Abstract

To address the critical challenge of synergistically enhancing both high-temperature mechanical properties and thermal conductivity in neutron-absorbing materials for dry storage of spent nuclear fuel, this study proposes an innovative strategy. This approach involves the controlled distribution, size, and crystalline states of nano-Al2O3 within an aluminum matrix. By combining plastic deformation and heat treatment, we aim to achieve a structurally integrated functional design. A systematic investigation was conducted on the microstructural evolution of Al2O3/10 wt.% B4C/Al composites in their forged, extruded, and heat-treated states. We also examined how these states affect high-temperature mechanical properties and thermal conductivity. The results indicate that applying hot extrusion deformation along with optimized heat treatment parameters (500 °C for 24 h) allows for a lamellar dispersion of nano-Al2O3 and a crystallographic transition from amorphous to γ-phase. As a result, the composite demonstrates a tensile strength of 144 MPa and an enhanced thermal conductivity of 181 W/(m·K) at 350 °C. These findings provide theoretical insights and technical support for ensuring the high density and long-term safety of spent fuel storage materials.

1. Introduction

With the rapid development of the global nuclear energy industry, dry storage technology for spent nuclear fuel has introduced unprecedented challenges for neutron-absorbing materials. These materials must simultaneously demonstrate excellent mechanical strength, efficient thermal conductivity, and stable neutron absorption efficiency under long-term high-temperature conditions (above 350 °C) [1,2,3]. Aluminum-based boron carbide composites are excellent candidates due to their lightweight and irradiation-resistant properties. However, their performance at elevated temperatures is frequently hindered by the trade-off between strength and thermal conductivity. For instance, micrometer-sized B4C reinforcements experience a significant decline in strength (falling below 50 MPa) at 300 °C due to load transfer failure [4,5,6]. Efforts to enhance mechanical performance through alloying the matrix frequently result in compromised thermal conductivity [7,8,9]. The root of this contradiction lies in the challenges of microstructural regulation. Achieving a synergistic optimization of the distribution of the reinforcing phase, the crystalline state, and the properties of the interfaces at the nanoscale has become a critical challenge in overcoming the limitations of integrated structural/functional material design.

In recent years, advancements in nanoparticle reinforcement technology have provided innovative solutions to challenges in composite materials. Researchers have significantly improved the high-temperature performance of B4C/Al composites by incorporating nano-reinforcements through methods such as aging precipitation, liquid stirring, and powder metallurgy. For example, Zhang Li et al. [10] employed nano-Mg2Si-β’ precipitation phases to enhance the room-temperature strength of 40 wt.% B4C/Al composites to 263 MPa. However, the Ostwald ripening of precipitation phases at elevated temperatures ultimately compromised the effectiveness of these strengthening mechanisms [11,12,13]. Additionally, a team led by Guo [14] modified the B4C/Al interface with titanium and used ultrasonic-assisted liquid stirring to disperse 1 wt.% Al2O3 particles, achieving a strength of 41 MPa at 350 °C. Nonetheless, challenges such as nanoparticle agglomeration and interface erosion limited the reinforcement content to below 1 wt.% [15]. The powder metallurgy method has gained significant attention due to its flexibility in processing. Pang et al. [16] introduced 2.5 wt.% γ-Al2O3 to enhance the strength at 350 °C to 101 MPa. However, the presence of high-density nanophases at the grain boundaries caused brittle fracture, resulting in an elongation rate of only 6%. Compared to the method of additive introduction, the nano-oxide particles formed by in situ autogeny are more uniformly dispersed within the matrix, effectively preventing the agglomeration of nanoparticles [17,18,19]. Meanwhile, Zan’s team [20] employed a forging process to align nano-Al2O3 along the grain boundaries, achieving a strength of 120 MPa at 370 °C. However, the ultrafine grain structure led to plastic collapse, with an elongation rate of less than 2%. Despite these incremental advancements, the studies highlighted three persistent challenges: (1) the inherent contradiction between achieving uniform nanoparticle dispersion and maximizing reinforcement content; (2) the conflicting relationship between the degradation of high-temperature plasticity and strength enhancement; and (3) the systematic neglect of thermal conductivity, a parameter that directly affects spent fuel storage density and the risk of thermal runaway [1,21,22].

Current research on B4C/Al composites predominantly focuses on linear optimization of single properties, failing to systematically reveal the synergistic enhancement mechanism between mechanical properties and thermal conductivity. For instance, there are limitations of single-strategy approaches: Conventional studies often rely on the grain boundary pinning effect of nano-Al2O3 for strength enhancement (e.g., inhibiting grain coarsening through dispersed particles [23]). However, the extremely low thermal conductivity (~3 W/(m·K)) of amorphous Al2O3 (am-Al2O3) severely blocks heat transfer pathways in the aluminum matrix, resulting in inadequate thermal management capabilities. While intensive plastic deformation can optimize particle dispersion to improve interfacial bonding, it tends to form ultrafine-grained structures that conversely increase grain boundary sliding resistance at elevated temperatures [24]. There are also contradictions in phase transformation control: Existing research indicates that although the am → γ-Al2O3 phase transition (γ-phase thermal conductivity: ~30 W/(m·K)) improves thermal performance, the regular crystal structure of γ-phase compromises grain boundary pinning efficacy, leading to strength degradation [25,26,27]. This enduring “strength-thermal conductivity” trade-off dilemma has long constrained the application scalability of B4C/Al composites.

This paper proposes a multi-process synergy-based optimization strategy: Breaking through the limitations of traditional single-process approaches (e.g., powder metallurgy or heat treatment), it innovatively integrates powder metallurgy preparation, plastic deformation (to regulate particle distribution and size), and heat treatment (to drive phase transformation). This multi-process coupling enables precise, multi-dimensional regulation of Al2O3 morphology, distribution, and phase state, forming a microstructural basis for the synergistic enhancement of “grain boundary pinning strengthening” and “thermal conductivity network conduction”. By simultaneously activating these dual mechanisms, the strategy overcomes the traditional trade-offs between strength, plasticity, and thermal conductivity in B4C/Al composites.

To verify this hypothesis, nano-Al2O3-reinforced B4C/Al composites will be fabricated through integrated powder metallurgy/plastic deformation/heat treatment processing. Systematic parameter optimization will regulate Al2O3 morphology/distribution/phase state, while combined microstructural characterization (Transmission electron microscopy (TEM), Backscattered electron diffraction (EBSD)) and performance testing (high-temperature tensile, LFA thermal conductivity) will establish “process-structure-property” correlations, ultimately elucidating the fundamental principles of multi-mechanism synergy.

2. Materials and Methods

The (B4C + Al2O3)/Al composites were fabricated using commercial sphere-shaped pure aluminum powders (99.5% purity) and granular-shaped B4C particles (95% purity) as raw materials. The mean sizes of the original aluminum powders and B4C particles were 1.5 μm and 7.0 μm, respectively

Al powder and B4C powder were dried in a vacuum drying oven (model DFZ-6092, Shanghai Donglu Instrument Equipment Co., Ltd., Shanghai, China) at 80 °C for 12 h (vacuum < 1 Pa). The dried Al powders were mixed with 10 wt.% B4C powders using a dual-motion dry mixing machine (cylinder speed: 14 r/min, paddle speed: 28 r/min) for 25 min to ensure homogeneity. The mixed powder was loaded into a cold isostatic pressure set (model SDJ50/260-600, Aviation Industry Corporation of China, Ltd., Beijing, China), where it was subjected to a pressure of 320 MPa for 5 s to achieve a density of 90–92 vol%. A box furnace (model KSL-1200X, Hefei Kejing Materials Technology Co., Ltd., Hefei, China) was utilized for sintering under vacuum conditions (<10−3 Pa) with a heating rate of 10 °C/min, reaching a temperature of 420 °C. The holding time was 12 h.

Sintered billets were preheated to 430 °C for 30 min, followed by forging at a pressure of 800 MPa and a strain rate of 1 mm/s. Stress relief after forming was accomplished through annealing at 200 °C for 2 h.

A 500-ton vertical extruder (WT-QY500, Hebei Hongrun Nuclear Equipment Technology Co., Ltd., Yanshan, China) was utilized for hot extrusion at a temperature of 465 °C, with an extrusion ratio of 5:1 and a speed of 0.5 mm/s. Following the extrusion process, the sample was annealed at 200 °C.

Annealing was conducted in a resistance furnace at temperatures of 500 °C and 580 °C, with a heating rate of 10 °C/min. The parameters of the heat treatment process are detailed in Table 1. After cooling in the furnace, the samples were prepared for analysis.

Table 1.

Parameters of heat treatment process.

Microstructure analysis of B4C and Al2O3 morphology was conducted using a TESCAN MIRA3 LMH (TESCAN ORSAY HOLDING a.s., Prague, Czech Republic) and a HITACHI SU810 scanning electron microscope (Hitachi High-Tech Corporation, Tokyo, Japan), both equipped with an EDS/EBSD system. The samples were analyzed after plasma polishing with an IB-09020CP-JEOL (JEOL Ltd., Tokyo, Japan), utilizing an argon gas beam with a current intensity of 3.5 and an accelerating voltage of 3–6 kV. A FEI TECNAI G2 F30 transmission electron microscope (FEI Company, Hillsboro, OR, USA) was employed to characterize the crystalline and interfacial structures of Al2O3. The TEM sample is prepared by metallographic grinding. Following this process, the sample is transferred to a focused ion beam (FIB) system for localized thinning to a precise thickness of approximately 60 nanometers. This thickness is critical to satisfy TEM analysis requirements, enabling the acquisition of clear images and diffraction information.

An MTS Landmark 370.25 tester was utilized to evaluate the mechanical properties at 350 °C, with a tensile rate of 1.2 mm/min. Density testing was conducted using the Archimedes drainage method in accordance with ASTM B962 standards [28], with specimen dimensions of Φ10 mm × 20 mm. Thermal conductivity was calculated using the laser flash method (type LFA427 (NETZSCH-Gerätebau GmbH, Selb, Bavaria, Germany)), following ASTM E1461 standards [29]) to determine thermal diffusivity. This was combined with specific heat capacity data (type DSC200F3 (NETZSCH-Gerätebau GmbH, Selb, Bavaria, Germany)) and density measurements to compute thermal conductivity at 350 °C.

3. Results

3.1. Microstructure and Properties of Forged Composites

The in situ nano-amorphous Al2O3/B4C/Al composites treated through forging demonstrate exceptional densification. As shown in Table 2, the post-forging treatment increases the relative density to 99.26%, nearing full densification. This densification process effectively eliminates residual porosity after sintering. Transmission electron microscopy (TEM) analysis reveals strong interfacial bonding between B4C and Al (Figure 1a), with no detectable voids or brittle phases, thereby providing a solid foundation for enhanced mechanical properties.

Table 2.

Properties of composites in different processing states.

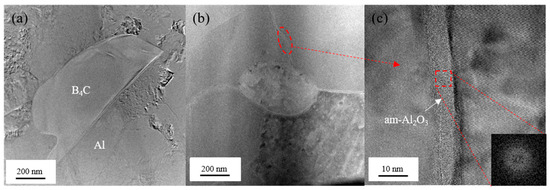

Figure 1.

TEM images of the composites in the upset state: (a) interface between boron carbide and the aluminum matrix; (b) continuous distribution of reticulated amorphous Al2O3 at grain boundaries; (c) high-resolution TEM image of amorphous Al2O3. (c) is a high-magnification image of the area enclosed by the red line in (b). The inset at the bottom right of (c) shows the diffraction pattern of the area enclosed by the red line in (c).

The forged composite demonstrates exceptional strength properties at 350 °C, achieving 149 MPa (Table 2). This enhancement in strength is primarily attributed to the strong pinning effect of continuous nanostructured amorphous Al2O3 networks, which have a thickness of 8–10 nm, located at the grain boundaries (Figure 1b,c). This network architecture effectively inhibits grain coarsening and dislocation glide at elevated temperatures, significantly increasing resistance to intergranular stress concentration. However, the continuous distribution of brittle amorphous Al2O3 phases concurrently limits the capacity for intergranular coordinated deformation, resulting in a relatively low plasticity of only 5%.

Despite optimized densification through forging, the thermal conductivity of the composite remains constrained by the intrinsic properties of amorphous aluminum oxide (am-Al2O3). As shown in Table 2, the forged material exhibits thermal conductivities of only 100 W/(m·K) at 350 °C, which is significantly lower than that of pure aluminum (237 W/(m·K)) [30]. This phenomenon can be attributed to the following mechanisms: (1) Thermal Barrier Network Effect: The continuous network of am-Al2O3 (thermal conductivity: 2–3 W/(m·K)) permeating the aluminum matrix disrupts heat conduction pathways between aluminum grains. (2) Interfacial Thermal Resistance: Enhanced phonon scattering at the B4C/am-Al2O3/aluminum multiphase interfaces further reduces the effective thermal conductivity [31]. (3) Grain Boundary Density Effect: While high-density grain boundaries improve mechanical properties, they introduce additional thermal resistance at the boundaries [32].

The forging process achieves high strength through grain boundary pinning, but it simultaneously reveals an inherent trade-off between strength and thermal conductivity. While the continuous nanostructured amorphous Al2O3 network effectively suppresses high-temperature grain coarsening via grain boundary pinning—resulting in a strength of 149 MPa at 350 °C—it also obstructs thermal conduction pathways and limits plastic deformation capacity, yielding an elongation rate of only 5%. This finding suggests that subsequent plastic deformation processes, such as hot extrusion, could fragment the continuous amorphous Al2O3 network, allowing for the preservation of grain boundary strengthening effects while restoring thermal transport pathways in the aluminum matrix. This approach offers a potential route for the synergistic optimization of mechanical and thermal properties.

3.2. Microstructure and Properties of Extruded Composites

Table 2 demonstrates that the hot extrusion process significantly enhances the densification of the composite, achieving a relative density of 99.66%. This densification can be attributed to the elimination of residual porosity through plastic flow mechanisms (see Figure 2a).

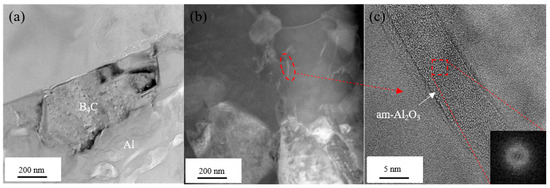

Figure 2.

TEM images of extruded composites: (a) boron carbide/aluminum matrix interface; (b) fragmented flake am-Al2O3; (c) high-resolution TEM image of am-Al2O3. (c) is a high-magnification image of the area enclosed by the red line in (b). The inset at the bottom right of (c) shows the diffraction pattern of the area enclosed by the red line in (c).

Table 2 illustrates that hot extrusion significantly affects the strength/plasticity balance of the composite. The composite exhibits a high-temperature tensile strength of 129 MPa at 350 °C after extrusion, which represents a 13% decrease compared to the upset condition (see Table 2). This reduction in strength is closely linked to the fragmentation and size reduction of the flaky am-Al2O3, which diminishes the grain boundary pinning effects. The fragmentation of am-Al2O3 lamellae (Figure 2b,c) promotes intergranular coordinated deformation within the aluminum matrix, resulting in an increased strain rate of 8% at 350 °C (Table 2).

The hot extrusion process restructured the thermal conduction network of the aluminum matrix, enhancing the thermal conductivity of the composite to 144 W/(m·K) (Table 2), representing a 44% improvement over the forging-processed state. The underlying mechanisms include improved matrix connectivity: the dispersed distribution of flaky am-Al2O3 (Figure 2b) reduced the coverage of continuous thermal insulation networks, thereby establishing efficient heat transfer pathways between aluminum grains. Additionally, reduced interfacial thermal resistance was observed, as fragmented am-Al2O3 lamellae (with a thickness of less than 10 nm) shortened phonon scattering paths at the interfaces. This study demonstrates that precise control of am-Al2O3 fragmentation enables the simultaneous optimization of mechanical and thermal properties. The proposed “am-Al2O3 continuum-aluminum matrix connectivity-grain boundary pinning strength” competition mechanism in hot extrusion establishes critical criteria for selecting processing windows for structurally functional integrated materials. Future research could further optimize thermal conductivity through coupled thermal treatments that induce am-Al2O3 to γ-Al2O3 phase transitions, potentially achieving breakthroughs in current thermal conductivity limits.

3.3. Microstructure and Properties of Heat-Treated Composites

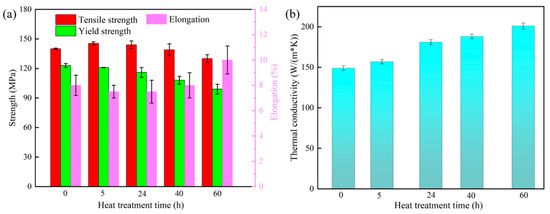

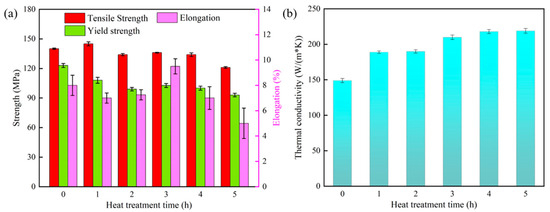

Figure 3 illustrates the high-temperature mechanical properties and thermal conductivity of the composites after heat treatment at 500 °C. As the duration of heat treatment increases from 0 to 60 h, the tensile strength of the material shows a non-monotonic trend: it initially increases and then decreases. The specific tensile strength values recorded are 140 MPa, 145 MPa, 144 MPa, 139 MPa, and 130 MPa, with the peak strength occurring at 5 h. After this point, the tensile strength declines at an increasing rate, resulting in an overall decrease of 7.14%. In contrast, the yield strength shows a continuous decline, decreasing stepwise from 123 MPa to 99 MPa, which is a cumulative reduction of 19.5%. Notably, the rate of decline accelerates in the later stages, with an 8.3% decrease observed during the interval from 40 to 60 h.

Figure 3.

Properties of 500 °C heat-treated composites at 350 °C: (a) mechanical properties; (b) thermal conductivity.

It is important to highlight the significant changes in the plastic behavior of the material. During the 0 to 40 h heat treatment, the elongation at break remains consistently stable, ranging from 7.5% to 8%. However, when the heat treatment duration is extended to 60 h, the elongation increases to 10%, representing a 33% rise. In terms of thermophysical properties, the thermal conductivity of the material also shows an upward trend. In the initial stage (0 to 24 h), the thermal conductivity gradually increases from 149 W/(m·K) to 181 W/(m·K), marking a 21.5% increase. When the heat treatment duration is extended to 40 h, the thermal conductivity rises further to 188 W/(m·K). At 60 h of heat treatment, the thermal conductivity jumps to 201 W/(m·K), indicating a 34.9% increase compared to the initial value.

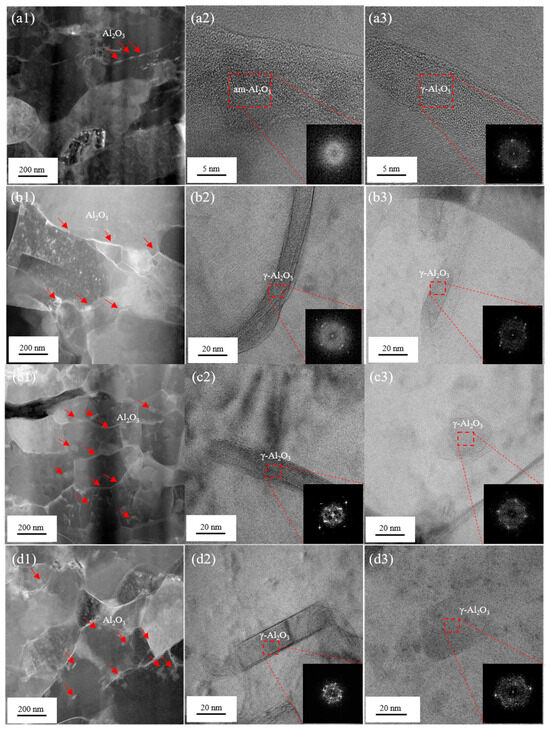

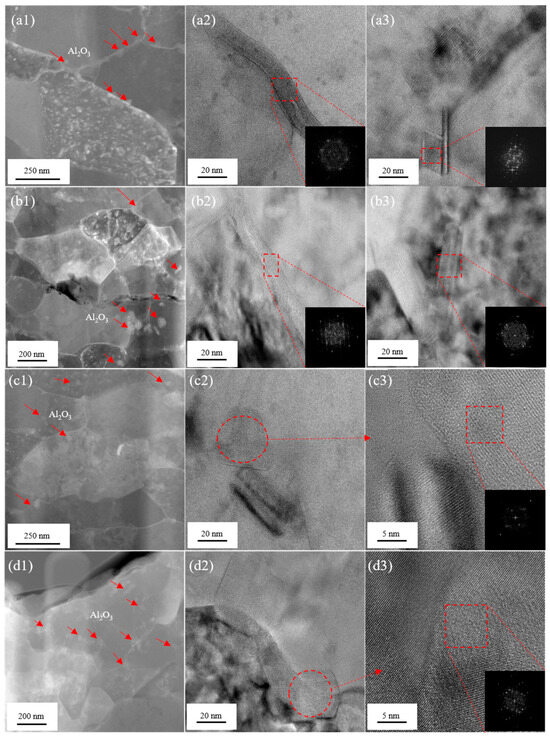

Figure 4 presents TEM images of the composites heat-treated at 500 °C for varying durations. As illustrated in Figure 4, some amorphous nano-Al2O3 in the matrix underwent a crystallographic transformation into γ-Al2O3 following a 500 °C treatment for 5 h, while the untransformed nano-Al2O3 retained its original lamellar morphology. The thickness of all flaky nano-Al2O3 stabilized at 10 nm and remained distributed along the grain boundaries in a reticular pattern. After 500 °C/24 h treatment, the composite microstructure exhibited coexisting plate-like γ-Al2O3 and short rod-like γ-Al2O3, with both plate-like/rod-shaped particles maintaining a thickness of 10 nm. Following 40 h treatment, γ-Al2O3 displayed a mixed morphology of spherical particles (20 nm) and rod-shaped particles (10 nm). At 60 h treatment, γ-Al2O3 still showed coexistence of short rod-like and spherical particles: the spherical γ-Al2O3 continued growing to 40 nm, while the rod-like γ-Al2O3 became shorter in length and wider in diameter compared to the 40 h treatment.

Figure 4.

TEM images of composites subjected to varying heat treatment durations at 500 °C: (a1–a3) 5 h; (b1–b3) 24 h; (c1–c3) 40 h; (d1–d3) 60 h. The red arrow in the figure indicates nano-Al2O3, and the inset in the lower right corner shows the diffraction pattern of the area enclosed by the red outline.

The high-temperature strengthening mechanisms of the heat-treated composite involve three key contributions: grain boundary strengthening from nano-Al2O3 located at the grain boundaries, fine-grain strengthening induced by nano-Al2O3 pinning the grain boundaries, and dislocation strengthening generated by Al2O3 stabilizing dislocations at the grain boundaries. Since γ-Al2O3 contributes less to grain boundary strengthening than amorphous Al2O3 (am-Al2O3), the transformation rate of am-Al2O3 to γ-Al2O3 increases with prolonged heat treatment time, accompanied by a morphological transition from lamellar to short-rod and spherical shapes. Consequently, its pinning effect on the grain boundaries gradually weakens, while the coordinated deformation capability of the grain boundaries at high temperatures improves, leading to a reduction in composite strength and an increase in plasticity [33].

Figure 5 depicts the two-stage decay of the strength of the composite at 350 °C following heat treatment at 580 °C. Initial Stage (0–2 h): During this phase, both tensile strength and yield strength decrease simultaneously from their initial values, reaching 134 MPa and 99 MPa, respectively. Plateau Stage (2–4 h): In this stage, the tensile strength stabilizes between 134 and 136 MPa, while the yield strength fluctuates between 99 and 102 MPa. Final Stage (5 h): Both strength parameters decline again, with tensile strength dropping to 121 MPa and yield strength decreasing to 93 MPa. These represent reductions of 11.2% and 8.8%, respectively, when compared to the values observed during the plateau stage. The evolution of the strain rate (Figure 5a) shows non-linear behavior. After 1 h of heat treatment, elongation decreases from 8% (in the as-extruded state) to 7%. During the 1–3 h period, it increases gradually to 9.5%. However, in the 3–5 h range, there is a sharp decline, with a sudden drop to 7% at 4 h and a further decrease to 5% at 5 h. This represents a reduction of 47.4% from the peak value. This dynamic interplay between strength and ductility highlights the competition between microstructural stabilization and thermal softening mechanisms during prolonged heat treatment.

Figure 5.

Properties of 580 °C heat-treated composites at 350 °C: (a) mechanical properties; (b) thermal conductivity.

The evolution of thermal conductivity, shown in Figure 5b, demonstrates a stepwise increase in the material’s thermal conductivity. After one hour of heat treatment, it reaches 189 W/(m·K) and stabilizes at 190 W/(m·K) during the two-hour treatment stage. When the heat treatment is extended to five hours, the thermal conductivity further increases to 219 W/(m·K) before entering a saturation phase, where the increase during the four-to-five-hour period is less than 0.5%.

Figure 6 shows TEM images of the composite at 580 °C under different heat treatment durations (1 h, 2 h, 3 h, 4 h). As depicted in Figure 6, the nano-Al2O3 within the matrix after treatment at 580 °C for one hour exhibited a mixed state of two phases, consisting of flakes and short rods of γ-Al2O3. In contrast, the treatment at 580 °C for two hours resulted in a notable phase transition of nano-Al2O3, with spherical γ-Al2O3 beginning to emerge. Some of these spherical particles penetrated into the interior of the grains, resulting in grain growth. Additionally, this treatment caused the enlargement of the grain boundaries and the spherical particles, with increased migration of particles into the interiors of the grains, away from the grain boundaries. After four hours of treatment, most of the nano-Al2O3 transformed into spherical shapes and became uniformly distributed, leading to the failure of grain boundary reinforcement.

Figure 6.

TEM images of composites subjected to varying heat treatment durations at 580 °C: (a1–a3) 1 h; (b1–b3) 2 h; (c1–c3) 3 h; (d1–d3) 4 h. The red arrow in the figure indicates nano-Al2O3, and the inset in the lower right corner shows the diffraction pattern of the area enclosed by the red outline.

For the heat-treated composite at 580 °C, as the heat treatment duration increases, changes occur not only in the crystallinity and size morphology of nano-Al2O3 within the microstructure but also in grain growth. This grain growth alters the distribution characteristics of nano-Al2O3, promoting the gradual migration of nano-Al2O3 particles originally located at the matrix grain boundaries into the interior of the matrix grains, where they begin to exert Orowan strengthening effects. Consequently, the contribution of the original grain boundary strengthening diminishes. Since the ability of nano-Al2O3 particles within the grains to pin dislocations is significantly weaker than that of those at the grain boundaries, the composite’s strength decreases while its elongation increases.

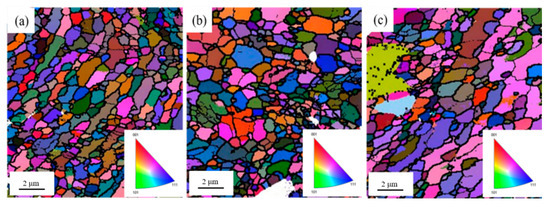

Figure 7 presents Electron Backscatter Diffraction (EBSD) images of the composite in various states. Grain size characterization indicates that the as-extruded composite matrix has an average grain diameter of 517 nm. Following a 24 h heat treatment at 500 °C, the average grain diameter remains approximately 520 nm, indicating no significant grain growth compared to the as-extruded state. This observation demonstrates that while nano-Al2O3 undergoes crystallographic and morphological changes at 500 °C, it effectively maintains the pinning of matrix grain boundaries. In contrast, after a 2 h heat treatment at 580 °C, the grain size increases to 677 nm, indicating substantial growth. This finding suggests that the pinning effect of nano-Al2O3 on grain boundaries weakens significantly at 580 °C, becoming inadequate to prevent recrystallization and grain coarsening in the matrix.

Figure 7.

EBSD images of the composite under different processing states: (a) as-extruded state; (b) 500 °C/24 h heat-treated state; (c) 580 °C/2 h heat-treated state.

When the composite is heat-treated at 500 °C and 580 °C, lamellar am-Al2O3 transforms sequentially into lamellar γ-Al2O3, short-rod γ-Al2O3, and spherical γ-Al2O3 as the heat treatment duration increases. At 500 °C, the matrix grains of the composite do not grow, and the nano-reinforcement phase remains distributed along the grain boundaries. In contrast, at 580 °C, the matrix grains grow, and with prolonged heat treatment, the nano-reinforcement phase detaches from the grain boundaries and migrates into the grain interiors. As the heat treatment time increases, the composite’s thermal conductivity gradually rises, while its strength gradually decreases, with the strength reduction being more pronounced at 580 °C. After heat treatment at 500 °C for 24 h, the composite exhibits optimal overall properties, achieving a tensile strength of 144 MPa and a thermal conductivity of 181 W/(m·K) measured at 350 °C.

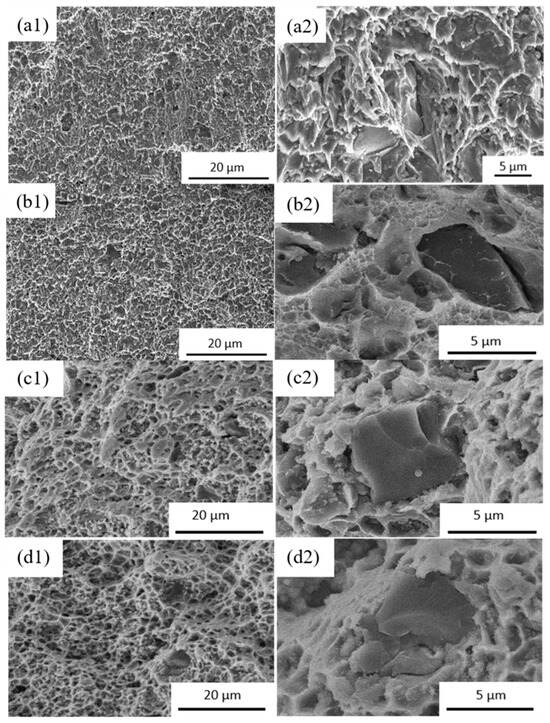

Figure 8 shows SEM photographs of the fracture morphology of composite materials under different conditions. In Figure 8(a1), dimples are sparse and shallow dimples, with some areas exposing the matrix or particle fracture surfaces directly. Smooth cleavage planes or intergranular cracks are visible at the interface separation sites, showing no obvious signs of plastic deformation and indicating an increased tendency toward brittle fracture. The fracture surfaces shown in Figure 8(b1,c1,d1) display densely distributed dimples with a relatively uniform overall morphology. Residual micro-protrusions or necking features are present at the edges of the dimples, indicating significant plastic deformation during fracture and confirming a ductile fracture mode. In Figure 8(a2,b2), the interface between the aluminum matrix and B4C particles is weakly bonded. Under applied stress, microcracks initially form around the particles, and crack propagation causes interface separation, leading to the formation of initial voids [34]. In the group with moderate interface bonding (Figure 8(c2,d2), particle pull-out occurs as the matrix undergoes plastic deformation to absorb energy, resulting in “cup-cone”-shaped dimples.

Figure 8.

The tensile fracture morphology of the fabricated B4C/Al composites: (a1,a2) as-forged state; (b1,b2) as-extruded state; (c1,c2) heat-treated state; (d1,d2) spheroidized state.

The transformation of nano-Al2O3 morphology from lamellar to spherical primarily involves modifying its geometric characteristics (such as aspect ratio and surface curvature) and spatial distribution to control interfacial interactions with the matrix and the distribution of the stress field. This, in turn, influences crack propagation behavior and long-term service stability. Crack propagation is fundamentally a stress release process driven by stress concentration at the crack tip, with its path directly affected by the morphology, distribution, and interfacial bonding strength between the reinforcement phase and the matrix [35]. Lamellar Al2O3 exhibits a high aspect ratio and is preferentially aligned along grain boundaries. Its interlayer interfaces tend to act as “low-resistance channels” for crack propagation. The anisotropy of the lamellar structure restricts transverse crack expansion, causing cracks to propagate preferentially along the long axis of the reinforcement phase in a linear manner. This behavior limits energy dissipation through crack deflection and accelerates material failure. Spherical γ-Al2O3, characterized by isotropy and high surface curvature, significantly impedes crack propagation. The curved interfaces of these spherical particles reflect stress waves at the crack tip, deflecting the crack propagation direction and effectively inhibiting crack growth. Long-term structural stability primarily depends on the level of internal stress concentration and the strength of interfacial bonding within the material. Lamellar structures, due to their significant stress concentrations, are prone to interfacial failure and fatigue damage during extended service. In contrast, spherical structures reduce stress concentration through their curved interfaces and optimized interfacial bonding, which delays damage accumulation and significantly enhances long-term structural stability.

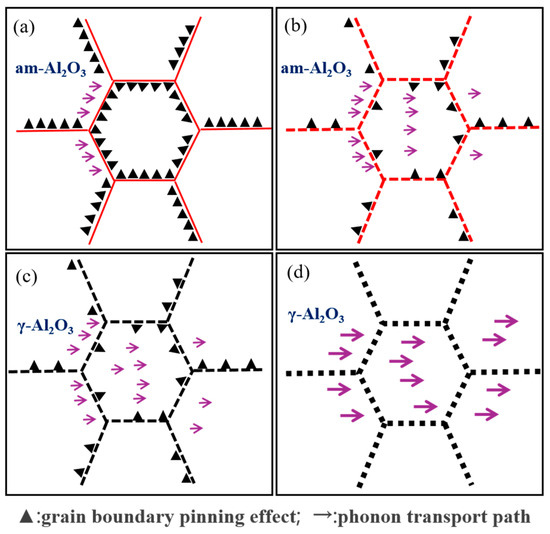

Figure 9 presents a schematic diagram of the synergistic enhancement mechanism between microstructure and properties in the composite. As previously described, the nano-amorphous Al2O3 (am-Al2O3) in the as-forged composite is continuously distributed along the grain boundaries, effectively pinning these boundaries and enhancing high-temperature mechanical properties. However, this continuous network of am-Al2O3 forms a “thermal barrier network” that obstructs heat conduction pathways between aluminum grains. In the as-extruded state, the nano-am-Al2O3 fragments into plate-like particles that remain distributed along the grain boundaries. These particles continue to provide significant grain boundary pinning at elevated temperatures, thereby preserving high-temperature mechanical performance. Meanwhile, the discontinuous distribution of am-Al2O3 re-establishes thermal conduction pathways through the matrix grains, substantially improving thermal conductivity.

Figure 9.

Schematic diagram of synergistic enhancement mechanism between microstructure and properties of the composite: (a) as-forged state; (b) as-extruded state; (c) heat-treated state; (d) spheroidized state. The solid lines in the figure represent a continuous distribution of aluminum oxide at the boundary, while the dashed lines indicate a discontinuous distribution of aluminum oxide. The red lines correspond to amorphous Al2O3, and the black lines represent γ-Al2O3. The dotted line in the figure represents spheroidalized Al2O3.

Mechanism of Phase Transition from Amorphous Al2O3 to γ-Al2O3 and Performance Enhancement: During heat treatment at 500 °C, amorphous Al2O3 (am-Al2O3) undergoes an in situ crystalline phase transition to lamellar γ-Al2O3. This transition significantly enhances the interfacial bond strength and thermal conductivity of the composite. Transmission electron microscopy (TEM) analysis revealed that after 5 h of heat treatment at 500 °C, am-Al2O3 in the composite transforms into lamellar γ-Al2O3, maintaining a thickness of approximately 10 nm, which is consistent with the original dimensions of am-Al2O3. This lamellar structure effectively suppresses high-temperature grain coarsening by anchoring the matrix grain boundaries through strong interfacial bonding. Thermal conductivity measurements indicate that after 24 h of heat treatment at 500 °C, the composite achieves a thermal conductivity of 181 W/(m·K) at 350 °C, representing a 21.5% improvement compared to its extruded state. The crystalline phase transition not only optimizes phonon transport pathways but also enhances thermal conductivity by minimizing interfacial thermal resistance.

Spheroidization Behavior of Nano-Al2O3 and Its Impact on Mechanical Property Degradation: When the heat treatment temperature was increased to 580 °C, significant spheroidization of γ-Al2O3 occurred, causing it to migrate into the interior of the matrix grains. This movement resulted in a loss of the pinning effect. Transmission electron microscopy (TEM) observations after 2 h of heat treatment showed that the diameter of the spherical γ-Al2O3 had increased to 20–30 nm, with some particles detaching from the grain boundaries and moving into the intragranular space. Extending the heat treatment time to 4 h led to the complete dominance of spherical γ-Al2O3, with its diameter further increasing to 30–50 nm and becoming uniformly distributed within the matrix grains. This uniformity undermines the grain boundary-strengthening mechanism, resulting in a continuous decrease in yield strength from 97 MPa in the extruded state at 350 °C to 72 MPa after 4 h of heat treatment at 580 °C. This trend indicates that the pinning ability of γ-Al2O3 at the grain boundaries diminishes as spheroidization intensifies, highlighting the crucial role of grain boundary distribution in regulating high-temperature mechanical properties.

The heat treatment process optimizes material properties by adjusting the phase state and distribution of Al2O3. A brief heat treatment at 500 °C achieves a balance between high strength and excellent thermal conductivity. On the other hand, the 580 °C treatment results in irreversible degradation of mechanical properties. The treatment at 500 °C maintains pinning, whereas the high-temperature spheroidization at 580 °C improves thermal conductivity.

In summary, the crystalline transition of Al2O3 is the primary factor driving the evolution of its material properties. The transition from amorphous Al2O3 (am-Al2O3) to gamma Al2O3 (γ-Al2O3) is characterized by a pinning effect, which results from the distribution of lamellar γ-Al2O3 along the grain boundaries. This effectively suppresses abnormal grain growth at elevated temperatures, helping to maintain the material’s strength under such conditions. The phase transformation of γ-Al2O3 leads to significant changes in the material’s properties. Specifically, the transition of the reinforced phase from a flake morphology to a spherical one results in reduced mechanical properties that were initially dependent on grain boundary reinforcement. However, the growth and distribution of spherical γ-Al2O3 within the grains create a new, highly efficient thermal conductivity network. As a result, thermal conductivity increases, but this improvement comes at the cost of a substantial reduction in mechanical properties. This indicates that enhancing thermal conductivity is not solely based on the amount of the highly thermally conductive phase present; it also requires decoupling the functions of “thermal conductive pathway” and “mechanical load-bearing” through careful microstructural design.

Al-based B4C composites are considered the most promising neutron-absorbing materials for spent fuel storage and transportation. For their application in dry spent fuel storage, these materials must evolve from single-function components to high-temperature, high-strength, high-thermal-conductivity structural/functional integrated materials [36]. Specifically, while maintaining excellent neutron absorption capacity, their structural strength under high-temperature service conditions should be further enhanced, thermal conductivity improved, and the high-temperature stability of the spent fuel storage structure ensured. This will increase the safety redundancy of dry spent fuel storage and reduce maintenance costs. This study enhances the high-temperature mechanical properties of Al-based composites by in situ introduction of a nano-Al2O3 phase, while precisely controlling the phase transformation of nano-Al2O3 through multi-process synergy to improve thermal conductivity and accelerate heat dissipation in the spent fuel storage structure. This research provides theoretical support for the engineering preparation and application of Al-based B4C neutron-absorbing materials. Existing processes, such as extrusion and heat treatment, are easily scalable for industrial production, offering significant engineering value.

4. Conclusions

This study systematically reveals the synergistic regulation mechanism of Al2O3 morphology and distribution on the high-temperature mechanical properties and thermal conductivity of B4C/Al composites. The key findings are summarized as follows:

- In as-forged composites, amorphous Al2O3 distributes continuously along the grain boundaries of the matrix, forming a strong pinning effect that significantly enhances high-temperature strength (exhibiting a tensile strength of 149 MPa at 350 °C). However, this continuous network structure blocks the thermal conduction pathways in the aluminum matrix, resulting in a low thermal conductivity of only 100 W/(m·K) at 350 °C.

- During hot extrusion, am-Al2O3 in B4C/Al composites breaks into flakes (100–200 nm) distributed along the grain boundaries. This distribution not only retains partial pinning effects (inhibiting grain coarsening) but also constructs continuous thermal conduction pathways in the aluminum matrix, increasing the composite’s thermal conductivity to approximately 144 W/(m·K). At 350 °C, the composite demonstrates excellent high-temperature mechanical properties, with a tensile strength of 129 MPa and an elongation at break of 8%.

- Heat treatment enhances the high-temperature mechanical properties and thermal conductivity of B4C/Al composites by regulating the distribution, size, morphology, and crystalline state of nano-Al2O3 within the aluminum matrix. Notably, the nano-Al2O3 undergoes sequential phase transformations during heat treatment: lamellar am-Al2O3 → lamellar γ-Al2O3 → short-rod γ-Al2O3 → spherical γ-Al2O3. The 500 °C/24 h heat treatment process emerges as the key optimization window, enabling the composite to simultaneously attain high strength (144 MPa) and high thermal conductivity (181 W/(m·K)) at 350 °C.

Author Contributions

C.H.: Conceptualization, Writing—original draft, Methodology, Investigation, Formal analysis, Data curation. L.L.: Writing—review and editing, Conceptualization, Validation, Investigation, Formal analysis, Supervision, Project administration. Q.L.: Writing—review and editing, Supervision, Funding acquisition, Conceptualization. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by Shenzhen Science and Technology Innovation Program (grant numbers: JSGG20220831110607013, WDZC20200821100123001).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Lingmin Li was employed by the company Beijing Onmicro Electronics Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- El-Samrah, M.G.; Tawfic, A.F.; Chidiac, S.E. Spent nuclear fuel interim dry storage; Design requirements, most common methods, and evolution: A review. Ann. Nucl. Energy 2021, 160, 108408. [Google Scholar] [CrossRef]

- Qi, Z.; Yang, Z.; Li, J.; Guo, Y.; Yang, G.; Yu, Y.; Zhang, J. The Advancement of Neutron-Shielding Materials for the Transportation and Storage of Spent Nuclear Fuel. Materials 2022, 15, 3255. [Google Scholar] [CrossRef]

- Zan, Y.N.; Zhang, Q.; Zhou, Y.T.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. Enhancing high-temperature strength of B4C–6061Al neutron absorber material by in-situ Mg(Al)B2. J. Nucl. Mater. 2019, 526, 151788. [Google Scholar] [CrossRef]

- Junaedi, H.; Ibrahim, M.; Ammar, H.; Samuel, A.; Soliman, M.; Almajid, A.; Samuel, F. Effect of testing temperature on the strength and fracture behavior of Al-B4C composites. J. Compos. Mater. 2015, 50, 429–435. [Google Scholar] [CrossRef]

- Gangolu, S.; Rao, A.; Prabhu, N.; Deshmukh, V.P.; Kashyap, B.P. Effects of temperature and strain rate on compressive flow behavior of aluminum-boron carbide composites. J. Compos. Mater. 2014, 48, 1313–1321. [Google Scholar] [CrossRef]

- Chen, X.G.; Stgeorges, L.; Roux, M. Mechanical Behavior of High Boron Content Al-B4C Metal Matrix Composites at Elevated Temperatures. Mater. Sci. Forum. 2012, 706–709, 631–637. [Google Scholar] [CrossRef]

- Lv, H.; Shang, Q.; Tan, J.; Dong, Q.; Zhou, Y.; Wu, G.; Yu, P.; Jiang, B.; Tang, A.; Pan, F. Breaking the trade-off between mechanical properties and thermal conductivity of magnesium alloys via regulating the partial Gibbs energy of alloying elements. Acta Mater. 2025, 289, 120894. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Akhtar, S.; Wang, P.; He, Z.; Jiao, X.; Ge, S.; Yuan, G.; Zhang, Y.; Li, X.; et al. Thermal conductivity of binary Al alloys with different alloying elements. J. Alloys Compd. 2025, 1010, 177257. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Chen, W.; Li, Z.; Hou, H.; Zhao, Y. Simultaneously improving thermal conductivity, mechanical properties and metal fluidity through Cu alloying in Mg-Zn-based alloys. J. Magnes. Alloys 2024, 12, 3823–3839. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, A. Study on Preparation, Microstructure and Tensile Properties of B4C/6061Al Composites. Hot Work. Technol. 2021, 50, 75–78. [Google Scholar]

- Suo, X.; Liao, H.; Hu, Y.; Dixit, U.; Petrov, P. Formation of Al15Mn3Si2 phase during solidification of a novel Al-12%Si-4%Cu-1.2%Mn heat-resistant alloy and its thermal stability. J. Mater. Eng. Perform. 2018, 27, 2910–2920. [Google Scholar] [CrossRef]

- Morri, A.; Ceschini, L.; Messieri, S.; Cerri, E.; Toschi, S. Mo addition to the A354 (Al-SiCu-Mg) casting alloy: Effects on microstructure and mechanical properties at room and high temperature. Metals 2018, 8, 393. [Google Scholar] [CrossRef]

- CCeschini, L.; Morri, A.; Toschi, S.; Seifeddine, S. Room and high temperature fatiguebehaviour of the A354 and C355 (Al-Si-Cu-Mg) alloys: Role of microstructure and heat treatment. Mater. Sci. Eng. A 2016, 653, 129–138. [Google Scholar] [CrossRef]

- Guo, Z.; Li, Q. Effect of Remelting Temperature and Stirring Time on the Microstructure of Al-B4C Composites. Contemp. Chem. Ind. 2018, 47, 2510–2513. [Google Scholar]

- Liu, W. Research on the Fabrication of Al-B4C-Al2O3 Composites by Liquid Process and Solid-State Distribution Technology. Master’s Thesis, Tsinghua University, Beijing, China, 2017. [Google Scholar]

- Pang, X.X. High-Temperature Strengthened Aluminum Matrix Boron Carbide Composite Materials: Design, Preparation, and Performance Study. Ph.D. Thesis, China Academy of Engineering Physics, Mianyang, China, 2019. [Google Scholar]

- Balog, M.; Simancik, F.; Krizik, P.; Nosko, M.; Rajner, W.; Walcher, M.; Qian, M. Novel ultrafine-grained aluminium metal matrix composites prepared from fine atomized Al powders. In Proceedings of the TMS 2014 Annual Meeting & Exhibition, San Diego, CA, USA, 16–20 February 2014; pp. 1425–1430. [Google Scholar]

- Balog, M.; Krizik, P.; Nosko, M.; Hajovska, Z.; Riglos, M.; Rajner, W.; Liu, D.; Simancik, F. Forged HITEMAL: Al-based MMCs strengthened with nanometric thick Al2O3 skeleton. Mater. Sci. Eng. A 2014, 613, 82–90. [Google Scholar] [CrossRef]

- Zan, Y.N.; Zhou, Y.T.; Li, X.N.; Ma, G.N.; Liu, Z.Y.; Wang, Q.Z.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Enhancing High-Temperature Strength and Thermal Stability of Al2O3/Al Composites by High-Temperature Pre-treatment of Ultrafine Al Powders. Acta Metall. Sin. 2020, 33, 913–921. [Google Scholar] [CrossRef]

- Zan, Y.N. High-Temperature Neutron Absorbing (B4C+Al2O3)/Al Composites: Preparation and Processing Research. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2020. [Google Scholar]

- Tanaka, H. Future perspective regarding nuclear power and fuel cycle in Japan and the world. At. Energy Soc. Jpn. 2018, 60, 152–156. [Google Scholar] [CrossRef][Green Version]

- Kim, K.; Sunghwan, C.; Junhee, H. Performance evaluation of METAMIC neutron absorber in spent fuel storage rack. Nucl. Eng. Technol. 2018, 50, 788–793. [Google Scholar] [CrossRef]

- Feng, S.; Li, Q.; Liu, W.; Shu, G.; Wang, X. Microstructure and mechanical properties of B4C/Al composite at elevated temperature strengthened with in situ Al2O3 network. Rare Met. 2020, 39, 671–679. [Google Scholar] [CrossRef]

- Zan, Y.N.; Zhou, Y.T.; Zhao, H.; Liu, Z.Y.; Wang, Q.Z.; Wang, D.; Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Enhancing high-temperature strength of (B4C+Al2O3)/Al designed for neutron absorbing materials by constructing lamellar structure. Compos. Part B Eng. 2020, 183, 107674. [Google Scholar] [CrossRef]

- Zan, Y.N.; Zhou, Y.T.; Liu, Z.Y.; Ma, G.N.; Wang, D.; Wang, Q.Z.; Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Enhancing strength and ductility synergy through heterogeneous structure design in nanoscale Al2O3 particulate reinforced Al composites. Mater. Des. 2019, 166, 107629. [Google Scholar] [CrossRef]

- Zan, Y.N.; Zhou, Y.T.; Liu, Z.Y.; Wang, Q.Z.; Wang, W.G.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Microstructure and mechanical properties of (B4C+Al2O3)/Al composites designed for neutron absorbing materials with both structural and functional usages. Mater. Sci. Eng. A 2020, 773, 138840. [Google Scholar] [CrossRef]

- Martin, B.; Tao, H.; Peter, K.; Maria, V.; Brandon, D.; Hanry, Y.; Julie, M.; Enrique, J. On the thermal stability of ultrafine-grained Al stabilized by in-situ amorphous Al2O3 network. Mater. Sci. Eng. A 2015, 648, 61–71. [Google Scholar]

- ASTM B962; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2023.

- ASTM E1461; Standard Test Method for Thermal Diffusivity by the Flash Method. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2022.

- Kentaro, F.L.; Diran, A. Thermal and Electrical Conductivity of Aluminum Alloys: Fundamentals, structure-property relationships, and pathways to enhance conductivity. Mater. Sci. Eng. A 2025, 924, 147766. [Google Scholar]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Samuel, A.H.; Thomas, A.M.; Mike, F.; Peter, P.; William, E.L.; Mike, R.; Salvatore, G. Thermal conductivity of WC: Microstructural design driven by first-principles simulations. Acta Mater. 2025, 283, 120517. [Google Scholar]

- Madeleine, B.; Marc, B. Particle pinning during grain growth-A new analytical model for predicting the mean limiting grain size but also grain size heterogeneity in a 2D polycrystalline context. Acta Mater. 2024, 277, 120174. [Google Scholar]

- Hu, Q.Y.; Chen, H.; Fu, W.J.; Zhou, L.M.; Deng, Y.Q. Effect of titanium element on the interfacial reactions and properties of B4C/Al composites fabricated by selective laser melting. Mater. Chem. Phys. 2025, 333, 130385. [Google Scholar] [CrossRef]

- Dai, X.L.; Wu, Q.L.; Li, X.; Wang, X.Q.; Shi, Y.X.; Zhou, Y.; Wen, S.F.; Shi, Y.S. Crack suppression and ductility modification of additive manufactured Ti6Al4V/W heterostructure interface via Nano-TiC reinforcement. Eng. Fail. Anal. 2025, 180, 109852. [Google Scholar] [CrossRef]

- Ha, W.; Kim, G.; Jung, Y.S.; Ahn, S.J. Experimental emulation of 10B(n, α)7Li reaction-induced microstructural evolution of Al-B4C neutron absorber used in the dry storage of spent nuclear fuel. J. Nucl. Mater. 2024, 593, 154977. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).