CFD Modelling of Refining Behaviour in EAF: Influence of Burner Arrangement and Oxygen Flow Rates

Abstract

1. Introduction

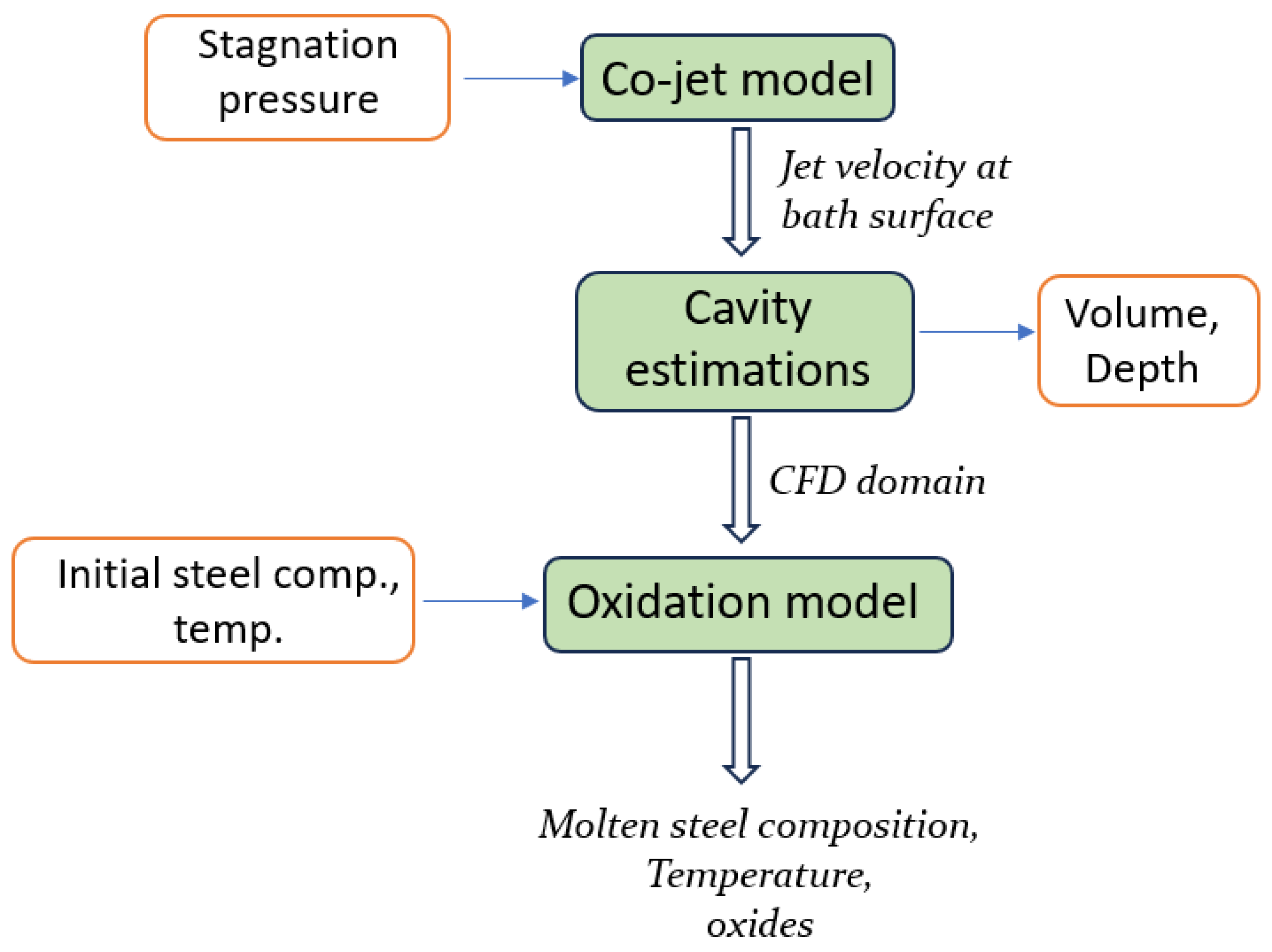

2. Methodology

2.1. Description of Refining Simulator

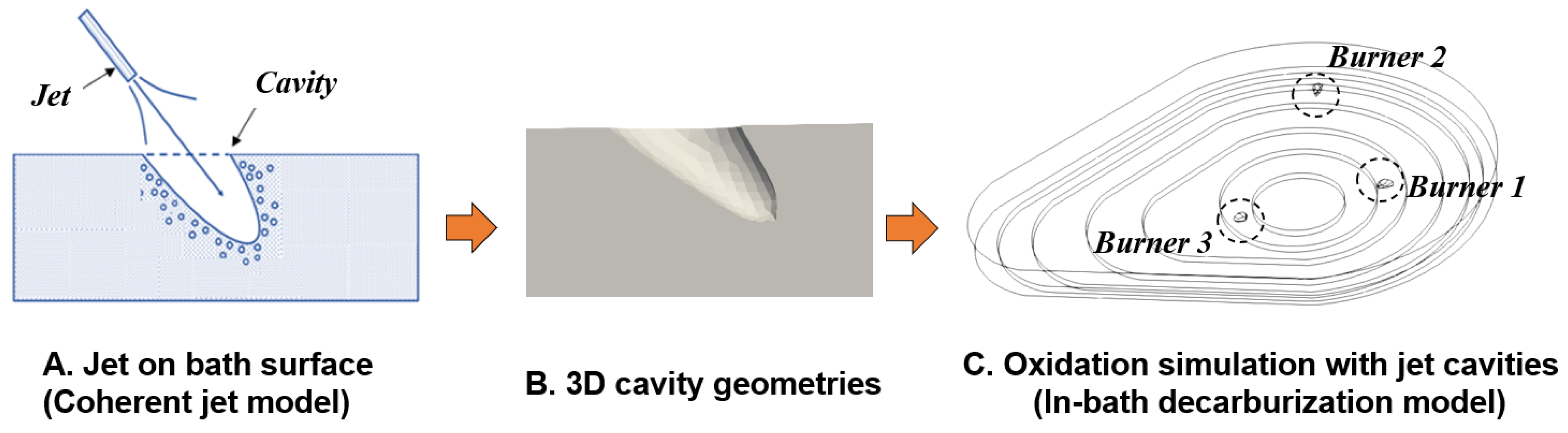

2.1.1. Coherent Jet Model

2.1.2. Estimation of Cavity Surfaces

2.1.3. In-Bath Oxidation Model

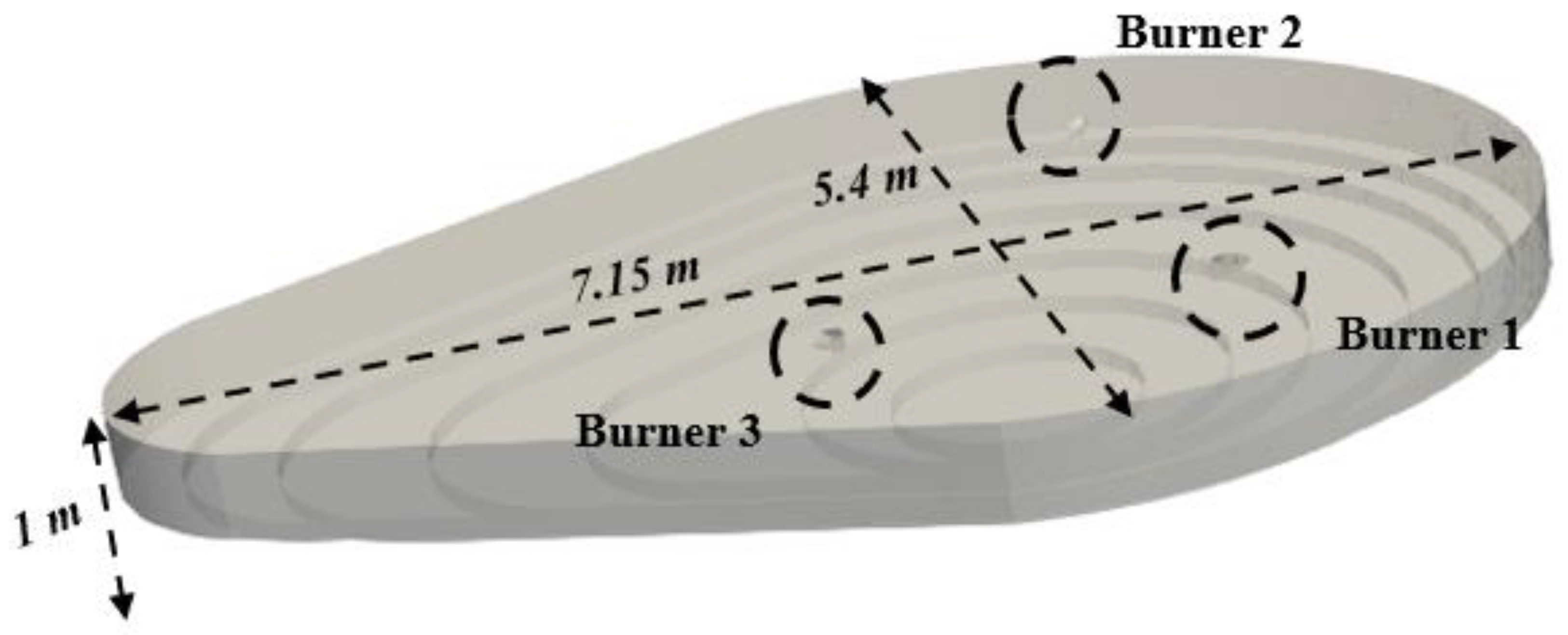

2.2. Computational Domain of Refining Simulator

3. Validation

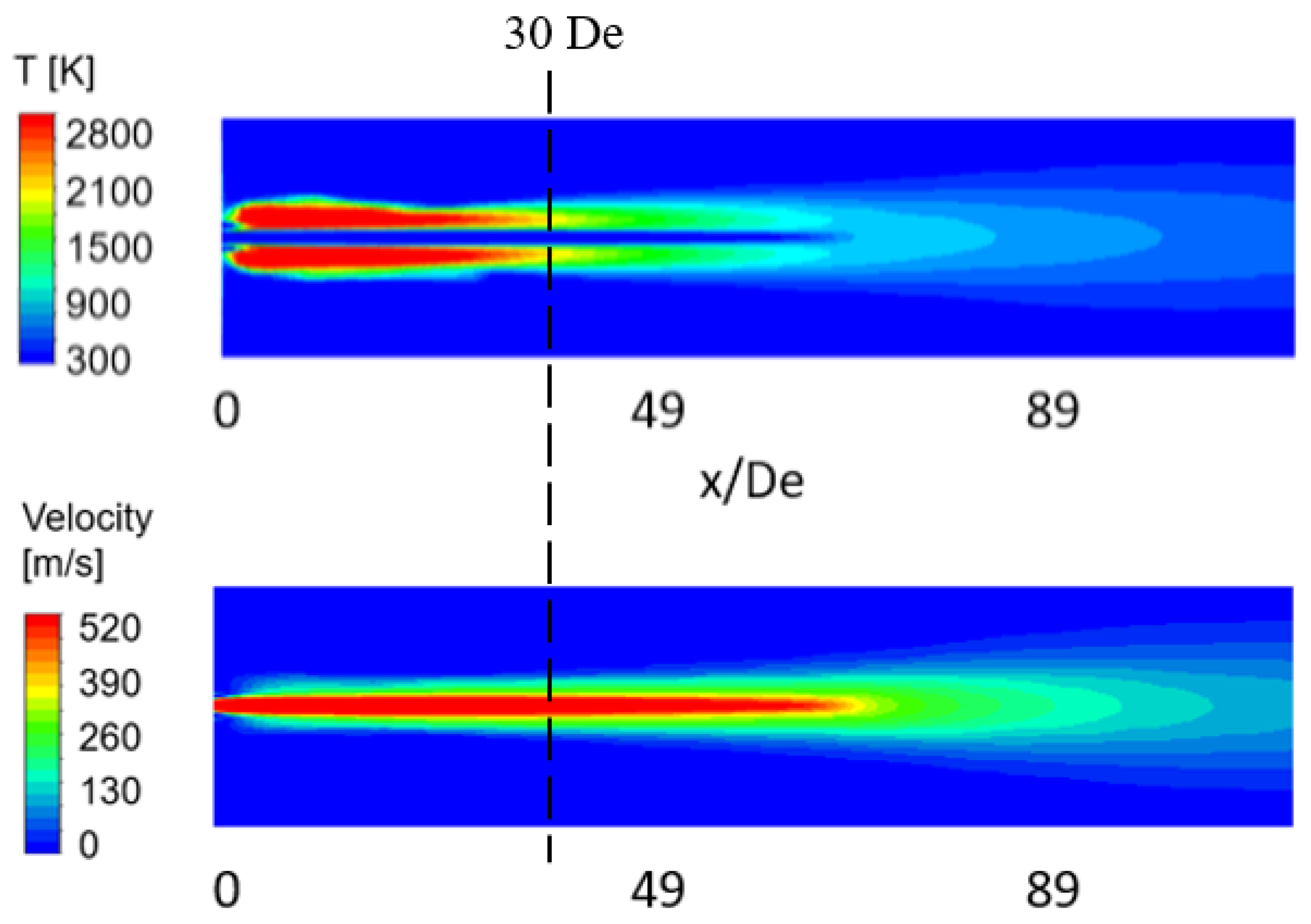

3.1. Validation of Co-Jet Model

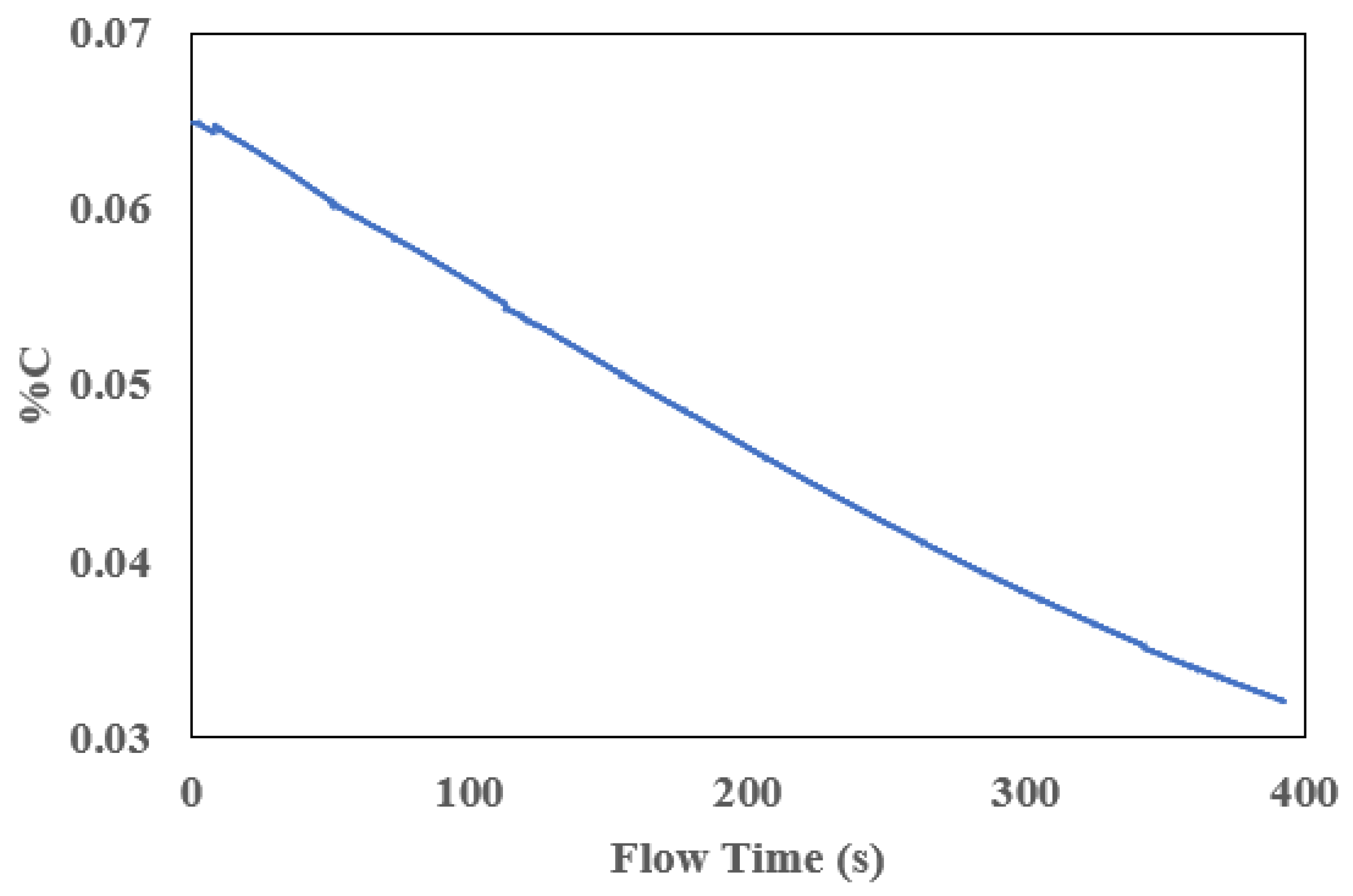

3.2. Validation of In-Bath Refining Model

4. Results

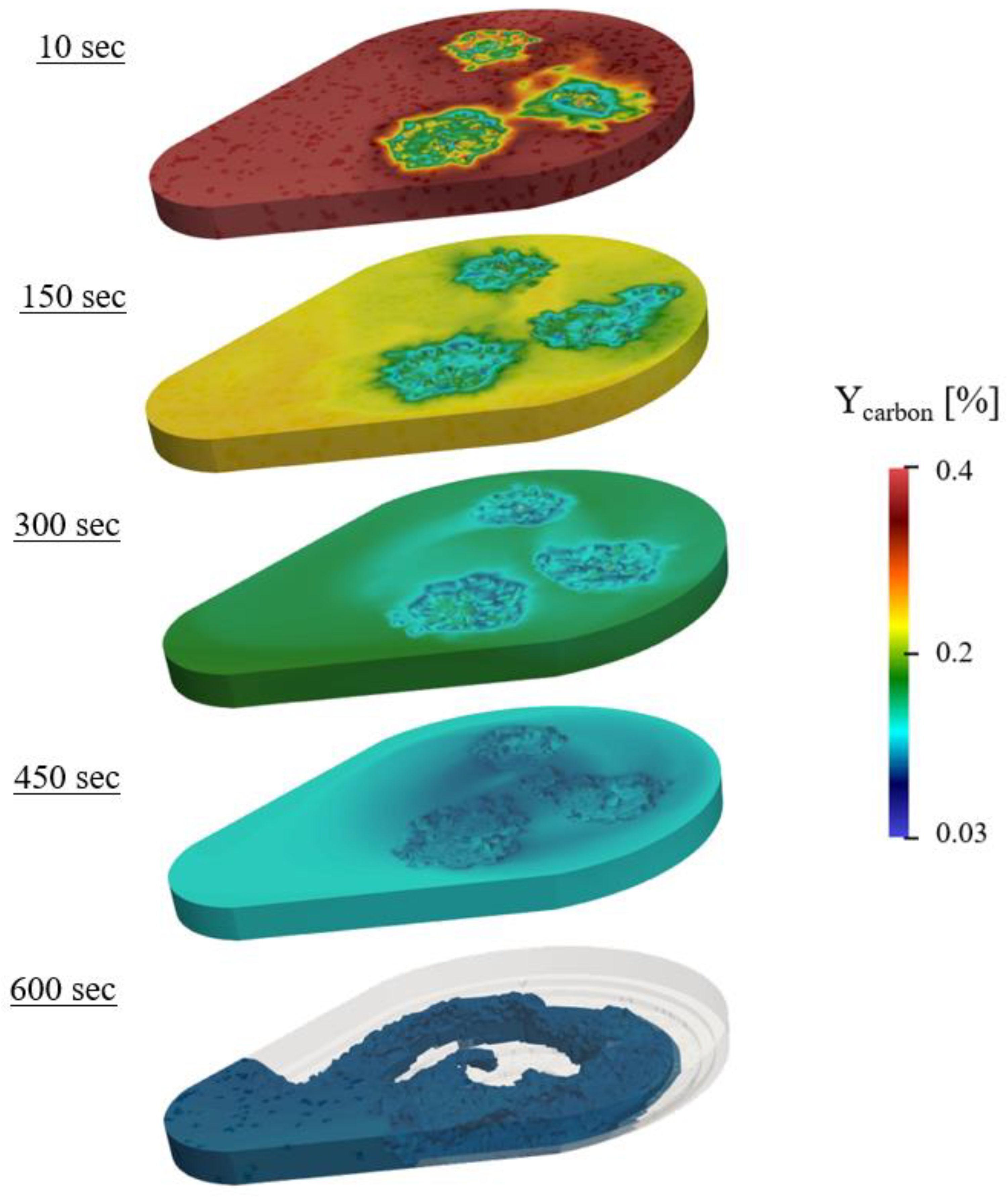

4.1. In-Bath Decarburization for Typical Initial Carbon Content

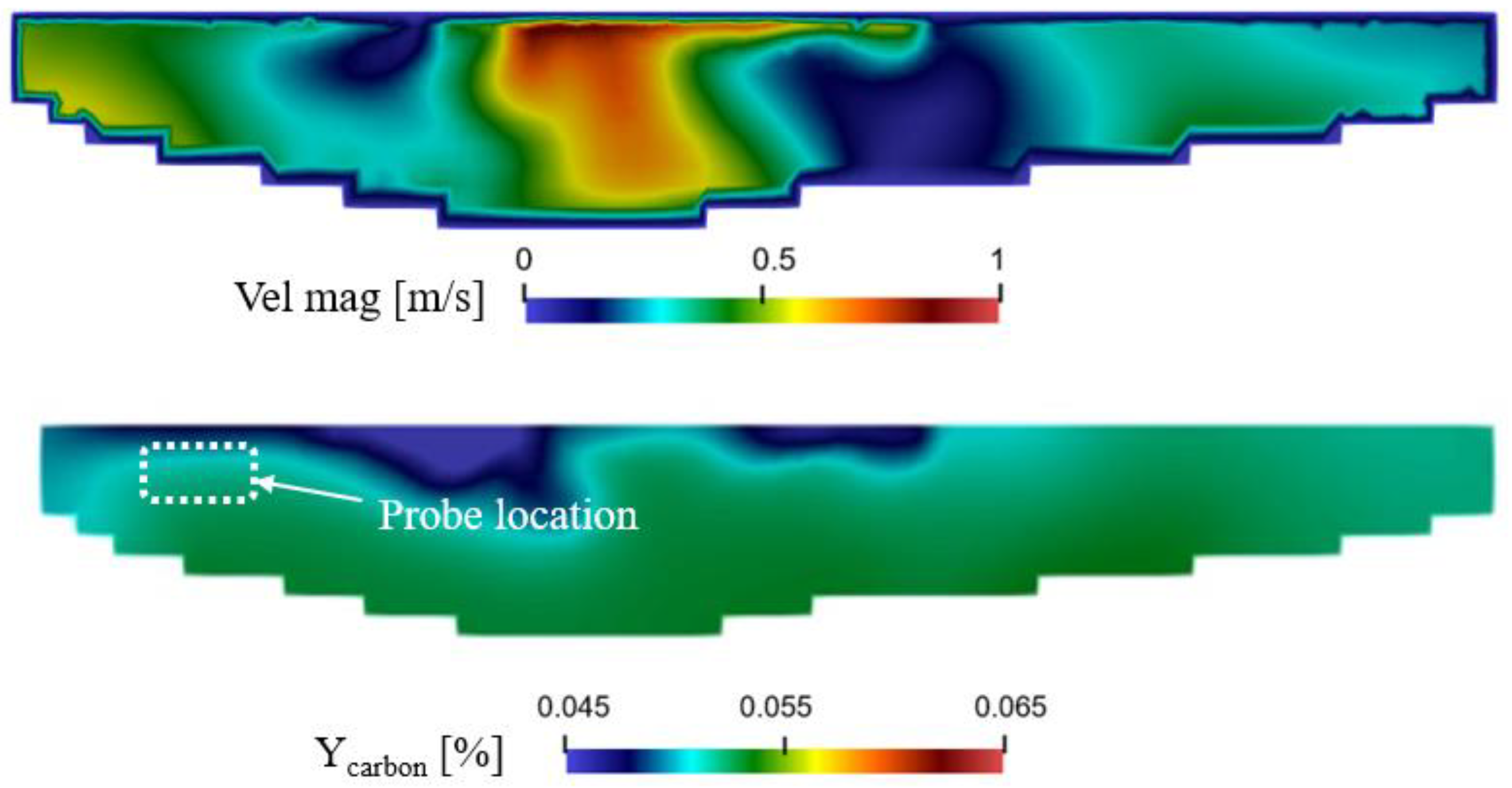

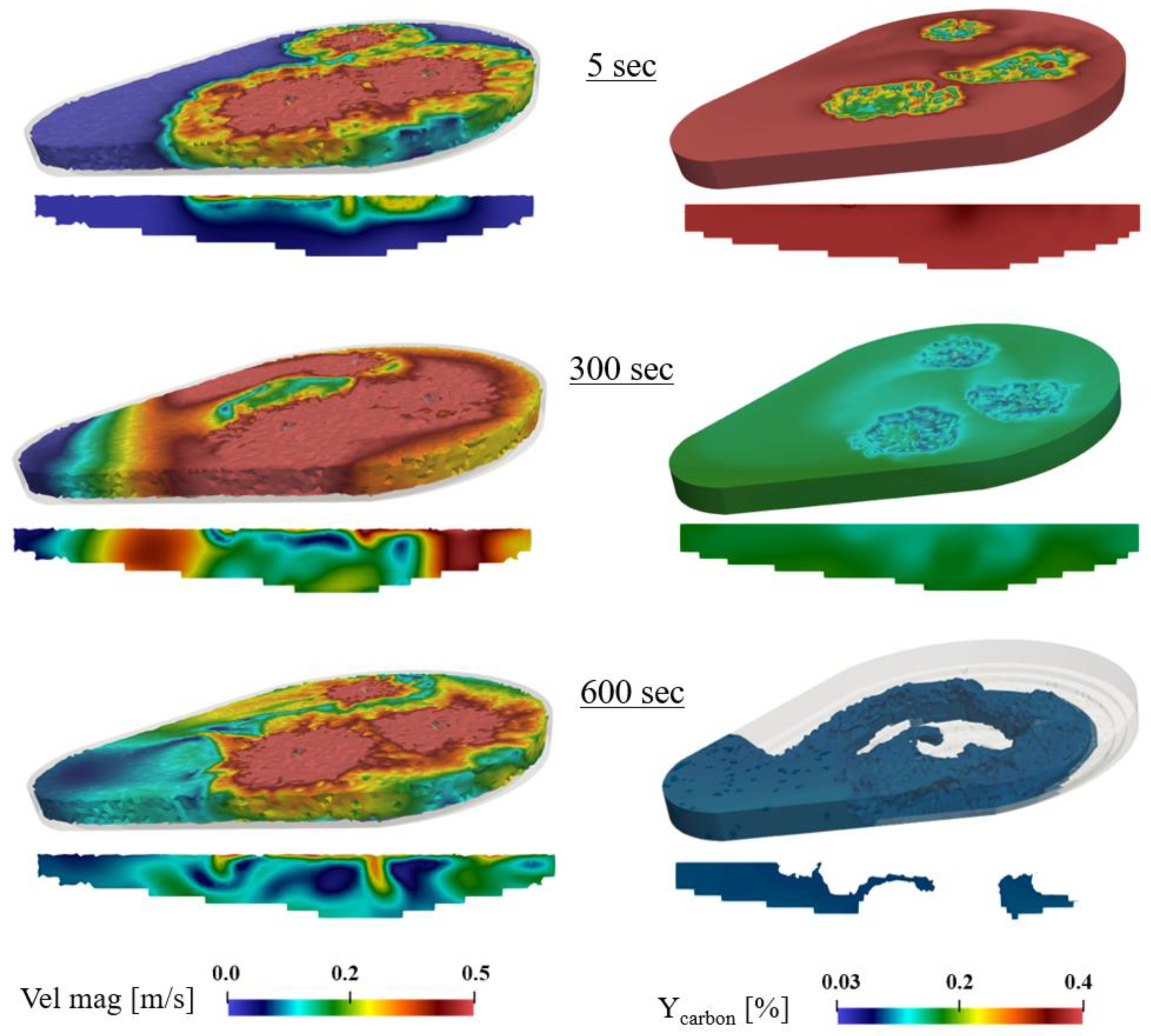

4.2. In-Bath Flow Velocity and Decarburization Dynamics

5. Discussion

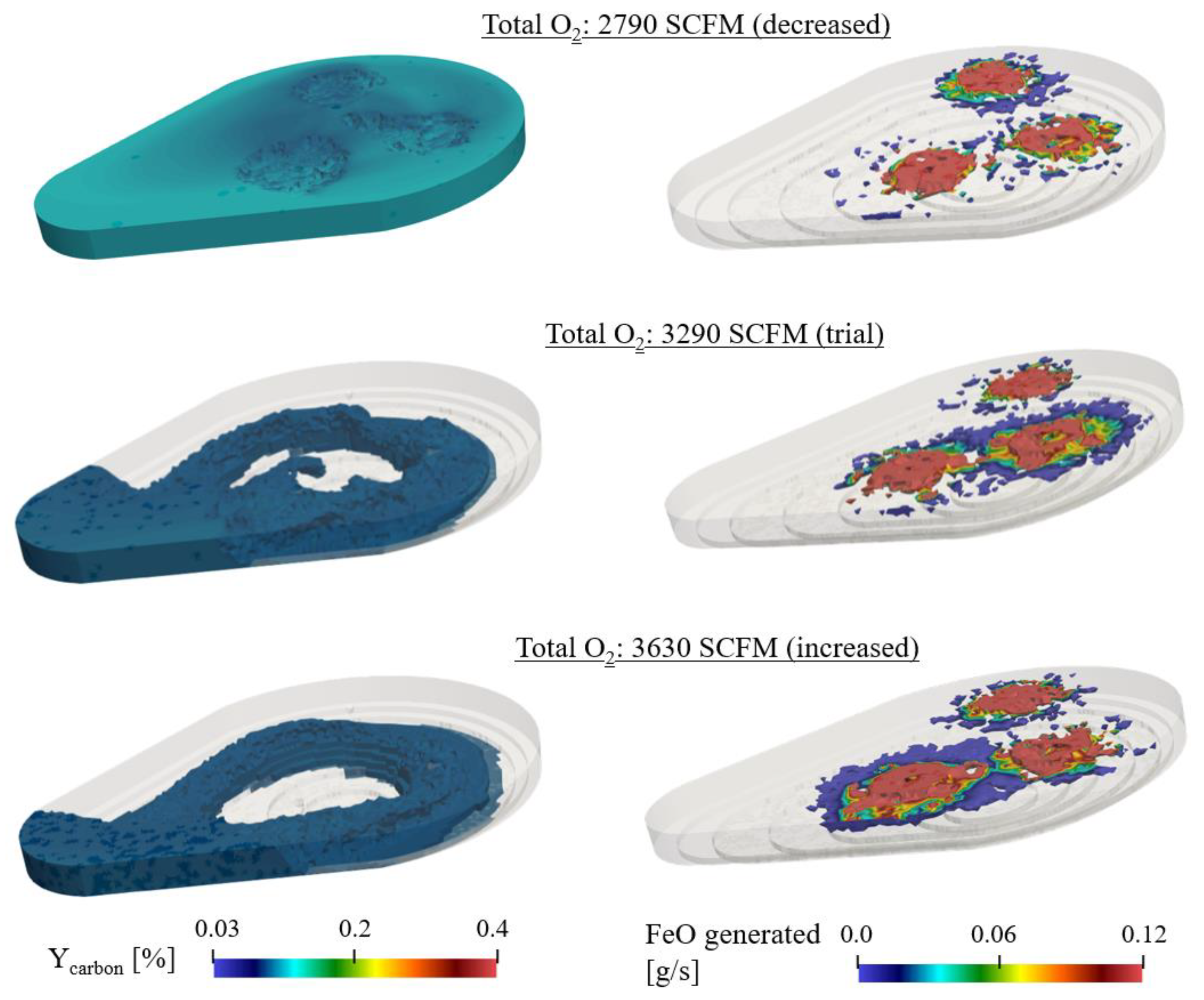

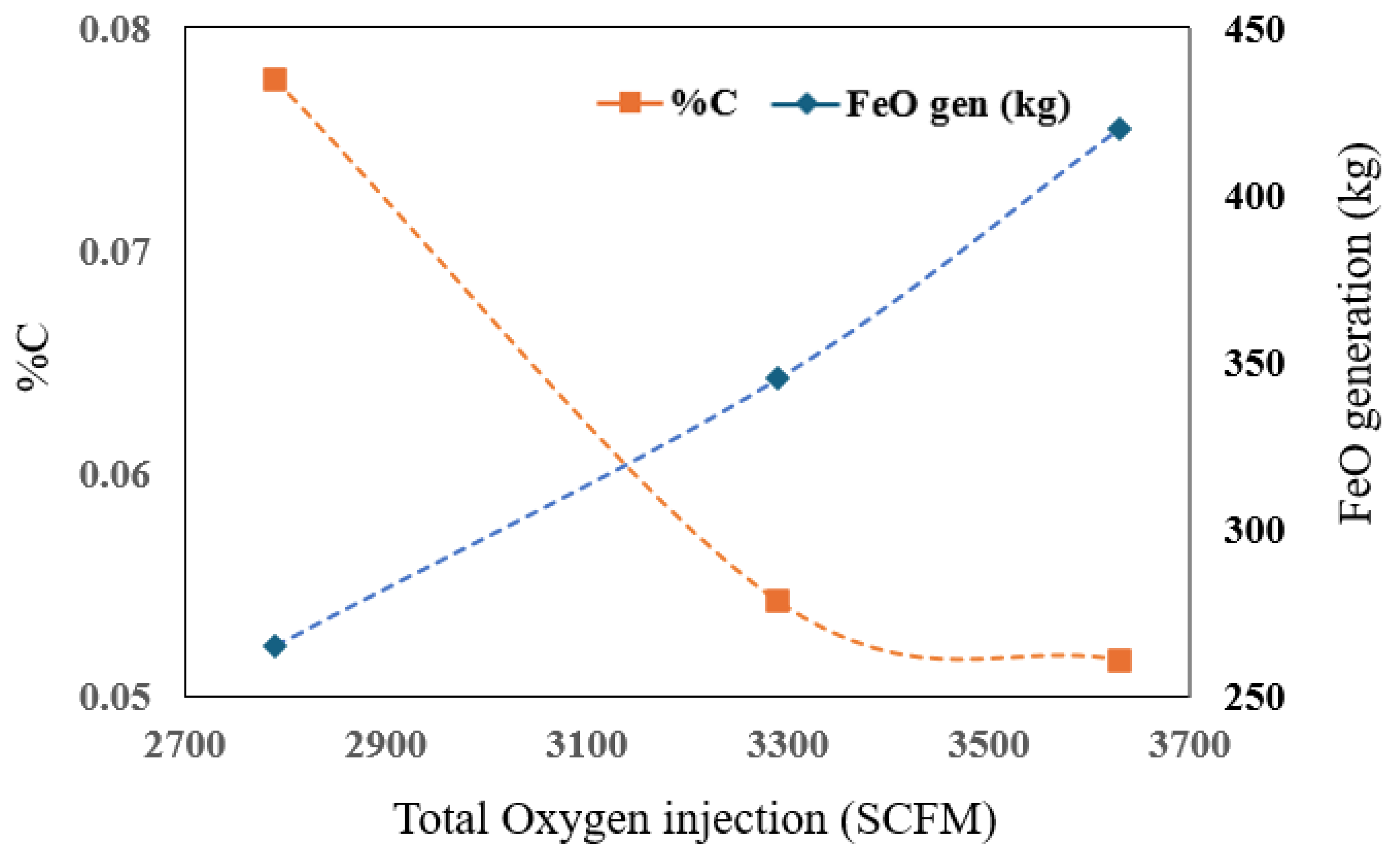

5.1. Impact of Varied Oxygen Flow Rates on Refining

5.2. Impact of Number of Burners on Refining

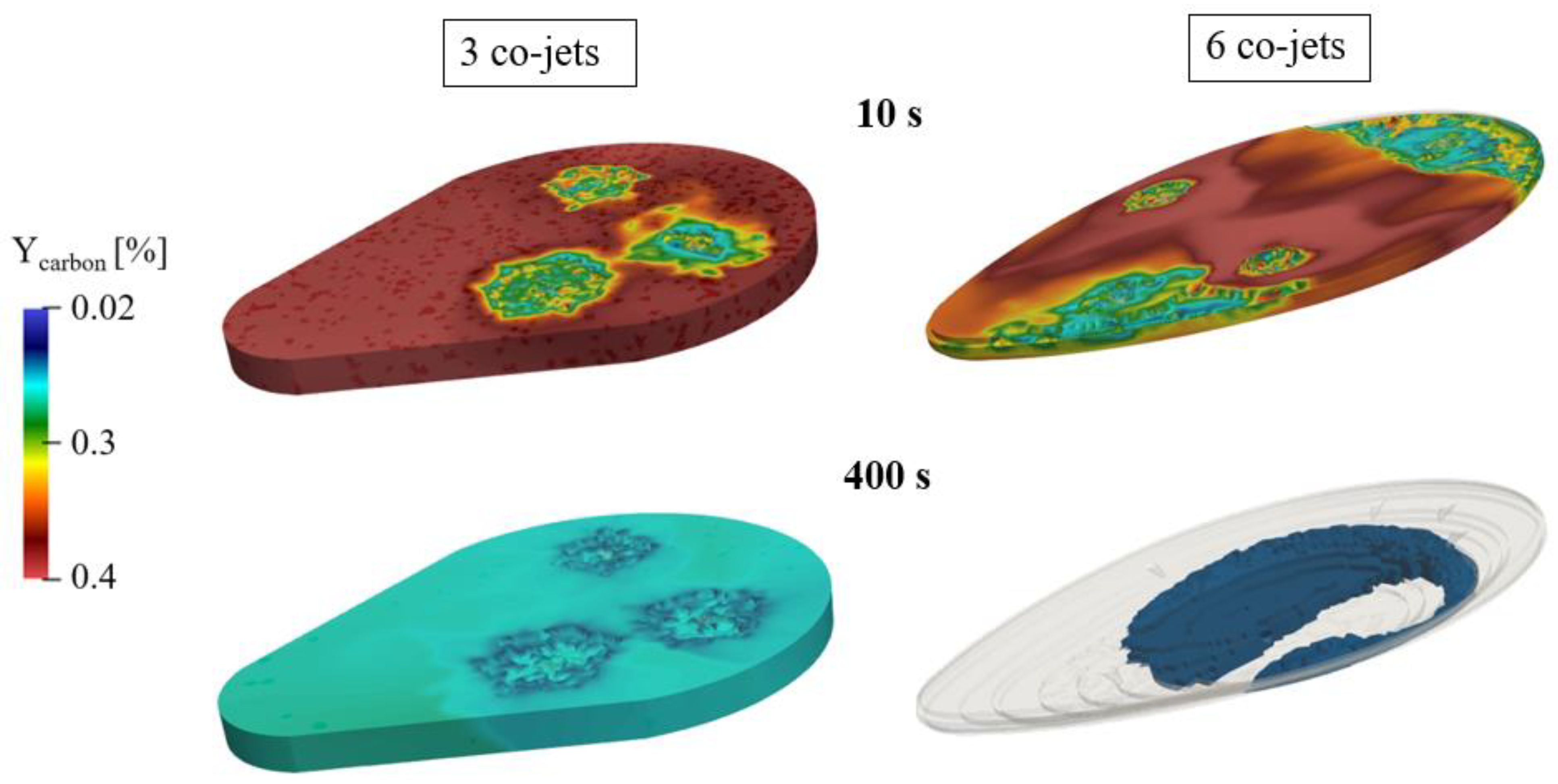

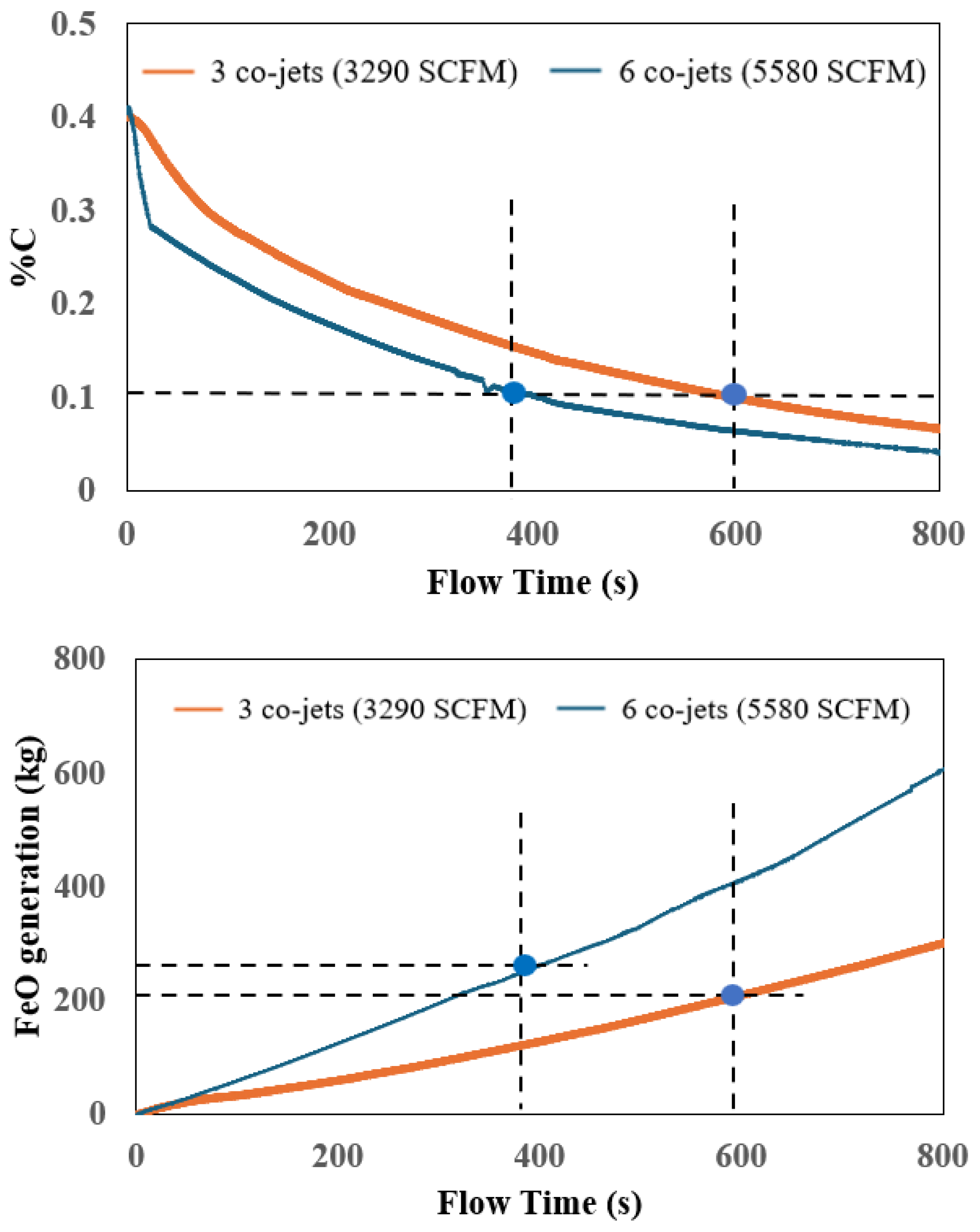

5.2.1. Comparison Between Three-Co-Jet- and Six-Co-Jet Domain with Baseline Injection Rates

5.2.2. Improved Refining Performance

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, H.; Yu, H.; Teng, L.; Seetharaman, S. Evaluation on Material and Heat Balance of EAF Processes with Introduction of CO2. J. Min. Metall. Sect. B Metall. 2015, 52, 1–8. [Google Scholar]

- Banks, R.B.; Chandrasekhara, D.V. Experimental investigation of the penetration of a high-velocity gas jet through a liquid surface. J. Fluid Mech. 1963, 15, 13–34. [Google Scholar]

- Ishikawa, H.; Mizoguchi, S.; Segawa, K. A model study on jet penetration and slopping in the LD converter. ISIJ Int. 1972, 58, 76–84. [Google Scholar][Green Version]

- Jones, J.; Safe, P.; Wiggins, B. Optimization of EAF operations through offgas system analysis. In Proceedings of the Electric Furnace Conference, Pittsburgh, PA, USA, 14–16 November 1999; Volume 57, pp. 459–480. [Google Scholar]

- Mathur, P.; Messina, C. Praxair CoJet™ technology–Principles and actual results from recent installations. AISE Steel Technol. 2001, 78, 21–25. [Google Scholar][Green Version]

- Thongjitr, P.; Kowitwarangkul, P.; Pratumwal, Y.; Otarawanna, S. Optimization of oxygen injection conditions with different molten steel levels in the EAF refining process by CFD simulation. Metals 2023, 13, 1507. [Google Scholar] [CrossRef]

- Odenthal, H.J.; Kemminger, A.; Krause, F.; Sankowski, L.; Uebber, N.; Vogl, N. Review on modeling and simulation of the electric arc furnace (EAF). Steel Res. Int. 2018, 89, 1700098. [Google Scholar][Green Version]

- Abraham, S.; Wang, Y.; Petty, R.; Sprague, T.; Franks, T.; Brown, E. Dynamic EAF Energy and Material Balance Model for On-Line Process Optimization. In Proceedings of the AISTech 2021—The Iron & Steel Technology Conference and Exposition, Nashville, TN, USA, 29 June–1 July 2021. [Google Scholar]

- Abadi, M.M.; Tang, H.; Rashidi, M.M. A review of simulation and numerical modeling of electric arc furnace (EAF) and its processes. Heliyon 2024, 10, e32157. [Google Scholar] [PubMed][Green Version]

- Matsuura, H.; Manning, C.P.; Fortes, R.A.; Fruehan, R.J. Development of a decarburization and slag formation model for the electric arc furnace. ISIJ Int. 2008, 48, 1197–1205. [Google Scholar][Green Version]

- Memoli, F.; Mapelli, C.; Ravanelli, P.; Corbella, M. Simulation of oxygen penetration and decarburisation in EAF using supersonic injection system. ISIJ Int. 2004, 44, 1342–1349. [Google Scholar][Green Version]

- Wei, J.H.; Zhu, D.P. Mathematical modeling of the argon-oxygen decarburization refining process of stainless steel: Part I. Mathematical model of the process. Metall. Mater. Trans. B 2002, 33, 111–119. [Google Scholar][Green Version]

- Anderson, J.E.; Farrenkopf, D.R. Coherent Gas Jet. U.S. Patent 5,823,762, 20 October 1998. [Google Scholar]

- Alam, M.; Naser, J.; Brooks, G. Computational fluid dynamics simulation of supersonic oxygen jet behavior at steelmaking temperature. Metall. Mater. Trans. B 2010, 41, 636–645. [Google Scholar][Green Version]

- Alam, M.; Irons, G.; Brooks, G.; Fontana, A.; Naser, J. Inclined jetting and splashing in electric arc furnace steelmaking. ISIJ Int. 2011, 51, 1439–1447. [Google Scholar][Green Version]

- Oltmann, H.; Pretorius, E.B.; Refractories, L.W.B. Simulation of the Refining Stage of the EAF Process. In Proceedings of the AISE Conference, Nashville, TN, USA, 30 September–2 October 2002. [Google Scholar]

- Szekely, J.; Asai, S. Decarburization of stainless steel: Part II. A mathematical model and a process optimization for industrial scale systems. Metall. Mater. Trans. B 1974, 5, 1573–1580. [Google Scholar][Green Version]

- Ekmekçi, Ī.; Yetisken, Y.; Çamdali, Ü. Mass balance modeling for electric arc furnace and ladle furnace system in steelmaking facility in Turkey. J. Iron Steel Res. Int. 2007, 14, 1–6. [Google Scholar][Green Version]

- Kirschen, M.; Pfeifer, H.; Wahlers, F.J.; Nirosta, T. Mass and energy balances of stainless steel EAF. In Proceedings of the 7th European Electric Steelmaking Conference, Venice, Italy, 26–29 May 2002; Volume 26, p. 29. [Google Scholar]

- Pfeifer, H.; Kirschen, M. Thermodynamic analysis of EAF energy efficiency and comparison with a statistical model of electric energy demand. In Proceedings of the 7th European Electric Steelmaking Conference, Venice, Italy, 26–29 May 2002; Volume 26, p. 1. [Google Scholar]

- Sano, M.; Mori, K. Fluid flow and mixing characteristics in a gas-stirred molten metal bath. Trans. Iron Steel Inst. Jpn. 1983, 23, 169–175. [Google Scholar][Green Version]

- Ramírez, M.; Alexis, J.; Trapaga, G.; Jönsson, P.; McKelliget, J. Modeling of a DC electric arc furnace—Mixing in the bath. ISIJ Int. 2001, 41, 1146–1155. [Google Scholar][Green Version]

- Björklund, J. Thermodynamic Aspects on Inclusion Composition and Oxygen Activity during Ladle Treatment. Doctoral Dissertation, KTH, Stockholm, Sweden, 2008. [Google Scholar]

- Sukmak, P.; Sukmak, G.; De Silva, P.; Horpibulsuk, S.; Kassawat, S.; Suddeepong, A. The potential of industrial waste: Electric arc furnace slag (EAF) as recycled road construction materials. Constr. Build. Mater. 2023, 368, 130393. [Google Scholar][Green Version]

- Tang, G.; Chen, Y.; Silaen, A.K.; Krotov, Y.; Riley, M.F.; Zhou, C.Q. Investigation on coherent jet potential core length in an electric arc furnace. Steel Res. Int. 2019, 90, 1800381. [Google Scholar][Green Version]

- Chen, Y.; Silaen, A.K.; Zhou, C.Q. 3D integrated modeling of supersonic coherent jet penetration and decarburization in EAF refining process. Processes 2020, 8, 700. [Google Scholar] [CrossRef]

- Ugarte, O.; Busa, N.; Konar, B.; Okosun, T.; Zhou, C.Q. Impact of Injection Rate on Flow Mixing during the Refining Stage in an Electric Arc Furnace. Metals 2024, 14, 134. [Google Scholar] [CrossRef]

- Fraser-Mitchell, A.H. Fundamentals of Aerodynamics, 5th ed.; Anderson, J.D., Ed.; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

| Surface | Type | Equation |

|---|---|---|

| Top, Side, and Bottom | Adiabatic, no-slip wall | dT/dx = 0, u = 0, v = 0, w = 0 |

| Approach | Velocity (m/s) | SCFM |

|---|---|---|

| Theory | 521.2 | 1288 |

| CFD | 513.7 | 1260 |

| Difference | 1.45% | 2.2% |

| Parameters | Value |

|---|---|

| Co-jet quantity | 3 |

| Steel liquid temperature | 1838 K (1565 °C) |

| Initial carbon content [%] | 0.065 |

| Oxygen rates [SCFM] | Burner 1:1150, Burner 2:930, Burner 3:1210 |

| Approach | Value |

|---|---|

| Experiment | 0.056 |

| Simulation | 0.0512 |

| Difference | 8.57% |

| Oxygen Injection [SCFM] | ||||

|---|---|---|---|---|

| Cases | Burner 1 | Burner 2 | Burner 3 | Total |

| 1 | 1150 | 930 | 1210 | 3290 |

| 2 | 1210 | 1210 | 1210 | 3630 |

| 3 | 930 | 930 | 930 | 2790 |

| Co-Jets | 3 | 6 (1 Door Lance) |

|---|---|---|

| Initial Carbon % | 0.40 | 0.41 |

| Initial Temp (K) | 1838 | 1850 |

| Mass Metal (t) | 140 | 139 |

| O2 inj. (SCFM) “baseline” | B1: 1150, B2: 930, B3: 1210 | B1–B6:1000 |

| Total SCFM | 3290 | 6000 |

| Cases | O2 (SCFM) | Time to Reach 0.1%C (s) | FeO Gen @0.1%C (kg) |

|---|---|---|---|

| 3 co-jets | 3290 | 595 | 200 |

| 6 co-jets | 6000 | 385 | 285 |

| Diff | 85% | −35% | 42.5% |

| Cases | O2 (SCFM) | Time to Reach 0.1%C (s) | FeO Gen @0.1%C (kg) |

|---|---|---|---|

| 3 co-jets | 3290 | 595 | 200 |

| 6 co-jets | 5580 | 395 | 257 |

| Diff | 70% | −32% | 28.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kottapalli, S.; Ugarte, O.; Konar, B.; Okosun, T.; Zhou, C.Q. CFD Modelling of Refining Behaviour in EAF: Influence of Burner Arrangement and Oxygen Flow Rates. Metals 2025, 15, 775. https://doi.org/10.3390/met15070775

Kottapalli S, Ugarte O, Konar B, Okosun T, Zhou CQ. CFD Modelling of Refining Behaviour in EAF: Influence of Burner Arrangement and Oxygen Flow Rates. Metals. 2025; 15(7):775. https://doi.org/10.3390/met15070775

Chicago/Turabian StyleKottapalli, Sathvika, Orlando Ugarte, Bikram Konar, Tyamo Okosun, and Chenn Q. Zhou. 2025. "CFD Modelling of Refining Behaviour in EAF: Influence of Burner Arrangement and Oxygen Flow Rates" Metals 15, no. 7: 775. https://doi.org/10.3390/met15070775

APA StyleKottapalli, S., Ugarte, O., Konar, B., Okosun, T., & Zhou, C. Q. (2025). CFD Modelling of Refining Behaviour in EAF: Influence of Burner Arrangement and Oxygen Flow Rates. Metals, 15(7), 775. https://doi.org/10.3390/met15070775