1. Introduction

Chromium–nickel austenitic stainless steels find widespread use in many industries owing to their corrosion resistance, facile machinability by cutting and plastic deformation, and reliable weldability. The wider application of these steels is limited by their susceptibility to intergranular corrosion in the temperature range of 500–700 °C and their initially low hardness and strength. Increasing the hardness and the strength is achieved through two main approaches: bulk cold working [

1,

2] and modification of the surface layers (SLs). A disadvantage of bulk cold working is the need for significant energy resources. In addition, this approach applies to a limited range of blanks and parts made of sheet material. Alternatively, the SL can be modified by low-temperature thermo-chemical diffusion processes (nitriding and/or carburizing) aimed at forming a supersaturated surface S-phase [

3,

4], surface cold working (SCW) processes [

5,

6], or a combination of both [

7,

8].

The SL and substrate can be viewed as a functionally linked system, and modification of the SL is required to prepare the system for the desired application. Hence, studies focus on significantly improving the desired properties of SLs, such as hardness, strength, wear resistance, crack resistance, and corrosion resistance, for specific applications in the most cost-effective manner. At the same time, the bulk material remains raw and tough; therefore, this approach is energy efficient, economical, provides added value, and is environmentally friendly in many cases.

The SLs are typically exposed to various external influences, including contact between SLs and other surfaces; high working stresses under load-bearing conditions, which are maximum in these layers; and direct exposure to the environment, which is often aggressive (seawater or other chemically active environments). As a result, the operational behavior of steel parts is directly correlated with the complex state of the SL, known as surface integrity (SI) [

9]. To achieve high efficiency in the SL modification processes, an integrated approach is needed to study the finishing process–SI–operating behavior correlations [

10].

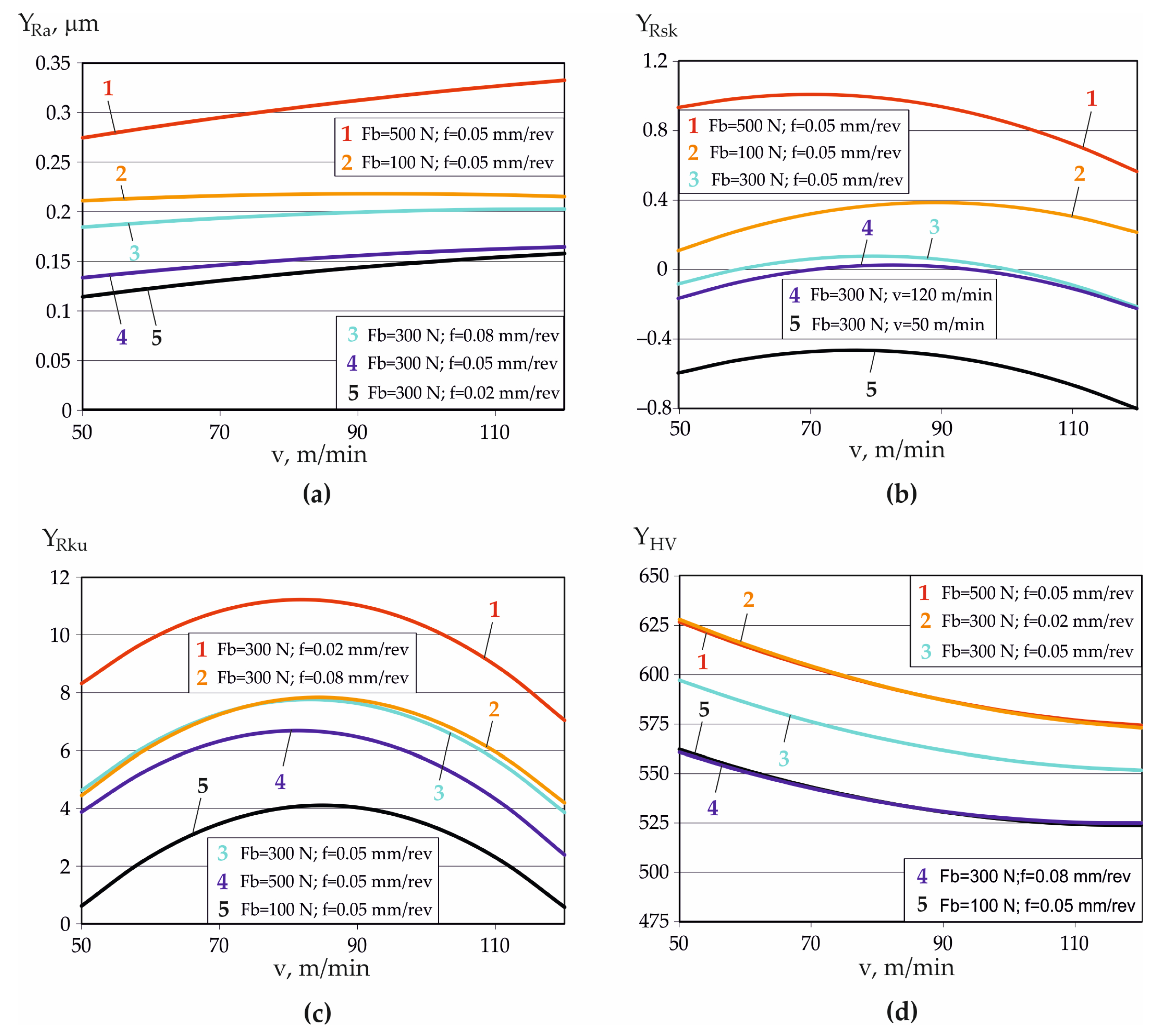

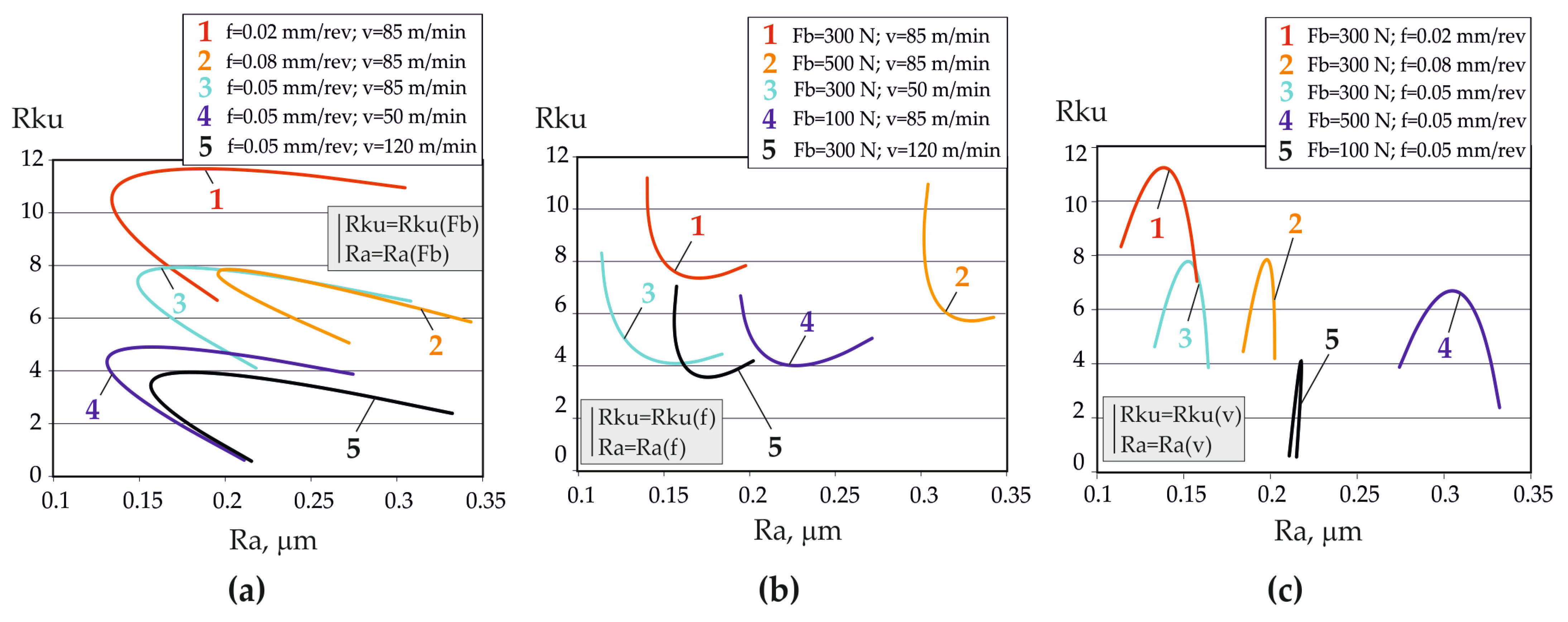

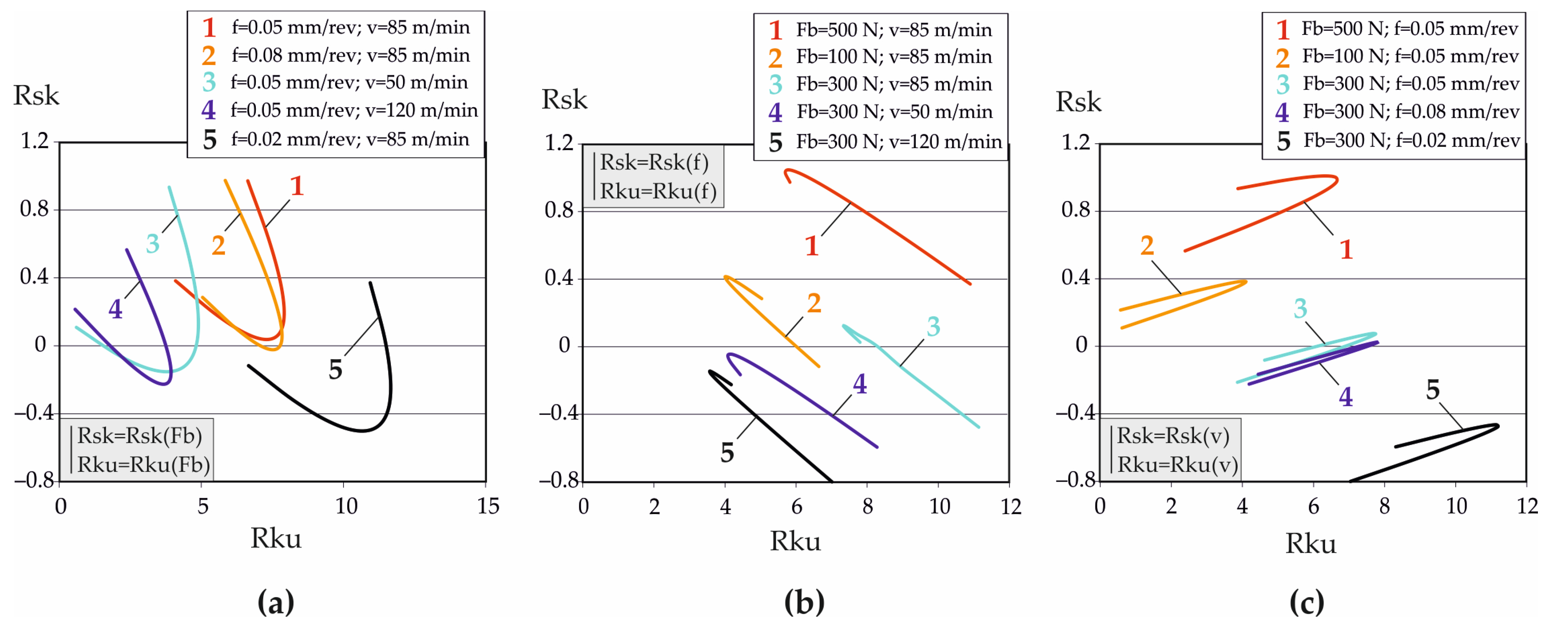

An effective approach for modifying SLs is static SCW (i.e., burnishing), which is implemented using a rigid and smooth deforming element that is pressed with a constant static force and relative motion against the surface being machined. Thus, the SL deforms plastically at a temperature lower than the recrystallization temperature of the processed material. As a result, the SL is modified owing to the following effects: (1) smoothing of microscale roughness (smoothing effect); (2) a significant increase in surface microhardness (strain-hardening effect); (3) introduction of useful residual compressive stresses in the surface and nearby subsurface layers; and (4) modification of the microstructure in the direction of grain refinement and orientation. Static SCW processes mainly differ from dynamic SCW processes in terms of the surface texture parameters. Notably, the smoothing effect is generally not observed in dynamic SCW processes [

11]. This result has also been confirmed for austenitic stainless steels after shot peening [

12] and laser shock peening [

13]. Unlike dynamic SCW, static SCW processes rely on a deforming element (tool) with a defined geometry and kinematics that precisely determine the interaction between the tool and the machined surface in time and space. This creates topographically anisotropic surfaces characterized by a drastic reduction in the roughness height parameters, such as the average roughness (Ra). In addition, the roughness shape parameters, namely skewness (Rsk) and kurtosis (Rku) [

14], are particularly sensitive to the type of tangential contact (roller friction or sliding friction) and the variation of the technological parameters in the corresponding static SCW process [

15,

16].

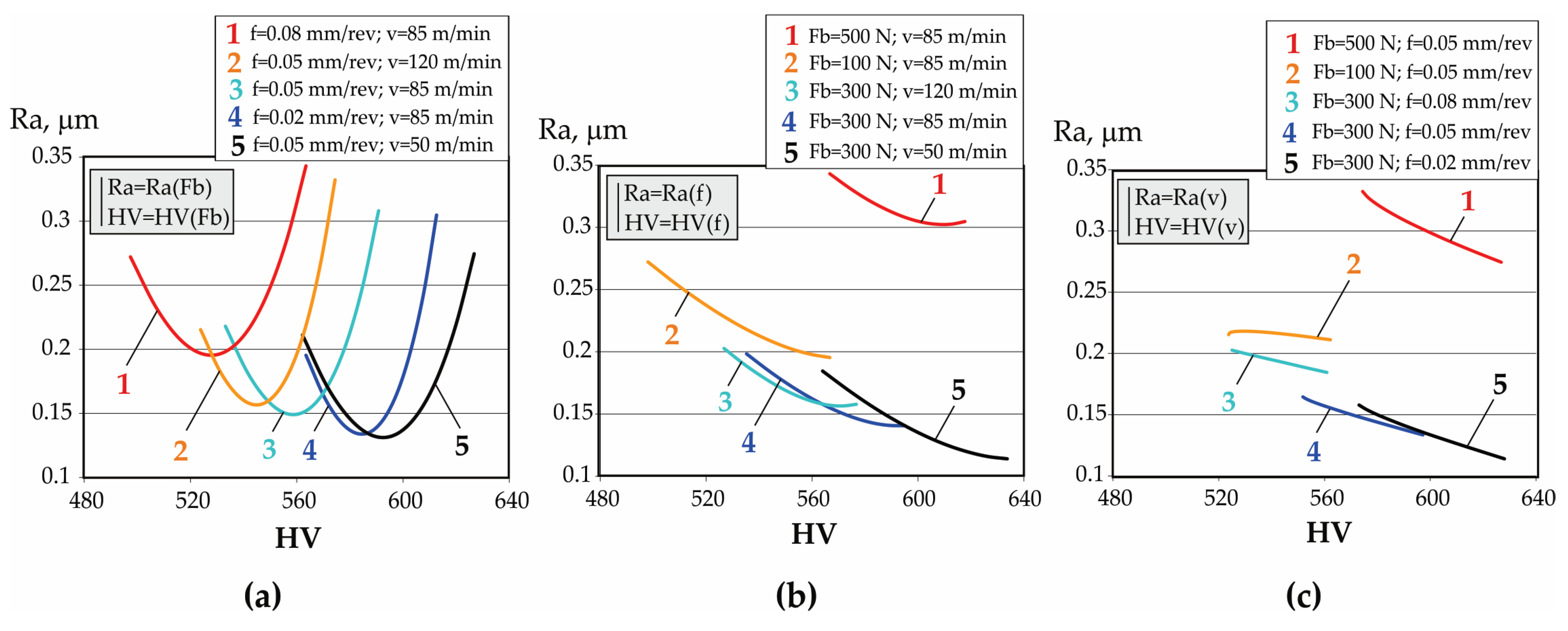

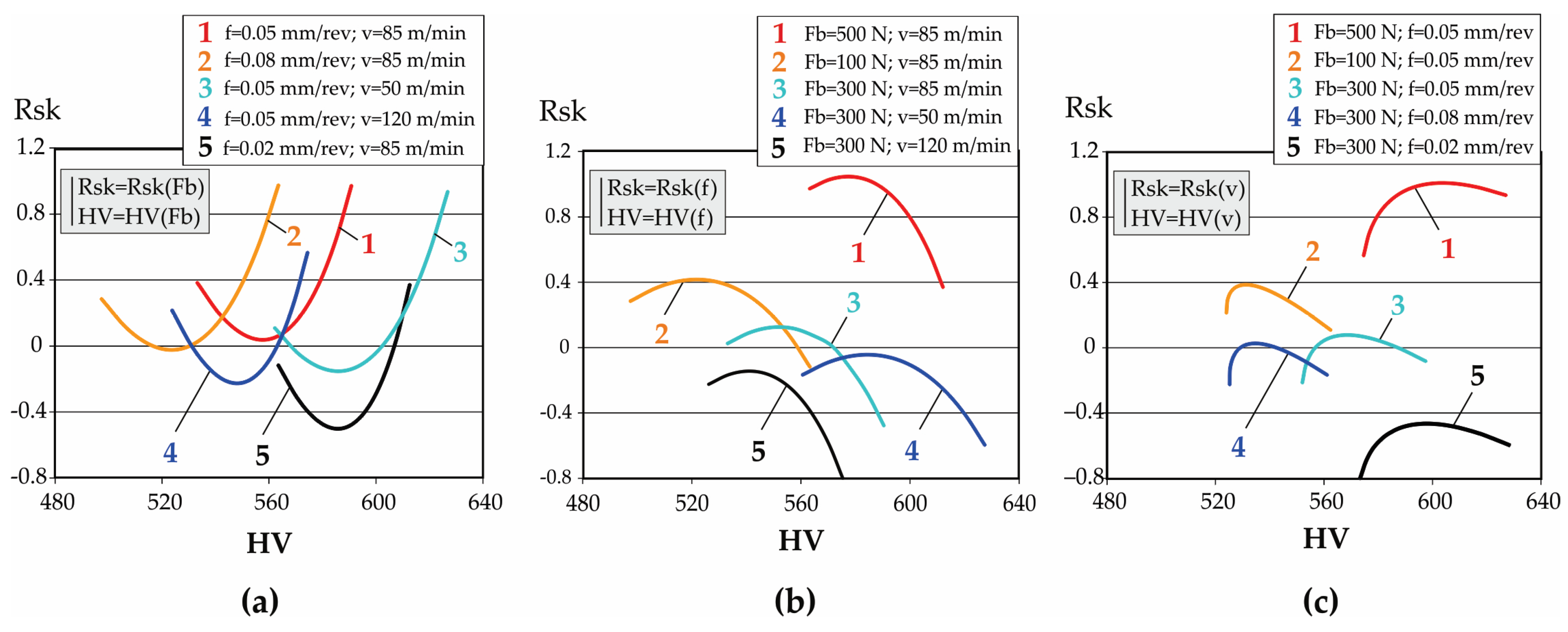

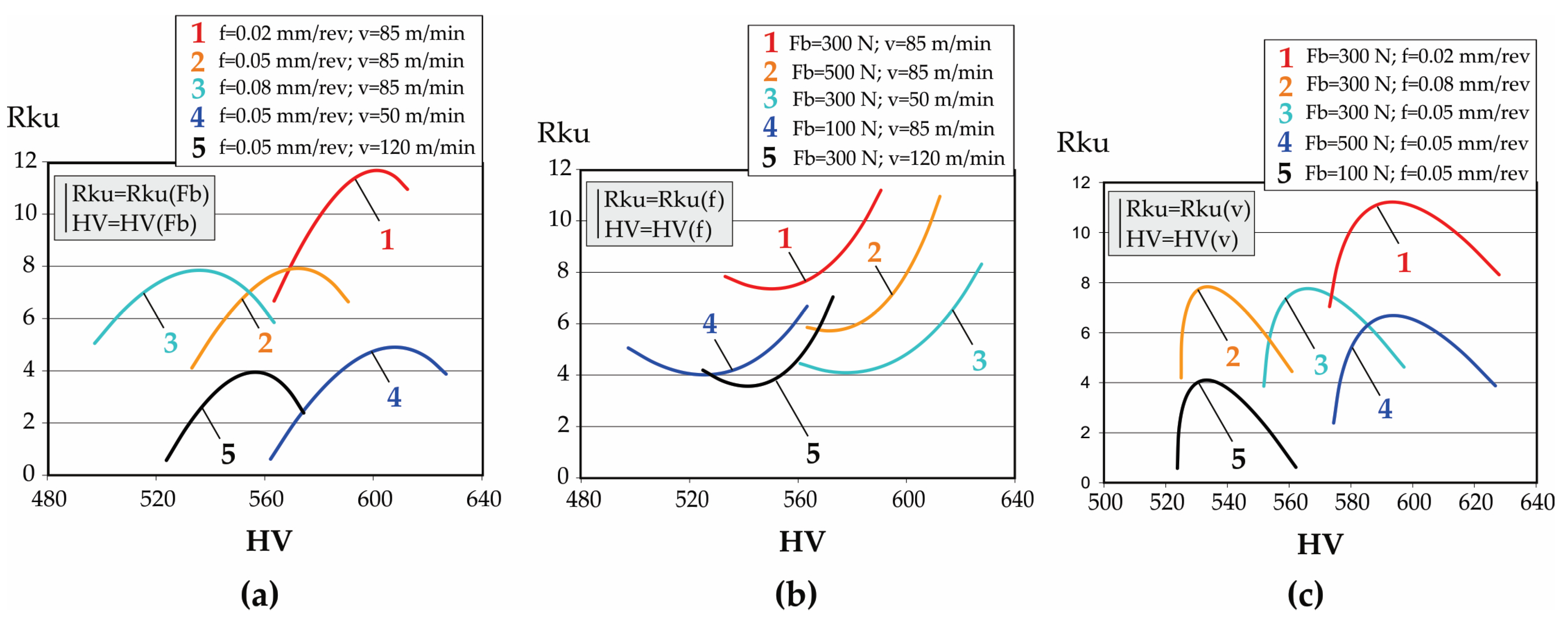

The four modification effects occur simultaneously because they have a common physical basis: severe surface plastic deformation in the SL. Therefore, for a specific material, the obtained SI characteristics (as quantitative indicators of these effects) are interdependent and influenced by the combination of technological SCW parameters. The surface texture parameters are correlated with the equivalent plastic deformation in SLs, of which the surface microhardness is a quantitative indicator.

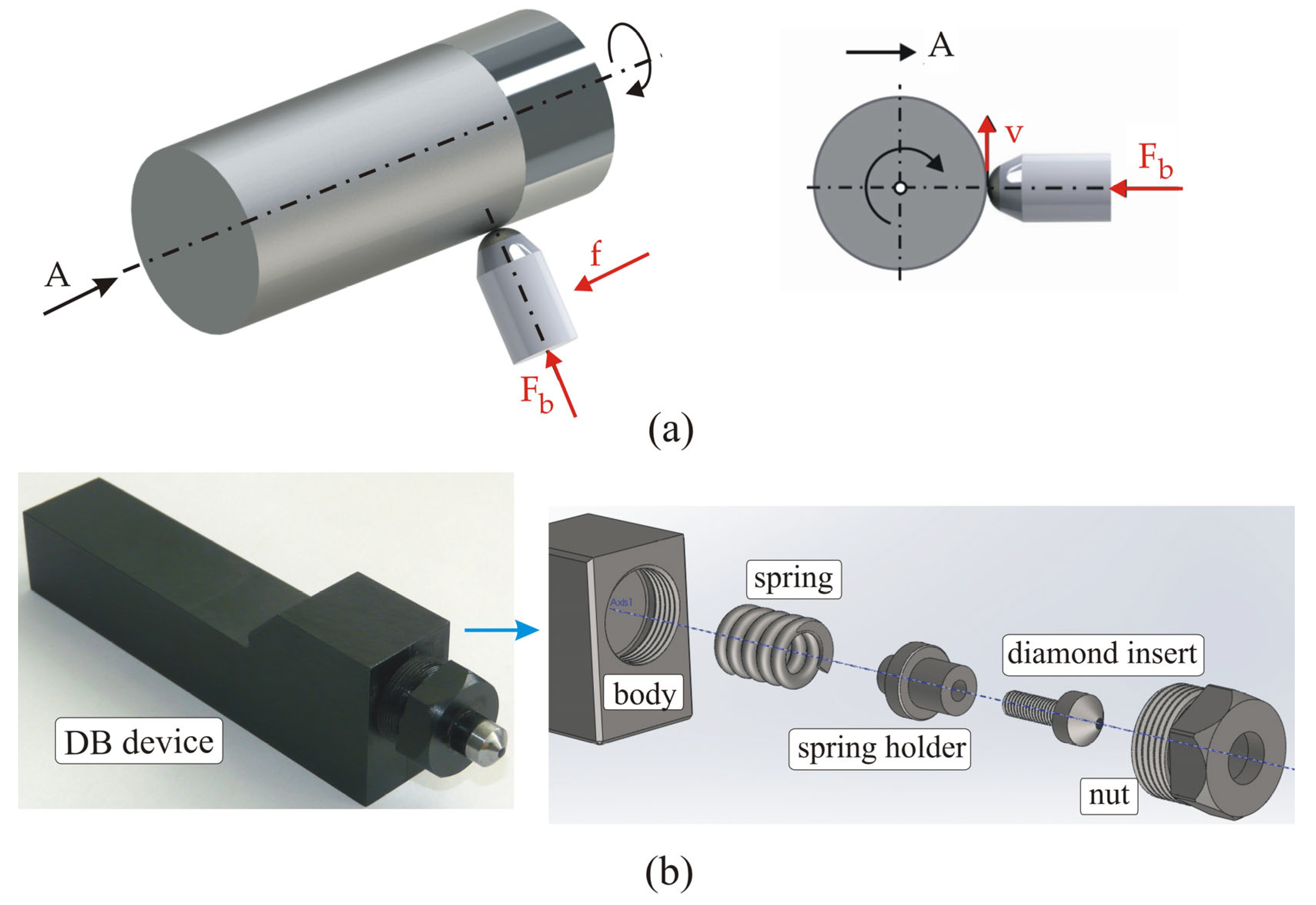

When the tangential contact between the deforming element and the SL is sliding friction, static SCW is known as slide burnishing. When slide burnishing is implemented using a diamond deforming insert, the method is called diamond burnishing (DB). DB was introduced in 1962 by General Electric to improve the SI of metal components. DB is a simple and effective finishing technique, and its main advantages over burnishing methods with rolling contact (e.g., hydrostatic ball burnishing) are the significantly simpler equipment and kinematics.

Extensive studies have been conducted on the influence of the governing factors in the DB process on the SI of samples made of chromium–nickel austenitic steels [

17,

18,

19,

20,

21]. These studies mainly considered the DB process–Ra 2D roughness parameter correlation [

18,

19] and the DB process–3D height and shape roughness parameter correlations [

17,

20,

21]. DB is an effective finishing process that provides a significant strain-hardening effect in austenitic stainless steels, indicated by significantly increased microhardness and residual compressive stresses [

18,

19,

20,

21]. Korzynski et al. [

20] predicted that the durability of the friction couple formed by 317Ti austenitic steel stem and graphite cord is increased by up to four times after DB, employing a reciprocating motion. To improve the fatigue behavior of AISI 304 austenitic stainless steels, Maximov et al. [

18,

19] examined the DB process–SI–rotating bending fatigue test correlations. Different types of DB processes increased the fatigue strength of AISI 304 steel by 23–38% compared with fine turning and polishing [

18]. The effects of DB and heat treatment on the rotating fatigue strength and corrosion resistance of AISI 304 austenitic stainless steel were also observed for two initial states, in correlation with the SI [

19].

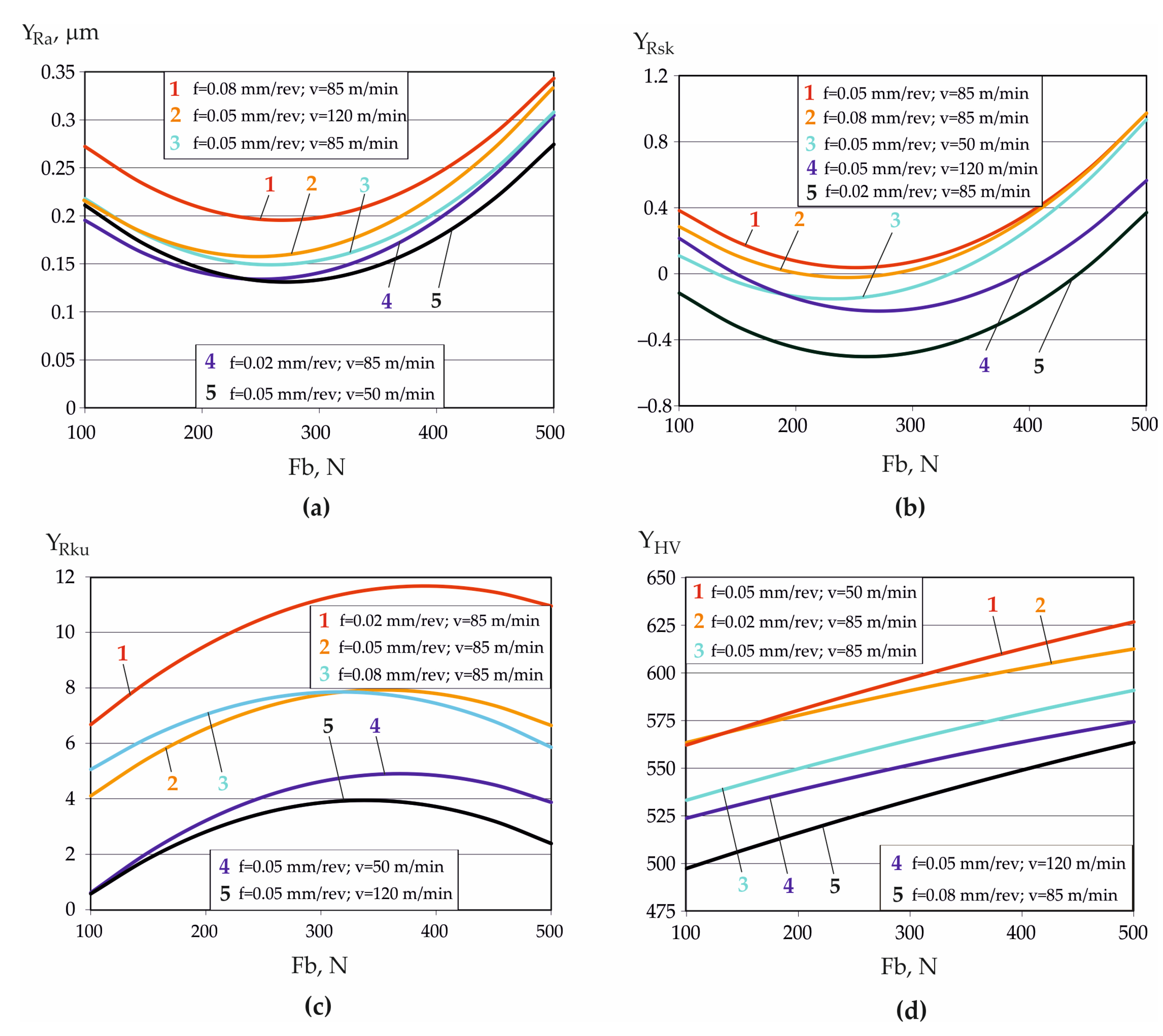

However, these studies [

17,

18,

19,

20,

21] lack explicit correlations between the characteristics of SI obtained via DB and the operating behavior. For the first time [

10], the explicit correlations between SI characteristics (including skewness and kurtosis shape roughness parameters) on the one hand and the rotating bending fatigue limit of diamond-burnished AISI 304 chromium–nickel austenitic stainless steels on the other hand were established. It was found that with the increase in both the skewness (as an algebraic number) and kurtosis shape roughness parameters, the fatigue limit increases. At the same time, the fatigue limit increases as the microhardness increases. Therefore, the maximization of surface microhardness is a very important factor in maximizing the fatigue limit of chromium–nickel austenitic steels processed by static SCW. Moreover, the increase in surface microhardness is an indicator of a more pronounced strain-hardening effect in the SL and thus is an important factor for increasing the wear resistance of contacting surfaces. The effectiveness of DB for increasing the sliding wear resistance of SLs in CuAl8Fe3 aluminum bronze [

22] and CuAl9Fe4 sliding bearing bushings [

23] was compared with that of fine turning under boundary lubrication and dry friction conditions.

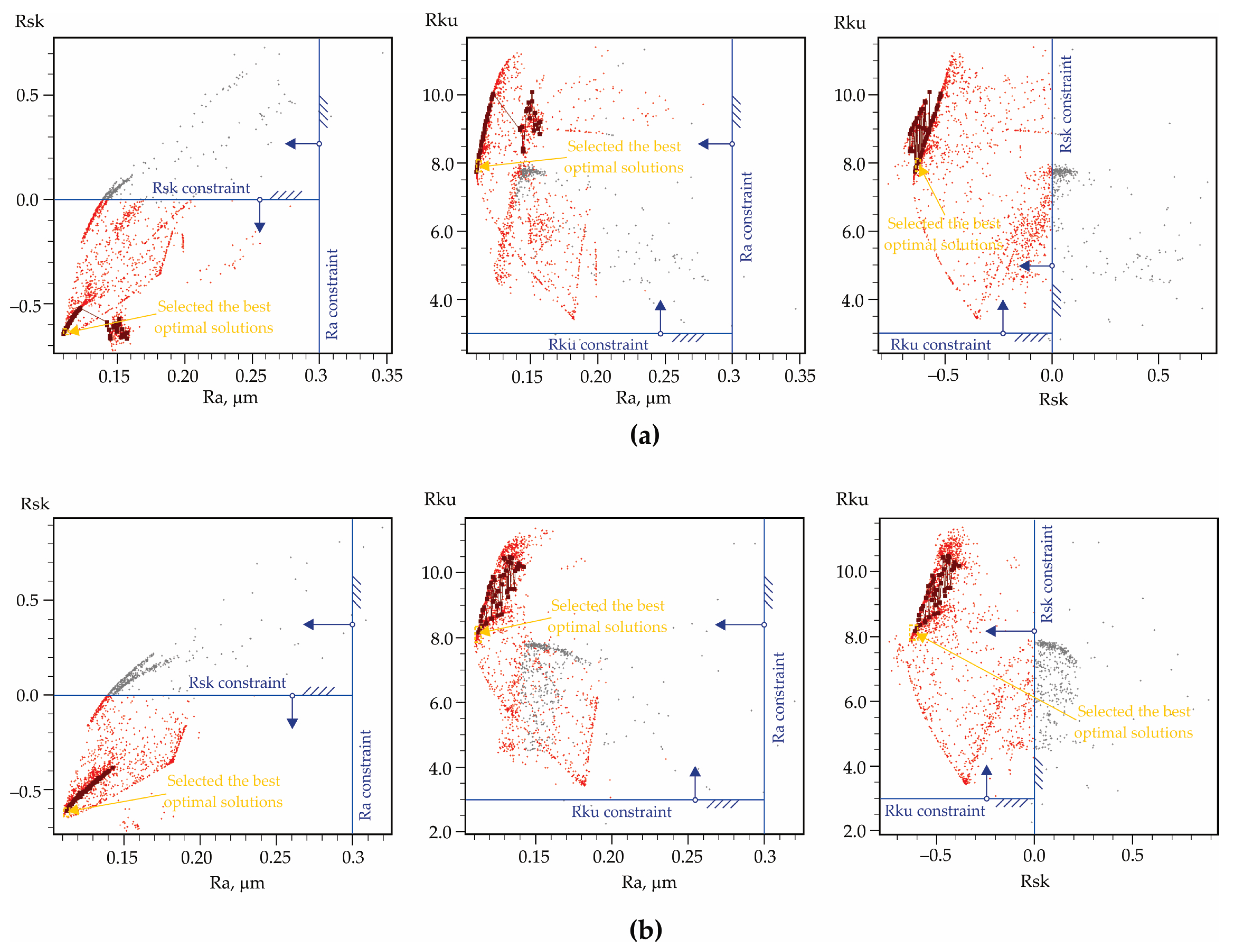

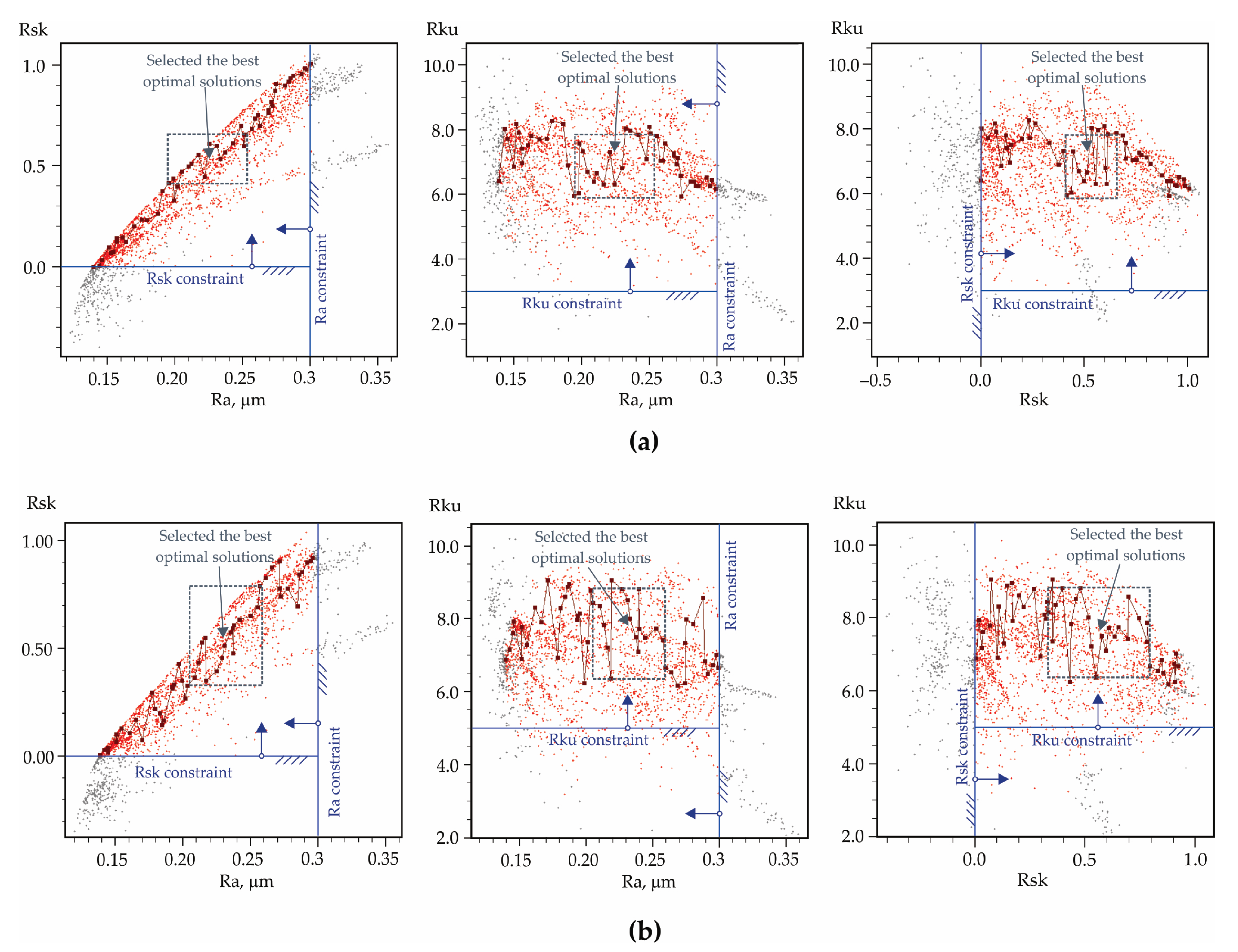

To improve the operational behavior (e.g., tribological, fatigue, corrosion) of austenitic stainless steel, it is necessary to determine the appropriate combination of DB technological parameters (i.e., governing factors) that provide the desired combination of SI characteristics under specific operating conditions. Hence, DB can be implemented as a smoothing, hardening, or mixed process [

24]. The primary aim of smoothing DB is to achieve a high-quality, smooth surface, whereas the hardening DB process aims to achieve maximum surface microhardness. There are combinations of technological parameters that provide both a low roughness and a high fatigue limit without reaching their corresponding extreme values. Such a compromise can be achieved through mixed DB. To define a specific process, DB optimization is required. One-objective optimization is often conducted using Taguchi’s method or analysis of variance because the objective function generally describes the roughness, microhardness, or wear resistance. To optimize the static SCW process for roughness and microhardness/hardness criteria, Taguchi’s orthogonal array technique [

25,

26,

27,

28,

29], fuzzy logic [

30], the Sugeno fuzzy neural system [

31], and artificial neural networks [

32] have been implemented. One-objective optimization of the roughness obtained in the ball burnishing process was carried out using an analysis of variance [

33,

34], as well as a response surface methodology and desirability function [

35].

Regarding multi-objective optimization, Taguchi’s method and analysis of variance are not applied. Typically, multi-objective optimizations are aimed at minimizing roughness and maximizing microhardness. The following approaches are used in this case: the Grey-based Taguchi method [

36,

37], MiniTab software [

38], a desirability function approach [

39], and non-dominated sorting genetic algorithm II (NSGA II) [

40,

41].

In these optimizations, the 2D roughness parameter Ra is often used for evaluating the resulting roughness. The DB process–SI–operating behavior correlations can be the basis for the cost-effective multi-objective optimization of DB when easy-to-measure SI characteristics with experimentally confirmed functional significance on the operating behavior are selected as objective functions.

Among them, the most accessible and easy-to-measure SI characteristics are the 2D and 3D roughness parameters. Although the standard 2D and 3D roughness height parameters Ra and Rq (Sa, Sq) are commonly used to identify the roughness level of contact surfaces, they are not sufficient to determine the operational behavior of the corresponding components. Notably, the functional significance of the skewness and kurtosis shape roughness parameters on tribological behavior under boundary lubrication and dry friction conditions has been investigated [

15,

42,

43,

44,

45]. Sedlacek et al. [

42] found that the combination of high kurtosis (Sku > 3) and negative skewness (Ssk < 0) at a constant mean roughness value (Sa = const.) reduced the friction and wear of hardened AISI 52,100 ball-bearing steel under boundary lubrication conditions. With this combination of shape parameters, the valleys of the SL function as micro-reservoirs that retain the lubricating substance. It is important to emphasize that the most dominant shape parameter is the Ssk parameter: the more negative the Ssk, the less friction and wear. In general, the negative skewness of smooth surfaces can improve the contact and lubrication conditions. Chang and Jeng [

43] found that

reduces the friction coefficient under boundary lubrication by two times compared with the surface characterized by a Gaussian ordinate distribution (i.e., when

). Furthermore, negatively skewed surfaces of smooth [

44] and rough [

45] 42CrMo4 steel discs improved the tribological behavior under dry sliding conditions. In their purest form, the shape roughness parameters–tribological behavior correlations have been established for conventionally processed surfaces, in which the influence of the surface plastic deformation is practically isolated [

42,

43,

44,

45].

When metal components are subjected to dynamic (cyclic) loading, the requirements for roughness parameters are different. Zabala et al. [

46] assumed that the influence of SL valleys on fatigue behavior dominates: a negative skewness shape parameter with larger absolute values is an indicator of deep valleys acting as micro-stress concentrators. Accordingly, to improve fatigue behavior, the respective machining process should provide positive skewness (Ssk > 0) and kurtosis less than 3 (Sku < 3) in combination with low values of the integral height parameters Ra (Sa) or Rq (Sq). Meanwhile, the main factors improving fatigue behavior are increased surface microhardness, modified microstructure, and the introduced residual compressive stresses in the surface and nearby subsurface layers [

10,

18,

19]. Hence, to more accurately predict the operational behavior of diamond-burnished components, it is necessary to know the correlations between the various SI characteristics, with a focus on the correlations between shape roughness parameters and surface microhardness. Such information ensures the correct selection of the governing factors in the DB process, thereby achieving the desired operating behavior of the diamond-burnished metal component.

In this context, knowledge of the DB process–roughness parameters–operating behavior correlations reduces the required variables to only three easy-to-measure roughness parameters (Ra, Rsk, Rku), and depending on the intended purpose of the surface, the appropriate magnitudes of the governing factors in the DB process can be chosen.

Thus, the present study aims to determine the explicit dependencies between the main parameters of the DB process for AISI 304 stainless steel and three functionally relevant roughness parameters, as well as the explicit correlations between selected characteristics of SI, while considering results from previous studies to support the cost-effective optimization of the DB process, depending on the intended function of the diamond-burnished surface.