A New Insight into the Electronic Structure Property Relationships in Glassy Ti-Zr-Nb-(Cu,Ni,Co) Alloys

Abstract

1. Introduction

- (i)

- Several TE-TL CCAs [39,40,41,42,43,44] and many conventional TE-TL alloys (e.g., [45,46,47]) can be prepared in both the amorphous and crystalline states depending on the cooling rate of the molten alloys. Thus, the study of alloys sharing this property could help to disentangle the role of topological and chemical disorder in forming their properties. Moreover, the study of these alloys elucidated the variation in GFA with composition in conventional TE-TL alloys [46,47].

- (ii)

- All TE-TL alloys show the split-band structure of the electronic density of states (DOS) within the valence band (VB) [39,43,48,49,50,51]. The DOS close to the Fermi level is dominated by d-electrons of TEs, whereas d-electrons of TLs are situated at higher binding energies, [52]. This results in a simple, often linear, variation in the DOS at , , with TL content over a considerable range of TL concentrations, which is reflected in similarly simple variations in physical properties closely related to (e.g., [39,52,53]). Furthermore, the position of and the width of the TL d-subbands depend on the TL content [52]. This results in band crossing (the transition from TE- to TL-dominated ), which strongly affects the physical properties of TE-TL alloys [39,52,54,55,56,57]. However, the split-band structure of the DOS makes the average number of valence electrons per atom (VEC) a poor approximation of the electronic structure (ES) of TE-TL alloys [52,58].

- (iii)

- Many TE-TL alloys can be prepared by simple melt-spinning into a glassy state for TL concentrations 20–70% [53,59]. Such a broad glass-forming range (GFR) facilitates a comparison between the models and experiment in binary alloys [60,61,62,63,64], and in corresponding multiprincipal element alloys it enables the study of the transition from a-HEAs to conventional metallic glasses with the same chemical make up [39,52,54,57,65,66,67,68,69]. Simultaneously, a broad GFR and simple, often linear variations in properties with composition enable a reliable extrapolation of the results for alloys to those of hypothetical pure amorphous TEs and TLs [39,53,63,64,66,67,68,69,70,71,72,73]. This method has been used in order to gain some insight into the properties of a pure amorphous Ti, Zr, Hf, and Cu which have not been obtained in an amorphous state so far [74]. We note that the method of accessing the properties of a pure amorphous element from the extrapolation of the results for its alloys is advantageous even in cases when this element has been obtained in the amorphous phase. Namely, very high cooling rates K/s required to produce pure amorphous element results in the samples which are too small for measurement of any property other than the atomic structure [74]. Further, such a high is likely to have a strong effect on the structure of an amorphous metal, which will differ from that obtained at lower .

2. Experimental Details

3. Results and Discussion

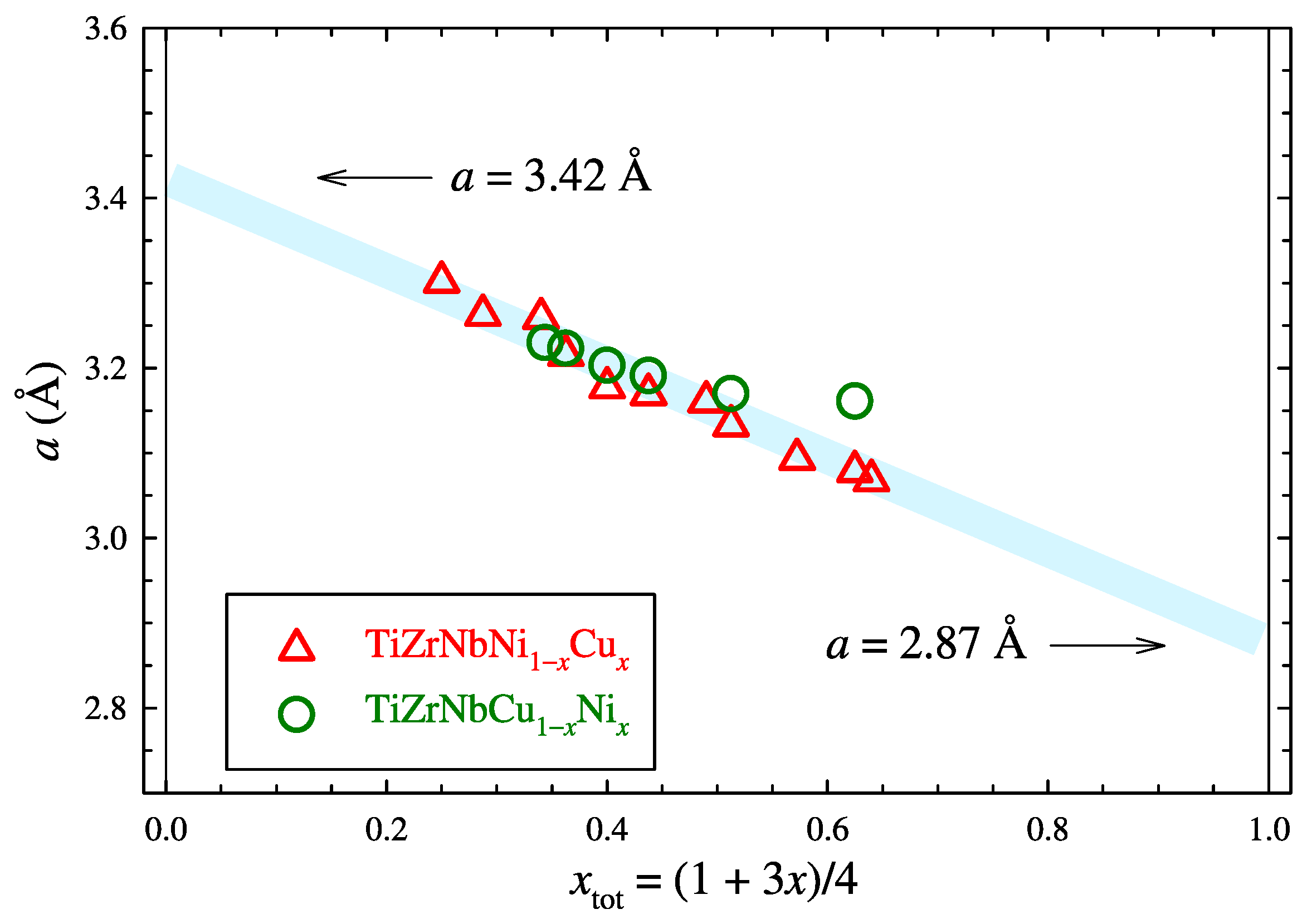

3.1. Lattice Parameters a

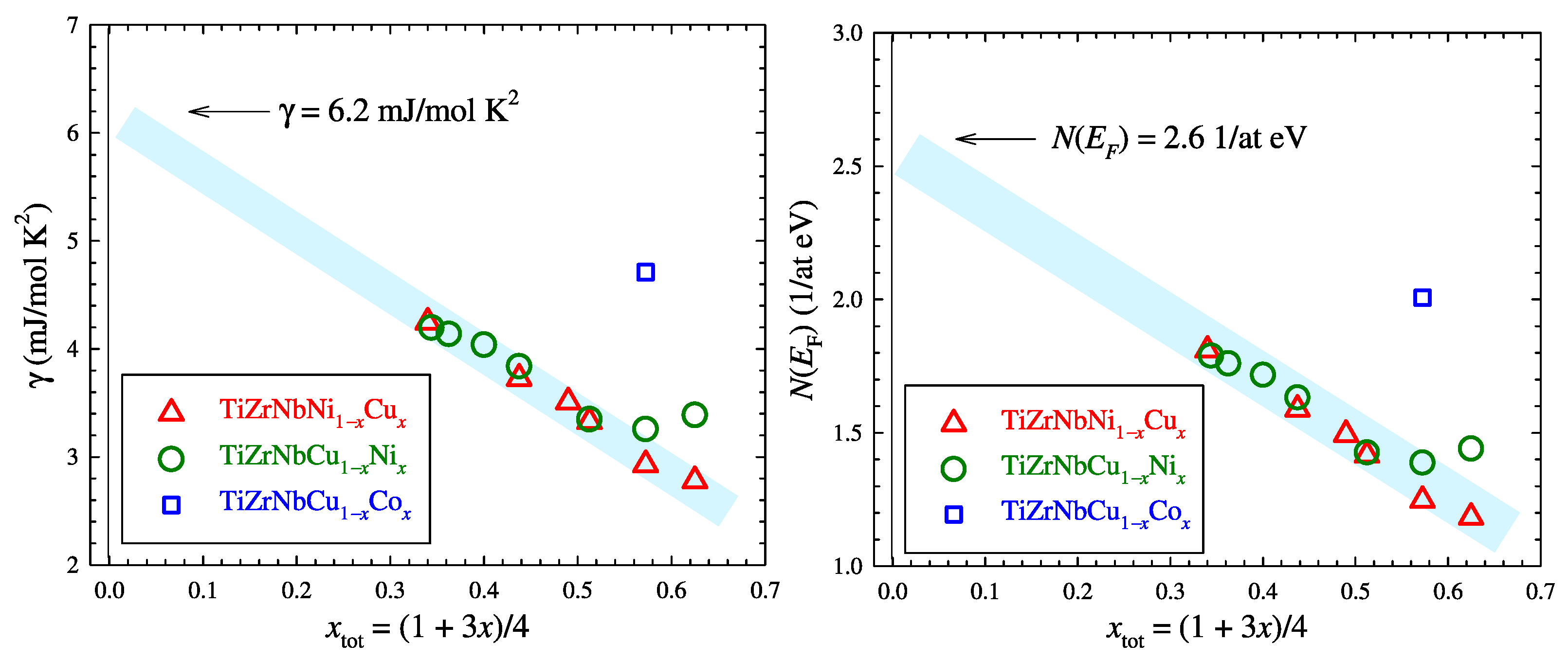

3.2. Sommerfeld Coefficient and Density of States

3.3. Magnetic Susceptibility

3.4. Superconducting Transition Temperature

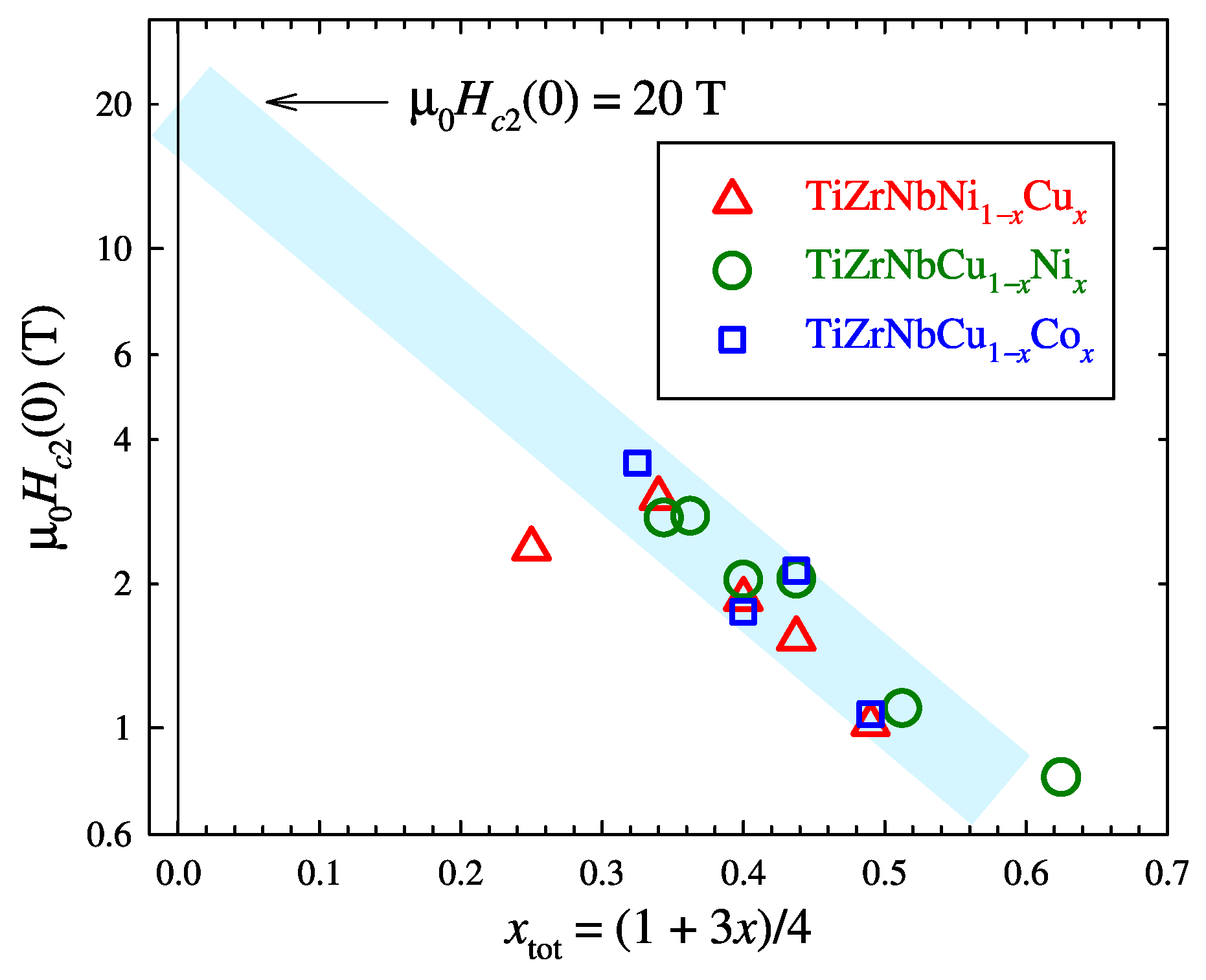

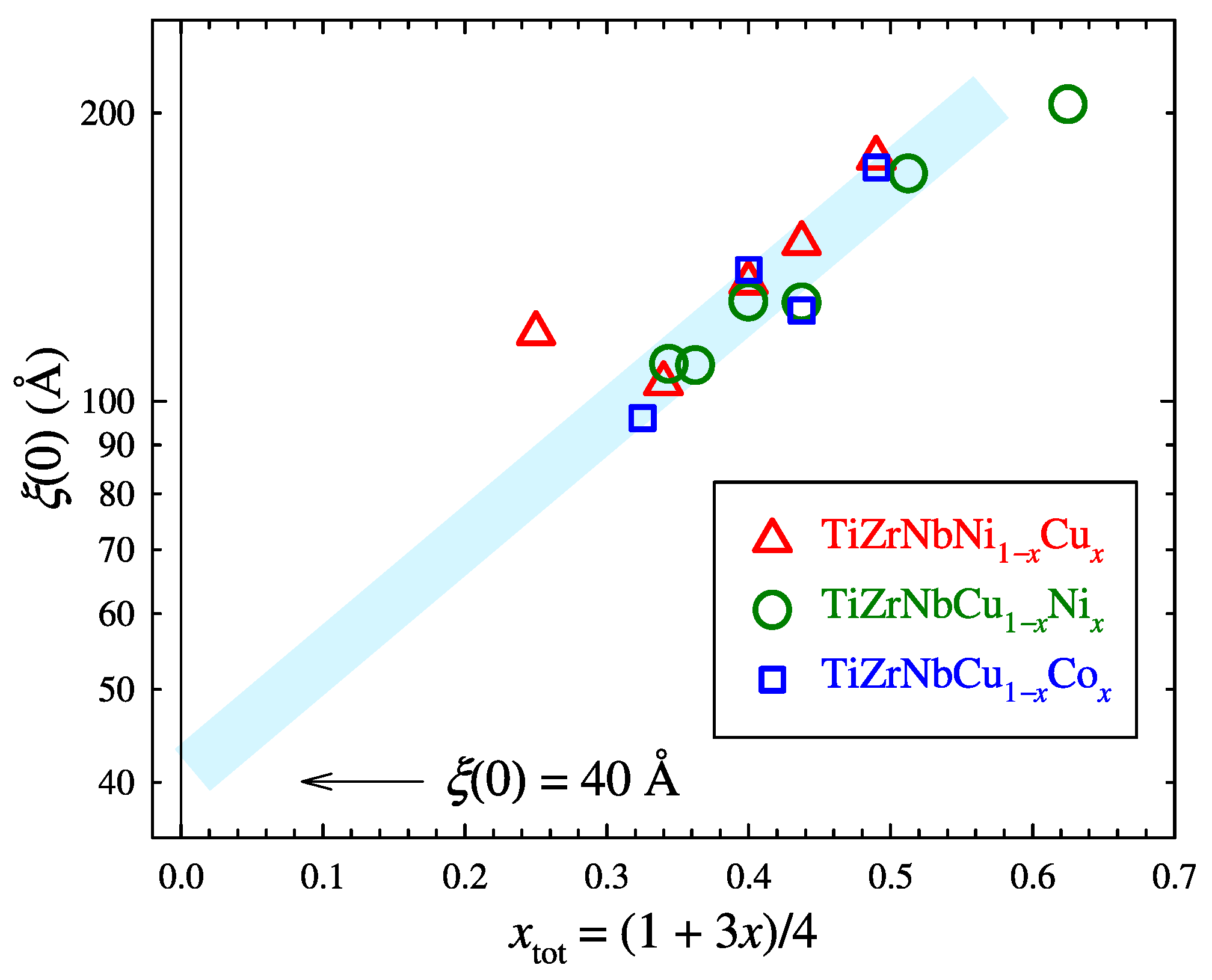

3.5. Upper Critical Magnetic Field and Coherence Length

3.6. VEC and Relationship in TE-TL Alloys

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miracle, D.B. High-entropy alloys as a bold step forward in alloy development. Nat. Commun. 2019, 10, 1805. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Wang, L.; Zhang, T.; Inoue, A. Bulk Glass Formation of Ti-Zr-Hf-Cu-M (M=Fe, Co, Ni) Alloys. Mater. Trans. 2002, 43, 277–280. [Google Scholar] [CrossRef]

- Cantor, B.; Kim, K.; Warren, P.J. Novel Multicomponent Amorphous Alloys. In Metastable, Mechanically Alloyed and Nanocrystalline Materials 2001; Trans Tech Publications Ltd.: Bäch, Switzerland, 2002; Volume 386, pp. 27–32. [Google Scholar] [CrossRef]

- Kim, K.; Warren, P.; Cantor, B. Metallic glass formation in multicomponent (Ti, Zr, Hf, Nb)–(Ni, Cu, Ag)–Al alloys. J. -Non-Cryst. Solids 2003, 317, 17–22. [Google Scholar] [CrossRef]

- Babić, E.; Bei, H. (Eds.) Compositional Complex Alloys: From Amorphous to High-Entropy (Special Issue of Materials). 2022. Available online: https://www.mdpi.com/journal/materials/special_issues/AHE (accessed on 27 May 2025).

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Senkov, O.; Miller, J.; Miracle, D.; Woodward, C. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat. Commun. 2015, 6, 6529. [Google Scholar] [CrossRef]

- Pickering, E.J.; Jones, N.G. High-entropy alloys: A critical assessment of their founding principles and future prospects. Int. Mater. Rev. 2016, 61, 183–202. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Q.; Lu, J.; Liu, C.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Guo, S. Phase selection rules for cast high-entropy alloys: An overview. Mater. Sci. Technol. 2015, 31, 1223–1230. [Google Scholar] [CrossRef]

- Miracle, D.; Senkov, O. A critical review of high-entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Ikeda, Y.; Grabowski, B.; Körmann, F. Ab initio phase stabilities and mechanical properties of multicomponent alloys: A comprehensive review for high-entropy alloys and compositionally complex alloys. Mater. Charact. 2019, 147, 464–511. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.W.; Liaw, P.K.; Zhang, Y. (Eds.) High-Entropy Alloys; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Cantor, B. Multicomponent high-entropy Cantor alloys. Prog. Mater. Sci. 2021, 120, 100754. [Google Scholar] [CrossRef]

- Chen, Y.; Dai, Z.W.; Jiang, J.Z. High entropy metallic glasses: Glass formation, crystallization and properties. J. Alloys Compd. 2021, 866, 158852. [Google Scholar] [CrossRef]

- Luan, H.; Li, K.; Shi, L.; Zhao, W.; Bu, H.; Gong, P.; Yao, K.F. Recent progress in high-entropy metallic glasses. J. Mater. Sci. Technol. 2023, 161, 50–62. [Google Scholar] [CrossRef]

- Firstov, G.; Kosorukova, T.; Koval, Y.; Odnosum, V. High Entropy Shape Memory Alloys. Mater. Today Proc. 2015, 2, S499–S503. [Google Scholar] [CrossRef]

- Firstov, G.S.; Kosorukova, T.A.; Koval, Y.N.; Verhovlyuk, P.A. Directions for High-Temperature Shape Memory Alloys’ Improvement: Straight Way to High-Entropy Materials? Shape Mem. Superelasticity 2015, 1, 400–407. [Google Scholar] [CrossRef]

- Kosorukova, T.A.; Gerstein, G.; Odnosum, V.V.; Koval, Y.N.; Maier, H.J.; Firstov, G.S. Microstructure Formation in Cast TiZrHfCoNiCu and CoNiCuAlGaIn High Entropy Shape Memory Alloys: A Comparison. Materials 2019, 12, 4227. [Google Scholar] [CrossRef]

- Piorunek, D.; Oluwabi, O.; Frenzel, J.; Kostka, A.; Maier, H.; Somsen, C.; Eggeler, G. Effect of off-stoichiometric compositions on microstructures and phase transformation behavior in Ni-Cu-Pd-Ti-Zr-Hf high entropy shape memory alloys. J. Alloys Compd. 2021, 857, 157467. [Google Scholar] [CrossRef]

- Kuo, S.Y.; Kao, W.P.; Chang, S.H.; Shen, T.E.; Yeh, J.W.; Tsai, C.W. Effect of Homogenization on the Transformation Temperatures and Mechanical Properties of Cu15Ni35Hf12.5Ti25Zr12.5 and Cu15Ni35Hf15Ti20Zr15 High-Entropy Shape Memory Alloys. Materials 2023, 16, 3212. [Google Scholar] [CrossRef] [PubMed]

- Adamo, C.G.; Srivastava, A.; Kumar, D.; Legese, S.S.; Sreeram, P.R.; Mangalassery, N.M.; Kawamura, Y.; Olu, F.E.; Tiwary, C.S.; Singh, A.K.; et al. Tailoring Ni/Fe Doping for Superior Thermoelectric Performance of Zr2Ni2-xFexSnSb (x = 0.30, 0.35, 0.40) High-Entropy Alloys. Energy Technol. 2024, 13, 2401718. [Google Scholar] [CrossRef]

- Edalati, P.; Floriano, R.; Mohammadi, A.; Li, Y.; Zepon, G.; Li, H.W.; Edalati, K. Reversible room temperature hydrogen storage in high-entropy alloy TiZrCrMnFeNi. Scr. Mater. 2020, 178, 387–390. [Google Scholar] [CrossRef]

- Andrade, G.; Zepon, G.; Edalati, K.; Mohammadi, A.; Ma, Z.; Li, H.W.; Floriano, R. Crystal structure and hydrogen storage properties of AB-type TiZrNbCrFeNi high-entropy alloy. Int. J. Hydrogen Energy 2023, 48, 13555–13565. [Google Scholar] [CrossRef]

- Qiu, H.J.; Fang, G.; Gao, J.; Wen, Y.; Lv, J.; Li, H.; Xie, G.; Liu, X.; Sun, S. Noble Metal-Free Nanoporous High-Entropy Alloys as Highly Efficient Electrocatalysts for Oxygen Evolution Reaction. ACS Mater. Lett. 2019, 1, 526–533. [Google Scholar] [CrossRef]

- Glasscott, M.W.; Pendergast, A.D.; Goines, S.; Bishop, A.R.; Hoang, A.T.; Renault, C.; Dick, J.E. Electrosynthesis of high-entropy metallic glass nanoparticles for designer, multi-functional electrocatalysis. Nat. Commun. 2019, 10, 2650. [Google Scholar] [CrossRef]

- Popescu, G.; Ghiban, B.; Popescu, C.A.; Rosu, L.; Truscă, R.; Carcea, I.; Soare, V.; Dumitrescu, D.; Constantin, I.; Olaru, M.T.; et al. New TiZrNbTaFe high-entropy alloy used for medical applications. Iop Conf. Ser. Mater. Sci. Eng. 2018, 400, 022049. [Google Scholar] [CrossRef]

- Takahashi, M.; Sato, K.; Togawa, G.; Takada, Y. Mechanical Properties of Ti-Nb-Cu Alloys for Dental Machining Applications. J. Funct. Biomater. 2022, 13, 263. [Google Scholar] [CrossRef]

- de Oliveira, T.G.; Fagundes, D.V.; Capellato, P.; Sachs, D.; da Silva, A.A.A.P. A Review of Biomaterials Based on High-Entropy Alloys. Metals 2022, 12, 1940. [Google Scholar] [CrossRef]

- Zhu, S.; Yang, Q.; Gan, K.; Yan, D.; Zhang, Y.; Liu, C.; Li, Z. A strong ferritic high-resistivity multicomponent alloy with tunable ordered coherent multicomponent nanoprecipitates. Acta Mater. 2022, 238, 118209. [Google Scholar] [CrossRef]

- Kitagawa, J.; Hamamoto, S.; Ishizu, N. Cutting Edge of High-Entropy Alloy Superconductors from the Perspective of Materials Research. Metals 2020, 10, 1078. [Google Scholar] [CrossRef]

- Yoshikazu Mizuguchi, M.R.K.; Matsuda, T.D. Superconductivity in CuAl2-type Co0.2Ni0.1Cu0.1Rh0.3Ir0.3Zr2 with a high-entropy-alloy transition metal site. Mater. Res. Lett. 2021, 9, 141–147. [Google Scholar] [CrossRef]

- Han, L.; Zhu, S.; Rao, Z.; Scheu, C.; Ponge, D.; Ludwig, A.; Zhang, H.; Gutfleisch, O.; Hahn, H.; Li, Z.; et al. Multifunctional high-entropy materials. Nat. Rev. Mater. 2024, 9, 846–865. [Google Scholar] [CrossRef]

- Inoue, A.; Kong, F.; Zhu, X.; Chen, J.; Men, H.; Botta, W.J. Development and industrialization of Zr- and Fe-based bulk metallic glasses and light metal-based metastable alloys. J. Alloys Compd. 2024, 979, 173546. [Google Scholar] [CrossRef]

- Babić, E.; Drobac, Đ.; Figueroa, I.A.; Laurent-Brocq, M.; Marohnić, Ž.; Mikšić Trontl, V.; Pajić, D.; Perrière, L.; Pervan, P.; Remenyi, G.; et al. Transition from High-Entropy to Conventional Alloys: Which Are Better? Materials 2021, 14, 5824. [Google Scholar] [CrossRef]

- Cunliffe, A.; Plummer, J.; Figueroa, I.; Todd, I. Glass formation in a high-entropy alloy system by design. Intermetallics 2012, 23, 204–207. [Google Scholar] [CrossRef]

- Meng, Y.; Duan, F.; Pan, J.; Li, Y. Phase stability of B2-ordered ZrTiHfCuNiFe high-entropy alloy. Intermetallics 2019, 111, 106515. [Google Scholar] [CrossRef]

- Nagase, T.; Takeuchi, A.; Amiya, K.; Egami, T. Solid state amorphization of metastable Al0.5TiZrPdCuNi high entropy alloy investigated by high voltage electron microscopy. Mater. Chem. Phys. 2018, 210, 291–300. [Google Scholar] [CrossRef]

- Babić, E.; Figueroa, I.A.; Mikšić Trontl, V.; Pervan, P.; Pletikosić, I.; Ristić, R.; Salčinović Fetić, A.; Skoko, Ž.; Starešinić, D.; Valla, T.; et al. Electronic structure–property relationship in an Al0.5TiZrPdCuNi high-entropy alloy. Appl. Phys. Lett. 2024, 124, 221903. [Google Scholar] [CrossRef]

- Park, H.J.; Na, Y.S.; Hong, S.H.; Kim, J.T.; Kim, Y.S.; Lim, K.R.; Park, J.M.; Kim, K.B. Phase evolution, microstructure and mechanical properties of equi-atomic substituted TiZrHfNiCu and TiZrHfNiCuM (M = Co, Nb) high-entropy alloys. Met. Mater. Int. 2016, 22, 551–556. [Google Scholar] [CrossRef]

- Köster, U.; Herold, U. Crystallization of metallic glasses. In Glassy Metals I; Güntherodt, H.J., Beck, H., Eds.; Springer: Berlin/Heidelberg, Germany, 1981; Volume 46, pp. 225–259. [Google Scholar] [CrossRef]

- Ristić, R.; Zadro, K.; Pajić, D.; Figueroa, I.A.; Babić, E. On the origin of bulk glass forming ability in Cu-Hf, Zr alloys. Europhys. Lett. 2016, 114, 17006. [Google Scholar] [CrossRef]

- Babić, E.; Ristić, R.; Figueroa, I.A.; Pajić, D.; Skoko, Ž.; Zadro, K. Electronic structure and glass forming ability in early and late transition metal alloys. Philos. Mag. 2018, 98, 693–709. [Google Scholar] [CrossRef]

- Amamou, A. d Band structure and alloying effects in crystalline and amorphous Zr2Co and Zr2Ni. Solid State Commun. 1980, 33, 1029–1034. [Google Scholar] [CrossRef]

- Oelhafen, P.; Hauser, E.; Güntherodt, H.J. Varying d-band splitting in glassy transition metal alloys. Solid State Commun. 1980, 35, 1017–1019. [Google Scholar] [CrossRef]

- Zehringer, R.; Oelhafen, P.; Güntherodt, H.J.; Yamada, Y.; Mizutani, U. Electronic structure of (Ni33Zr67)85X15 (X=Ti, V, Cr, Mn, Fe, Co and Cu) Metallic glasses studied by photoelectron spectroscopy. Mater. Sci. Eng. 1988, 99, 317–320. [Google Scholar] [CrossRef]

- Babić, E.; Biljaković, K.; Figueroa, A.I.; Kuršumović, A.; Mikšić Trontl, V.; Pajić, D.; Pervan, P.; Ristić, R.; Starešinić, D. High-entropy alloys: New challenge in materials science. In Proceedings of the Solid-State Science & Research Meeting 2017, Zagreb, Croatia, 28–30 June 2017; Institut Ruđer Bošković: Zagreb, Croatia, 2017; p. 25. [Google Scholar]

- Pervan, P.; Mikšić Trontl, V.; Figueroa, I.A.; Valla, T.; Pletikosić, I.; Babić, E. Compositionally Complex Alloys: Some Insights from Photoemission Spectroscopy. Materials 2023, 16, 1486. [Google Scholar] [CrossRef]

- Ristić, R.; Cooper, J.; Zadro, K.; Pajić, D.; Ivkov, J.; Babić, E. Ideal solution behaviour of glassy Cu–Ti,Zr,Hf alloys and properties of amorphous copper. J. Alloys Compd. 2015, 621, 136–145. [Google Scholar] [CrossRef]

- Kuveždić, M.; Tafra, E.; Basletić, M.; Ristić, R.; Pervan, P.; Mikšić Trontl, V.; Figueroa, I.A.; Babić, E. Change of electronic properties on transition from high-entropy to Ni-rich (TiZrNbCu)1-xNix alloys. J. -Non-Cryst. Solids 2020, 531, 119865. [Google Scholar] [CrossRef]

- Ivkov, J.; Babic, E.; Jacobs, R.L. Hall effect and electronic structure of glassy Zr 3d alloys. J. Phys. Met. Phys. 1984, 14, L53. [Google Scholar] [CrossRef]

- From, M.; Muir, W.B. Thermoelectric power of Fe-Zr and Co-Zr metallic glasses. Phys. Rev. B 1986, 33, 3736–3739. [Google Scholar] [CrossRef] [PubMed]

- Kuveždić, M.; Tafra, E.; Figueroa, I.A.; Basletić, M. (Magneto)Transport Properties of (TiZrNbNi)1-xCux and (TiZrNbCu)1-xCox Complex Amorphous Alloys. Materials 2023, 16, 1711. [Google Scholar] [CrossRef] [PubMed]

- Babić, E.; Ristić, R.; Miljak, M.; Scott, M.; Gregan, G. Superconductivity in zirconium-nickel glasses. Solid State Commun. 1981, 39, 139–141. [Google Scholar] [CrossRef]

- Cheng, Y.; Ma, E. Atomic-level structure and structure–property relationship in metallic glasses. Prog. Mater. Sci. 2011, 56, 379–473. [Google Scholar] [CrossRef]

- Moruzzi, V.L.; Oelhafen, P.; Williams, A.R.; Lapka, R.; Güntherodt, H.J.; Kübler, J. Theoretical and experimental electronic structure of Zr-based transition-metal glasses containing Fe, Co, Ni, Cu, Rh, and Pd. Phys. Rev. B 1983, 27, 2049–2054. [Google Scholar] [CrossRef]

- Jank, W.; Hausleitner, C.; Hafner, J. Self-Consistent Electronic Structure of NixZr1-x Glasses. Europhys. Lett. 1991, 16, 473. [Google Scholar] [CrossRef]

- Hafner, J.; Hausleitner, C.; Jank, W.; Turek, I. First-principles calculations of the structural, electronic, and magnetic properties of transition-metal glasses. J. Non-Cryst. Solids 1992, 150, 307–313. [Google Scholar] [CrossRef]

- Bakonyi, I. Atomic volumes and local structure of metallic glasses. Acta Mater. 2005, 53, 2509–2520. [Google Scholar] [CrossRef]

- Bakonyi, I. Electronic properties and atomic structure of (Ti, Zr, Hf)-(Ni, Cu) metallic glasses. J. -Non-Cryst. Solids 1995, 180, 131–150. [Google Scholar] [CrossRef]

- Biljaković, K.; Remenyi, G.; Figueroa, I.A.; Ristić, R.; Pajić, D.; Kuršumović, A.; Starešinić, D.; Zadro, K.; Babić, E. Electronic structure and properties of (TiZrNbCu)1-xNix high entropy amorphous alloys. J. Alloys Compd. 2017, 695, 2661–2668. [Google Scholar] [CrossRef]

- Babić, E.; Pajić, D.; Zadro, K.; Biljaković, K.; Trontl, V.M.; Pervan, P.; Starešinić, D.; Figueroa, I.A.; Kuršumović, A.; Michalik, Š.; et al. Structure property relationship in (TiZrNbCu)1-x Nix metallic glasses. J. Mater. Res. 2018, 33, 3170–3183. [Google Scholar] [CrossRef]

- Ristić, R.; Figueroa, I.A.; Lachová, A.; Michalik, Š.; Mikšić Trontl, V.; Pervan, P.; Zadro, K.; Pajić, D.; Babić, E. Transition from high-entropy to Cu-based (TiZrNbNi)1-xCux metallic glasses. J. Appl. Phys. 2019, 126, 154105. [Google Scholar] [CrossRef]

- Figueroa, I.A.; Ristić, R.; Kuršumović, A.; Biljaković, K.; Starešinić, D.; Pajić, D.; Remenyi, G.; Babić, E. Properties of (TiZrNbCu)1-xNix metallic glasses. J. Alloys Compd. 2018, 745, 455–459. [Google Scholar] [CrossRef]

- Ristić, R.; Figueroa, I.A.; Salčinović Fetić, A.; Zadro, K.; Mikšić Trontl, V.; Pervan, P.; Babić, E. Transition from high-entropy to conventional (TiZrNbCu)1-xCox metallic glasses. J. Appl. Phys. 2021, 130, 195102. [Google Scholar] [CrossRef]

- Ristić, R.; Babić, E. Properties and atomic structure of amorphous zirconioum. Fiz. A 2005, 14, 97–106. [Google Scholar]

- Ristić, R.; Babić, E. Thermodynamic properties and atomic structure of amorphous zirconium. Mater. Sci. Eng. A 2007, 449–451, 569–572. [Google Scholar] [CrossRef]

- Ristić, R.; Babić, E.; Pajić, D.; Zadro, K.; Kuršumović, A.; Figueroa, I.; Davies, H.; Todd, I.; Varga, L.; Bakonyi, I. Properties and atomic structure of amorphous early transition metals. J. Alloys Compd. 2010, 504, S194–S197. [Google Scholar] [CrossRef]

- Tafra, E.; Basletić, M.; Ristić, R.; Babić, E.; Hamzić, A. Enhanced superconductivity in Hf-base metallic glasses. J. Phys. Condens. Matter 2008, 20, 425215. [Google Scholar] [CrossRef]

- Han, X.; Wu, G.; He, D.S.; Hong, X. Single-element amorphous metals. Interdiscip. Mater. 2024, 3, 480–491. [Google Scholar] [CrossRef]

- Senkov, O.N.; Gorsse, S.; Wheeler, R.; Payton, E.J.; Miracle, D.B. Effect of Re on the Microstructure and Mechanical Properties of NbTiZr and TaTiZr Equiatomic Alloys. Metals 2021, 11, 1819. [Google Scholar] [CrossRef]

- Senkov, O.; Rao, S.; Chaput, K.; Woodward, C. Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys. Acta Mater. 2018, 151, 201–215. [Google Scholar] [CrossRef]

- Hu, S.; Li, T.; Li, Q.; Liu, D. Microstructure evolution, deformation mechanism, and mechanical properties of biomedical TiZrNb medium entropy alloy processed using equal channel angular pressing. Intermetallics 2022, 151, 107725. [Google Scholar] [CrossRef]

- Košuth, F.; Cedervall, J.; Ek, G.; Gabáni, S.; Pristáš, G.; Orendáč, M.; Bačkai, J.; Onufriienko, O.; Szabó, P.; Flachbart, K. Superconductivity in TiZrNb and TiZrNbHf bulk equimolar alloys. Low Temp. Phys. 2024, 50, 663–667. [Google Scholar] [CrossRef]

- Bracq, G.; Laurent-Brocq, M.; Perrière, L.; Pirès, R.; Joubert, J.M.; Guillot, I. The fcc solid solution stability in the Co-Cr-Fe-Mn-Ni multi-component system. Acta Mater. 2017, 128, 327–336. [Google Scholar] [CrossRef]

- Calvayrac, Y.; Chevalier, J.P.; Harmelin, M.; Quivy, A.; Bigot, J. On the stability and structure of Cu-Zr based glasses. Philos. Mag. B 1983, 48, 323–332. [Google Scholar] [CrossRef]

- Kittel, C. Introduction to Solid State Physics, 8th ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Qi, L. Effects of electronic structures on mechanical properties of transition metals and alloys. Comput. Mater. Sci. 2019, 163, 11–16. [Google Scholar] [CrossRef]

- Dynes, R.C.; Varma, C.M. Superconductivity and electronic density of states. J. Phys. F Met. Phys. 1976, 6, L215. [Google Scholar] [CrossRef]

- Remenyi, G.; Biljaković, K.; Starešinić, D.; Dominko, D.; Ristić, R.; Babić, E.; Figueroa, I.A.; Davies, H.A. Looking for footprint of bulk metallic glass in electronic and phonon heat capacities of Cu55Hf45-xTix alloys. Appl. Phys. Lett. 2014, 104, 171906. [Google Scholar] [CrossRef]

- Bakonyi, I.; Ebert, H.; Liechtenstein, A.I. Electronic structure and magnetic susceptibility of the different structural modifications of Ti, Zr, and Hf metals. Phys. Rev. B 1993, 48, 7841–7849. [Google Scholar] [CrossRef]

- Sonier, J.E.; Hundley, M.F.; Thompson, J.D. Effect of delocalized vortex core states on the specific heat of Nb. Phys. Rev. B 2006, 73, 132504. [Google Scholar] [CrossRef]

- R. Ristić, M.S.; Babić, E. Correlation between mechanical, thermal and electronic properties in Zr–Ni, Cu amorphous alloys. Philos. Mag. 2007, 87, 5629–5637. [Google Scholar] [CrossRef]

- Collings, E.; Smith, R. The magnetic susceptibility of niobium. J. Less Common Met. 1972, 27, 389–401. [Google Scholar] [CrossRef]

- Place, C.M.; Rhodes, P. Paramagnetic orbital susceptibilities of transition metals. Phys. Status Solidi (b) 1971, 47, 475–486. [Google Scholar] [CrossRef]

- Koželj, P.; Vrtnik, S.; Jelen, A.; Jazbec, S.; Jagličić, Z.; Maiti, S.; Feuerbacher, M.; Steurer, W.; Dolinšek, J. Discovery of a Superconducting High-Entropy Alloy. Phys. Rev. Lett. 2014, 113, 107001. [Google Scholar] [CrossRef]

- Sun, L.; Cava, R.J. High-entropy alloy superconductors: Status, opportunities, and challenges. Phys. Rev. Mater. 2019, 3, 090301. [Google Scholar] [CrossRef]

- Kim, G.; Lee, M.H.; Yun, J.H.; Rawat, P.; Jung, S.G.; Choi, W.; You, T.S.; Kim, S.J.; Rhyee, J.S. Strongly correlated and strongly coupled s-wave superconductivity of the high-entropy alloy Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6 compound. Acta Mater. 2020, 186, 250–256. [Google Scholar] [CrossRef]

- Li, L.; Tian, H.; Hu, X.; Zeng, L.; Li, K.; Yu, P.; Wang, K.; Chen, R.; Xiang, Z.; Yao, D.X.; et al. Large upper critical fields and strong coupling superconductivity in the medium-entropy alloy (Ti1/3Hf1/3Ta1/3)1-xNbx. Supercond. Sci. Technol. 2024, 38, 015025. [Google Scholar] [CrossRef]

- Jung, S.G.; Han, Y.; Kim, J.H.; Hidayati, R.; Rhyee, J.S.; Lee, J.M.; Kang, W.N.; Choi, W.S.; Jeon, H.R.; Suk, J.; et al. High critical current density and high-tolerance superconductivity in high-entropy alloy thin films. Nat. Commun. 2022, 13, 3373. [Google Scholar] [CrossRef]

- Xu, X.; Yang, W.; Song, H.; Wang, J.; Yu, L.; Ren, Z.; Liu, B. Structural sequence and superconductivity in high-entropy Mo-W-Re-Ru-Pd alloys. Scr. Mater. 2024, 243, 115986. [Google Scholar] [CrossRef]

- Altounian, Z.; Strom-Olsen, J.O. Superconductivity and spin fluctuations in M-Zr metallic glasses (M = Cu,Ni,Co,and Fe). Phys. Rev. B 1983, 27, 4149–4156. [Google Scholar] [CrossRef]

- Karkut, M.G.; Hake, R.R. Upper critical fields and superconducting transition temperatures of some zirconium-base amorphous transition-metal alloys. Phys. Rev. B 1983, 28, 1396–1418. [Google Scholar] [CrossRef]

- Stolze, K.; Tao, J.; von Rohr, F.O.; Kong, T.; Cava, R.J. Sc–Zr–Nb–Rh–Pd and Sc–Zr–Nb–Ta–Rh–Pd High-Entropy Alloy Superconductors on a CsCl-Type Lattice. Chem. Mater. 2018, 30, 906–914. [Google Scholar] [CrossRef]

- Babić, E.; Ristić, R.; Miljak, M.; Scott, M.G. Electronic and magnetic properties of Zr-3d glasses. In Proceedings of the 4th International Conference on Rapidly Quenched Metals, Sendai, Japan, 24–28 August 1981; The Japan Institute of Metals: Sendai, Japan, 1982; pp. 1079–1082. [Google Scholar]

- Tinkham, M. Introduction to Superconductivity, 2nd ed.; Dover Publications: Mineola, NY, USA, 2004. [Google Scholar]

- McMillan, W.L. Transition Temperature of Strong-Coupled Superconductors. Phys. Rev. 1968, 167, 331–344. [Google Scholar] [CrossRef]

- Clogston, A.M. Upper Limit for the Critical Field in Hard Superconductors. Phys. Rev. Lett. 1962, 9, 266–267. [Google Scholar] [CrossRef]

- Wu, J.; Liu, B.; Cui, Y.; Zhu, Q.; Xiao, G.; Wang, H.; Wu, S.; Cao, G.; Ren, Z. Polymorphism and superconductivity in the V-Nb-Mo-Al-Ga high-entropy alloys. Sci. China Mater. 2020, 63, 823–831. [Google Scholar] [CrossRef]

- Gabáni, S.; Cedervall, J.; Ek, G.; Pristáš, G.; Orendáč, M.; Bačkai, J.; Onufriienko, O.; Gažo, E.; Flachbart, K. Search for superconductivity in hydrides of TiZrNb, TiZrNbHf and TiZrNbHfTa equimolar alloys. Phys. B Condens. Matter 2023, 648, 414414. [Google Scholar] [CrossRef]

- Werthamer, N.R.; Helfand, E.; Hohenberg, P.C. Temperature and Purity Dependence of the Superconducting Critical Field, Hc2. III. Electron Spin and Spin-Orbit Effects. Phys. Rev. 1966, 147, 295–302. [Google Scholar] [CrossRef]

- Banno, N. Low-temperature superconductors: Nb3Sn, Nb3Al, and NbTi. Superconductivity 2023, 6, 100047. [Google Scholar] [CrossRef]

- Novosel, N.; Galić, S.; Pajić, D.; Skoko, Ž.; Lončarek, I.; Mustapić, M.; Zadro, K.; Babić, E. Enhancement of the critical current density in MgB2 wires doped with Ni nanoparticles. Supercond. Sci. Technol. 2012, 25, 095018. [Google Scholar] [CrossRef]

- Xun, K.; Zhang, B.; Wang, Q.; Zhang, Z.; Ding, J.; Ma, E. Local chemical inhomogeneities in TiZrNb-based refractory high-entropy alloys. J. Mater. Sci. Technol. 2023, 135, 221–230. [Google Scholar] [CrossRef]

- Collver, M.M.; Hammond, R.H. Superconductivity in “Amorphous” Transition-Metal Alloy Films. Phys. Rev. Lett. 1973, 30, 92–95. [Google Scholar] [CrossRef]

- Matthias, B.T. Empirical Relation between Superconductivity and the Number of Valence Electrons per Atom. Phys. Rev. 1955, 97, 74–76. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuveždić, M.; Basletić, M.; Tafra, E.; Zadro, K.; Ristić, R.; Starešinić, D.; Figueroa, I.A.; Babić, E. A New Insight into the Electronic Structure Property Relationships in Glassy Ti-Zr-Nb-(Cu,Ni,Co) Alloys. Metals 2025, 15, 719. https://doi.org/10.3390/met15070719

Kuveždić M, Basletić M, Tafra E, Zadro K, Ristić R, Starešinić D, Figueroa IA, Babić E. A New Insight into the Electronic Structure Property Relationships in Glassy Ti-Zr-Nb-(Cu,Ni,Co) Alloys. Metals. 2025; 15(7):719. https://doi.org/10.3390/met15070719

Chicago/Turabian StyleKuveždić, Marko, Mario Basletić, Emil Tafra, Krešo Zadro, Ramir Ristić, Damir Starešinić, Ignacio Alejandro Figueroa, and Emil Babić. 2025. "A New Insight into the Electronic Structure Property Relationships in Glassy Ti-Zr-Nb-(Cu,Ni,Co) Alloys" Metals 15, no. 7: 719. https://doi.org/10.3390/met15070719

APA StyleKuveždić, M., Basletić, M., Tafra, E., Zadro, K., Ristić, R., Starešinić, D., Figueroa, I. A., & Babić, E. (2025). A New Insight into the Electronic Structure Property Relationships in Glassy Ti-Zr-Nb-(Cu,Ni,Co) Alloys. Metals, 15(7), 719. https://doi.org/10.3390/met15070719