The Effect of N/O Elements on the Microstructure and Mechanical Properties of Ti-N-O Alloys

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization Methods

3. Results and Discussion

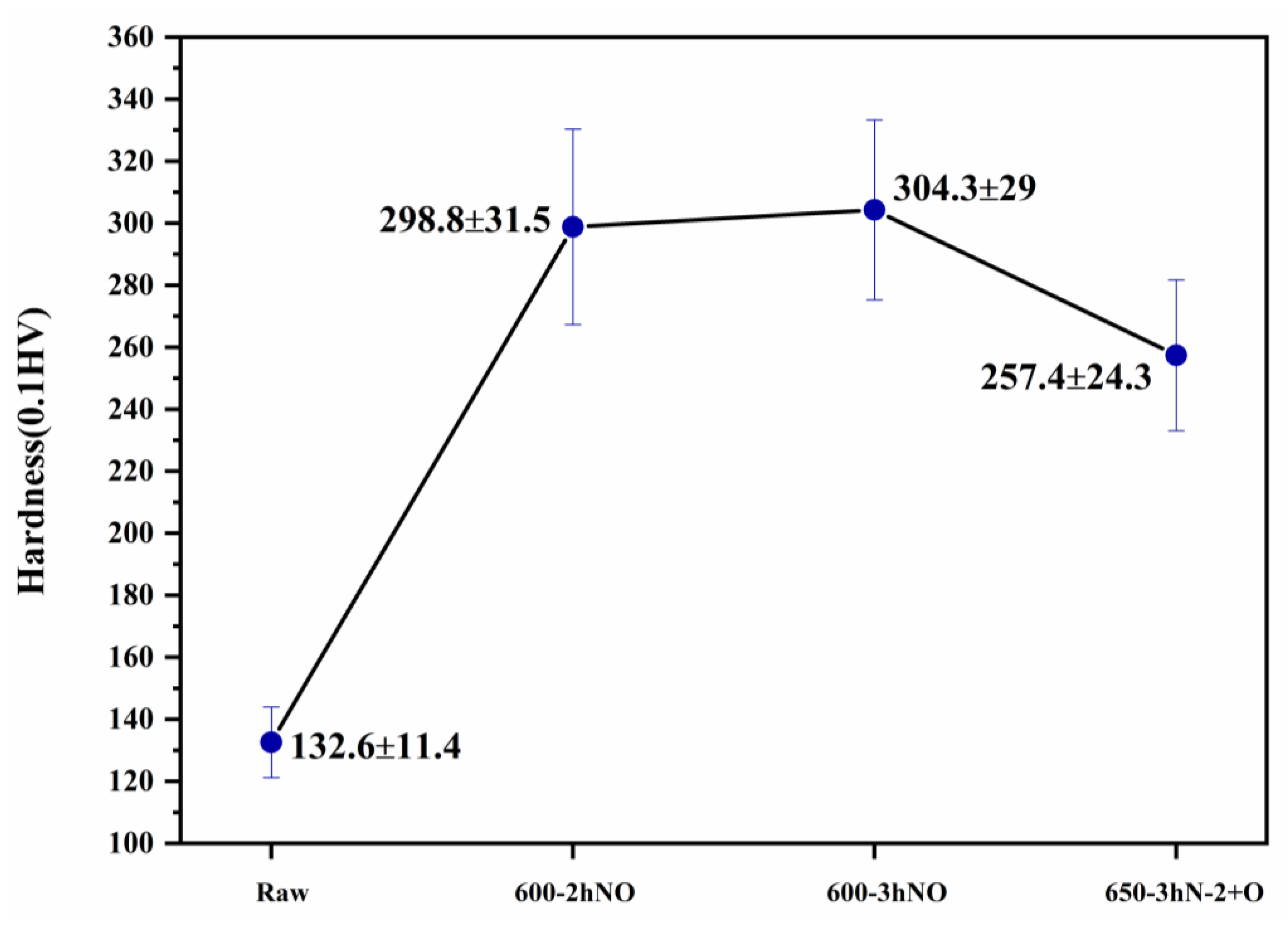

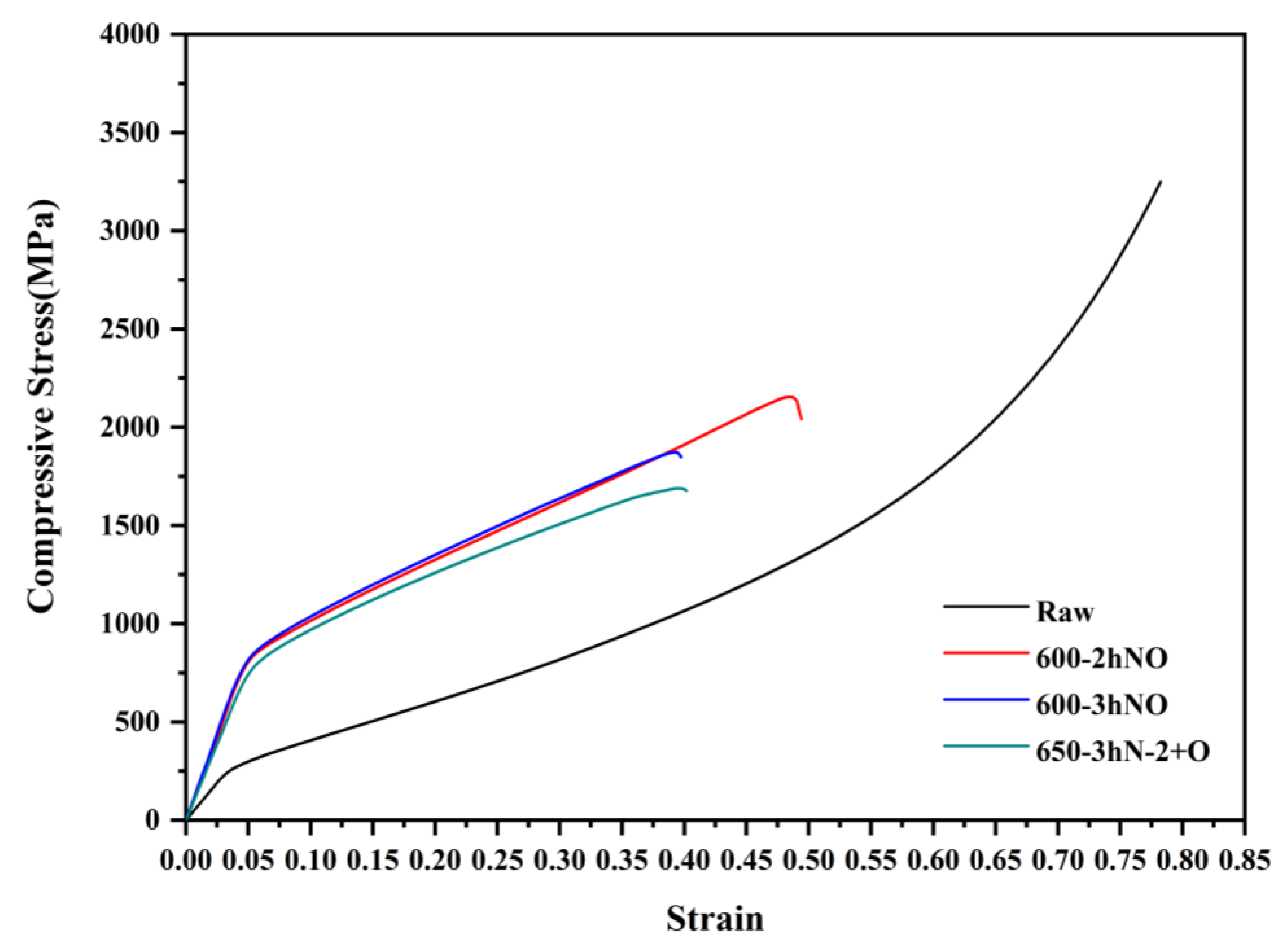

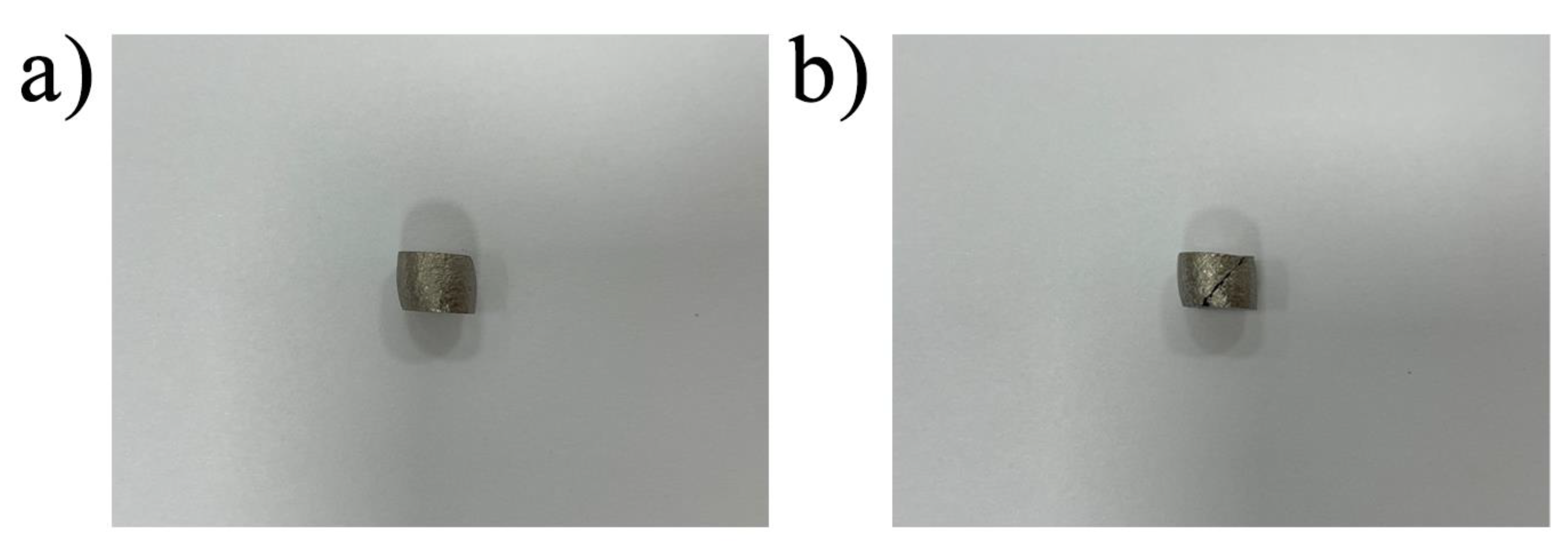

3.1. Mechanical Properties

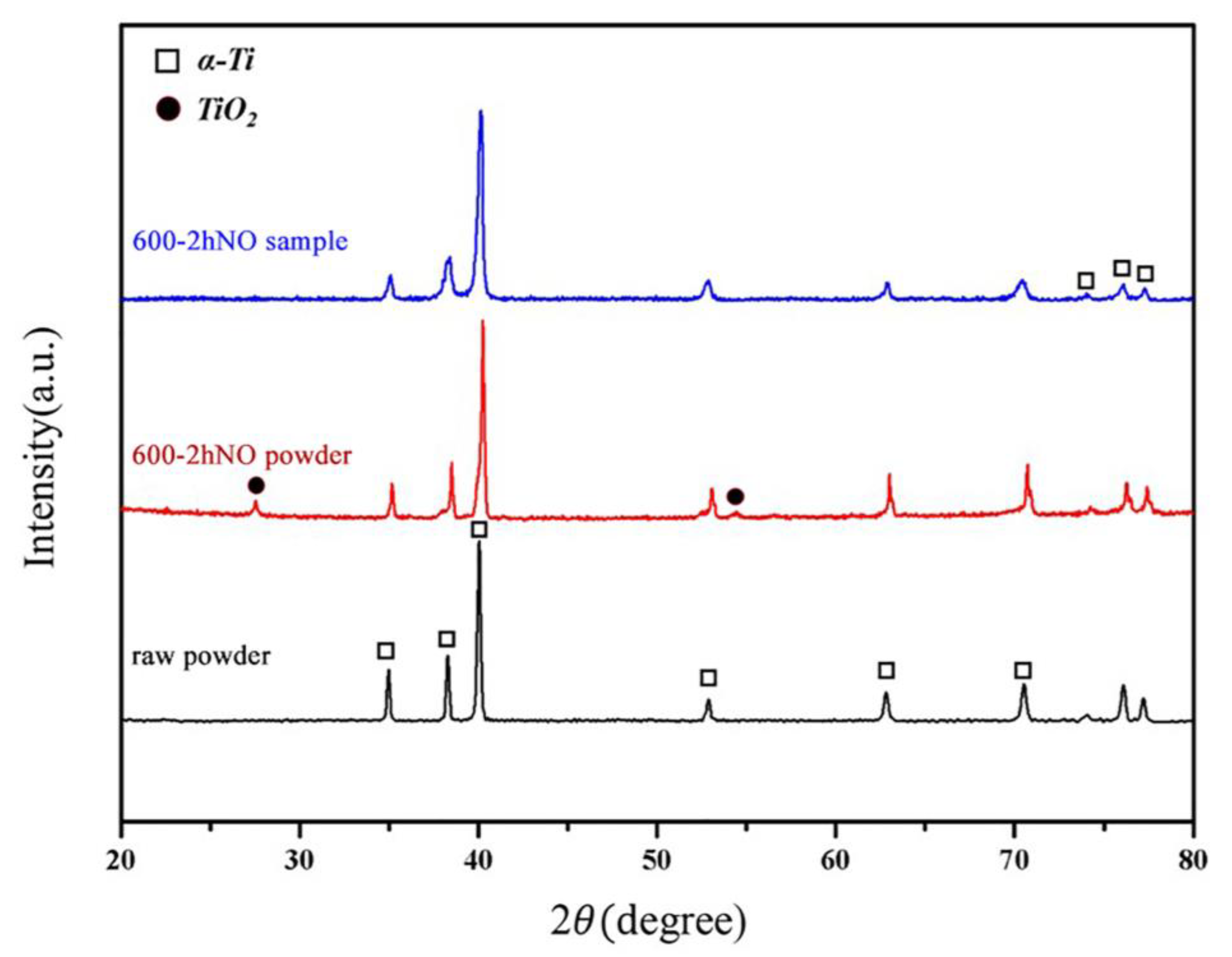

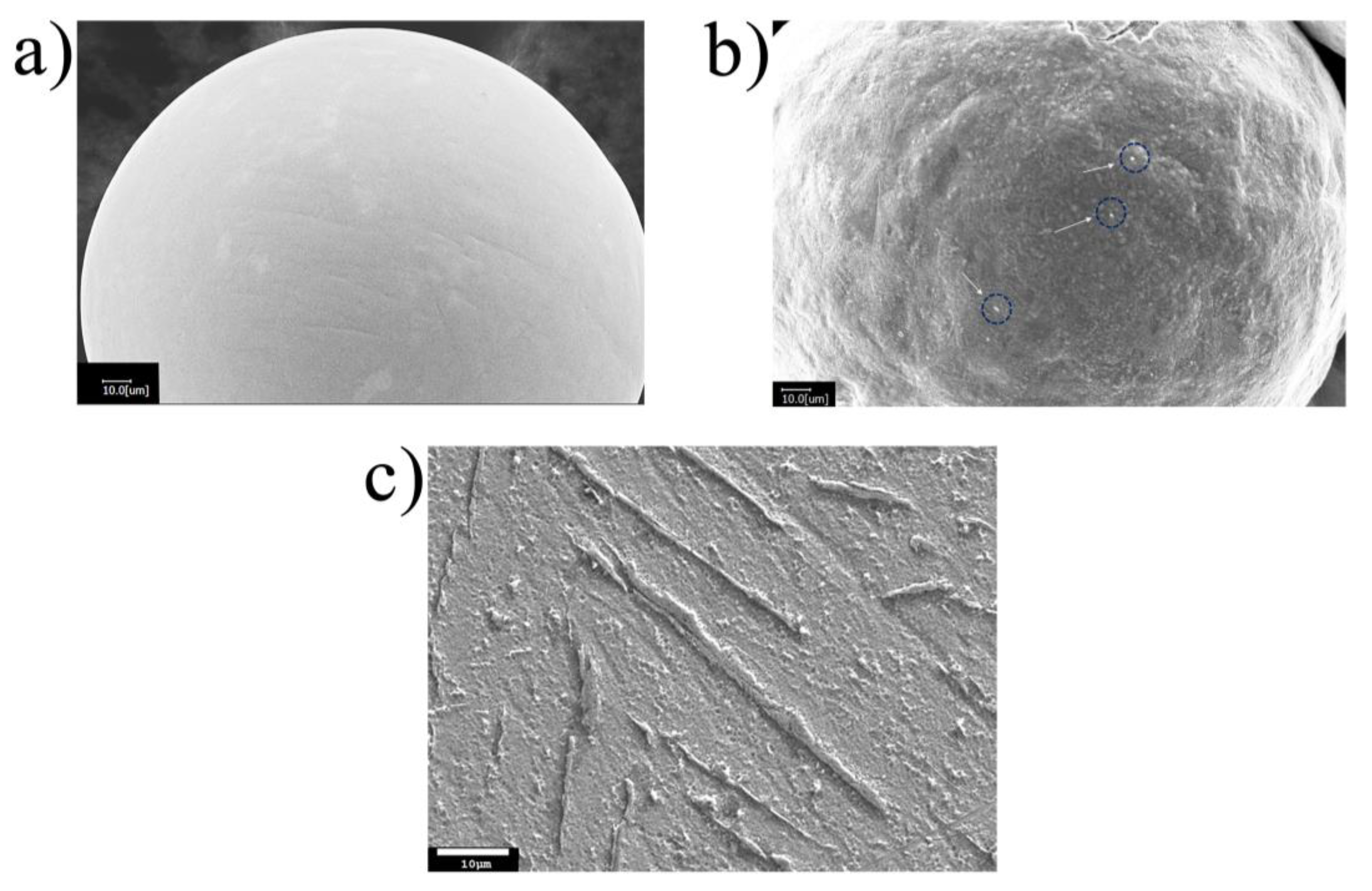

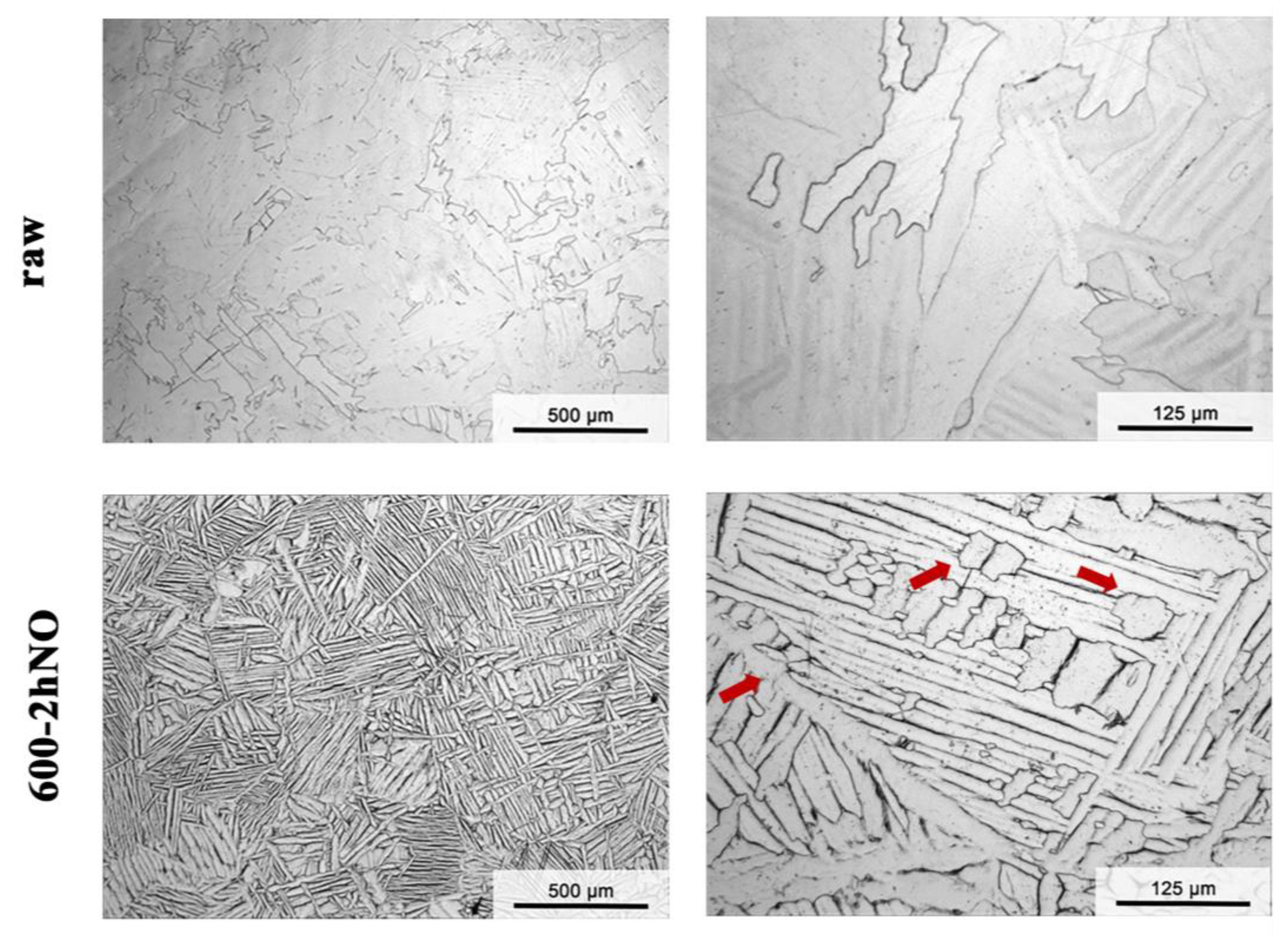

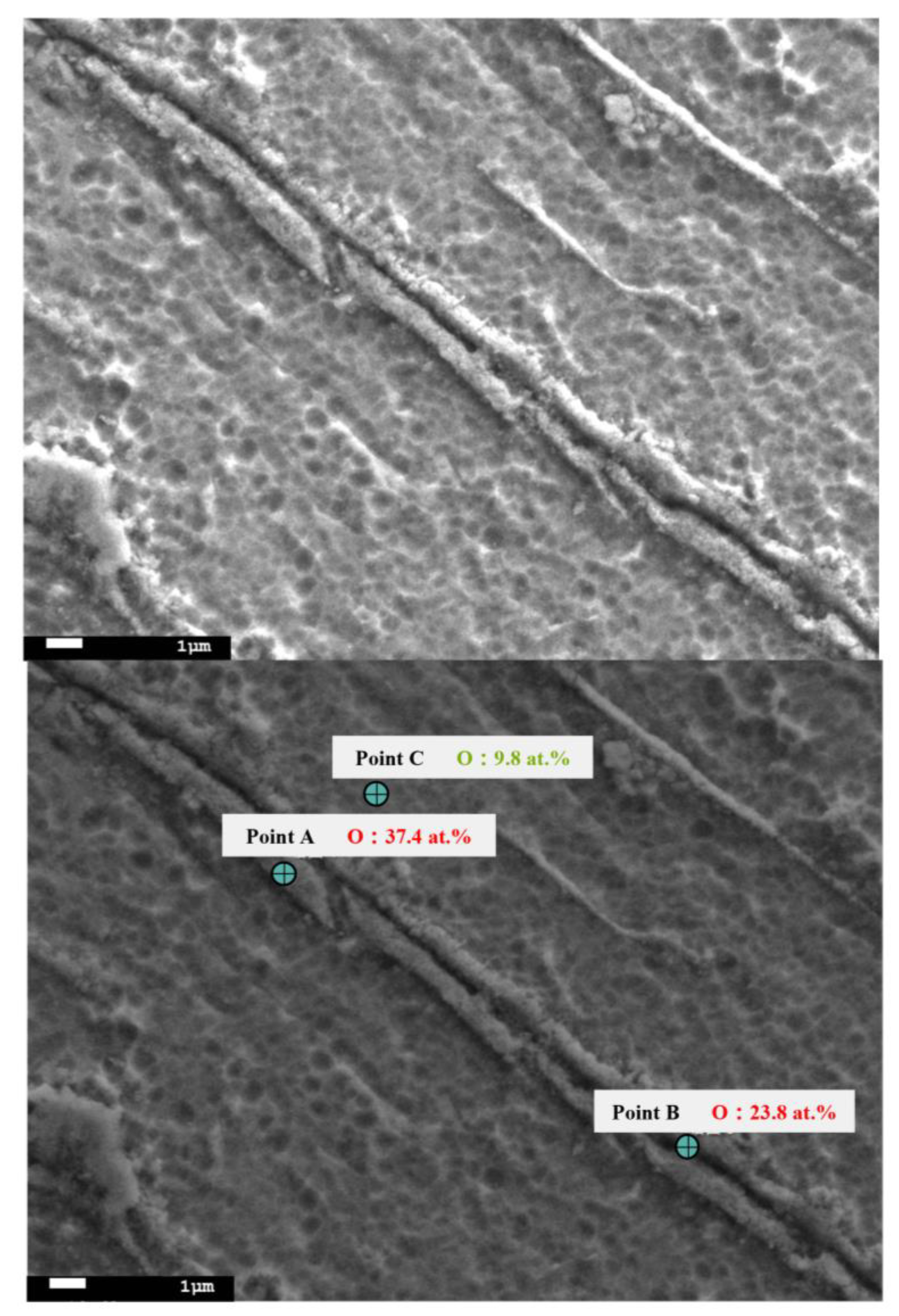

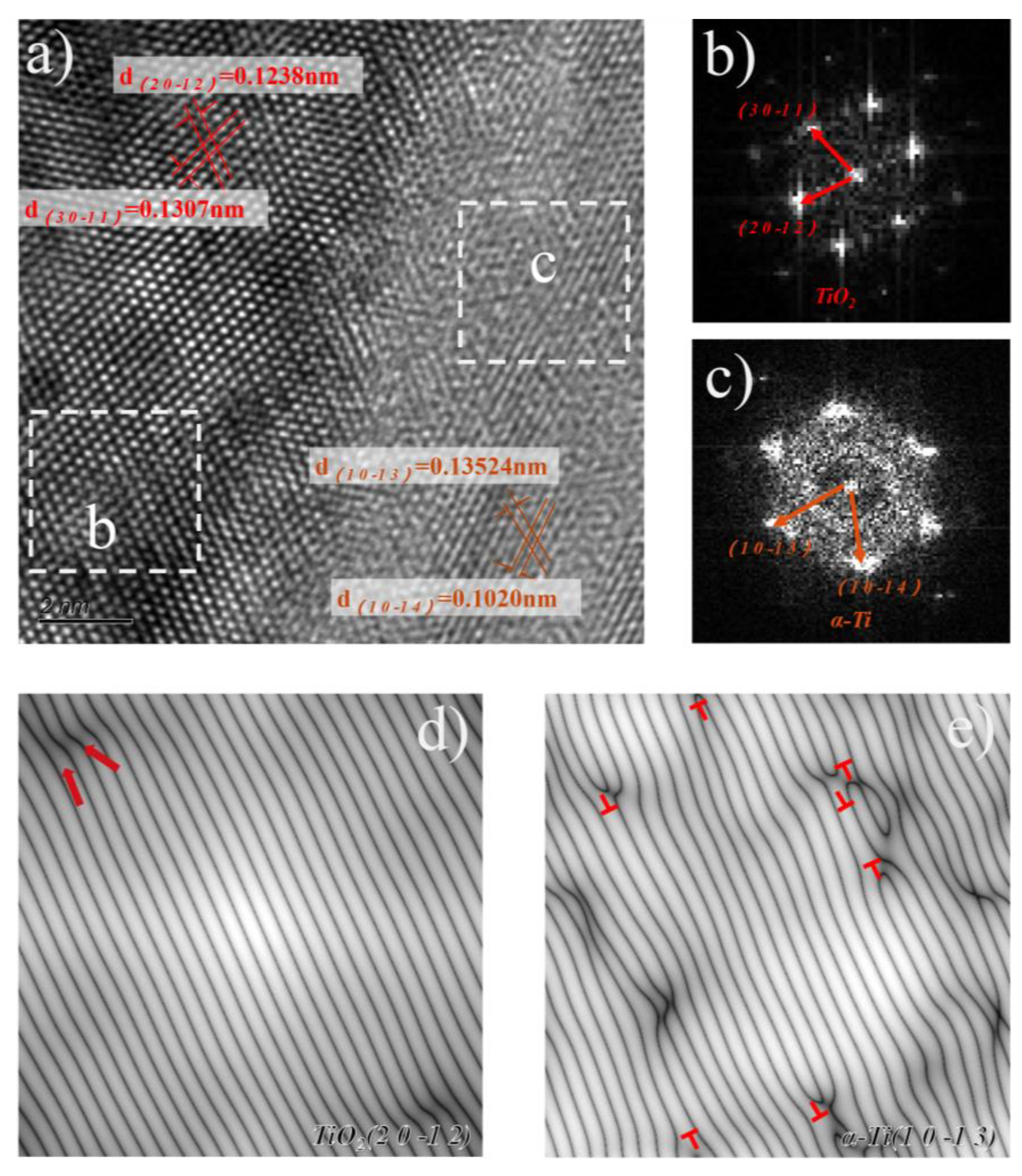

3.2. Microstructure

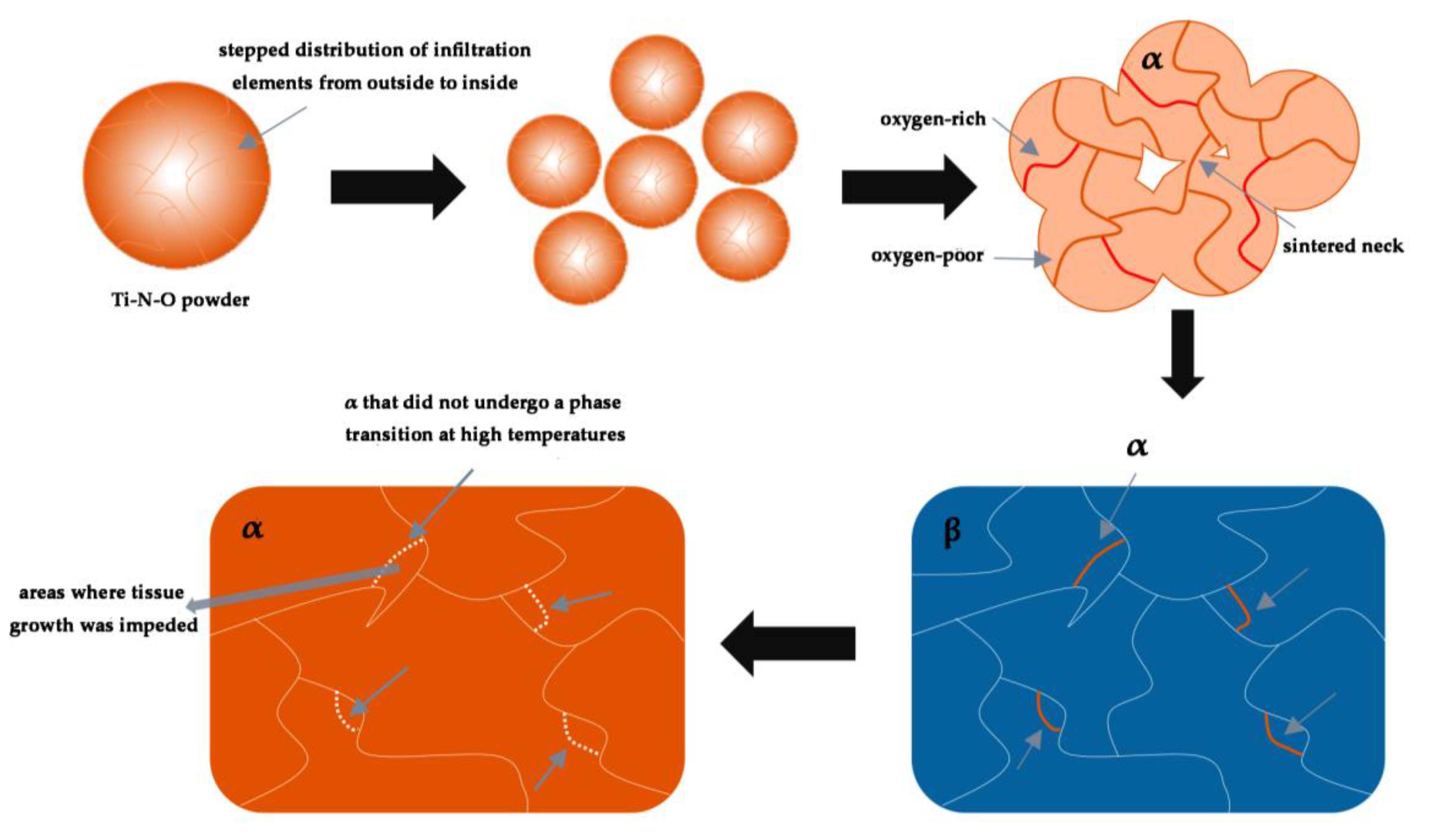

3.3. Organization Formation of Ti-N-O Alloys During Sintering

4. Conclusions

- The yield strength of the Ti-N-O alloy prepared by powder oxynitriding at 600 °C for 2 h was 666 MPa, which was 203% higher than that of the cp-Ti, and the hardness was 298.8 HV0.1, which was 125% higher.

- In the process of preparing the Ti-N-O powder, TiO2 was formed on the surface of the powders. After the powder was sintered into a bulk, TiO2 did not completely disappear, forming a second phase strengthening effect on the matrix, and a large number of dislocations could be observed nearby.

- The local O element aggregation played a stabilizing role, and the original morphology of the α phase was partially preserved, showing a lath + equiaxed α phase structure.

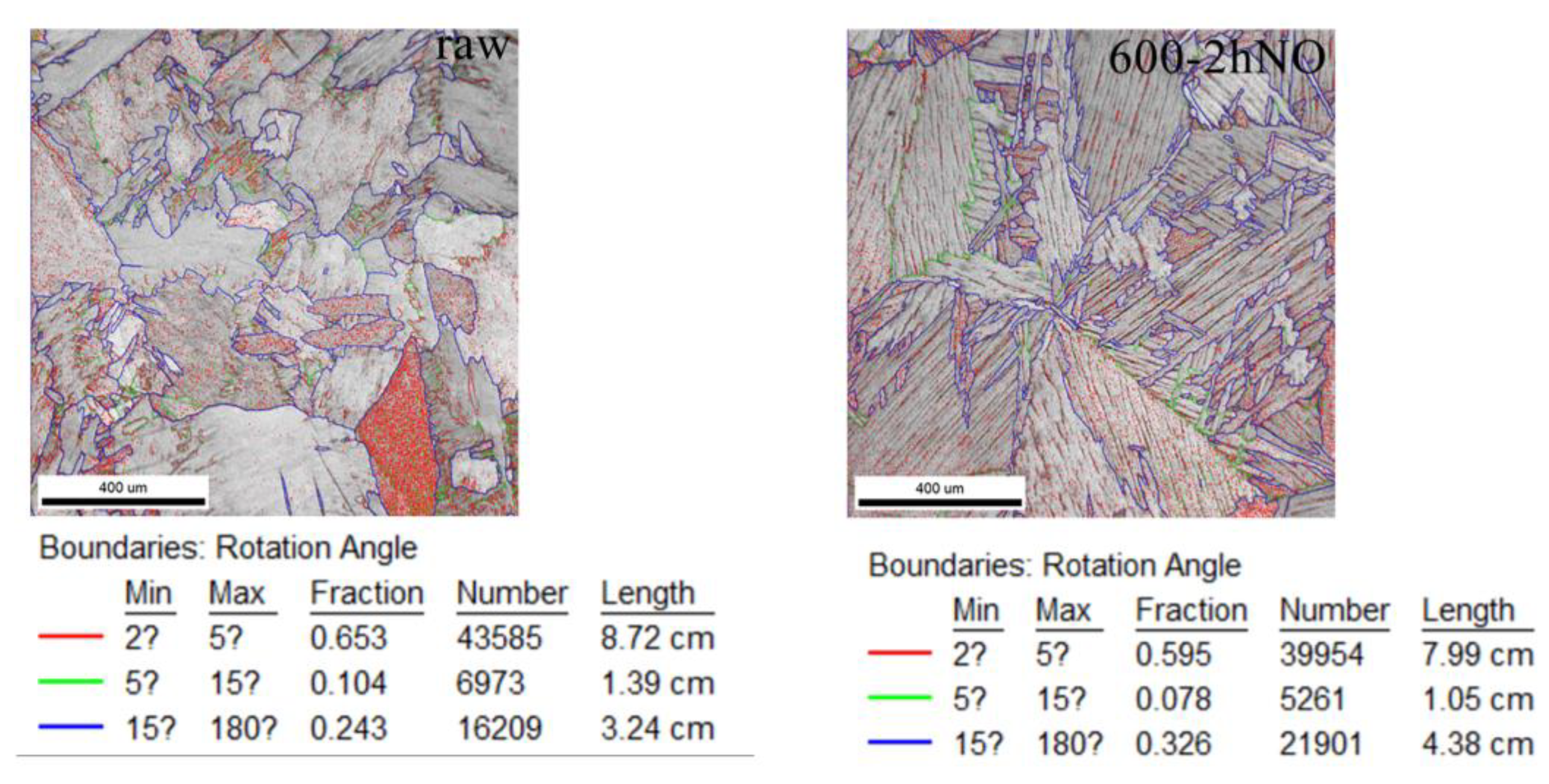

- More large-angle grain boundaries were produced in the Ti-N-O alloy, which was due to the extrusion deformation between powders leading to the edge breaking, and the sintering temperature rise was equivalent to recrystallization.

- Due to the low strength of cp-Ti, its application was previously limited. The Ti-N-O alloys prepared in this study have excellent mechanical properties and are prepared as bulk materials. This makes many applications possible, such as orthopedic load-bearing implants, core components of sports equipment, and so on.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agrawal, R.K.; Pandey, V.; Barhanpurkar-Naik, A.; Wani, M.R.; Chattopadhyay, K.; Singh, V. Effect of Ultrasonic Shot Peening Duration on Microstructure, Corrosion Behavior and Cell Response of Cp-Ti. Ultrasonics 2020, 104, 106110. [Google Scholar] [CrossRef] [PubMed]

- Li, X.P.; Ji, G.; Eder, K.; Yang, L.M.; Addad, A.; Vleugels, J.; Van Humbeeck, J.; Cairney, J.M.; Kruth, J.P. Additive Manufacturing of a Novel Alpha Titanium Alloy from Commercially Pure Titanium with Minor Addition of Mo2C. Materialia 2018, 4, 227–236. [Google Scholar] [CrossRef]

- Maj, Ł.; Muhaffel, F.; Jarzębska, A.; Trelka, A.; Trembecka-Wójciga, K.; Kawałko, J.; Kulczyk, M.; Bieda, M.; Çimenoğlu, H. Enhancing the Tribological Performance of MAO Coatings through Hydrostatic Extrusion of Cp-Ti. J. Alloys Compd. 2025, 1010, 178246. [Google Scholar] [CrossRef]

- Ma, T.-H.; Chang, L.; Zhao, J.-P.; Zhou, C.-Y. Comparation of Non-Proportional Hardening Behavior and Microscopic Mechanism for CP-Ti under Strain-Controlled and Stress-Controlled Multiaxial Low Cycle Fatigue. J. Alloys Compd. 2024, 1003, 175724. [Google Scholar] [CrossRef]

- Atik, B.; Bozkurt, Y.B.; Kavasoğlu, Y.S.; Kovacı, H.; Çelik, A. Pitting Corrosion Performance of Plasma Oxidized Cp-Ti and Effects of Fabrication Methods. Surf. Coat. Technol. 2024, 478, 130384. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Shah, F.A.; Trobos, M.; Thomsen, P.; Palmquist, A. Commercially Pure Titanium (Cp-Ti) versus Titanium Alloy (Ti6Al4V) Materials as Bone Anchored Implants—Is One Truly Better than the Other? Mater. Sci. Eng. C 2016, 62, 960–966. [Google Scholar] [CrossRef]

- Senocak, T.C. Characterization and Performance of Tantalum-Tungsten Based Coatings Deposited on Cp-Ti Substrates by PVD Technique. Mater. Today Commun. 2023, 37, 107091. [Google Scholar] [CrossRef]

- In Vivo Assessment of Bone Enhancement in the Case of 3D-Printed Implants Functionalized with Lithium-Doped Biological-Derived Hydroxyapatite Coatings: A Preliminary Study on Rabbits. Available online: https://www.mdpi.com/2079-6412/10/10/992 (accessed on 11 May 2025).

- Choi, S.-W.; Jeong, J.S.; Won, J.W.; Hong, J.K.; Choi, Y.S. Grade-4 Commercially Pure Titanium with Ultrahigh Strength Achieved by Twinning-Induced Grain Refinement through Cryogenic Deformation. J. Mater. Sci. Technol. 2021, 66, 193–201. [Google Scholar] [CrossRef]

- Cai, Z.; Xiang, T.; Bao, W.; Chen, J.; Gao, T.; Xie, G. Enhancing Strength and Ductility of Pure Titanium by Interstitial Oxygen Atoms. Mater. Sci. Eng. A 2022, 854, 143806. [Google Scholar] [CrossRef]

- Aslan Çakır, M.; Yetim, T.; Bozkurt, Y.B.; Kovacı, H.; Çelik, A. Wear and Tribocorrosion Behavior of UV Curable Coated CP-Ti. Mater. Lett. 2023, 331, 133518. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Commercially Pure (CP) Titanium and Alpha Alloys. In Titanium; Engineering Materials, Processes; Springer: Berlin/Heidelberg, Germany, 2007; pp. 175–201. ISBN 978-3-540-71397-5. [Google Scholar]

- Bosco, R.; Edreira, E.R.U.; Wolke, J.G.C.; Leeuwenburgh, S.C.G.; Van Den Beucken, J.J.J.P.; Jansen, J.A. Instructive Coatings for Biological Guidance of Bone Implants. Surf. Coat. Technol. 2013, 233, 91–98. [Google Scholar] [CrossRef]

- Mohammadi, M.; Akbari, A.; Warchomicka, F.; Pichon, L. Depth Profiling Characterization of the Nitride Layers on Gas Nitrided Commercially Pure Titanium. Mater. Charact. 2021, 181, 111453. [Google Scholar] [CrossRef]

- Körkel, A.F.K.; Jellesen, M.S.; Foss, M.; Ceccato, M.; Somers, M.A.J.; Christiansen, T.L. Thermochemical Oxidation of Commercially Pure Titanium; Controlled Formation of Robust White Titanium Oxide Layers for Biomedical Applications. Surf. Coat. Technol. 2023, 467, 129716. [Google Scholar] [CrossRef]

- Ye, Y.; Kure-Chu, S.-Z.; Sun, Z.; Matsubara, T.; Tang, G.; Hihara, T.; Okido, M.; Yashiro, H. Self-Lubricated Nanoporous TiO2-TiN Films Fabricated on Nanocrystalline Layer of Titanium with Enhanced Tribological Properties. Surf. Coat. Technol. 2018, 351, 162–170. [Google Scholar] [CrossRef]

- Yaskiv, O.I.; Pohrelyuk, I.M.; Fedirko, V.M.; Lee, D.B.; Tkachuk, O.V. Formation of Oxynitrides on Titanium Alloys by Gas Diffusion Treatment. Thin Solid Film. 2011, 519, 6508–6514. [Google Scholar] [CrossRef]

- Raju, K.A.K.; Biswas, A. Surface Modifications and Coatings to Improve Osseointegration and Antimicrobial Activity on Titanium Surfaces: A Statistical Review over the Last Decade. J. Orthop. 2025, 67, 68–87. [Google Scholar] [CrossRef]

- Fang, Y.; Liu, C.; Jin, K.; Wei, X.; Zhao, X.; Bei, H.; Zhang, Z. Additive Manufacturing of Titanium Alloys with Enhanced Strength and Uniform Ductility via Multi-Element Alloying. J. Mater. Res. Technol. 2023, 24, 6854–6860. [Google Scholar] [CrossRef]

- Additive Manufacturing of Ultrafine-Grained High-Strength Titanium Alloys|Nature. Available online: https://www.nature.com/articles/s41586-019-1783-1 (accessed on 27 February 2025).

- Wang, H.; Luo, H.L.; Chen, J.Q.; Tang, J.C.; Yao, X.Y.; Zhou, Y.H.; Yan, M. Cost-Affordable, Biomedical Ti-5Fe Alloy Developed Using Elemental Powders and Laser in-Situ Alloying Additive Manufacturing. Mater. Charact. 2021, 182, 111526. [Google Scholar] [CrossRef]

- Effect of Solution Treatment Temperature on Microstructure, Mechanical Properties and Corrosion Resistance of Ultra-High Nitrogen Stainless Steel|Metallurgical and Materials Transactions A. Available online: https://link.springer.com/article/10.1007/s11661-024-07568-5 (accessed on 27 February 2025).

- Zhang, Z.-H.; Liu, Z.-F.; Lu, J.-F.; Shen, X.-B.; Wang, F.-C.; Wang, Y.-D. The Sintering Mechanism in Spark Plasma Sintering—Proof of the Occurrence of Spark Discharge. Scr. Mater. 2014, 81, 56–59. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.; Yan, C.; Wang, P.; Yang, H.; Qian, X.; Yang, K.; Xu, S.; Lin, J. Microstructure, Thermal Properties and Irradiation Behaviors of Uranium Nitride (UN) Nuclear Fuel Densified by Spark Plasma Sintering (SPS). J. Nucl. Mater. 2025, 608, 155709. [Google Scholar] [CrossRef]

- Silva, M.C.L.; Leite, M.M.B.; Raimundo, R.A.; Henriques, G.F.; Valcacer, S.M.; Mashhadikarimi, M.; Morales, M.A.; Gomes, U.U. Consolidation and Mechanical Properties of WC-Al2O3 Composite Prepared via High Energy Ball Milling and Spark Plasma Sintering. Ceram. Int. 2022, 48, 19026–19035. [Google Scholar] [CrossRef]

- Zabihi, M.; Emadoddin, E.; Qods, F. Enhanced Mechanical Behavior and Texture Development of Al/Al2O3 Composites Produced by Spark Plasma Sintering (SPS) and Vacuum Hot Pressing (VHP) Followed by Simple Shear Extrusion (SSE). J. Mater. Res. Technol. 2024, 33, 796–805. [Google Scholar] [CrossRef]

- Liu, L.; Hou, Z.; Zhang, B.; Ye, F.; Zhang, Z.; Zhou, Y. A New Heating Route of Spark Plasma Sintering and Its Effect on Alumina Ceramic Densification. Mater. Sci. Eng. A 2013, 559, 462–466. [Google Scholar] [CrossRef]

- Low-Temperature Nitriding of Pure Titanium by Using Hollow Cathode RF-DC Plasma—IOPscience. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/202/1/012026 (accessed on 27 February 2025).

- Liu, J.; Wang, Z.; Ye, Z.; Jin, W.; Chen, Z.; Hu, Y.; Wu, J.; Chen, D.; Bai, B.; Wang, X.; et al. Improved Dry Sliding Wear Behavior of TA1 Titanium by Low-Temperature Plasma Nitriding by CCPN Method. Vacuum 2024, 221, 112945. [Google Scholar] [CrossRef]

- Kikuchi, S.; Akebono, H.; Ueno, A.; Ameyama, K. Formation of Commercially Pure Titanium with a Bimodal Nitrogen Diffusion Phase Using Plasma Nitriding and Spark Plasma Sintering. Powder Technol. 2018, 330, 349–356. [Google Scholar] [CrossRef]

- Dong, S.; Song, Y.; Savvakin, D.; Ivasishin, O.; Cheng, T. Impact of Hot Rolling on the Evolution of Microstructure and Mechanical Properties of Sintered Commercially Pure Ti Compacts. J. Mater. Res. Technol. 2024, 31, 133–141. [Google Scholar] [CrossRef]

- Zhao, P.-C.; Yuan, G.-J.; Wang, R.-Z.; Guan, B.; Jia, Y.-F.; Zhang, X.-C.; Tu, S.-T. Grain-Refining and Strengthening Mechanisms of Bulk Ultrafine Grained CP-Ti Processed by L-ECAP and MDF. J. Mater. Sci. Technol. 2021, 83, 196–207. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Zhang, W.; Wang, X.; Lu, J.W.; Zhao, Y.H. Microstructure and Mechanical Property Evolutions of Bulk Core-Shell Structured Ti-N Alloys during Annealing. J. Alloys Compd. 2017, 710, 418–423. [Google Scholar] [CrossRef]

- Ye, J.; Lin, X.; Quan, L.; Yang, H.; Fu, S. Transformation of Guinier-Preston Zone in a Pre-Deformed Mg-Zn-Y-Zr Alloy. Mater. Lett. 2020, 258, 126815. [Google Scholar] [CrossRef]

| Process of Powder Nitriding/Oxynitriding | Sample |

|---|---|

| Raw | |

| Oxynitriding at 600 °C for 2h | 600-2hNO |

| Oxynitriding at 600 °C for 3h | 600-3hNO |

| Nitriding at 650 °C for 3 h, repeat the process twice; keep the first nitriding unchanged, and introduce air for the last 20 min of the second nitriding, i.e., oxynitriding | 650-3hN-2+O |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Chen, R.; Zhang, C.; Xu, Z.; Hu, H.; Zhou, X.; Cui, G. The Effect of N/O Elements on the Microstructure and Mechanical Properties of Ti-N-O Alloys. Metals 2025, 15, 554. https://doi.org/10.3390/met15050554

Shi M, Chen R, Zhang C, Xu Z, Hu H, Zhou X, Cui G. The Effect of N/O Elements on the Microstructure and Mechanical Properties of Ti-N-O Alloys. Metals. 2025; 15(5):554. https://doi.org/10.3390/met15050554

Chicago/Turabian StyleShi, Mingqi, Ruiduo Chen, Chengsong Zhang, Zhenzhao Xu, Hanke Hu, Xiaolong Zhou, and Guodong Cui. 2025. "The Effect of N/O Elements on the Microstructure and Mechanical Properties of Ti-N-O Alloys" Metals 15, no. 5: 554. https://doi.org/10.3390/met15050554

APA StyleShi, M., Chen, R., Zhang, C., Xu, Z., Hu, H., Zhou, X., & Cui, G. (2025). The Effect of N/O Elements on the Microstructure and Mechanical Properties of Ti-N-O Alloys. Metals, 15(5), 554. https://doi.org/10.3390/met15050554