Microstructural Features and Mechanical Properties of Laser–MIG Hybrid Welded–Brazed Ti/Al Butt Joints with Different Filler Wires

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

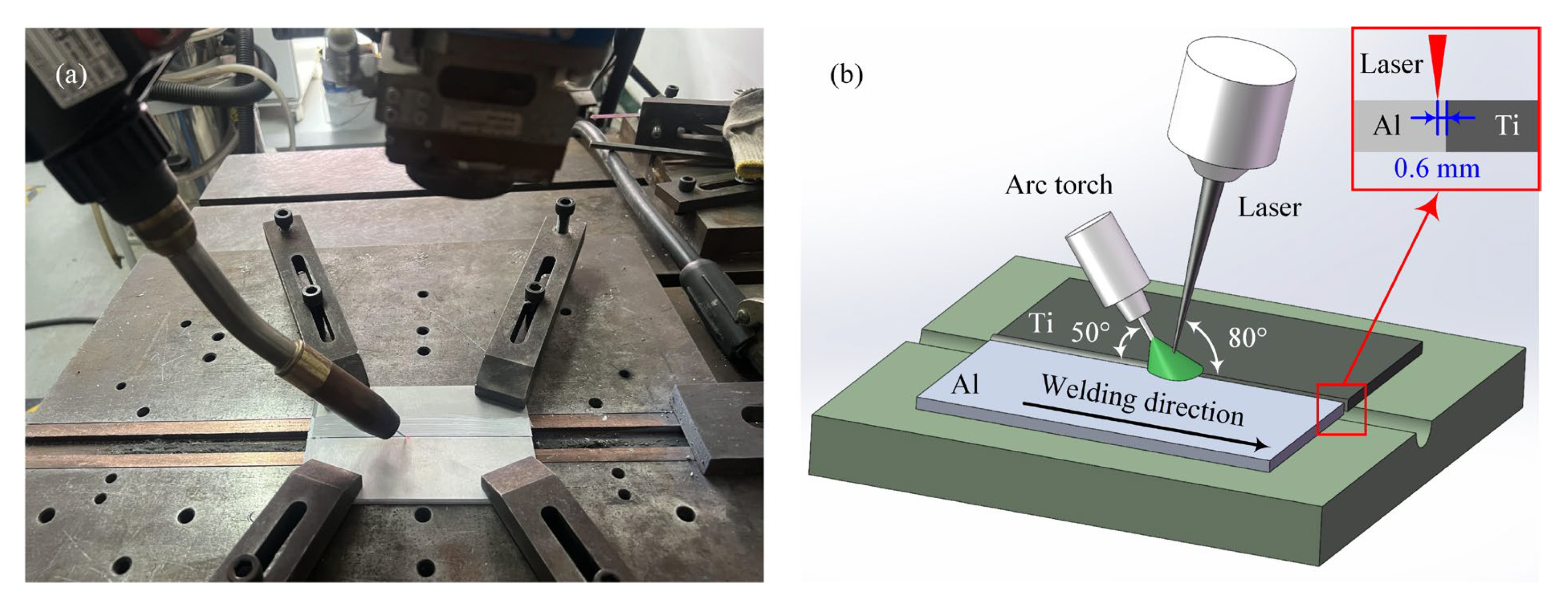

2.2. Welding–Brazing Procedure

2.3. Microstructure and Mechanical Property Tests

3. Results and Discussion

3.1. Weld Formation

3.2. Microstructural Features

3.3. Mechanical Properties

4. Conclusions

- (1)

- Compared with the ER5356 and ER2319 filler wires, the spreading and wetting of melted metal on the Ti base metal was the best when using the ER4043 filler wire, which had the largest spreading distance and the smallest wetting angle. Furthermore, the unspread phenomenon was exhibited on the rear surface of the joint with the ER5356 filler wire.

- (2)

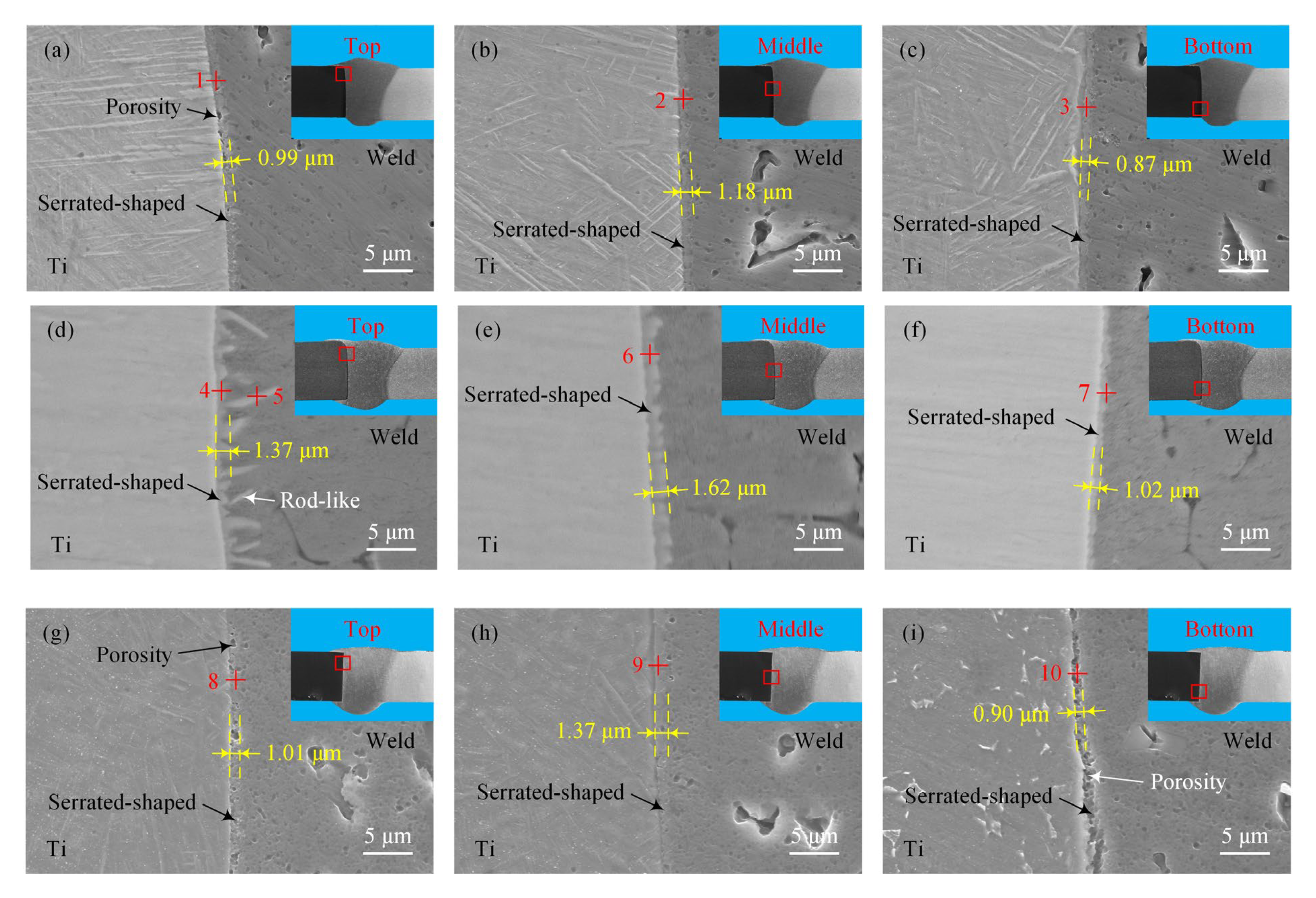

- Two-layer IMCs composed of serrated-shaped and rod-like IMCs were generated in the top region of the interface of the joints with the ER4043 filler wire, but only serrated-shaped IMCs could be observed in the middle and bottom regions. Only single-layer serrated-shaped IMCs appeared in the joints with the ER5356 and ER2319 filler wires. The phase compositions of all the IMCs were inferred to consist of TiAl3.

- (3)

- The average thickness of the IMC layer in the same region was almost the same for joints with the ER5356 and ER2319 filler wires, which was smaller than that of joints with the ER4043 filler wire. Meanwhile, for all the joints with the three different filler wires, the average thickness was largest in the middle region, while the smallest was in the bottom region.

- (4)

- The microhardness distribution of the joints with different filler wires had the same variation tendency: lowest in the weld metal zone, highest in the Al base metal zone, and in-between in the heat-affected zone. The average microhardness in the weld metal reached up to 77.7 HV, 91.2 HV and 85.4 HV in the joints with the ER5356, ER4043 and ER2319 filler wires, respectively.

- (5)

- The average tensile strength of the joints with the ER5356, ER4043 and ER2319 filler wires was 106 MPa, 238 MPa and 192 MPa, respectively. The poor spreading and wetting of the melted metal on the Ti base metal might be the main reason for the joints with the ER5356 filler wire having the lowest average tensile strength. The tensile testing specimens all fractured at the IMC layer, and the fractures all showed a mixed brittle–ductile fracture feature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dou, T.; Yang, J.; Zeng, Y.; Zheng, M.; Xu, W.; Shi, J.; Zhang, H. The influence of FeCoCrNi HEA porous coating on dynamic wetting and spreading behaviors of AlSi alloy on steel substrate by laser irradiation. J. Manuf. Process. 2024, 125, 38–49. [Google Scholar] [CrossRef]

- Soni, R.; Verna, R.; Gary, R.K.; Sharma, V. A critical review of recent advances in the aerospace materials. Mater. Today Proc. 2024, 113, 180–184. [Google Scholar] [CrossRef]

- Möller, F.; Thomy, C.; Vollertsen, F. Joining of titanium aluminum seat tracks for aircraft applications system technology and joint properties. Weld. World 2012, 56, 108–114. [Google Scholar] [CrossRef]

- Xia, Y.; Ma, Z.; Du, Q.; Jiu, Y.; Guo, P.; Qin, J.; Li, S.; Zhang, X.; Zhou, P.; Hu, J.; et al. Microstructure and properties of the TiAl/GH3030 dissimilar joints vacuum-brazed with a Ti-based amorphous filler metal. Mater. Charact. 2024, 207, 113520. [Google Scholar] [CrossRef]

- Zhao, H.; Yu, M.; Jiang, Z.; Zhou, L.; Song, X. Interfacial microstructure and mechanical properties of Al/Ti dissimilar joints fabricated via friction stir welding. J. Alloys Compd. 2019, 789, 139–149. [Google Scholar] [CrossRef]

- Malikova, A.; Vitoshkina, I.; Orishicha, A.; Filippova, A.; Karpova, E. Microstructure and mechanical properties of laser welded joints of Al-Cu-Li and Ti-Al-V alloys. J. Manuf. Process. 2020, 53, 201–212. [Google Scholar] [CrossRef]

- Chen, X.; Lei, Z.; Chen, Y.; Han, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S. Microstructure and tensile properties of Ti/Al dissimilar joint by laser welding-brazing at sub-atmospheric pressure. J. Manuf. Process. 2020, 56, 19–27. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y.; Huang, J. Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J. Alloys Compd. 2011, 509, 891–898. [Google Scholar] [CrossRef]

- Song, L.; Wei, S.; Rao, W.; Li, Z.; Zhang, Y. Optimization of welding parameters during Ti-TA2/5A06Al dissimilar double-sided cold arc metal inert gas welding. J. Mater. Eng. Perform. 2022, 31, 9714–9726. [Google Scholar] [CrossRef]

- Kuryntsev, S. A review: Laser welding of dissimilar materials (Al/Fe, Al/Ti, Al/Cu)-methods and techniques, microstructure and properties. Materials 2022, 15, 122. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Gu, Y.; Zeng, X. Microstructure and tensile behavior of laser arc hybrid welded dissimilar Al and Ti alloys. Materials 2014, 7, 1590–1602. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Yang, Y.; Feng, J.; Zhang, L. Properties study on Ti/Al butt joining by GMAW/GTAW hybrid welding-brazing. Mater. Res. Express 2023, 10, 116518. [Google Scholar] [CrossRef]

- Lin, H.L.; Chen, P.A. Effects of parameters on welding performance of the Ti/Al butt-joint in advanced plasma-MIG hybrid welding. Int. J. Adv. Manuf. Technol. 2024, 130, 2065–2083. [Google Scholar] [CrossRef]

- Xu, W.; Wang, W.; Yang, Q.; Xiong, J.; Zhang, L.; He, H. CMT twin welding-brazing of aluminum to titanium. Weld. World 2022, 66, 1121–1130. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Nobile, R.; Mele, C.; Tarantino, A.; Casalino, G. Analysis of the process parameters, post-weld heat treatment and peening effects on microstructure and mechanical performance of Ti-Al dissimilar laser weldings. Metals 2021, 11, 1257. [Google Scholar] [CrossRef]

- Zhao, J.; Geng, S.; Jiang, P.; Song, M.; Xu, B.; Luo, Q. Experimental and numerical research on formation mechanism of intermetallic compounds in laser brazing welding for Ti/Al dissimilar alloy. J. Mater. Res. Technol. 2024, 31, 2930–2944. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, S.; Wu, J.; Ma, Y.; Xu, L.; Li, H.; Yuan, J.; Yang, B.; Tan, C.; Wu, T. Homogenizing interfacial IMC distribution and enhancing strength of laser welded-brazed Al/Ti butt joint by oscillated scanning. J. Mater. Res. Technol. 2025, 35, 6226–6236. [Google Scholar] [CrossRef]

- Chen, X.; Lei, Z.; Chen, Y.; Han, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S.; Jiang, N. Effect of laser beam oscillation on laser welding-brazing of Ti/Al dissimilar metals. Materials 2019, 12, 4165. [Google Scholar] [CrossRef]

- Casalino, G.; Leo, P.; Mortello, M.; Perulli, P.; Varone, A. Effects of laser offset and hybrid welding on microstructure and IMC in Fe-Al dissimilar welding. Metals 2017, 7, 282. [Google Scholar] [CrossRef]

- Shaker, M.A.; Jain, M.K.; Chen, J.Z. Deformation behavior of steel-to-aluminum tailor blanks made by laser/MIG hybrid and cold metal transfer brazing methods. Int. J. Adv. Manuf. Technol. 2020, 110, 3061–3076. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Mei, S.; Wang, L.; Zeng, X. Parameter optimization and mechanism of laser-arc hybrid welding of dissimilar Al alloy and stainless steel. Int. J. Adv. Manuf. Technol. 2014, 74, 199–208. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, H.; Zhao, X.; Zhao, H.; Liu, F.; Yang, B.; Chen, B.; Tan, C. The effect of inhomogeneous microstructure on the properties of laser-MIG hybrid welded 316L/AH36 dissimilar joints. J. Mater. Res. Technol. 2024, 28, 4088–4096. [Google Scholar] [CrossRef]

- Furuya, H.S.; Sato, Y.T.; Sato, Y.S.; Kokawa, H.; Tatsumi, Y. Strength improvement through grain refinement of intermetallic compound at Al/Fe dissimilar joint interface by the addition of alloying elements. Metall. Mater. Trans. A 2018, 49A, 527–536. [Google Scholar] [CrossRef]

- Wang, T.; Shukla, S.; Gwalani, B.; Komarasamy, M.; Reza-Nieto, L.; Mishra, R.S. Effect of reactive alloy elements on friction stir welded butt joints of metallurgically immiscible magnesium alloys and steel. J. Manuf. Process. 2019, 39, 138–145. [Google Scholar] [CrossRef]

- Yu, G.; Chen, S.; Zhao, Z.; Wen, Z.; Huang, J.; Yang, J.; Chen, S. Comparative study of laser welding-brazing of aluminum alloy to galvanized steel butted joints using five different filler wires. Opt. Laser Technol. 2022, 147, 107618. [Google Scholar] [CrossRef]

- Pouranvari, M.; Abbasi, M. Dissimilar gas tungsten arc weld-brazing of Al/steel using Al–Si filler metal: Microstructure and strengthening mechanisms. J. Alloys Compd. 2018, 749, 121–127. [Google Scholar] [CrossRef]

- Wang, S.; Qin, G.; Su, Y. Laser-MIG arc hybrid brazing-fusion welding of Al alloy to Galvanized steel with different filler metals. Acta Metall. Sin. (Engl. Lett.) 2013, 26, 177–182. [Google Scholar] [CrossRef]

- Chen, Z.; Cai, C.; Yu, J.; Huang, J.; Chen, H.; Li, L. Microstructure evolution and fracture behavior of laser welded-brazed titanium/aluminum joints with various gap sizes. J. Mater. Res. Technol. 2024, 29, 714–727. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, H.; Liu, F.; Yang, B.; Chen, B.; Tan, C. Influence of energy ration on microstructure and mechanical properties in the transition zone of hybrid laser-MIG welded Ah36/316L dissimilar joints. J. Mater. Res. Technol. 2021, 15, 4487–4501. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, Z.; Xue, J. Microstructure and mechanical properties of Ti/Al dissimilar joints produced by laser-MIG welding-brazing. Int. J. Mod. Phys. B 2019, 33, 1940030. [Google Scholar] [CrossRef]

- Han, X.; Yang, Z.; Ma, Y.; Shi, C.; Xin, Z. Porosity distribution and mechanical response of laser-MIG hybrid butt welded 6082-T6 aluminum alloy joint. Opt. Laser Technol. 2020, 132, 106511. [Google Scholar] [CrossRef]

| Metals | Al | Ti | Si | Fe | Cu | Mn | Zn | Mg | V |

|---|---|---|---|---|---|---|---|---|---|

| TC4 | 6.19 | Bal. | / | 0.21 | / | / | / | / | 3.95 |

| 5083 | Bal. | 0.12 | 0.34 | 0.37 | 0.08 | 0.65 | 0.19 | 4.57 | / |

| ER5356 | Bal. | 0.13 | 0.22 | 0.36 | 0.07 | 0.78 | 0.06 | 5.23 | / |

| ER4043 | Bal. | 0.18 | 5.27 | 0.61 | 0.26 | 0.04 | 0.11 | 0.05 | / |

| ER2319 | Bal. | 0.16 | 0.18 | 0.26 | 6.37 | 0.35 | 0.10 | 0.18 | 0.11 |

| Parameters | Laser Power (kW) | Welding Speed (m/min) | Wire Feeding Speed (m/min) | Welding Current (A) | Welding Voltage (V) | Laser Offset Distance (mm) |

|---|---|---|---|---|---|---|

| Values | 2.2 | 1.5 | 6.5 | 112 | 18.2 | 0.6 |

| Locations | Al | Ti | Si | Possible Phase |

|---|---|---|---|---|

| 1 | 75.41 | 21.07 | 3.52 | TiAl3 |

| 2 | 72.33 | 23.81 | 3.86 | TiAl3 |

| 3 | 77.47 | 20.17 | 2.36 | TiAl3 |

| 4 | 72.31 | 23.23 | 4.46 | TiAl3 |

| 5 | 71.62 | 24.73 | 3.65 | TiAl3 |

| 6 | 69.56 | 24.32 | 6.12 | TiAl3 |

| 7 | 77.24 | 21.21 | 1.55 | TiAl3 |

| 8 | 74.21 | 33.37 | 2.42 | TiAl3 |

| 9 | 73.36 | 24.05 | 2.59 | TiAl3 |

| 10 | 77.33 | 20.34 | 2.33 | TiAl3 |

| Locations | Ti | Si | Al |

|---|---|---|---|

| 1 | 0.96 | 6.15 | 92.89 |

| 2 | 91.36 | 3.77 | 4.87 |

| 3 | 1.39 | 5.18 | 93.43 |

| 4 | 90.37 | 3.76 | 5.87 |

| 5 | 0.17 | 5.76 | 94.57 |

| 6 | 0.87 | 5.97 | 93.16 |

| 7 | 0.57 | 6.02 | 93.41 |

| 8 | 92.02 | 3.19 | 4.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Yang, Z.; Huang, Y.; Zhu, H.; Dong, S. Microstructural Features and Mechanical Properties of Laser–MIG Hybrid Welded–Brazed Ti/Al Butt Joints with Different Filler Wires. Metals 2025, 15, 674. https://doi.org/10.3390/met15060674

Zhao X, Yang Z, Huang Y, Zhu H, Dong S. Microstructural Features and Mechanical Properties of Laser–MIG Hybrid Welded–Brazed Ti/Al Butt Joints with Different Filler Wires. Metals. 2025; 15(6):674. https://doi.org/10.3390/met15060674

Chicago/Turabian StyleZhao, Xin, Zhibin Yang, Yonghao Huang, Hongjun Zhu, and Shaozheng Dong. 2025. "Microstructural Features and Mechanical Properties of Laser–MIG Hybrid Welded–Brazed Ti/Al Butt Joints with Different Filler Wires" Metals 15, no. 6: 674. https://doi.org/10.3390/met15060674

APA StyleZhao, X., Yang, Z., Huang, Y., Zhu, H., & Dong, S. (2025). Microstructural Features and Mechanical Properties of Laser–MIG Hybrid Welded–Brazed Ti/Al Butt Joints with Different Filler Wires. Metals, 15(6), 674. https://doi.org/10.3390/met15060674