Design Optimization of Key Structural Parameters for Tension Measuring Rollers in Temper Mill Units

Abstract

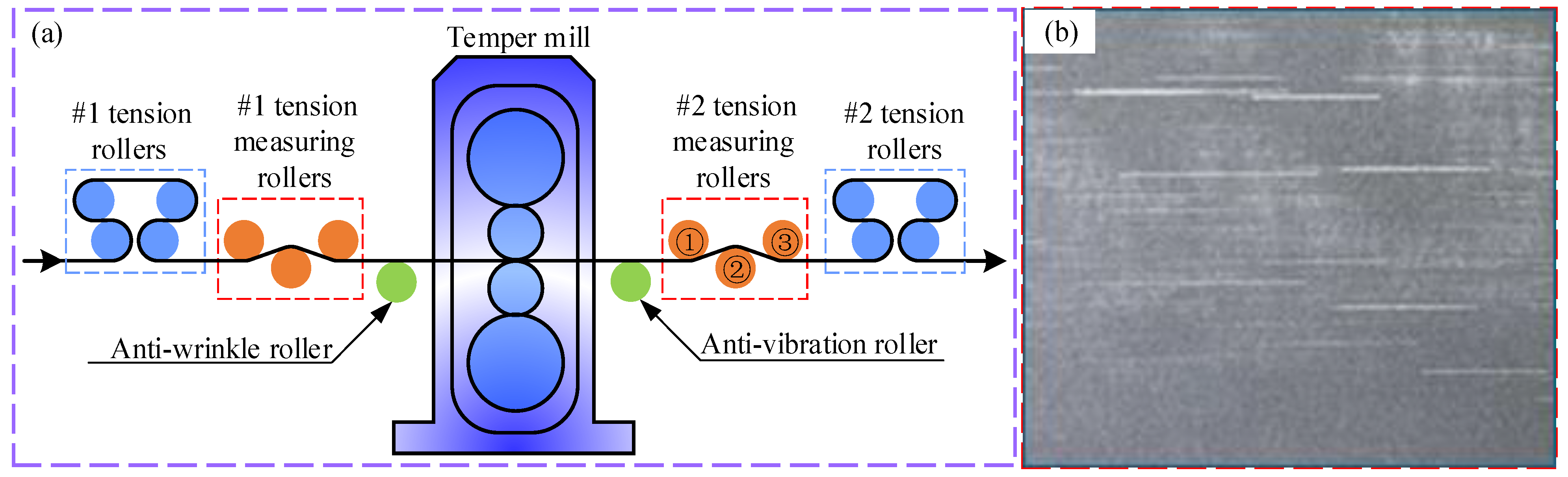

1. Introduction

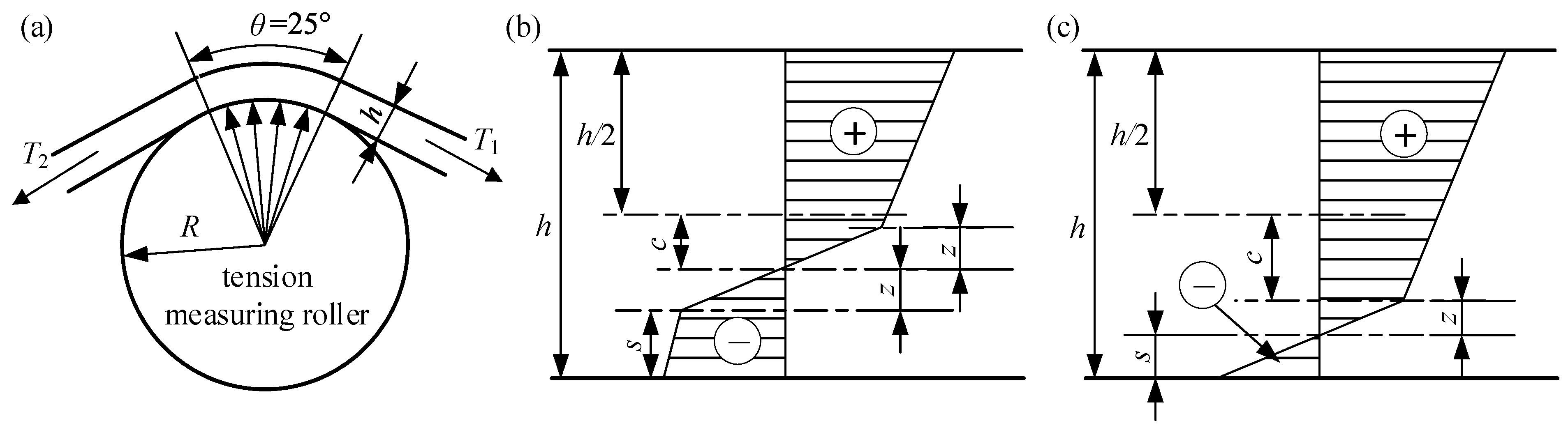

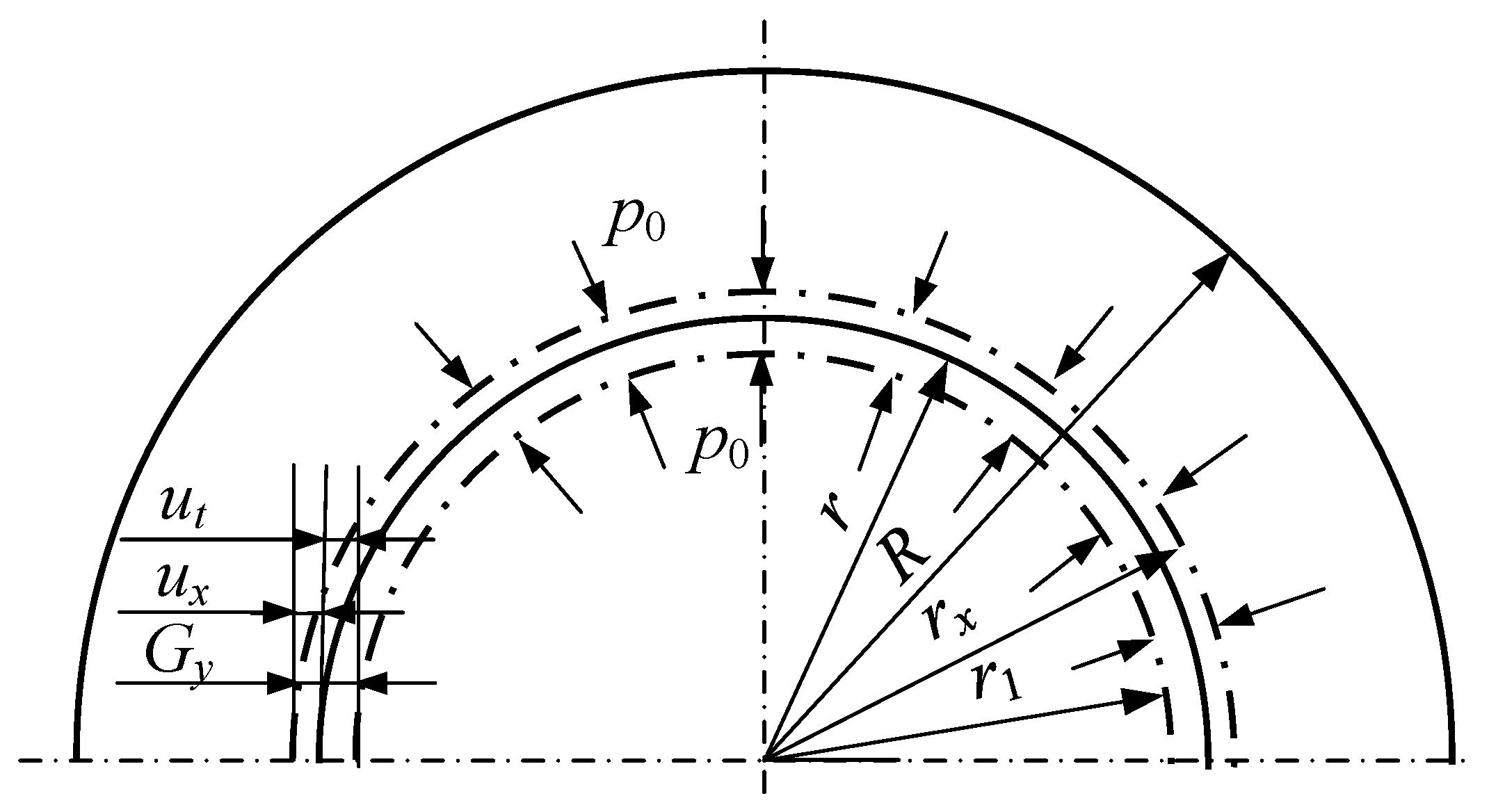

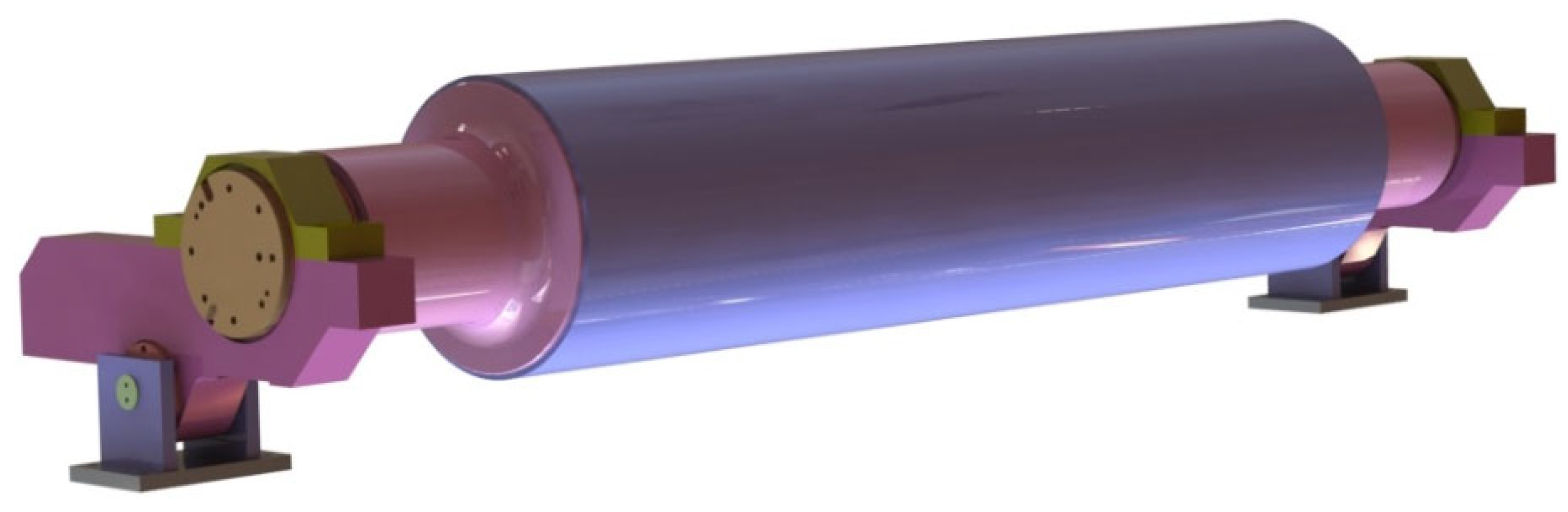

2. Optimization of Tension Measuring Roller Diameter and Warpage Verification

2.1. Warpage Calculation Model

2.2. Warpage Verification of Steel Strip

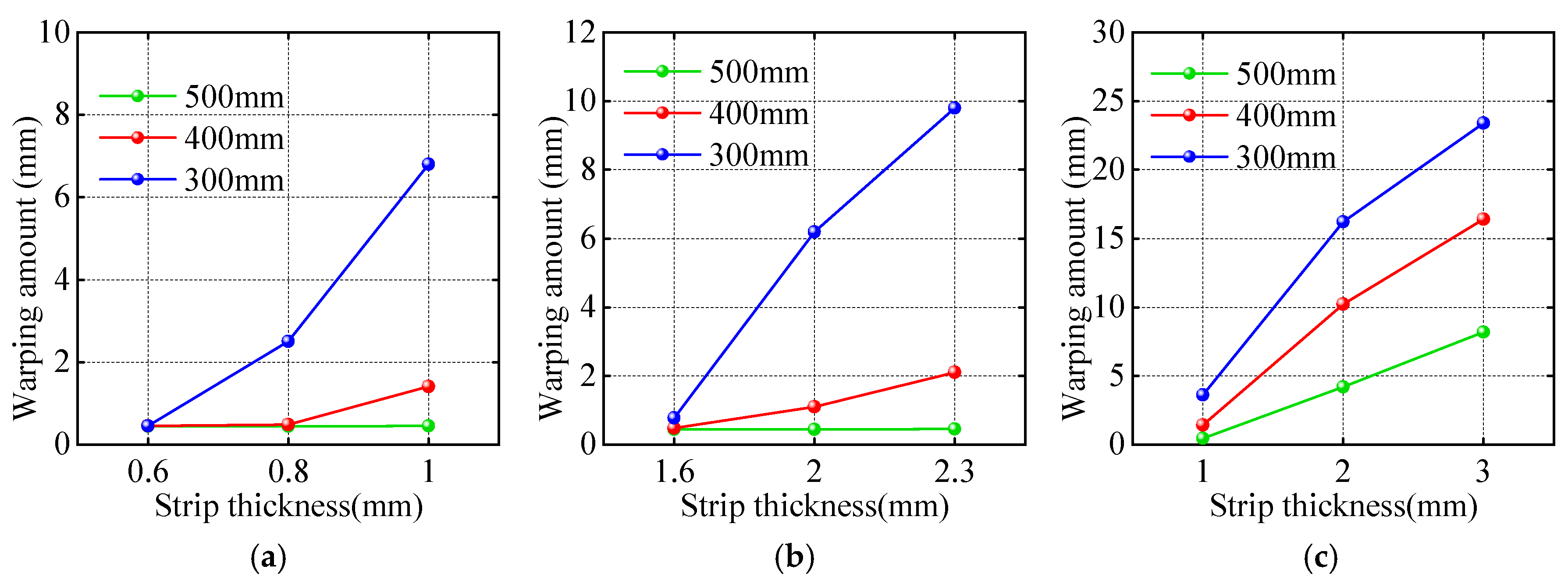

2.2.1. Warpage Amount for Different Steel Grades and Thicknesses

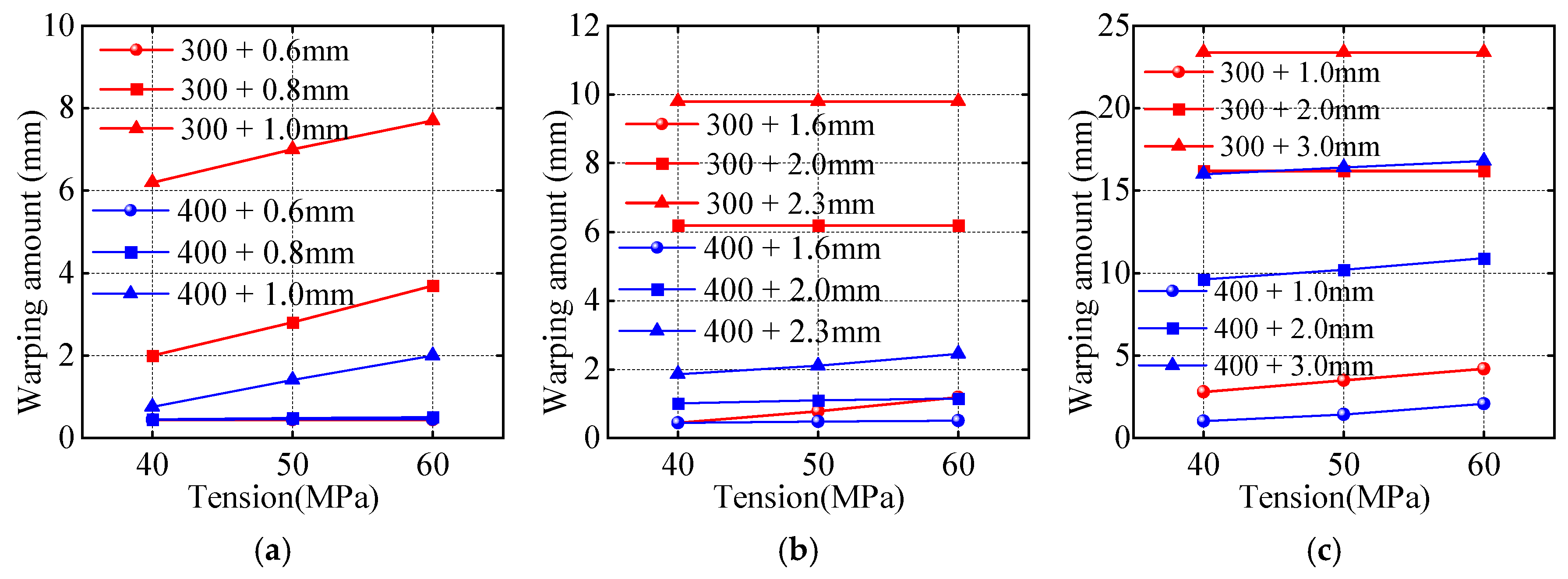

2.2.2. Warpage Amount for Different Tensions

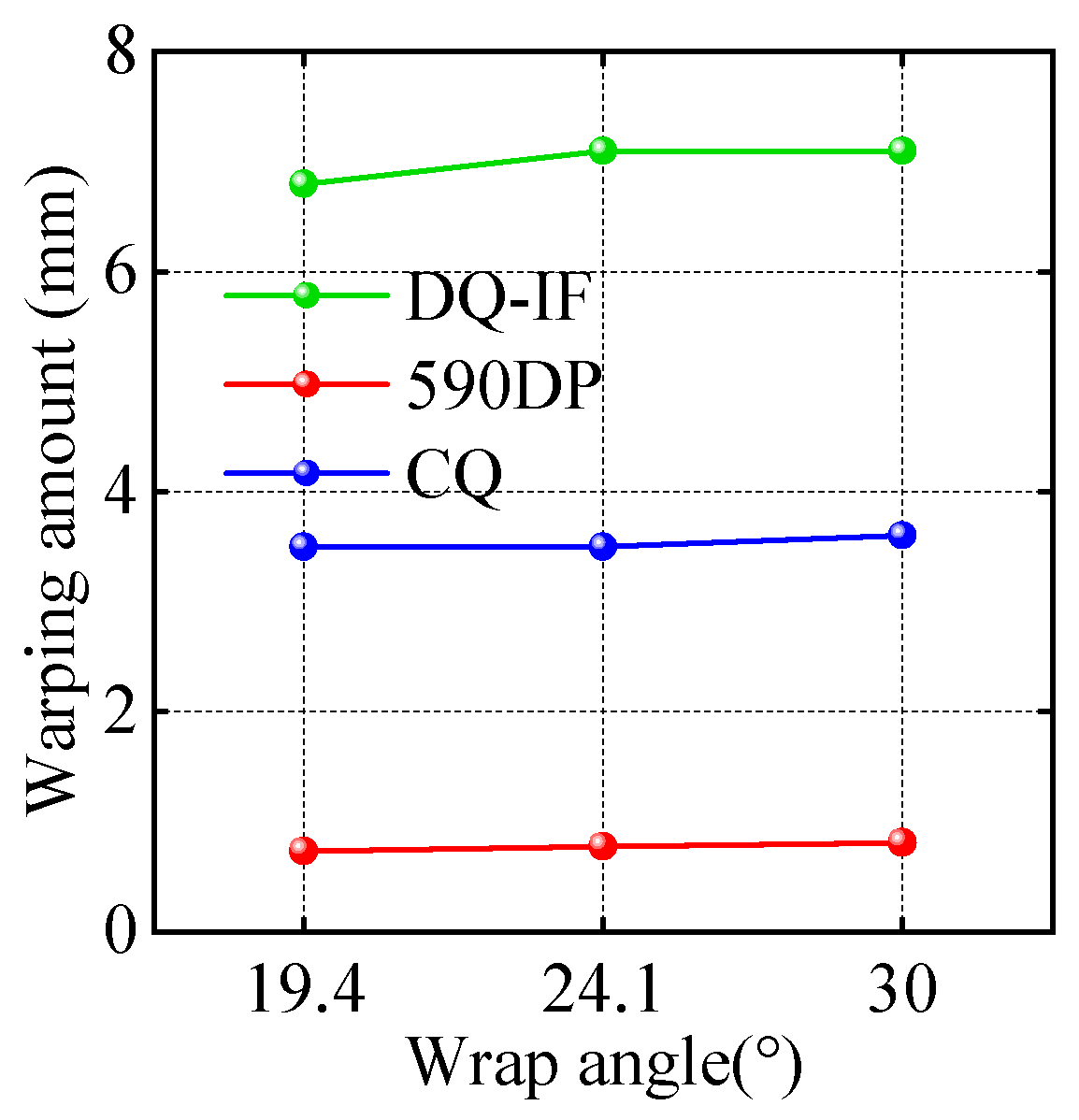

2.2.3. Warpage Amount for Different Wrap Angles

2.3. Summary of This Section

3. Optimization of Tension Measuring Roller Sleeve Wall Thickness and Wrap Angle, and Scratch Verification

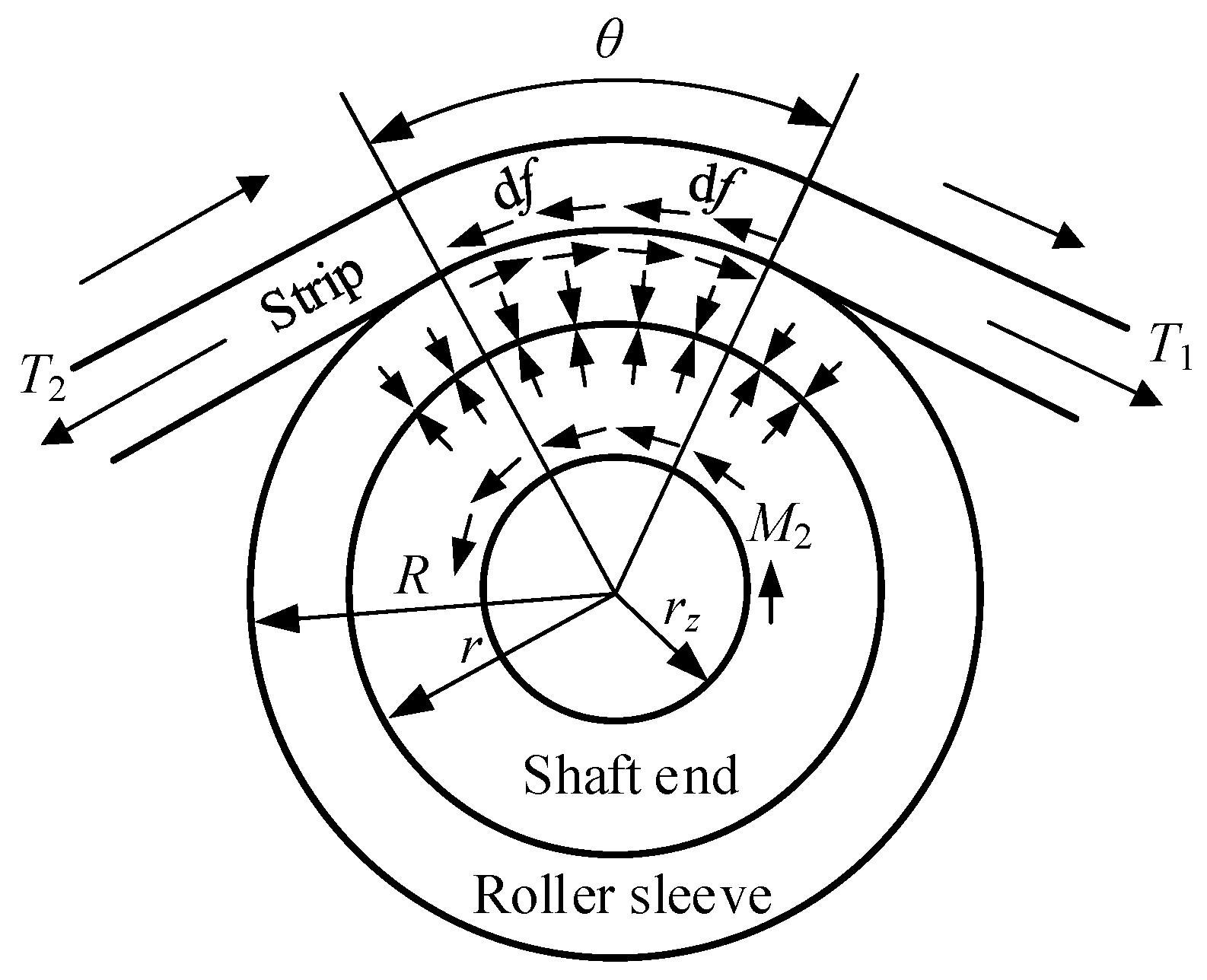

3.1. Force Analysis of the Tension Measuring Roller

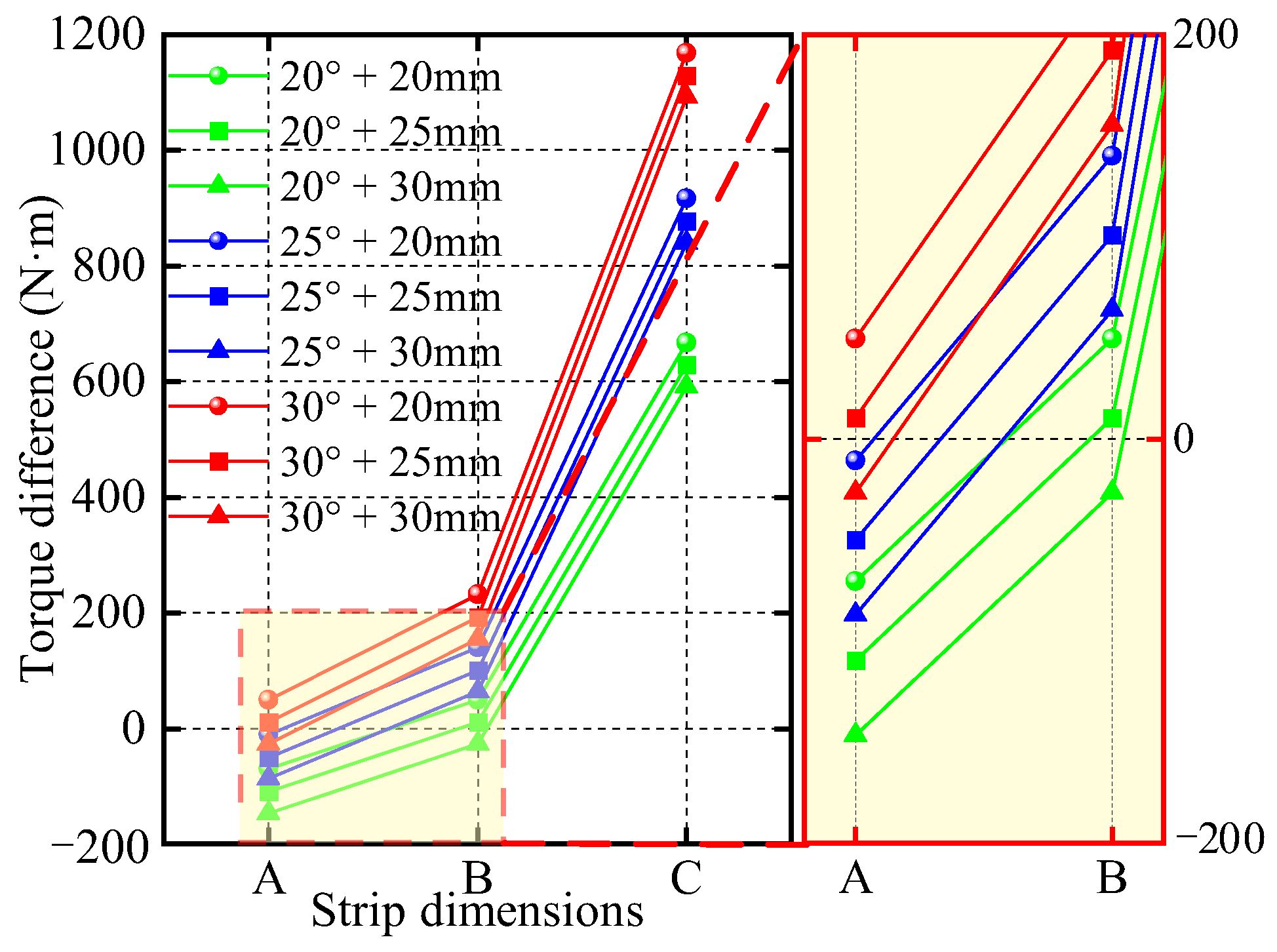

3.2. Scratch Verification of Steel Strip

3.3. Summary of This Section

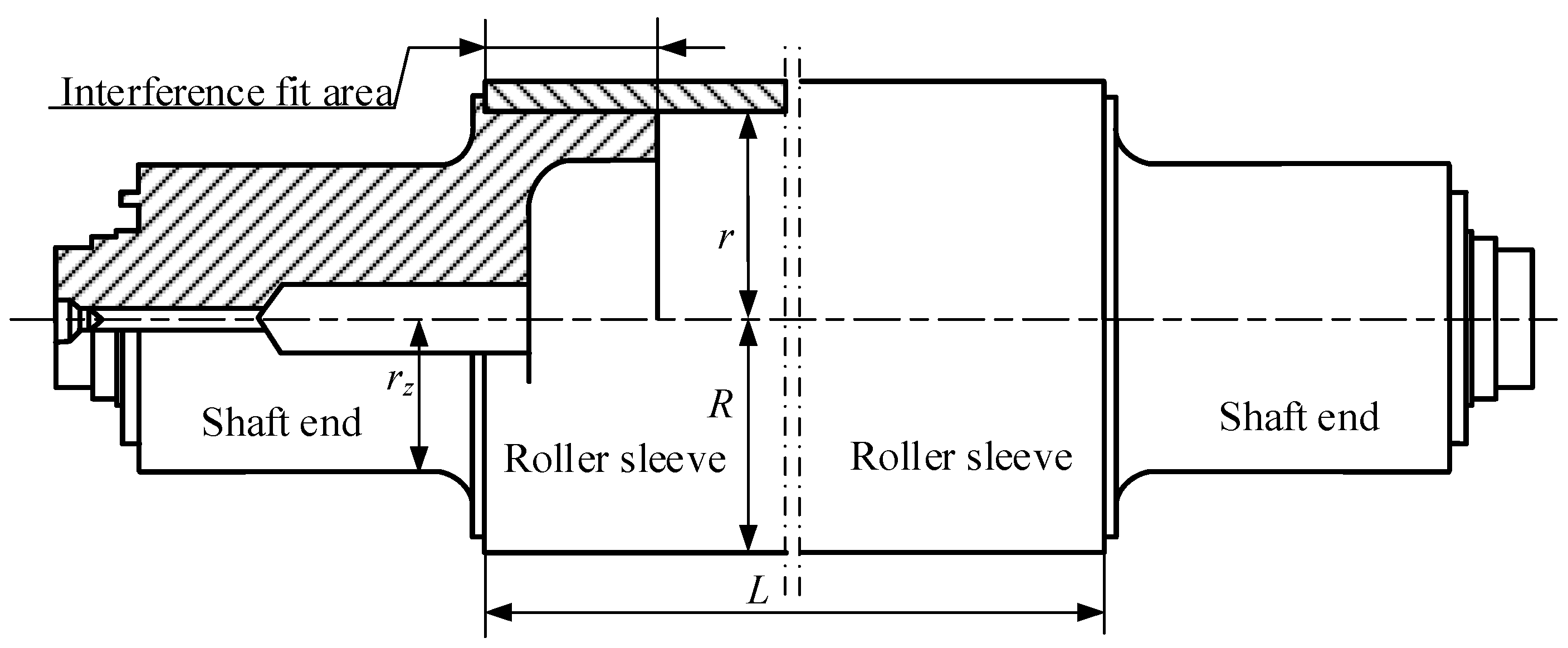

4. Verification of the Connection Safety of Tension Measuring Roller Sleeve and Shaft End

4.1. Stress and Deformation of Roller Sleeve and Shaft End

4.2. Verification of the Connection Safety

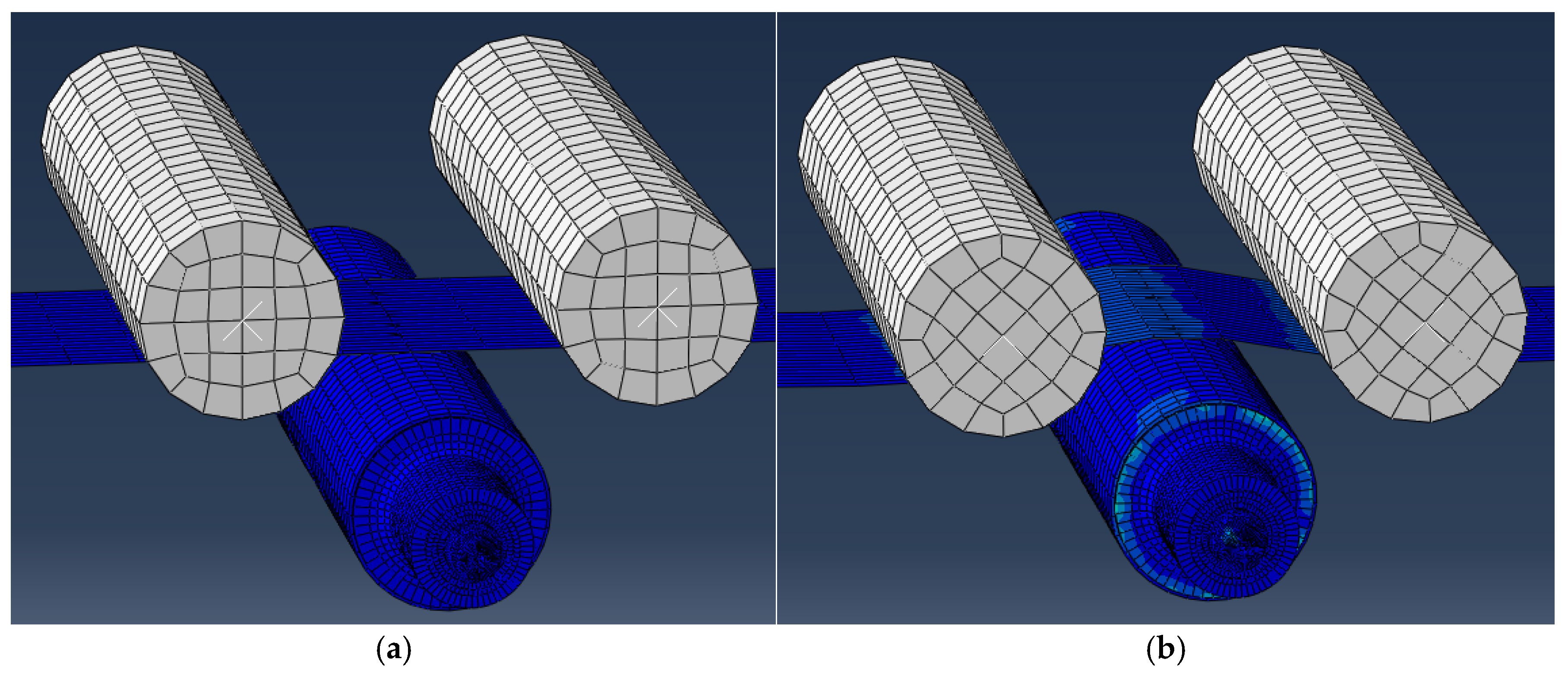

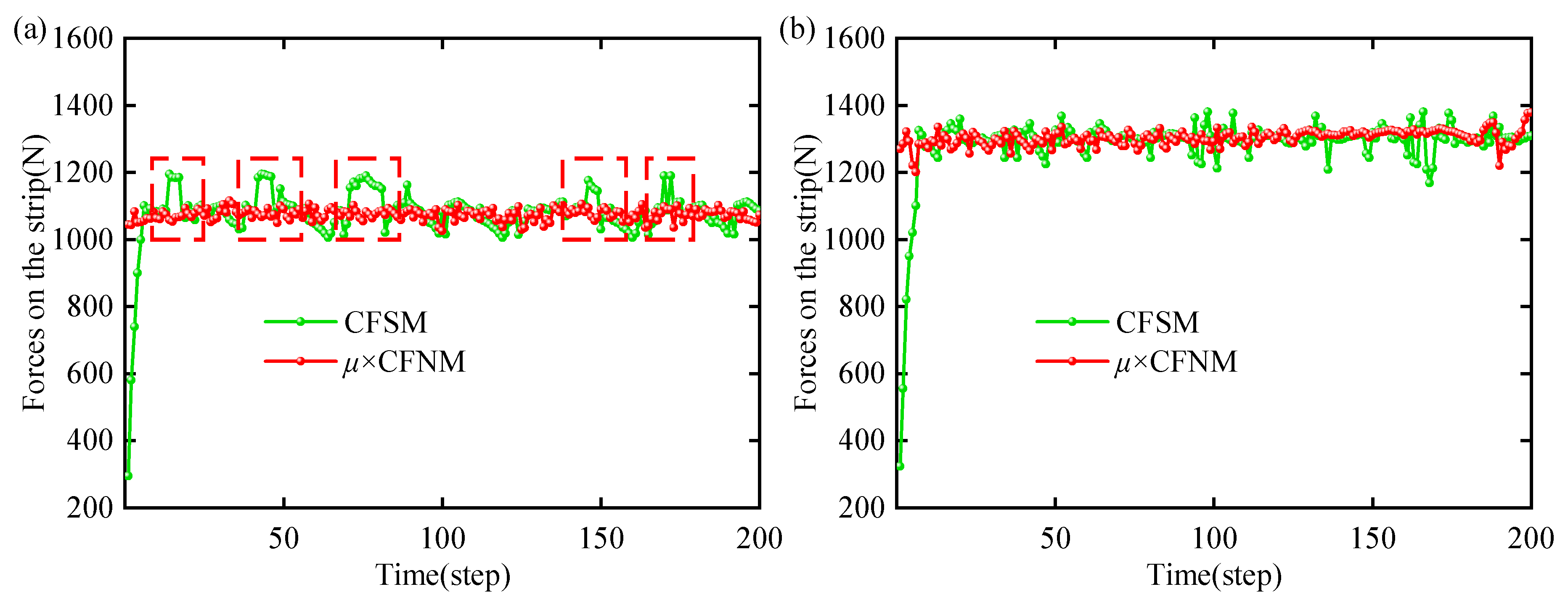

5. Verification by Finite Element Simulation

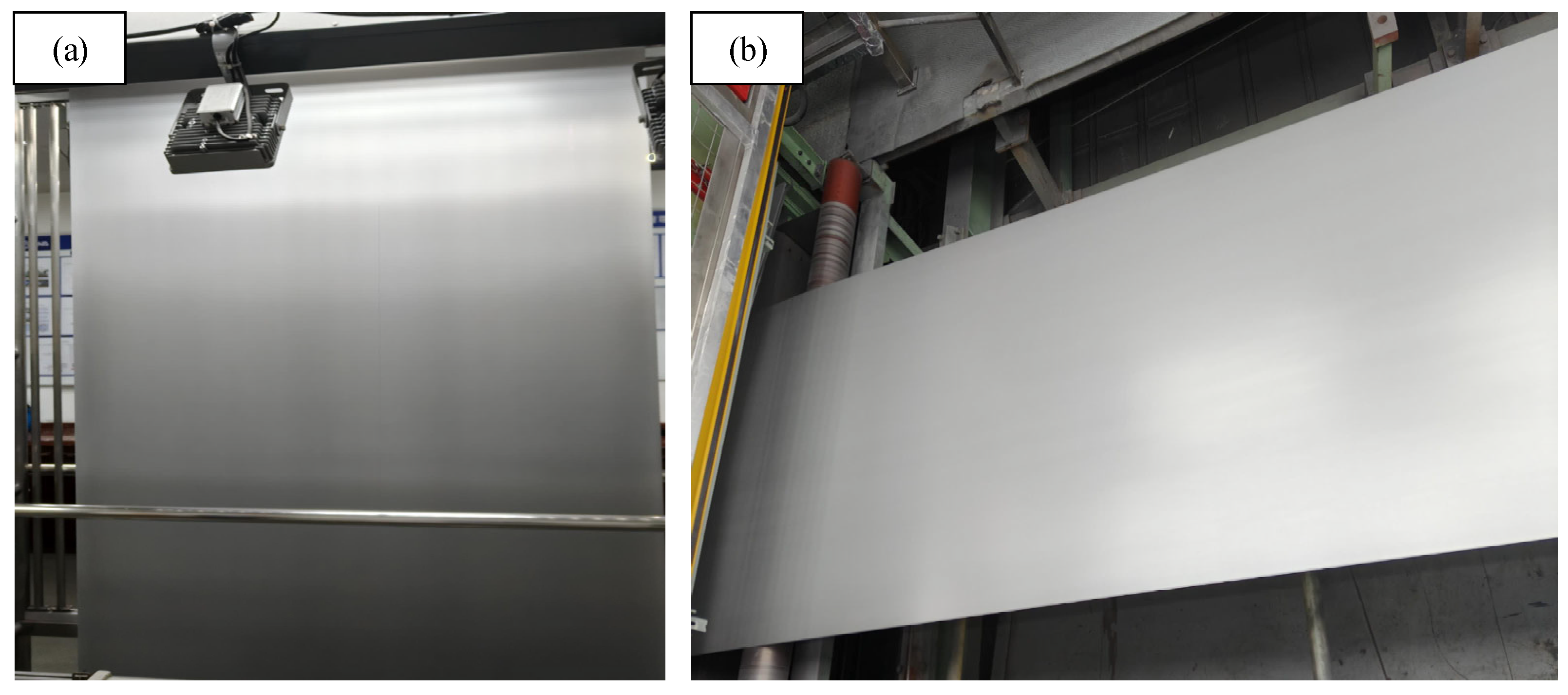

6. Production Trials of the Unit

7. Conclusions

- (1)

- It was confirmed by this research that the steel strip scratch defects caused by the tension measuring roller in temper rolling are due to relative sliding between the steel strip and the tension measuring roller. The fundamental reason for this is that the driving torque of the steel strip on the tension measuring roller is insufficient to overcome its total rotational resistance torque. The steel strip wrap angle, tension measuring roller sleeve outer diameter, and wall thickness are key structural parameters that influence this torque balance.

- (2)

- The structural parameters of the tension roller were optimized and verified to achieve the ideal warpage, scratching, and connection safety based on theoretical calculations and finite element analysis. By establishing corresponding mechanical models and simulation models, the influence of parameters such as the roller sleeve outer diameter, roller sleeve thickness, and steel strip wrap angle on the amount of steel strip warpage, the driving torque, and the stress on the connection parts was systematically evaluated. In the warpage verification, the results showed that, when the roller sleeve outer diameter was 500 mm, the warpage of the DQ-IF and 590DP steel grades fluctuated from around 1 mm to 1.5 mm, which is far less than 1% of the steel strip length, while 300 mm and 400 mm roller sleeve outer diameters led to warpage as high as 23 mm and 16 mm for some thicknesses, far exceeding the acceptable range. In the scratching verification, by comparing the difference between the driving torque and the total resistance torque, it was found that, under the conditions of a roller sleeve outer diameter of 500 mm and a wrap angle of 30°, when the roller sleeve thickness was 20 mm or 25 mm, the torque difference was positive and retained a certain margin, meeting the safety requirement for no scratching. Finally, comprehensively considering the verification results from all aspects, the optimal solution was determined to be a combination of a roller sleeve outer diameter of 500 mm, a roller sleeve thickness of 20 mm, and a wrap angle of 30°, and this solution satisfies the structural connection safety requirements. In the connection safety verification, the calculation results showed that the relative sliding safety factor met the requirements for both 20 mm and 25 mm roller sleeve thicknesses.

- (3)

- The results of theoretical analysis, finite element simulation, and actual production tests consistently indicated that the optimized tension roller structural parameters can effectively prevent relative sliding between the steel strip and the tension roller, completely eliminating scratch defects on the lower surface of the steel strip. The finite element simulation results show that, when using the optimized parameter combination of a roller sleeve outer diameter of 500 mm, a roller sleeve thickness of 20 mm, and a wrap angle of 30°, the total tangential force (CFSM) on the contact surface between the steel strip and the roller sleeve fluctuates stably around the limit of the maximum static friction force (μ × CFNM), and that there is no situation where the CFSM is consistently greater than μ × CFNM, confirming that no slipping occurred. The actual production tests, after adopting the optimized solution, involved vertical and horizontal inspections on steel strips of multiple steel grades and specifications, and the results showed that scratch defects no longer appeared on the steel strip surfaces, indicating that the scratching problem was completely resolved. The tension roller structural optimization scheme proposed in this study has achieved success in actual industrial applications, indicating that is provides a reliable technical approach to solving the scratching problem in temper rolling.

- (4)

- In the theoretical analysis and simulation modeling process of this study, some parameters were simplified, and the complexity of the actual production environment may have a certain impact on the results. For example, the friction coefficient may change with factors such as the temperature and lubrication state, while it may have been assumed as a constant in this model. Furthermore, this study mainly conducted detailed verification for specific steel grades and specifications. When extending the optimized solution to other steel grades and a wider range of thicknesses, further verification and adaptive adjustments are needed. Future research can consider introducing more complex models to more comprehensively consider various influencing factors in the actual production environment, which would thereby further enhance the universality and robustness of the optimized solution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Schulte, C.; Abel, D.; Teller, M.; Hirt, G.; Lohmar, J. Modeling and exploiting the strip tension influence on surface imprinting during temper rolling of cold-rolled steel. Adv. Ind. Manuf. Eng. 2021, 3, 100045. [Google Scholar] [CrossRef]

- Ogarkov, N.N.; Yu Zvyagina, E. Influence of disturbances in temper mills on work roll surface reproduction onto temper-rolled strips. Metallurgist 2025, 68, 1455–1461. [Google Scholar] [CrossRef]

- Xu, D.; Yang, Q.; Wang, X.; He, H.; Sun, Y.; Li, W. An experimental investigation of steel surface topography transfer by cold rolling. Micromachines 2020, 11, 916. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Zhang, Q.; Zhang, X.; Yu, M.; Wang, B. Control method for steel strip roughness in two-stand temper mill rolling. Chin. J. Mech. Eng. 2015, 28, 573–579. [Google Scholar] [CrossRef]

- Wang, R.; Bai, Z.H.; Du, J.C.; Wang, Y.X.; Cui, Y.Y.; Guo, Z.S.; Song, Z.F. Comprehensive tension setting optimisation technique for a cold rolled strip during continuous annealing. Ironmak. Steelmak. 2018, 45, 523–527. [Google Scholar] [CrossRef]

- Wang, D.C.; Liu, H.M.; Liu, J. Research and development trend of shape control for cold rolling strip. Chin. J. Mech. Eng. 2017, 30, 1248–1261. [Google Scholar] [CrossRef]

- Li, C.S.; Chen, J.S.; Han, W.L.; Li, Y.Y.; Fu, B. Thermal Scratch on Surface of SUS430 Stainless Steel Strip in Cold Rolling Process. J. Iron Steel Res. Int. 2014, 21, 282–286. [Google Scholar] [CrossRef]

- Chen, J.S.; Li, C.S. Prediction and control of thermal scratch defect on surface of strip in tandem cold rolling. J. Iron Steel Res. Int. 2015, 22, 106–114. [Google Scholar] [CrossRef]

- Kenmochi, K.; Yarita, I.; Abe, H.; Fukuhara, A.; Komatu, T.; Kaito, H. Effect of micro-defects on the surface brightness of cold-rolled stainless-steel strip. J. Mater. Process. Technol. 1997, 69, 106–111. [Google Scholar] [CrossRef]

- Lu, J.; Zhu, M.; Ma, X.; Wu, K. Steel strip surface defect detection method based on improved YOLOv5s. Biomimetics 2024, 9, 28. [Google Scholar] [CrossRef]

- Tang, B.; Chen, L.; Sun, W.; Lin, Z.K. Review of surface defect detection of steel products based on machine vision. IET Image Process. 2023, 17, 303–322. [Google Scholar] [CrossRef]

- Song, S.H.; Sul, S.K. A new tension controller for continuous strip processing line. IEEE Trans. Ind. Appl. 2000, 36, 633–639. [Google Scholar] [CrossRef]

- Sutcliffe, M.P.F.; Rayner, P.J. Experimental measurements of load and strip profile in thin strip rolling. Int. J. Mech. Sci. 1998, 40, 887–899. [Google Scholar] [CrossRef]

- Hrabovský, L.; Nenička, P.; Fries, J. Laboratory machine verification of force transmission provided by friction acting on the drive drum of a conveyor belt. Machines 2023, 11, 544. [Google Scholar] [CrossRef]

- Coubrough, G.J.; Alinger, M.J.; Van Tyne, C.J. Angle of contact between sheet and die during stretch–bend deformation as determined on the bending-under-tension friction test system. J. Mater. Process. Technol. 2002, 130, 69–75. [Google Scholar] [CrossRef]

- Kumar, S.; Edachery, V.; Velpula, S.; Govindaraju, A.; Choudhury, S.K.; Kailas, S.V. Influence of surface roughness, friction coefficient, and wrap angle on clinching joint strength and its correlation with belt friction phenomenon. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 326–337. [Google Scholar] [CrossRef]

- Horng, J.H.; Lin, J.F.; Li, K.Y. Effect of surface roughness on steel roller scuffing. Wear 1995, 184, 203–212. [Google Scholar] [CrossRef]

- Whitworth, D.P.D.; Harrison, M.C. Tension variations in pliable material in production machinery. Appl. Math. Model. 1983, 7, 189–196. [Google Scholar] [CrossRef]

- Xu, X.M.; Zhang, W.X.; Ding, X.L.; Zhang, M.; Wei, S.H. Design and analysis of a novel tension control method for winding machine. Chin. J. Mech. Eng. 2018, 31, 101. [Google Scholar] [CrossRef]

- Noh, J.; Lee, Y.; Kim, M.; Lee, C. Control of Fluctuational Tension in Roll-to-Roll Manufacturing Systems under Acceleration and Deceleration Conditions. Int. J. Precis. Eng. Manuf. Green Technol. 2025, 1, 1–16. [Google Scholar] [CrossRef]

- Hwang, J.K.; Kim, S.J.; Kim, K.J. Influence of Roll Diameter on Material Deformation and Properties during Wire Flat Rolling. Appl. Sci. 2021, 11, 8381. [Google Scholar] [CrossRef]

- Li, B.; Li, P.; Zhou, R.; Feng, X.Q.; Zhou, K. Contact mechanics in tribological and contact damage-related problems: A review. Tribol. Int. 2022, 171, 107534. [Google Scholar] [CrossRef]

- Ning, K.; Wang, J.; Li, P.; Xiang, D.; Hou, D. Multi-objective intelligent cooperative design for interference fit of the conical sleeve. J. Mech. Sci. Technol. 2021, 35, 3569–3578. [Google Scholar] [CrossRef]

- Ma, L.; Ma, Z.; Jia, W.; Lv, Y.; Jiang, Y.; Xu, H.; Liu, P. Research and verification on neutral layer offset of bar in two-roll straightening process. Int. J. Adv. Manuf. Technol. 2015, 79, 1519–1529. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Tieu, A.K. Elastic–plastic finite element method simulation of thin strip with tension in cold rolling. J. Mater. Process. Technol. 2002, 130, 511–515. [Google Scholar] [CrossRef]

- Xiao, H.; Ren, Z.; Liu, X. New mechanism describing the limiting producible thickness in ultra-thin strip rolling. Int. J. Mech. Sci. 2017, 133, 788–793. [Google Scholar] [CrossRef]

- Kasai, D.; Komori, A.; Ishii, A.; Yamada, K.; Ogawa, S. Strip warpage behavior and mechanism in single roll driven rolling. ISIJ Int. 2016, 56, 1815–1824. [Google Scholar] [CrossRef]

- Nakahara, T.; Baek, K.S.; Chen, H.; Ishida, M. Relationship between surface oxide layer and transient traction characteristics for two steel rollers under unlubricated and water lubricated conditions. Wear 2011, 271, 25–31. [Google Scholar] [CrossRef]

- Bayoumi, L.S.; Lee, Y. Effect of interstand tension on roll load, torque and workpiece deformation in the rod rolling process. J. Mater. Process. Technol. 2004, 145, 7–13. [Google Scholar] [CrossRef]

- Hashimoto, H. Friction characteristics between paper and steel roller under mixed lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 226, 1127–1140. [Google Scholar] [CrossRef]

- Marconnet, P.; Pottier, B.; Rasolofondraibe, L.; Dron, J.P.; Kerroumi, S. Measuring load distribution on the outer raceways of rotating machines. Mech. Syst. Signal Process. 2016, 66, 582–596. [Google Scholar] [CrossRef]

- Biron, G.; Vadean, A.; Tudose, L. Optimal design of interference fit assemblies subjected to fatigue loads: A sequential approximate multi-objective optimization approach. Struct. Multidiscip. Optim. 2013, 47, 441–451. [Google Scholar] [CrossRef]

- Wu, H.M.; Liu, H.M.; Yu, B.Q.; Yang, L.P. Determination of interference fit value on entire roller embedded shapemeter roll. J. Cent. South Univ. 2014, 21, 4503–4508. [Google Scholar] [CrossRef]

- Park, Y. Correlation analysis between coiling tension and the sleeve’s hoop stress. Mech. Ind. 2024, 25, 33. [Google Scholar] [CrossRef]

| Parameter | Existing Value | Optimized Value 1 | Optimized Value 2 |

|---|---|---|---|

| Roller Sleeve Outer Diameter (mm) | 500 | 400 | 300 |

| Roller Sleeve Wall Thickness (mm) | 30 | 25 | 20 |

| Steel Strip Wrap Angle (°) | 20 | 25 | 30 |

| Steel Strip Code | A | B | C |

|---|---|---|---|

| Steel Grade | DQ-IF | DQ-IF | CQ |

| Steel Strip Specification (mm) | 0.5 × 900 | 0.7 × 1300 | 2.0 × 1600 |

| Entry Tension T2 (kN) | 35.28 | 53.51 | 147.39 |

| Steel Strip Code | Roller Sleeve Wall Thickness (mm) | Exit Tension T1 (kN) | Radial Load P0 (kN) | Inertial Torque (N·m) | Bearing Seal Resistance Torque (N·m) | Total Resistance Torque (N·m) | Driving Torque (N·m) |

|---|---|---|---|---|---|---|---|

| A | 20 | 36.5 | 24.1 | 174.4 | 120.5 | 294.9 | 313.2 |

| 25 | 36.5 | 25.3 | 198.8 | 126.2 | 325.1 | 313.2 | |

| 30 | 36.5 | 26.4 | 221.6 | 131.9 | 353.5 | 313.2 | |

| B | 20 | 55.4 | 30.5 | 174.4 | 152.7 | 327.1 | 475.0 |

| 25 | 55.4 | 31.7 | 198.8 | 158.4 | 357.3 | 475.0 | |

| 30 | 55.4 | 32.8 | 221.6 | 164.1 | 385.7 | 475.0 | |

| C | 20 | 152.6 | 63.7 | 174.4 | 318.6 | 493.0 | 1308.3 |

| 25 | 152.6 | 64.9 | 198.8 | 324.4 | 523.2 | 1308.3 | |

| 30 | 152.6 | 66.0 | 221.6 | 330.0 | 551.7 | 1308.3 |

| Steel Strip Code | Roller Sleeve Wall Thickness (mm) | Exit Tension T1 (kN) | Radial Load P0 (kN) | Inertial Torque (N·m) | Bearing Seal Resistance Torque (N·m) | Total Resistance Torque (N·m) | Driving Torque (N·m) |

|---|---|---|---|---|---|---|---|

| A | 20 | 36.9 | 27.2 | 174.4 | 136.2 | 310.6 | 393.2 |

| 25 | 36.9 | 28.4 | 198.8 | 141.9 | 340.8 | 393.2 | |

| 30 | 36.9 | 29.5 | 221.6 | 147.6 | 369.2 | 393.2 | |

| B | 20 | 55.9 | 35.3 | 174.4 | 176.5 | 350.9 | 596.3 |

| 25 | 55.9 | 26.5 | 198.8 | 198.8 | 381.1 | 596.3 | |

| 30 | 55.9 | 27.6 | 221.6 | 221.6 | 409.6 | 596.3 | |

| C | 20 | 154.0 | 76.8 | 174.4 | 384.2 | 558.7 | 1642.5 |

| 25 | 154.0 | 78.0 | 198.8 | 390.0 | 588.8 | 1642.5 | |

| 30 | 154.0 | 79.1 | 221.6 | 395.7 | 617.3 | 1642.5 |

| Steel Strip Code | Roller Sleeve Wall Thickness (mm) | Exit Tension T1 (kN) | Radial Load P0 (kN) | Inertial Torque (N·m) | Bearing Seal Resistance Torque (N·m) | Total Resistance Torque (N·m) | Driving Torque (N·m) |

|---|---|---|---|---|---|---|---|

| A | 20 | 37.2 | 30.4 | 174.4 | 151.9 | 326.3 | 473.9 |

| 25 | 37.2 | 31.5 | 198.8 | 157.6 | 356.5 | 473.9 | |

| 30 | 37.2 | 32.7 | 221.6 | 163.3 | 384.9 | 473.9 | |

| B | 20 | 56.4 | 40.1 | 174.4 | 200.3 | 374.7 | 718.7 |

| 25 | 56.4 | 41.2 | 198.8 | 206.1 | 404.9 | 718.7 | |

| 30 | 56.4 | 42.4 | 221.6 | 211.7 | 433.4 | 718.7 | |

| C | 20 | 155.3 | 90.0 | 174.4 | 449.8 | 624.3 | 1979.7 |

| 25 | 155.3 | 91.1 | 198.8 | 455.6 | 654.4 | 1979.7 | |

| 30 | 155.3 | 92.3 | 221.6 | 461.3 | 682.9 | 1979.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zhu, S.; Wang, Z.; Zhu, J.; Bai, Z. Design Optimization of Key Structural Parameters for Tension Measuring Rollers in Temper Mill Units. Metals 2025, 15, 593. https://doi.org/10.3390/met15060593

Zhang J, Zhu S, Wang Z, Zhu J, Bai Z. Design Optimization of Key Structural Parameters for Tension Measuring Rollers in Temper Mill Units. Metals. 2025; 15(6):593. https://doi.org/10.3390/met15060593

Chicago/Turabian StyleZhang, Ji, Sihua Zhu, Zhixuan Wang, Jiahao Zhu, and Zhenhua Bai. 2025. "Design Optimization of Key Structural Parameters for Tension Measuring Rollers in Temper Mill Units" Metals 15, no. 6: 593. https://doi.org/10.3390/met15060593

APA StyleZhang, J., Zhu, S., Wang, Z., Zhu, J., & Bai, Z. (2025). Design Optimization of Key Structural Parameters for Tension Measuring Rollers in Temper Mill Units. Metals, 15(6), 593. https://doi.org/10.3390/met15060593