Abstract

This study investigates the grain characteristics and high-temperature tensile properties of an additively manufactured (AM) TA15 titanium alloy. Directed energy deposition (DED) was utilized for its high material efficiency and design flexibility to explore the alloy’s applicability in aerospace manufacturing, where TA15 is valued for its excellent high-temperature performance. A comparative analysis between DED and hot-rolled TA15 alloys was conducted at 25 °C and 600 °C to examine the influence of grain size and crystallographic texture on mechanical behavior. The AM TA15 alloy exhibited superior tensile properties at both temperatures compared to its hot-rolled counterpart. Microstructural analysis revealed finer grain size, stronger α-phase diffraction intensity, and altered grain boundary misorientation in the AM alloy after high-temperature testing, accompanied by improved plasticity. These findings highlight the potential of thermal process optimization and microstructural tailoring to enhance the high-temperature performance of AM TA15, offering valuable insights for the fabrication of critical aerospace components.

1. Introduction

Compared to traditional subtractive manufacturing methods, additive manufacturing (AM) fabricates complex three-dimensional structures directly through layer-by-layer material deposition. This approach significantly reduces material waste and enables the production of components with high geometrical complexity [1,2,3]. These advantages have led to the widespread adoption of AM in industries such as aerospace, medical devices, and automotive manufacturing, where lightweight materials and intricate structural designs are critically important [4,5,6].

The TA15 titanium alloy is a high-performance material primarily composed of titanium, with aluminum, zirconium, and other elements as the main alloying additions. As a representative near-α titanium alloy, it exhibits excellent characteristics such as high specific strength, corrosion resistance, and good plastic deformability, making it widely utilized in the aerospace industry [7,8,9]. Due to its outstanding high-temperature mechanical properties and oxidation resistance, TA15 is commonly employed in the fabrication of critical components—such as wing spars, fuselage structural elements, and engine mounts—that must withstand prolonged service in high-temperature environments. In recent years, the growing demand for lightweight structures and enhanced high-temperature performance in aerospace applications has underscored the increasing significance of additive manufacturing in the production of TA15 alloy components [10,11]. Particularly for engine parts operating under extreme thermal conditions, the high-temperature tensile behavior of TA15 has become a research focus, crucial for ensuring adequate safety and reliability in harsh service environments. Additively manufactured components can integrate internal cooling channels or lightweight porous structures, which enhance heat dissipation efficiency and reduce the risk of localized thermal failure. Moreover, the rapid solidification inherent in laser-based AM processes leads to fine and uniform grain structures and metastable phases, which contribute to improved microstructural stability at elevated temperatures, as well as enhanced creep and fatigue resistance.

The high-temperature tensile properties of titanium alloys are significantly influenced by microstructural features such as grain size and grain boundaries [12,13,14]. Li et al. [15] reported that coarser grains enhance creep resistance at high temperatures by suppressing grain boundary sliding. Introducing reinforcing phases like TiB and TiC can refine grains and improve tensile strength, as demonstrated by Wang et al. [16]. Nagarjuna et al. [17] observed that the yield and tensile strength of a Cu-1.5 wt.% Ti alloy peaked at 450 °C but declined at higher temperatures, with ductile fracture behavior. Yang et al. [18] reported that a Ti-40Al-15Nb alloy achieved a tensile strength of 666.4 MPa at 850 °C, attributed to dislocation interactions in the γ phase. Reinforcing phases have also been shown to improve high-temperature performance. Zhao et al. [19] showed that controlling deformation temperature and strain rate enabled a Ti5553 alloy to exhibit super plasticity at 850 °C. Liu et al. [20] found that in a Ti55 alloy, rising temperatures promoted a transition from low-angle to high-angle grain boundaries, leading to equiaxed grains and improved ductility. Similarly, Zang et al. [21] demonstrated that a Ti-3Al-3Mo-3Zr alloy can achieve high strength and ductility at varied temperatures through tailored microstructures. Temperature-dependent behavior was further confirmed by Dineshkumar et al. [22], who observed decreased tensile and yield strength but increased elongation in Ti-6Al-4V with rising temperature. Guo et al. [23] noted that grain boundary refinement enhanced both strength and toughness in high-Si titanium alloys. Hao et al. [24] showed that dynamic recrystallization and periodization of α-phase lamellae at 600–800 °C improved ductility in Ti-6Al-2Zr-1Mo-1V. Additionally, Matsumoto et al. [25] found that adjusting strain rate and temperature promoted α′ martensite transformation, enhancing ductility and toughness. Overall, controlling grain structure, temperature, and strain rate is key to optimizing high-temperature performance in titanium alloys [19]. In summary, the microstructure of titanium alloys largely determines their high-temperature tensile properties. By properly controlling grain size and phase composition and distribution, introducing reinforcing phases, and regulating temperature and strain rate, the high-temperature performance of titanium alloys can be optimized. Although extensive research has been conducted on the microstructure and high-temperature mechanical properties of titanium alloys, studies focusing on alloys without reinforcing phases remain limited. Moreover, comparative analyses between titanium alloys produced by additive manufacturing and those obtained through conventional methods such as hot rolling are still relatively scarce.

Although extensive studies have examined the relationship between high-temperature tensile properties and microstructures of various titanium alloys, systematic investigations on TA15 titanium alloys under extreme high-temperature conditions remain limited. In particular, the failure mechanisms during high-temperature tensile loading require further exploration. This study addresses this gap by comparing the high-temperature tensile behavior of additively manufactured and hot-rolled TA15 alloys over a temperature range from room temperature to 600 °C. Furthermore, the high-temperature performance of the additively manufactured alloy is analyzed in relation to its texture and microstructural characteristics.

2. Experimental Materials and Methods

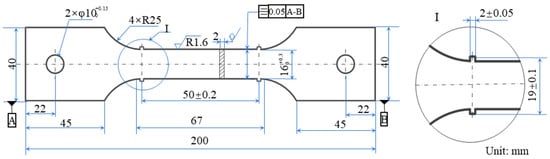

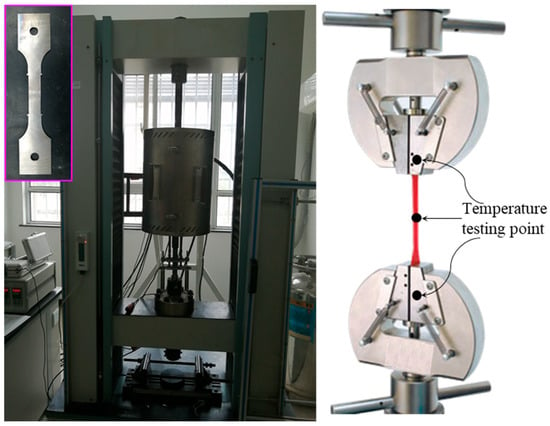

The optimized experimental parameters for the additive manufacturing of the TA15 titanium alloy using directed energy deposition were as follows: a laser power of 2400 W, scanning speed of 10 mm/s, powder feeding rate of 8 g/min, laser spot diameter of 4 mm, and layer height of 0.6 mm along the Z-axis. These settings were chosen based on prior research demonstrating their efficacy in reducing porosity and maintaining a stable melt pool in TA15 alloys [26]. Following fabrication, the specimens were annealed at 750 °C for 4 h to relieve residual stress and stabilize the microstructure. For comparison, TA15 titanium alloy plates produced by conventional hot rolling were also tested. High-temperature tensile specimens had an overall length of 200 mm, as shown in Figure 1. The tensile tests were conducted using a DDL100 universal testing machine (Changchun Mechanical Science Research Institute, Changchun, China), as depicted in Figure 2. The heating system employed electric resistance heating, with three temperature sensors positioned at both ends of the grips and at the center of the specimen. These sensors ensured precise temperature monitoring, with real-time data transmitted to an industrial control computer. All tensile tests were carried out in accordance with GB/T 4338-2006.

Figure 1.

High-temperature tensile test sample size of TA15 alloy.

Figure 2.

DDL100 high-temperature tensile test device.

Given that the typical high-temperature service range of the TA15 titanium alloy is between 550 °C and 600 °C, tensile tests in this study were conducted at both room temperature (25 °C) and 600 °C. The hot-rolled specimens tested at room temperature and 600 °C are designated as HR 25 and HR 600, respectively. Similarly, the specimens fabricated via laser-directed energy deposition are labeled as AM 25 for room temperature and AM 600 for 600 °C. The specific testing temperature conditions are shown in Table 1.

Table 1.

Sample preparation method, numbering, and testing temperature.

Specimens of size 10 mm × 10 mm × 10 mm were cut using a wire electrical discharge machining (EDM) technique. The specimens were then ground using silicon carbide abrasive papers with grit sizes of 320#, 500#, 800#, 1000#, 1500#, and 2000#, respectively. Subsequently, the ground surfaces were polished using a polishing machine. The polished surfaces were etched for 20–25 s using Keller’s reagent with a composition of H2O:HNO3:HCl:HF = 190:5:3:1. After etching, the metallographic surfaces were cleaned with anhydrous ethanol and then dried. The microstructures and fracture morphologies were observed using an S-3400N variable vacuum tungsten filament scanning electron microscope (SEM) (Hitachi, Tokyo, Japan) and a JSM-7001F thermal field emission SEM (JEOL, Tokyo, Japan). The phase structure of the TA15 metallographic specimens was determined using a D8 ADVANCE X-ray diffractometer (BRUKER, Bremen, Germany).

3. Results and Discussion

3.1. XRD Analysis

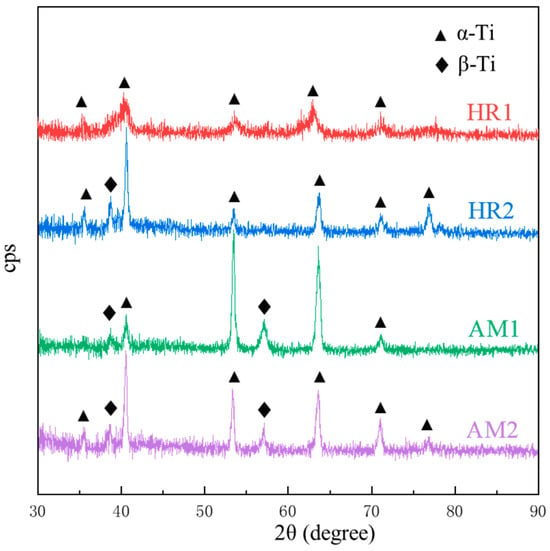

To further analyze the phase composition of additively manufactured and hot-rolled TA15 titanium alloys, selected specimens (HR 25, HR 600, AM 25, and AM 600) were subjected to X-ray diffraction (XRD) analysis, and the results are shown in Figure 3. After indexing the obtained XRD patterns, it was found that all specimens exhibited diffraction peaks corresponding to the α phase, and some specimens also showed diffraction peaks of the β phase, indicating that the specimens are primarily composed of α and β phases. The diffraction peaks of the α phase in the AM specimens were stronger than those in the HR specimens, which is related to their α + β lamellar structure. Overall, there is virtually no difference in phase composition between the hot-rolled TA15 titanium alloy and the alloy produced by directed energy deposition. However, the additively manufactured TA15 alloy exhibits a weak β-Ti diffraction peak near 57°, indicating the presence of a small amount of retained β phase. Additionally, no significant phase changes are observed between the specimens tested at 25 °C and 600 °C, as a temperature of 600 °C is insufficient to induce phase transformation in titanium alloys. It should be acknowledged that due to the lack of accurate characterization using EBSD, the peak and phase information is only of reference value. Moreover, the studies by Wang et al. [27] and Huang et al. [28] also provide valuable references for phase identification in XRD analysis.

Figure 3.

XRD patterns under different experimental conditions.

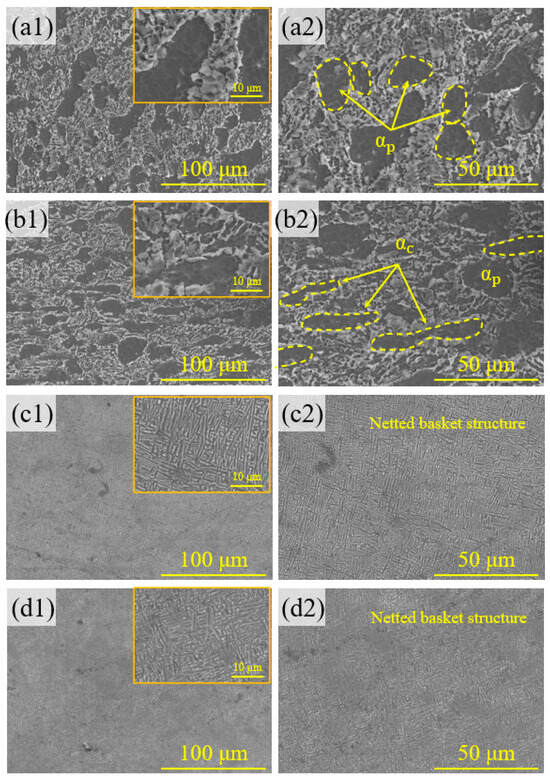

3.2. Microstructure (25 °C and 600 °C)

Figure 4 shows the microstructures of TA15 alloy specimens observed by SEM after tensile testing at room temperature (25 °C) and 600 °C. The microstructure of the hot-rolled TA15 alloy (HR 25) at room temperature mainly consists of primary equiaxed α phase (αp) and β phase distributed at its grain boundaries. The average grain size of the α phase is approximately 28 μm. After the high-temperature tensile test at 600 °C, the HR 600 specimen still has a small amount of primary equiaxed α phase (αp) but is mainly composed of a large number of columnar α phases (αc) and transformed β-phase structures. The grain size was found to be approximately 40 μm × 5 μm. This is mainly because the primary equiaxed α phase (αp) softened at 600 °C and underwent significant plastic deformation under the large tensile force, causing a large amount of αp to transform into αc with different lengths and thicknesses. The microstructure of the additively manufactured TA15 alloy tensile specimen (AM 25) at room temperature is mainly basketweave-like, as shown in Figure 4(c1,c2). Most of the AM 25 structure is lamellar, with thin, strip-like α phases interlaced with residual lamellar β grain boundaries, exhibiting a typical lamellar α + β structure. The measured average grain size is approximately 10 μm × 2 μm. After the high-temperature tensile test at 600 °C, the AM 600 structure still has similar basketweave characteristics, but the length and thickness of most α phases have slightly decreased compared to the AM 25 specimen, with little overall change. Generally, as the grain size decreases, the number of grain boundaries increases. Grain boundaries can hinder the movement of dislocations; when dislocations encounter grain boundaries during motion, they become pinned, requiring greater stress to continue moving. Therefore, fine-grained metallic materials require greater external force to undergo plastic deformation under tensile load, which enhances the tensile strength of the material. During the tensile process of fine-grained metals, the large number of grain boundaries significantly impedes dislocation motion, increasing the resistance to dislocation movement during plastic deformation. As a result, after the material reaches its yield strength, its ability to continue deforming weakens, and thus, the elongation may decrease [29,30]. However, quantitative grain size or texture data could not be obtained without EBSD, thus limiting our claims. Future studies should employ EBSD to verify these findings.

Figure 4.

Microstructure under different experimental conditions: (a1,a2) HR 25, (b1,b2) HR 600, (c1,c2) AM 25, and (d1,d2) AM 600.

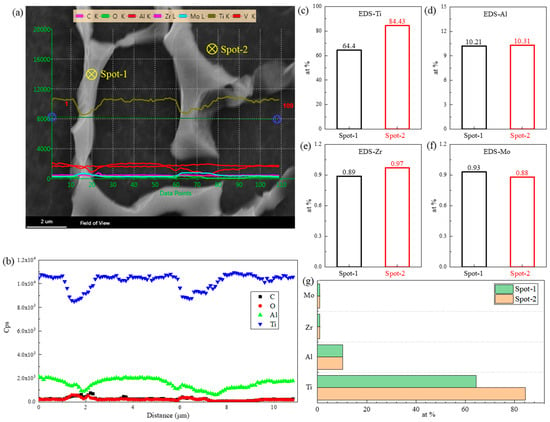

Figure 5 shows the detection results of elemental content in the microstructure of the additively manufactured TA15 titanium alloy. The EDS line-scan results shown in Figure 5b indicate that the content of Ti and Al elements significantly decreases from the α phase to the β phase and then increases again when returning to the α phase. The elemental content test results for Spot-1 located in the β phase and Spot-2 located in the α phase are shown in Figure 5c–g. The results show that the Ti content in Spot-1 of the β phase is approximately 64.4 at%, which is significantly lower than the Ti content of 84.43 at% in Spot-2 of the α phase. Other elements such as Al, Zr, and Mo are present in smaller amounts and show little difference. In Figure 5a, a total of 109 points were tested using line scanning.

Figure 5.

Comparison of elemental content distribution in different microstructures of TA15 titanium alloy. (a) Comparison of line scan position and microstructure, (b) EDS line scan test results, (c) Ti content comparison, (d) Al content comparison, (e) Zr content comparison, (f) Mo content comparison, and (g) overall comparison of various elements.

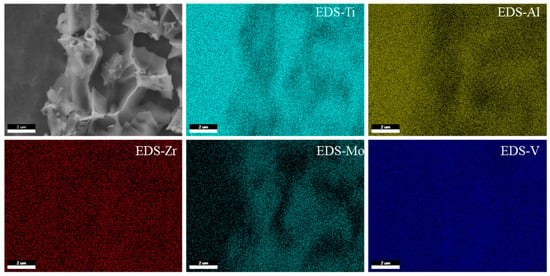

To further confirm the elemental content variations in different structures, Figure 6 shows the EDS mapping results for the additively manufactured TA15 titanium alloy. The results indicate that the α phase has a relatively lower Ti and Al content, appearing darker in the maps. Conversely, the Mo content in the α phase is higher than that in the β phase. Additionally, the content differences in the Zr and V elements are not significant.

Figure 6.

EDS mapping analysis of TA15 titanium alloy.

3.3. Comparison of Additive Manufacturing and Hot Rolling in Titanium Alloys

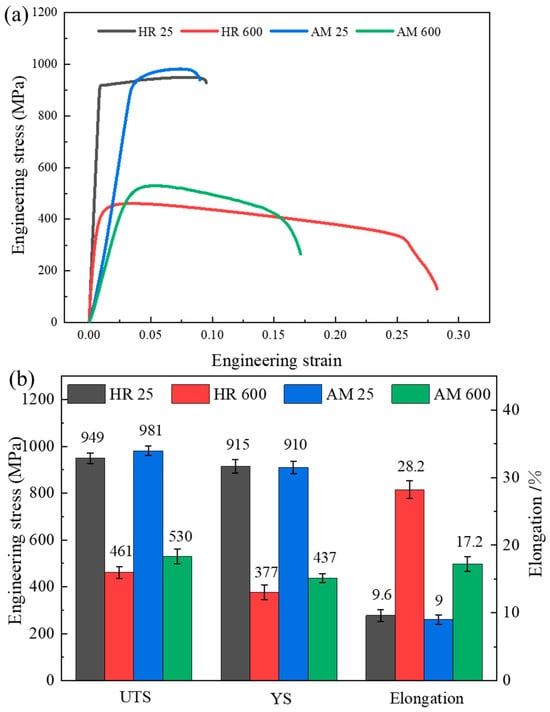

Figure 7 and Table 2 shows the tensile properties of additively manufactured and hot-rolled TA15 alloys under different experimental conditions. As can be seen from Figure 7, with the increase in tensile test temperature, the strength and ductility of the TA15 alloy show opposite trends. Compared with tensile tests at room temperature, the tensile specimens at high temperatures have significantly reduced tensile strength but greatly increased ductility. However, additively manufactured TA15 is relatively less affected by temperature and exhibits better deformation resistance. Compared with hot-rolled TA15, the additively manufactured TA15 alloy has the best tensile properties at room temperature and 600 °C, with a tensile strength of 981 MPa at room temperature and 530 MPa at 600 °C. The ultimate tensile strength (UTS) of AM 25 is the highest, with a yield strength (YS) of 910 MPa, but its elongation (ε) is the lowest at 9%, indicating that additively manufactured TA15 has the highest strength but the lowest ductility at room temperature. The UTS of HR 25 is second only to AM 25, at 949 MPa. Among them, the elongation of HR 600 is most affected by the change in test temperature, with elongations of 9.6% at room temperature and 28.2% at high temperature, a significant increase of 18.6%, much higher than that of the additively manufactured TA15 alloy. At this time, the hot-rolled TA15 alloy exhibits obvious low strength and high ductility. This is mainly because during high-temperature tensile testing, the high-temperature environment causes a sharp increase in the internal energy of the TA15 alloy, softening the α phase and reducing its strength. The matrix structure mainly undergoes plastic deformation, and the deformed structure reaches a dynamic equilibrium position. Compared with room-temperature tensile testing, dynamic recovery and dynamic recrystallization are more likely to occur within the structure, ultimately leading to completely different tensile properties at high temperatures compared to room temperature [31]. Combining this finding with the analysis of Figure 4, when the tensile temperature is 600 °C, the coarse primary α phase of AM 600 is crushed into fine and equiaxed α phases, increasing the number of grain boundaries within the alloy matrix and further reducing the dislocation density of the matrix structure. Therefore, during high-temperature tensile deformation, grain boundary sliding is more likely to occur, ultimately resulting in a significant increase in the ductility of the TA15 alloy.

Figure 7.

(a) Engineering stress vs. engineering strain curves under different experimental conditions and (b) comparison of tensile results.

Table 2.

Results for tensile properties of different samples.

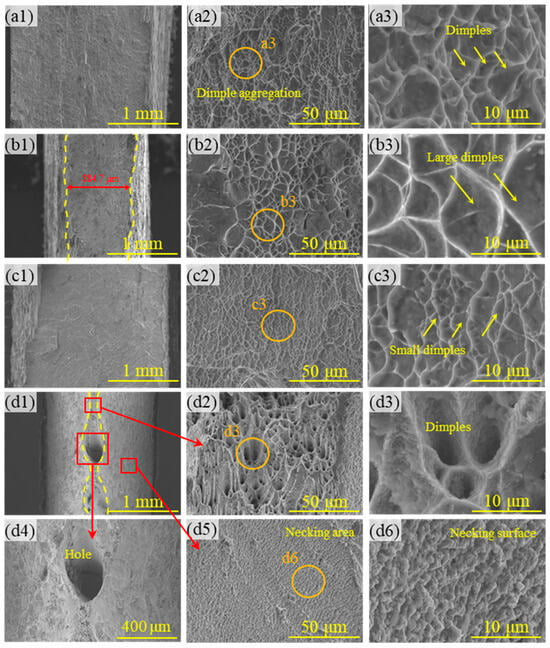

Figure 8 shows the SEM images of the tensile fracture surfaces of additively manufactured and hot-rolled TA15 alloys at room temperature and 600 °C. The tensile fracture surface of the hot-rolled TA15 alloy is covered with numerous small dimples, and the surface is relatively flat without any cleavage planes, indicating a typical dimple rupture as shown in Figure 8(a1–a3). As can be seen from Figure 8(b1), the hot-rolled TA15 alloy specimen showed a significant necking phenomenon at the fracture surface during the tensile process at 600 °C, with a reduction in the cross-sectional area and a narrowing of the fracture width to 884.7 μm, which directly led to a significant increase in elongation during tensile deformation. Compared with the fracture surface of HR 25, the fracture surface at 600 °C has larger dimples that are fewer in number, with many microvoids interspersed between the large dimples. The tensile fracture surfaces of the hot-rolled TA15 alloy at room temperature and 600 °C show characteristics of ductile fracture, with a rupture mode of dimple fracture.

Figure 8.

Tensile fracture morphology under different experimental conditions: (a1–a3) HR 25, (b1–b3) HR 600, (c1–c3) AM 25, and (d1–d6) AM 600.

As shown in Figure 8(c1–c3), the tensile fracture surface of the additively manufactured TA15 alloy at room temperature is characterized by numerous small dimples, which are primarily distributed in a mesh-like pattern with uniform size. The tensile fracture surface of the additively manufactured TA15 alloy specimen at 600 °C exhibits the most severe necking phenomenon, with almost no distinct fracture area, as depicted in Figure 8(d1). This is mainly attributed to the more pronounced softening of the additively manufactured TA15 alloy at 600 °C, which leads to uneven plastic deformation and stress concentration during tensile deformation, thereby triggering the necking phenomenon. As can be seen from Figure 8(d2,d5), the fracture surface is primarily divided into two parts. The central part is a narrow fracture area with numerous deep pores, and there is a visible pit at the center of the fracture surface, as shown in Figure 8(d4). During the additive manufacturing process, powder particles can partially obstruct the laser, leading to the incomplete melting of some powder. This can result in defects during the subsequent solidification process. In addition, bubbles may form in the molten pool during laser cladding, which can eventually lead to the formation of relatively large pore defects [32]. On the other hand, the sides of the fracture are wider necking surfaces with numerous micro protrusions, resulting in a higher surface roughness, as shown in Figure 8(d6).

For conventional plastic metals, the higher the tensile temperature, the better the ductility, and the higher the corresponding tensile fracture elongation. The tensile fracture elongation of additively manufactured TA15 at 600 °C is 17.2%, which is approximately 91.1% higher than that at 25 °C (Figure 7). In addition, the reduction in area is also more pronounced (Figure 8). For near-α titanium alloys, Cai et al. [33] also found that as the test temperature increased from 400 °C to 600 °C, the tensile fracture elongation gradually increased from 6.3% to 16.3%. The dynamic recrystallization (DRX) temperature range for titanium alloys typically lies between 700 °C and 1000 °C, depending on alloy composition and deformation conditions. Therefore, at the experimental temperature of 600 °C, DRX is unlikely to occur [34,35]. However, in this study, electron backscatter diffraction (EBSD) analysis was not performed in sufficient depth to definitively confirm the absence of recrystallization. Demott et al. employed 3D-EBSD techniques to analyze the microstructure evolution of laser additively manufactured Ti-6Al-4V, including α-phase crystallographic orientation, variant distribution, grain boundary network, and variant selection behavior [36,37]. In titanium alloys, the α-to-β-phase transformation at elevated temperatures involves a complex set of dynamic mechanisms. These include atomic diffusion, dislocation slip, dynamic recrystallization, and interphase boundary migration, all acting synergistically. Initially, the diffusion of alloying elements leads to the formation of metastable structures, destabilizing the α phase. Subsequently, dislocation slip and DRX processes release stored energy, promoting the nucleation of the new β phase. The migration of phase boundaries via stepwise mechanisms, coordinated by dislocation motion, facilitates the structural transformation. Ultimately, the balance between stored energy and thermal activation governs the kinetics and extent of the phase transformation.

4. Conclusions

This paper mainly compares the high-temperature tensile properties of additively manufactured and hot-rolled TA15 titanium alloys, and the conclusions are as follows:

- (1)

- The additively manufactured TA15 titanium alloy exhibited superior tensile properties at both room temperature and 600 °C compared to conventionally hot-rolled TA15. Among the tested specimens, AM 25 showed the highest tensile strength, reaching 981 MPa. At 600 °C, AM 600 maintained a tensile strength of 530 MPa, significantly higher than that of HR 600 (461 MPa). Furthermore, the elongation of AM 600 reached 17.14%, representing an approximately 91.1% improvement over AM 25, indicating enhanced high-temperature ductility.

- (2)

- Post-deformation microstructural analysis of AM 600 revealed that the coarse primary α phase was refined into fine equiaxed α grains, with an increase in grain boundary density and a reduction in dislocation density within the matrix. These microstructural changes facilitated grain boundary sliding during high-temperature deformation, thereby significantly enhancing the ductility of the TA15 alloy.

- (3)

- During tensile testing at 600 °C, AM 600 exhibited pronounced necking, with numerous deep dimples observed in the central region of the fracture surface and wider necking zones on both sides. This fracture morphology suggests that the α phase in AM 600 underwent substantial softening at elevated temperatures, resulting in localized plastic deformation and stress concentration, ultimately leading to necking.

- (4)

- Through the optimization of additive manufacturing parameters and post-processing heat treatment conditions, the high-temperature performance of the TA15 titanium alloy can be effectively improved. These findings provide theoretical support for the application of AM TA15 alloys in aerospace components, particularly under high-temperature service conditions, where controlling microstructural features can significantly enhance mechanical performance.

Author Contributions

Conceptualization, P.L., Q.Y. and Z.D.; methodology, Q.Y., H.X. and M.H.; software, M.H.; validation, P.L., Q.Y., Z.D., H.X. and M.H.; formal analysis, P.L., Q.Y., H.X., D.K. and M.H.; investigation, Q.Y., Z.D., H.X., D.K. and M.H.; resources, Z.D. and H.X.; data curation, P.L., Z.D., H.X., D.K. and M.H.; writing—original draft preparation, P.L.; writing—review and editing, P.L.; supervision, P.L., Q.Y., Z.D., H.X. and M.H.; project administration, P.L. and D.K.; funding acquisition, P.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (No. 52305363), China Postdoctoral Science Foundation Funded Project (No. 2024M760714), and Postgraduate Research & Practice Innovation Program of Jiangsu Province (Nos. KYCX24_3939 and SJCX24_2403).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Bobbio, L.D.; Otis, R.A.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; Liu, Z.K.; Beese, A.M. Additive manufacturing of a functionally graded material from Ti-6Al-4V to Invar: Experimental characterization and thermodynamic calculations. Acta Mater. 2017, 127, 133–142. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, W.; Leng, J.; Liu, X.; Xu, H.; Ding, H.; Zhou, J.; Cui, L. Review and Research Prospects on Additive Manufacturing Technology for Agricultural Manufacturing. Agriculture 2024, 14, 1207. [Google Scholar] [CrossRef]

- Daroonparvar, M.; Helmer, A.; Ralls, A.M.; Khan, M.U.F.; Kasar, A.K.; Gupta, R.K.; Misra, M.; Shao, S.; Menezes, P.L.; Shamsaei, N. Pitting corrosion behavior and corrosion protection performance of cold sprayed double layered noble barrier coating on magnesium-based alloy in chloride containing solutions. J. Magnes. Alloys 2023, 11, 3099–3119. [Google Scholar] [CrossRef]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef]

- Jiang, N.; Wang, Y.; Chu, J.; Kawasaki, S.; Tang, C.; Cheng, L.; Du, Y.; Shashank, B.S.; Singh, D.N.; Han, X. Bio-mediated soil improvement: An introspection into processes, materials, characterization and applications. Soil Use Manag. 2022, 38, 68–93. [Google Scholar] [CrossRef]

- Sun, J.; Han, Y.; Cui, K. Innovative fabrication of porous titanium coating on titanium by cold spraying and vacuum sintering. Mater. Lett. 2008, 62, 3623–3625. [Google Scholar] [CrossRef]

- Li, P.; Wang, Y.; Li, L.; Gong, Y.; Zhou, J.; Lu, J. Ablation oxidation and surface quality during laser polishing of TA15 aviation titanium alloy. J. Mater. Res. Technol. 2023, 23, 6101–6114. [Google Scholar] [CrossRef]

- Tabie, V.M.; Li, C.; Saifu, W.; Li, J.; Xu, X. Mechanical properties of near alpha titanium alloys for high-temperature applications—A review. Aircr. Eng. Aerosp. Technol. 2020, 92, 521–540. [Google Scholar] [CrossRef]

- Yang, J.; Song, Y.; Dong, K.; Han, E.-H. Research progress on the corrosion behavior of titanium alloys. Corros. Rev. 2023, 41, 5–20. [Google Scholar] [CrossRef]

- Li, P.; Liu, B.; Li, L.; Gong, Y.; Zhou, J.; Lu, J. Study on surface quality of ultrasonic assisted underwater laser polishing. J. Mater. Res. Technol. 2023, 27, 5761–5771. [Google Scholar] [CrossRef]

- Li, H.; Bei, Q.; Li, B.; Haruna, S.A.; Marimuthu, M.; Hassan, M.; Ding, Z.; Chen, Q. A novel enzymatic biosensor for CIP in food based on UCNPs and colorimetric strategy of potassium titanium oxalate. J. Food Compos. Anal. 2024, 125, 105827. [Google Scholar] [CrossRef]

- Su, Y.; Kong, F.; You, F.H.; Wang, X.; Chen, Y. The high-temperature deformation behavior of a novel near-α titanium alloy and hot-forging based on the processing map. Vacuum 2020, 173, 109135. [Google Scholar] [CrossRef]

- Liu, J.; Qi, Y.; Hamadou, A.H.; Ahmed, Z.; Guo, Q.; Zhang, J.; Xu, B. Effect of high-temperature drying at different moisture levels on texture of dried noodles: Insights into gluten aggregation and pore distribution. J. Cereal Sci. 2024, 115, 103817. [Google Scholar] [CrossRef]

- Zhang, L.; Pellegrino, A.; Townsend, D.; Petrinic, N. Strain rate and temperature dependent strain localization of a near α titanium alloy. Int. J. Impact Eng. 2020, 145, 103676. [Google Scholar] [CrossRef]

- Li, S.; Deng, T.; Zhang, Y.; Liang, Y.; Li, R.; Dong, T. Review on the Creep Resistance of High-Temperature Titanium Alloy. Trans. Indian Inst. Met. 2021, 74, 215–222. [Google Scholar] [CrossRef]

- Wang, H.W.; Qi, J.Q.; Zou, C.M.; Zhu, D.D.; Wei, Z.J. High-temperature tensile strengths of in situ synthesized TiC/Ti-alloy composites. Mater. Sci. Eng. A 2012, 545, 209–213. [Google Scholar] [CrossRef]

- Nagarjuna, S.; Srinivas, M. High temperature tensile behaviour of a Cu-1.5 wt.% Ti alloy. Mater. Sci. Eng. A 2002, 335, 89–93. [Google Scholar] [CrossRef]

- Yang, C.T.; Lu, Y.C.; Koo, C.H. The high temperature tensile properties and microstructural analysis of Ti-40Al-15Nb alloy. Intermetallics 2002, 10, 161–169. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, F.; Torrens, R.; Bolzoni, L. Allotropic phase transformation and high-temperature tensile deformation behaviour of powder metallurgy Ti-5553 alloy. Int. J. Refract. Met. Hard Mater. 2020, 90, 105235. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Xiong, L.; Liu, T.; He, L. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Zang, M.C.; Niu, H.Z.; Liu, S.; Yu, J.S.; Zhang, H.R.; Zhang, D.L. Achieving high tensile strength-ductility synergy of a fully-lamellar structured near alpha titanium alloy at extra-low temperatures. J. Alloys Compd. 2022, 923, 166363. [Google Scholar] [CrossRef]

- Dineshkumar, S.; Sriram, S.; Surendran, R.; Dhinakaran, V. Experimental investigation of tensile properties of Ti-6Al-4V alloy at elevated temperature. Int. J. Recent Technol. Eng. 2019, 8, 103–107. [Google Scholar]

- Guo, R.; Liu, B.; Xu, R.; Cao, Y.; Qiu, J.; Chen, F.; Yan, Z.; Liu, Y. Microstructure and mechanical properties of powder metallurgy high temperature titanium alloy with high Si content. Mater. Sci. Eng. A 2020, 777, 138993. [Google Scholar] [CrossRef]

- Hao, F.; Xiao, J.; Feng, Y.; Wang, Y.; Ju, J.; Du, Y.; Wang, K.; Xue, L.; Nie, Z.; Tan, C. Tensile deformation behavior of a near-titanium alloy Ti-6Al-2Zr-1Mo-1V under a wide temperature range. J. Mater. Res. Technol. 2020, 9, 2818–2831. [Google Scholar] [CrossRef]

- Matsumoto, H.; Nishihara, T.; Iwagaki, Y.; Shiraishi, T.; Ono, Y.; Chiba, A. Microstructural evolution and deformation mode under high-temperature-tensile-deformation of the Ti-6Al-4V alloy with the metastable α’ martensite starting microstructure. Mater. Sci. Eng. A 2016, 661, 68–78. [Google Scholar] [CrossRef]

- Li, P.; Wang, S.; Li, X.; Yin, J.U.N.; Gao, H.; Xiang, X. Preparation of TC4-TA15 Bimetallic Materials by Laser Melting Deposition: Microstructure and Mechanical Properties at the Interfacial Union. JOM 2024, 77, 1873–1884. [Google Scholar] [CrossRef]

- Wang, D.; Li, H.; Zheng, W. Oxidation behaviors of TA15 titanium alloy and TiBw reinforced TA15 matrix composites prepared by spark plasma sintering. J. Mater. Sci. Technol. 2020, 37, 46–54. [Google Scholar] [CrossRef]

- Huang, S.; Sun, B.; Guo, S. Microstructure and property evaluation of TA15 titanium alloy fabricated by selective laser melting after heat treatment. Opt. Laser Technol. 2021, 144, 107422. [Google Scholar] [CrossRef]

- Wei, K.; Hu, R.; Yin, D.; Xiao, L.; Pang, S.; Cao, Y.; Zhou, H.; Zhao, Y.; Zhu, Y. Grain size effect on tensile properties and slip systems of pure magnesium. Acta Mater. 2021, 206, 116604. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, L.; Li, L.; Kong, D.; Ma, R.; Liu, L. Microstructure evolution of 2205 duplex stainless steel (DSS) and inconel 718 dissimilar welded joints and impact on corrosion and mechanical behavior. Mater. Sci. Eng. A 2025, 929, 148136. [Google Scholar] [CrossRef]

- Narayana, P.L.; Kim, S.W.; Hong, J.K.; Reddy, N.S.; Yeom, J.T. Tensile properties of a newly developed high-temperature titanium alloy at room temperature and 650 °C. Mater. Sci. Eng. A 2018, 718, 287–291. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, J.; Lv, J.; Meng, X.; Li, P.; Huang, S. A novel hybrid ultrasonic and electromagnetic field assisted laser cladding: Experimental study and synergistic effects. J. Mater. Process. Technol. 2022, 307, 117658. [Google Scholar] [CrossRef]

- Cai, C.; Song, B.; Xue, P.; Wei, Q.; Yan, C.; Shi, Y. A novel near α-Ti alloy prepared by hot isostatic pressing: Microstructure evolution mechanism and high temperature tensile properties. Mater. Des. 2016, 106, 371–379. [Google Scholar] [CrossRef]

- Wang, X.X.; Liu, T.; Zhang, R.X.; Jin, H.J.; Zhao, X.N.; Wu, W.H.; Cheng, J. Texture evolution related to static recrystallization during annealing of TA15 alloy tube formed by flow forming. J. Mater. Res. Technol. 2023, 24, 5769–5781. [Google Scholar] [CrossRef]

- Wang, K.; Liu, G.; Tao, W.; Zhao, J.; Huang, K. Study on the mixed dynamic recrystallization mechanism during the globularization process of laser-welded TA15 Ti-alloy joint under hot tensile deformation. Mater. Charact. 2017, 126, 57–63. [Google Scholar] [CrossRef]

- DeMott, R.; Haghdadi, N.; Gandomkar, Z.; Liao, X.; Ringer, S.; Primig, S. Formation and 3D morphology of interconnected α microstructures in additively manufactured Ti-6Al-4V. Materialia 2021, 20, 101201. [Google Scholar] [CrossRef]

- DeMott, R.; Haghdadi, N.; Liao, X.; Ringer, S.P.; Primig, S. 3D characterization of microstructural evolution and variant selection in additively manufactured Ti-6Al-4 V. J. Mater. Sci. 2021, 56, 14763–14782. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).