Molecular Dynamics Simulation of the Effect of B2-NiAl Phase Volume Fractions on Mechanical Properties and Deformation Mechanisms of Dual-Phase FeNiAl Alloys

Abstract

1. Introduction

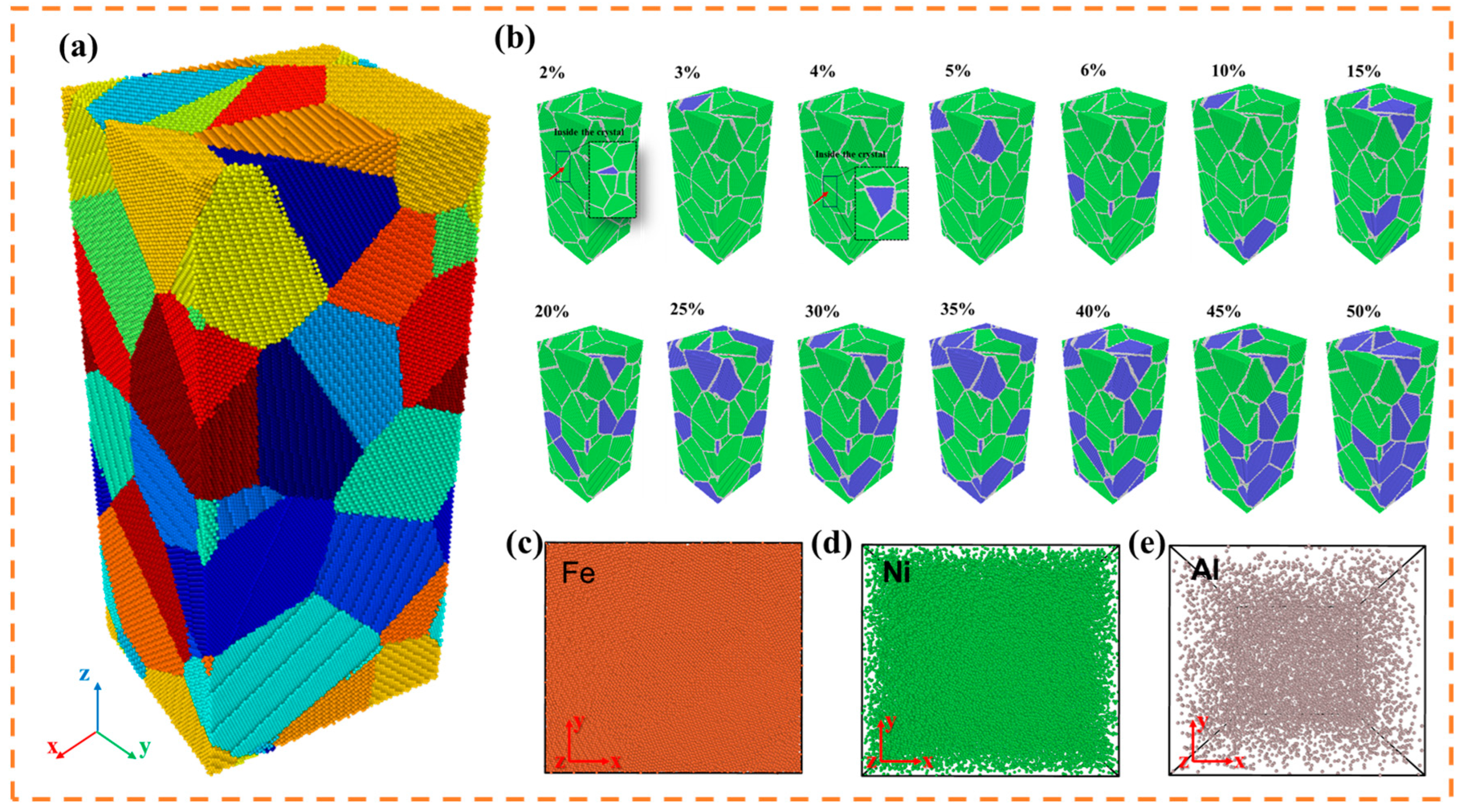

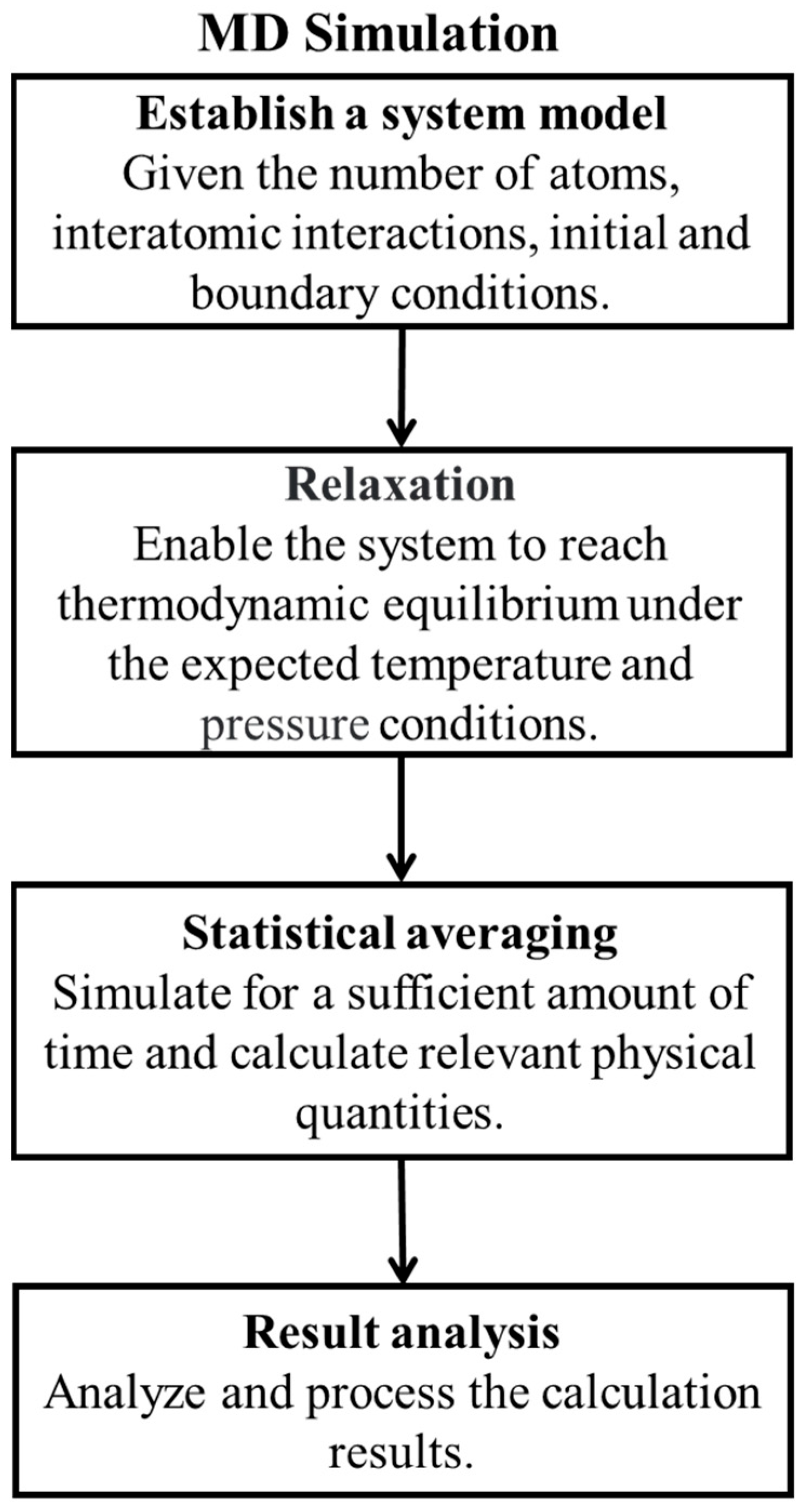

2. Simulation Methods

3. Results and Discussion

3.1. Mechanical Properties

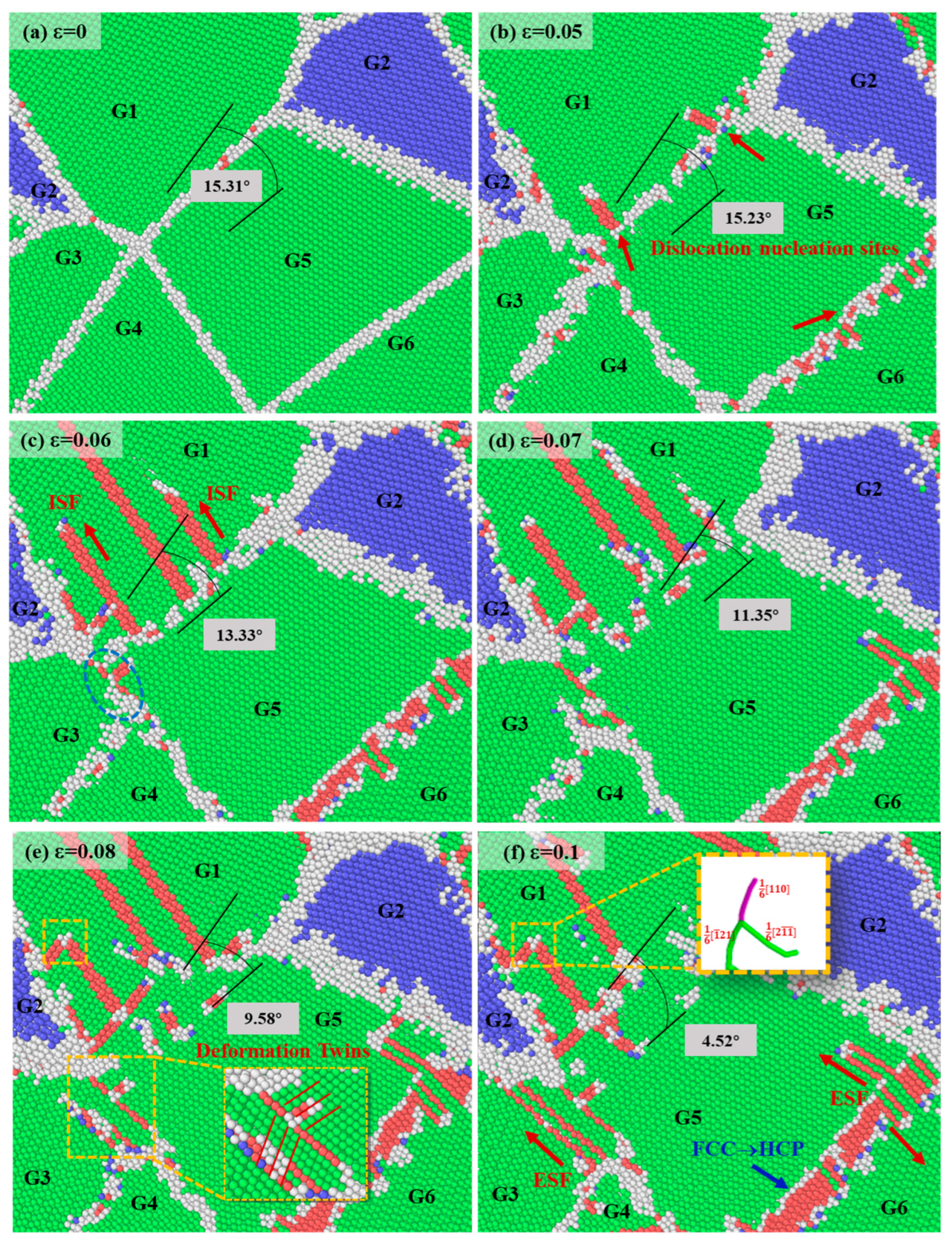

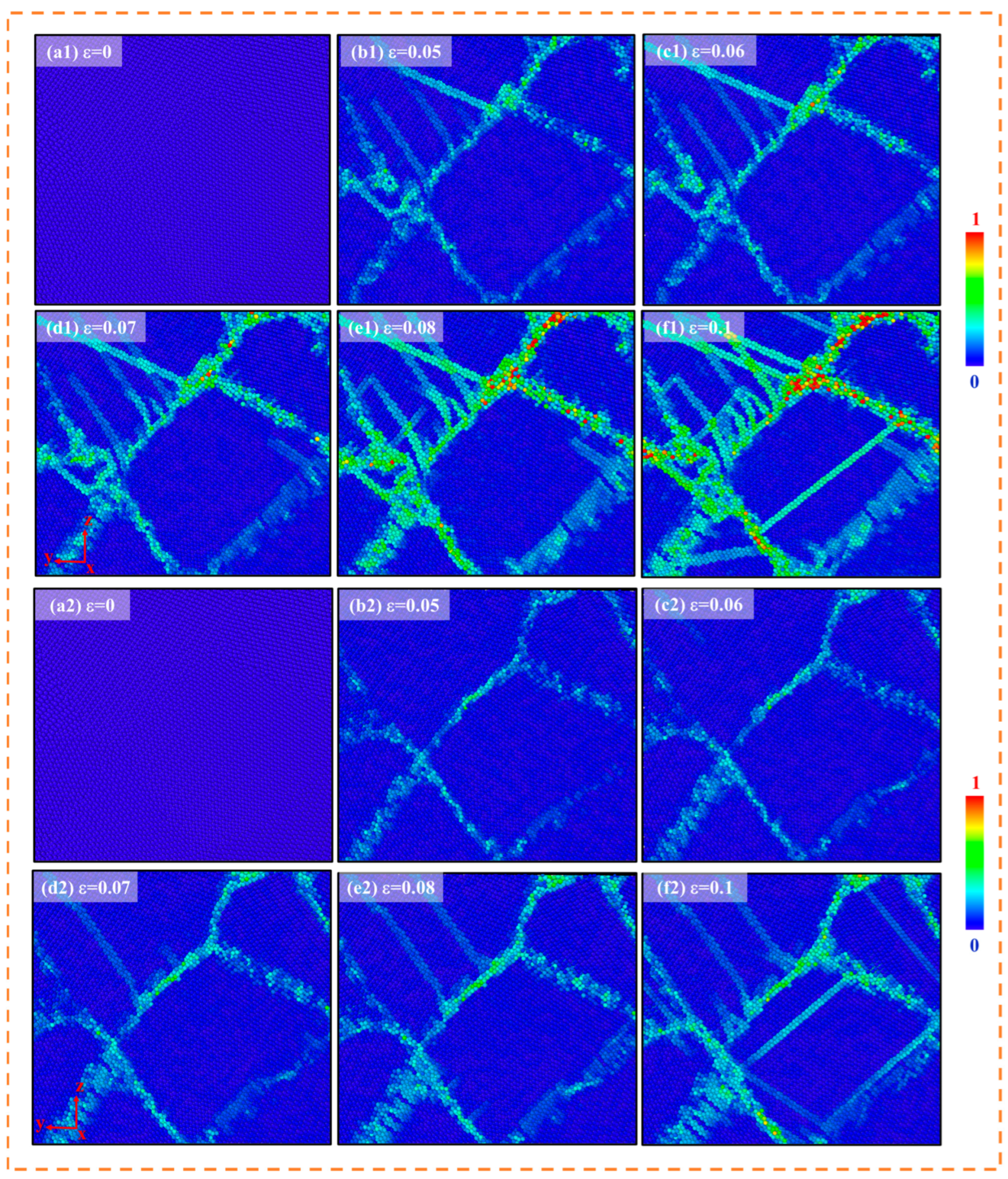

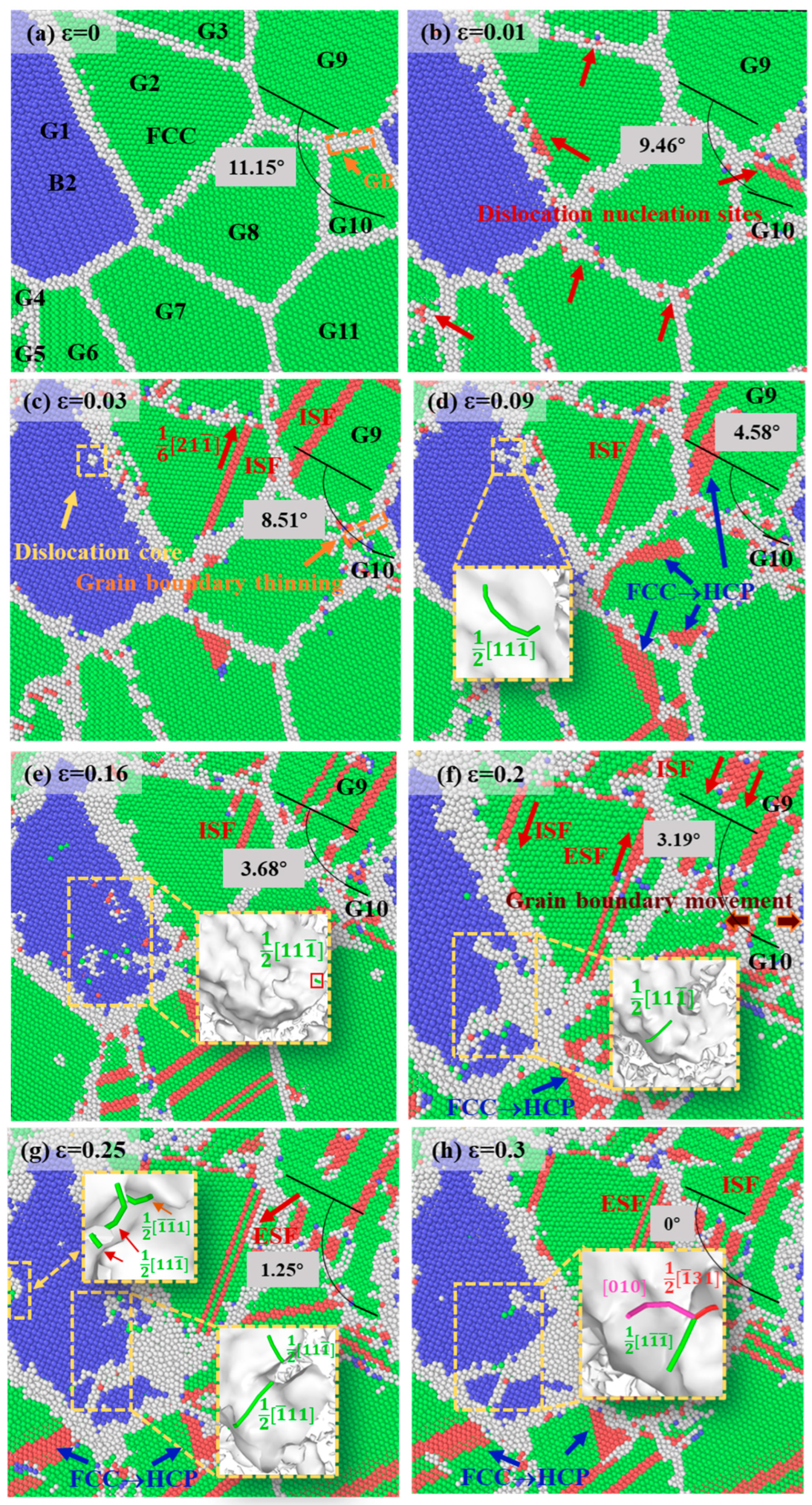

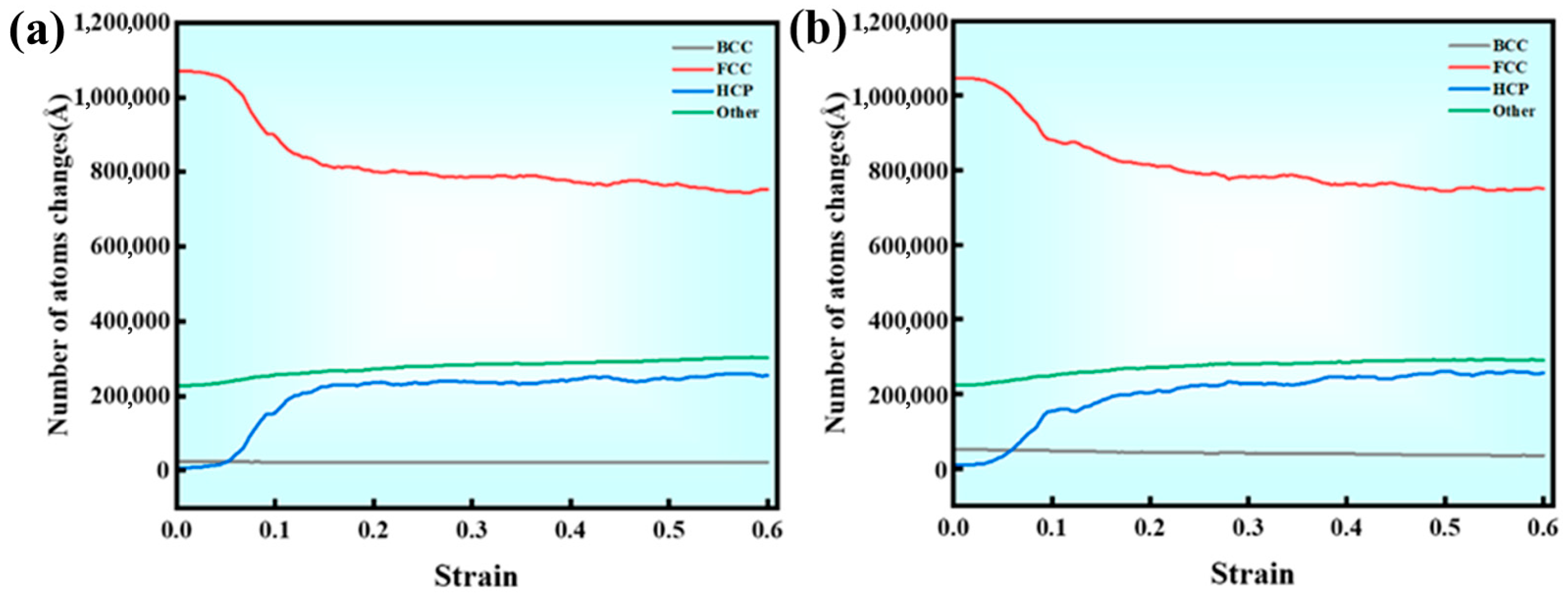

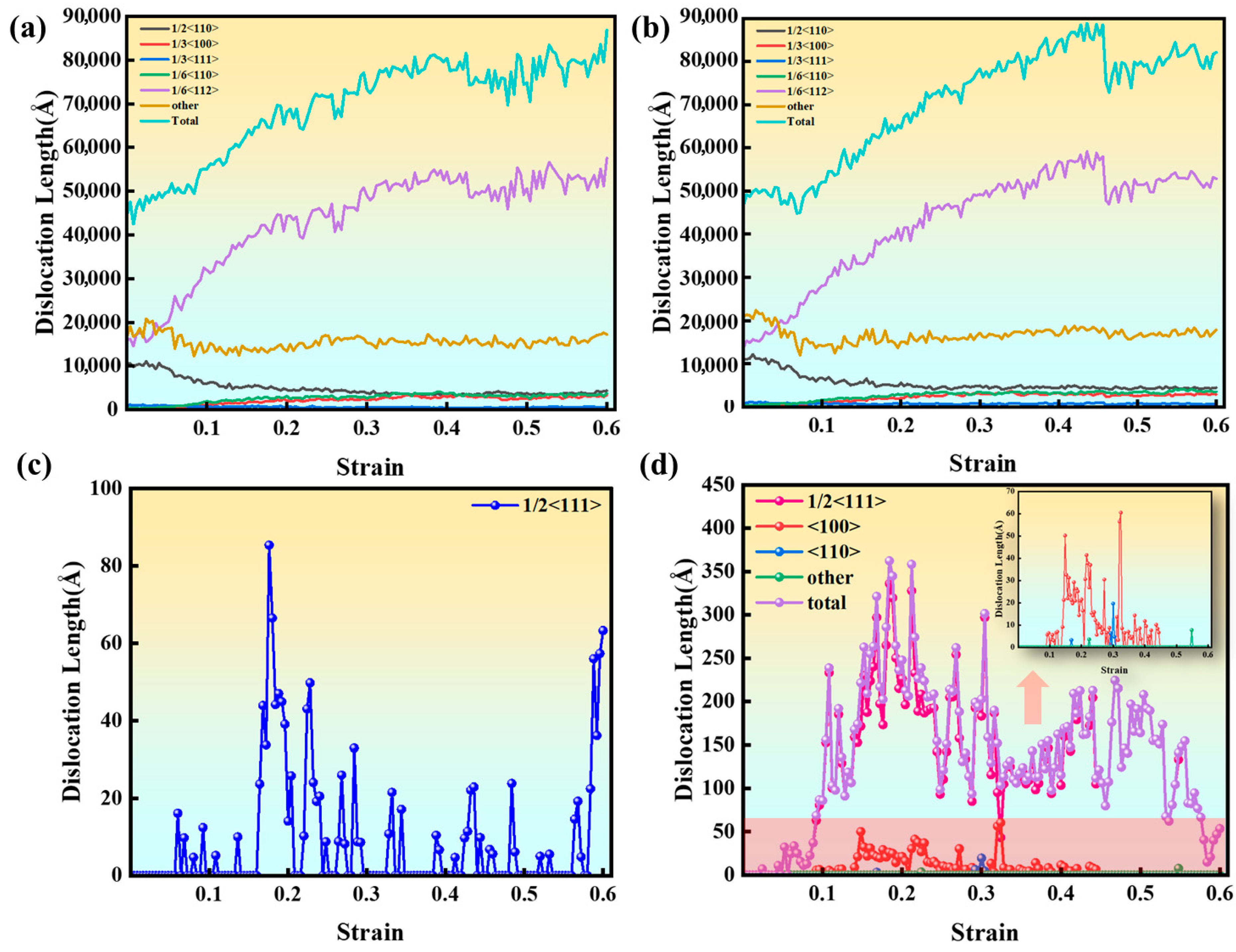

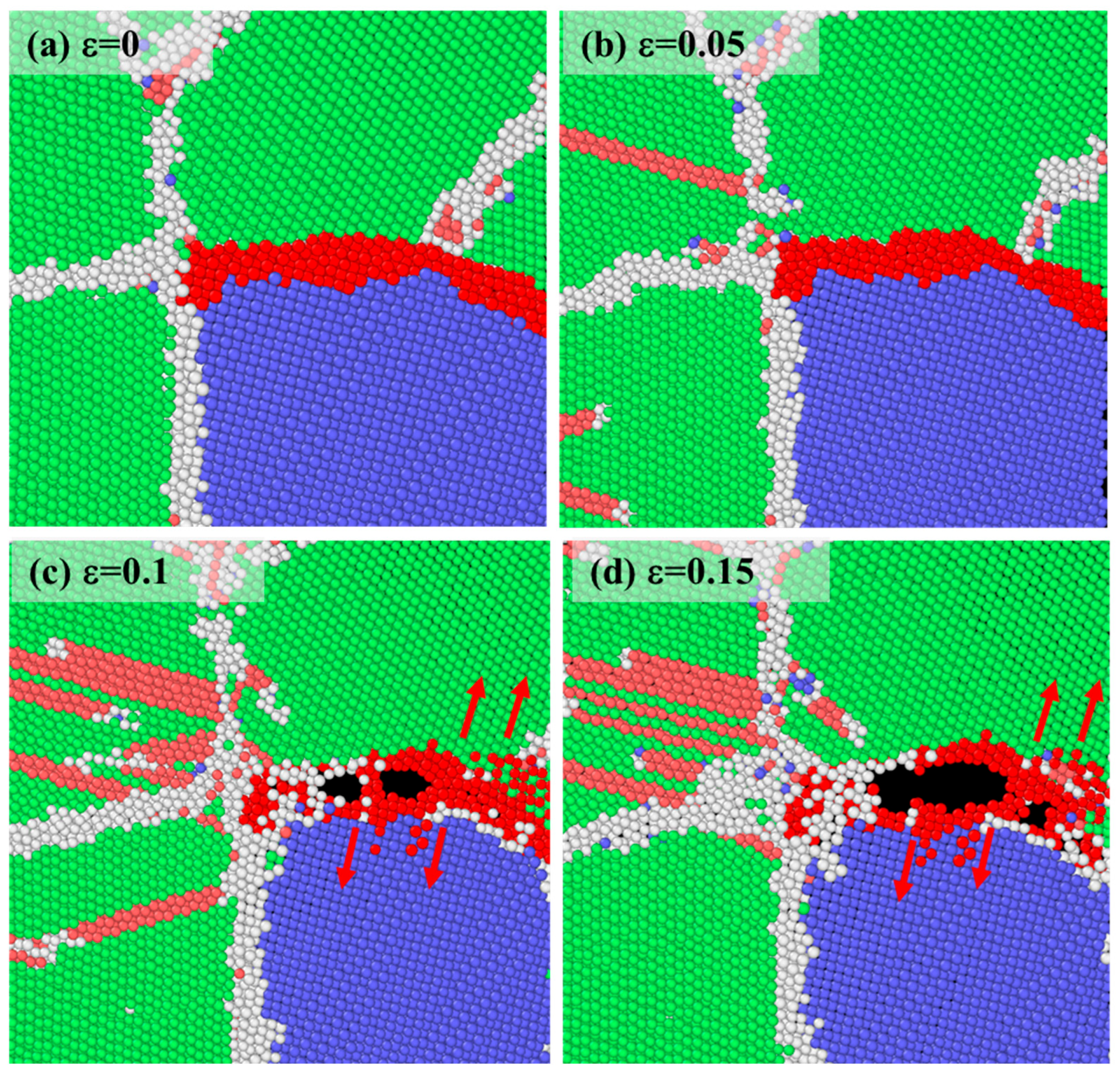

3.2. Evolution of Deformation Mechanisms

4. Conclusions

- (1)

- The B2 phase volume fraction nonlinearly modulates mechanical properties, with an optimal value (3%) achieving simultaneous enhancement of strength and plasticity. When the B2 phase volume fraction is 3%, the yield strength and ultimate tensile strength of the dual-phase FeNiAl alloy reach maximum values of 4.52 GPa and 4.74 GPa, representing approximately 13% and 5.3% improvements compared to the single-phase FCC-FeNiAl alloy. The material exhibits both high strength and good plasticity, primarily attributed to the B2 phase hindering dislocation motion through the back stress strengthening mechanism. However, when the B2 phase volume fraction exceeds 5%, excessive hard phases intensify stress concentration at grain boundaries, inducing micro-crack nucleation and significantly reducing ductility.

- (2)

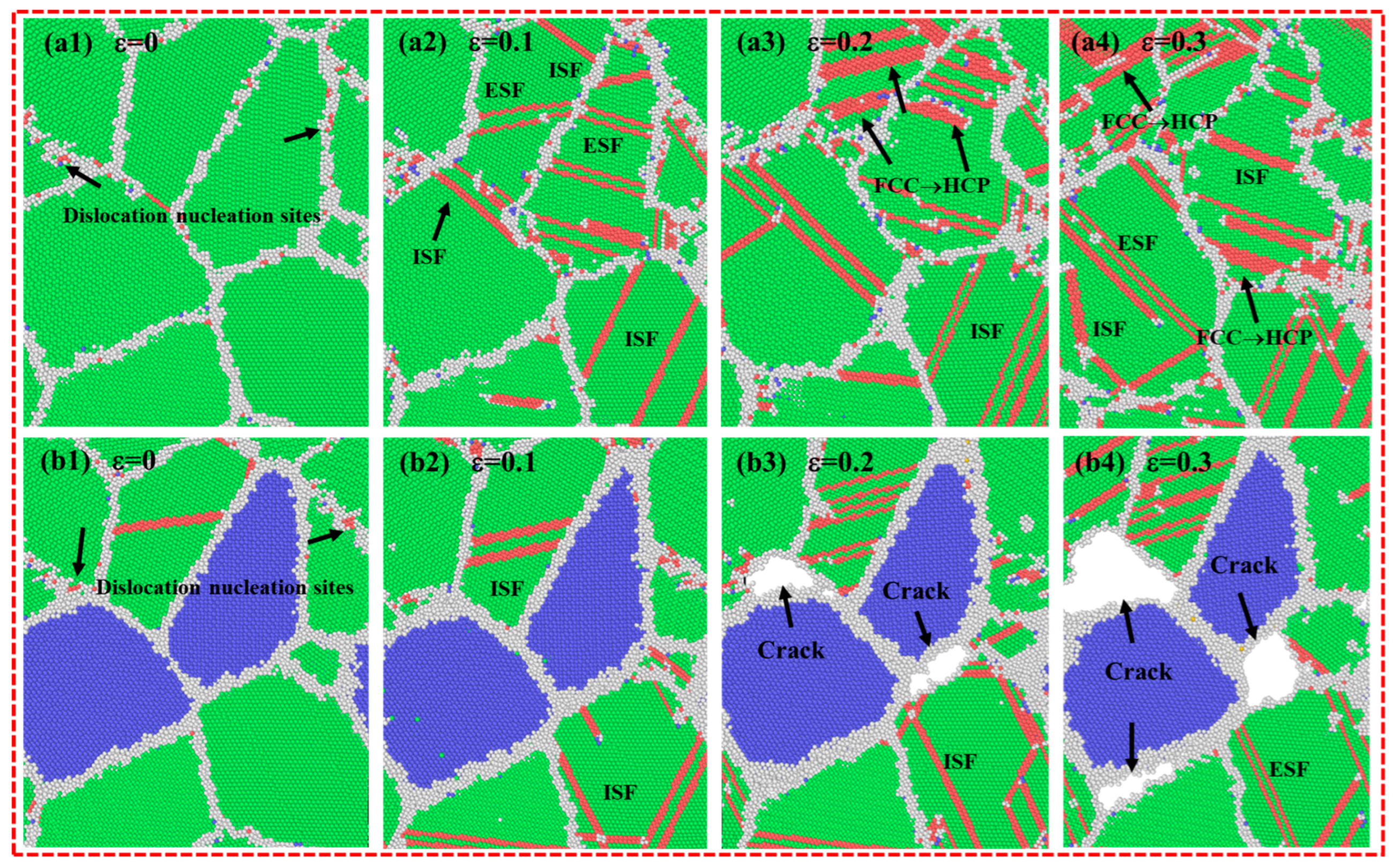

- The B2 phase influences deformation mechanisms by regulating dislocation behavior and GB stability. At low B2 phase volume fractions (3%), grain rotation is suppressed (misorientation change is only 5.01°), enhancing GB stability and reducing disordered atomic diffusion. At high B2 phase volume fractions (5%), GB migration and small grain coalescence are promoted, triggering martensitic phase transformation. Additionally, dislocations generated within the B2 phase in the 3% B2 phase alloy primarily involve superdislocation pairs coupled with APB slip, while the 5% B2 phase alloy activates secondary slip systems, forming Lomer–Cottrell dislocation locks.

- (3)

- Multi-slip system coordination and complex dislocation interactions are the main mechanisms of strain hardening. In the dual-phase alloy, the FCC phase dominates plastic deformation, with dislocations propagating along the {110}<111> slip system to form SFs. The B2 phase enhances strength through the APB-dragging effect of superdislocation pairs. Dislocation interactions and double cross-slip phenomena significantly increase dislocation density, but excessive dislocation tangles lead to localized stress concentrations, becoming potential sites for crack nucleation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Mu, Y.; Liang, Y.; Sheng, J.; Zhang, C.; Guo, Z.; Yang, G.; Sun, T.; Wang, Y.; Lin, J. A novel approach to coating for improving the comprehensive high-temperature service performance of TiAl alloys. Acta Mater. 2025, 283, 120500. [Google Scholar] [CrossRef]

- Ismail, F.; Vorontsov, V.; Lindley, T.; Hardy, M.; Dye, D.; Shollock, B.A. Alloying effects on oxidation mechanisms in polycrystalline Co–Ni base superalloys. Corros. Sci. 2017, 116, 44–52. [Google Scholar] [CrossRef]

- Blades, W.H.; Reinke, P. From alloy to oxide: Capturing the early stages of oxidation on Ni–Cr (100) alloys. ACS Appl. Mater. Interfaces 2018, 10, 43219–43229. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Lu, Y.; Zhang, B.; Liang, N.; Wu, G.; Sha, G.; Liu, J.; Zhao, Y. Microstructural origins of high strength and high ductility in an AlCoCrFeNi2. 1 eutectic high-entropy alloy. Acta Mater. 2017, 141, 59–66. [Google Scholar] [CrossRef]

- Hong, Y.; Wang, C.; Lei, J.; Yang, T.; Ji, V.; Song, P.; Huang, T.; Zhang, X. Combined effect of B2 phase transformation and FCC/BCC lamellar structure on the mechanical property of heat treated dual-phase Al0. 7CoCrFeNi high entropy alloy. J. Alloys Compd. 2025, 1020, 179456. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Chen, C.; Zhang, L.; Zhang, L. The structural stability and mechanical properties of doped Al2Cu precipitates with different elements by first-principles calculations. Comput. Condens. Matter 2024, 41, e00957. [Google Scholar] [CrossRef]

- Chen, T.; Parish, C.M.; Yang, Y.; Tan, L. High-temperature strengthening mechanisms of Laves and B2 precipitates in a novel ferritic alloy. Mater. Sci. Eng. A 2018, 720, 110–116. [Google Scholar] [CrossRef]

- Li, Z.; Fu, L.; Peng, J.; Zheng, H.; Ji, X.; Sun, Y.; Ma, S.; Shan, A. Improving mechanical properties of an FCC high-entropy alloy by γ′ and B2 precipitates strengthening. Mater. Charact. 2020, 159, 109989. [Google Scholar] [CrossRef]

- Jiang, C.; Ma, H.; Chen, Y.; Wang, N.; Zhao, Q.; Wu, G.; Zhu, L.; Luo, J.; Zhao, Y. Crack propagation behavior of dual-phase steel at low temperature. Int. J. Fatigue 2022, 155, 106633. [Google Scholar] [CrossRef]

- Wu, S.; Qiao, X.; Zheng, M. Ultrahigh strength Mg-Y-Ni alloys obtained by regulating second phases. J. Mater. Sci. Technol. 2020, 45, 117–124. [Google Scholar] [CrossRef]

- Ye, Z.; Li, C.; Zheng, M.; Zhang, X.; Yang, X.; Wang, Q.; Gu, J. Realizing superior strength-ductility combination in dual-phase AlFeCoNiV high-entropy alloy through composition and microstructure design. Mater. Res. Lett. 2022, 10, 736–743. [Google Scholar] [CrossRef]

- Niu, M.; Qiu, S.; Yu, Q.; Li, W.; Zhang, S.; Guo, J.; Luan, J.; Wang, W.; Yang, T.; Wang, X. Achieving excellent elevated-temperature mechanical properties in dual-phase high-entropy alloys via nanoscale co-precipitation and heterostructure engineering. Acta Mater. 2025, 284, 120634. [Google Scholar] [CrossRef]

- Gao, B.; Hu, R.; Pan, Z.; Chen, X.; Liu, Y.; Xiao, L.; Cao, Y.; Li, Y.; Lai, Q.; Zhou, H. Strengthening and ductilization of laminate dual-phase steels with high martensite content. J. Mater. Sci. Technol. 2021, 65, 29–37. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; In’, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D. LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Hillel, G.; Galaeva, E.; Edry, I.; Fuks, D.; Pinkas, M.; Meshi, L. Understanding the formation mechanisms and stability of the Anti-Phase boundaries (APBs) in Al-Fe B2. J. Alloys Compd. 2024, 970, 172639. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Ji, W.; Zhou, R.; Vivegananthan, P.; Wu, M.S.; Gao, H.; Zhou, K. Recent progress in gradient-structured metals and alloys. Prog. Mater. Sci. 2023, 140, 101194. [Google Scholar] [CrossRef]

- Ren, J.; Gui, Y.; Gao, Q.; Wang, Q.; Bai, Y.; Li, J.; Xue, H.; Lu, X.; Tang, F. Mechanical response and plastic deformation in single-and dual-phase polycrystalline FeNiAl alloys: Molecular dynamics analysis. J. Mater. Sci. 2024, 59, 14405–14419. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Faken, D.; Jónsson, H. Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 1994, 2, 279–286. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Farkas, D.; Caro, A. Model interatomic potentials for Fe–Ni–Cr–Co–Al high-entropy alloys. J. Mater. Res. 2020, 35, 3031–3040. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Chen, C.; Gui, Y.; Tang, X.; Li, Y.; Wang, C.; Sheng, J.; Zhang, Z.; Lu, X.; Ren, J. Atomic-Scale Study on the Composition Optimization and Deformation Mechanism of FeNiAl Alloys. Metals 2025, 15, 460. [Google Scholar] [CrossRef]

- Shimokawa, T.; Fujii, K.; Niiyama, T. Atomic simulation study of the factors affecting nucleation in deformation-induced martensitic transformation in grains and at grain boundaries in pure iron. Acta Mater 2024, 265, 119629. [Google Scholar] [CrossRef]

- Rida, A.; Rouhaud, E.; Makke, A.; Micoulaut, M.; Mantisi, B. Study of the effects of grain size on the mechanical properties of nanocrystalline copper using molecular dynamics simulation with initial realistic samples. Philos. Mag. 2017, 97, 2387–2405. [Google Scholar] [CrossRef]

- Sumigawa, T.; Onozuka, S.; Kim, B.; Abe, M.; Shima, H.; Umeno, Y.; Kitamura, T. Unique damage process in micro-sized copper single crystal with double-slip orientation in response to near-[112] tension-compression fatigue. Mater. Sci. Eng. A 2024, 909, 146842. [Google Scholar] [CrossRef]

- Dong, S.; Liu, X.-Y.; Zhou, C. Atomistic modeling of plastic deformation in B2-FeAl/Al nanolayered composites. J. Mater. Sci. 2021, 56, 17080–17095. [Google Scholar] [CrossRef]

- Paidar, V.; Čák, M. Three types of dislocation core structure in B2 alloys. Intermetallics 2016, 73, 21–25. [Google Scholar] [CrossRef]

- Han, S.; Laube, S.; Chen, Z.; Kauffmann, A.; Heilmaier, M.; Inui, H. Operative slip system and dislocation behavior in a brittle refractory high-entropy alloy with the B2 ordered structure. J. Alloys Compd. 2025, 1020, 179361. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Javanbakht, M.; Levitas, V.I. Interaction between phase transformations and dislocations at the nanoscale. Part 2: Phase field simulation examples. J. Mech. Phys. Solids 2015, 82, 164–185. [Google Scholar] [CrossRef]

- Javanbakht; Levitas, V.I. Phase field simulations of plastic strain-induced phase transformations under high pressure and large shear. Phys. Rev. B 2016, 94, 214104. [Google Scholar] [CrossRef]

- Fang, Q.; Chen, Y.; Li, J.; Jiang, C.; Liu, B.; Liu, Y.; Liaw, P.K. Probing the phase transformation and dislocation evolution in dual-phase high-entropy alloys. Int. J. Plast. 2019, 114, 161–173. [Google Scholar] [CrossRef]

- Lu, W.; Luo, X.; Yang, Y.; Zhang, J.; Huang, B. Huang. Effects of Al addition on structural evolution and mechanical properties of the CrCoNi medium-entropy alloy. Mater. Chem. Phys. 2019, 238, 121841. [Google Scholar] [CrossRef]

- Chen, S.; Aitken, Z.; Wu, Z.; Yu, Z.; Banerjee, R.; Zhang, Y. Hall-Petch and inverse Hall-Petch relations in high-entropy CoNiFeAlxCu1-x alloys. Mater. Sci. Eng. A 2020, 773, 138873. [Google Scholar] [CrossRef]

- Fang, Q.; Li, L.; Li, J.; Wu, H.; Huang, Z.; Liu, B.; Liu, Y.; Liaw, P.K. A statistical theory of probability-dependent precipitation strengthening in metals and alloys. J. Mech. Phys. Solids 2019, 122, 177–189. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, W.; Gui, Y.; Tang, X.; Lu, X.; Sheng, J.; Zhang, Z.; Ren, J. Molecular Dynamics Simulation of the Effect of B2-NiAl Phase Volume Fractions on Mechanical Properties and Deformation Mechanisms of Dual-Phase FeNiAl Alloys. Metals 2025, 15, 738. https://doi.org/10.3390/met15070738

Xiang W, Gui Y, Tang X, Lu X, Sheng J, Zhang Z, Ren J. Molecular Dynamics Simulation of the Effect of B2-NiAl Phase Volume Fractions on Mechanical Properties and Deformation Mechanisms of Dual-Phase FeNiAl Alloys. Metals. 2025; 15(7):738. https://doi.org/10.3390/met15070738

Chicago/Turabian StyleXiang, Wang, Yachen Gui, Xingchang Tang, Xuefeng Lu, Jie Sheng, Zhijian Zhang, and Junqiang Ren. 2025. "Molecular Dynamics Simulation of the Effect of B2-NiAl Phase Volume Fractions on Mechanical Properties and Deformation Mechanisms of Dual-Phase FeNiAl Alloys" Metals 15, no. 7: 738. https://doi.org/10.3390/met15070738

APA StyleXiang, W., Gui, Y., Tang, X., Lu, X., Sheng, J., Zhang, Z., & Ren, J. (2025). Molecular Dynamics Simulation of the Effect of B2-NiAl Phase Volume Fractions on Mechanical Properties and Deformation Mechanisms of Dual-Phase FeNiAl Alloys. Metals, 15(7), 738. https://doi.org/10.3390/met15070738