Hot Deformation and Predictive Modelling of β-Ti-15Mo Alloy: Linking Flow Stress, ω-Phase Evolution, and Thermomechanical Behaviour

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Composition and Heat Treatment

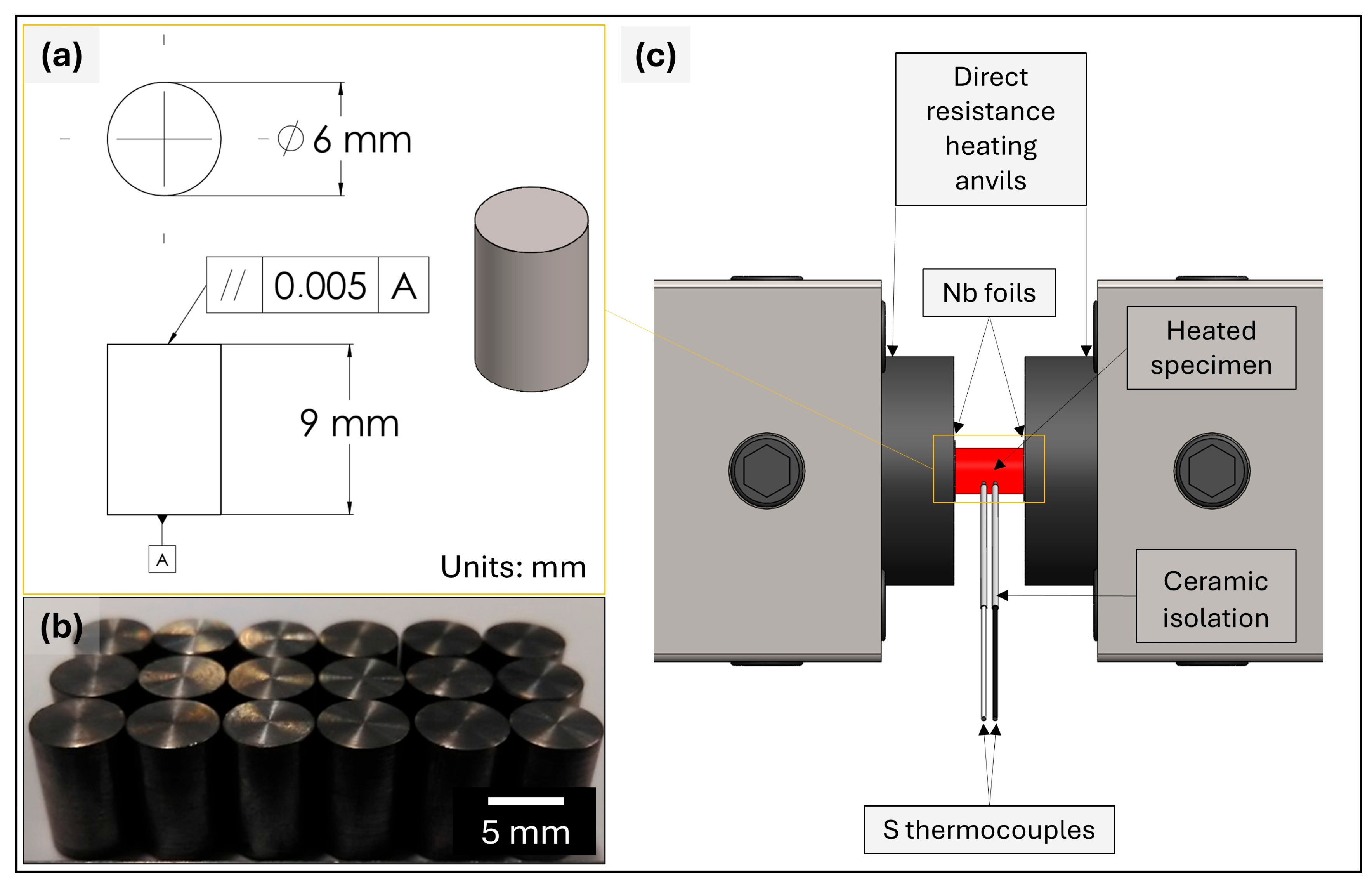

2.2. Specimen Preparation and Hot Compression Test

2.3. Constitutive Modelling Methodology

2.4. Microstructural Characterisation

2.5. X-Ray Diffraction

3. Results

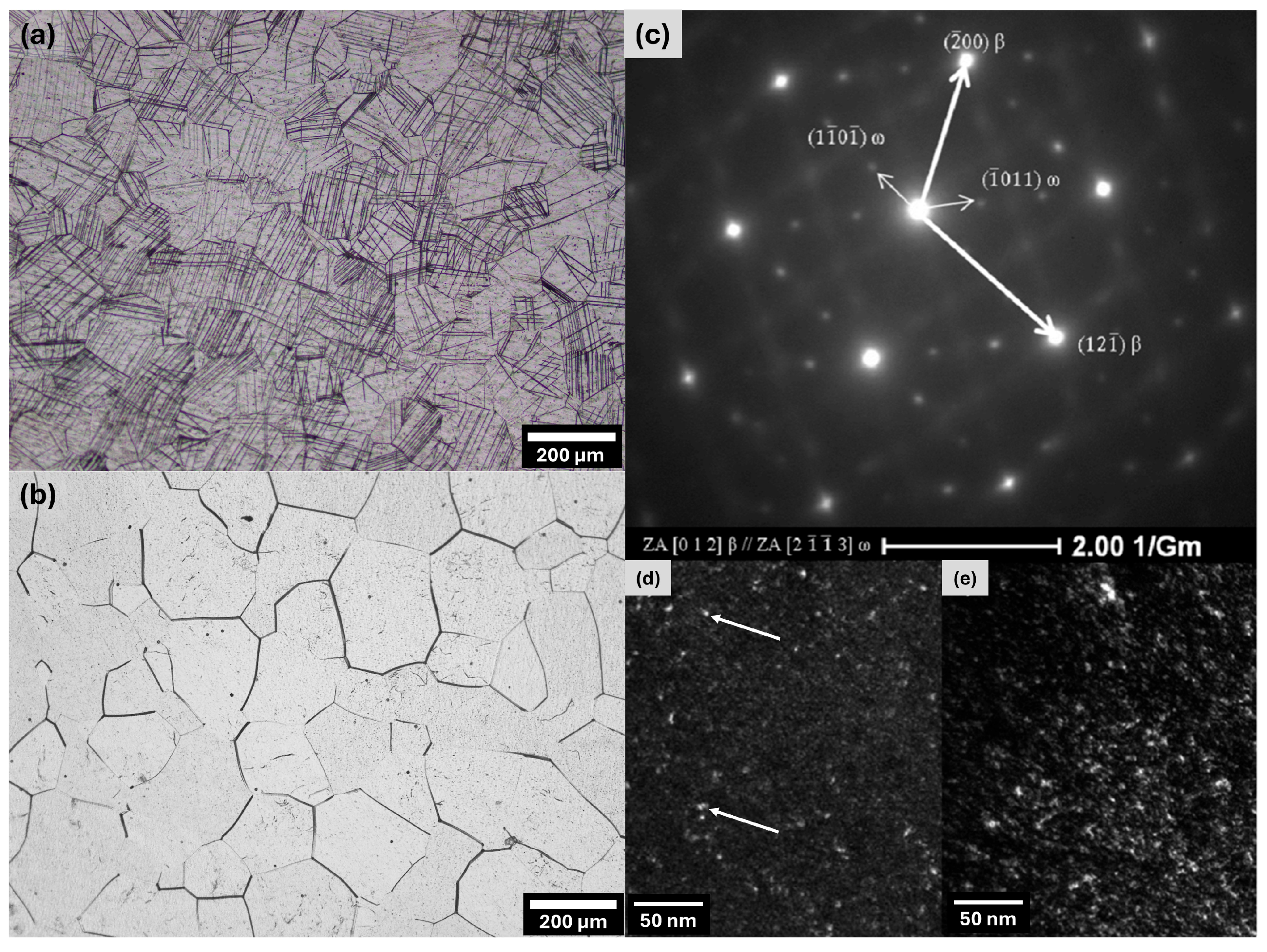

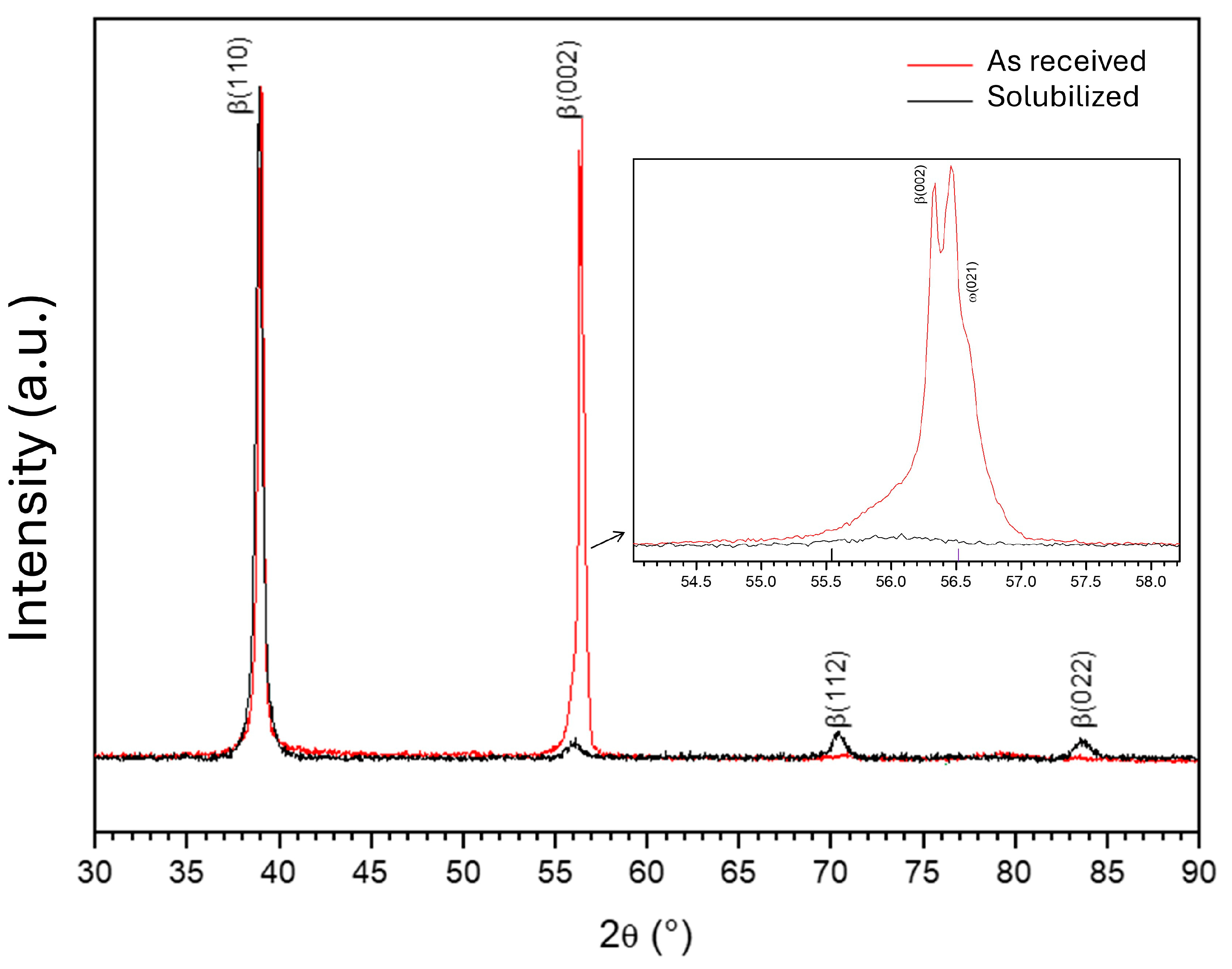

3.1. Initial Material Characterisation

3.2. Compressive Flow Stress Curves

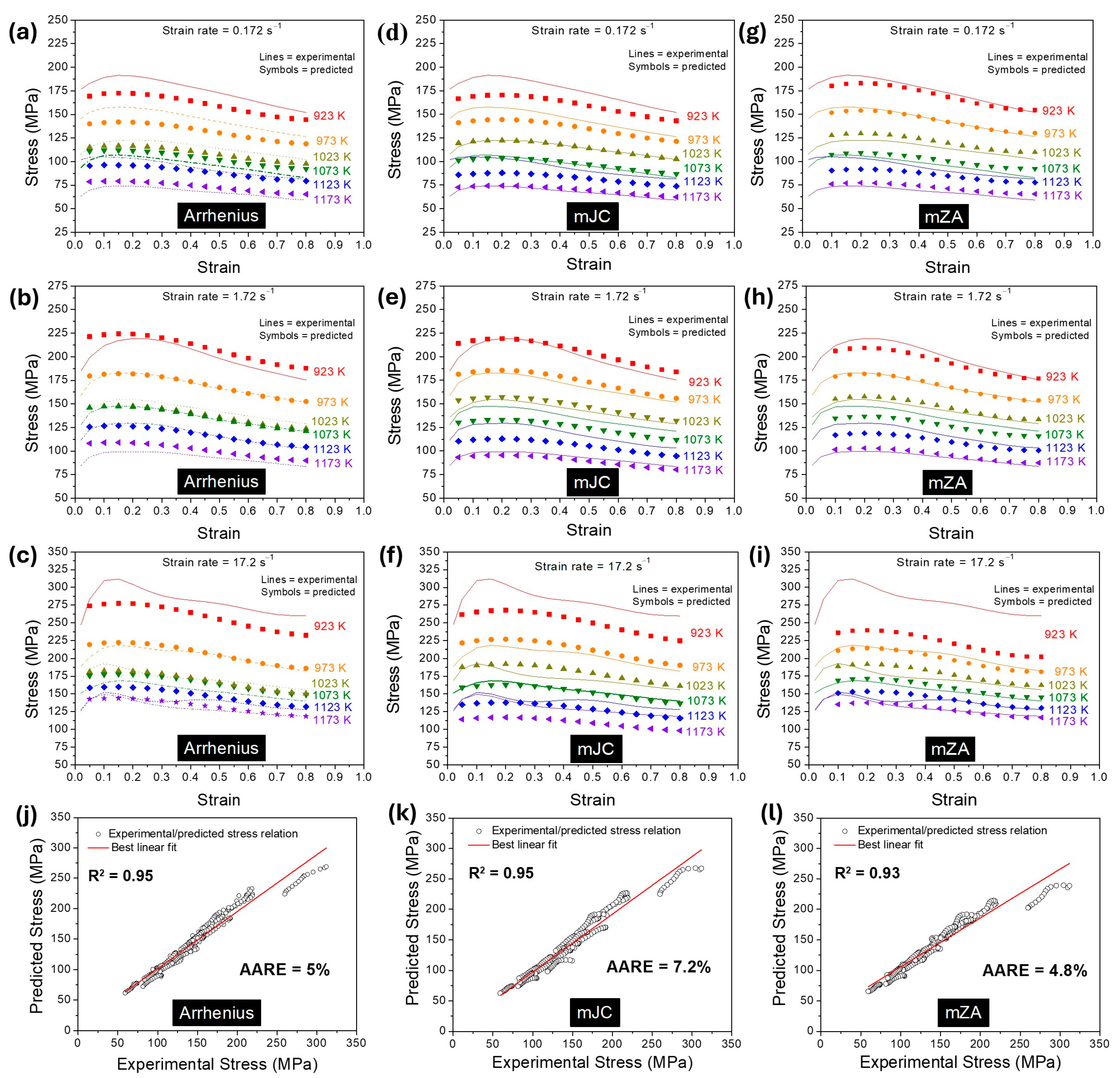

3.3. Constitutive Equation Derivation

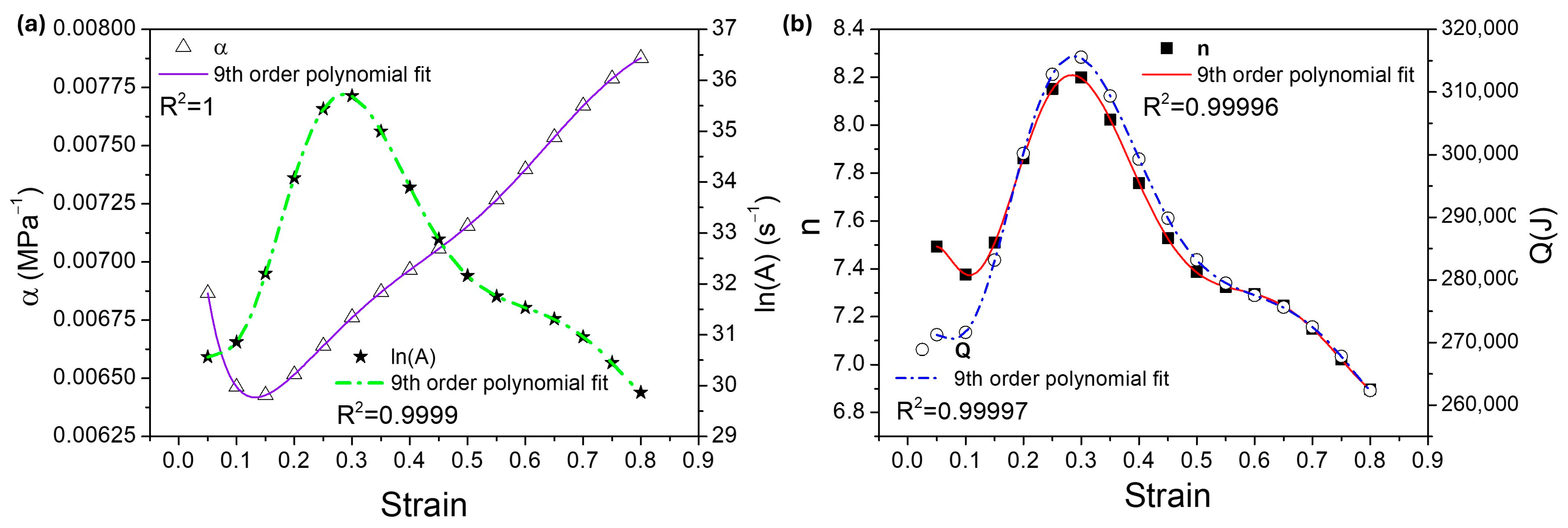

3.4. Post Deformation Microstructure Characterisation

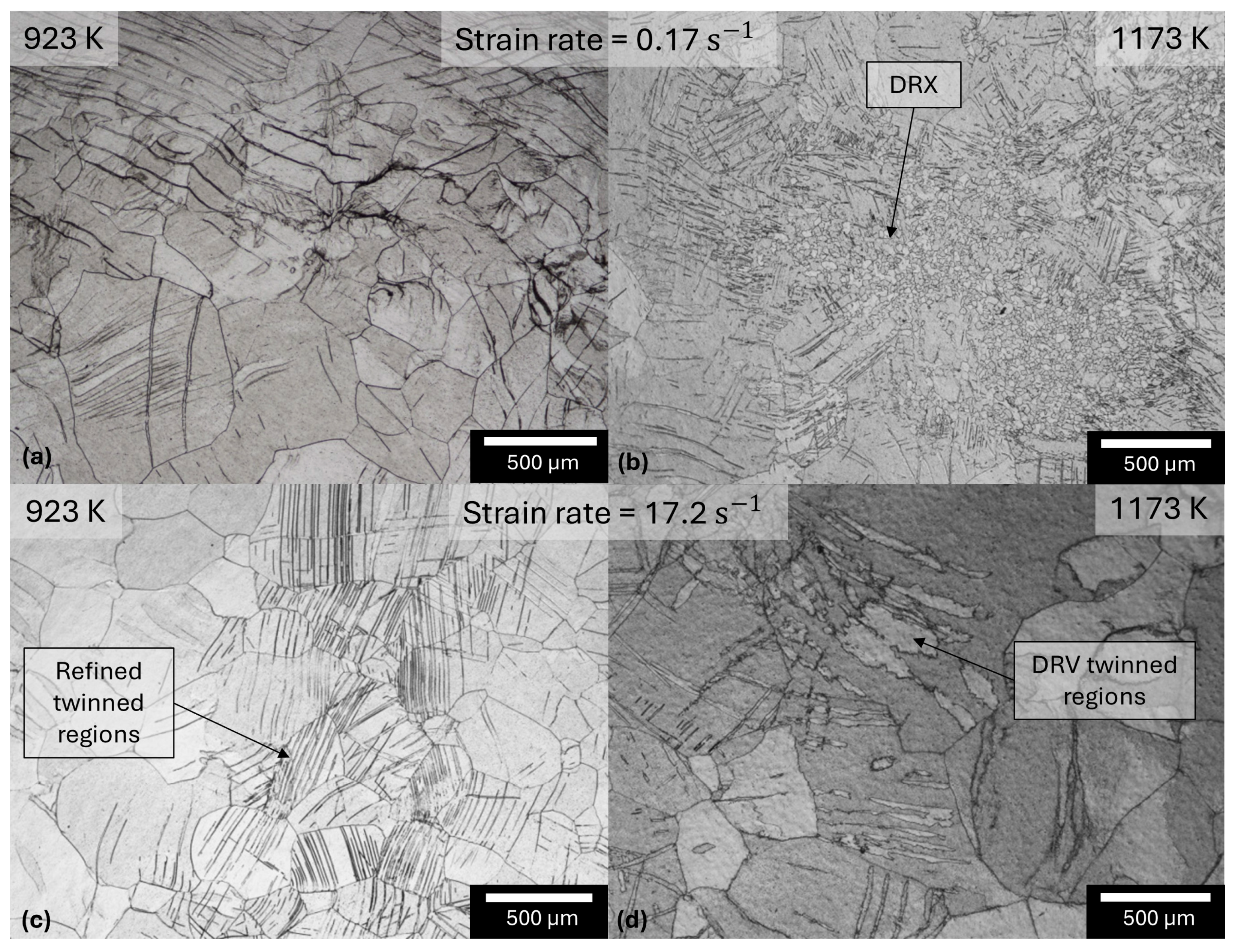

3.5. Structural Analysis

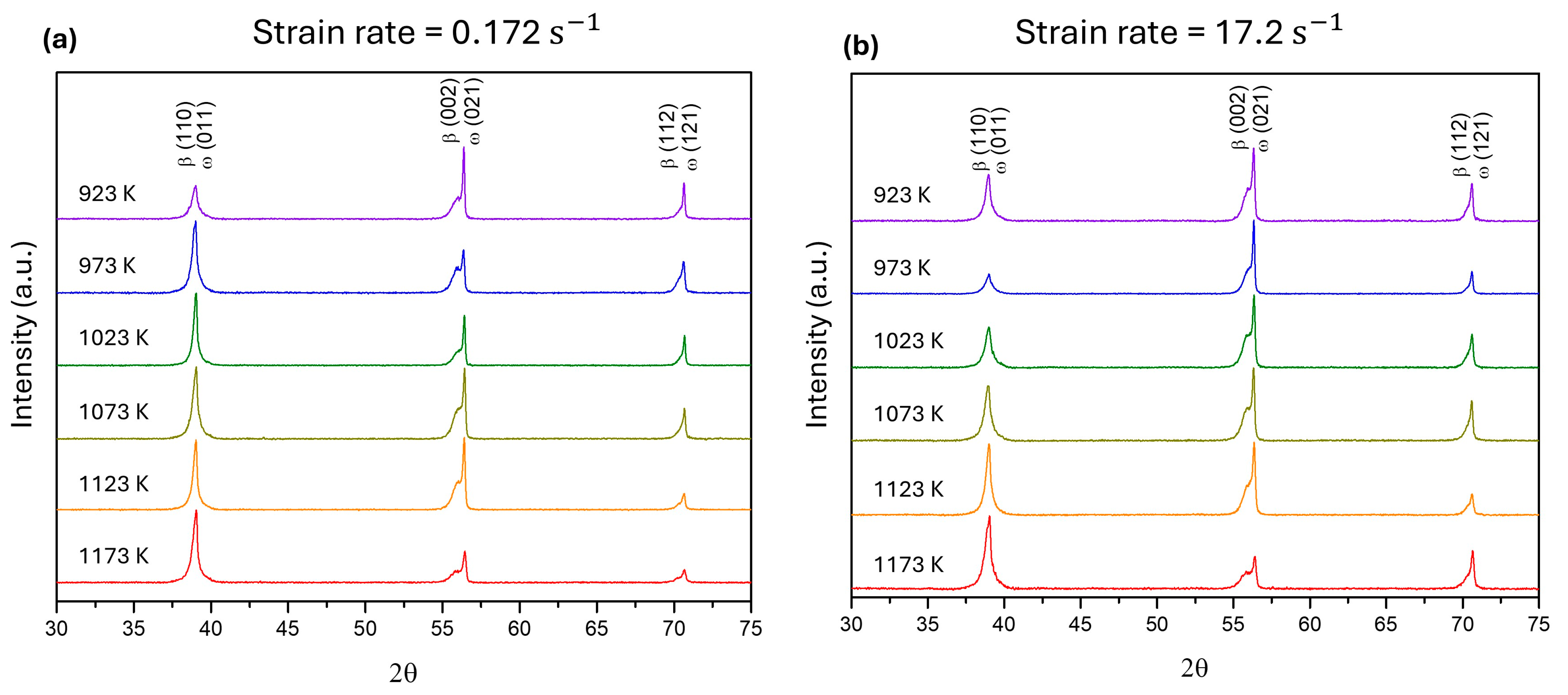

4. Discussion

5. Conclusions

- Microstructural evolution during deformation showed that softening mechanisms like DRV and DRX became more active at higher temperatures and lower strain rates. Although the presence of nanoscale obstacles—potentially including ω-phase precipitates—may affect dislocation mobility and recovery, further imaging evidence would be needed to confirm their specific role in this process.

- Using the experimental flow data, a strain-compensated Arrhenius-type constitutive model was successfully developed and calibrated. The model predicts flow stress evolution with good accuracy and yields an apparent activation energy of approximately 234 kJ/mol, consistent with DRV/DRX-controlled mechanisms in β-Ti alloys.

- The Zener–Hollomon (Z) parameter analysis effectively captured the deformation regime transitions, with high-Z conditions potentially associated with ω-phase formation and the resulting strengthening effect, whereas low-Z conditions favoured dynamic softening processes.

- X-ray diffraction (XRD) analysis evidenced the dissolution of the ω-phase during high-temperature deformation, validating the model predictions and explaining the observed stress–strain responses. High-contrast BSE imaging revealed morphological features indicative of recrystallisation, particularly at elevated temperatures and low strain rates. These microstructural observations, together with characteristic flow softening in the stress–strain curves, support the occurrence of dynamic recrystallisation (DRX) under specific thermomechanical conditions. However, in the absence of crystallographic orientation data, the interpretation remains indirect, and further work is needed to confirm the underlying mechanisms.

- These findings provide a physical basis for optimising the thermomechanical processing of β-Ti-15Mo alloys, particularly for biomedical applications. Controlling deformation temperature and strain rate is key to suppressing ω-phase formation and promoting dynamic restoration mechanisms that enhance hot workability and final properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants–A Review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Froes, F. Titanium: Physical Metallurgy, Processing, and Applications; ASM International: Novelty, OH, USA, 2015. [Google Scholar]

- Semiatin, S.; Bieler, T. The Effect of Alpha Platelet Thickness on Plastic Flow during Hot Working of TI–6Al–4V with a Trans-formed Microstructure. Acta Mater. 2001, 49, 3565–3573. [Google Scholar] [CrossRef]

- Takemoto, Y.; Shimizu, I.; Sakakibara, A.; Hida, M.; Mantani, Y. Tensile Behavior and Cold Workability of Ti-Mo Alloys. Mater. Trans. 2004, 45, 1571–1576. [Google Scholar] [CrossRef]

- Lee, W.-S.; Lin, C.-F.; Chen, T.-H.; Hwang, H.-H. Effects of Strain Rate and Temperature on Mechanical Behaviour of Ti–15Mo–5Zr–3Al Alloy. J. Mech. Behav. Biomed. Mater. 2008, 1, 336–344. [Google Scholar] [CrossRef]

- Zardiackas, L.D.; Mitchell, D.W.; Disegi, J.A. Characterization of Ti-15Mo Beta Titanium Alloy for Orthopaedic Implant Applications. In Medical Applications of Titanium and Its Alloys: The Material and Biological Issues; ASTM International: West Conshohocken, PA, USA, 1996; STP1272-EB. [Google Scholar]

- Ballor, J.; Li, T.; Prima, F.; Boehlert, C.J.; Devaraj, A. A Review of the Metastable Omega Phase in Beta Titanium Alloys: The Phase Transformation Mechanisms and Its Effect on Mechanical Properties. Int. Mater. Rev. 2023, 68, 26–45. [Google Scholar] [CrossRef]

- Matsumoto, H.; Kitamura, M.; Li, Y.; Koizumi, Y.; Chiba, A. Hot Forging Characteristic of Ti–5Al–5V–5Mo–3Cr Alloy with Single Metastable β Microstructure. Mater. Sci. Eng. A 2014, 611, 337–344. [Google Scholar] [CrossRef]

- Jablokov, V.R.; Nutt, M.J.; Richelsoph, M.E.; Freese, H.L. The Application of Ti–15Mo Beta Titanium Alloy in High Strength Structural Orthopaedic Applications. J. ASTM Int. 2005, 2, 1–18. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Y.; Zhou, W.; Zhao, Q.; Huang, S. In-Situ Investigation on Tensile Deformation and Fracture Behaviors of a New Metastable β Titanium Alloy. Mater. Sci. Eng. A 2021, 799, 140187. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, J.Y.; Marteleur, M.; Gloriant, T.; Vermaut, P.; Laillé, D.; Castany, P.; Curfs, C.; Jacques, P.J.; Prima, F. Investiga-tion of Early Stage Deformation Mechanisms in a Metastable β Titanium Alloy Showing Combined Twinning-Induced Plasticity and Transformation-Induced Plasticity Effects. Acta Mater. 2013, 61, 6406–6417. [Google Scholar] [CrossRef]

- Yao, K.; Min, X. Static and Dynamic Hall—Petch Relations in {332}<113> TWIP Ti–15Mo Alloy. Mater. Sci. Eng. A 2021, 827, 142044. [Google Scholar] [CrossRef]

- Zhang, S.; Min, X.; Li, Y.; Wang, W.; Li, P.; Li, M. Effects of Deformation and Phase Transformation Microstructures on Springback Behavior and Biocompatibility in β-Type Ti–15Mo Alloy. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 621–635. [Google Scholar] [CrossRef]

- Chen, W.; Cao, S.; Kou, W.; Zhang, J.; Wang, Y.; Zha, Y.; Pan, Y.; Hu, Q.; Sun, Q.; Sun, J. Origin of the Ductile-to-Brittle Transi-tion of Metastable β-Titanium Alloys: Self-Hardening of ω-Precipitates. Acta Mater. 2019, 170, 187–204. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Mei, W.; Sun, J. Role of Omega Phase Evolution in Plastic Deformation of Twinning-Induced Plasticity β Ti–12V–2Fe–1Al Alloy. Mater. Des. 2020, 186, 108282. [Google Scholar] [CrossRef]

- Gupta, A.; Khatirkar, R.; Singh, J. A Review of Microstructure and Texture Evolution during Plastic Deformation and Heat Treatment of β-Ti Alloys. J. Alloys Compd. 2022, 899, 163242. [Google Scholar] [CrossRef]

- Wang, X.L.; Li, L.; Mei, W.; Wang, W.L.; Sun, J. Dependence of Stress-Induced Omega Transition and Mechanical Twinning on Phase Stability in Metastable β Ti–V Alloys. Mater. Charact. 2015, 107, 149–155. [Google Scholar] [CrossRef]

- Hanada, S.; Yoshio, T.; Izumi, O. Effect of Plastic Deformation Modes on Tensile Properties of Beta Titanium Alloys. Trans. Jpn. Inst. Met. 1986, 27, 496–503. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Zhao, X.; Niinomi, M.; Nakai, M.; Hieda, J. Effect of Deformation-Induced ω Phase on the Mechanical Properties of Metastable β-Type Ti-V Alloys. Mater. Trans. 2012, 53, 1379–1384. [Google Scholar] [CrossRef]

- Wang, F.; Shen, J.; Zhang, Y.; Ning, Y. A Modified Constitutive Model for the Description of the Flow Behavior of the Ti-10V-2Fe-3Al Alloy during Hot Plastic Deformation. Metals 2019, 9, 844. [Google Scholar] [CrossRef]

- Shokry, A. Modified Fields-Backofen and Zerilli-Armstrong Constitutive Models to Predict the Hot Deformation Behavior in Titanium-Based Alloys. Sci. Rep. 2024, 14, 8359. [Google Scholar] [CrossRef]

- Li, C.M.; Huang, L.; Li, C.L.; Hui, S.X.; Yu, Y.; Zhao, M.J.; Guo, S.Q.; Li, J.J. Research Progress on Hot Deformation Behavior of High-Strength β Titanium Alloy: Flow Behavior and Constitutive Model. Rare Met. 2022, 41, 1434–1455. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Du, X.; Yang, C.; Wang, K. Thermal Deformation Behavior and Microstructural Evolution Mechanism of TC4 Titanium Alloy Based on Hot Processing Map. JOM 2024, 76, 5233–5246. [Google Scholar] [CrossRef]

- Ghosh, S.; Hamada, A.; Patnamsetty, M.; Borek, W.; Gouda, M.; Chiba, A.; Ebied, S. Constitutive Modeling and Hot Defor-mation Processing Map of a New Biomaterial Ti–14Cr Alloy. J. Mater. Res. Technol. 2022, 20, 4097–4113. [Google Scholar] [CrossRef]

- Li, Y.; Chen, H.; Du, L.; Yang, F.; Zhang, Y.; Li, D. Characterization and Unified Modelling of Creep and Viscoplasticity De-formation of Titanium Alloy at Elevated Temperature. Int. J. Plast. 2024, 173, 103892. [Google Scholar] [CrossRef]

- Wang, L.; Fan, X.G.; Zhan, M.; Chen, Q. Experimental Characterization and Physical Modeling of Strain Path Dependent Mi-crostructure Evolution: A Case Study of Primary Hot Working of Titanium Alloy. Int. J. Plast. 2022, 158, 103450. [Google Scholar] [CrossRef]

- Fan, X.G.; Yang, H. Internal-State-Variable Based Self-Consistent Constitutive Modeling for Hot Working of Two-Phase Tita-nium Alloys Coupling Microstructure Evolution. Int. J. Plast. 2011, 27, 1833–1852. [Google Scholar] [CrossRef]

- Park, C.W.; Choi, M.S.; Lee, H.; Yoon, J.; Javadinejad, H.R.; Kim, J.H. High-Temperature Deformation Behavior and Micro-structural Evolution of as-Cast and Hot Rolled Β21S Alloy during Hot Deformation. J. Mater. Res. Technol. 2020, 9, 13555–13569. [Google Scholar] [CrossRef]

- Ettouney, O.; Hardt, D.E. A Method for In-Process Failure Prediction in Cold Upset Forging. J. Eng. Ind. 1983, 105, 161–167. [Google Scholar] [CrossRef]

- Dieter, G.E.; Kuhn, H.A.; Semiatin, S.L. Handbook of Workability and Process Design; ASM International: Novelty, OH, USA, 2003. [Google Scholar]

- Sela, A.; Ortiz-de-Zarate, G.; Soler, D.; Germain, G.; Gallegos, L.; Arrazola, P.J. Adiabatic Self-Heating Determination for Ti6Al4V at Different Temperatures. Int. J. Heat Mass Transf. 2023, 204, 123747. [Google Scholar] [CrossRef]

- Guerra, A.P.d.B.; Jorge, A.M.; Roche, V.; Bolfarini, C. Hot Deformation Behavior of a Beta Metastable TMZF Alloy: Micro-structural and Constitutive Phenomenological Analysis. Metals 2021, 11, 1769. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadeh, A. Flow Stress Prediction at Hot Working Conditions. Mater. Sci. Eng. A 2010, 527, 1160–1164. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Xia, Y. A Constitutive Description of Tensile Behavior for Brass over a Wide Range of Strain Rates. Mater. Sci. Eng. A 2004, 372, 186–190. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Borah, U.; Bhaduri, A.K.; Sivaprasad, P.V. A Thermo-Viscoplastic Constitutive Model to Predict El-evated-Temperature Flow Behaviour in a Titanium-Modified Austenitic Stainless Steel. Mater. Sci. Eng. A 2009, 526, 1–6. [Google Scholar] [CrossRef]

| A | n | Q | ln(A) |

|---|---|---|---|

| B0 = 0.00822 | C0 = 6.56 | D0 = 251,322.58 | E0 = 24.64 |

| B1 = −0.04349 | C1 = 51.84 | D1 = 1,190,855.25 | E1 = 154.84 |

| B2 = 0.4264 | C2 = −1038.48 | D2 = −26,097,954.46 | E2 = −3125.31 |

| B3 = −2.33425 | C3 = 9455.35 | D3 = 261,496,784.01 | E3 = 30,514.35 |

| B4 = 8.3427 | C4 = −44726.79 | D4 = −1,301,255,235.43 | E4 = −151,228.72 |

| B5 = −19.98226 | C5 = 121,285.14 | D5 = 3,630,254,373.54 | E5 = 423,552.45 |

| B6 = 31.48779 | C6 = −196,990.99 | D6 = −6,009,363,810.81 | E6 = −706,422.84 |

| B7 = −31.0255 | C7 = 190,179.49 | D7 = 5,893,001,646.99 | E7 = 699,277.88 |

| B8 = 17.226185 | C8 = −100,965.92 | D8 = −3,176,170,940.51 | E8 = −380,811.47 |

| B9 = −4.1021907 | C9 = 22,765.39 | D9 = 727,525,079.69 | E9 = 88,167.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guerra, A.d.B.; Jorge Junior, A.M.; Koga, G.Y.; Bolfarini, C. Hot Deformation and Predictive Modelling of β-Ti-15Mo Alloy: Linking Flow Stress, ω-Phase Evolution, and Thermomechanical Behaviour. Metals 2025, 15, 877. https://doi.org/10.3390/met15080877

Guerra AdB, Jorge Junior AM, Koga GY, Bolfarini C. Hot Deformation and Predictive Modelling of β-Ti-15Mo Alloy: Linking Flow Stress, ω-Phase Evolution, and Thermomechanical Behaviour. Metals. 2025; 15(8):877. https://doi.org/10.3390/met15080877

Chicago/Turabian StyleGuerra, Arthur de Bribean, Alberto Moreira Jorge Junior, Guilherme Yuuki Koga, and Claudemiro Bolfarini. 2025. "Hot Deformation and Predictive Modelling of β-Ti-15Mo Alloy: Linking Flow Stress, ω-Phase Evolution, and Thermomechanical Behaviour" Metals 15, no. 8: 877. https://doi.org/10.3390/met15080877

APA StyleGuerra, A. d. B., Jorge Junior, A. M., Koga, G. Y., & Bolfarini, C. (2025). Hot Deformation and Predictive Modelling of β-Ti-15Mo Alloy: Linking Flow Stress, ω-Phase Evolution, and Thermomechanical Behaviour. Metals, 15(8), 877. https://doi.org/10.3390/met15080877