Numerical Simulation of Fluid Flow, Heat Transfer, and Solidification in AISI 304 Stainless Steel Twin-Roll Strip Casting

Abstract

1. Introduction

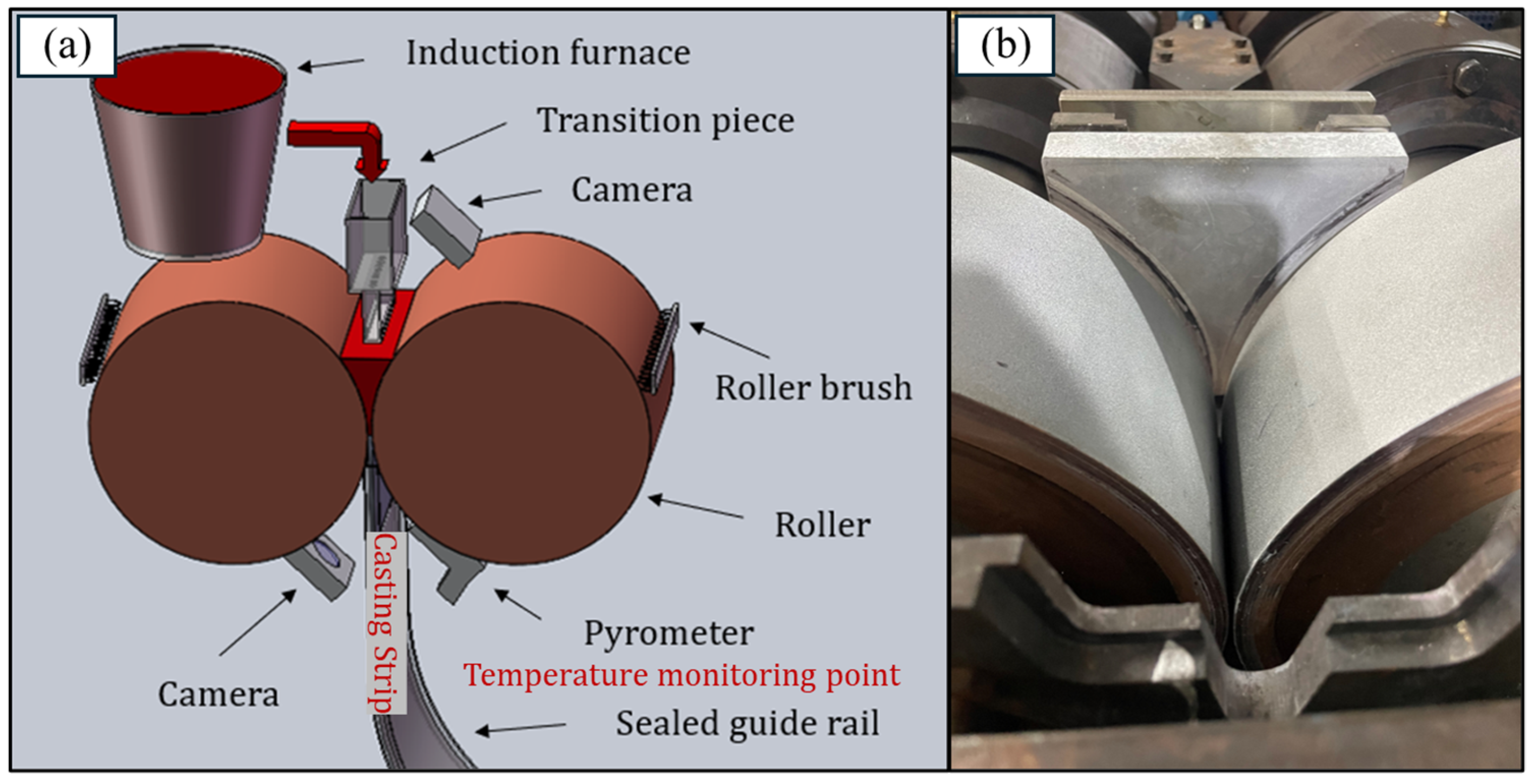

2. Experimental Methods

2.1. Casting Procedure and Material

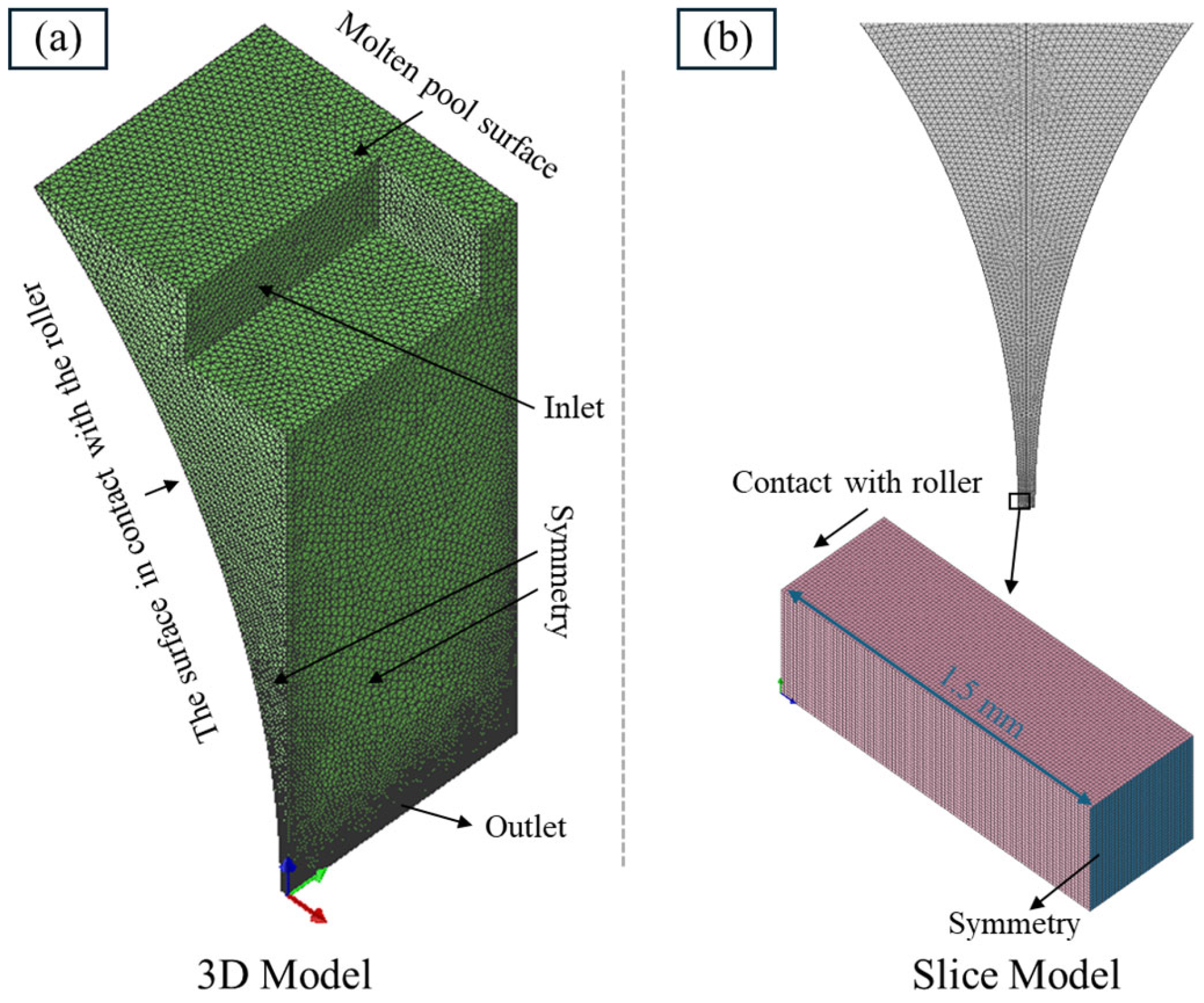

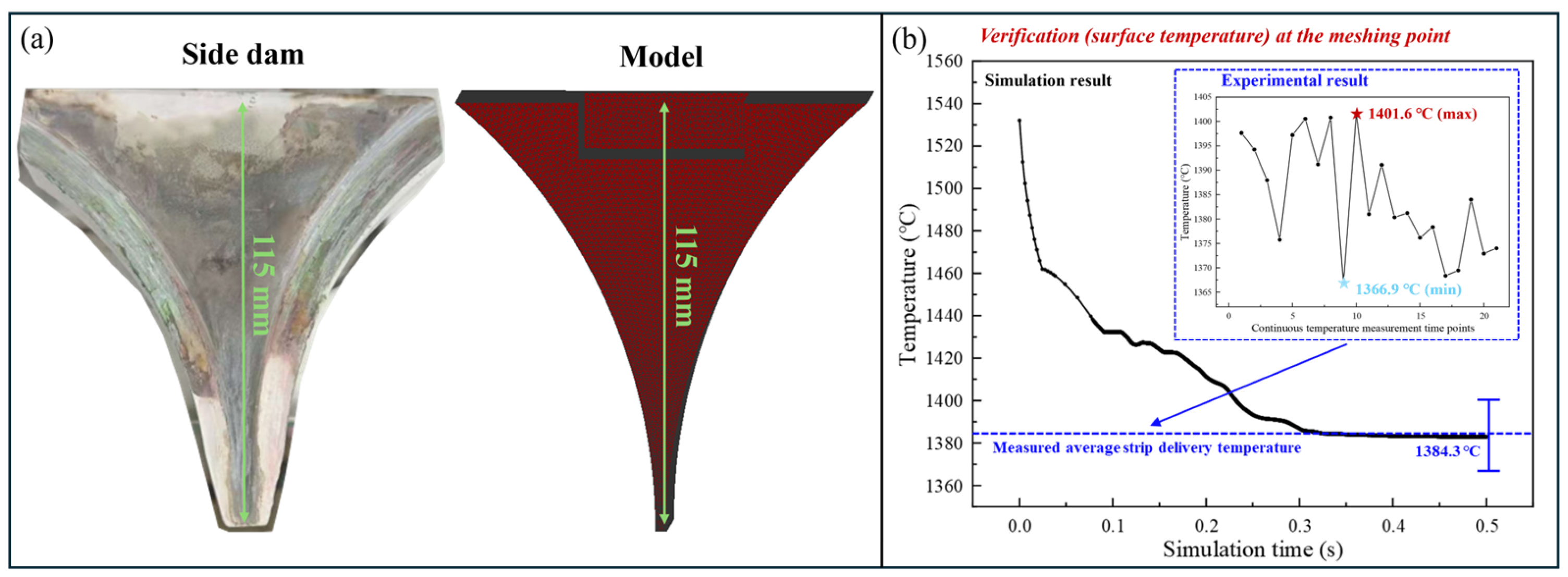

2.2. Modeling

2.3. Assumptions and Governing Equations

- A quarter-symmetry geometry was constructed based on the symmetrical distribution of flow and temperature fields in the molten pool.

- The casting process was treated as a steady-state process.

- The influence of segregation behavior on heat transfer and fluid flow was neglected.

- Except for the roller/steel interface, heat transfer on the other surfaces had a very minor influence on the results and was ignored in the calculation process.

- Free surface fluctuations were not incorporated in the model.

2.4. Initial/Boundary Conditions

3. Results and Discussion

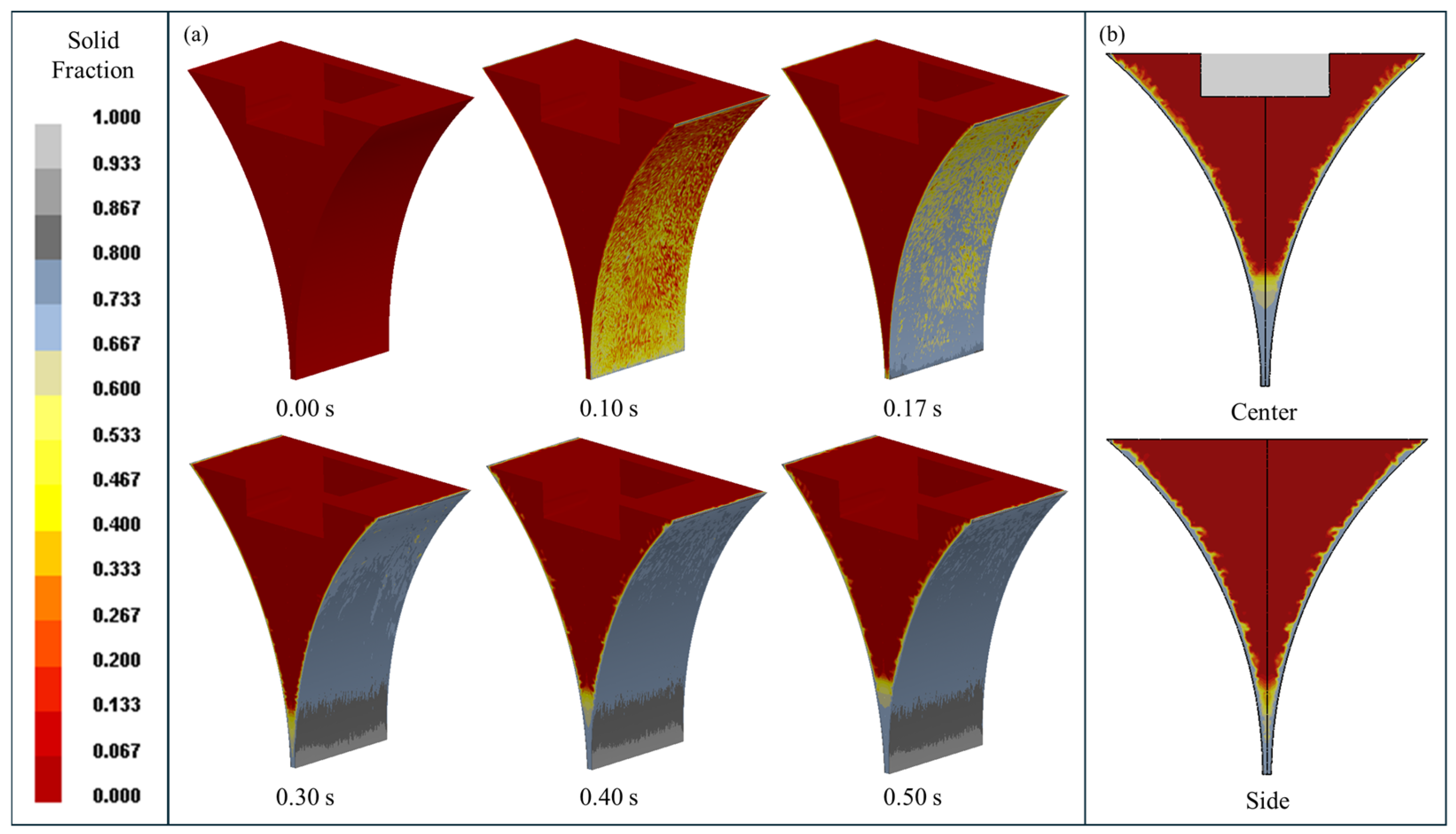

3.1. Evolutions of Macroscopic Physical Field for Twin-Roll Strip Casting

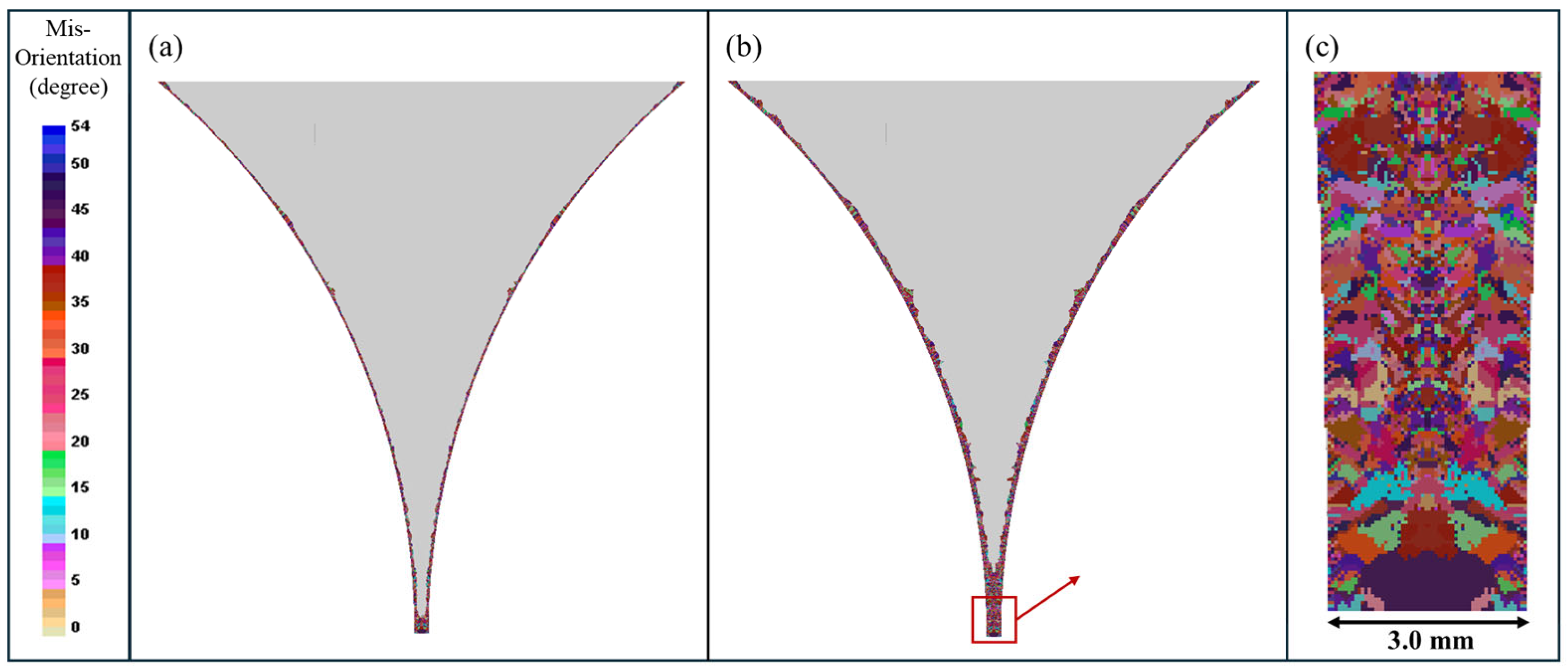

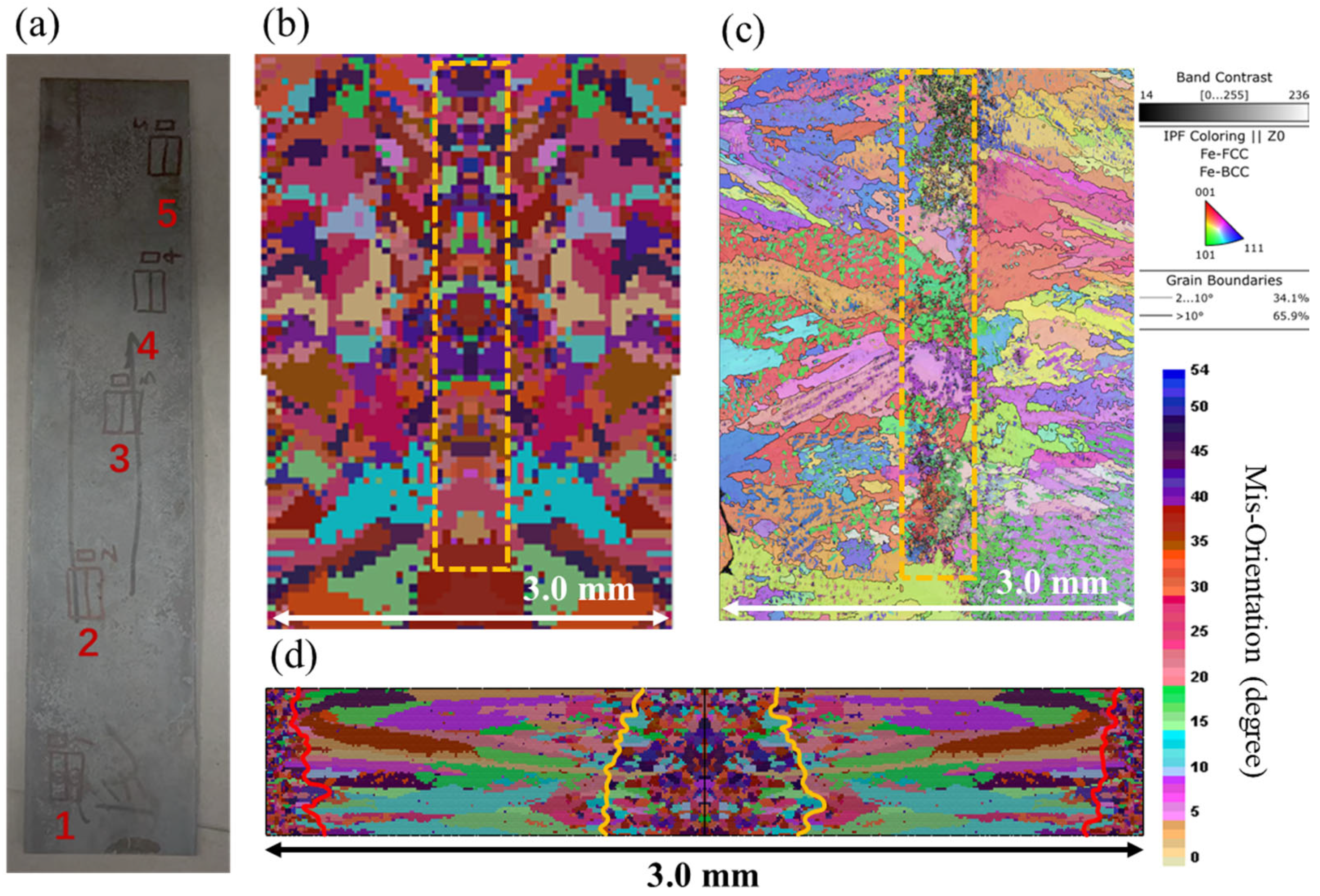

3.2. Evolutions of Solidification Structure for Twin-Roll Strip Casting

3.3. Comparisons Between Modeling and Experiment

3.4. Influence of Superheat on Solidification and Macrostructure Formation for Twin-Roll Strip Casting

4. Conclusions

- The model demonstrated high accuracy through temperature field predictions deviating less than 5% from experimental measurements (average 1384.3 °C) and solidification structure simulations matching EBSD-observed equiaxed grain fractions within 5% error.

- The flow field and flow trajectory showed obvious recirculation zones: the center area was mainly composed of large recirculation zones, and many small recirculation zones appeared at the edges. The position of the kiss point becomes a key process indicator, and its distance from the bottom of the pool is inversely proportional to the superheat (15.8 mm at 30 °C and 6.2 mm at 110 °C).

- Parametric studies further established that low superheat (30 °C) increased melt viscosity, restricted convection, and promoted coarse columnar grains (equiaxed fraction: 8.9%), whereas high superheat (110 °C) enhanced fluid renewal and equiaxed nucleation (26.5%) despite lower total solidification (8.3%).

- For AISI 304 stainless steel, expanding the equiaxed zone improved ductility, while grain refinement contributed to boundary strengthening. Consequently, control of superheat enables solidification structure to be adjusted according to the target mechanical properties. In industry, monitoring the location of the kiss point can enable real-time diagnosis of solidification, rolling force, and quality risks of steel strips.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chu, T.; Xu, W.; Bai, M. Insights into the Influence of Tensile and Compressive Strain on the Microstructure and Corrosion Performance of 304 L Stainless Steel. Metals 2024, 14, 1281. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, Y.; Dai, W.; Long, R. Mechanical Properties of 304 Austenite Stainless Steel Manufactured by Laser Metal Deposition. Mater. Sci. Eng. A 2019, 758, 60–70. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Y.; Xu, D.; Zeng, Y.; Li, L.; Wang, Z.; Jiang, F. Effects of Layer-by-Layer Ultrasonic Impact Treatment on Microstructure and Mechanical Properties of 304 Stainless Steel Manufactured by Directed Energy Deposition. Addit. Manuf. 2023, 68, 103523. [Google Scholar] [CrossRef]

- Mino, T.; Asakawa, M.; Lee, D.; Fujiwara, T.; Matsuzaki, K.; Kobayashi, M. Twin-Roll Strip Casting of AZ61 Magnesium Alloy and Improvement of Formability by Structure-Control Rolling. J. Mater. Process. Technol. 2006, 177, 534–538. [Google Scholar] [CrossRef]

- Daamen, M.; Haase, C.; Dierdorf, J.; Molodov, D.A.; Hirt, G. Twin-Roll Strip Casting: A Competitive Alternative for the Production of High-Manganese Steels with Advanced Mechanical Properties. Mater. Sci. Eng. A 2015, 627, 72–81. [Google Scholar] [CrossRef]

- Liu, H.; Li, W.; Pei, Z.; Yan, M. Mg-Based Materials with Quasiamorphous Phase Produced by Vertical Twin-Roll Casting Process. Metals 2020, 10, 452. [Google Scholar] [CrossRef]

- Wang, H.; Wang, W.; Lyu, P.; Wu, S. Hot Deformation Behavior of Free-Al 2.43 Wt.% Si Electrical Steel Strip Produced by Twin-Roll Strip Casting and Its Effect on Microstructure and Texture. Materials 2024, 17, 3152. [Google Scholar] [CrossRef]

- Münster, D.; Hirt, G. Copper Clad Steel Strips Produced by a Modified Twin-Roll Casting Process. Metals 2019, 9, 1156. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, K.; Zhang, X.; Liu, H.; Zhang, W.; Wang, J. Microstructure Characteristics, Mechanical Properties and Strain Hardening Behavior of B2 Intermetallic Compound-Strengthening Fe-16Mn-9Al-0.8C-3Ni Steel Fabricated by Twin-Roll Strip Casting, Cold Rolling and Annealing. Materials 2023, 16, 5417. [Google Scholar] [CrossRef]

- Lu, C.; Pan, Z.; Wang, W.; Zeng, J.; Gao, X.; Liu, X.; Zhu, C. High-Temperature Simulation Study of Cracking Mechanism During the Strip Casting Process of P-Containing Weathering Steel. Metall. Mater. Trans. B 2024, 55, 2626–2637. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Tang, S.; Zhang, W.; Liu, Z. Edge Cracking Prevention in 2507 Super Duplex Stainless Steel by Twin-Roll Strip Casting and Its Microstructure and Properties. J. Mater. Process. Technol. 2019, 266, 246–254. [Google Scholar] [CrossRef]

- Hao, Y.; Cao, G.; Li, C.; Li, J.; Liu, W.; Zhang, W.; Liu, Z. The Aging Precipitation Behavior of 20Cr-24Ni-6Mo Super-Austenitic Stainless Steel Processed by Conventional Casting and Twin-Roll Strip Casting. Mater. Charact. 2019, 147, 21–30. [Google Scholar] [CrossRef]

- Cheon, B.-H.; Kim, H.-W.; Lee, J.-C. Asymmetric Rolling of Strip-Cast Al–5.5Mg–0.3Cu Alloy Sheet: Effects on the Formability and Mechanical Properties. Mater. Sci. Eng. A 2011, 528, 5223–5227. [Google Scholar] [CrossRef]

- Miao, Y.-C.; Zhang, X.-M.; Di, H.-S.; Wang, G.-D. Numerical Simulation of the Fluid Flow, Heat Transfer, and Solidification of Twin-Roll Strip Casting. J. Mater. Process. Technol. 2006, 174, 7–13. [Google Scholar] [CrossRef]

- Stolbchenko, M.; Grydin, O.; Schaper, M. Manufacturing and Characterization of Twin-Roll Cast Aluminum-Steel Clad Strips. Adv. Eng. Mater. 2019, 21, 1800454. [Google Scholar] [CrossRef]

- Zeng, J.; Koitzsch, R.; Pfeifer, H.; Friedrich, B. Numerical Simulation of the Twin-Roll Casting Process of Magnesium Alloy Strip. J. Mater. Process. Technol. 2009, 209, 2321–2328. [Google Scholar] [CrossRef]

- Bai, C.; Wang, B.; Ma, J.; Zhang, J.; Pan, W. Modeling Effect of Cooling Conditions on Solidification Process during Thermal Cycle of Rollers in Twin-Roll Strip Casting. J. Iron Steel Res. Int. 2023, 30, 64–73. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, B.; Zhang, Q.; Ma, J.; Zhang, J. Numerical Simulation of Filling Process During Twin-Roll Strip Casting. Metall. Mater. Trans. B 2014, 45, 262–271. [Google Scholar] [CrossRef]

- Mahmoudi, J. Numerical Simulation of the Nozzle Configuration in Strip Casting Process. J. Manuf. Process. 2022, 77, 561–587. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, J.Y.; Li, X.M.; Qi, W.H. Simulation of Solidification Microstructure in Twin-Roll Casting Strip. Comput. Mater. Sci. 2010, 49, S135–S139. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, Y.; Liu, L.; Ren, X.; Zhang, Y.; Fang, Y.; Yang, Q. Numerical Simulation on the Stress Field of Austenite Stainless Steel during Twin-Roll Strip Casting Process. Comput. Mater. Sci. 2012, 52, 61–67. [Google Scholar] [CrossRef]

- Zhang, X.M.; Jiang, Z.Y.; Yang, L.M.; Liu, X.H.; Wang, G.D.; Tieu, A.K. Modelling of Coupling Flow and Temperature Fields in Molten Pool during Twin-Roll Strip Casting Process. J. Mater. Process. Technol. 2007, 187–188, 339–343. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, C.; Wei, C. Numerical Simulation of Thermal Field of Work Roll during Top Side-Pouring Twin-Roll Casting of Steel. ISIJ Int. 2017, 57, 1811–1820. [Google Scholar] [CrossRef]

- Cao, X.; Zhu, G.; Yue, B.; Qiao, S.; Gao, X.; Guo, N.; Xu, M. Research on Cast-Rolling Force in Twin-Roll Continuous Strip Casting Based on Uncertainty Analysis. Mater. Today Commun. 2020, 24, 101100. [Google Scholar] [CrossRef]

- Lu, J.; Liu, L.; Pan, W.; Wang, W.; Dou, K. New Model for Heat Transfer of Copper Roller in Twin-Roll Strip Casting to Assist Experimental and Industrial Process. Int. J. Therm. Sci. 2025, 213, 109826. [Google Scholar] [CrossRef]

- Bai, L.; Wang, B.; Zhong, H.; Ni, J.; Zhai, Q.; Zhang, J. Experimental and Numerical Simulations of the Solidification Process in Continuous Casting of Slab. Metals 2016, 6, 53. [Google Scholar] [CrossRef]

| Element | C | Cr | Ni | Mn | Si |

|---|---|---|---|---|---|

| wt.% | 0.045 | 18.25 | 8.1 | 1.25 | 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Wang, W.; Dou, K. Numerical Simulation of Fluid Flow, Heat Transfer, and Solidification in AISI 304 Stainless Steel Twin-Roll Strip Casting. Metals 2025, 15, 749. https://doi.org/10.3390/met15070749

Lu J, Wang W, Dou K. Numerical Simulation of Fluid Flow, Heat Transfer, and Solidification in AISI 304 Stainless Steel Twin-Roll Strip Casting. Metals. 2025; 15(7):749. https://doi.org/10.3390/met15070749

Chicago/Turabian StyleLu, Jingzhou, Wanlin Wang, and Kun Dou. 2025. "Numerical Simulation of Fluid Flow, Heat Transfer, and Solidification in AISI 304 Stainless Steel Twin-Roll Strip Casting" Metals 15, no. 7: 749. https://doi.org/10.3390/met15070749

APA StyleLu, J., Wang, W., & Dou, K. (2025). Numerical Simulation of Fluid Flow, Heat Transfer, and Solidification in AISI 304 Stainless Steel Twin-Roll Strip Casting. Metals, 15(7), 749. https://doi.org/10.3390/met15070749