Synthesis of Iron-Based and Aluminum-Based Bimetals: A Systematic Review

Abstract

1. Introduction

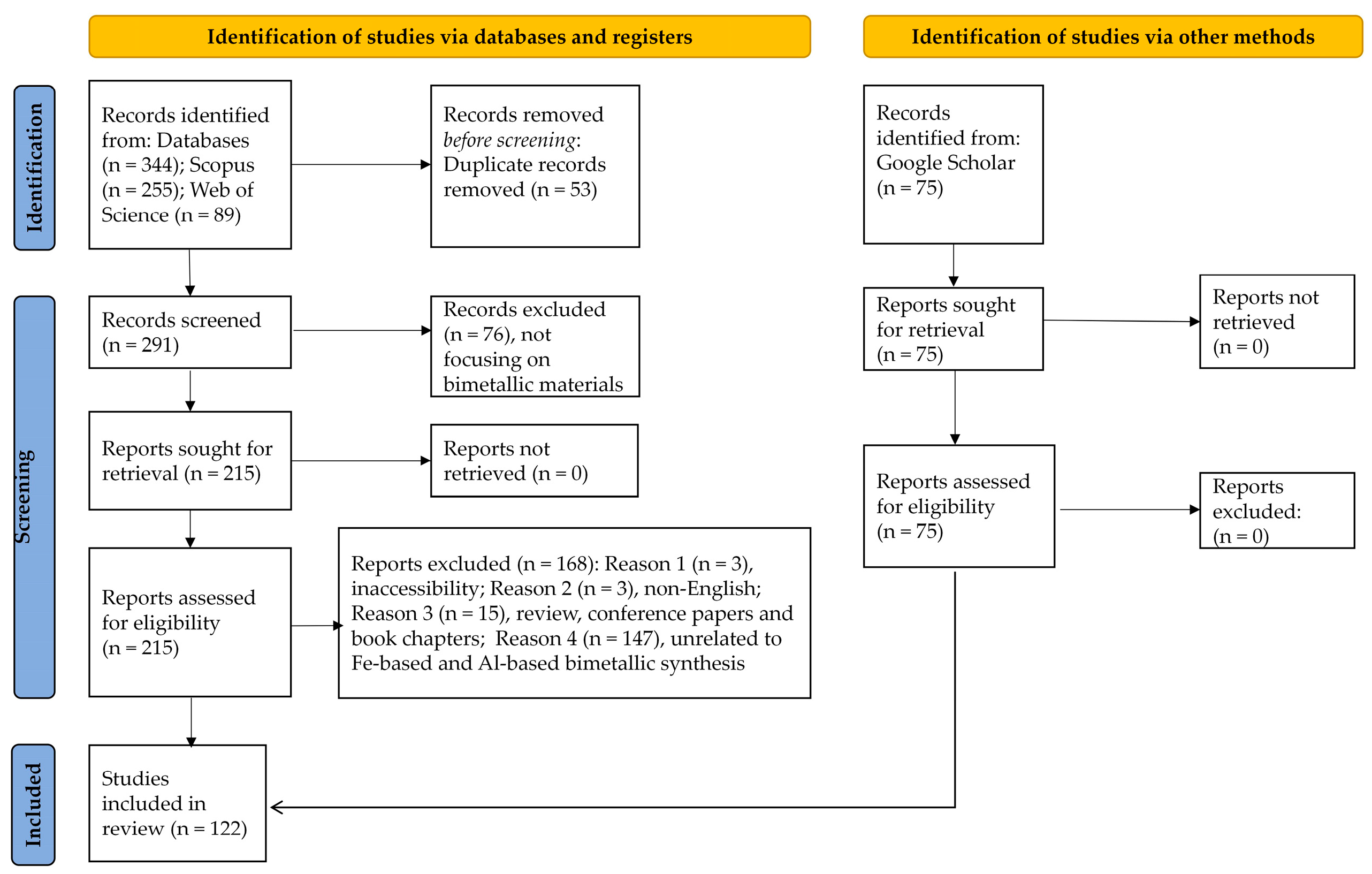

2. Materials and Methods

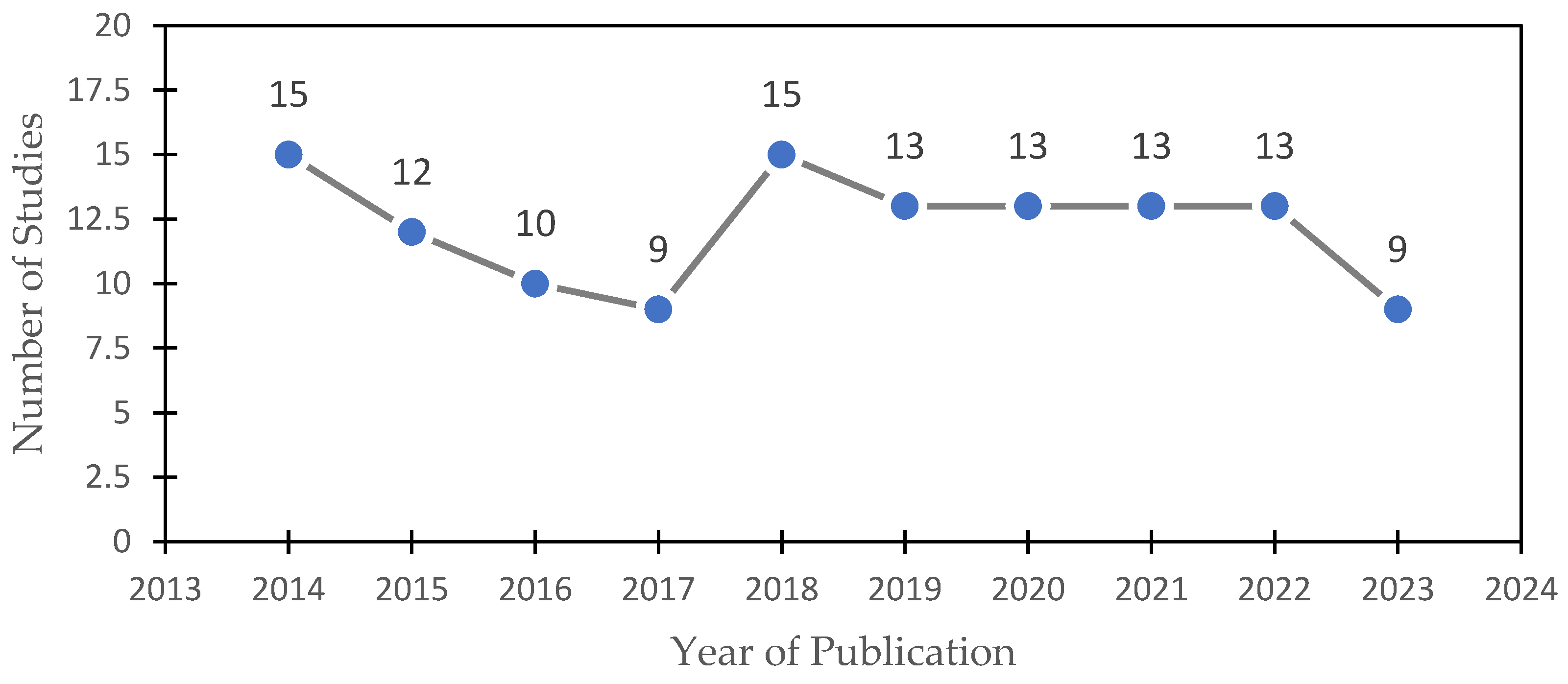

2.1. Bimetal Research Publication Trends

2.2. Active Countries

2.3. Active Journals

2.4. Active Institutions

2.5. Active Authors

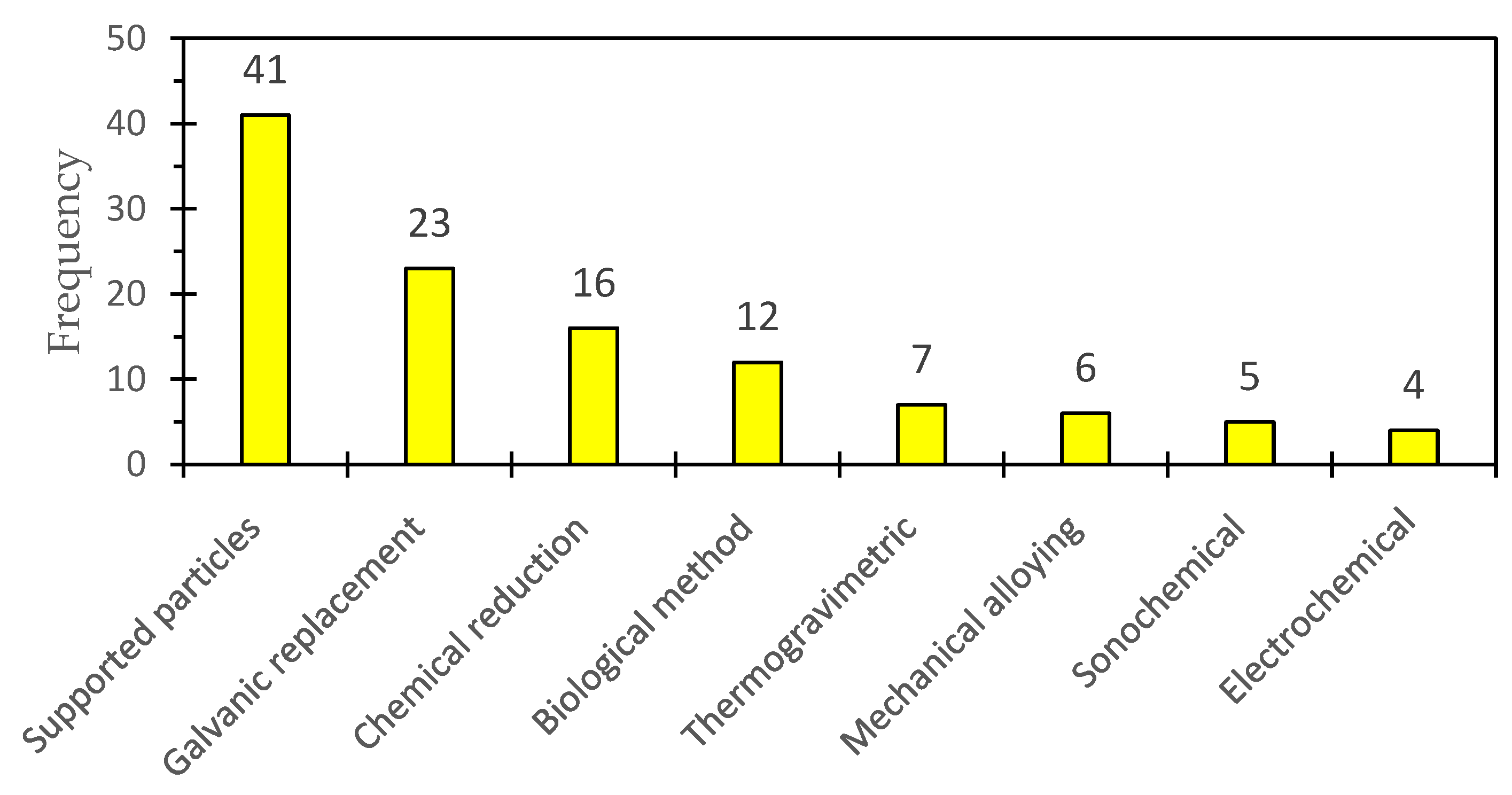

2.6. Most-Used Synthesis Methods

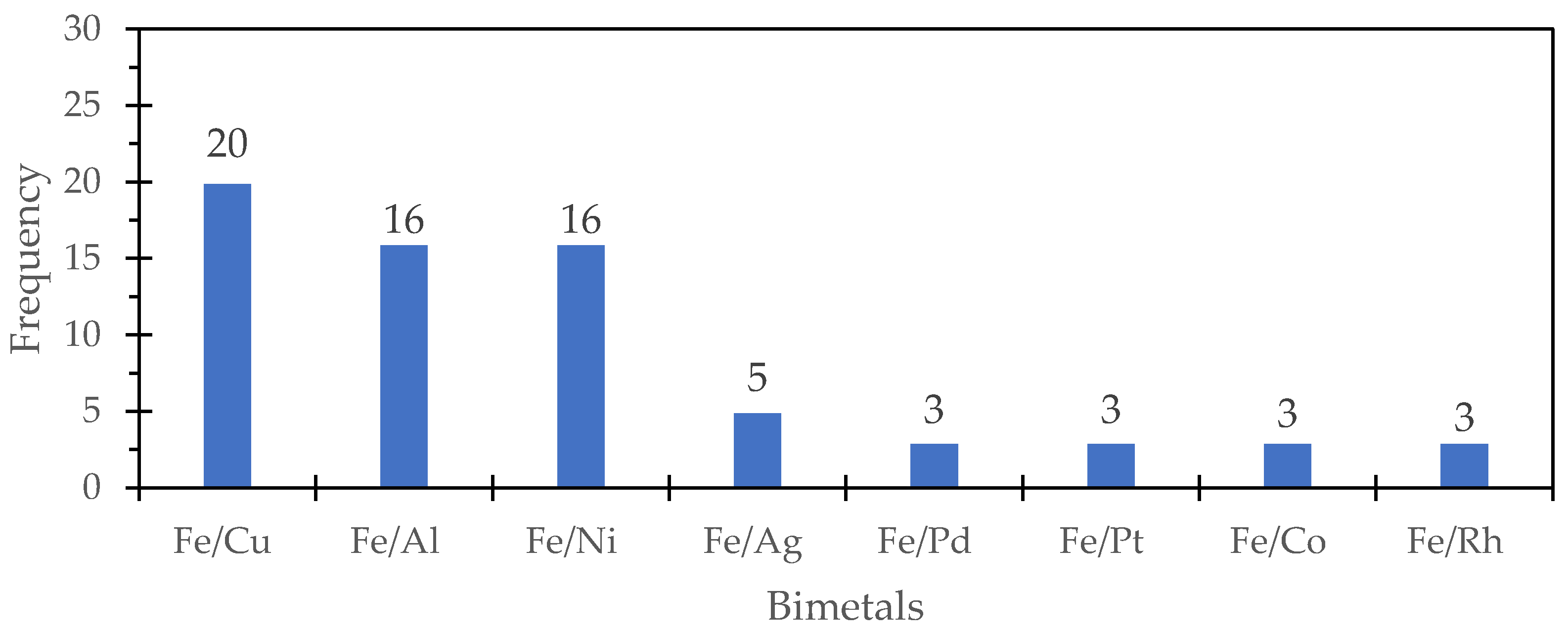

2.7. Most-Synthesized Iron-Based and Aluminum-Based Bimetals

3. Physical Methods for Synthesizing Iron-Based and Aluminum-Based Bimetals

3.1. Mechanical Alloying

| Bimetal System | Experimental Materials | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Fe-Cu/Al collar | Fe powder (99.9% pure @125 µm particle size), Cu powder (99.5% @100 µm particles size), aluminum collar substrate | Simple synthesis process Cost-effective Solid-state diffusion (non-melting process) Environmentally friendly process | Time-intensive in milling process Energy-intensive in milling process | [49] |

| Cu-Fe/CNT | Pure Fe powder, electrolytic Cu powder, and multi-walled carbon nanotubes (CNTs) | CNTs as reinforcement to Cu/Fe bimetals, application of controlled atmosphere (argon) | Time-intensive in milling process Energy-intensive in milling process Multi-step synthesis | [50] |

| Fe/Ag nanocomposite | Carbonyl Fe and Ag2O powders | Annealing process at 550 °C Vacuum-drying Controlled atmosphere (hexane + Ar) | Time intensive milling Energy-intensive milling Other energy requirements | [52] |

| Fe/Ag nanocomposite | Carbonyl Fe and Ag2O powders | Attrition milling in hexane under Ar Vacuum-drying Heat treatment at 550 °C in H2 | Time-intensive milling High-energy milling Other energy requirements | [53] |

| Fe/Ag, Fe/Cu nanocomposites | Carbonyl Fe, Ag nanoxide, Fe and cuprous oxide nanopowders | Attrition milling in hexane under Ar Consolidation process at 400 MPa Application of cold-sintering application of hydrogen treatment (450 °C) | Time-intensive milling High-energy milling Other energy requirements Material costs | [54] |

| Fe/Ag, Fe/Cu nanocomposites | Carbonyl Fe, silver oxide, Fe and cuprous oxide nanopowders | Attrition milling in hexane application of cold-sintering compression process at 3 GPa | Time-intensive milling High-energy milling Other energy requirements Material costs | [55] |

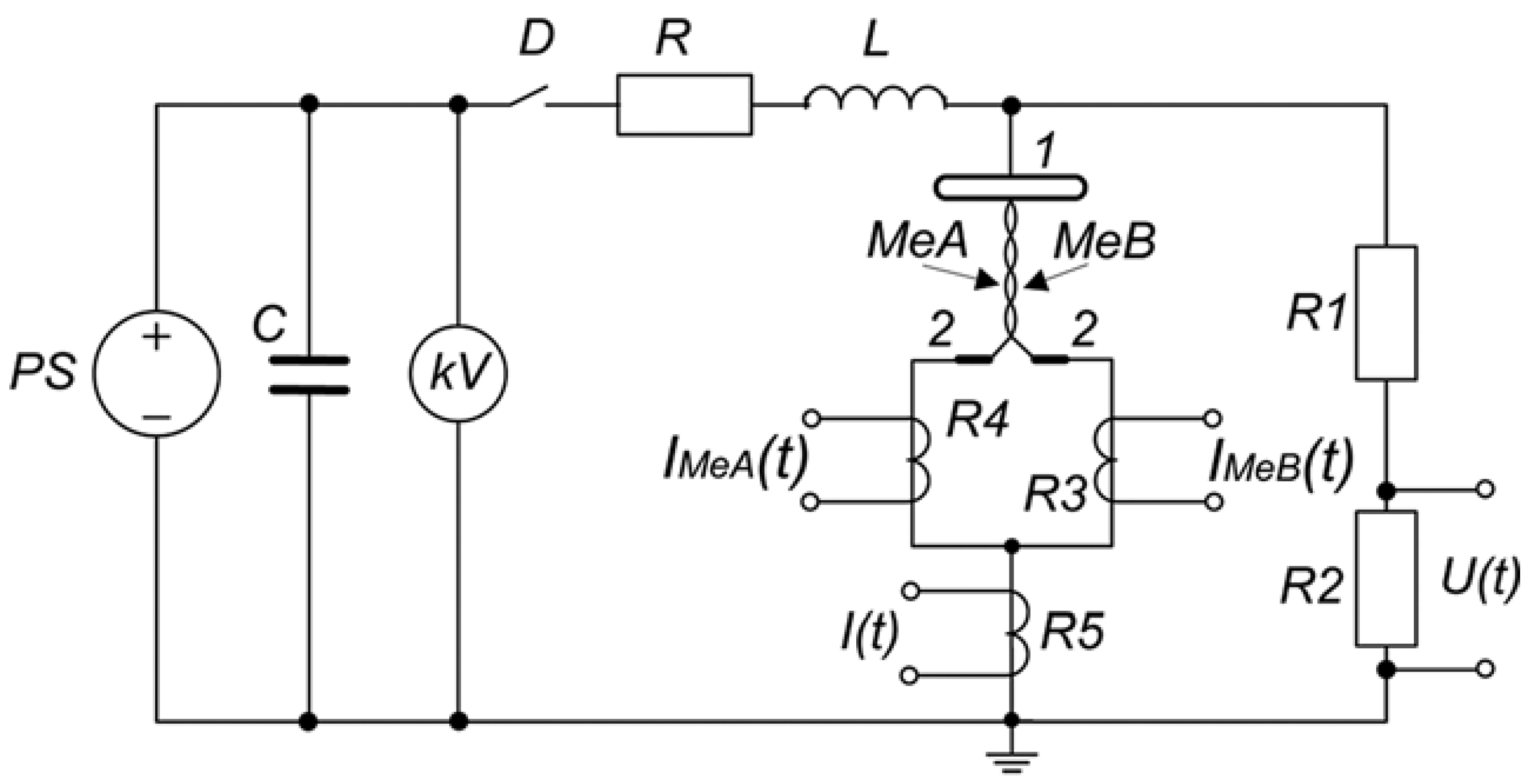

3.2. Electrical Explosion of Metal Wires

3.3. Radiolysis

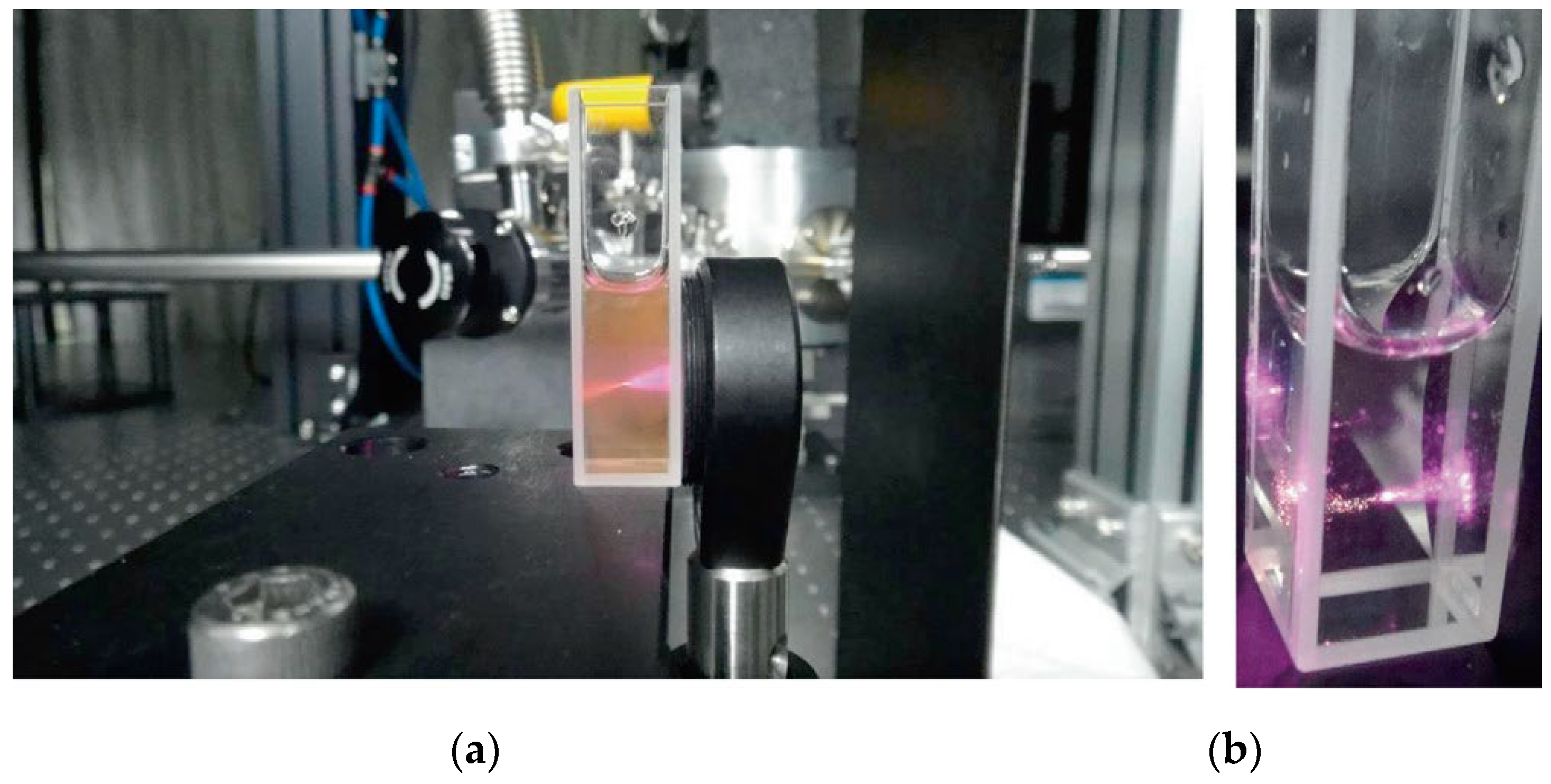

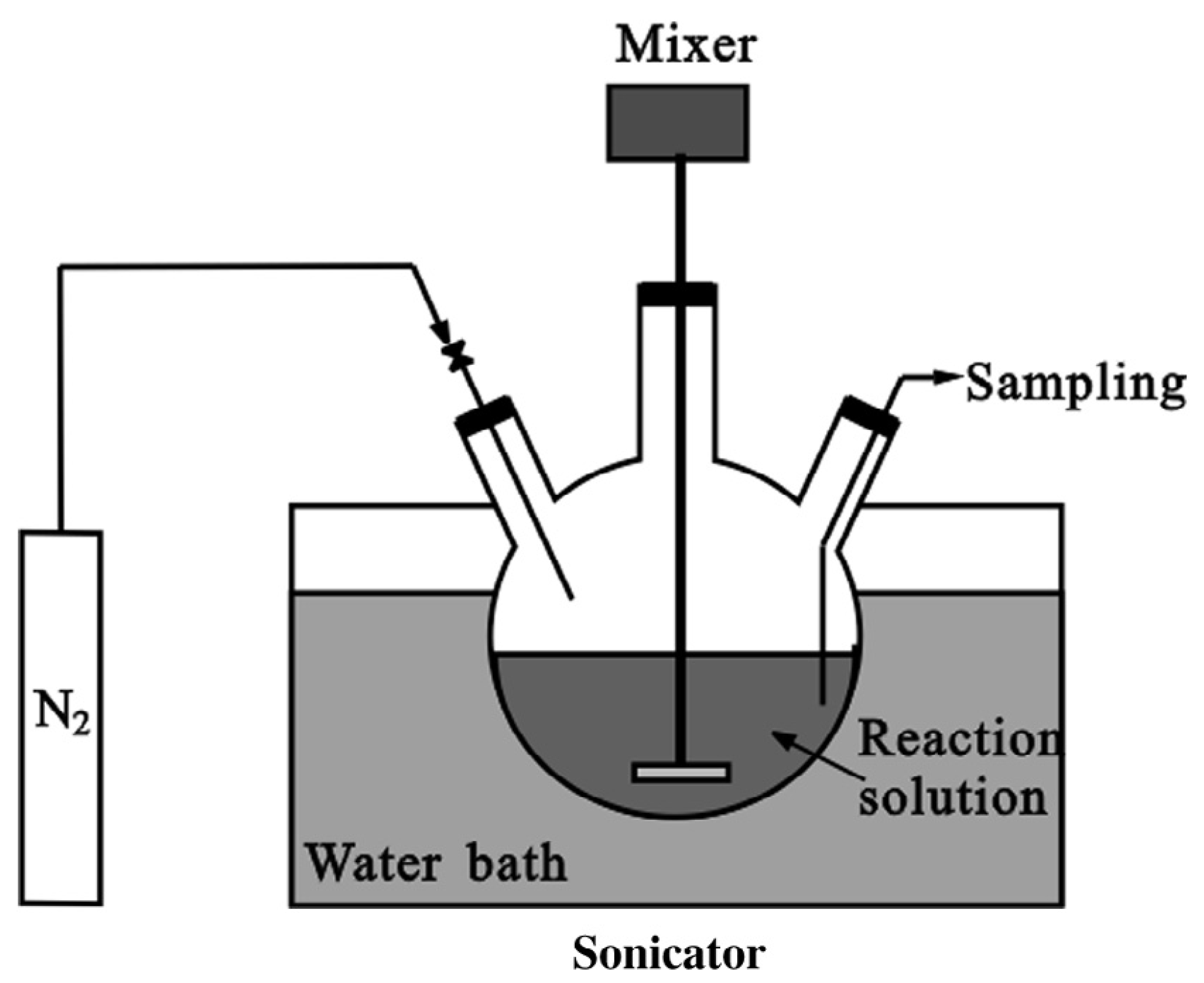

3.4. Sonochemical Method

| Bimetal System | Experimental Materials | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Ni/Fe | FeSO4·7H2O, NiSO4·6H2O, NaBH4 (reducing agent) | Mild synthesis conditions Sequential reduction process Versatile synthesis process | Multiple washing steps using deionized water | [69] |

| s-Fe/Cu | Sponge iron (s-Fe) particles, CuSO4·5H2O | Simple and fast process Low energy requirement Magnetic recoverability | Ultrasound equipment dependency | [70] |

| Fe/Cu-GO | FeSO4·7H2O, CuSO4·5H2O, graphene oxide (GO), NaBH4 (reducing agent) | Magnetic recoverability Low-cost process Graphene oxide as a support pH-neutral synthesis | Multi-step process | [71] |

| Fe-Mn/KB | Mn(NO3)2, Fe(NO3)3, melamine, ketjenblack carbon | Mild calcination conditions Nitrogen atmosphere calcination Carbon support integration (ketjenblack) | Energy requirements in calcination, heating ang drying Long duration of heating and drying requirements Multiple processing steps | [72] |

| Fe-Mn@SCAs | MnSO4, C6H5Na3O7·2H2O, K3[Fe(CN)6], corn starch | Eco-friendly support material High porosity of the bimetallic material | Time-intensive synthesis process Energy requirements in the synthesis Multi-step process | [73] |

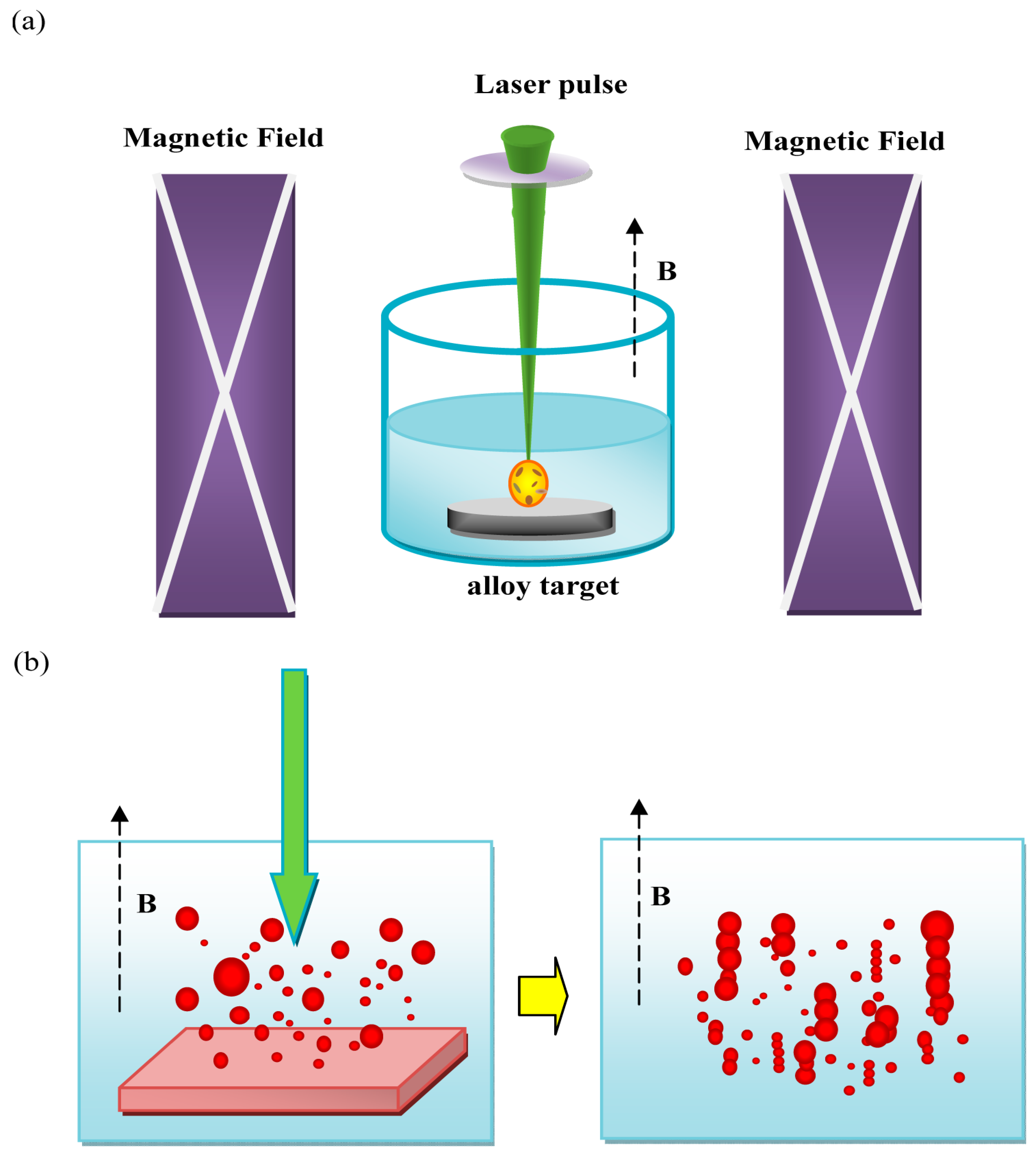

3.5. Magnetic Field-Assisted Laser Ablation in Liquid (MF-LAL)

3.6. Influence of Characteristics of Synthesized Bimetals by Physical Methods to Their Properties

4. Chemical Methods for Synthesizing Iron-Based and Aluminum-Based Bimetals

4.1. Chemical Reduction

4.2. Chemical Dealloying

4.3. Seed-Mediated Growth

4.4. Electrochemical Synthesis

4.5. Galvanic Replacement

| Bimetal System | Experimental Materials | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| Fe/Cu | Metal precursors: CuSO4, ZVI | Simple synthesis process Controlled Cu mass loading | High Cu loading can be costly (e.g., 1.26 g Cu/g Fe) | [123] |

| Fe/Cu | Metal precursors: CuSO4·5H2O, nZVI | Simple and controllable synthesis Storage of particles under nitrogen atmosphere | Energy requirements in the overall process Long processing time | [124,125] |

| Fe/Cu | Metal precursors: CuSO4·5H2O, nZVI | Controlled Cu loading Efficient Cu deposition Use of nitrogen atmosphere in the process | Multi-step synthesis method Drying requirements at 80 °C | [126] |

| Fe/Cu | Metal precursors: CuSO4, CuCl2, ZVI | Wide temperature range studied Variable Cu2+ concentrations Controlled Cu loading pH influence studied Stirring speed was also varied | Longer coverage of study Time-intensive study Material and cost considerations | [127] |

| Fe/Cu | Metal precursors: CuSO4·5H2O, nZVI | Simplicity of the process Controlled Cu loading and mixing speed Mild operating temperature (40 °C) Fixed Cu2+ concentration | Energy requirements in drying (40 °C for 40 min) | [128] |

| Fe/Cu | Metal precursors: CuSO4, ZVI | Use of electroless plating in the synthesis Fixed copper concentration (11.25 g/L CuSO4·5H2O) Controlled temperature (70 ± 1 °C) in the process Controlled agitation | Complex chemical system involvement of many chemicals Processing temperature requirements (70 ± 1 °C) | [129] |

| Fe/Cu | Metal precursors: CuSO4·5H2O, ZVI | Versatile synthesis method Controlled Cu/Fe mass ratio Room-temperature drying Use of argon atmosphere | Long drying time Refrigeration storage adds complexity | [130] |

| Fe/Al | Metal precursors: FeSO4, ZVAl | Simple synthesis method Rapid synthesis (15 min reaction time) Controlled Fe mass loading | Use of concentrated HCl | [131,132] |

| Fe/Al | Metal precursors: FeSO4·7H2O, ZVAl | Simple synthesis method Controlled pH in the synthesis Controlled addition of NaBH4 solution Use of nitrogen atmosphere | Energy-intensive process Long processing time | [133] |

| Mg/Fe | Metal precursors: FeSO4·7H2O, ZVMg | Simple and versatile synthesis method Rapid synthesis process (2 min reaction time) Controlled Mg/Fe ratios | High energy requirement for freeze-drying Long drying time | [134] |

| Fe/Al | Metal precursors: FeCl3·6H2O, ZVAl | Simple synthesis method Involving acid-washing of ZVAl particles Good control over Fe/Al ratio Mild reaction conditions | Requiring acid (HCl) pretreatment | [135,136] |

| Fe/Al | Metal precursors: FeSO4, ZVAl | Controlled Fe loading Al powder is pretreated with HCl and deionized water Use of nitrogen atmosphere | Use of HCl in acid pretreatment Long drying time | [137] |

| Fe/Al | Metal precursors: FeCl3, ZVAl | Simple synthesis Al powder is pretreated with HCl Controlled Fe loading Processing under ambient conditions | Use of HCl in acid pretreatment | [138] |

| Fe/Cu | Metal precursors: CuSO4·5H2O, ZVI | Simple synthesis method Rapid synthesis (15 min reaction time) Pretreatment of ZVI with dilute HCl Room-temperature drying Controlled Cu/Fe ratio Use of argon atmosphere in the process | Use of HCl in acid pretreatment Long drying time | [139] |

| Fe/Al | Metal precursors: FeCl2, Al alloys (1050, 2024, 3003, 5083, 6061, and 7075) | Simplicity and versatility of the process Mild temperature conditions (25–50 °C) Shorter reaction times (15–60 min) Magnetic recoverability of the particles | Involving different types of Al alloys (adds material cost) Dependence on acid (HCl) concentration | [140] |

| Fe/Al | Metal precursors: Ferric chloride, Al scrap | Simple synthesis process Efficient Fe deposition Pretreatment of Al scrap with HCl Use of Al scrap as ZVAl source | Use of HCl in acid pretreatment | [141] |

| Fe/Al | Metal precursors: FeCl3, Al scraps | Versatile and innovative synthesis method Controlled Fe deposition Mild drying conditions (40 °C) Adjustable reaction durations (0.5 to 6 h) Magnetic recoverability of the particles Use of Al scraps as ZVAl source | Labor-intensive process Long processing time (up to 6 h) | [142] |

| Fe/Al | Metal precursors: ZVI (source of Fe2+), ZVAl | Simple process Room-temperature drying Use of argon atmosphere | Long drying time (24 h) Use of strong acid (HCl) in the process Refrigerator storage requirement for the particles | [144,145] |

| Fe/Al | Metal precursors: ZVI (source of Fe2+), ZVAl | Simple process Room-temperature drying No acid (HCl) treatment involved Use of argon atmosphere | Long drying time (24 h) Refrigerator storage requirement for the particles | [146] |

4.6. Thermogravimetric Method

4.7. Supported Particles

4.7.1. Carbon-Based Materials as Support

4.7.2. Alumina (Al2O3) as Support

4.7.3. Silica as Support

4.7.4. Minerals as Supports

| Bimetal System | Experimental Materials | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| Be@Fe-Cu | Metal precursors: FeCl3∙6H2O, CuSO4∙5H2O Others: Bentonite, NaBH4 (reducing agent) Support: Bentonite (Be) | Mild synthesis conditions Sequential metal impregnation for controlled deposition Use of an inert argon atmosphere Magnetic recoverability of the particles | Multi-step synthesis process Long processing time | [193] |

| B-Fe/Ni | Metal precursors: FeCl3∙6H2O, NiSO4∙6H2O Others: Bentonite, NaBH4 Support: Bentonite (B) | Scalable and simple synthesis process Controlled chemical reduction via NaBH4 Use of inert nitrogen atmosphere | Energy-intensive drying requirement Long processing time | [194] |

| K-Fe/Pd | Metal precursors: FeCl3∙6H2O, CuCl2∙2H2O Others: Natural kaolinite, NaBH4 Support: Kaolinite (K) | Versatile synthesis process Ultrasonic treatment improves Pd deposition Use of inert nitrogen atmosphere | Energy-intensive drying requirement Multiple ethanol washing steps Long processing time | [197] |

| Cu/Fe@zeolite | Metal precursors: FeSO4·7H2O, CuCl2·2H2O Other(s): Zeolite Support: Zeolite | Multiple synthesis routes provide flexibility Simplicity of the synthesis methods Controlled stirring and centrifugation in the syntheses | Time-Consuming Processes Energy-intensive drying requirement for Cu/Fe@zeolite-2 synthesis | [200] |

| Di-Fe/Ni | Metal precursors: FeCl3∙6H2O, NiSO4∙6H2O Others: Diatomite (Di), NaBH4 Support: Diatomite (Di) | Simplicity and versatility of the synthesis Controlled addition of NaBH4 solution Use of nitrogen atmosphere | Multi-step process Multiple ethanol washing steps Pre-processing of diatomite is required Moderate temperature (60 °C) drying is required Long processing time | [201] |

| Pal-Fe/Ni | Metal precursors: FeCl3∙6H2O, NiSO4∙6H2O Others: Palygorskite, NaBH4 Support: Palygorskite (Pal) | Versatility of the synthesis method Controlled addition of NaBH4 solution Controlled stirring and centrifugation in the process Use of nitrogen atmosphere | Multi-step procedure Pre-processing of palygorskite is required Drying requirements of the overall process Long processing time | [202] |

| Sep-Fe/Ni | Metal precursors: FeCl3, NiSO4∙6H2O Others: Sepiolite, NaBH4 Support: Sepiolite (Sep) | Versatility of the process Controlled Ni/Fe composition Controlled addition of NaBH4 solution Use of nitrogen atmosphere | Drying requirements of the overall process Pre-processing of sepiolite is required Long processing time | [203] |

4.7.5. Other Material Supports

4.8. Influence of Characteristics of Synthesized Bimetals by Chemical Methods to Their Properties

5. Biological Methods for Synthesizing Iron-Based and Aluminum-Based Bimetals

| Bimetal System | Experimental Materials | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| Fe-Ni | Metal precursors: Fe(NO3)3, Ni(NO3)2 Reducing agent: Pithecellobium dulce legume mesocarp extract | Eco-friendly synthesis Simple and cost-effective Efficient metal ion reduction Surfactant-assisted stability Controlled nanoparticle formation | Process variability Longer preparation time (multi-step process) | [215] |

| Fe-Pd | Metal precursors: FeCl3·6H2O, PdCl2 Reducing agent: Eucalyptus leaf extract | Green synthesis approach Simple process Enhanced stability Reduced contamination | Variability in leaf extract composition Time-intensive preparation Energy consumption Limited reduction efficiency | [216] |

| Fe-Cu | Metal precursors: FeSO4·7H2O, CuSO4 Reducing agent: Green tea extract | Eco-friendly synthesis Controlled copper loading Improved stability Simple and scalable process | Time-consuming process Batch-to-batch variability Energy consumption Limited control over particle size | [217] |

| Fe-Cu | Metal precursors: FeSO4·7H2O, CuSO4·5H2O Reducing agent: Green tea extract | Green synthesis approach Simple and efficient process | Potential batch variability Energy consumption Limited control over particle size | [218] |

| C-Fe-Ni | Metal precursors: FeCl3·6H2O, NiCl2·6H2O Reducing agent: Eucalyptus leaf extract | Eco-friendly synthesis Cost-effective materials Simple preparation method Improved stability via calcination | Time-intensive process Batch-to-batch variability Energy-intensive steps Potential agglomeration | [219] |

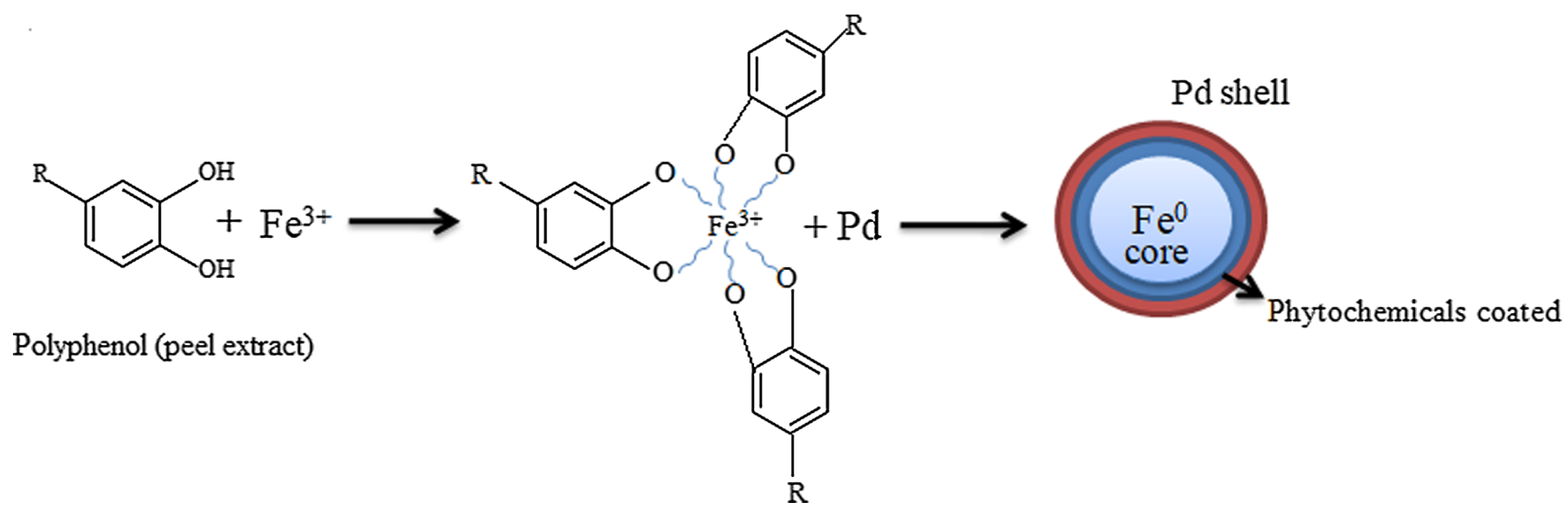

| Fe-Pd | Metal precursors: Fe (III) chloride, Potassium hexachloropalladate (IV) Reducing agent: Pomegranate peel extract | Eco-friendly synthesis Cost-effective and sustainable process Enhanced stability Controlled bimetallic composition | Time-intensive synthesis Batch-to-batch variability Energy consumption | [220] |

| Chitosan(CS)-stabilized Fe-Cu | Metal precursors: FeSO4·7H2O, CuSO4·5H2O Reducing agent: NaBH4 Stabilizing agent: Chitosan | Enhanced stability Controlled cu loading Efficient reduction process Oxygen-free synthesis | Energy-intensive process Complex synthesis procedure | [223] |

| Fe–Al bimetal chitosan bentonite (Fe–Al bimetal@bent) complex | Metal precursors: Fe2SO4, Al powder Stabilizing agents: Chitosan, Na-bentonite | Simple synthesis process Effective ph control Improved structural stability Vacuum-drying enhancing purity | Use of concentrated acid Energy and time-intensive drying process Centrifugation step complexity | [224] |

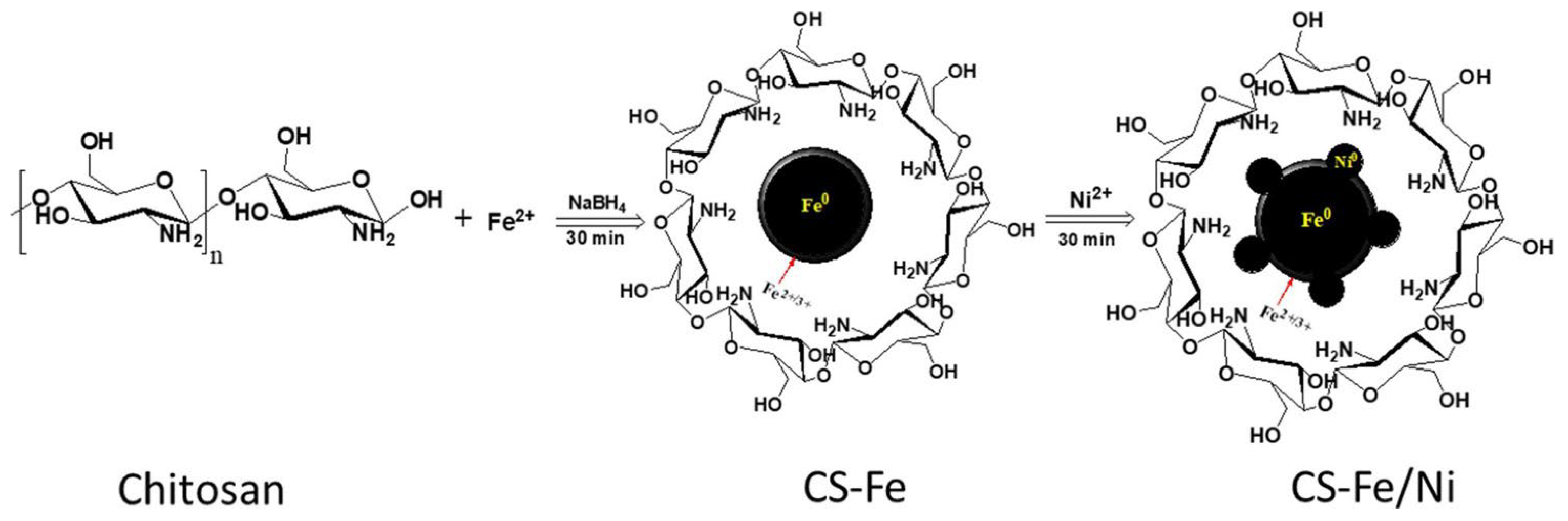

| Chitosan (CS)-Fe-Ni | Metal precursors: FeCl3·6H2O, NiSO4·6H2O Reducing agent: NaBH4 Stabilizing agent: Chitosan | Green synthesis approach Controlled reduction process Effective metal loading Lyophilization for long-term stability | Intricate synthesis method Labor-intensive process | [225] |

| Chitosan–Cu–Fe bimetal complex | Metal precursors: FeCl3·6H2O, NiSO4·6H2O Reducing agent: NaBH4 Stabilizing agent: Chitosan | Simple and efficient synthesis Good metal loading control Improved swelling properties | Chitosan involving acid dissolution Limited structural control | [226] |

| ZVFe–Cu/Alg–LS | Metal precursors: FeSO4·7H2O, CuSO4·5H2O Stabilizing agents: Sodium alginate, limestone | Environmentally friendly synthesis Improved stability Controlled release of zero-valent iron (ZVI) and copper | Multi-step process Requires multiple washing steps | [230] |

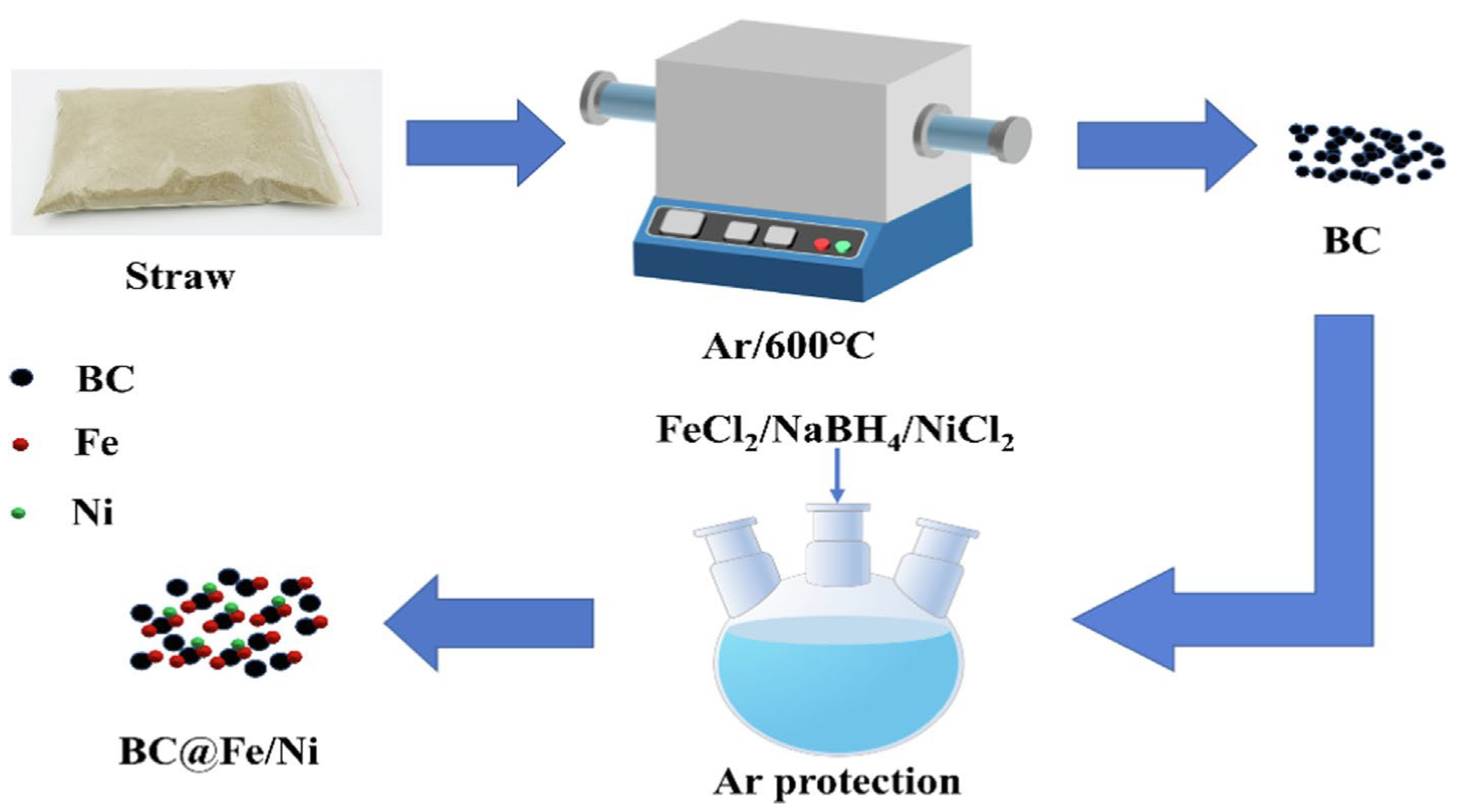

| Fe–Cu@MCC | Metal precursors: FeCl2·4H2O, CuCl2·2H2O Reducing agent: NaBH4 Stabilizing agent: Microcrystalline cellulose (MCC) | Magnetic recoverability of the catalysts Support material (MCC) improves stability MCC as biodegradable and nontoxic support | Complex multi-step process | [236] |

Influence of Characteristics of Synthesized Bimetals by Biological Methods to Their Properties

6. Summary and Future Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ZVMs | Zero-valent metals |

| ZVI | Zero-valent iron |

| HOCs | Halogenated organic compounds |

| TCE | Trichloroethylene |

| PCP | Pentachlorophenol |

| ZVAl | Zero-valent aluminum |

| AMD | Acid mine drainage |

| MF-LAL | Magnetic field-assisted laser ablation in liquid |

| PVP | Polyvinylpyrrolidone |

| TCD | Trisodium citrate dehydrate |

| PSTT | Potassium sodium tartrate tetrahydrate |

| EDTA | Disodium ethylenediaminetetraacetate dehydrate |

| En | Ethylenediamine |

| TEA | Triethanolamine |

| AAS | Atomic absorption spectroscopy |

| ORR | Oxygen reduction reaction |

| LDH | Layered double hydroxide |

| CNTs | Carbon nanotubes |

| MWCNTs | Multi-walled carbon nanotubes |

| CNF | Carbon nanofibers |

| PAN | Polyacrylonitrile |

| DMF | Dimethylformamide |

| MC | Mesoporous carbon |

| MB | Modified biochar |

| BC | Biochar |

| FMBC | Fe–Co-modified biochar |

| nZVIC-SBC | Fe-Cu-municipal sludge-derived biochar nanoparticles |

| ZF@CBC | Zn/Fe nanoparticles on corncob biochar (CBC) |

| AC | Activated carbon |

| PAC | Powder-activated carbon |

| CAC | Commercial activated carbon |

| ALD | Atomic layer deposition |

| PVDF | Polyvinylidene difluoride |

| HMS | Hollow mesoporous silica sphere |

| TMOS | Tetramethyl orthosilicate |

| CEC | Cation exchange capacity |

| Be@Fe-Cu | Fe-Cu on bentonite |

| B-Fe/Ni | Fe/Ni on bentonite |

| K-Fe/Pd | K-Fe/Pd on kaolinite |

| Cu/Fe@zeolite | Cu/Fe on zeolite |

| Di-Fe/Ni | Fe/Ni on diatomite |

| Pal-Fe/Ni | Fe/Ni on palygorskite |

| Sep-Fe/Ni | Fe/Ni on sepiolite |

| ASF@NC | N-doped carbon layer functionalized on aluminum silicate fibers |

| PDA | Polydopamine |

| PAM | Polyacrylamide |

| PEI | Polyethylenimine |

| Cu/Fe-BM@FA | Cu/Fe bimetallic modified fly ash |

| GT-nZVI/Cu | Green tea extract-based nZVI/Cu particles |

| C–Fe/Ni NPs | Calcined Fe/Ni nanoparticles |

| CMC | Carboxymethyl cellulose |

| CS | Chitosan |

| CS-Fe-Cu | Chitosan (CS)-stabilized Fe/Cu |

| Fe–Al bimetal @ bent | Fe–Al bimetal chitosan bentonite complex |

| Alg–LS | Alginate–limestone |

| Fe–Cu@MCC | Fe-Cu immobilized on microcrystalline cellulose |

References

- Yan, Z.; Ouyang, J.; Wu, B.; Liu, C.; Wang, H.; Wang, A.; Li, Z.A.B. Nonmetallic modified zero-valent iron for remediating halogenated organic compounds and heavy metals: A comprehensive review. Environ. Sci. Ecotechnol. 2024, 21, 100417. [Google Scholar] [CrossRef] [PubMed]

- Silwamba, M.; Ito, M.; Tabelin, C.B.; Park, I.; Jeon, S.; Takada, M.; Kubo, Y.; Hokari, N.; Tsunekawa, M.; Hiroyoshi, N. Simultaneous extraction and recovery of lead using citrate and micro-scale zero-valent iron for decontamination of polluted shooting range soils. Environ. Adv. 2021, 5, 100115. [Google Scholar] [CrossRef]

- Silwamba, M.; Ito, M.; Hiroyoshi, N.; Tabelin, C.B.; Fukushima, T.; Park, I.; Jeon, S.; Igarashi, T.; Sato, T.; Nyambe, I.; et al. Detoxification of lead-bearing zinc plant leach residues from Kabwe, Zambia by coupled extraction-cementation method. J. Environ. Chem. Eng. 2020, 8, 104197. [Google Scholar] [CrossRef]

- Silwamba, M.; Ito, M.; Hiroyoshi, N.; Tabelin, C.B.; Hashizume, R.; Fukushima, T.; Park, I.; Jeon, S.; Igarashi, T.; Sato, T.; et al. Alkaline leaching and concurrent cementation of dissolved Pb and Zn from zinc plant leach residues. Minerals 2022, 12, 393. [Google Scholar] [CrossRef]

- Seng, S.; Tabelin, C.B.; Kojima, M.; Hiroyoshi, N.; Ito, M. Galvanic microencapsulation (GME) using zero-valent aluminum and zero-valent iron to suppress pyrite oxidation. Mater. Trans. 2019, 60, 277–286. [Google Scholar] [CrossRef]

- Seng, S.; Tabelin, C.B.; Makino, Y.; Chea, M.; Phengsaart, T.; Park, I.; Hiroyoshi, N.; Ito, M. Improvement of flotation and suppression of pyrite oxidation using phosphate-enhanced galvanic microencapsulation (GME) in a ball mill with steel ball media. Miner. Eng. 2019, 143, 105931. [Google Scholar] [CrossRef]

- Choi, S.; Jeon, S.; Park, I.; Tabelin, C.B.; Ito, M.; Hiroyoshi, N. Enhanced cementation of Cd2+, Co2+, Ni2+, and Zn2+ on Al from sulfate solutions by activated carbon addition. Hydrometallurgy 2021, 201, 105580. [Google Scholar] [CrossRef]

- Jeon, S.; Bright, S.; Park, I.; Tabelin, C.B.; Ito, M.; Hiroyoshi, N. A simple and efficient recovery technique for gold ions from ammonium thiosulfate medium by galvanic interactions of zero-valent aluminum and activated carbon: A parametric and mechanistic study of cementation. Hydrometallurgy 2022, 208, 105815. [Google Scholar] [CrossRef]

- Chiu, P.C. Applications of zero-valent iron (ZVI) and nanoscale ZVI to municipal and decentralized drinking water systems—A review. Nov. Solut. Water Pollut. 2013, 237–249. [Google Scholar] [CrossRef]

- Fu, F.; Dionysiou, D.D.; Liu, H. The use of zero-valent iron for groundwater remediation and wastewater treatment: A review. J. Hazard. Mater. 2014, 267, 194–205. [Google Scholar] [CrossRef]

- Mueller, N.C.; Nowack, B. Nanoparticles for remediation: Solving big problems with little particles. Elements 2010, 6, 395–400. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, W.; Cai, Z.; Han, B.; Qian, T.; Zhao, D. An overview of preparation and applications of stabilized zero-valent iron nanoparticles for soil and groundwater remediation. Water Res. 2016, 100, 245–266. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.; Ito, M.; Tabelin, C.B.; Pongsumrankul, R.; Tanaka, S.; Kitajima, N.; Saito, A.; Park, I.; Hiroyoshi, N. A physical separation scheme to improve ammonium thiosulfate leaching of gold by separation of base metals in crushed mobile phones. Miner. Eng. 2019, 138, 168–177. [Google Scholar] [CrossRef]

- Jeon, S.; Tabelin, C.B.; Park, I.; Nagata, Y.; Ito, M.; Hiroyoshi, N. Ammonium thiosulfate extraction of gold from printed circuit boards (PCBs) of end-of-life mobile phones and its recovery from pregnant leach solution by cementation. Hydrometallurgy 2020, 191, 105214. [Google Scholar] [CrossRef]

- Chen, S.Y.; Chen, W.H.; Shih, C.J. Heavy metal removal from wastewater using zero-valent iron nanoparticles. Water Sci. Technol. 2008, 58, 1947–1954. [Google Scholar] [CrossRef]

- Wang, C.B.; Zhang, W.X. Synthesizing nanoscale iron particles for rapid and complete dechlorination of TCE and PCBs. Environ. Sci. Technol. 1997, 31, 2154–2156. [Google Scholar] [CrossRef]

- Cheng, S.F.; Wu, S.C. The enhancement methods for the degradation of TCE by zero-valent metals. Chemosphere 2000, 41, 1263–1270. [Google Scholar] [CrossRef]

- Sun, Y.; Li, J.; Huang, T.; Guan, X. The influences of iron characteristics, operating conditions and solution chemistry on contaminants removal by zero-valent iron: A review. Water Res. 2016, 100, 277–295. [Google Scholar] [CrossRef]

- Zaleska-Medynska, A.; Marchelek, M.; Diak, M.; Grabowska, E. Noble metal-based bimetallic nanoparticles: The effect of the structure on the optical, catalytic and photocatalytic properties. Adv. Colloid Interface Sci. 2016, 229, 80–107. [Google Scholar] [CrossRef]

- Rodriguez, J.A.; Goodman, D.W. The nature of the metal-metal bond in bimetallic surfaces. Science 1992, 257, 897–903. [Google Scholar] [CrossRef]

- Kitchin, J.R.; Nørskov, J.K.; Barteau, M.A.; Chen, J.G. Modification of the surface electronic and chemical properties of Pt(111) by subsurface 3d transition metals. J. Chem. Phys. 2004, 120, 10240–10246. [Google Scholar] [CrossRef] [PubMed]

- Guan, X.; Sun, Y.; Qin, H.; Li, J.; Lo, I.M.; He, D.; Dong, H. The limitations of applying zero-valent iron technology in contaminants sequestration and the corresponding countermeasures: The development in zero-valent iron technology in the last two decades (1994–2014). Water Res. 2015, 75, 224–248. [Google Scholar] [CrossRef]

- Huo, X.; Zhou, P.; Liu, Y.; Cheng, F.; Liu, Y.; Cheng, X.; Zhang, Y.; Wang, Q. Removal of contaminants by activating peroxymonosulfate (PMS) using zero valent iron (ZVI)-based bimetallic particles (ZVI/Cu, ZVI/Co, ZVI/Ni, and ZVI/Ag). RSC Adv. 2020, 10, 28232–28242. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Khatri, J.; Singh, T.A.; Gandhimathi, R.; Ramesh, S.T. Review of zero-valent aluminium based water and wastewater treatment methods. Chemosphere 2018, 200, 621–631. [Google Scholar] [CrossRef]

- Fu, F.; Cheng, Z.; Lu, J. Synthesis and use of bimetals and bimetal oxides in contaminants removal from water: A review. RSC Adv. 2015, 5, 85395–85409. [Google Scholar] [CrossRef]

- Sankar, M.; Dimitratos, N.; Miedziak, P.J.; Wells, P.P.; Kiely, C.J.; Hutchings, G.J. Designing bimetallic catalysts for a green and sustainable future. Chem. Soc. Rev. 2012, 41, 8099–8139. [Google Scholar] [CrossRef]

- Yu, W.; Porosoff, M.D.; Chen, J.G. Review of Pt-based bimetallic catalysis: From model surfaces to supported catalysts. Chem. Rev. 2012, 112, 5780–5817. [Google Scholar] [CrossRef]

- Bokare, A.D.; Choi, W. Zero-valent aluminum for oxidative degradation of aqueous organic pollutants. Environ. Sci. Technol. 2009, 43, 7130–7135. [Google Scholar] [CrossRef]

- Kim, J.; Choi, H.; Kim, D.; Park, J.Y. Operando surface studies on metal-oxide interfaces of bimetal and mixed catalysts. ACS Catal. 2021, 11, 8645–8677. [Google Scholar] [CrossRef]

- Scaria, J.; Nidheesh, P.V.; Kumar, M.S. Synthesis and applications of various bimetallic nanomaterials in water and wastewater treatment. J. Environ. Manag. 2020, 259, 110011. [Google Scholar] [CrossRef]

- Quiton, K.G.N.; Lu, M.C.; Huang, Y.H. Synthesis and catalytic utilization of bimetallic systems for wastewater remediation: A review. Chemosphere 2021, 262, 128371. [Google Scholar] [CrossRef]

- Liu, W.J.; Qian, T.T.; Jiang, H. Bimetallic Fe nanoparticles: Recent advances in synthesis and application in catalytic elimination of environmental pollutants. Chem. Eng. J. 2014, 236, 448–463. [Google Scholar] [CrossRef]

- Aryee, A.A.; Liu, Y.; Han, R.; Qu, L. Bimetallic adsorbents for wastewater treatment: A review. Environ. Chem. Lett. 2023, 21, 1811–1835. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef]

- Andrews, R. The place of systematic reviews in education research. Br. J. Educ. Stud. 2005, 53, 399–416. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. bmj 2021, 372, n71. [Google Scholar] [CrossRef]

- James, S.L.; Adams, C.J.; Bolm, C.; Braga, D.; Collier, P.; Friščić, T.; Grepioni, F.; Harris, K.D.M.; Hyett, G.; Jones, W.; et al. Mechanochemistry: Opportunities for new and cleaner synthesis. Chem. Soc. Rev. 2012, 41, 413–447. [Google Scholar] [CrossRef]

- Imawaka, K.; Sugita, M.; Takewaki, T.; Tanaka, S. Mechanochemical synthesis of bimetallic CoZn-ZIFs with sodalite structure. Polyhedron 2019, 158, 290–295. [Google Scholar] [CrossRef]

- Thakkar, K.N.; Mhatre, S.S.; Parikh, R.Y. Biological synthesis of metallic nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2010, 6, 257–262. [Google Scholar] [CrossRef]

- Chen, J.C.; Lin, Z.H.; Ma, X.X. Evidence of the production of silver nanoparticles via pretreatment of Phoma sp. 3.2883 with silver nitrate. Lett. Appl. Microbiol. 2003, 37, 105–108. [Google Scholar] [CrossRef]

- Li, Y.; Duan, X.; Qian, Y.; Yang, L.; Liao, H. Nanocrystalline silver particles: Synthesis, agglomeration, and sputtering induced by electron beam. J. Colloid Interface Sci. 1999, 209, 347–349. [Google Scholar] [CrossRef] [PubMed]

- Benjamin, J.S. Dispersion strengthened superalloys by mechanical alloying. Metall. Trans. 1970, 1, 2943–2951. [Google Scholar] [CrossRef]

- Lyu, H.; Gao, B.; He, F.; Ding, C.; Tang, J.; Crittenden, J.C. Ball-milled carbon nanomaterials for energy and environmental applications. ACS Sustain. Chem. Eng. 2017, 5, 9568–9585. [Google Scholar] [CrossRef]

- Wang, P.; Hu, J.; Liu, T.; Han, G.; Ma, W.M.; Li, J. New insights into ball-milled zero-valent iron composites for pollution remediation: An overview. J. Clean. Prod. 2023, 385, 135513. [Google Scholar] [CrossRef]

- Ai, D.; Wei, T.; Meng, Y.; Chen, X.; Wang, B. Ball milling sulfur-doped nano zero-valent iron@ biochar composite for the efficient removal of phosphorus from water: Performance and mechanisms. Bioresour. Technol. 2022, 357, 127316. [Google Scholar] [CrossRef]

- Gao, J.; Wang, W.; Rondinone, A.J.; He, F.; Liang, L. Degradation of trichloroethene with a novel ball milled Fe–C nanocomposite. J. Hazard. Mater. 2015, 300, 443–450. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, B.; He, F.; Bradley, M.J.; Tratnyek, P.G. Mechanochemically sulfidated microscale zero valent iron: Pathways, kinetics, mechanism, and efficiency of trichloroethylene dechlorination. Environ. Sci. Technol. 2017, 51, 12653–12662. [Google Scholar] [CrossRef]

- Friščić, T.; Mottillo, C.; Titi, H.M. Mechanochemistry for synthesis. Angew. Chem. 2020, 132, 1030–1041. [Google Scholar] [CrossRef]

- Hawili, A.A.; Ghommem, M.; Alami, A.H.; Alasad, S.; Egilmez, M.; Zaid, W.A. Utilizing aluminum sheets with FeCu deposits as cheap water cleaning electrodes. Appl. Surf. Sci. Adv. 2022, 7, 100193. [Google Scholar] [CrossRef]

- Vishlaghi, M.B.; Ataie, A. Investigation on solid solubility and physical properties of Cu–Fe/CNT nano-composite prepared via mechanical alloying route. Powder Technol. 2014, 268, 102–109. [Google Scholar] [CrossRef]

- Schoenitz, M.; Dreizin, E.L. Structure and properties of Al–Mg mechanical alloys. J. Mater. Res. 2003, 18, 1827–1836. [Google Scholar] [CrossRef]

- Sharipova, A.; Swain, S.K.; Gotman, I.; Starosvetsky, D.; Psakhie, S.G.; Unger, R.; Gutmanas, E.Y. Mechanical, degradation and drug-release behavior of nano-grained Fe-Ag composites for biomedical applications. J. Mech. Behav. Biomed. Mater. 2018, 86, 240–249. [Google Scholar] [CrossRef]

- Sharipova, A.; Gotman, I.; Psakhie, S.G.; Gutmanas, E.Y. Biodegradable nanocomposite Fe–Ag load-bearing scaffolds for bone healing. J. Mech. Behav. Biomed. Mater. 2019, 98, 246–254. [Google Scholar] [CrossRef]

- Sharipova, A.F.; Psakhie, S.G.; Gotman, I.; Gutmanas, E.Y. Smart nanocomposites based on Fe–Ag and Fe–Cu nanopowders for biodegradable high-strength implants with slow drug release. Phys. Mesomech. 2020, 23, 128–134. [Google Scholar] [CrossRef]

- Sharipova, A.F.; Psakhye, S.G.; Gotman, I.; Lerner, M.I.; Lozhkomoev, A.S.; Gutmanas, E.Y. Cold Sintering of Fe–Ag and Fe–Cu Nanocomposites by Consolidation in the High-Pressure Gradient. Russ. J. Non-Ferr. Met. 2019, 60, 162–168. [Google Scholar] [CrossRef]

- Romanova, V.M.; Ivanenkov, G.V.; Mingaleev, A.R.; Ter-Oganesyan, A.E.; Shelkovenko, T.A.; Pikuz, S.A. Electric explosion of fine wires: Three groups of materials. Plasma Phys. Rep. 2015, 41, 617–636. [Google Scholar] [CrossRef]

- Sahai, A.; Goswami, N.; Kaushik, S.D.; Tripathi, S. Cu/Cu2O/CuO nanoparticles: Novel synthesis by exploding wire technique and extensive characterization. Appl. Surf. Sci. 2016, 390, 974–983. [Google Scholar] [CrossRef]

- Park, G.H.; Lee, G.Y.; Kim, H.A.; Lee, A.Y.; Oh, H.R.; Kim, S.Y.; Kim, D.H.; Lee, M.H. Evaluation of alloying effect on the formation of Ni-Fe nanosized powders by pulsed wire discharge. Mater. Sci. Eng. B 2016, 212, 24–29. [Google Scholar] [CrossRef]

- Bland, S.N.; Krasik, Y.E.; Yanuka, D.; Gardner, R.; MacDonald, J.; Virozub, A.; Efimov, S.; Gleizer, S.; Chaturvedi, N. Generation of highly symmetric, cylindrically convergent shockwaves in water. Phys. Plasmas 2017, 24, 082702. [Google Scholar] [CrossRef]

- Shelkovenko, T.A.; Pikuz, S.A.; Hammer, D.A. A review of projection radiography of plasma and biological objects in X-pinch radiation. Plasma Phys. Rep. 2016, 42, 226–268. [Google Scholar] [CrossRef]

- Tokoi, Y.; Orikawa, T.; Suzuki, T.; Nakayama, T.; Suematsu, H.; Niihara, K. Phase Control of Ti–Fe Nanoparticles Prepared by Pulsed Wire Discharge. Jpn. J. Appl. Phys. 2011, 50, 01BJ06. [Google Scholar] [CrossRef]

- Ishihara, S.; Koishi, T.; Orikawa, T.; Suematsu, H.; Nakayama, T.; Suzuki, T.; Niihara, K. Synthesis of intermetallic NiAl compound nanoparticles by pulsed wire discharge of twisted Ni and Al wires. Intermetallics 2012, 23, 134–142. [Google Scholar] [CrossRef]

- Pervikov, A.; Glazkova, E.; Lerner, M. Energy characteristics of the electrical explosion of two intertwined wires made of dissimilar metals. Phys. Plasmas 2018, 25, 070701. [Google Scholar] [CrossRef]

- Lerner, M.I.; Psakhie, S.G.; Lozhkomoev, A.S.; Sharipova, A.F.; Pervikov, A.V.; Gotman, I.; Gutmanas, E.Y. Fe–Cu nanocomposites by high pressure consolidation of powders prepared by electric explosion of wires. Adv. Eng. Mater. 2018, 20, 1701024. [Google Scholar] [CrossRef]

- Chau, J.L.H.; Chen, C.Y.; Yang, C.C. Facile synthesis of bimetallic nanoparticles by femtosecond laser irradiation method. Arab. J. Chem. 2017, 10, S1395–S1401. [Google Scholar] [CrossRef]

- Suslick, K.S.; Fang, M.; Hyeon, T. Sonochemical synthesis of iron colloids. J. Am. Chem. Soc. 1996, 118, 11960–11961. [Google Scholar] [CrossRef]

- Gogate, P.R.; Sutkar, V.S.; Pandit, A.B. Sonochemical reactors: Important design and scale up considerations with a special emphasis on heterogeneous systems. Chem. Eng. J. 2011, 166, 1066–1082. [Google Scholar] [CrossRef]

- Shirsath, S.R.; Pinjari, D.V.; Gogate, P.R.; Sonawane, S.H.; Pandit, D.A. Ultrasound assisted synthesis of doped TiO2 nano-particles: Characterization and comparison of effectiveness for photocatalytic oxidation of dyestuff effluent. Ultrason. Sonochem. 2013, 20, 277–286. [Google Scholar] [CrossRef]

- Zhao, D.; Zheng, Y.; Li, M.; Baig, S.A.; Wu, D.; Xu, X. Catalytic dechlorination of 2, 4-dichlorophenol by Ni/Fe nanoparticles prepared in the presence of ultrasonic irradiation. Ultrason. Sonochem. 2014, 21, 1714–1721. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, Z.; Deng, D.; Ju, Y.; Ren, L.; Xiang, M.; Li, L.; Li, H. Synthesis of millimeter-scale sponge Fe/Cu bimetallic particles removing TBBPA and insights of degradation mechanism. Chem. Eng. J. 2017, 325, 279–288. [Google Scholar] [CrossRef]

- Tabrizian, P.; Ma, W.; Bakr, A.; Rahaman, M.S. pH-sensitive and magnetically separable Fe/Cu bimetallic nanoparticles supported by graphene oxide (GO) for high-efficiency removal of tetracyclines. J. Colloid Interface Sci. 2019, 534, 549–562. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Shi, P.; Wu, J.; Qi, X.; Liu, Y.; Li, G. Trace Bimetallic Iron/Manganese Co-Doped N-Ketjenblack Carbon Electrocatalyst for Robust Oxygen Reduction Reaction. J. Electrochem. Soc. 2021, 168, 060502. [Google Scholar] [CrossRef]

- Geng, C.; Lin, R.; Yang, P.; Liu, P.; Guo, L.; Fang, Y.; Cui, B. Mild routine to prepare Fe-Mn bimetallic nano-cluster (Fe-Mn NCs) and its magnetic starch-based composite adsorbent (Fe-Mn@ SCAs) for wide pH range adsorption for Hg (II) sewage. J. Taiwan Inst. Chem. Eng. 2023, 144, 104768. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, P.; Xiao, J.; Li, H.B.; Wang, C.X.; Yang, G.W. A general strategy for one-step fabrication of one-dimensional magnetic nanoparticle chains based on laser ablation in liquid. Laser Phys. Lett. 2014, 11, 056001. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, P.; Xiao, J.; Li, H.; Wang, C.; Yang, G. A microfibre assembly of an iron-carbon composite with giant magnetisation. Sci. Rep. 2013, 3, 3051. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, P.; Yang, G. Fabrication of one-dimensional chain of iron-based bimetallic alloying nanoparticles with unique magnetizations. Cryst. Growth Des. 2014, 14, 5847–5855. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y. Bimetallic nanocrystals: Liquid-phase synthesis and catalytic applications. Adv. Mater. 2011, 23, 1044–1060. [Google Scholar] [CrossRef]

- Gilroy, K.D.; Ruditskiy, A.; Peng, H.C.; Qin, D.; Xia, Y. Bimetallic nanocrystals: Syntheses, properties, and applications. Chem. Rev. 2016, 116, 10414–10472. [Google Scholar] [CrossRef]

- Raut, S.S.; Shetty, R.; Raju, N.M.; Kamble, S.P.; Kulkarni, P.S. Screening of zero valent mono/bimetallic catalysts and recommendation of Raney Ni (without reducing agent) for dechlorination of 4-chlorophenol. Chemosphere 2020, 250, 126298. [Google Scholar] [CrossRef]

- Ou, J.H.; Sheu, Y.T.; Tsang, D.C.; Sun, Y.J.; Kao, C.M. Application of iron/aluminum bimetallic nanoparticle system for chromium-contaminated groundwater remediation. Chemosphere 2020, 256, 127158. [Google Scholar] [CrossRef]

- Wang, Q.; Tian, C.; Shi, B.; Wang, D.; Feng, C. Efficiency and mechanism of micro-and nano-plastic removal with polymeric Al-Fe bimetallic coagulants: Role of Fe addition. J. Hazard. Mater. 2023, 448, 130978. [Google Scholar] [CrossRef] [PubMed]

- Sepúlveda, P.; Rubio, M.A.; Baltazar, S.E.; Rojas-Nunez, J.; Llamazares, J.S.; Garcia, A.G.; Arancibia-Miranda, N. As (V) removal capacity of FeCu bimetallic nanoparticles in aqueous solutions: The influence of Cu content and morphologic changes in bimetallic nanoparticles. J. Colloid Interface Sci. 2018, 524, 177–187. [Google Scholar] [CrossRef] [PubMed]

- Ulucan-Altuntas, K.; Kuzu, S.L. Modelling and optimization of dye removal by Fe/Cu bimetallic nanoparticles coated with different Cu ratios. Mater. Res. Express 2019, 6, 1150a4. [Google Scholar] [CrossRef]

- Abdel-Aziz, A.B.; Mohamed, N.; El-taweel, R.M.; Husien, S.; Fahim, I.S.; Said, L.A.; Radwan, A.G. Crystal violet removal using bimetallic Fe0–Cu and its composites with fava bean activated carbon. Results Eng. 2023, 20, 101420. [Google Scholar] [CrossRef]

- Muradova, G.G.; Gadjieva, S.R.; Di Palma, L.; Vilardi, G. Nitrates removal by bimetallic nanoparticles in water. Chem. Eng. Trans. 2016, 47, 205–210. [Google Scholar]

- Torres-Blancas, T.; Roa-Morales, G.; Ureña-Núñez, F.; Barrera-Díaz, C.; Dorazco-González, A.; Natividad, R. Ozonation enhancement by Fe–Cu biometallic particles. J. Taiwan Inst. Chem. Eng. 2017, 74, 225–232. [Google Scholar] [CrossRef]

- Naser, R.; Shahwan, T. Comparative assessment of the decolorization of aqueous bromophenol blue using Fe nanoparticles and Fe-Ni bimetallic nanoparticles. Desalination Water Treat. 2019, 159, 64416. [Google Scholar] [CrossRef]

- Weng, X.; Sun, Q.; Lin, S.; Chen, Z.; Megharaj, M.; Naidu, R. Enhancement of catalytic degradation of amoxicillin in aqueous solution using clay supported bimetallic Fe/Ni nanoparticles. Chemosphere 2014, 103, 80–85. [Google Scholar] [CrossRef]

- Zhou, X.; Jing, G.; Lv, B.; Zhou, Z.; Zhu, R. Highly efficient removal of chromium (VI) by Fe/Ni bimetallic nanoparticles in an ultrasound-assisted system. Chemosphere 2016, 160, 332–341. [Google Scholar] [CrossRef]

- Zhou, S.; Li, Y.; Chen, J.; Liu, Z.; Wang, Z.; Na, P. Enhanced Cr (VI) removal from aqueous solutions using Ni/Fe bimetallic nanoparticles: Characterization, kinetics and mechanism. RSC Adv. 2014, 4, 50699–50707. [Google Scholar] [CrossRef]

- Mansouriieh, N.; Sohrabi, M.R.; Khosravi, M. Adsorption kinetics and thermodynamics of organophosphorus profenofos pesticide onto Fe/Ni bimetallic nanoparticles. Int. J. Environ. Sci. Technol. 2016, 13, 1393–1404. [Google Scholar] [CrossRef]

- Liao, H.; Zhu, W.; Duan, T.; Zhang, Y.; He, G.; Wei, Y.; Zhou, J. Beaded segments like bi-metallic nano-zero-valent iron-titanium for the fast and efficient adsorption and reduction of U (VI) in aqueous solutions. Colloids Surf. A Physicochem. Eng. Asp. 2021, 613, 126080. [Google Scholar] [CrossRef]

- Koryam, A.A.; El-Wakeel, S.T.; Radwan, E.K.; Darwish, E.S.; Abdel Fattah, A.M. One-step room-temperature synthesis of bimetallic nanoscale zero-valent FeCo by hydrazine reduction: Effect of metal salts and application in contaminated water treatment. ACS Omega 2022, 7, 34810–34823. [Google Scholar] [CrossRef]

- Qureshi, S.S.; Memon, S.A.; Ram, N.; Saeed, S.; Mubarak, N.M.; Karri, R.R. Rapid adsorption of selenium removal using iron manganese-based micro adsorbent. Sci. Rep. 2022, 12, 17207. [Google Scholar] [CrossRef]

- Guo, D.J.; Ding, Y. Porous nanostructured metals for electrocatalysis. Electroanalysis 2012, 24, 2035–2043. [Google Scholar] [CrossRef]

- Shen, W.N.; Dunn, B.; Moore, C.D.; Goorsky, M.S.; Radetic, T.; Gronsky, R. Synthesis of nanoporous bismuth films by liquid-phase deposition. J. Mater. Chem. 2000, 10, 657–662. [Google Scholar] [CrossRef]

- Luo, H.; Sun, L.; Lu, Y.; Yan. Electrodeposition of mesoporous semimetal and magnetic metal films from lyotropic liquid crystalline phases. Langmuir 2004, 20, 10218–10222. [Google Scholar] [CrossRef]

- Wang, X.; Qi, Z.; Zhao, C.; Wang, W.; Zhang, Z. Influence of alloy composition and dealloying solution on the formation and microstructure of monolithic nanoporous silver through chemical dealloying of Al−Ag alloys. J. Phys. Chem. C 2009, 113, 13139–13150. [Google Scholar] [CrossRef]

- Chen, L.; Guo, H.; Fujita, T.; Hirata, A.; Zhang, W.; Inoue, A.; Chen, M. Nanoporous PdNi bimetallic catalyst with enhanced electrocatalytic performances for electro-oxidation and oxygen reduction reactions. Adv. Funct. Mater. 2011, 21, 4364–4370. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, M. Nanoporous metals for catalytic and optical applications. MRS Bull. 2009, 34, 569–576. [Google Scholar] [CrossRef]

- Han, B.; Xu, C. Nanoporous PdFe alloy as highly active and durable electrocatalyst for oxygen reduction reaction. Int. J. Hydrogen Energy 2014, 39, 18247–18255. [Google Scholar] [CrossRef]

- Tian, C.; Chen, D.; Lu, N.; Li, Y.; Cui, R.; Han, Z.; Zhang, G. Electrochemical bisphenol A sensor based on nanoporous PtFe alloy and graphene modified glassy carbon electrode. J. Electroanal. Chem. 2018, 830, 27–33. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, Y.W.; Tao, F.F. Shape control of bimetallic nanocatalysts through well-designed colloidal chemistry approaches. Chem. Soc. Rev. 2012, 41, 8050–8065. [Google Scholar] [CrossRef]

- Chen, S.; Jenkins, S.V.; Tao, J.; Zhu, Y.; Chen, J. Anisotropic seeded growth of Cu–M (M= Au, Pt, or Pd) bimetallic nanorods with tunable optical and catalytic properties. J. Phys. Chem. C 2013, 117, 8924–8932. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, W.; Fennell, D.E. Rapid dechlorination of 1, 2, 3, 4-TCDD by Ag/Fe bimetallic particles. Chem. Eng. J. 2015, 273, 465–471. [Google Scholar] [CrossRef]

- Huang, C.C.; Lo, S.L.; Lien, H.L. Vitamin B12-mediated hydrodechlorination of dichloromethane by bimetallic Cu/Al particles. Chem. Eng. J. 2015, 273, 413–420. [Google Scholar] [CrossRef]

- Zhou, X.J.; Harmer, A.J.; Heinig, N.F.; Leung, K.T. Parametric study on electrochemical deposition of copper nanoparticles on an ultrathin polypyrrole film deposited on a gold film electrode. Langmuir 2004, 20, 5109–5113. [Google Scholar] [CrossRef]

- Yancey, D.F.; Carino, E.V.; Crooks, R.M. Electrochemical synthesis and electrocatalytic properties of Au@ Pt dendrimer-encapsulated nanoparticles. J. Am. Chem. Soc. 2010, 132, 10988–10989. [Google Scholar] [CrossRef]

- Tremont, R.J.; Cruz, G.; Cabrera, C.R. Pt electrodeposition on a copper surface modified with 3-mercaptopropyltrimethoxysilane and 1-propanethiol. J. Electroanal. Chem. 2003, 558, 65–74. [Google Scholar] [CrossRef]

- Stiger, R.M.; Gorer, S.; Craft, B.; Penner, R.M. Investigations of electrochemical silver nanocrystal growth on hydrogen-terminated silicon (100). Langmuir 1999, 15, 790–798. [Google Scholar] [CrossRef]

- Ortega, J.M. Electrodeposition of copper on poly (o-aminophenol) modified platinum electrode. Thin Solid Film. 2000, 360, 159–165. [Google Scholar] [CrossRef]

- Claussen, J.C.; Franklin, A.D.; ul Haque, A.; Porterfield, D.M.; Fisher, T.S. Electrochemical biosensor of nanocube-augmented carbon nanotube networks. ACS Nano 2009, 3, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Zhang, W.D.; Gunasekaran, S. An amperometric non-enzymatic glucose sensor by electrodepositing copper nanocubes onto vertically well-aligned multi-walled carbon nanotube arrays. Biosens. Bioelectron. 2010, 26, 279–284. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Chen, L.; Wang, X.; Yao, W.; Zhang, Q. Recent advances in noble metal based composite nanocatalysts: Colloidal synthesis, properties, and catalytic applications. Nanoscale 2015, 7, 10559–10583. [Google Scholar] [CrossRef]

- Hyeon, T. Chemical synthesis of magnetic nanoparticles. Chem. Commun. 2003, 9, 927–934. [Google Scholar] [CrossRef]

- Kang, K.M.; Kim, H.W.; Shim, I.W.; Kwak, H.Y. Catalytic test of supported Ni catalysts with core/shell structure for dry reforming of methane. Fuel Process. Technol. 2011, 92, 1236–1243. [Google Scholar] [CrossRef]

- Duan, S.; Wang, R. Bimetallic nanostructures with magnetic and noble metals and their physicochemical applications. Prog. Nat. Sci. Mater. Int. 2013, 23, 113–126. [Google Scholar] [CrossRef]

- Riva, J.S.; Pozo-López, G.; Condo, A.M.; Fabietti, L.M.; Urreta, S.E. Low temperature ferromagnetism in Rh-rich Fe-Rh granular nanowires. J. Alloys Compd. 2018, 747, 1008–1017. [Google Scholar] [CrossRef]

- Riva, J.S.; Pozo-López, G.; Condo, A.M.; Viqueira, M.S.; Urreta, S.E.; Cornejo, D.R.; Fabietti, L.M. Biphasic FeRh nanowires synthesized by AC electrodeposition. J. Alloys Compd. 2016, 688, 804–813. [Google Scholar] [CrossRef]

- Riva, J.S.; Pozo-López, G.; Condó, A.M.; Levingston, J.M.; Fabietti, L.M.; Urreta, S.E. Magnetic viscosity in iron-rhodium nanowires. J. Alloys Compd. 2017, 709, 531–534. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, J.; Xia, Q.; Zhang, X.; Song, Y.; Yao, Z. Accelerating Fe (iii)/Fe (ii) redox cycling by Zn 0 in micro-nano dendritic Fe–Zn alloy for enhanced Fenton-like degradation of phenol. New J. Chem. 2023, 47, 17508–17516. [Google Scholar] [CrossRef]

- Zhang, H.; Jin, M.; Wang, J.; Li, W.; Camargo, P.H.; Kim, M.J.; Yang, D.; Xie, Z.; Xia, Y. Synthesis of Pd−Pt bimetallic nanocrystals with a concave structure through a bromide-induced galvanic replacement reaction. J. Am. Chem. Soc. 2011, 33, 6078–6089. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Li, H.; Lai, B.; Yang, P.; Gou, M.; Zhou, Y.; Sun, G. Removal of high-concentration CI acid orange 7 from aqueous solution by zerovalent iron/copper (Fe/Cu) bimetallic particles. Ind. Eng. Chem. Res. 2014, 53, 2605–2613. [Google Scholar] [CrossRef]

- Mahmoud, M.S.; Mahmoud, A.S. Wastewater treatment using nano bimetallic iron/copper, adsorption isotherm, kinetic studies, and artificial intelligence neural networks. Emergent Mater. 2021, 4, 1455–1463. [Google Scholar] [CrossRef]

- Mahmoud, A.S.; Mohamed, N.Y.; Mostafa, M.K.; Mahmoud, M.S. Effective chromium adsorption from aqueous solutions and tannery wastewater using bimetallic Fe/Cu nanoparticles: Response surface methodology and artificial neural network. Air Soil Water Res. 2021, 14, 11786221211028162. [Google Scholar] [CrossRef]

- Lai, B.; Zhang, Y.; Chen, Z.; Yang, P.; Zhou, Y.; Wang, J. Removal of p-nitrophenol (PNP) in aqueous solution by the micron-scale iron–copper (Fe/Cu) bimetallic particles. Appl. Catal. B Environ. 2014, 144, 816–830. [Google Scholar] [CrossRef]

- Lai, B.; Zhang, Y.H.; Yuan, Y.; Chen, Z.Y.; Yang, P. Influence of preparation conditions on characteristics, reactivity, and operational life of microsized Fe/Cu bimetallic particles. Ind. Eng. Chem. Res. 2014, 53, 12295–12304. [Google Scholar] [CrossRef]

- Xiong, Z.; Lai, B.; Yang, P.; Zhou, Y.; Wang, J.; Fang, S. Comparative study on the reactivity of Fe/Cu bimetallic particles and zero valent iron (ZVI) under different conditions of N2, air or without aeration. J. Hazard. Mater. 2015, 297, 261–268. [Google Scholar] [CrossRef]

- Ren, Y.; Lai, B. Comparative study on the characteristics, operational life and reactivity of Fe/Cu bimetallic particles prepared by electroless and displacement plating process. RSC Adv. 2016, 6, 58302–58314. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.H.; Ma, L.M. Simultaneously degradation of 2, 4-Dichlorophenol and EDTA in aqueous solution by the bimetallic Cu–Fe/O2 system. Environ. Sci. Pollut. Res. 2015, 22, 1186–1198. [Google Scholar] [CrossRef]

- Fu, F.; Cheng, Z.; Dionysiou, D.D.; Tang, B. Fe/Al bimetallic particles for the fast and highly efficient removal of Cr (VI) over a wide pH range: Performance and mechanism. J. Hazard. Mater. 2015, 298, 261–269. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Fu, F.; Dionysiou, D.D.; Tang, B. Adsorption, oxidation, and reduction behavior of arsenic in the removal of aqueous As (III) by mesoporous Fe/Al bimetallic particles. Water Res. 2016, 96, 22–31. [Google Scholar] [CrossRef]

- Xiang, S.; Cheng, W.; Nie, X.; Ding, C.; Yi, F.; Asiri, A.M.; Marwani, H.M. Zero-valent iron-aluminum for the fast and effective U (VI) removal. J. Taiwan Inst. Chem. Eng. 2018, 85, 186–192. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Pu, S.; Ni, R.; Lin, Y.; Liu, Y. Novel Fenton-like system (Mg/Fe-O2) for degradation of 4-chlorophenol. Environ. Pollut. 2019, 250, 906–913. [Google Scholar] [CrossRef]

- Aghaei, E.; Wang, Z.; Tadesse, B.; Tabelin, C.B.; Quadir, Z.; Alorro, R.D. Performance evaluation of Fe-Al bimetallic particles for the removal of potentially toxic elements from combined acid mine drainage-effluents from refractory gold ore processing. Minerals 2021, 11, 590. [Google Scholar] [CrossRef]

- Aghaei, E.; Tadesse, B.; Tabelin, C.B.; Alorro, R.D. Mercury sequestration from synthetic and real gold processing wastewaters using Fe–Al bimetallic particles. J. Clean. Prod. 2022, 372, 133482. [Google Scholar] [CrossRef]

- He, Y.; Sun, H.; Liu, W.; Yang, W.; Lin, A. Study on removal effect of Cr (VI) and surface reaction mechanisms by bimetallic system in aqueous solution. Environ. Technol. 2020, 41, 1867–1876. [Google Scholar] [CrossRef]

- Yeh, L.; Yen, C.H.; Kao, Y.L.; Lien, H.L.; Chang, S.M. Inactivation of Escherichia coli by dual-functional zerovalent Fe/Al composites in water. Chemosphere 2022, 299, 134371. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.H.; Hao, Y.; Ma, L.M. The degradation of EDTA by the bimetallic Fe–Cu/O2 system. Chem. Eng. J. 2014, 250, 354–365. [Google Scholar] [CrossRef]

- Park, I.; Ito, M.; Jeon, S.; Tabelin, C.B.; Phengsaart, T.; Silwamba, M.; Hiroyoshi, N. A novel recycling route for aluminum alloys: Synthesis of Fe/Al bimetallic materials and magnetic separation. Miner. Eng. 2023, 201, 108202. [Google Scholar] [CrossRef]

- Lien, H.L.; Yu, C.H.; Kamali, S.; Sahu, R.S. Bimetallic Fe/Al system: An all-in-one solid-phase Fenton reagent for generation of hydroxyl radicals under oxic conditions. Sci. Total Environ. 2019, 673, 480–488. [Google Scholar] [CrossRef]

- Tabelin, C.B.; Resabal, V.J.T.; Park, I.; Villanueva, M.G.B.; Choi, S.; Ebio, R.; Cabural, P.J.; Villacorte-Tabelin, M.; Orbecido, A.; Alorro, R.D.; et al. Repurposing of aluminum scrap into magnetic Al0/ZVI bimetallic materials: Two-stage mechanical-chemical synthesis and characterization of products. J. Clean. Prod. 2021, 317, 128285. [Google Scholar] [CrossRef]

- Sun, Y.; Xia, Y. Mechanistic study on the replacement reaction between silver nanostructures and chloroauric acid in aqueous medium. J. Am. Chem. Soc. 2004, 126, 3892–3901. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.H.; Ma, L.M. Elimination of 4-chlorophenol in aqueous solution by the bimetallic Al–Fe/O2 at normal temperature and pressure. Chem. Eng. J. 2014, 236, 274–284. [Google Scholar] [CrossRef]

- Fan, J.H.; Liu, X.; Ma, L.M. EDTA enhanced degradation of 4-bromophenol by Al0–Fe0–O2 system. Chem. Eng. J. 2015, 263, 71–82. [Google Scholar] [CrossRef]

- Fan, J.; Wang, H.; Ma, L. Oxalate-assisted oxidative degradation of 4-chlorophenol in a bimetallic, zero-valent iron–aluminum/air/water system. Environ. Sci. Pollut. Res. 2016, 23, 16686–16698. [Google Scholar] [CrossRef]

- Khoshandam, B.; Kumar, R.V.; Jamshidi, E. Simulation of non-catalytic gas–solid reactions: Application of grain model for the reduction of cobalt oxide with methane. Miner. Process. Extr. Metall. 2005, 114, 10–22. [Google Scholar] [CrossRef]

- Khoshandam, B.; Kumar, R.V.; Jamshidi, E. Kinetics of reduction of manganese oxide by methane. Can. Metall. Q. 2007, 46, 365–371. [Google Scholar] [CrossRef]

- Yape, E.O.; Anacleto, N.M. Direct smelting of chromite and laterite ores with carbon under argon atmosphere. Adv. Mater. Res. 2014, 849, 170–176. [Google Scholar] [CrossRef]

- Balangao, J.K.B.; Podiotan, F.J.C.; Ambolode, A.E.C.; Anacleto, N.M.; Namoco, C.S., Jr. Production of Iron-Chromium-Nickel Metal Alloys via Reduction of Mixed Chromite Ore from Zambales and Laterite Ore from Taganito, Surigao del Norte under Argon Atmosphere. Indian J. Sci. Technol. 2018, 11, 1–11. [Google Scholar]

- Balangao, J.K.B.; Podiotan, F.J.C.; Ambolode, A.E.C.; Anacleto, N.M. Isothermal Reduction Smelting of Mixed Chromite-Laterite Samples with Coconut Charcoal as Reductant under Argon Atmosphere in a Vertical Electric Arc Furnace. Int. J. Mech. Eng. Technol. 2022, 13, 46–53. [Google Scholar]

- Meshkini Far, R.; Ischenko, O.V.; Dyachenko, A.G.; Bieda, O.; Gaidai, S.V.; Lisnyak, V.V. CO2 hydrogenation into CH4 over Ni–Fe catalysts. Funct. Mater. Lett. 2018, 11, 1850057. [Google Scholar] [CrossRef]

- Tang, H.; Li, S.; Gong, D.; Guan, Y.; Liu, Y. Bimetallic Ni-Fe catalysts derived from layered double hydroxides for CO methanation from syngas. Front. Chem. Sci. Eng. 2017, 11, 613–623. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Sun, K.; Gao, G.; Li, C.; Zhang, L.; Zhang, S.; Xu, L.; Hu, G.; Hu, X. Selective hydrogenation of furfural and its derivative over bimetallic NiFe-based catalysts: Understanding the synergy between Ni sites and Ni–Fe alloy. Renew. Energy 2021, 170, 1114–1128. [Google Scholar] [CrossRef]

- Li, D.; Koike, M.; Wang, L.; Nakagawa, Y.; Xu, Y.; Tomishige, K. Regenerability of hydrotalcite-derived nickel–iron alloy nanoparticles for syngas production from biomass tar. ChemSusChem 2014, 7, 510–522. [Google Scholar] [CrossRef]

- Zhao, J.; Shi, R.; Waterhouse, G.I.; Zhang, T. Selective photothermal CO2 reduction to CO, CH4, alkanes, alkenes over bimetallic alloy catalysts derived from layered double hydroxide nanosheets. Nano Energy 2022, 102, 107650. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, J.; An, K.; Zhang, S.; Liu, G.; Liu, Y. Highly dispersed Ni–Fe alloy catalysts on MgAl2O4 derived from hydrotalcite for direct ethanol synthesis from syngas. Energy Technol. 2020, 8, 2000205. [Google Scholar] [CrossRef]

- De Masi, D.; Asensio, J.M.; Fazzini, P.F.; Lacroix, L.M.; Chaudret, B. Engineering iron–nickel nanoparticles for magnetically induced CO2 methanation in continuous flow. Angew. Chem. Int. Ed. 2020, 59, 6187–6191. [Google Scholar] [CrossRef]

- Ferrando, R.; Jellinek, J.; Johnston, R.L. Nanoalloys: From theory to applications of alloy clusters and nanoparticles. Chem. Rev. 2008, 108, 845–910. [Google Scholar] [CrossRef]

- Zhang, L.; Lepper, M.; Stark, M.; Menzel, T.; Lungerich, D.; Jux, N.; Hieringer, W.; Steinrück, H.P.; Marbach, H. On the critical role of the substrate: The adsorption behaviour of tetrabenzoporphyrins on different metal surfaces. Phys. Chem. Chem. Phys. 2017, 19, 20281–20289. [Google Scholar] [CrossRef]

- Wang, J.; Wu, A.; Qiu, Z.; Li, A.; Qin, W.; Huang, H. N-CNT supported Fe/Ce bimetallic catalyst for Al-air aqueous batteries. Appl. Surf. Sci. 2023, 608, 155185. [Google Scholar] [CrossRef]

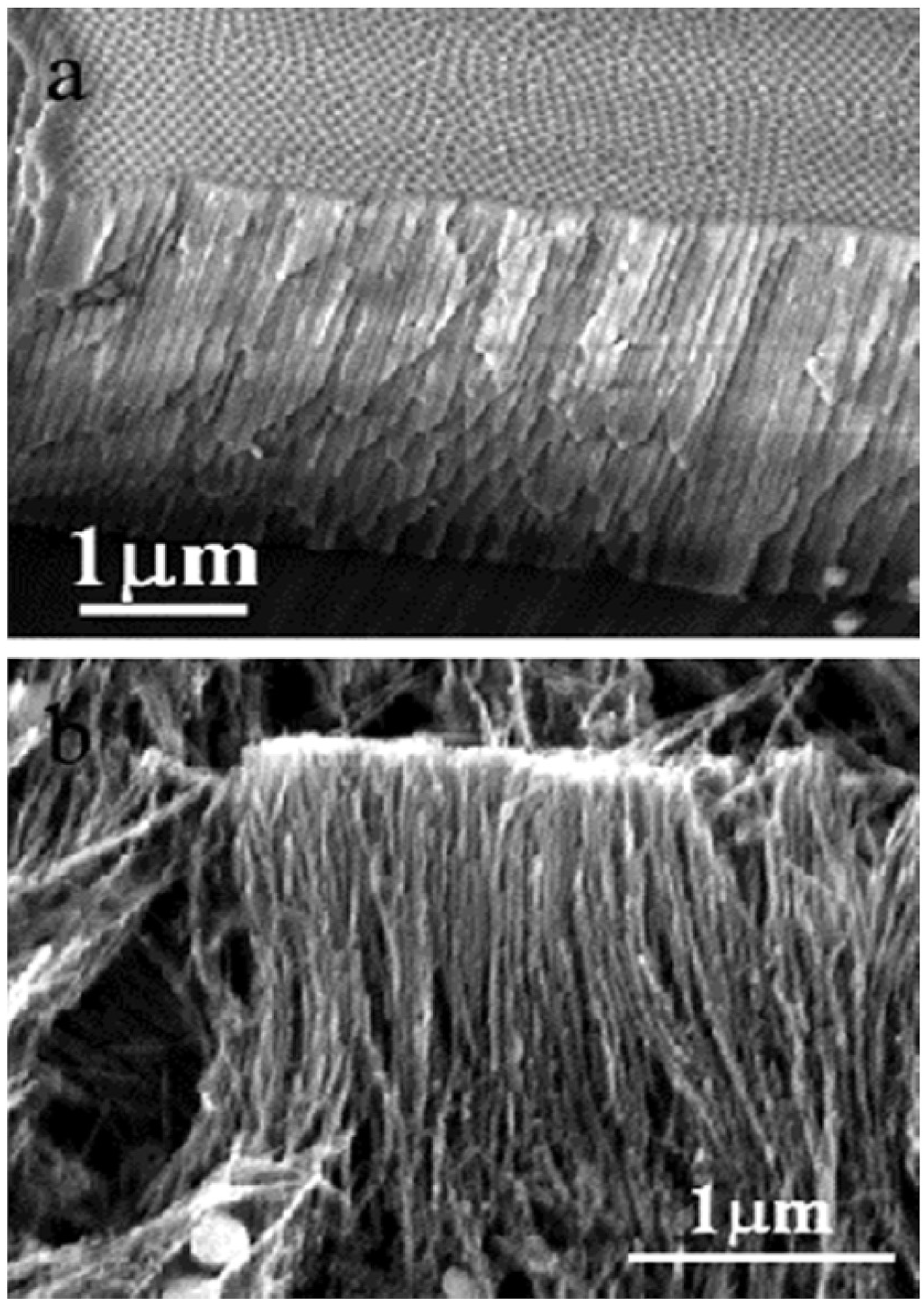

- Tian, F.; Zhong, S.; Nie, W.; Zeng, M.; Chen, B.; Liu, X. Multi-walled carbon nanotubes prepared with low-cost Fe-Al bimetallic catalysts for high-rate rechargeable Li-ion batteries. J. Solid State Electrochem. 2020, 24, 667–674. [Google Scholar] [CrossRef]

- Wang, J.; Liu, C.; Li, J.; Luo, R.; Hu, X.; Sun, X.; Shen, J.; Han, W.; Wang, L. In-situ incorporation of iron-copper bimetallic particles in electrospun carbon nanofibers as an efficient Fenton catalyst. Appl. Catal. B Environ. 2017, 207, 316–325. [Google Scholar] [CrossRef]

- Nam, G.; Park, J.; Choi, M.; Oh, P.; Park, S.; Kim, M.G.; Park, N.; Cho, J.; Lee, J.S. Carbon-coated core–shell Fe–Cu nanoparticles as highly active and durable electrocatalysts for a Zn–air battery. ACS Nano 2015, 9, 6493–6501. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, H.; Zhao, G. Iron-copper bimetallic nanoparticles embedded within ordered mesoporous carbon as effective and stable heterogeneous Fenton catalyst for the degradation of organic contaminants. Appl. Catal. B Environ. 2015, 164, 396–406. [Google Scholar] [CrossRef]

- Wu, H.; Feng, Q.; Lu, P.; Chen, M.; Yang, H. Degradation mechanisms of cefotaxime using biochar supported Co/Fe bimetallic nanoparticles. Environ. Sci. Water Res. Technol. 2018, 4, 964–975. [Google Scholar] [CrossRef]

- Wu, H.; Feng, Q. Fabrication of bimetallic Ag/Fe immobilized on modified biochar for removal of carbon tetrachloride. J. Environ. Sci. 2017, 54, 346–357. [Google Scholar] [CrossRef]

- Xing, X.; Ren, X.; Alharbi, N.S.; Chen, C. Biochar-supported Fe/Ni bimetallic nanoparticles for the efficient removal of Cr (VI) from aqueous solution. J. Mol. Liq. 2022, 359, 119257. [Google Scholar] [CrossRef]

- Hao, J.; Wu, L.; Lu, X.; Zeng, Y.; Jia, B.; Luo, T.; He, S.; Liang, L. A stable Fe/Co bimetallic modified biochar for ofloxacin removal from water: Adsorption behavior and mechanisms. RSC Adv. 2022, 12, 31650–31662. [Google Scholar] [CrossRef]

- Ji, J.; Xu, S.; Ma, Z.; Mou, Y. Trivalent antimony removal using carbonaceous nanomaterial loaded with zero-valent bimetal (iron/copper) and their effect on seed growth. Chemosphere 2022, 296, 134047. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, Y.; Chen, Q.; Liu, R.; Wang, H. Unraveling adsorption characteristics and removal mechanism of novel Zn/Fe-bimetal-loaded and starch-coated corn cobs biochar for Pb (II) and Cd (II) in wastewater. J. Mol. Liq. 2023, 391, 123375. [Google Scholar] [CrossRef]

- Bose, S.; Mukherjee, T.; Rahaman, M. Simultaneous adsorption of manganese and fluoride from aqueous solution via bimetal impregnated activated carbon derived from waste tire: Response surface method modeling approach. Environ. Prog. Sustain. Energy 2021, 40, e13600. [Google Scholar] [CrossRef]

- Danmaliki, G.I.; Saleh, T.A. Effects of bimetallic Ce/Fe nanoparticles on the desulfurization of thiophenes using activated carbon. Chem. Eng. J. 2017, 307, 914–927. [Google Scholar] [CrossRef]

- Tian, H.; Chen, C.; Zhu, T.; Zhu, B.; Sun, Y. Characterization and degradation mechanism of bimetallic iron-based/AC activated persulfate for PAHs-contaminated soil remediation. Chemosphere 2021, 267, 128875. [Google Scholar] [CrossRef]

- Kakavandi, B.; Kalantary, R.R.; Farzadkia, M.; Mahvi, A.H.; Esrafili, A.; Azari, A.; Yari, A.R.; Javid, A.B. Enhanced chromium (VI) removal using activated carbon modified by zero valent iron and silver bimetallic nanoparticles. J. Environ. Health Sci. Eng. 2014, 12, 115. [Google Scholar] [CrossRef]

- Fong, W.M.; Affam, A.C.; Chung, W.C. Synthesis of Ag/Fe/CAC for colour and COD removal from methylene blue dye wastewater. Int. J. Environ. Sci. Technol. 2020, 17, 3485–3494. [Google Scholar] [CrossRef]

- Rahaman, M.; Das, A.; Bose, S. Development of copper—Iron bimetallic nanoparticle impregnated activated carbon derived from coconut husk and its efficacy as a novel adsorbent toward the removal of chromium (VI) from aqueous solution. Water Environ. Res. 2021, 93, 1417–1427. [Google Scholar] [CrossRef]

- Zhao, R.; Du, X.; Cao, K.; Gong, M.; Li, Y.; Ai, J.; Ye, R.; Chen, R.; Shan, B. Highly dispersed Fe-decorated Ni nanoparticles prepared by atomic layer deposition for dry reforming of methane. Int. J. Hydrogen Energy 2023, 48, 28780–28791. [Google Scholar] [CrossRef]

- Mutz, B.; Belimov, M.; Wang, W.; Sprenger, P.; Serrer, M.A.; Wang, D.; Pfeifer, P.; Kleist, W.; Grunwaldt, J.D. Potential of an alumina-supported Ni3Fe catalyst in the methanation of CO2: Impact of alloy formation on activity and stability. ACS Catal. 2017, 7, 6802–6814. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, Z.; Tian, P.; Sheng, Y.; Xu, J.; Han, Y.F. Oxidative degradation of nitrobenzene by a Fenton-like reaction with Fe-Cu bimetallic catalysts. Appl. Catal. B Environ. 2019, 244, 1–10. [Google Scholar] [CrossRef]

- Liuzzi, D.; Pérez-Alonso, F.J.; Rojas, S. Ru-M (M= Fe or Co) Catalysts with high Ru surface concentration for Fischer-Tropsch synthesis. Fuel 2021, 293, 120435. [Google Scholar] [CrossRef]

- Zhang, L.; Meng, Z.; Zang, S. Preparation and characterization of Pd/Fe bimetallic nanoparticles immobilized on Al2O3/PVDF membrane: Parameter optimization and dechlorination of dichloroacetic acid. J. Environ. Sci. 2015, 31, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, A.C.; Sahoo, M.K.; Bellamkonda, S.; Parida, K.M.; Rao, G.R. Enhanced photodegradation of dyes and mixed dyes by heterogeneous mesoporous Co–Fe/Al2O3–MCM-41 nanocomposites: Nanoparticles formation, semiconductor behavior and mesoporosity. RSC Adv. 2016, 6, 94263–94277. [Google Scholar] [CrossRef]

- Munoz, M.; de Pedro, Z.M.; Casas, J.A.; Rodriguez, J.J. Improved γ-alumina-supported Pd and Rh catalysts for hydrodechlorination of chlorophenols. Appl. Catal. A Gen. 2014, 488, 78–85. [Google Scholar] [CrossRef]

- Wang, J.; Liu, C.; Tong, L.; Li, J.; Luo, R.; Qi, J.; Li, Y.; Wang, L. Iron–copper bimetallic nanoparticles supported on hollow mesoporous silica spheres: An effective heterogeneous Fenton catalyst for orange II degradation. RSC Adv. 2015, 5, 69593–69605. [Google Scholar] [CrossRef]

- Wang, J.; Liu, C.; Hussain, I.; Li, C.; Li, J.; Sun, X.; Shen, J.; Han, W.; Wang, L. Iron–copper bimetallic nanoparticles supported on hollow mesoporous silica spheres: The effect of Fe/Cu ratio on heterogeneous Fenton degradation of a dye. RSC Adv. 2016, 6, 54623–54635. [Google Scholar] [CrossRef]

- Lin, H.; Zhong, X.; Ciotonea, C.; Fan, X.; Mao, X.; Li, Y.; Deng, B.; Zhang, H.; Royer, S. Efficient degradation of clofibric acid by electro-enhanced peroxydisulfate activation with Fe-Cu/SBA-15 catalyst. Appl. Catal. B Environ. 2018, 230, 1–10. [Google Scholar] [CrossRef]

- Yan, H.; Qu, H.; Bai, H.; Zhong, Q. Property, active species and reaction mechanism of NO and NH3 over mesoporous Fe-Al-SBA-15 via microwave assisted synthesis for NH3-SCR. J. Mol. Catal. A Chem. 2015, 403, 1–9. [Google Scholar] [CrossRef]

- Kurniawan, A.; Sutiono, H.; Ju, Y.H.; Soetaredjo, F.E.; Ayucitra, A.; Yudha, A.; Ismadji, S. Utilization of rarasaponin natural surfactant for organo-bentonite preparation: Application for methylene blue removal from aqueous effluent. Microporous Mesoporous Mater. 2011, 142, 184–193. [Google Scholar] [CrossRef]

- Campos, B.; Aguilar-Carrillo, J.; Algarra, M.; Gonçalves, M.A.; Rodríguez-Castellón, E.; da Silva, J.C.E.; Bobos, I. Adsorption of uranyl ions on kaolinite, montmorillonite, humic acid and composite clay material. Appl. Clay Sci. 2013, 85, 53–63. [Google Scholar] [CrossRef]

- Zhou, C.H.; Zhang, D.; Tong, D.S.; Wu, L.M.; Yu, W.H.; Ismadji, S. Paper-like composites of cellulose acetate–organo-montmorillonite for removal of hazardous anionic dye in water. Chem. Eng. J. 2012, 209, 223–234. [Google Scholar] [CrossRef]

- Murray, H.H. Applied Clay Mineralogy: Occurrences, Processing and Applications of Kaolins, Bentonites, Palygorskite–Sepiolite, and Common Clays; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Sabouri, M.R.; Sohrabi, M.R.; Zeraatkar Moghaddam, A. Response surface method Optimization of the Dyes Degradation using Zero-Valent Iron based Bimetallic Nanoparticle on the Bentonite Clay Surface. Pollution 2020, 6, 581–595. [Google Scholar]

- Weng, X.; Cai, W.; Lan, R.; Sun, Q.; Chen, Z. Simultaneous removal of amoxicillin, ampicillin and penicillin by clay supported Fe/Ni bimetallic nanoparticles. Environ. Pollut. 2018, 236, 562–569. [Google Scholar] [CrossRef] [PubMed]

- Jiang, M.Q.; Jin, X.Y.; Lu, X.Q.; Chen, Z.L. Adsorption of Pb (II), Cd (II), Ni (II) and Cu (II) onto natural kaolinite clay. Desalination 2010, 252, 33–39. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, S.; Chen, Z.; Megharaj, M.; Naidu, R. Kaolinite-supported nanoscale zero-valent iron for removal of Pb2+ from aqueous solution: Reactivity, characterization and mechanism. Water Res. 2011, 45, 3481–3488. [Google Scholar] [CrossRef]

- Jin, X.; Chen, Z.; Wang, T.; Chen, Z.; Megharaj, M.; Naidu, R. Simultaneous removal of co-contaminants: Acid brilliant violet and Cu 2+ by functional bimetallic Fe/Pd nanoparticles. J. Nanopart. Res. 2014, 16, 2657. [Google Scholar] [CrossRef]

- Masters, A.F.; Maschmeyer, T. Zeolites—From curiosity to cornerstone. Microporous Mesoporous Mater. 2011, 142, 423–438. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; El-Kamash, A.M.; Hung, Y.T. Applications of nano-zeolite in wastewater treatment: An overview. Water 2022, 14, 137. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, L.; Mao, Y.; Zhou, Z.; Wu, D. Enhancing the degradation of bisphenol A by dioxygen activation using bimetallic Cu/Fe@ zeolite: Critical role of Cu (I) and superoxide radical. Sep. Purif. Technol. 2020, 253, 117550. [Google Scholar] [CrossRef]

- Ezzatahmadi, N.; Bao, T.; Liu, H.; Millar, G.J.; Ayoko, G.A.; Zhu, J.; Zhu, R.; Liang, X.; He, H.; Xi, Y. Catalytic degradation of Orange II in aqueous solution using diatomite-supported bimetallic Fe/Ni nanoparticles. RSC Adv. 2018, 8, 7687–7696. [Google Scholar] [CrossRef]

- Ezzatahmadi, N.; Millar, G.J.; Ayoko, G.A.; Zhu, J.; Zhu, R.; Liang, X.; He, H.; Xi, Y. Degradation of 2,4-dichlorophenol using palygorskite-supported bimetallic Fe/Ni nanocomposite as a heterogeneous catalyst. Appl. Clay Sci. 2019, 168, 276–286. [Google Scholar] [CrossRef]

- Ezzatahmadi, N.; Marshall, D.L.; Hou, K.; Ayoko, G.A.; Millar, G.J.; Xi, Y. Simultaneous adsorption and degradation of 2, 4-dichlorophenol on sepiolite-supported bimetallic Fe/Ni nanoparticles. J. Environ. Chem. Eng. 2019, 7, 102955. [Google Scholar] [CrossRef]

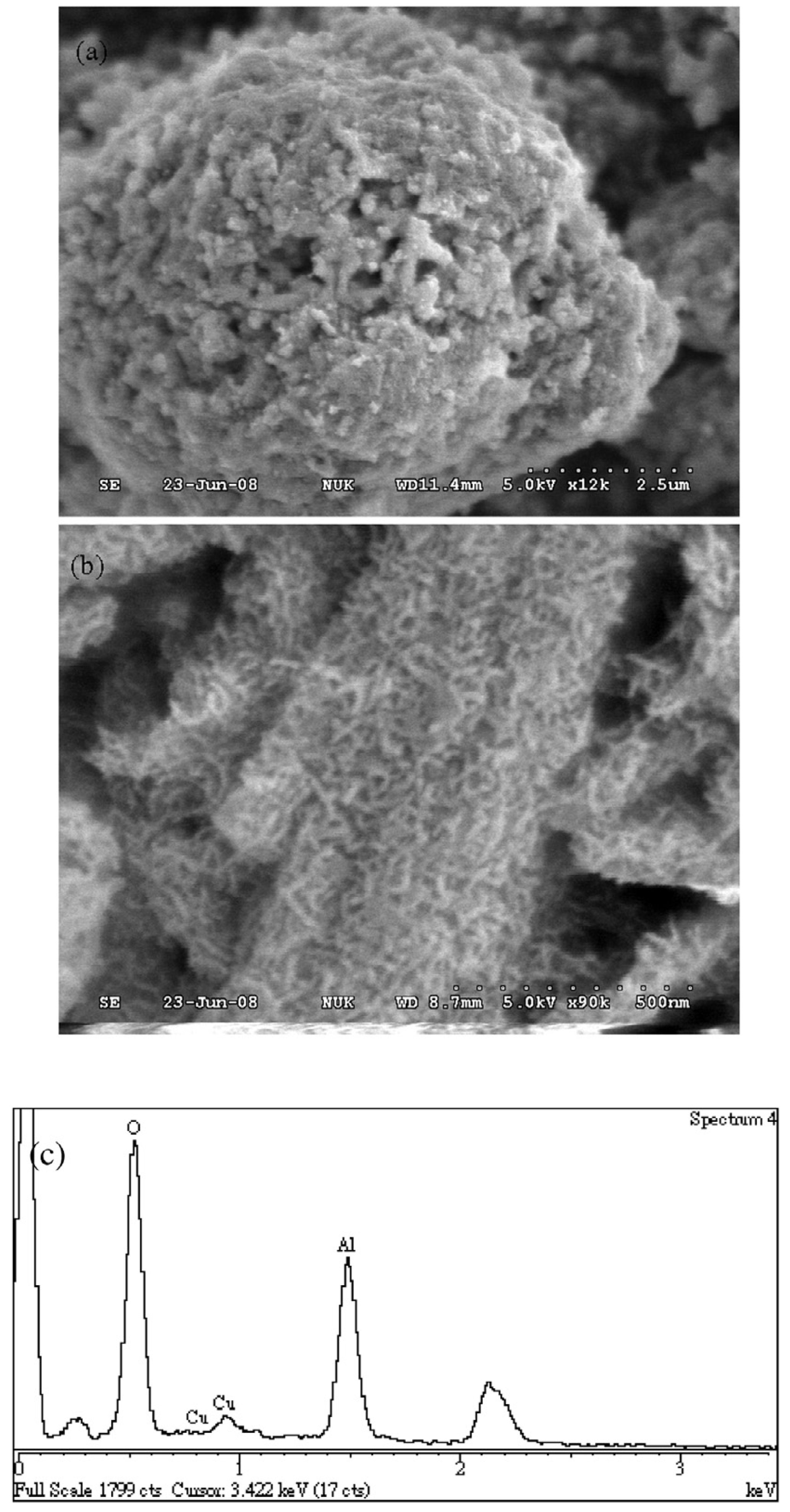

- Svarovskaya, N.; Bakina, O.; Glazkova, E.; Rodkevich, N.; Lerner, M.; Vornakova, E.; Chzhou, V.; Naumova, L. Synthesis of novel hierarchical micro/nanostructures AlOOH/AlFe and their application for As (V) removal. Environ. Sci. Pollut. Res. 2022, 29, 1246–1258. [Google Scholar] [CrossRef]

- Hina, R.; Arafa, I.; Al-Khateeb, F. Gas phase hydrodechlorination of CCl4 over Pd–Cu and Pd–Fe bimetallic catalysts supported on an AlF3 matrix. Prog. React. Kinet. Mech. 2016, 41, 29–38. [Google Scholar] [CrossRef]

- Xi, J.; Wang, Q.; Duan, X.; Zhang, N.; Yu, J.; Sun, H.; Wang, S. Continuous flow reduction of organic dyes over Pd-Fe alloy based fibrous catalyst in a fixed-bed system. Chem. Eng. Sci. 2021, 231, 116303. [Google Scholar] [CrossRef]

- Aftab, T.B.; Hussain, A.; Li, D. Application of a novel bimetallic hydrogel based on iron and cobalt for the synergistic catalytic degradation of Congo Red dye. J. Chin. Chem. Soc. 2019, 66, 919–927. [Google Scholar] [CrossRef]

- Shi, D.; Ouyang, Z.; Zhao, Y.; Xiong, J.; Shi, X. Catalytic reduction of hexavalent chromium using iron/palladium bimetallic nanoparticle-assembled filter paper. Nanomaterials 2019, 9, 1183. [Google Scholar] [CrossRef]

- Ge, W.; Li, S.; Jiang, M.; He, G.; Zhang, W. Cu/Fe bimetallic modified fly ash: An economical adsorbent for enhanced phosphorus removal from aqueous solutions. Water Air Soil Pollut. 2022, 233, 182. [Google Scholar] [CrossRef]

- Balangao, J.K.B.; Ramos, M.S.K. Production of Autoclaved Aerated Concretes with Fly Ash from a Coal Power Plant in Misamis Oriental, Philippines. Indian J. Sci. Technol. 2019, 12, 1–16. [Google Scholar] [CrossRef]

- Balangao, J.K.B.; Caingles, V.K.S.; Baguhin, I.A. Morphological and environmental characterization of lime sludge/fly ash stabilized sub-base materials. Sci. Int. 2023, 35, 283–290. [Google Scholar]

- Deplanche, K.; Caldelari, I.; Mikheenko, I.P.; Sargent, F.; Macaskie, L.E. Involvement of hydrogenases in the formation of highly catalytic Pd (0) nanoparticles by bioreduction of Pd (II) using Escherichia coli mutant strains. Microbiology 2010, 156, 2630–2640. [Google Scholar] [CrossRef] [PubMed]

- Pantidos, N.; Horsfall, L.E. Biological synthesis of metallic nanoparticles by bacteria, fungi and plants. J. Nanomed. Nanotechnol. 2014, 5, 1000233. [Google Scholar] [CrossRef]

- Yong, P.; Rowson, N.A.; Farr, J.P.G.; Harris, I.R.; Macaskie, L.E. Bioaccumulation of palladium by Desulfovibrio desulfuricans. J. Chem. Technol. Biotechnol. 2002, 77, 593–601. [Google Scholar] [CrossRef]

- Alruqi, S.S.; Al-Thabaiti, S.A.; Khan, Z. Iron-nickel bimetallic nanoparticles: Surfactant assisted synthesis and their catalytic activities. J. Mol. Liq. 2019, 282, 448–455. [Google Scholar] [CrossRef]

- Lin, Y.; Jin, X.; Khan, N.I.; Owens, G.; Chen, Z. Efficient removal of As (III) by calcined green synthesized bimetallic Fe/Pd nanoparticles based on adsorption and oxidation. J. Clean. Prod. 2021, 286, 124987. [Google Scholar] [CrossRef]

- Zhang, J.; Niu, Y.; Zhou, Y.; Ju, S.; Gu, Y. Green preparation of nano-zero-valent iron-copper bimetals for nitrate removal: Characterization, reduction reaction pathway, and mechanisms. Adv. Powder Technol. 2022, 33, 103807. [Google Scholar] [CrossRef]

- Zhu, F.; Ma, S.; Liu, T.; Deng, X. Green synthesis of nano zero-valent iron/Cu by green tea to remove hexavalent chromium from groundwater. J. Clean. Prod. 2018, 174, 184–190. [Google Scholar] [CrossRef]

- Lin, Y.; Jin, X.; Khan, N.I.; Owens, G.; Chen, Z. Bimetallic Fe/Ni nanoparticles derived from green synthesis for the removal of arsenic (V) in mine wastewater. J. Environ. Manag. 2022, 301, 113838. [Google Scholar] [CrossRef]

- Gopal, G.; Ravikumar, K.V.G.; Salma, M.; Chandrasekaran, N.; Mukherjee, A. Green synthesized Fe/Pd and in-situ Bentonite-Fe/Pd composite for efficient tetracycline removal. J. Environ. Chem. Eng. 2020, 8, 104126. [Google Scholar] [CrossRef]

- Kazemi, M.; Jahanshahi, M.; Peyravi, M. Hexavalent chromium removal by multilayer membrane assisted by photocatalytic couple nanoparticle from both permeate and retentate. J. Hazard. Mater. 2018, 344, 12–22. [Google Scholar] [CrossRef]

- Liu, T.; Yang, X.; Wang, Z.L.; Yan, X. Enhanced chitosan beads-supported Fe0-nanoparticles for removal of heavy metals from electroplating wastewater in permeable reactive barriers. Water Res. 2013, 47, 6691–6700. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Huang, D.; Lai, C.; Xu, P.; Zeng, G.; Wan, J.; Tang, L.; Dong, H.; Huang, B.; Hu, T. Difunctional chitosan-stabilized Fe/Cu bimetallic nanoparticles for removal of hexavalent chromium wastewater. Sci. Total Environ. 2018, 644, 1181–1189. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Zhu, Q.; Wang, A.; Weng, M.; Xing, Z. Composite of chitosan and bentonite cladding Fe–Al bimetal: Effective removal of nitrate and by-products from wastewater. Environ. Res. 2020, 184, 109336. [Google Scholar] [CrossRef]

- Anju, R.P.P.; Sunil, J.T.; Dinoop, L. Chitosan stabilized Fe/Ni bimetallic nanoparticles for the removal of cationic and anionic triphenylmethane dyes from water. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100295. [Google Scholar]

- Rashid, S.; Shen, C.; Chen, X.; Li, S.; Chen, Y.; Wen, Y.; Liu, J. Enhanced catalytic ability of chitosan–Cu–Fe bimetal complex for the removal of dyes in aqueous solution. RSC Adv. 2015, 5, 90731–90741. [Google Scholar] [CrossRef]

- Silva, E.C.; Soares, V.R.; Fajardo, A.R. Removal of pharmaceuticals from aqueous medium by alginate/polypyrrole/ZnFe2O4 beads via magnetic field enhanced adsorption. Chemosphere 2023, 316, 137734. [Google Scholar] [CrossRef]

- Wasilewska, M.; Deryło-Marczewska, A. Adsorption of non-steroidal anti-inflammatory drugs on alginate-carbon composites—Equilibrium and kinetics. Materials 2022, 15, 6049. [Google Scholar] [CrossRef]

- Ragab, A.H.; Hussein, H.S.; Ahmed, I.A.; Abualnaja, K.M.; AlMasoud, N. An efficient strategy for enhancing the adsorption of antibiotics and drugs from aqueous solutions using an effective limestone-activated carbon–alginate nanocomposite. Molecules 2021, 26, 5180. [Google Scholar] [CrossRef]

- Ahmed, I.A.; Hussein, H.S.; ALOthman, Z.A.; ALanazi, A.G.; Alsaiari, N.S.; Khalid, A. Green synthesis of Fe–Cu bimetallic supported on alginate-limestone nanocomposite for the removal of drugs from contaminated water. Polymers 2023, 15, 1221. [Google Scholar] [CrossRef]

- Wu, X.; Lu, C.; Zhang, W.; Yuan, G.; Xiong, R.; Zhang, X. A novel reagentless approach for synthesizing cellulose nanocrystal-supported palladium nanoparticles with enhanced catalytic performance. J. Mater. Chem. A 2013, 1, 8645–8652. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Baran, N.Y.; Baran, T.; Menteş, A. Fabrication and application of cellulose Schiff base supported Pd (II) catalyst for fast and simple synthesis of biaryls via Suzuki coupling reaction. Appl. Catal. A Gen. 2017, 531, 36–44. [Google Scholar] [CrossRef]

- Mandal, B.H.; Rahman, M.L.; Yusoff, M.M.; Chong, K.F.; Sarkar, S.M. Bio-waste corn-cob cellulose supported poly (hydroxamic acid) copper complex for Huisgen reaction: Waste to wealth approach. Carbohydr. Polym. 2017, 156, 175–181. [Google Scholar] [CrossRef]

- Bhardwaj, M.; Sahi, S.; Mahajan, H.; Paul, S.; Clark, J.H. Novel heterogeneous catalyst systems based on Pd (0) nanoparticles onto amine functionalized silica-cellulose substrates [Pd (0)-EDA/SCs]: Synthesis, characterization and catalytic activity toward C–C and C–S coupling reactions in water under limiting basic conditions. J. Mol. Catal. A Chem. 2015, 408, 48–59. [Google Scholar]

- Karami, S.; Zeynizadeh, B.; Shokri, Z. Cellulose supported bimetallic Fe–Cu nanoparticles: A magnetically recoverable nanocatalyst for quick reduction of nitroarenes to amines in water. Cellulose 2018, 25, 3295–3305. [Google Scholar] [CrossRef]

| Country | Frequency | % (n = 122) | C/D |

|---|---|---|---|

| China | 76 | 62.3 | 45.2 |

| Russia | 7 | 5.7 | 16.0 |

| Australia | 6 | 4.9 | 23.8 |

| India | 6 | 4.9 | 16.7 |

| Taiwan | 5 | 4.1 | 27.2 |

| Iran | 5 | 4.1 | 64.0 |

| Egypt | 4 | 3.3 | 14.0 |

| Israel | 4 | 3.3 | 12.8 |

| Argentina | 3 | 2.4 | 4.3 |

| Saudi Arabia | 3 | 2.4 | 95.0 |

| Journal | Frequency | % (n = 122) | C/D | Country | Journal Rank |

|---|---|---|---|---|---|

| RSC Advances | 8 | 6.6 | 48.0 | UK | Q1 |

| Chemical Engineering Journal | 7 | 5.7 | 70.4 | The Netherlands | Q1 |

| Chemosphere | 7 | 5.7 | 41.6 | UK | Q1 |

| Applied Catalysis B: Environmental | 5 | 4.1 | 203.0 | The Netherlands | Q1 |

| Journal of Cleaner Production | 4 | 3.3 | 59.0 | UK | Q1 |

| Environmental Science and Pollution Research | 3 | 2.4 | 10.3 | Germany | Q1 |

| Journal of the Taiwan Institute of Chemical Engineers | 3 | 2.4 | 17.3 | Taiwan | Q1 |

| Journal of Hazardous Materials | 3 | 2.4 | 80.7 | The Netherlands | Q1 |

| Journal of Alloys and Compounds | 3 | 2.4 | 14.3 | The Netherlands | Q1 |

| Journal of Molecular Liquids | 3 | 2.4 | 8.3 | The Netherlands | Q1 |

| Institution | Frequency | % (n = 122) | Country |

|---|---|---|---|

| Tongji University | 7 | 5.7 | China |

| Institute of Strength Physics and Materials Science | 6 | 4.9 | Russia |

| Fujian Normal University | 5 | 4.1 | China |

| Sichuan University | 5 | 4.1 | China |

| Nanjing University of Science and Technology | 4 | 3.3 | China |

| Technion–Israel Institute of Technology | 4 | 3.3 | Israel |

| Tianjin University | 3 | 2.4 | China |

| China University of Mining and Technology | 3 | 2.4 | China |

| Chinese Academy of Sciences | 3 | 2.4 | China |

| Queensland University of Technology | 3 | 2.4 | Australia |

| Consejo Nacional de Investigaciones Científicas y Tecnicas (CONICET) | 3 | 2.4 | Argentina |

| Author | Frequency | % (n = 122) | Country |

|---|---|---|---|

| A. Sharipova | 4 | 3.3 | Israel/Russia |

| Xin Liu | 3 | 2.4 | China |

| Jing Wang | 3 | 2.4 | China |

| J.S. Riva | 3 | 2.4 | Argentina |

| Naeim Ezzatahmadi | 3 | 2.4 | Australia |

| Xiulan Weng | 2 | 1.6 | China |

| Hongwei Wu | 2 | 1.6 | China |

| Bo Lai | 2 | 1.6 | China |

| Yuanqiong Lin | 2 | 1.6 | China |

| Jin-Hong Fan | 2 | 1.6 | China |

| Elham Aghaei | 2 | 1.6 | Australia |

| Bimetal System | Method | Characteristics of Synthesized Bimetals | Properties | Reference |

|---|---|---|---|---|

| Fe-Cu/aluminum collar | Mechanical Alloying | Presence of Fe and Cu seen deposited on aluminum substrate; coating of up to 500 nm layer thickness | Magnetic | [49] |

| Cu-Fe/CNT | Mechanical Alloying | CNT additions to Cu-Fe at 2, 5, and 10 (wt.%); Cu-Fe shown as agglomerate microparticles, larger at 2 and 5 wt.% CNT, decreased in size at 10 wt.% CNT | Magnetic | [50] |

| Fe/Ag nanocomposite | Mechanical Alloying | Nanocomposite structure, Fe-5Ag, Fe-10Ag (vol.%) | Optimal combined strength and ductility after annealing at 550 °C, biomedical suitability | [52] |

| Fe/Ag nanocomposite | Mechanical Alloying | 70% and 75% Macroporous, Fe-5Ag and Fe-10Ag (vol%) | High compressive strength, high bending strength, high ductility, biodegradability | [53] |

| Fe/Ag, Fe/Cu nanocomposites | Mechanical Alloying | Nanocomposite structure, Fe–10% Ag, Fe–20% Ag, and Fe–25% Cu (vol%) | High strength and ductility, biodegradability | [54] |

| Fe/Ag, Fe/Cu nanocomposites | Mechanical Alloying | Nanocomposite structure, Fe–10% Ag, Fe–20% Ag, and Fe–25% Cu (vol%) | Densities close to theoretical values, High plasticity, bending strength | [55] |

| Fe/Cu | Electrical Explosion of Metal Wires | Nanostructured, near-fully dense, 72 Fe–28 Cu, 47 Fe–53 Cu, and 28 Fe–72 Cu (wt%) | High yield strength (Fe-rich, 72 Fe–28 Cu): 700 MPa; high bending strength (Fe-rich, 72 Fe–28 Cu): 920 MPa; greater ductility (Cu-rich, 28 Fe–72 Cu); lower electrical resistivity (Cu-rich, 28 Fe–72 Cu) | [64] |

| Fe/Pt | Radiolysis | Nanometer-sized fine particles | Eco-friendly, improved dispersibility with PVP addition, controllability of mean particle size with PVP addition | [65] |

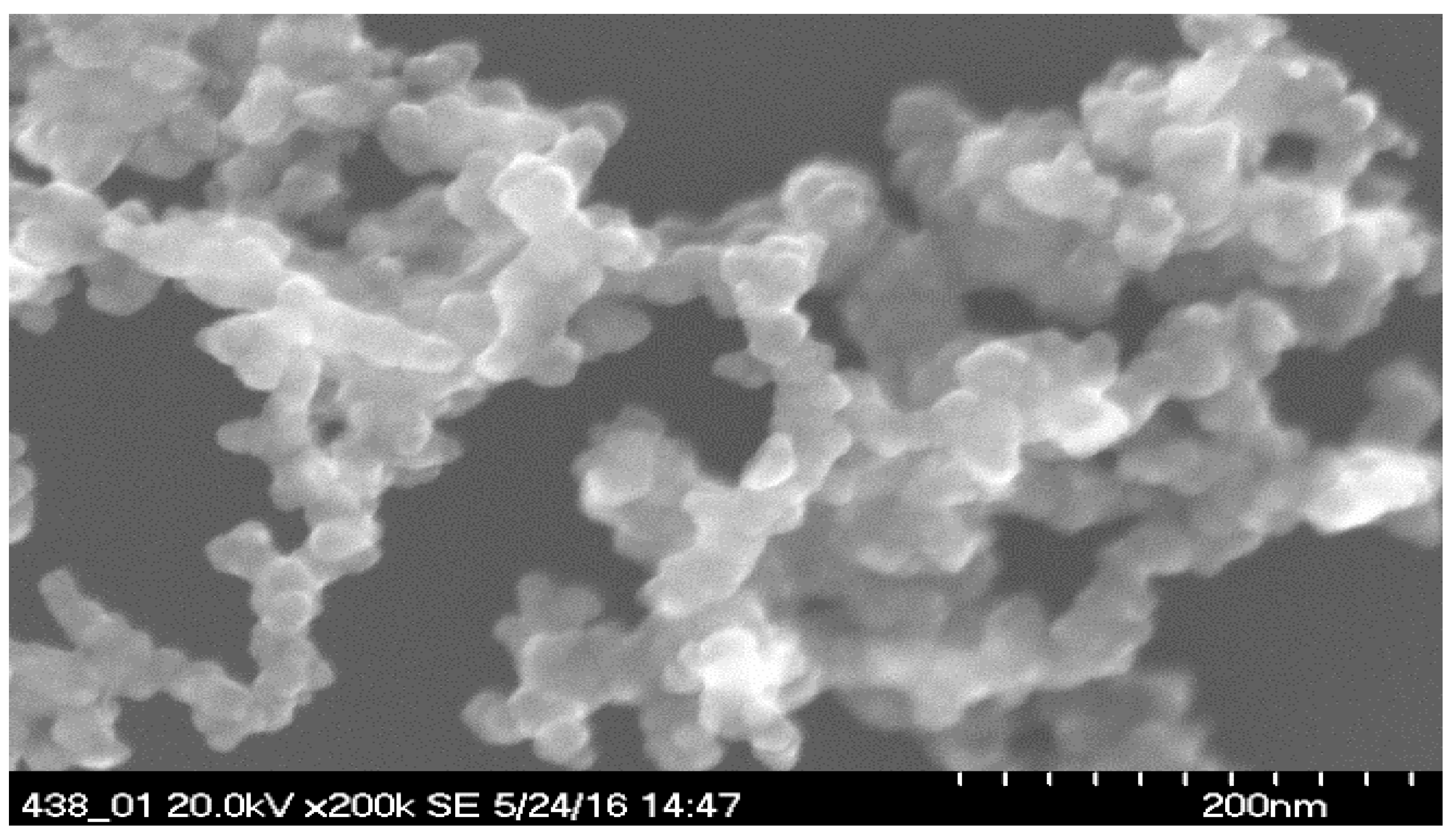

| Ni/Fe | Sonochemical | Spherically shaped nanoparticles | Adsorptive and catalytic capability, enhanced dispersity, reduced agglomeration | [69] |