Irradiation Performance of a Multiphase MoNbTiVZr Refractory High-Entropy Alloy: Role of Zr-Rich Phase Precipitation

Abstract

1. Introduction

2. Materials and Methods

3. Results

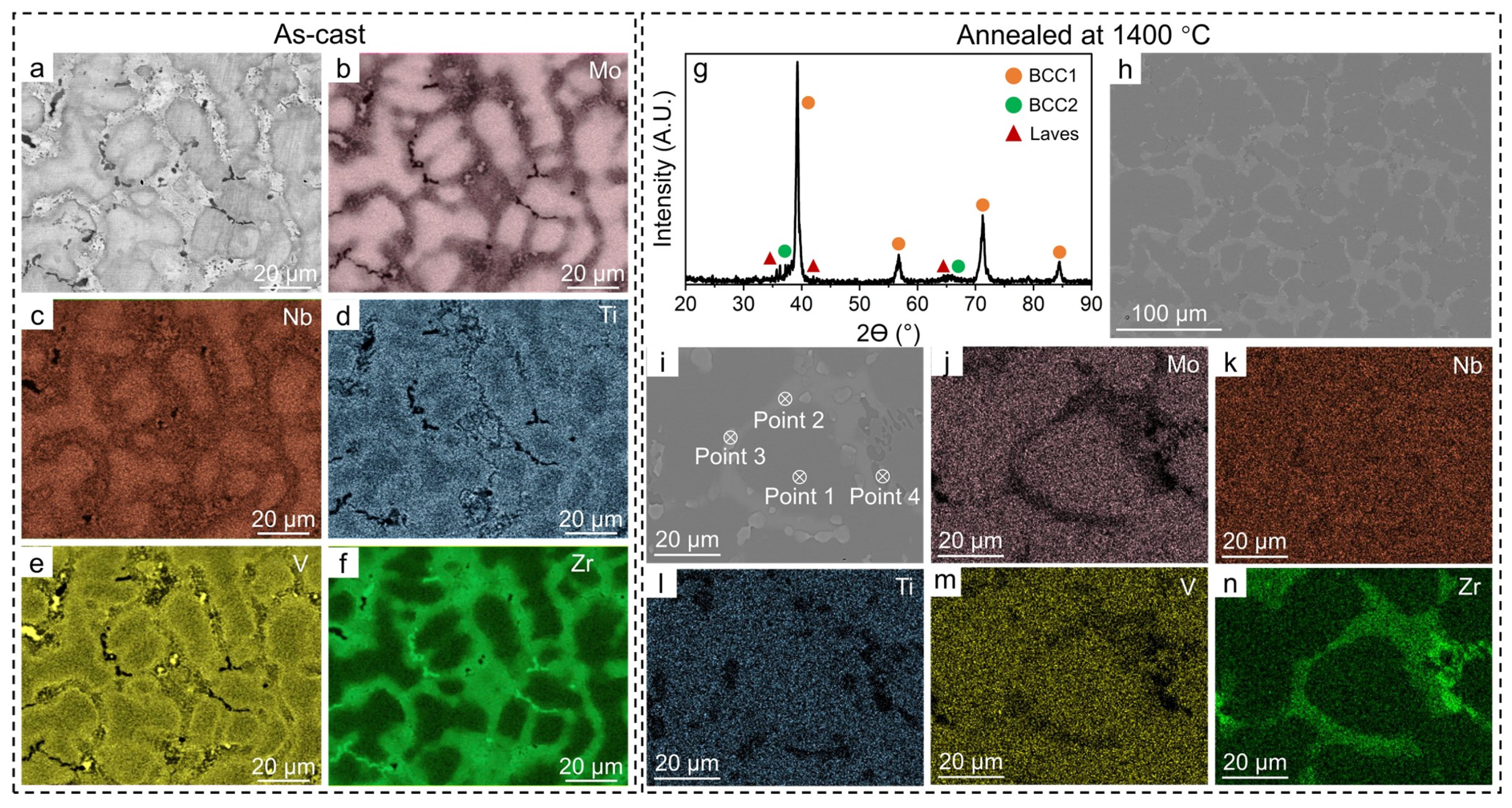

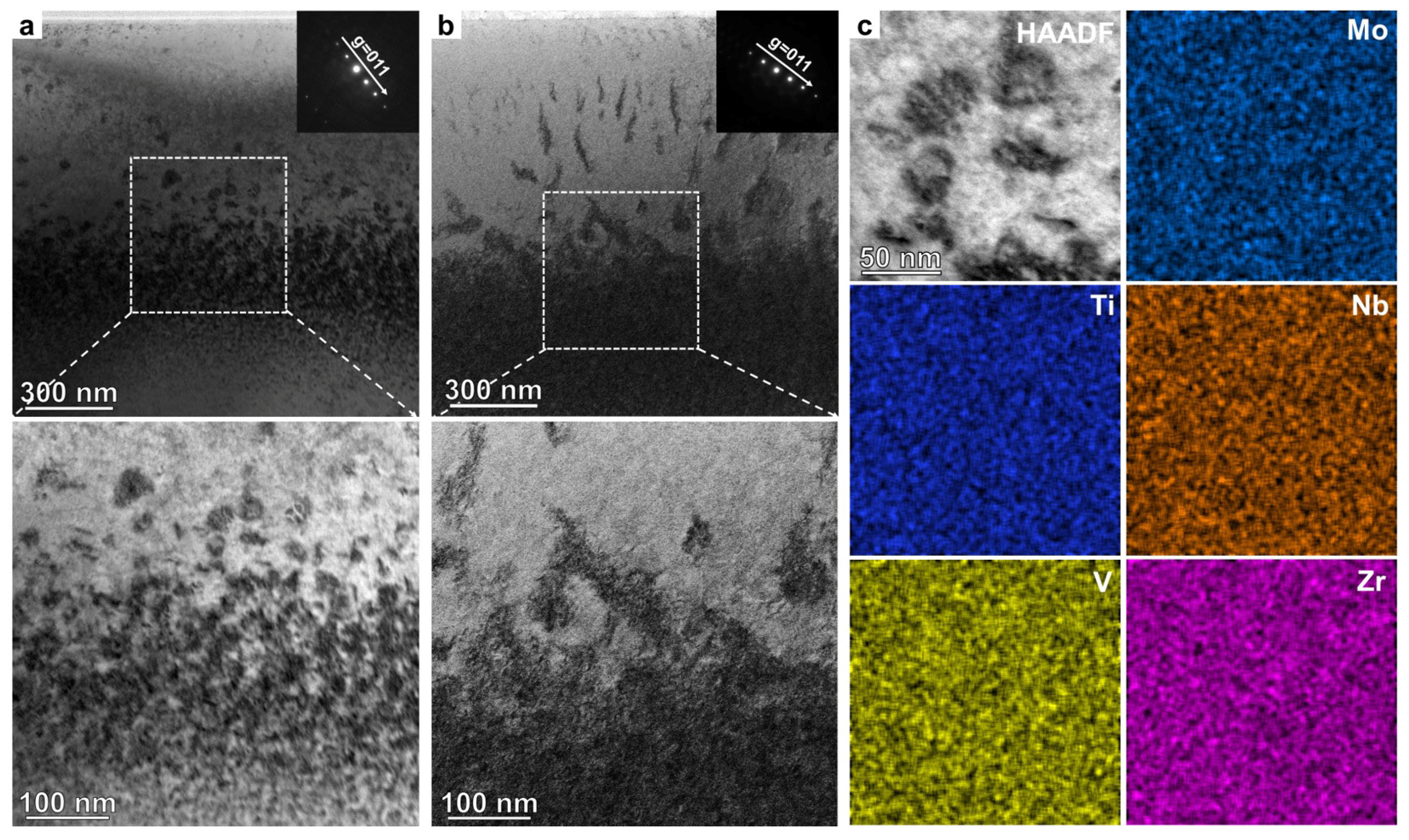

3.1. Pre-Irradiation Characterization

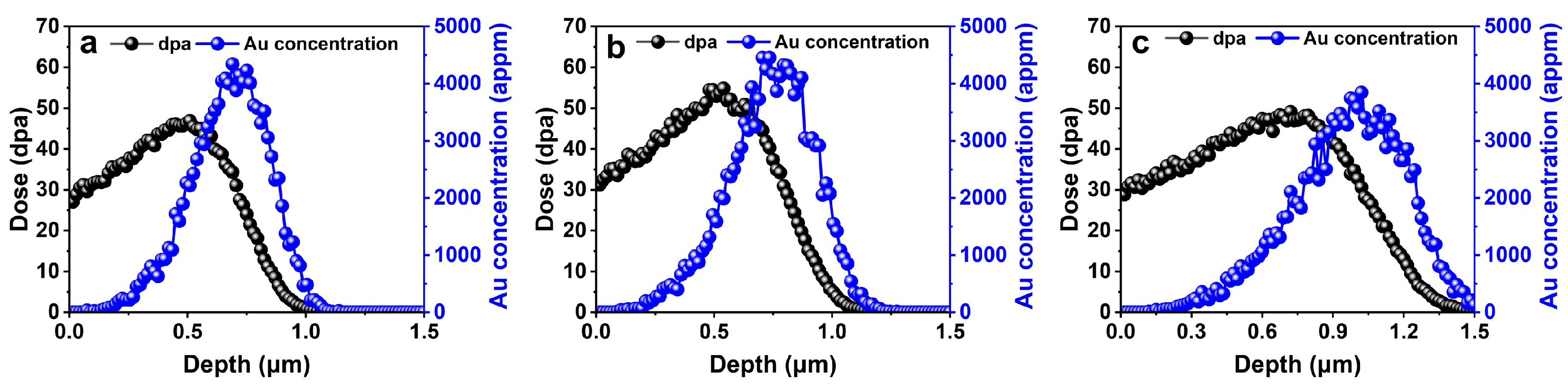

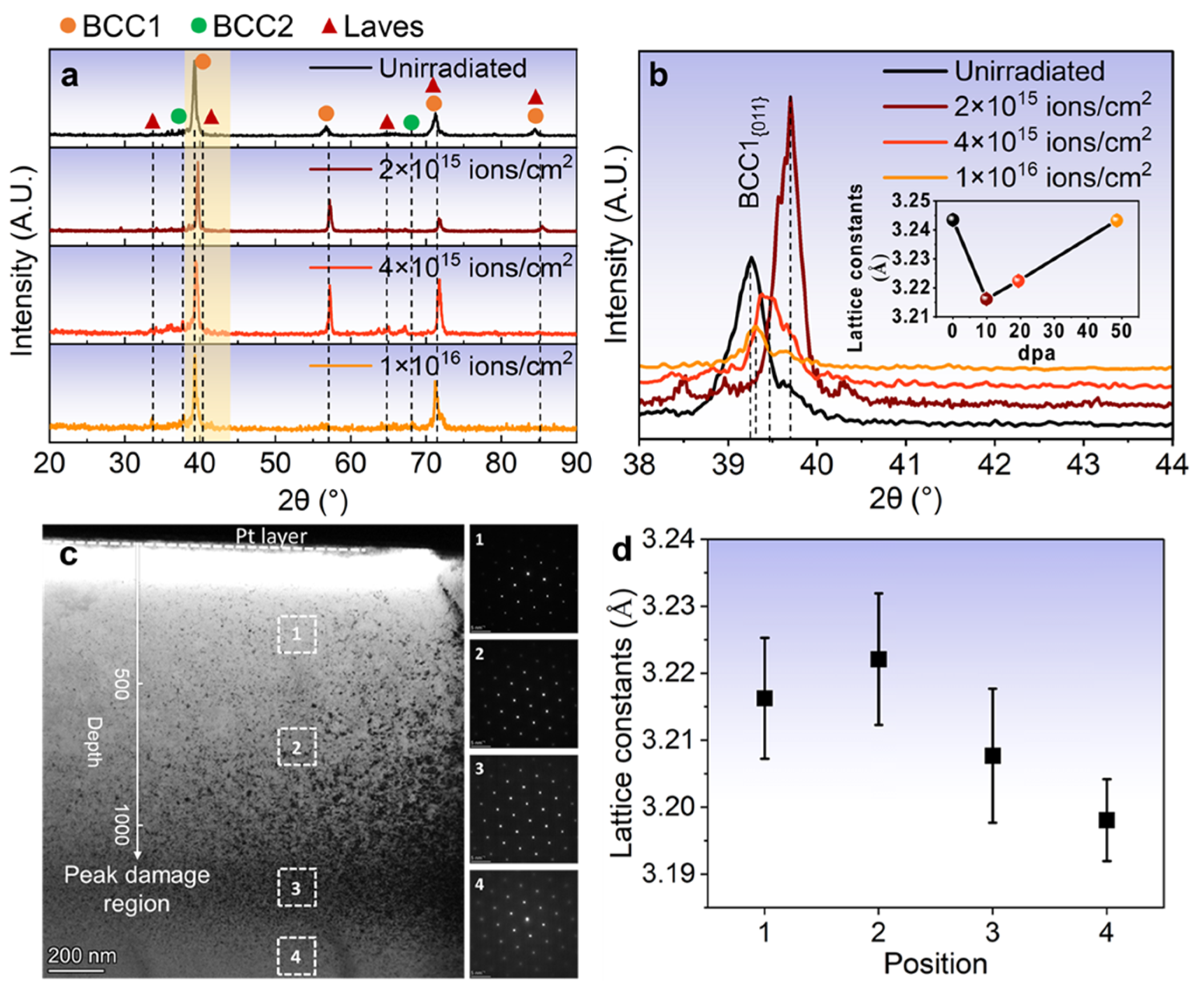

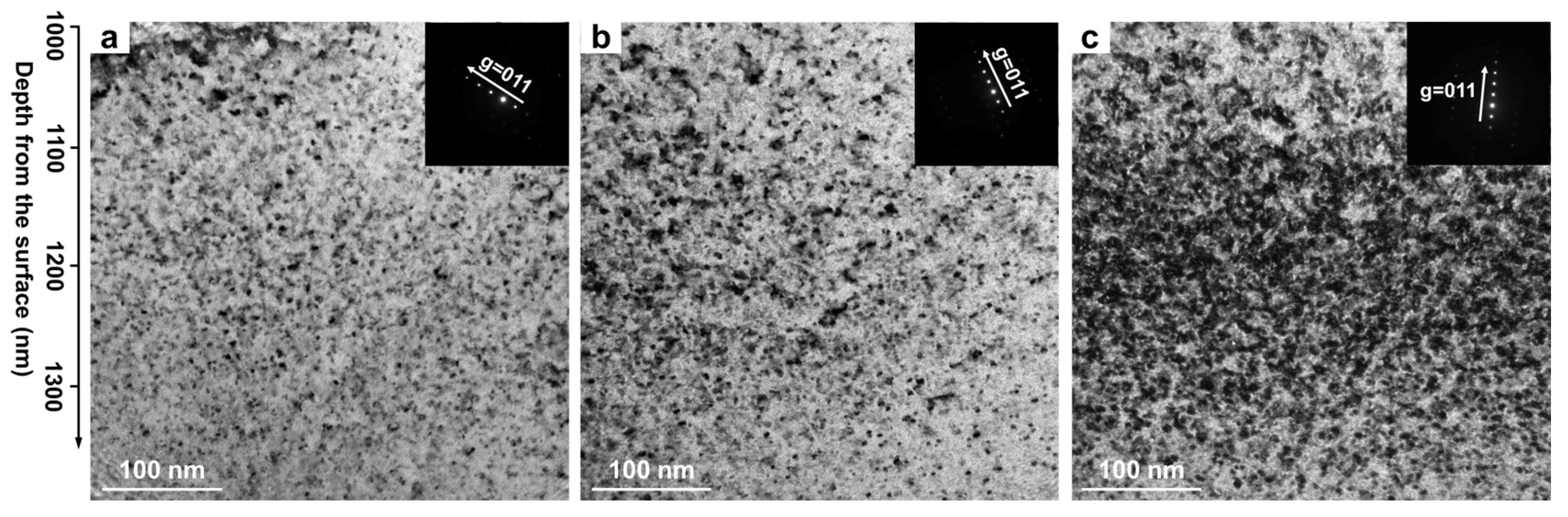

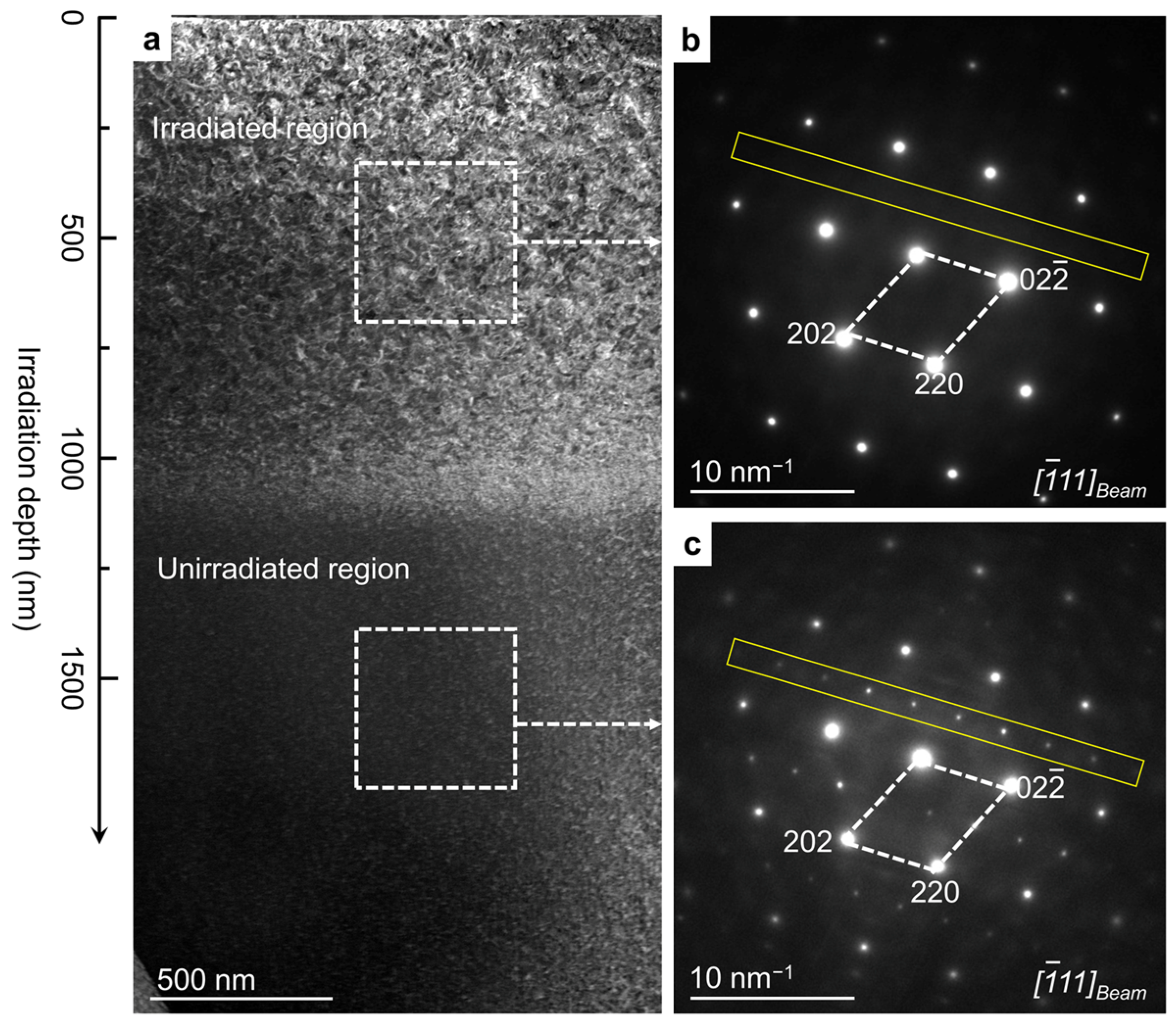

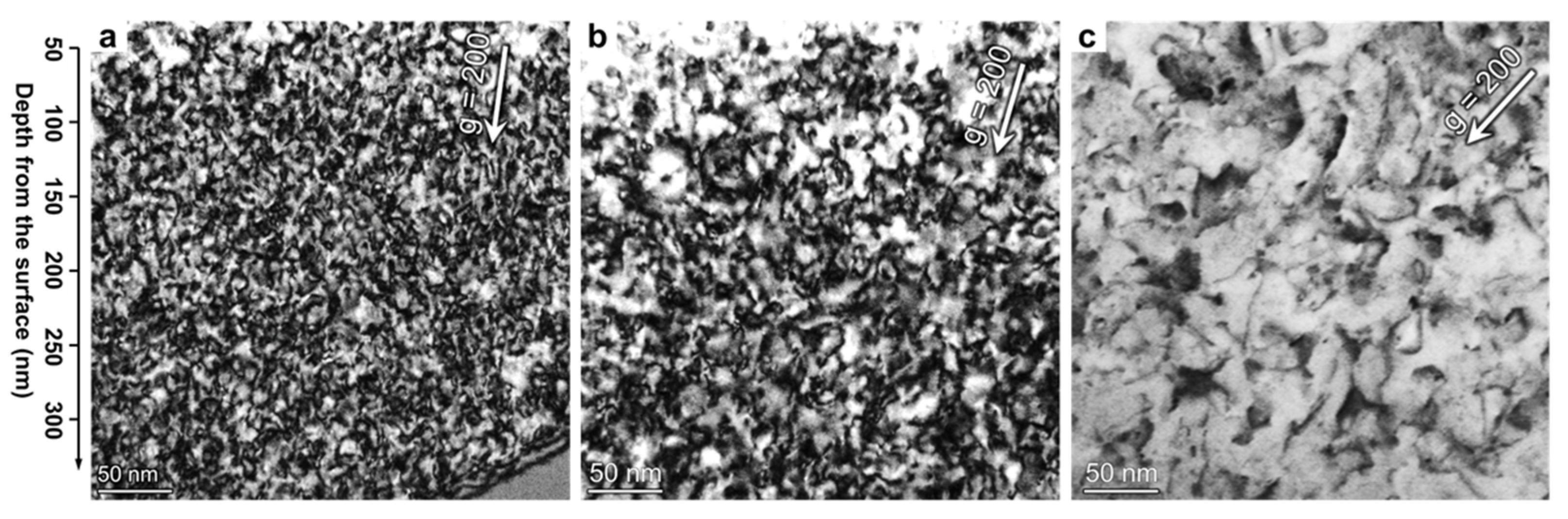

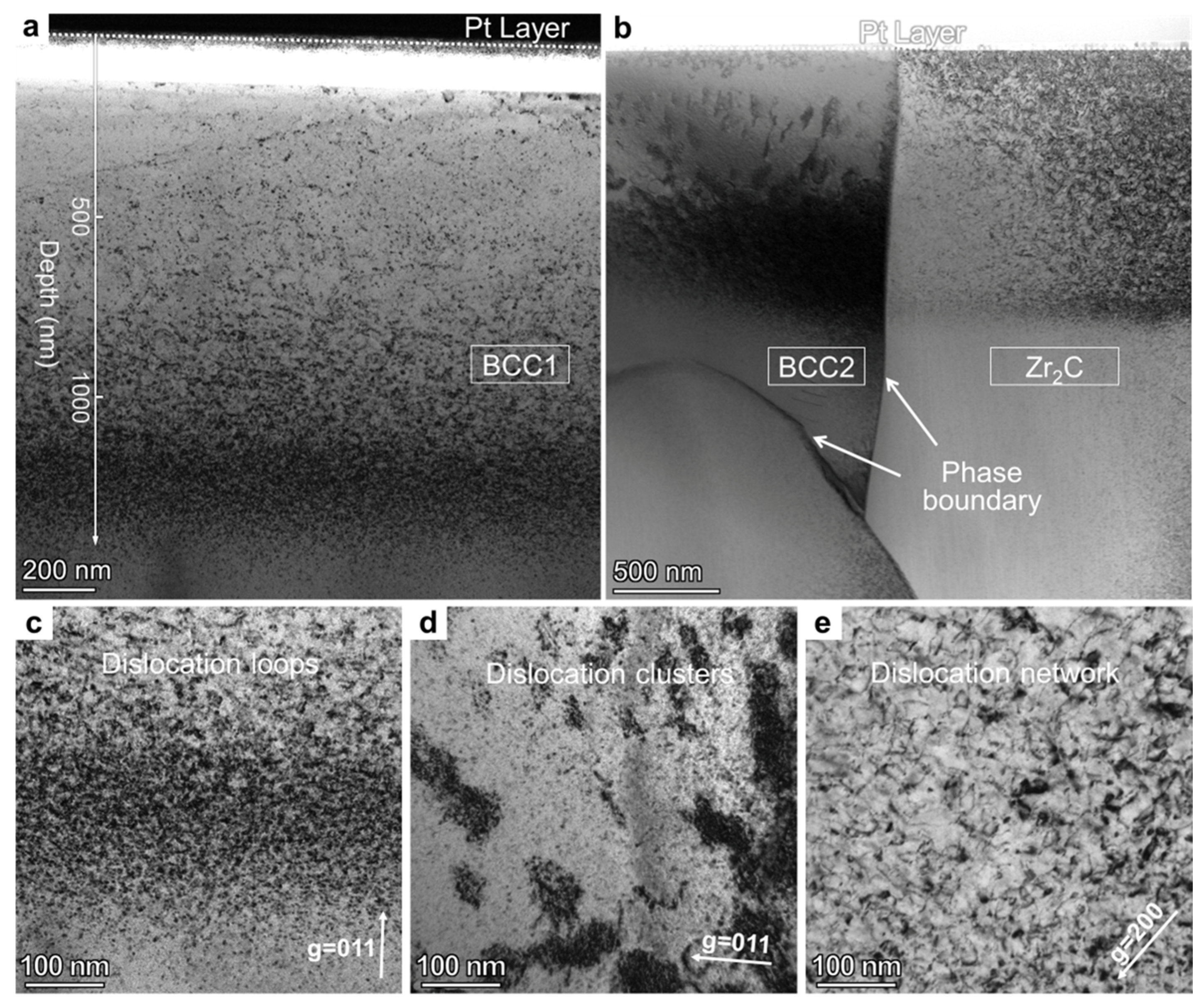

3.2. Irradiation Defects

3.3. Irradiation Hardening

4. Discussion

4.1. Microstructure of MoNbTiVZr RHEA Before Irradiation

4.2. Microstructure Change Caused by Irradiation

4.3. Irradiation Hardening

4.4. Effect of Zr-Rich Phase Precipitation on Irradiation Performance

5. Conclusions

- (1)

- The MoNbTiVZr RHEA underwent significant phase separation characterized by Zr precipitation during annealing, forming a near-equiatomic BCC1, Zr-rich BCC2, (Mo,V)Zr Laves phase, and ordered Zr2C carbide.

- (2)

- The BCC1 phase demonstrated the slowest dislocation growth with increasing irradiation doses. While dispersed dislocation loops predominated in BCC1, the BCC2 phase developed large dislocation clusters and the Zr2C phase formed dislocation networks. The BCC1 phase exhibited the most pronounced irradiation hardening corresponding to its fine, dispersed dislocation loop characteristics.

- (3)

- The precipitation of Zr-rich phases accelerated irradiation-induced defect evolution by disrupting the chemical homogeneity of MoNbTiVZr RHEA. Thus, optimizing Zr solubility to avoid excessive Zr precipitation is critical for designing nuclear-grade BCC-structured RHEAs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Jin, K.; Lu, C.; Wang, L.M.; Qu, J.; Weber, W.J.; Zhang, Y.; Bei, H. Effects of compositional complexity on the ion-irradiation induced swelling and hardening in Ni-containing equiatomic alloys. Scr. Mater. 2016, 119, 65–70. [Google Scholar] [CrossRef]

- Xia, S.; Gao, M.C.; Yang, T.; Liaw, P.K.; Zhang, Y. Phase stability and microstructures of high entropy alloys ion irradiated to high doses. J. Nucl. Mater. 2016, 480, 100–108. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.P. Development and exploration of refractory high entropy alloys—A review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef]

- Shi, T.; Lei, P.H.; Yan, X.; Li, J.; Zhou, Y.D.; Wang, Y.P.; Su, Z.X.; Dou, Y.K.; He, X.F.; Yun, D.; et al. Current development of body-centered cubic high-entropy alloys for nuclear applications. Tungsten 2021, 3, 197–217. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Lee, C.; Song, G.; Gao, M.C.; Feng, R.; Chen, P.; Brechtl, J.; Chen, Y.; An, K.; Guo, W.; Poplawsky, J.D.; et al. Lattice distortion in a strong and ductile refractory high-entropy alloy. Acta Mater. 2018, 160, 158–172. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Azevedo, C.R.F. Selection of fuel cladding material for nuclear fission reactors. Eng. Fail. Anal. 2011, 18, 1943–1962. [Google Scholar] [CrossRef]

- Chen, B.; Zhuo, L. Latest progress on refractory high entropy alloys: Composition, fabrication, post processing, performance, simulation and prospect. Int. J. Refract. Met. Hard Mater. 2023, 110, 105993. [Google Scholar] [CrossRef]

- Shi, T.; Su, Z.; Li, J.; Liu, C.; Yang, J.; He, X.; Yun, D.; Peng, Q.; Lu, C. Distinct point defect behaviours in body-centered cubic medium-entropy alloy NbZrTi induced by severe lattice distortion. Acta Mater. 2022, 229, 117806. [Google Scholar] [CrossRef]

- Kang, B.; Lee, J.; Ryu, H.J.; Hong, S.H. Ultra-high strength WNbMoTaV high-entropy alloys with fine grain structure fabricated by powder metallurgical process. Mater. Sci. Eng. A 2018, 712, 616–624. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Han, Z.D.; Luan, H.W.; Liu, X.; Chen, N.; Li, X.Y.; Shao, Y.; Yao, K.F. Microstructures and mechanical properties of TixNbMoTaW refractory high-entropy alloys. Mater. Sci. Eng. A 2018, 712, 380–385. [Google Scholar] [CrossRef]

- Shen, S.; Chen, F.; Tang, X.; Lin, J.; Ge, G.; Liu, J. Effects of carbon doping on irradiation resistance of Fe38Mn40Ni11Al4Cr7 high entropy alloys. J. Nucl. Mater. 2020, 540, 152380. [Google Scholar] [CrossRef]

- Hoffman, A.; He, L.; Luebbe, M.; Pommerenke, H.; Duan, J.; Cao, P.; Sridharan, K.; Lu, Z.; Wen, H. Effects of Al and Ti Additions on Irradiation Behavior of FeMnNiCr Multi-Principal-Element Alloy. JOM 2020, 72, 150–159. [Google Scholar] [CrossRef]

- Cheng, Z.; Sun, J.; Gao, X.; Wang, Y.; Cui, J.; Wang, T.; Chang, H. Irradiation effects in high-entropy alloys and their applications. J. Alloys Compd. 2023, 930, 166768. [Google Scholar] [CrossRef]

- Eshed, E.; Larianovsky, N.; Kovalevsky, A.; Demyanetz, A.K. Effect of Zr on the Microstructure of Second- and Third-Generation BCC HEAs. JOM 2019, 71, 673–682. [Google Scholar] [CrossRef]

- Zhou, J.; Kirk, M.; Baldo, P.; Guo, S.; Lu, F. Phase stability of novel HfNbTaTiVZr refractory high entropy alloy under ion irradiation. Mater. Lett. 2021, 305, 130789. [Google Scholar] [CrossRef]

- Behera, M.; Panigrahi, A.; Bönisch, M.; Shankar, G.; Mishra, P.K. Structural stability and thermal expansion of TiTaNbMoZr refractory high entropy alloy. J. Alloys Compd. 2022, 892, 162154. [Google Scholar] [CrossRef]

- Li, T.X.; Jiao, W.N.; Miao, J.W.; Lu, Y.P.; Guo, E.Y.; Wang, T.M.; Li, T.J.; Liaw, P.K. A novel ZrNbMoTaW refractory high-entropy alloy with in-situ forming heterogeneous structure. Mater. Sci. Eng. A 2021, 827, 142061. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system: Microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Kareer, A.; Waite, J.C.; Li, B.; Couet, A.; Armstrong, D.E.J.; Wilkinson, A.J. Short communication: ‘Low activation, refractory, high entropy alloys for nuclear applications’. J. Nucl. Mater. 2019, 526, 151744. [Google Scholar] [CrossRef]

- Senkov, O.N.; Rao, S.; Chaput, K.J.; Woodward, C. Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys. Acta Mater. 2018, 151, 201–215. [Google Scholar] [CrossRef]

- Li, D.; Jia, N.; Huang, H.; Chen, S.; Dou, Y.; He, X.; Yang, W.; Xue, Y.; Hua, Z.; Zhang, F.; et al. Helium ion irradiation enhanced precipitation and the impact on cavity formation in a HfNbZrTi refractory high entropy alloy. J. Nucl. Mater. 2021, 552, 153023. [Google Scholar] [CrossRef]

- Peng, S.; Jin, K.; Yi, X.; Dong, Z.; Guo, X.; Liu, Y.; Cheng, Y.; Jia, N.; Duan, H.; Xue, J. Mechanical behavior of the HfNbZrTi high entropy alloy after ion irradiation based on micro-pillar compression tests. J. Alloys Compd. 2022, 892, 162043. [Google Scholar] [CrossRef]

- Chen, W.; Tang, Q.H.; Wang, H.; Xie, Y.C.; Yan, X.H.; Dai, P.Q. Microstructure and mechanical properties of a novel refractory AlNbTiZr high-entropy alloy. Mater. Sci. Technol. 2018, 34, 1309–1315. [Google Scholar] [CrossRef]

- King, D.J.M.; Cheung, S.T.Y.; Humphry-Baker, S.A.; Parkin, C.; Couet, A.; Cortie, M.B.; Lumpkin, G.R.; Middleburgh, S.C.; Knowles, A.J. High temperature, low neutron cross-section high-entropy alloys in the Nb-Ti-V-Zr system. Acta Mater. 2019, 166, 435–446. [Google Scholar] [CrossRef]

- Wu, Y.D.; Cai, Y.H.; Chen, X.H.; Wang, T.; Si, J.J.; Wang, L.; Wang, Y.D.; Hui, X.D. Phase composition and solid solution strengthening effect in TiZrNbMoV high-entropy alloys. Mater. Des. 2015, 83, 651–660. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Zhu, Z.B.; Huang, H.F.; He, T.; Yan, H.W.; Zhang, Y.A.; Lu, Y.P.; Wang, T.M.; Li, T.N.G. Microstructures, mechanical properties, and irradiation tolerance of the Ti-Zr-Nb-V-Mo refractory high-entropy alloys. Intermetallics 2023, 157, 11. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Han, E.H.; Xiang, C. Irradiation behaviors of two novel single-phase bcc-structure high-entropy alloys for accident-tolerant fuel cladding. J. Mater. Sci. Technol. 2021, 84, 230–238. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Han, J.F.; An, Z.; Zheng, G.Q.; Bai, F.; Li, Z.H.; Wang, P.; Liao, X.D.; Liu, M.T.; Chen, S.L.; Song, M.J.; et al. An ion beam facility based on a 3 MV tandetron accelerator in Sichuan University, China. Nucl. Instrum. Methods Phys. Res. Sect. B 2018, 418, 68–73. [Google Scholar] [CrossRef]

- Gosset, D.; Dollé, M.; Simeone, D.; Baldinozzi, G.; Thomé, L. Structural evolution of zirconium carbide under ion irradiation. J. Nucl. Mater. 2008, 373, 123–129. [Google Scholar] [CrossRef]

- Hu, W.T.; Xiang, J.Y.; Zhang, Y.; Liu, S.C.; Chen, C.K.; Wang, P.; Wang, H.T.; Wen, F.S.; Xu, B.; He, J.L.; et al. Superstructural nanodomains of ordered carbon vacancies in nonstoichiometric ZrC0.61. J. Mater. Res. 2012, 27, 1230–1236. [Google Scholar] [CrossRef]

- Wei, B.; Wang, Y.; Zhang, H.; Wang, D.; Peng, S.; Zhou, Y. Microstructure evolution of nonstoichiometric ZrC0.6 with ordered carbon vacancies under ion irradiation. Mater. Lett. 2018, 228, 254–257. [Google Scholar] [CrossRef]

- Gusev, A.I.; Rempel, A.A. Superstructures of Non-Stoichiometric Interstitial Compounds and the Distribution Functions of Interstitial Atoms. Phys. Status Solidi A 1993, 135, 15–58. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, H.; Gao, X.; Ren, C.; Gao, J.; Zhang, H.; Zheng, S.; Jin, Q.; Zhao, Y.; Lu, C.; et al. A promising new class of irradiation tolerant materials: Ti2ZrHfV0.5Mo0.2 high-entropy alloy. J. Mater. Sci. Technol. 2019, 35, 369–373. [Google Scholar] [CrossRef]

- Mu, J.; Jin, X.; Zhang, M.; Qiao, J. Ion irradiation-induced hardening model in Ti-Zr-Hf-V-Mo-Ta refractory high-entropy alloys. Acta Mater. 2025, 285, 120617. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Hardie, C.D.; Roberts, S.G.; Bushby, A.J. Understanding the effects of ion irradiation using nanoindentation techniques. J. Nucl. Mater. 2015, 462, 391–401. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, L.; Yu, L.; Duan, H. Modelling nano-indentation of ion-irradiated FCC single crystals by strain-gradient crystal plasticity theory. Int. J. Plast. 2019, 116, 216–231. [Google Scholar] [CrossRef]

- Nie, J.; Lin, P.; Liu, Y.; Zhang, H.; Wang, X. Simulation of the irradiation effect on hardness of Chinese HTGR A508-3 steels with CPFEM. Nucl. Eng. Technol. 2019, 51, 1970–1977. [Google Scholar] [CrossRef]

- Xiao, X.; Li, S.; Yu, L. Effect of irradiation damage and indenter radius on pop-in and indentation stress-strain relations: Crystal plasticity finite element simulation. Int. J. Mech. Sci. 2021, 199, 106430. [Google Scholar] [CrossRef]

- Vasudevamurthy, G.; Knight, T.W.; Roberts, E.; Adams, T.M. Laboratory production of zirconium carbide compacts for use in inert matrix fuels. J. Nucl. Mater. 2008, 374, 241–247. [Google Scholar] [CrossRef]

- Wang, X.G.; Sun, M.; Liu, J.X.; Liu, X.Q.; Ke, Y.B.; Jiang, W.B.; Wang, H.; Fang, Q.F.; Wang, X.P. Effects of vanadium content on the microstructure and tensile properties of NbTiVxZr high-entropy alloys. J. Alloys Compd. 2024, 987, 174227. [Google Scholar] [CrossRef]

- Tang, Y.; Xie, Z.; Yang, T.; Peng, Y.; Liu, Y. Refractory multi-principal element alloys MoxNbTiZry: Microstructure, mechanical properties and oxidation resistance. Int. J. Refract. Met. Hard Mater. 2025, 130, 107138. [Google Scholar] [CrossRef]

- Liu, J.; Li, B.-S.; Gardner, H.; Gong, Y.; Liu, F.; He, G.; Moorehead, M.; Parkin, C.; Couet, A.; Wilkinson, A.J.; et al. Origin of age softening in the refractory high-entropy alloys. Sci. Adv. 2023, 9, eadj1511. [Google Scholar] [CrossRef]

- Belcher, C.H.; Kamp, D.; To, S.; Lu, Y.; Chassaing, D.; Boll, T.; MacDonald, B.E.; Lee, E.M.Y.; Apelian, D.; Lavernia, E.J. The origin and control of interstitial impurities in refractory complex concentrated alloys. J. Alloys Compd. 2025, 1010, 177520. [Google Scholar] [CrossRef]

- Davey, T.; Suzuki, K.; Miura, H.; Chen, Y. Stability and structural properties of vacancy-ordered and -disordered ZrCx. RSC Adv. 2021, 11, 32573–32589. [Google Scholar] [CrossRef] [PubMed]

- Klueh, R.L.; Shingledecker, J.P.; Swindeman, R.W.; Hoelzer, D.T. Oxide dispersion-strengthened steels: A comparison of some commercial and experimental alloys. J. Nucl. Mater. 2005, 341, 103–114. [Google Scholar] [CrossRef]

- Monnet, G. Multiscale modeling of irradiation hardening: Application to important nuclear materials. J. Nucl. Mater. 2018, 508, 609–627. [Google Scholar] [CrossRef]

- Chen, W.Y.; Kirk, M.A.; Hashimoto, N.; Yeh, J.W.; Liu, X.; Chen, Y. Irradiation effects on Al0.3CoCrFeNi and CoCrMnFeNi high-entropy alloys, and 316H stainless steel at 500 °C. J. Nucl. Mater. 2020, 539, 152324. [Google Scholar] [CrossRef]

- Wan, H.; Su, Z.; Yan, X.; Yang, J.; Lu, Y.; Shi, T.; Guo, S.; Gao, N.; Tang, Y.; He, X.; et al. Microstructures and hardening effects of refractory high entropy alloys irradiated by Proton & He ion dual beam. Mater. Charact. 2024, 209, 113741. [Google Scholar] [CrossRef]

- Du, J.; Jiang, S.; Cao, P.; Xu, C.; Wu, Y.; Chen, H.; Fu, E.; Lu, Z. Superior radiation tolerance via reversible disordering–ordering transition of coherent superlattices. Nat. Mater. 2023, 22, 442–449. [Google Scholar] [CrossRef]

- Xu, H.; Feng, Y.; He, D.; Jiang, C.; Hou, T.; Liu, X.; Li, W.; Wang, H.; Xiao, X. Integrated effect of aging and heavy ion radiation on FeNiCrAl duplex alloy for accident-tolerant fuel cladding. Acta Mater. 2023, 255, 119026. [Google Scholar] [CrossRef]

| Positions | Chemical Compositions/at.% | ||||

|---|---|---|---|---|---|

| Mo | Nb | Ti | V | Zr | |

| Point 1 (Dendrites) | 20.9 | 22.6 | 21.7 | 21.1 | 13.6 |

| Point 2 (Channels) | 8.9 | 18.9 | 21.5 | 12.0 | 38.7 |

| Point 3 (Gray particles) | 25.1 | 9.5 | 7.4 | 28.6 | 29.4 |

| Point 4 (Dark particles) | 0.1 | 1.4 | 4.5 | 0.5 | 93.5 |

| Phases | Chemical Compositions/at.% | ||||

|---|---|---|---|---|---|

| Mo | Nb | Ti | V | Zr | |

| BCC1 | 20.5 | 22.1 | 22.4 | 19.3 | 15.7 |

| BCC2 | 8.5 | 17.4 | 22.4 | 11.2 | 40.5 |

| Laves | 24.8 | 8.1 | 7.0 | 29.7 | 30.4 |

| Zr2C | 0.0 | 1.0 | 4.3 | 0.0 | 94.7 |

| Phases | Melting Points (°C) | Fluences (ions/cm2) | Peak Damages (dpa) | Peak Damage Depths (μm) |

|---|---|---|---|---|

| BCC1 | 2112 | 2 × 1015 | 9.4 | 0.51 |

| 4 × 1015 | 18.7 | |||

| 1 × 1016 | 46.9 | |||

| BCC2 | 1987 | 2 × 1015 | 11.0 | 0.54 |

| 4 × 1015 | 21.9 | |||

| 1 × 1016 | 54.8 | |||

| Zr2C | 3400 [35] | 2 × 1015 | 9.8 | 0.72 |

| 4 × 1015 | 19.6 | |||

| 1 × 1016 | 49.1 |

| Phases | Fluences (Ions/cm2) | Average Hardness (GPa) | Hardness Increments (GPa) | Hardening Rates (%) |

|---|---|---|---|---|

| BCC1 | 0 | 7.35 | / | / |

| 4 × 1015 | 8.35 | 1.00 | 13.6 | |

| 1 × 1016 | 9.48 | 2.13 | 29.0 | |

| BCC2 | 0 | 7.86 | / | / |

| 4 × 1015 | 8.07 | 0.21 | 2.7 | |

| 1 × 1016 | 7.99 | 0.13 | 1.6 | |

| Zr2C | 0 | 16.71 | / | / |

| 4 × 1015 | 17.23 | 0.52 | 3.1 | |

| 1 × 1016 | 16.97 | 0.26 | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yong, L.; Zhong, Y.; Xin, H.; Li, A.; Xie, D.; Wu, L.; Yang, J. Irradiation Performance of a Multiphase MoNbTiVZr Refractory High-Entropy Alloy: Role of Zr-Rich Phase Precipitation. Metals 2025, 15, 720. https://doi.org/10.3390/met15070720

Yong L, Zhong Y, Xin H, Li A, Xie D, Wu L, Yang J. Irradiation Performance of a Multiphase MoNbTiVZr Refractory High-Entropy Alloy: Role of Zr-Rich Phase Precipitation. Metals. 2025; 15(7):720. https://doi.org/10.3390/met15070720

Chicago/Turabian StyleYong, Liqiu, Yilong Zhong, Hongyang Xin, An Li, Dongsheng Xie, Lu Wu, and Jijun Yang. 2025. "Irradiation Performance of a Multiphase MoNbTiVZr Refractory High-Entropy Alloy: Role of Zr-Rich Phase Precipitation" Metals 15, no. 7: 720. https://doi.org/10.3390/met15070720

APA StyleYong, L., Zhong, Y., Xin, H., Li, A., Xie, D., Wu, L., & Yang, J. (2025). Irradiation Performance of a Multiphase MoNbTiVZr Refractory High-Entropy Alloy: Role of Zr-Rich Phase Precipitation. Metals, 15(7), 720. https://doi.org/10.3390/met15070720