Cerium Addition Enhances Impact Energy Stability in S355NL Steel by Tailoring Microstructure and Inclusions

Abstract

1. Introduction

2. Experimental Section

3. Results and Discussion

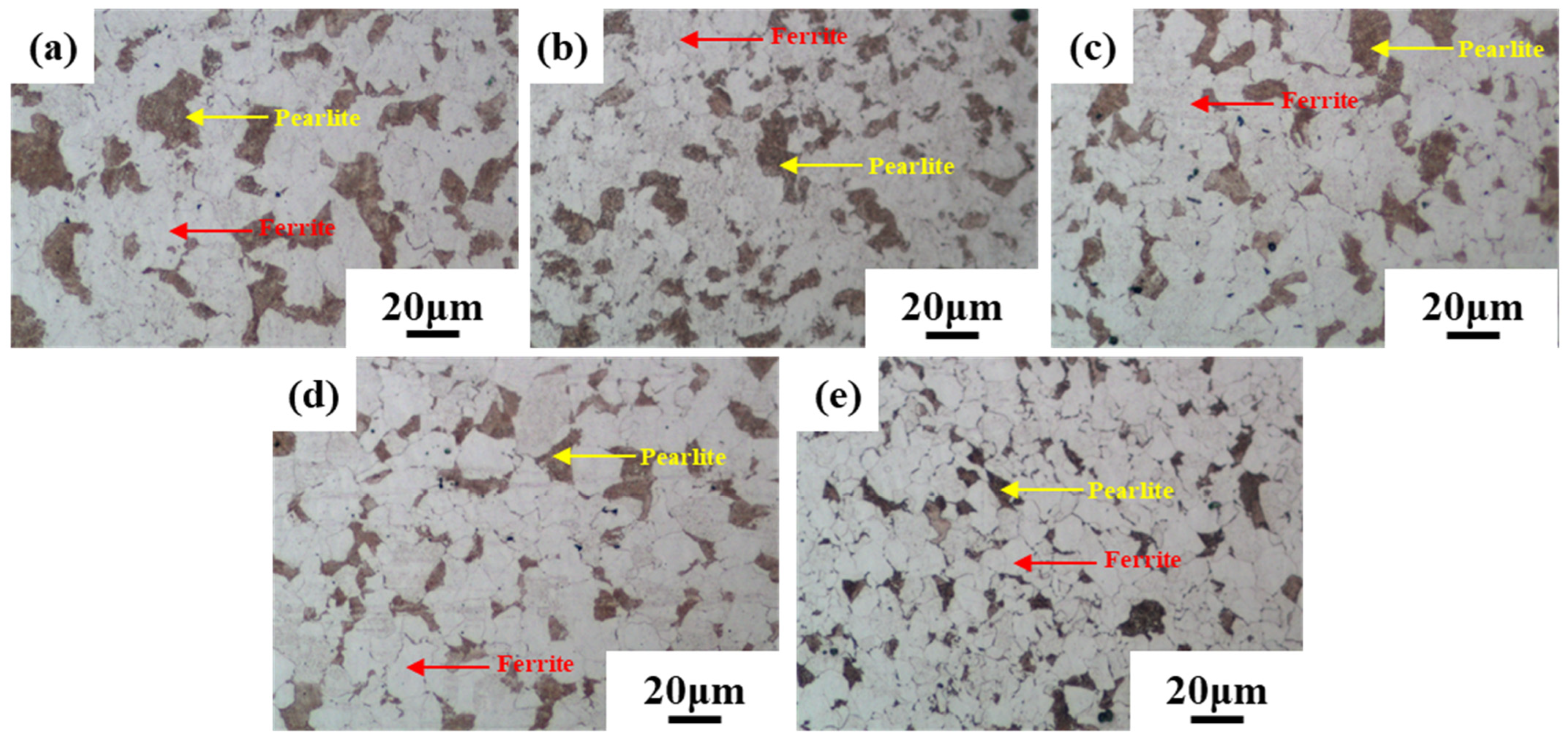

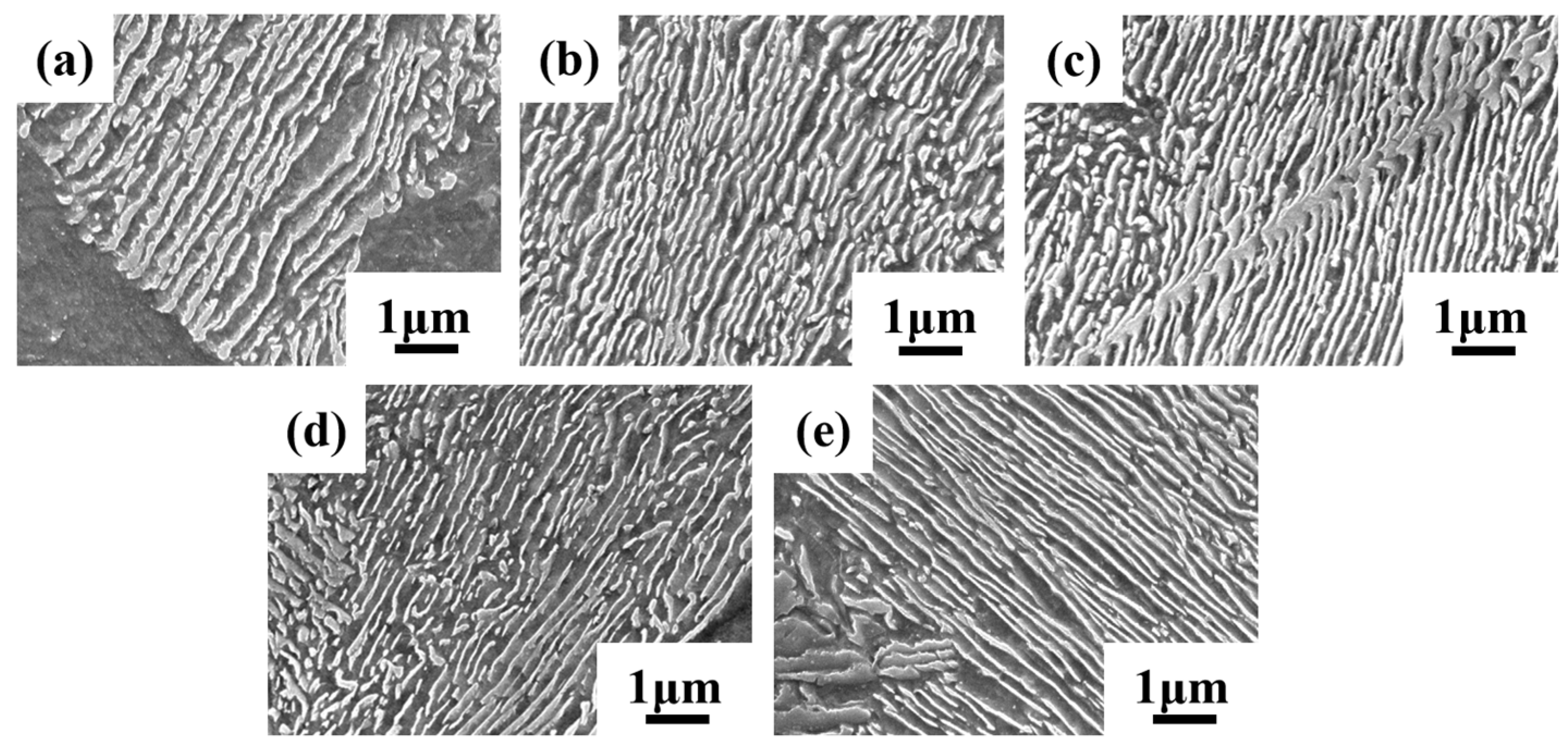

3.1. Microstructural Evolution

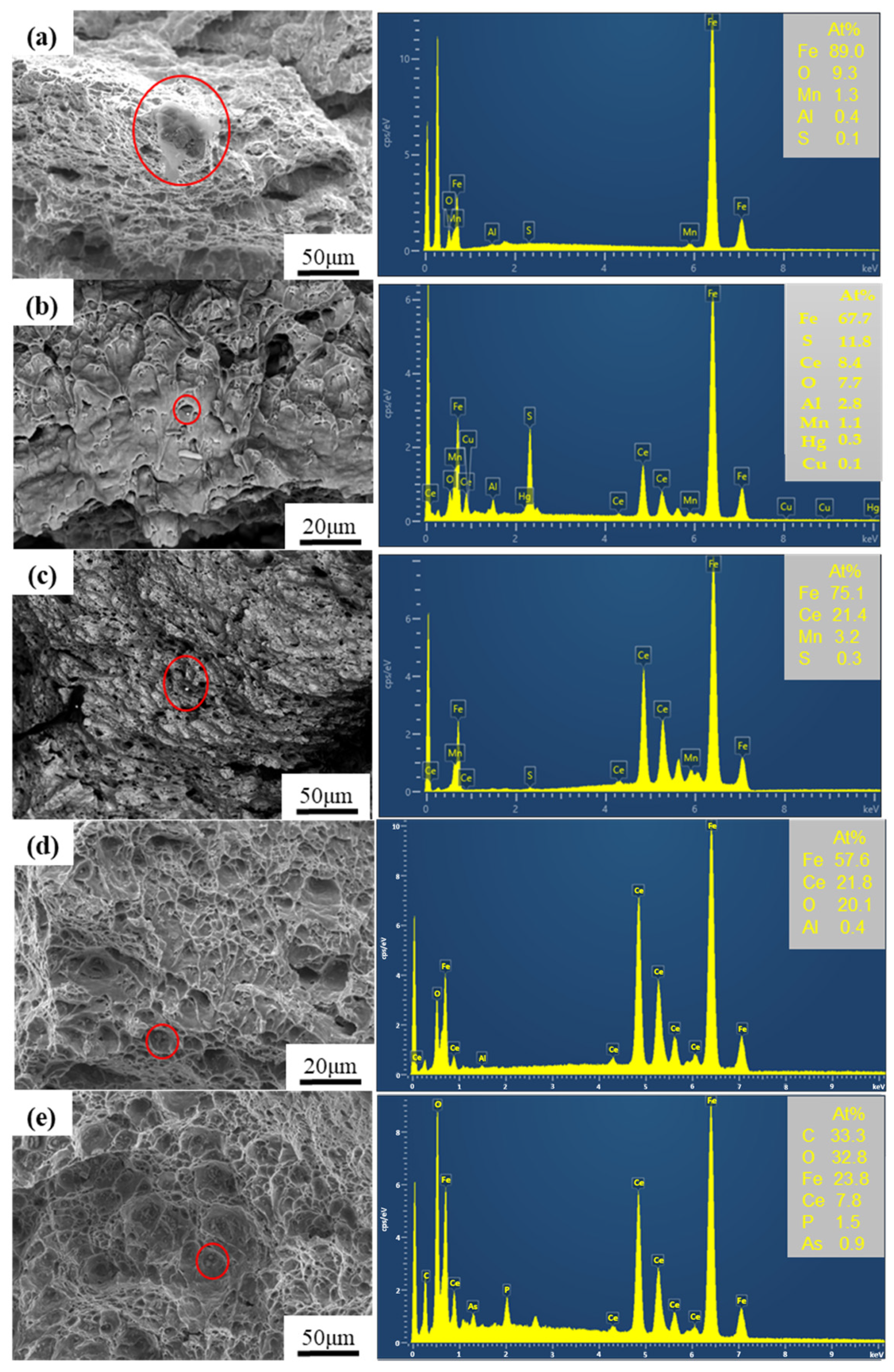

3.2. Inclusion Modification

3.3. Impact Performance Optimization

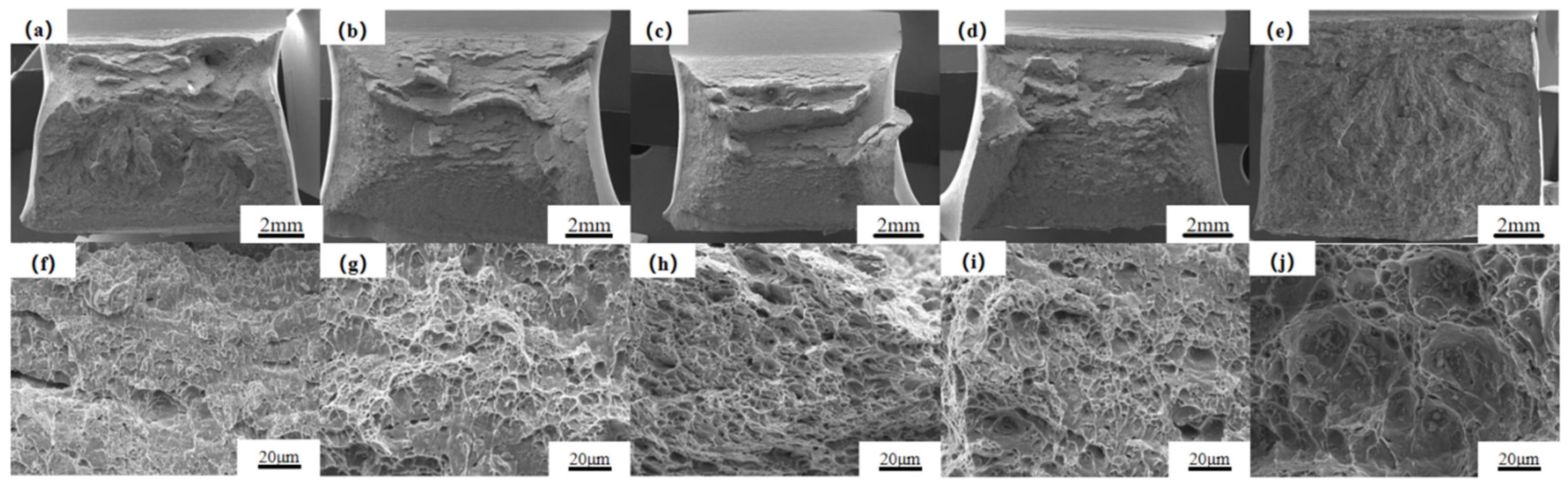

3.4. Impact Fractography Analysis

3.5. Mechanism Analysis of Performance Improvement

4. Conclusions

- An optimal Ce addition window (0.0011–0.0049 wt.%) in S355 NL steel is obtained. Within this range, the addition of Ce significantly improves impact toughness and suppresses fluctuations in Charpy impact energy.

- Ce addition promotes grain size reduction and narrows pearlite interlamellar spacing. At 0.0011 wt.% Ce, the total inclusion count drops by ≈70%, and the mean diameter decreases to 2.11 µm, entirely eliminating coarse (>10 µm) inclusions. With the addition of Ce at 0.086 wt.%, however, the inclusion density rises to over 1000 inclusions with a mean diameter of 2.81 µm, leading to the re-emergence of large-size inclusions that act as crack initiation sites.

- Charpy V-notch tests show that the 0.0011 wt.% Ce-added steel exhibits the highest absorbed energies (257 J transverse, 270 J longitudinal) and achieves an isotropy ratio of ~1.01. Steels with higher Ce addition suffer reduced absorbed energies and increased anisotropy due to the presence of coarse and stress-concentrating inclusions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.; Kim, Y.W.; Lee, J.H. Effect of Tungsten Addition on the Mechanical Properties and Corrosion Resistance of S355NL Forging Steel. Met. Mater. Int. 2012, 18, 217–223. [Google Scholar] [CrossRef]

- Klusák, J.; Seitl, S. Very high cycle fatigue tests of high strength steels S355 J0 and S355 J2. Procedia Struct. Integr. 2019, 17, 576–581. [Google Scholar] [CrossRef]

- Alaoui, A.E.M.; Thevenet, D.; Zeghloul, A. Propagation of small fatigue cracks from notched specimens in S355NL steel. Proc. Appl. Math. Mech. 2004, 4, 278–279. [Google Scholar] [CrossRef]

- Smoljan, B.; Iljkić, D. Microstructure and mechanical properties of steel castings. In Proceedings of the Proceedings Book of the 8th International Foundrymen Conference, Opatija, Croatia, 5–7 June 2008. [Google Scholar]

- Pickering, B.F. Non-Metallic Inclusions in Steel. Br. Corros. J. 1978, 13, 55–56. [Google Scholar] [CrossRef]

- Li, D.; Wang, P.; Chen, X.-Q.; Fu, P.; Luan, Y.; Hu, X.; Liu, H.; Sun, M.; Chen, Y.; Cao, Y.; et al. Low-oxygen rare earth steels. Nat. Mater. 2022, 21, 1137–1143. [Google Scholar] [CrossRef]

- Yang, C.; Li, Z.; Liu, P.; Luan, Y.; Li, D.; Li, Y.; ul Haq Tariq, N. Influence of trace rare earth elements on very high cycle fatigue behavior of hot rolled bearing steel. Int. J. Fatigue 2023, 176, 107877. [Google Scholar] [CrossRef]

- Yang, C.; Luan, Y.; Li, D.; Li, Y.; Tariq, N.u.H. Very high cycle fatigue behavior of bearing steel with rare earth addition. Int. J. Fatigue 2020, 131, 105263. [Google Scholar] [CrossRef]

- Yang, C.; Luan, Y.; Li, D.; Li, Y. Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel. J. Mater. Sci. Technol. 2019, 35, 1298–1308. [Google Scholar] [CrossRef]

- Kumar, V.; Deva, A.; Chattopadhyay, K. Effect of Addition of Rare Earth Element Cerium on the Microstructure and Mechanical Properties of Microalloyed Peritectic Grade Steel. Trans. Indian Inst. Met. 2024, 77, 3751–3758. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Yang, S.; Chen, C.; Li, J.; Li, X. Investigation on the control of inclusions and tensile strength in Ce-treated P110-grade oil casing steel. Sci. Rep. 2024, 14, 14840. [Google Scholar] [CrossRef]

- Zhang, X.; Zhi, J.; Song, X.; Diao, W.; Lu, B.; An, S. Influence of cerium on impact toughness, tensile properties and inclusion of industrial Al-killed steel Q355B. J. Mater. Res. Technol. 2024, 32, 1118–1126. [Google Scholar] [CrossRef]

- Song, C.; Xie, Z.; Zhang, Z.; Wang, H.; Sun, Z.; Yang, Y.; Yu, H.; Cheng, J. Effect of Ce on the microstructure, mechanical properties and dislocation state in low-carbon low-alloy steels. Mater. Sci. Eng. A 2025, 927, 148009. [Google Scholar] [CrossRef]

- Zhang, X.; Zhi, J.; Song, X.; An, S. Formation mechanism of cerium-based inclusions and effect on microstructure and impact toughness in Q355ME. Mater. Und Werkst. 2025, 56, 353–363. [Google Scholar] [CrossRef]

- Szucki, M.; Kalisz, D.; Gerasin, S.; Mrówka, N.M.; Iwanciw, J.; Semiryagin, S. Analysis of the effect of cerium on the formation of non-metallic inclusions in low-carbon steel. Sci. Rep. 2023, 13, 8294. [Google Scholar] [CrossRef]

- Xi, Z.; Sun, T.; Xiao, H.; Fan, Z.; Liu, T.; Lian, X.; Li, J.; Dong, H. Effects of Rare Earth Elements on Inclusions and Impact Toughness in a Weathering Steel. Trans. Indian Inst. Met. 2024, 77, 831–841. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z.; Li, B.; Chen, W.; Zhang, J.; Mao, J. Inclusions modification by rare earth in steel and the resulting properties: A review. J. Rare Earths 2024, 42, 431–445. [Google Scholar] [CrossRef]

- GB/T 229-2020; Metallic Materials—Charpy Pendulum Impact Test Method. Standards Press of China: Beijing, China, 2020.

- Li, Y.; Sun, S.; Yang, H.; Chen, C.; Ma, S.; Mao, Y.; Sun, M.; Cao, H.; Jiang, Z. Effect of Ce and Nb on the Microstructure and Properties of 65Si2CrV Spring Steel for Automobile Valve. J. Mater. Eng. Perform. 2024, 34, 9795–9812. [Google Scholar] [CrossRef]

- Torkamani, H.; Raygan, S.; Garcia-Mateo, C.; Rassizadehghani, J.; Palizdar, Y.; San-Martin, D. Evolution of Pearlite Microstructure in Low-Carbon Cast Microalloyed Steel Due to the Addition of La and Ce. Metall. Mater. Trans. 2018, 49, 4495–4508. [Google Scholar] [CrossRef]

- Cheng, S.; Hou, T.; Zheng, Y.; Yin, C.; Wu, K. Effect of Rare Earth Elements on Microstructure and Tensile Behavior of Nb-Containing Microalloyed Steels. Materials 2024, 17, 1701. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, C.; Yang, R. Chemical State of Cosegregation of P and Ce at Ferrite Grain Boundary. Chin. J. Eng. 1993, 15, 43–47. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, C.; Yang, R. Study of Ce-P Cosegregation on Grain Boundaries by AES and Computer Modelling. Chin. J. Eng. 1990, 12, 542–546. [Google Scholar] [CrossRef]

- Zhu, J.; Xie, J.; Zhang, Z.; Huang, H. Microstructure and Obdurability Improvement Mechanisms of the La-Microalloyed H13 Steel. Steel Res. Int. 2018, 89, 1800044. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Sun, M.; Chen, C.-Y.; Jiang, Z.-H. Experimental Study on Rare Earth and Magnesium Composite Treatment of 49MnVS3 Non-quenched and Tempered Steel. Steel Res. Int. 2021, 92, 2100190. [Google Scholar] [CrossRef]

- Pan, F.; Zhang, J.; Chen, H.-L.; Su, Y.-H.; Kuo, C.-L.; Su, Y.-H.; Chen, S.-H.; Lin, K.-J.; Hsieh, P.-H.; Hwang, W.-S.J.M. Effects of rare earth metals on steel microstructures. Materials 2016, 9, 417. [Google Scholar] [CrossRef] [PubMed]

- Feng, L. Effect of Non-metallic Inclusions on the Local Stress Concentration within Materials. J. Mech. Eng. 2013, 49, 41. [Google Scholar] [CrossRef]

- Wang, H.; Shao, K.; Niu, Y.; Qiao, J.; Pan, H.; Qiu, S. Influence mechanism of rare earth (RE) on inclusion modification in non-oriented silicon steel. Metall. Res. Technol. 2024, 121, 604. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, Y.; Xu, X.; Fu, J. Modification of Inclusion in High-Strength Steel Treated with Rare Earth. J. Mater. Res. Technol. 2025, 36, 470–480. [Google Scholar] [CrossRef]

- Pasebani, S.; Charit, I.; Wu, Y.Q.; Butt, D.P.; Cole, J.I. Mechanical alloying of lanthana-bearing nanostructured ferritic steels. Acta Mater. 2013, 61, 5605–5617. [Google Scholar] [CrossRef]

- Liu, H.; Fu, P.; Liu, H.; Cao, Y.; Sun, C.; Du, N.; Li, D. Effects of Rare Earth elements on microstructure evolution and mechanical properties of 718H pre-hardened mold steel. J. Mater. Sci. Technol. 2020, 50, 245–256. [Google Scholar] [CrossRef]

- Tong, L.X.; Long, C.; Wei, F.Z.; Shi, L.T.; Xiang, X.D.; Han, D. Effects of Modified Inclusions and Precipitates Alloyed by Rare Earth Element on Corrosion and Impact Properties in Low Alloy Steel. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 1719–1730. [Google Scholar]

- Yue, L.J.; Wang, L.L.; Wang, L.M. Influence of rare earth element on the mechanical properties of clean weathering steel. Chin. Rare Earths 2014, 35, 20–26. [Google Scholar]

- Liang, Y.y.; Ni, P.y.; Liu, Q.l.; Li, Y. Effect of Rare Earth Metal Alloying on Inclusion Evolution in High-Strength Oil Casing Steel. Metall. Mater. Trans. B 2024, 55, 3158–3173. [Google Scholar] [CrossRef]

- He, F.y.; Hu, W.x.; Liu, L.j.; He, W.; Ma, S.b.; Zhang, X.d.; Yang, Z.h.; Wang, W. Effect of Ce Addition on Microstructure, Thermal Conductivity, and Mechanical Properties of As-Cast and As-Extruded Mg–3Sn Alloys. Materials 2024, 17, 4251. [Google Scholar] [CrossRef]

- Kang, J.; Yu, Y.C.; Zhang, J.L.; Chen, C.; Wang, S.B. Effect of rare earth on inclusion evolution in industrial production of HRB500E steel. Metall. Res. Technol. 2021, 118, 220. [Google Scholar] [CrossRef]

- Zhai, F.; Wang, L.; Gao, X.; Feng, Y.; Zhao, S.; Wang, L. Study on Phases Formation and Modification Ability of Rare Earth Elements La, Ce, Sm and Er in Al–Zn–Mg–Cu–Zr Alloy. Trans. Indian Inst. Met. 2021, 74, 2639–2649. [Google Scholar] [CrossRef]

| Steel No. | C | Si | Mn | P | S | Nb | V | Al | Ti | Cr | Ni | Mo | Cu | H | N | T[O] | Ce |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.15 | 0.14 | 1.39 | <0.005 | 0.0027 | 0.034 | 0.037 | 0.036 | <0.001 | <0.03 | <0.03 | 0.019 | <0.03 | <0.0001 | 0.002 | 0.0009 | 0 |

| 2 | 0.15 | 0.15 | 1.39 | <0.005 | <0.001 | 0.034 | 0.040 | 0.046 | <0.001 | <0.03 | <0.03 | 0.020 | <0.03 | <0.0001 | 0.002 | 0.0008 | 0.0011 |

| 3 | 0.15 | 0.20 | 1.38 | 0.006 | 0.0018 | 0.037 | 0.035 | 0.047 | <0.001 | <0.03 | <0.03 | 0.020 | <0.03 | <0.0001 | 0.0015 | 0.0008 | 0.0049 |

| 4 | 0.15 | 0.15 | 1.39 | <0.005 | <0.001 | 0.035 | 0.040 | 0.049 | <0.001 | <0.03 | <0.03 | 0.019 | <0.03 | <0.0001 | 0.0021 | 0.0006 | 0.019 |

| 5 | 0.15 | 0.15 | 1.40 | <0.005 | <0.001 | 0.034 | 0.039 | 0.050 | <0.001 | <0.03 | <0.03 | 0.019 | <0.03 | <0.0001 | 0.002 | 0.0007 | 0.086 |

| Steel No. | Ce Content/wt.% | Average Grain Size/μm | Interlamellar Spacing of Pearlite/μm |

|---|---|---|---|

| 1 | 0 | 5.27 | 204 |

| 2 | 0.0011 | 4.88 | 169 |

| 3 | 0.0049 | 4.98 | 159 |

| 4 | 0.019 | 4.97 | 150 |

| 5 | 0.086 | 4.65 | 156 |

| Sample | Number | 1–2 μm /% | 2–5 μm /% | 5–10 μm /% | >10 μm /% | Average /μm | Max /μm | Density /mm−2 |

|---|---|---|---|---|---|---|---|---|

| No. 1 | 254 | 37.01 | 58.72 | 3.54 | 0.73 | 2.62 | 10.70 | 9.45 |

| No. 2 | 74 | 55.41 | 41.89 | 2.70 | 0 | 2.11 | 7.68 | 2.47 |

| No. 3 | 376 | 40.14 | 56.65 | 3.2 | 0 | 2.28 | 8.82 | 14.24 |

| No. 4 | 689 | 41.83 | 48.88 | 9.29 | 0 | 2.42 | 9.81 | 24.47 |

| No. 5 | 1071 | 47.18 | 51.07 | 1.49 | 0.26 | 2.81 | 12.49 | 38.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Xie, B.; Sun, M. Cerium Addition Enhances Impact Energy Stability in S355NL Steel by Tailoring Microstructure and Inclusions. Metals 2025, 15, 802. https://doi.org/10.3390/met15070802

Yang J, Xie B, Sun M. Cerium Addition Enhances Impact Energy Stability in S355NL Steel by Tailoring Microstructure and Inclusions. Metals. 2025; 15(7):802. https://doi.org/10.3390/met15070802

Chicago/Turabian StyleYang, Jiandong, Bijun Xie, and Mingyue Sun. 2025. "Cerium Addition Enhances Impact Energy Stability in S355NL Steel by Tailoring Microstructure and Inclusions" Metals 15, no. 7: 802. https://doi.org/10.3390/met15070802

APA StyleYang, J., Xie, B., & Sun, M. (2025). Cerium Addition Enhances Impact Energy Stability in S355NL Steel by Tailoring Microstructure and Inclusions. Metals, 15(7), 802. https://doi.org/10.3390/met15070802