CrossRef]

- Yessenzhulov, A.; Abdulabekov, E. The New and Reconstructed Facilities at the Enterprise TNK Kazchrome JSC. In Proceedings of the Best Available Technologies for Steel and Ferroalloys Production, Moscow, Russia, 14 October 2020. [Google Scholar]

- Shabanov, E.Z.; Saulebek, Z.K.; Akhmetov, A.S.; Mukhtarkhanova, G.K. Smelting of High-Carbon Ferrochromium from Pre-Reduced Chromite Raw Materials. CIS Iron Steel Rev. 2024, 27, 15–19. [Google Scholar] [CrossRef]

- Kapan, S.; Çamdali, Ü.; Celik, N. Determination of the Mass Balance of High-Carbon Ferrochrome in a Submerged Arc Furnace. High Temp. Mater. Processes 2024, 28, 1–8. [Google Scholar] [CrossRef]

- Raj, H.; Paswan, D.N.; Jha, S.K. Optimization of Process Parameter for Smelting and Reduction of Ferrochrome. Int. J. Eng. Res. Technol. 2016, 5, 509–513. [Google Scholar]

- Jundibayev, M.K.; Myrzagaliev, A.A. Review of methods for agglomeration of chromium-containing dust and gas-cleaning sludge in ferrochrome smelting. Bull. Aktobe Reg. Univ. K. Zhubanov 2025, 1, 235–241. [Google Scholar]

- Zhuchkov, V.I.; Zayakin, O.V.; Sychev, A.V. Slags and Dusts of Ferroalloy Production. Russ. Metall. Metally 2020, 2020, 662–666. [Google Scholar] [CrossRef]

- Ajay, C.; Durga, R. Sustainable Use of Ferrochrome Slag and Quarry Dust Composites as Cement-Bound Layers of Flexible Pavement. Glob. NEST J. 2024, 26, 1–9. [Google Scholar] [CrossRef]

- Zapate, V.; Patil, V.A.; Takkalaki, S.R.; Sawant, R.S. Effect of Ferrochrome Slag as Partial Replacement of Coarse Aggregate on Strength and Durability of Concrete. Int. Eng. J. Res. Dev. 2023, 8, 7. [Google Scholar]

- Al-Jabri, K.S. Research on the Use of Ferro-Chrome Slag in Civil Engineering Applications. MATEC Web Conf. 2018, 149, 01017. [Google Scholar] [CrossRef]

- Jena, S.; Panigrahi, R. Evaluation of Durability and Microstructural Properties of Geopolymer Concrete with Ferrochrome Slag as Coarse Aggregate. Iran J. Sci. Technol. Trans. Civ. Eng. 2021, 46, 1201–1210. [Google Scholar] [CrossRef]

- Kozhamuratov, R.U.; Safarov, R.Z.; Shomanova, Z.K.; Nosenko, Y.G. Recycling of Ferroalloy Production Waste. In Proceedings of the International Scientific Conference “Global Science and Innovations 2017”, Bursa, Turkey, 4 December 2017; pp. 207–213. [Google Scholar]

- Zhuchkov, V.I.; Zayakin, O.V.; Sychev, A.V. The Study of the Characteristics and Possibilities of Using Slags and Dusts from Ferrochrome Production. In Proceedings of the Infacon XVI: International Ferro-Alloys Congress, Trondheim, Norway, 27–29 September 2021. [Google Scholar] [CrossRef]

- Zhuchkov, V.I.; Leontyev, L.I.; Zayakin, O.V. Promising Measures to Reduce the Harmful Effects of Man-made Waste from Ferroalloy Production. KnE Mater. Sci. 2019, 5, 263–270. [Google Scholar] [CrossRef]

- Myrzagaliev, A.A.; Almagambetov, M.S.; Alimbaev, S.A.; Ulmaganbetov, N.A. The Use of Poor Chromium-Containing Braces for Smelting High-Carbon Ferrochrome. Bull. Sci. 2020, 1, 342–349. [Google Scholar]

- Zhunusov, A.K.; Tolymbekova, L.B.; Bykov, P.O.; Zayakin, O.V. Melting Ferrochrome Using Chrome-Ore Briquettes. Metallurgist 2023, 67, 606–613. [Google Scholar] [CrossRef]

- Omarova, A.E.; Isagulova, D.A.; Kvon, S.S.; Kovaleva, T.V. The Choice of Binder for the Production of Briquettes from Highly Dispersed Dust of Ferroalloy Production. Proc. Univ. 2023, 3, 79–83. [Google Scholar] [CrossRef]

- Pavlov, A.V.; Alimbaev, S.A.; Murzagaliev, A.A.; Khalitov, T.V. The Use of Poor Chromium-Containing Cans for Smelting High-Carbon Ferrochrome. In Proceedings of the International Scientific Conference “Physico-Chemical Foundations of Metallurgical Processes Named After Academician A.M. Samarin”, Vyksa, Russia, 10–14 October 2019; pp. 66–67. [Google Scholar]

- Kascheev, I.D.; Zhuchkov, V.I.; Zayakin, O.V. Forming and Utilizing Ferrochromium Production Waste. Mater. Sci. Forum 2020, 989, 492–497. [Google Scholar] [CrossRef]

- Salkynbaev, B.Z.; Musabekov, Z.B.; Dosekenov, M.S.; Almukhamedova, A.K. Processing of Aspiration Dust from High-Carbon Ferrochrome Crushing. Bull. Aktobe Reg. Univ. Named K. Zhubanov 2021, 3, 79–83. [Google Scholar]

- Makhambetov, Y.; Akhmetov, A.; Gabdullin, S.; Shabanov, Y.; Toleukadyr, R.; Saulebek, Z.; Myrzagaliyev, A. Study of Ferrochrome Smelting Technology Using Briquettes with Various Carbonaceous Reducers. Acta Metall. Slovaca 2024, 30, 113–119. [Google Scholar] [CrossRef]

- Sokic, M.; Markovic, D.; Korac, M. Agglomeration of Ferroalloy Wastes for Recycling in Metallurgical Processes. Metalurgija 2019, 58, 81–84. [Google Scholar]

- Sariyev, O.; Abdirashit, A.; Almagambetov, M.; Nurgali, N.; Kelamanov, B.; Yessengaliyev, D.; Mukhambetkaliyev, A. Assessment of Physicochemical Properties of Dust from Crushing High-Carbon Ferrochrome: Methods for Agglomeration. Materials 2025, 18, 903. [Google Scholar] [CrossRef] [PubMed]

- Sariyev, O.; Almagambetov, M.; Nurgali, N.; Abikenova, G.; Kelamanov, B.; Yessengaliyev, D.; Abdirashit, A. Development of a Briquetting Method for Dust from High-Carbon Ferrochrome Crushing Using Vibropressing on an Industrial Scale and Its Subsequent Remelting. Materials 2025, 18, 2608. [Google Scholar] [CrossRef]

- Mikic, T.; Sokic, M.; Dimitrijevic, M. Recycling and Briquetting of Sludge from Wet Gas Cleaning of Ferroalloy Production. Metall. Mater. Eng. 2022, 28, 313–324. [Google Scholar]

- Shomanova, Z.; Safarov, R.; Tashmukhambetova, Z.; Sassykova, L.; Nosenko, Y.; Mukanova, R. Complex Research of Ferroalloys Production Wastes by Physical and Chemical Methods. J. Chem. Technol. Metall. 2021, 56, 629–636. [Google Scholar]

- Dorofeev, G.A.; Barsukova, E.Y. On the Choice of a Rational Method for Agglomeration of Fine Materials of Technogenic and Natural Origin. Bull. Sci. Tech. Econ. Inf. Ferrous Metall. 2015, 12, 73–80. [Google Scholar]

- Das, R.; Mondal, M.K.; Pramanik, S. Effect of Extrusion on the Physical and Mechanical Properties of Briquette Made with Blast Furnace Flue Dust and Iron Ore Fines. J. Inst. Eng. India Ser. D 2022, 103, 473–478. [Google Scholar] [CrossRef]

- Bizhanov, A.M.; Malysheva, T. Metallurgical Properties of Blast Furnace Extruded Briquettes (BREX) Based on Hematite Concentrate. Mater. Sci. Forum 2020, 989, 492–497. [Google Scholar] [CrossRef]

- Kurunov, I.; Bizhanov, A. Stiff Extrusion Briquetting in Metallurgy; Topics in Mining, Metallurgy and Materials Engineering; Springer International Publishing: Cham, Switzerland, 2018; Volume 1, p. 169. [Google Scholar] [CrossRef]

- GOST 24765-81; Iron Ore Materials. Method for Determination of Cold Crushing Strength. Committee for Standards of the Council of Ministers of the USSR: Moscow, Russia, 1981.

- GOST 25471-82; Iron Ore Raw Materials. Method for Determination of Drop Strength. Committee for Standards of the Council of Ministers of the USSR: Moscow, Russia, 1982.

- GOST 15137-77; Iron Ore Raw Materials. Method for Determination of Strength under Impact and Abrasion. Committee for Standards of the Council of Ministers of the USSR: Moscow, Russia, 1978.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).