Microstructural Characterization of Martensitic Stainless Steel Blades Manufactured by Directed Energy Deposition (DED)

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. DED Processing

2.3. Heat Treating

2.4. Analytical Methods

3. Results

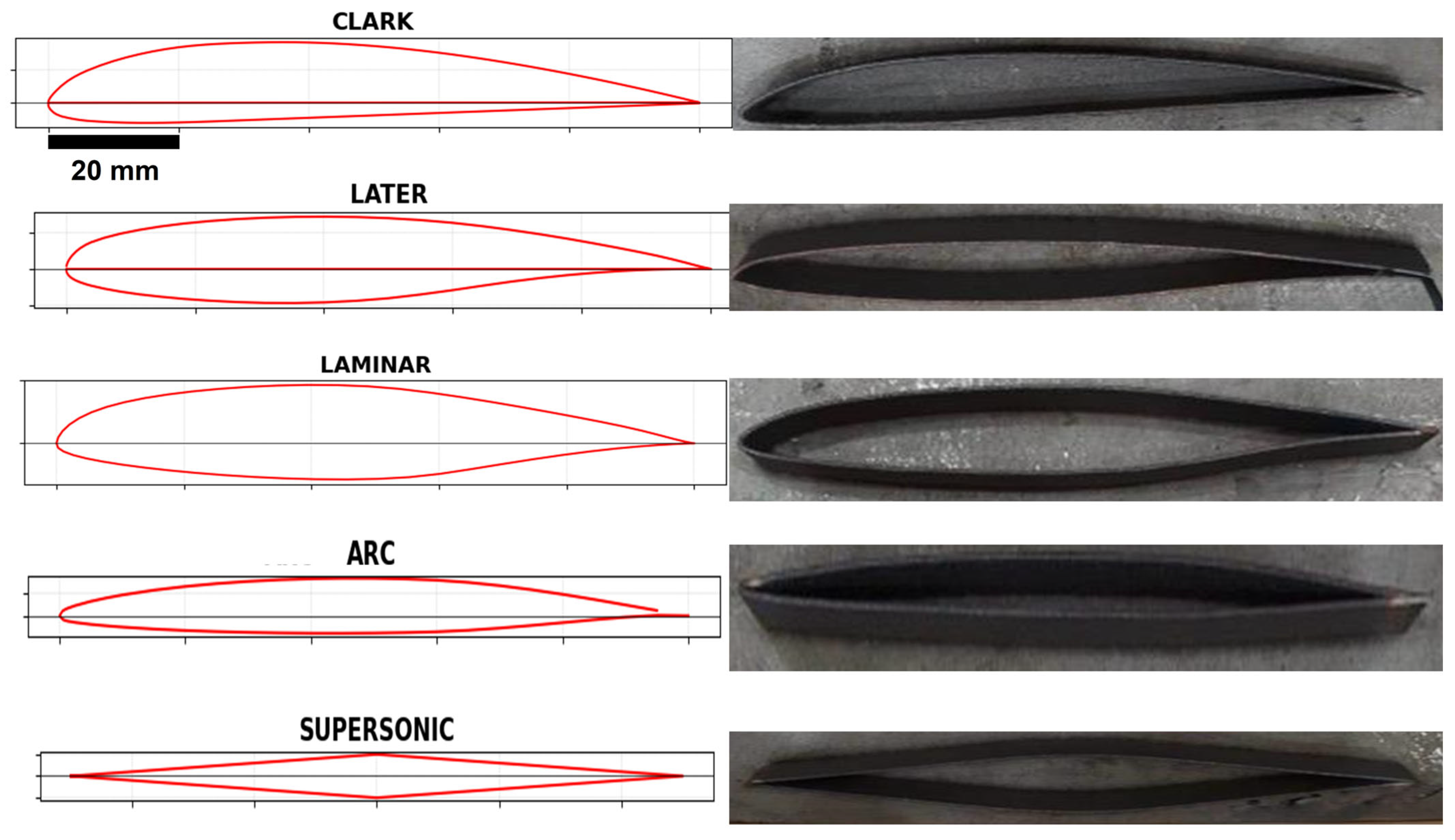

3.1. Fabrication of the Blades

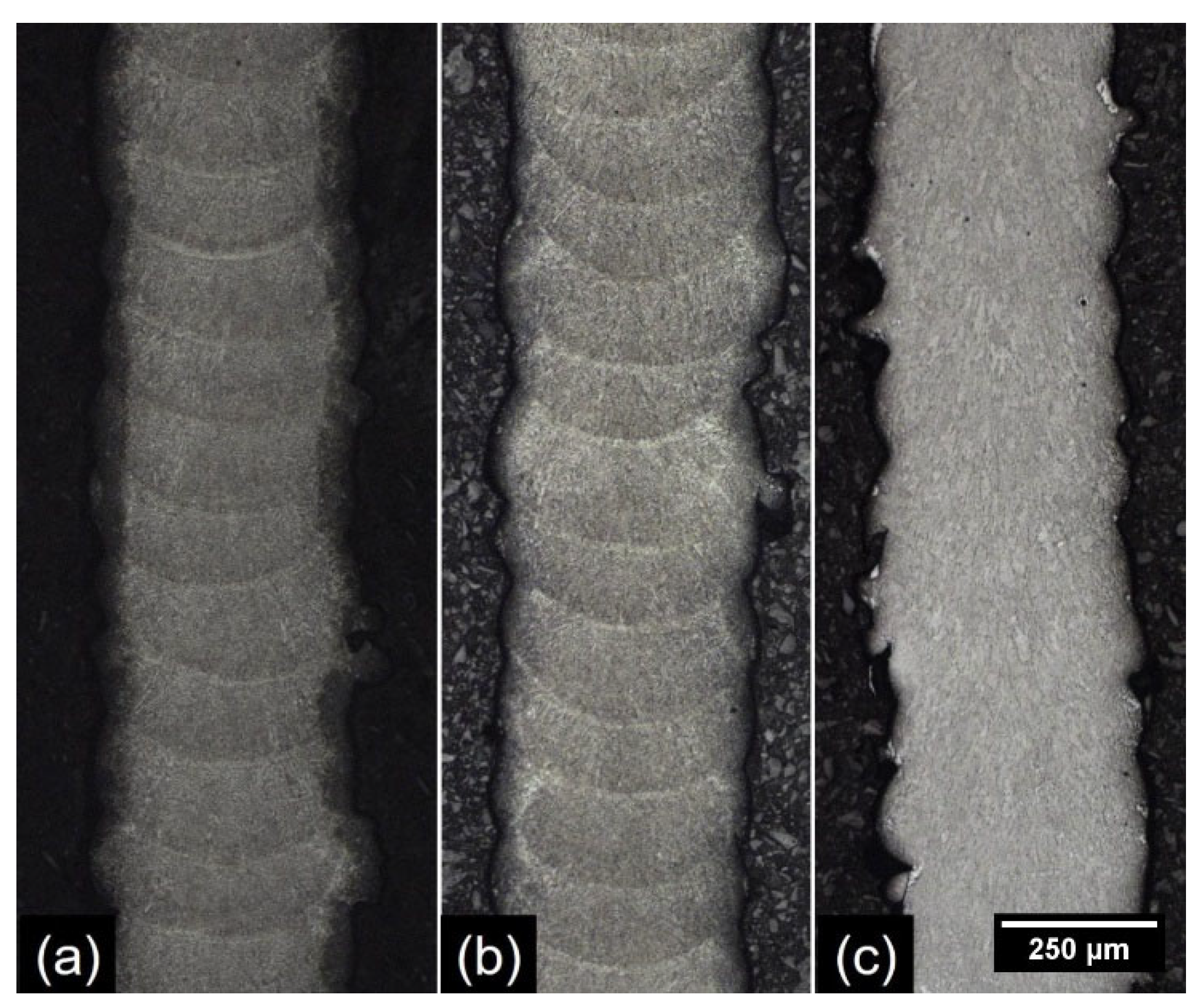

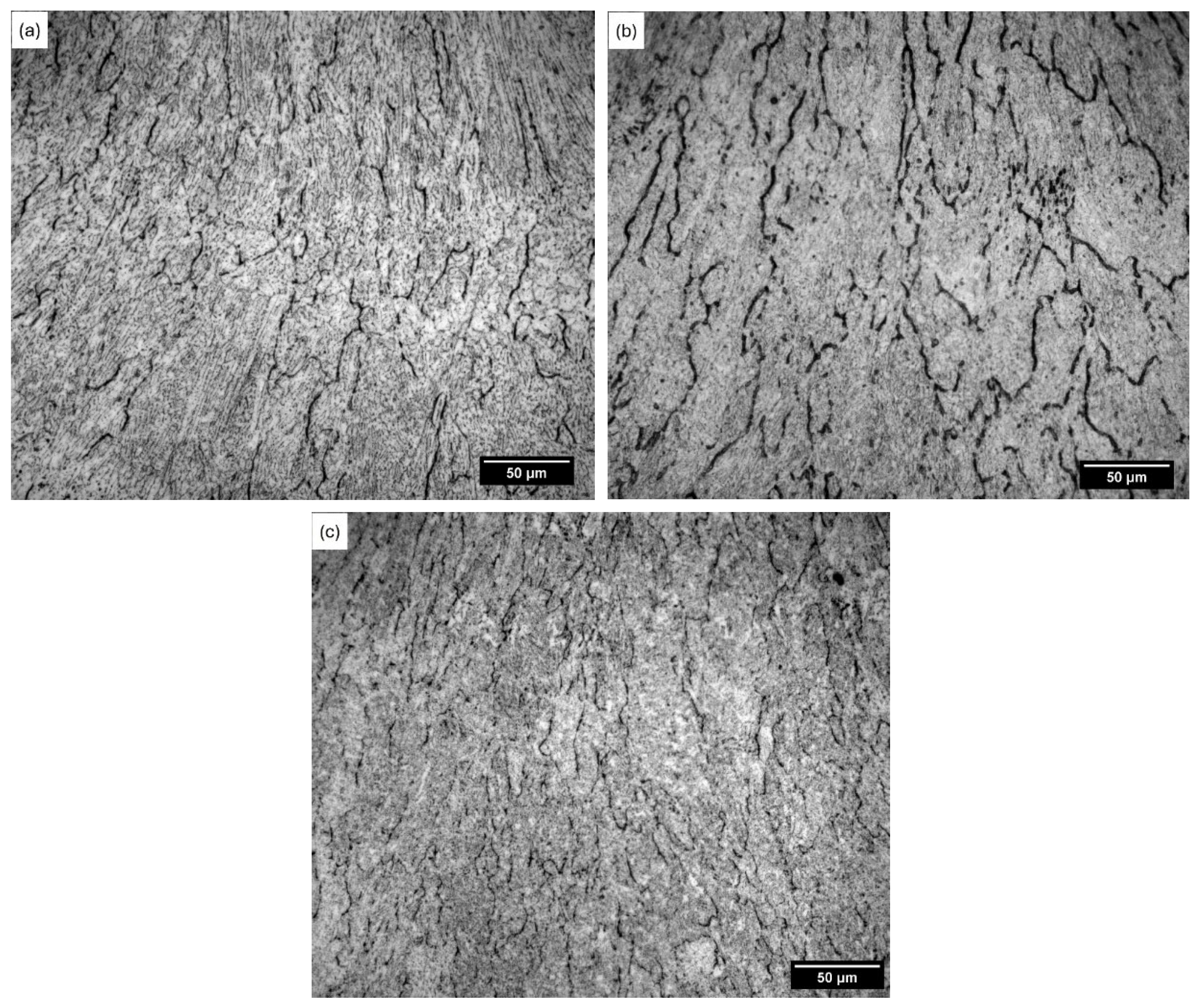

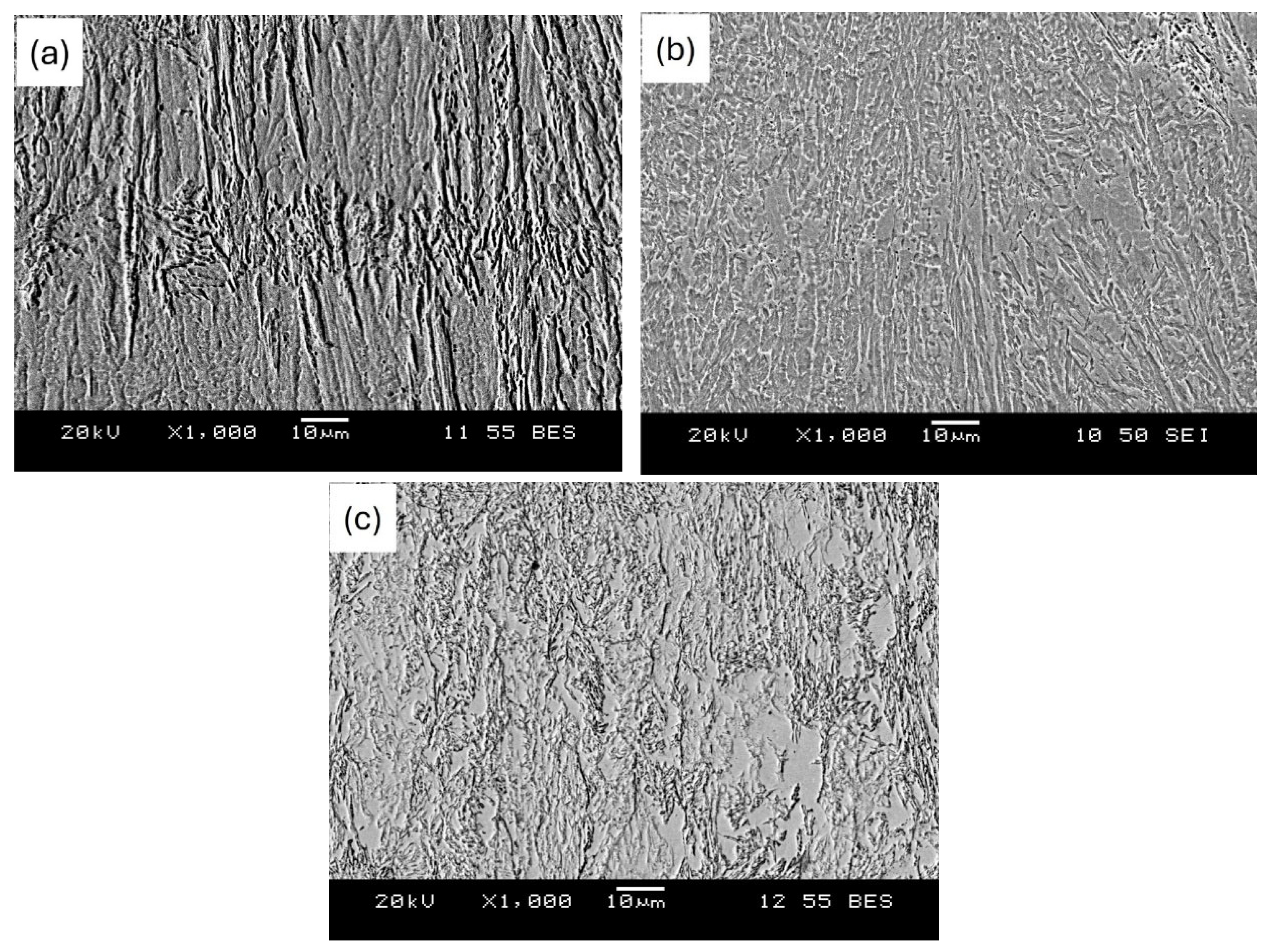

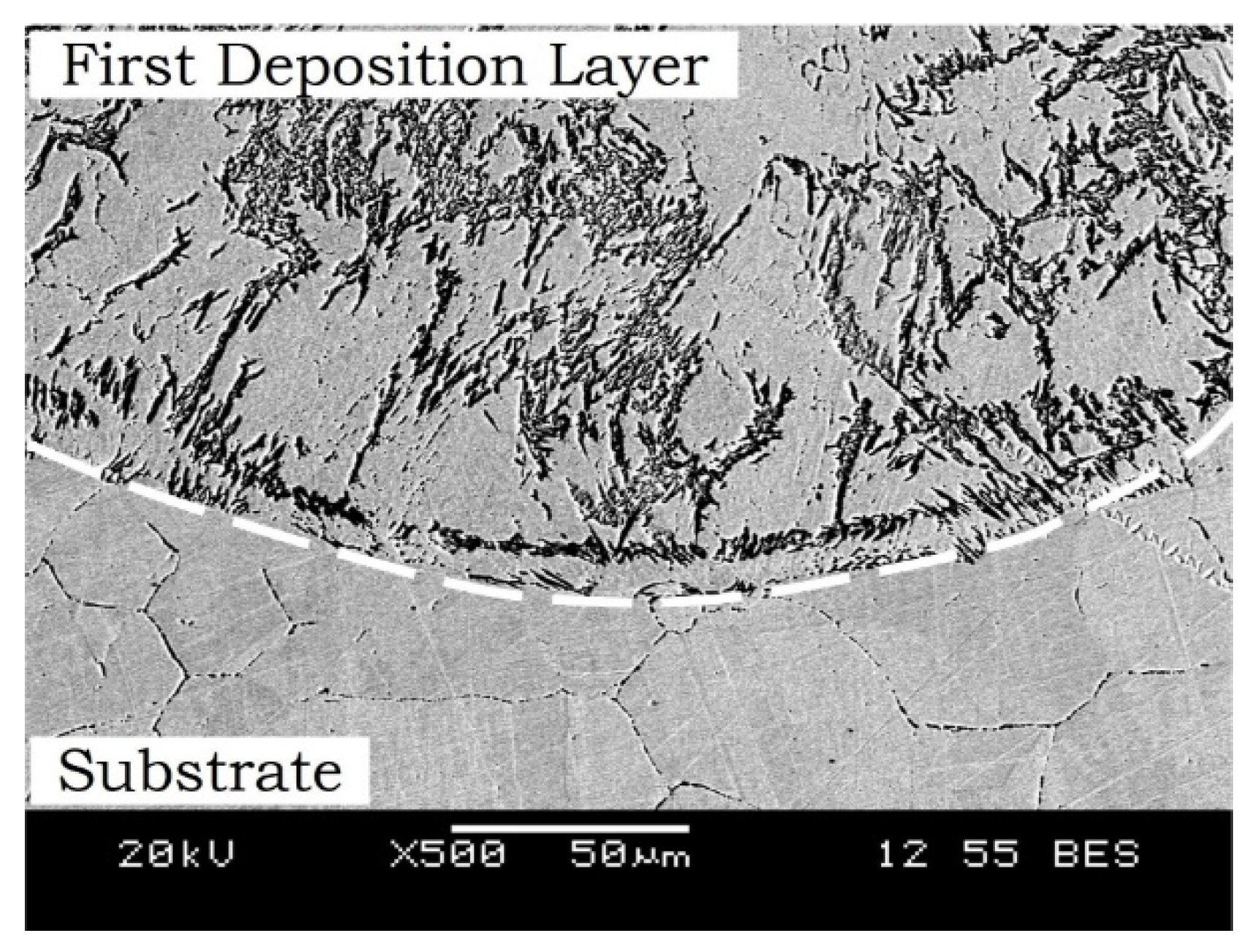

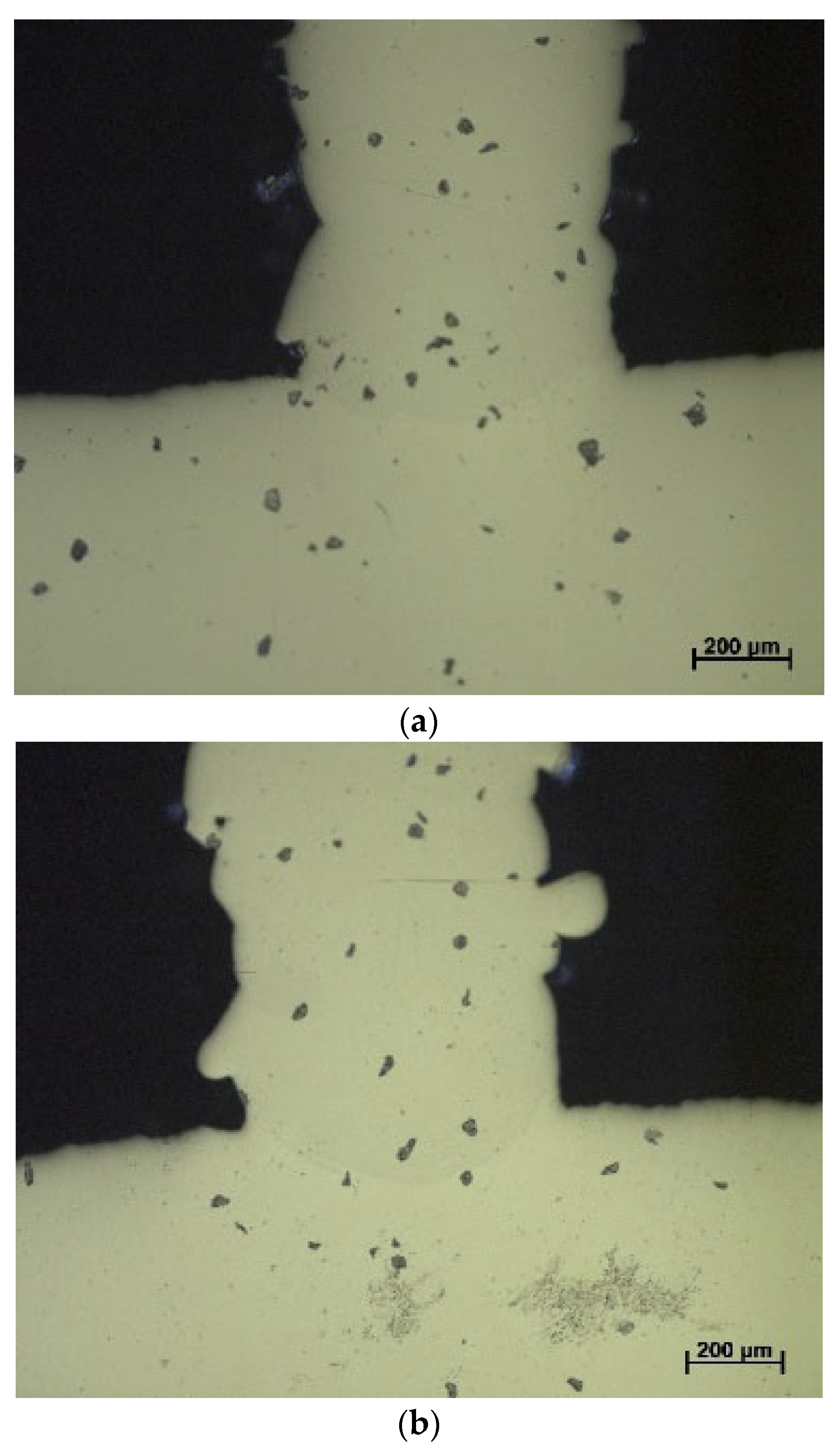

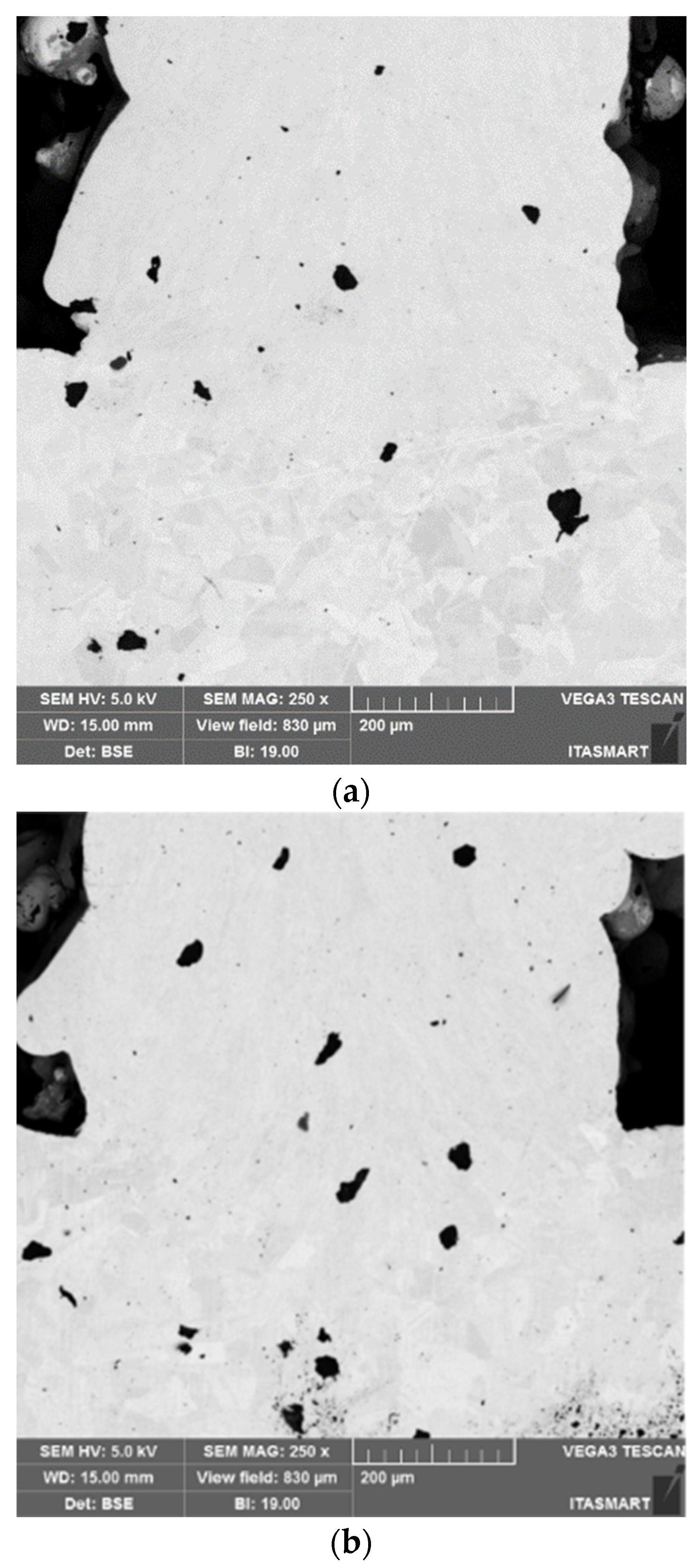

3.2. Microstructure

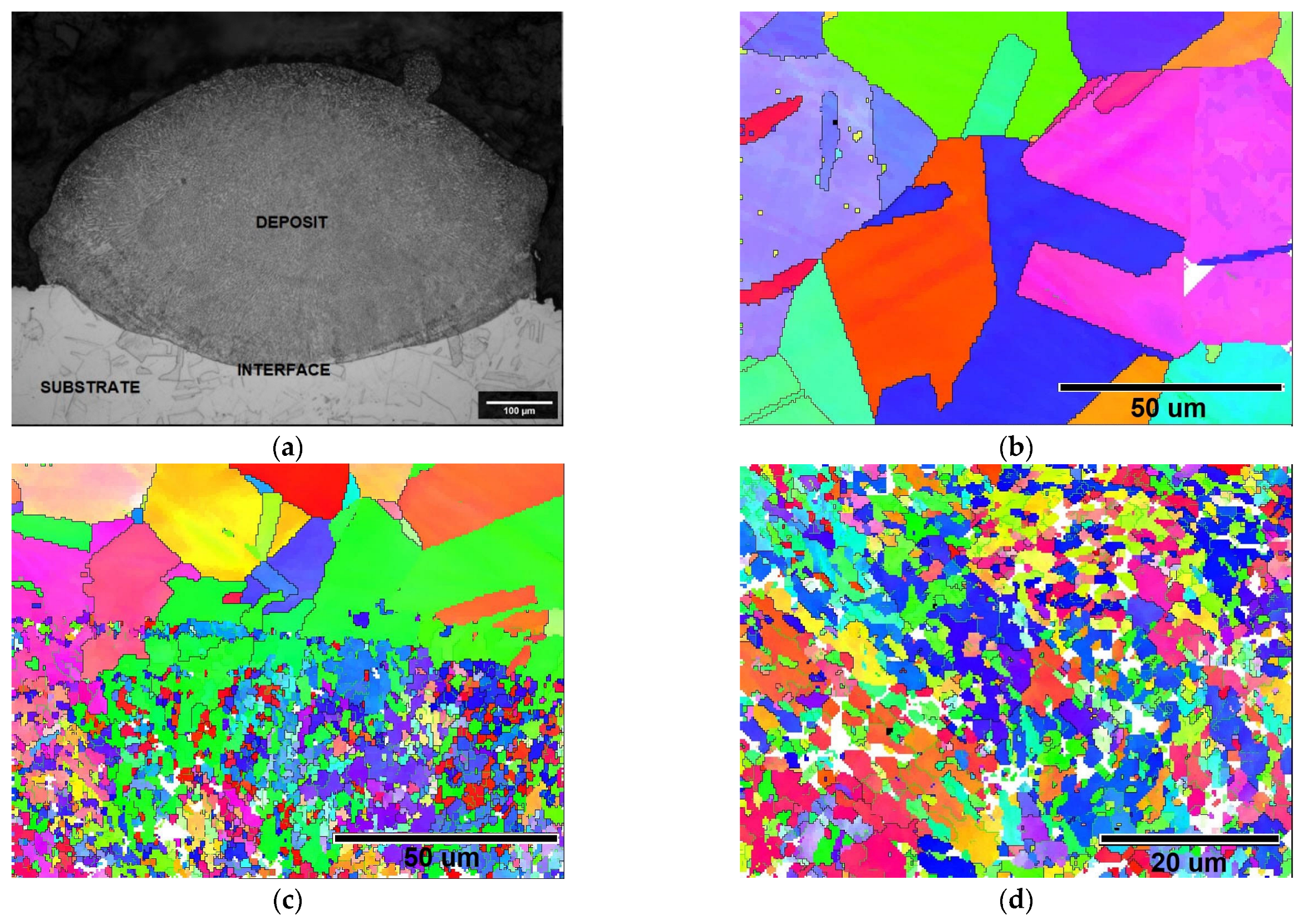

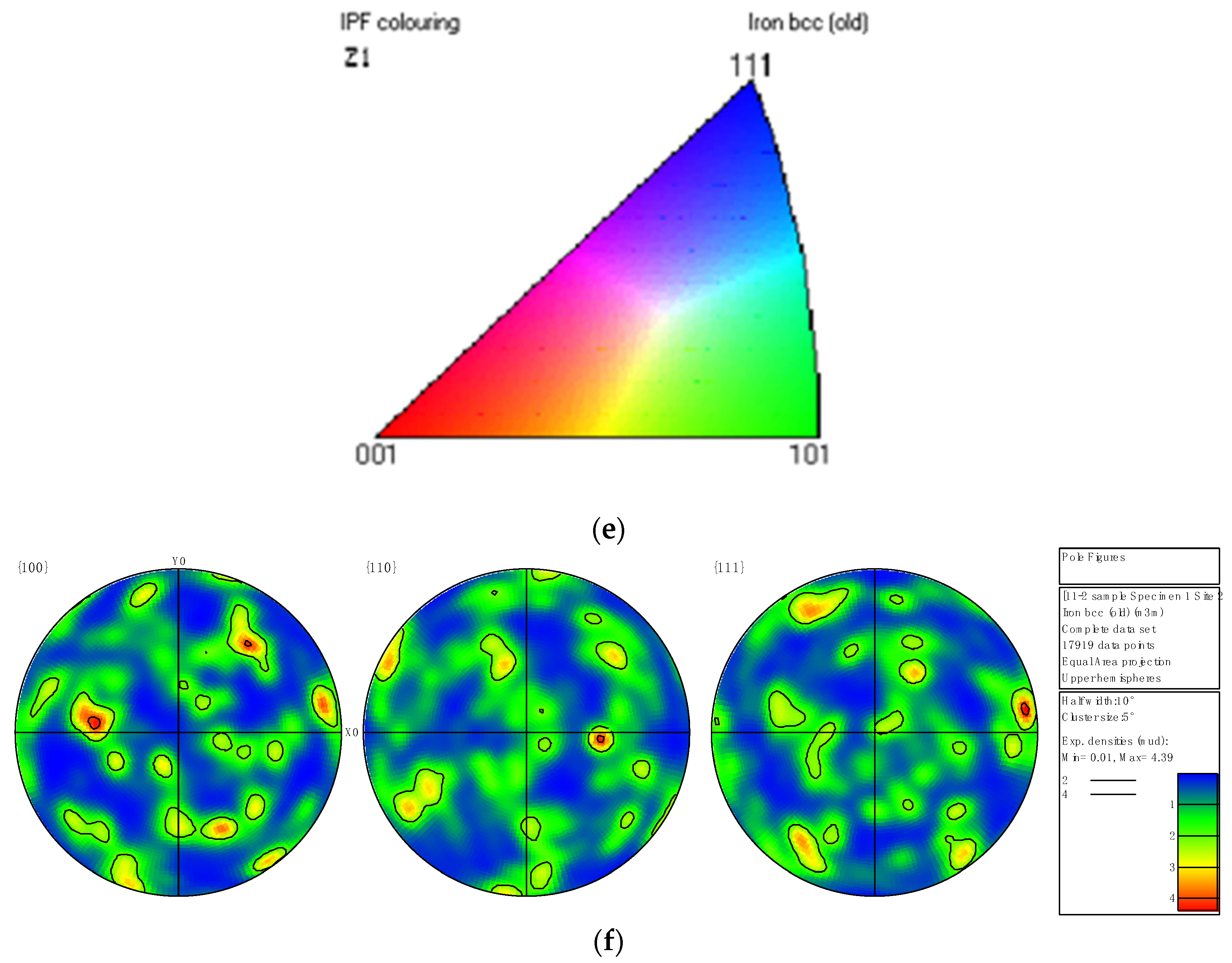

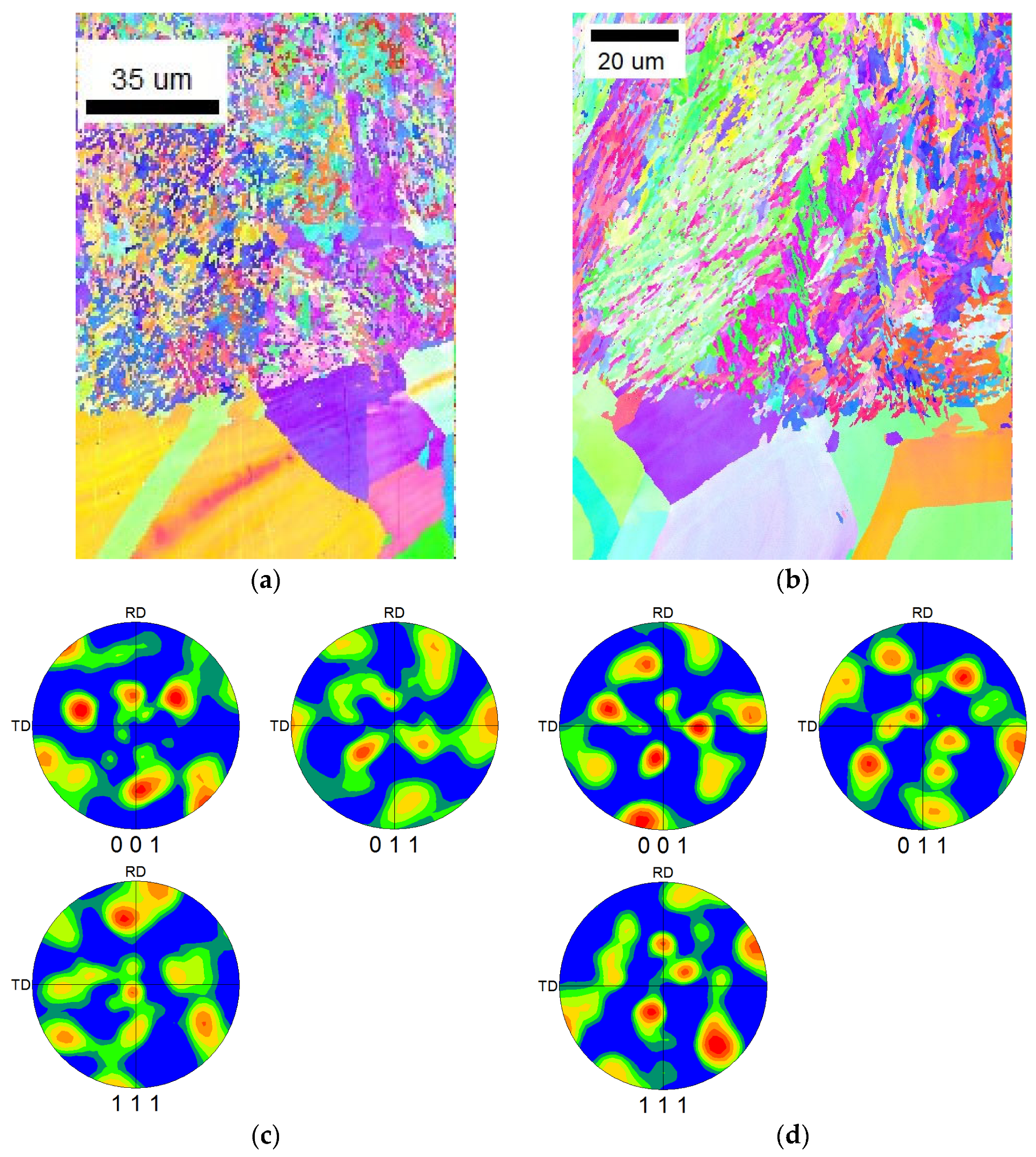

3.3. Crystallographic Orientations

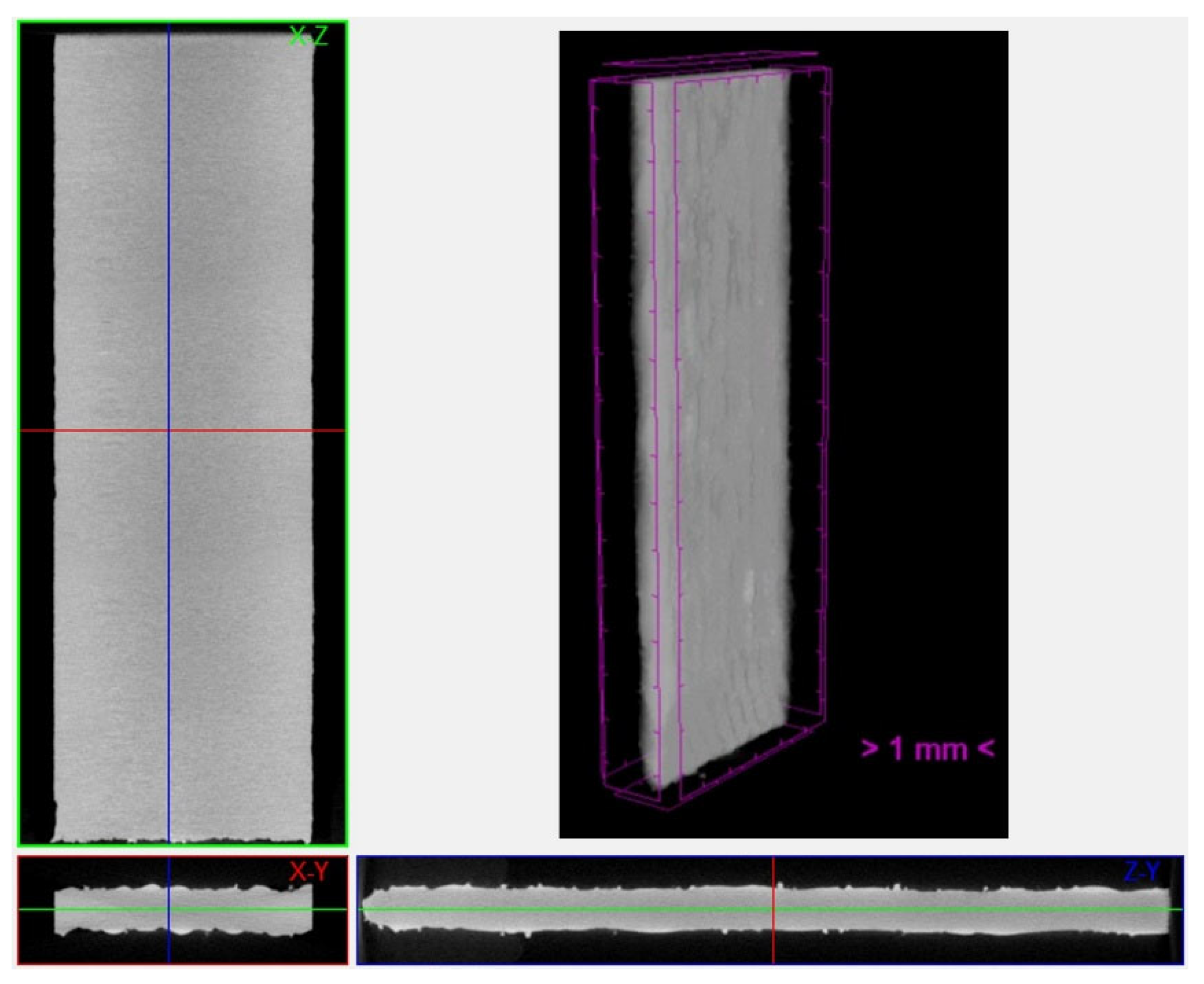

3.4. Tomograph

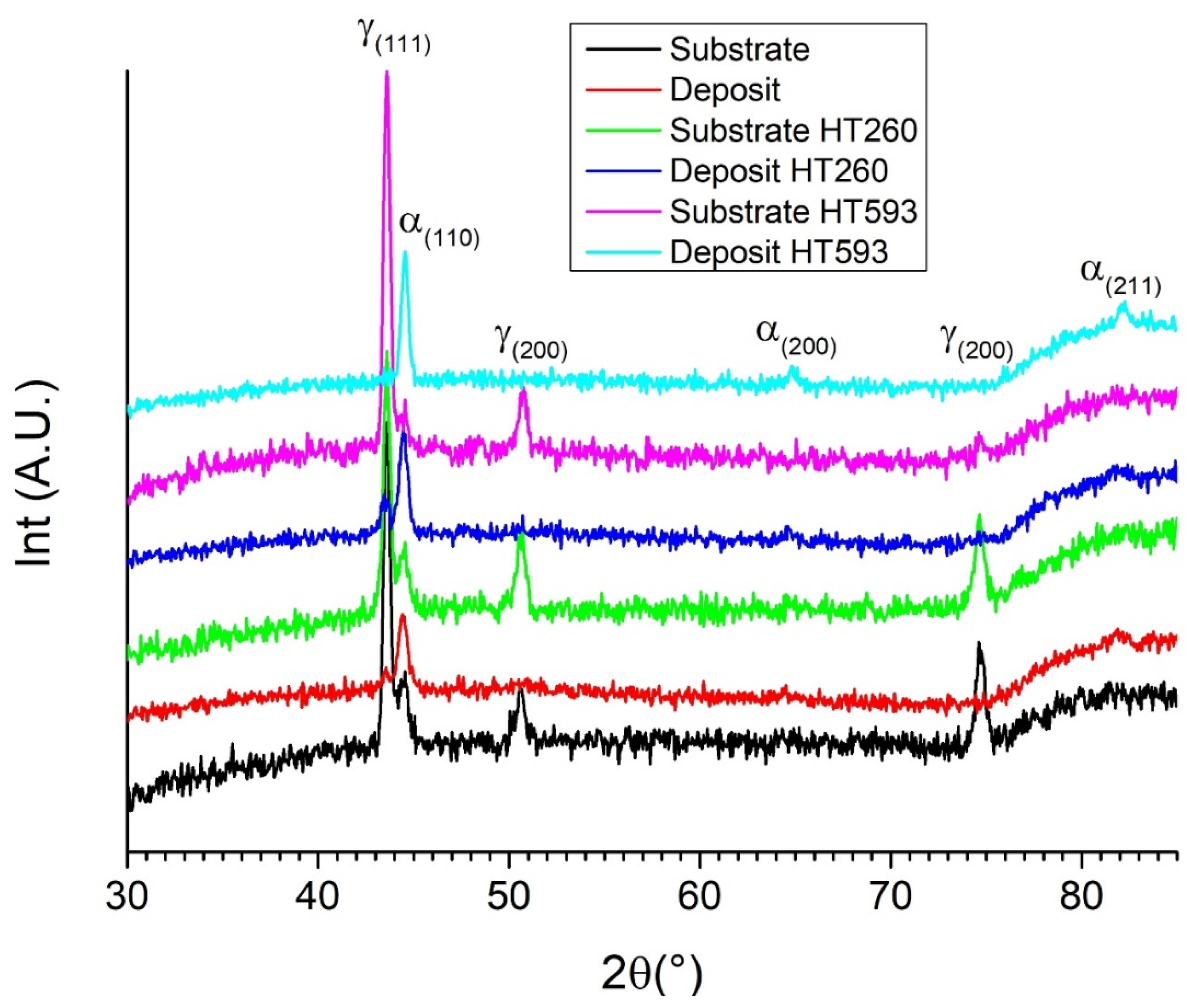

3.5. X-Ray Diffractometry

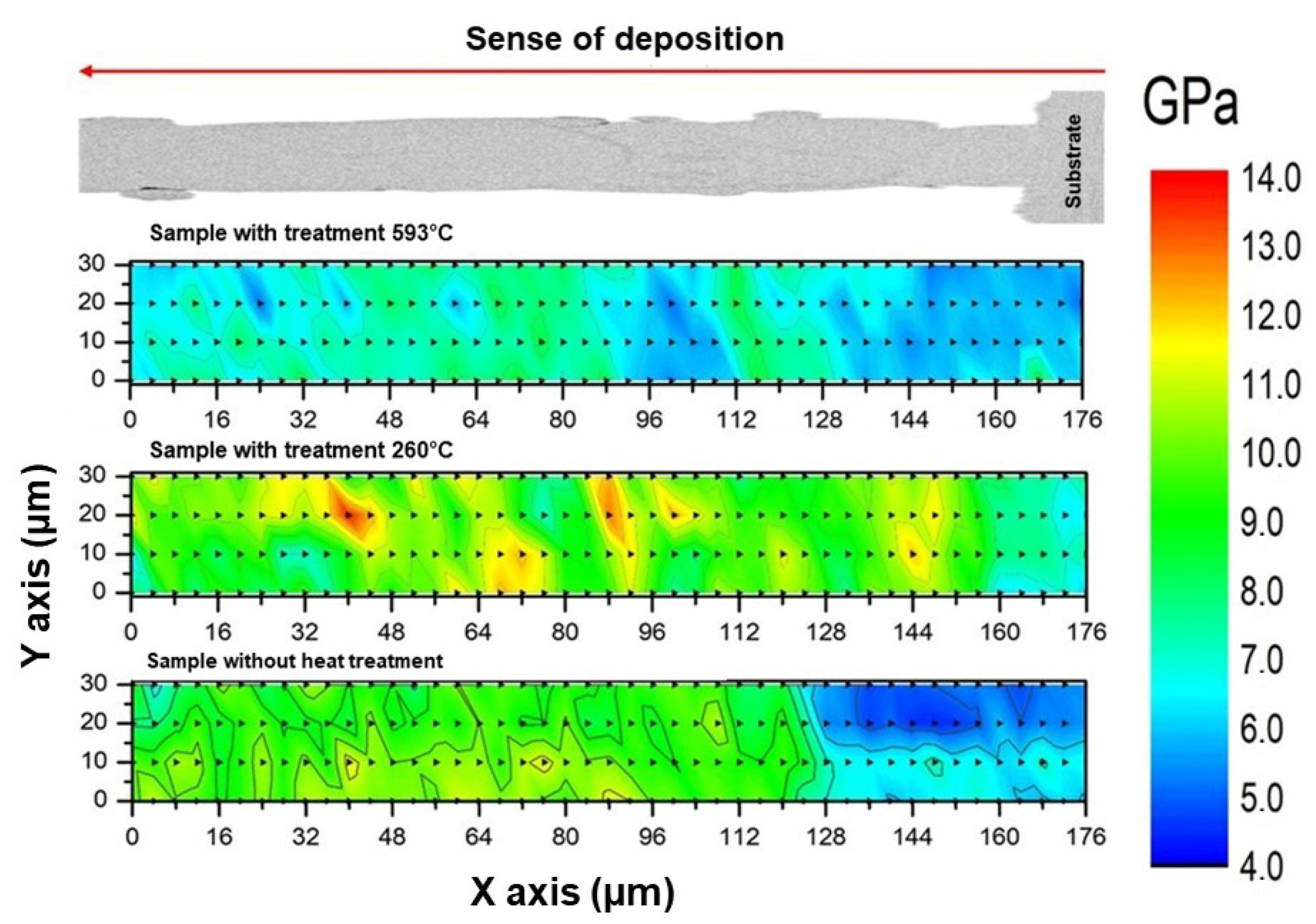

3.6. Nanoindentation

3.7. Residual Stresses

3.8. Roughness

3.9. Salt Spray Corrosion

4. General Discussion

4.1. Comparison with Previous Studies

4.2. Effect of Processing Parameters

4.3. Impact of Heat Treatment

4.4. Performance of Different Blade Geometries

4.5. Practical Implications

4.6. Future Perspectives

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Badiru, A.B. Comprehensive project management of high-end additive manufacturing equipment. In Additive Manufacturing Handbook; CRC Press: Boca Raton, FL, USA, 2018; pp. 37–48. [Google Scholar]

- Kumar, S.A.; Prasad, R.V.S. Basic principles of additive manufacturing: Different additive manufacturing technologies. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 17–35. [Google Scholar]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of directed energy deposition-based additive manufacturing in repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Blaha, R.; Hajnys, J.; Mesicek, J.; Mechali, A.; Krisak, D.; Pagac, M. Review of Directed Energy Deposition (DED) in Component Repair. In International conference on From Smart City to Smart Factory for Sustainable Future; Springer Nature: Cham, Switzerland, 2024; pp. 197–205. [Google Scholar]

- Tarancón, A.; Esposito, V. 3D Printing for Energy Applications; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Singh, A. Production, Fabrication, Selection of Stainless Steel; Dolphin Books: New Delhi, India, 1991. [Google Scholar]

- Lu, Z.L.; Li, D.C.; Tong, Z.Q.; Lu, Q.P.; Traore, M.M.; Zhang, A.F.; Lu, B.H. Investigation into the direct laser forming process of steam turbine blade. Opt. Lasers Eng. 2011, 49, 1101–1110. [Google Scholar] [CrossRef]

- Lu, Z.L.; Zhang, A.F.; Tong, Z.Q.; Yang, X.H.; Li, D.C.; Lu, B.H. Fabricating the steam turbine blade by direct laser forming. Mater. Manuf. Process. 2011, 26, 879–885. [Google Scholar] [CrossRef]

- Lucacci, G. Steels and alloys for turbine blades in ultra-supercritical power plants. In Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants; Woodhead Publishing: New Delhi, Delhi, 2017; pp. 175–196. [Google Scholar]

- Özdemir, N. Investigation of the mechanical properties of friction-welded joints between AISI 304L and AISI 4340 steel as a function rotational speed. Mater. Lett. 2005, 59, 2504–2509. [Google Scholar] [CrossRef]

- Sabri, K.; Si-Chaib, M.O.; Gaceb, M. Effect of Rejuvenation Heat Treatment on the Degraded Turbine Blades. J. Fail. Anal. Prev. 2021, 21, 74–82. [Google Scholar] [CrossRef]

- ASTM E407-99; Standard Practice for Microetching Metals and Alloys. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/e0407-99.html (accessed on 12 May 2025).

- ASTM D1654; Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments. American Society for Testing and Materials: West Conshohocken, PA, USA, 2024. Available online: https://store.astm.org/d1654-08r16e01.html (accessed on 12 May 2025).

- Boulila, A.; Boujelbene, M.; Fekiri, C.; Hammami, A. Optimization of manufacturing complex-shaped gas turbine blades. Measurement 2019, 135, 768–781. [Google Scholar] [CrossRef]

- Vdovin, R.A.; Smelov, V.G.; Sufiiarov, V.S.; Borisov, E.V. Designing of the digital casting process for the gas turbine engine blades with a single-crystal structure. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2018; Volume 441. [Google Scholar]

- Bansod, A.V.; Patil, A.P.; Verma, J.; Shukla, S. Microstructure, mechanical and electrochemical evaluation of dissimilar low Ni SS and 304 SS using different filler materials. Mater. Res. 2019, 22, e20170203. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Mahamood, R.M.; Akinlabi, S.A. Advanced Manufacturing Techniques Using Laser Material Processing. In Advances in Civil and Industrial Engineering; IGI Global: Hershey, PA, USA, 2016. [Google Scholar]

- Senthilkumaran, K.; Pandey, P.M.; Rao, P.V.M. Influence of building strategies on the accuracy of parts in selective laser sintering. Mater. Des. 2009, 30, 2946–2954. [Google Scholar] [CrossRef]

- Dauntless Flight School, Airfoil Design. Available online: http://faatest.com/books/flt/chapter17/airfoildesign.htm (accessed on 12 May 2025).

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Kong, C.; Adabifiroozjaei, E.; Li, S. Microstructure, post thermal treatment response, and tribological properties of 3D printed 17-4 PH stainless steel. Wear 2020, 456–457, 203367. [Google Scholar] [CrossRef]

- Xu, N.; Shen, J.; Zhou, J.; Hu, S. Microstructure and Pitting Corrosion Resistance of AISI 430 Ferritic Stainless Steel Joints Fabricated by Ultrasonic Vibration Assisted Cold Metal Transfer Technique. Metals 2022, 12, 382. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E.; Sherif, M.Y. Phase Transformations in Metals and Alloys; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Khoshnaw, F. (Ed.) Welding of Metallic Materials Methods, Metallurgy, and Performance; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- ASTM E407-99; Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 1999.

- Hemmati, I.; Ocelík, V.; De Hosson, J.T.M. Microstructural characterization of AISI 431 martensitic stainless steel laser-deposited coatings. J. Mater. Sci. 2011, 46, 3405–3414. [Google Scholar] [CrossRef]

- Liu, Y.; Li, A.; Cheng, X.; Zhang, S.Q.; Wang, H.M. Effects of heat treatment on microstructure and tensile properties of laser melting deposited AISI 431 martensitic stainless steel. Mater. Sci. Eng. A 2016, 666, 27–33. [Google Scholar] [CrossRef]

- Yin, Y.; Tan, Q.; Bermingham, M.; Mo, N.; Zhang, J.; Zhang, M.X. Laser additive manufacturing of steels. Int. Mater. Rev. 2022, 67, 487–573. [Google Scholar] [CrossRef]

- Dowling, N.E.; Kampe, S.L.; Vanlandingham Kral, M. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Lima, A.S.; Nascimento, A.M.; Abreu, H.F.G.; De Lima-Neto, P. Sensitization evaluation of the austenitic stainless steel AISI 304L, 316L, 321 and 347. J. Mater. Sci. 2005, 40, 139–144. [Google Scholar] [CrossRef]

- Doerr, C.; Kim, J.Y.; Singh, P.; Wall, J.J.; Jacobs, L.J. Evaluation of sensitization in stainless steel 304 and 304L using nonlinear Rayleigh waves. NDT E Int. 2017, 88, 17–23. [Google Scholar] [CrossRef]

- Fonda, R.W.; Rowenhorst, D.J. Crystallographic Variability in Additive Manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1249, 012007. [Google Scholar] [CrossRef]

- Kim, D.-K.; Woo, W.; Kim, E.-Y.; Choi, S.-H. Microstructure and mechanical characteristics of multi-layered materials composed of 316L stainless steel and ferritic steel produced by direct energy deposition. J. Alloys Compd. 2019, 774, 896–907. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, P.; Alizadeh-Sh, M. Welding metallurgy of dissimilar AISI 430/DQSK steels resistance spot welds. Weld. J. 2015, 94, 203s–210s. [Google Scholar]

- Gan, W.; Huang, Z.; Liu, C.; Wang, Y.; Zhang, H.; Ni, H. Effect of Mg treatment on inclusion behaviors in 430 ferritic stainless steel during solidification. J. Mater. Res. Technol. 2024, 28, 3349–3364. [Google Scholar] [CrossRef]

- Margerit, P.; Weisz-Patrault, D.; Ravi-Chandar, K.; Constantinescu, A. Tensile and ductile fracture properties of as-printed 316L stainless steel thin walls obtained by directed energy deposition. Addit. Manuf. 2021, 37, 101664. [Google Scholar] [CrossRef]

- Scheuer, C.J.; Cardoso, R.P.; Mafra, M.; Brunatto, S.F. AISI 420 martensitic stainless steel low-temperature plasma assisted carburizing kinetics. Surf. Coat Technol. 2013, 214, 30–37. [Google Scholar] [CrossRef]

- Samuel, E.I.; Paulose, N.; Nandagopal, M.; Selvi, S.P.; Babu, S.N.; Mannan, S.L. Tensile deformation and work hardening behaviour of aisi 431 martensitic stainless steel at elevated temperatures. High Temp. Mater. Process. 2020, 38, 916–926. [Google Scholar] [CrossRef]

- Saboori, A.; Piscopo, G.; Lai, M.; Salmi, A.; Biamino, S. An investigation on the effect of deposition pattern on the microstructure, mechanical properties and residual stress of 316L produced by Directed Energy Deposition. Mater. Sci. Eng. A 2020, 780, 139179. [Google Scholar] [CrossRef]

- Kumaran, M.; Senthilkumar, V.; Justus Panicke, C.T.; Shishir, R. Investigating the residual stress in additive manufacturing of repair work by directed energy deposition process on SS316L hot rolled steel substrate. Mater. Today Proc. 2021, 47, 4475–4478. [Google Scholar] [CrossRef]

- Vyatskikh, A.L.; Wang, X.; Haley, J.; Zheng, B.; Valdevit, L.; Lavernia, E.J.; Schoenung, J.M. Residual stress mitigation in directed energy deposition. Mater. Sci. Eng. A 2023, 871, 144845. [Google Scholar] [CrossRef]

- Buono, V.T.L.; Gonzalez, B.M.; Andrade, M.S. Strain aging of AISI 430 ferritic stainless steel. Scr. Mater. 1997, 38, 185–190. [Google Scholar] [CrossRef]

- Lu, X.; Chiumenti, M.; Cervera, M.; Li, J.; Lin, X.; Ma, L.; Zhang, G.; Liang, E. Substrate design to minimize residual stresses in Directed Energy Deposition AM processes. Mater. Des. 2021, 202, 109525. [Google Scholar] [CrossRef]

| Type | C | S | Ni | Cr | Si | Fe |

|---|---|---|---|---|---|---|

| Substrate | 0.07 | 0.03 | 9.5 | 18.5 | 0.75 | ~Balance |

| Powder | 0.150–0.250 | 0.030 | 1.25–2.50 | 15.00–17.00 | 1.00 | ~Balance |

| Laser Power | Process Speed | Powder Flow |

|---|---|---|

| 400 W | 1800 mm·min−1 | 4.70 g·min−1 |

| 400 W | 2000 mm·min−1 | 4.70 g·min−1 |

| 450 W | 2000 mm·min−1 | 4.70 g·min−1 |

| 450 W | 1800 mm·min−1 | 8.42 g·min−1 |

| 450 W * | 2000 mm·min−1 * | 8.42 g·min−1 * |

| 450 W | 2200 mm·min−1 | 8.42 g·min−1 |

| Type | Pos. 1 | Pos. 2 | Pos. 3 | Average | StDev |

|---|---|---|---|---|---|

| Supersonic | −68 | −98 | −158 | −108 | 46 |

| Later | −209 | −95 | −113 | −139 | 61 |

| Clark | −109 | −129 | −179 | −139 | 36 |

| Arc | −120 | −242 | −110 | −157 | 73 |

| Laminar | −210 | −168 | −151 | −176 | 30 |

| Blade Geometries | Ra (µm) | Rz (µm) |

|---|---|---|

| Later | 23.3 | 324.7 |

| Supersonic | 24.9 | 259.9 |

| Arc | 28.1 | 248.6 |

| Laminar | 21.8 | 279.9 |

| Clark | 21.8 | 289.2 |

| Average ± Standard Deviation | 24 ± 3 | 278 ± 27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, C.C.d.A.; Siqueira, R.H.M.d.; Nuñez, J.G.; Mariani, F.E.; Coelho, R.T.; Chen, D.; Lima, M.S.F.d. Microstructural Characterization of Martensitic Stainless Steel Blades Manufactured by Directed Energy Deposition (DED). Metals 2025, 15, 612. https://doi.org/10.3390/met15060612

Ferreira CCdA, Siqueira RHMd, Nuñez JG, Mariani FE, Coelho RT, Chen D, Lima MSFd. Microstructural Characterization of Martensitic Stainless Steel Blades Manufactured by Directed Energy Deposition (DED). Metals. 2025; 15(6):612. https://doi.org/10.3390/met15060612

Chicago/Turabian StyleFerreira, Caroline Cristine de Andrade, Rafael Humberto Mota de Siqueira, Johan Grass Nuñez, Fábio Edson Mariani, Reginaldo Teixeira Coelho, Daolun Chen, and Milton Sérgio Fernandes de Lima. 2025. "Microstructural Characterization of Martensitic Stainless Steel Blades Manufactured by Directed Energy Deposition (DED)" Metals 15, no. 6: 612. https://doi.org/10.3390/met15060612

APA StyleFerreira, C. C. d. A., Siqueira, R. H. M. d., Nuñez, J. G., Mariani, F. E., Coelho, R. T., Chen, D., & Lima, M. S. F. d. (2025). Microstructural Characterization of Martensitic Stainless Steel Blades Manufactured by Directed Energy Deposition (DED). Metals, 15(6), 612. https://doi.org/10.3390/met15060612