Abstract

The present study was carried out using a cold-drawn wire of Ni50.8Ti at.% subjected to post-deformation solution treatment at 700 °C for 1 h to obtain a fine-grained recrystallized structure. Subsequent aging was carried out at a temperature range of 300, 430, and 500 °C for 1, 10, and 20 h. The time–temperature aging mode strongly affects the aging-induced microstructure. Variation of the aging-induced microstructure (using various aging modes) permits precise tuning of the characteristic temperature of the martensitic transformations and their specific temperature ranges upon cooling and heating. The latent heat and hysteresis exhibit different evolution vs. aging durations; this finding remains fair when using different aging temperatures. The aging mode strongly affects the stress–temperature behavior: (i) a dramatical expansion of the temperature range of realization of the transformation yield stress (σtr); and (ii) the magnitude of σtr at a chosen test temperature is generally determined by the position of the Ms temperature. An additional contribution of competing factors is discussed. The efficiency of the aging temperature under isochronous aging is significantly higher than the efficiency of the aging time under isothermal aging. Aging at 430 °C for 10–20 h provides the highest resource for the recovery strain. The strain–temperature behavior strongly depends on the relative position of the Rs and Ms temperatures (onset of B2→R and R→B19′ transformations, respectively). The regularities obtained can be used to predict the set of functional and mechanical properties of titanium nickelide.

1. Introduction

Among smart materials, Ni-rich NiTi alloys remain extremely attractive due to their unique combination of mechanical properties and functional behavior [1,2], which exhibits an expressed dependance on the microstructure [3,4]. The peculiarities of the aging-induced microstructure, which is characterized by the size, shape, and distribution of the Ti3Ni4 precipitates, strongly affect the transformation [5,6,7] and functional behavior of an alloy [8,9,10]. Comparative studies of functional behavior are traditionally carried out at room temperature. Meanwhile, shape memory alloys (SMAs) exhibit the strong stress/strain-temperature dependence of all their characteristics [3,9,10,11,12].

The effect of the aging mode on the transformation and mechanical behavior is mostly studied for recrystallized NiTi alloys with relatively coarse grain [13,14,15,16,17]. Note that in these studies, the causal relationship between the aging mode, aging-induced microstructure, and transformation behavior [5,18] is described in detail. In the works devoted to mechanical behavior, the authors trace the relationship of the aging mode and mechanical behavior with a lack of attention to the microstructure. Thus, the causal relationship between the aging-induced microstructure, transformation, and stress-temperature behavior remains unexplored.

In recent years, significant efforts on the part of various scientific groups have been aimed at obtaining fine-grained shape memory alloys, since subsequent aging brings the combination of the high strength characteristics inherent in fine-grained materials and a significant shape recovery response [7,9].

The transformation behaviors in fine-grained alloys with a grain size of 5.6–12 µm were studied in separate works using aging modes in the temperature range of 250–550 °C for 1–48 h [19,20,21]; however, structural studies were limited to evaluating the grain size. In ref. [21], the mechanical tests were performed using thermocycling at room temperature. The authors of ref. [22] studied the aging-induced microstructure and transformation temperatures in an ultrafine-grained (grain/subgrain size less than 5 µm) Ni50.9Ti (at.%) alloy after aging at 430 °C (1 h); similar studies, after aging in the temperature range of 300–500 °C (1 h), were carried out in ref. [23] using an alloy of Ni50.9Ti (at.%) with a nano-crystalline microstructure (average grain/subgrain size of 80 nm). The effect of a short heat treatment of 450–600 °C for 10 min on the mechanical properties in an alloy of Ni50.9Ti (at.%) with a grain/subgrain size of 0.1–5 µm was analyzed in [24] at room temperature. In [25,26], the effect of a grain size in the range of 0.01–0.1 µm obtained by electric pulse treatment of Ti–50.9 at.% Ni was studied using tensile tests in a temperature range of −100 °C ≤ T ≤ 170 °C without aging. As a result, it was established that the yield stress mainly depends on the wire microstructure (decreases with increasing pulse time) but varies only slightly with the test temperature.

Since the data described in published works are limited to tests mostly at a room temperature, the comparative tests of an alloy with a different structure (or aging mode) cannot be considered legal due to ignoring the Clapeyron–Clausius equation (which comprises the relationship between the test temperature and the Ms temperature [27] and dramatically depends on the microstructure and transformation behavior [10,28]). The study of the mechanical properties at different deformation temperatures was carried out in the following works [25,26]; however, these studies were limited by the grain size, accumulated strains and aging time.

The lack of articles devoted to studies of ultrafine-grained and nanocrystalline SMAs is caused by the problem of obtaining such a structure “in its purest form” due to the temperature regimes of the technological processing when recovery co-occurs with aging. It is also important to note that as far as the effect of the Ni content in NiTi alloys shows a pronounced effect on the aging-induced microstructure and MTs (martensitic transformations) [3,29,30], as well as on the mechanical and functional behavior [29], the results of studies performed by different scientific groups using NiTi alloys with different Ni content in each study can hardly be comparable.

To reveal and analyze the link between the aging mode, aging-induced microstructure, MTs and mechanical behavior, systematic studies using an alloy with the same Ni content and of one melting must be performed. These studies, covering the aging modes and test temperatures in a wide time–temperature range, will reveal an additional scope to the tuning of transformation and mechanical behavior. The research performed in the framework of this work fills the indicated gap. It reveals the correlation between the aging mode, aging-induced microstructure, MTs, including latent heat and thermal hysteresis, and tensile–temperature behavior of Ni-rich fine-grained alloys.

2. Materials and Methods

The studies were carried out using a Ni50.8Ti alloy manufactured by ‘‘MATEK-SMA’’ (Moscow, Russia) in accordance with the technological process described in [31]. A 0.8 mm hot-drawn wire was solution-treated at 700 °C for 15 min and then finished by cold drawing to obtain a 0.6 mm wire with an accumulated logarithmic strain of e = 0.6. A similar processing using multipass cold rolling was performed to obtain a 0.15 mm thick band with the same accumulated strain for preparing foils for the structural studies.

All the samples were solution-treated at 700 °C for 1 h (followed by water quenching) and subsequent isothermal aging at 300, 430, and 500 °C for 1, 5, 10 and 20 h. Foils for the structural analysis were prepared by electropolishing of band samples to a thickness of 0.1 mm and then finished by ion bombardment using a “Gatan PIPS II”. Structural studies were carried out using a JEM-2100 transmission electron microscope (TEM, JEOL, Tokyo, Japan) operated at 200 kV. SEM studies were performed using a JSM-7600F microscope (JEOL, Tokyo, Japan). Samples were prepared electrolytically at a voltage of 20 V using a solution of 30 vol.% nitric acid and 70 vol.% methanol at a temperature of −20 °C.

The average grain size in the original fine-grained structure after solution treatment at 700 °C was determined using the random linear intercept method after sampling no less than 300 grains using ref. [32]. The diameter and thickness of the Ti3Ni4 precipitates were measured using TEM and SEM images, with sampling of no less than 7 pictures and 300 precipitates, as well as the linear frequency of the precipitate’s distribution.

Calorimetric studies and tensile tests were carried out using the wire samples. The martensitic transformations (MTs) were studied using a “Mettler Toledo DSC 3+” calorimeter (Mettler Toledo, Schwerzenbach, Switzerland) under a heating/cooling rate of 10 °C/min in the range of −100 °C ≤ T ≤ +100 °C. The onset and endset temperatures of the MTs were determined using [33].

The tensile tests were carried out using an “INSTRON 5966” (INSTRON, Norwood, MA, USA) in a temperature range of −196 ≤ T ≤ +100 °C with a speed of 20 mm/min. Tensile tests were carried out in accordance with ref. [34] using wire samples 10 mm long. The onset temperatures Ms of the forward MTs R→B19′ or B2→(R)→B19′ and the Rs temperatures off B2→R or each structural state were chosen as a test temperature in all cases based on the differential scanning calorimetry (DSC) results.

3. Results

3.1. Microstructure Studies

After cold rolling (drawing), a highly developed dislocation substructure of B2 austenite with partial amorphization is observed (see [35] for details). Subsequent heat treatment at 700 °C for 1 h forms a fine-grained recrystallized structure of B2 austenite with an average grain size of 7.3 µm. The grains of 4–12 µm in size occupy 82% of the volume; the maximum grain size does not exceed 27 µm (Figure 1a,b).

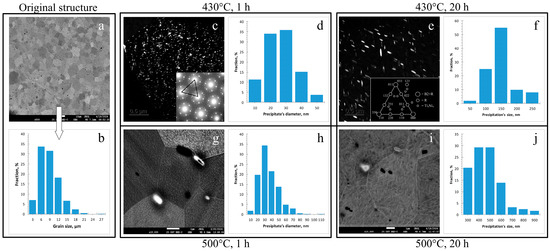

Figure 1.

Microstructure evolution under aging and histograms: an original recrystallized structure, SEM (a,b); aging at 430 °C, 1 h, TEM, dark field (c,d); selected-area electron diffraction patterns (SAEDP) <111>B2 zone axis (e); aging at 430 °C, 20 h, TEM, dark field (e,f); interpretation of SAED by [36]; aging at 500 °C 1 h, SEM (g,h); and aging at 500 °C, 20 h, SEM (i,j).

Additional low-temperature aging at 300 °C for 1–20 h does not bring about visible structure changes in the TEM pictures; the reflexes inherent to Ti3Ni4 precipitates are not revealed in the SAEDP; therefore, the corresponding images are omitted.

Aging at 430 °C (1 h) brings about dramatical changes: Ti3Ni4 precipitates are visualized in the matrix (Figure 1c,d); their average diameter amounts to 26 nm, the average thickness amounts to 15 nm and the linear frequency to 8.2 p/µm; their distribution is uniform. After aging for 20 h, the precipitate’s diameter increases up to 140 nm (Figure 1e,f); the average thickness, up to 20 nm; and the linear frequency decreases to 3.5 p/µm. The interpretation of the SAED patterns shown in Figure 1e (marked with the triangular shape) corresponds to the indexed triangular given in Figure 1e.

After aging at 500 °C (1 h), the precipitate’s diameter amounts to 36 nm (Figure 1j,h), which is somewhat higher than after aging at 430 °C (1 h); the average thickness increases to 25 nm and the linear frequency increases to 5.7 p/µm. After aging for 20 h, the average diameter increases to 410 nm (Figure 1i,j), the average thickness increases to 50 nm and the linear frequency drops to 1.6 p/µm.

3.2. Evolution of MTs

In the calorimetric curves, we can observe the different intensities of evolution of the transformation peaks vs. the aging modes. Since in as-deformed material, all the MTs are suppressed, the corresponding curves are omitted. After solution treatment at 700 °C (1 h), the single-stage direct transformation B2→B19′ with a peak at −31 °C is observed; the reverse transformation B19′→B2 is detected with a peak at −6 °C (Table 1 and Figure 2).

Table 1.

Characteristic temperatures of the MTs.

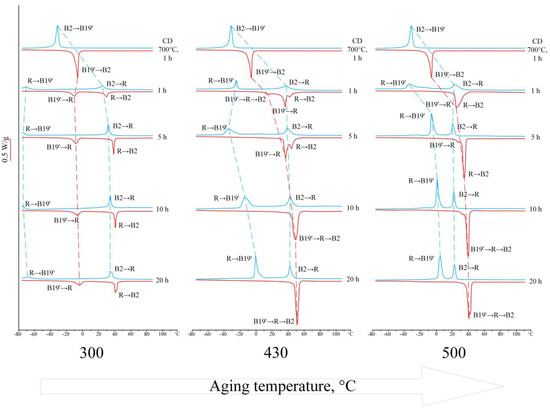

Figure 2.

Calorimetric curves after aging (dashed lines trace the peaks shifting). After high-temperature aging at 500 °C for 1 h, the forward transformation shows similar two-stage behavior regardless of the aging time. Aging for 5 h shifts the R→B19′ transformation to higher temperatures. After aging for 1 and 5 h, on heating, the two-stage B19′→R and R→B2 MTs proceed, and their bottoms merge. After aging for 10–20 h, the convergence of the direct transformations B2→R and R→B19′ continues. On heating, the single B19′→R→B2 transformation is recorded.

Subsequent low-temperature aging at 300 °C for 1 h brings about suppression of the B2→B19′ transformation. The sequential MTs of B2→R and R→B19′ are recorded on cooling and the reverse MTs of B19′→R and R→B2 are determined on heating regardless of the aging time. The peak temperatures show relative stability under an increase in the aging time (see the dashed lines).

After aging at 430 °C for 1 h, a similar two-stage forward transformation of B2→R and R→B19′ is observed regardless of the aging time. The reverse MTs show three stages via B19′→R→B2, B19′→R and R→B2. We suppose that the forward MT of B2→R→B19′ is not is visualized due to its blur in a wide temperature range. As the aging time increases to 5 h, the R→B19′ transformation shifts to a lower temperature; the bottoms of the reverse B19′→R and R→B2 transformations merge. On further aging development (10–20 h), the R→B19′ transformation shifts to a higher temperature, and on heating, a single reverse transformation B19′→R→B2 is recorded. The dashed lines permit tracing of the shift of the peaks with the increase in the aging duration. This aging temperature provides the most intensive shifting of the transformation peaks.

The diagrams shown in Figure 3 permit us to trace the shift of the onset and endset temperatures of the MTs and their temperature ranges –MS (a–c) upon cooling and –Af (d–f) upon heating.

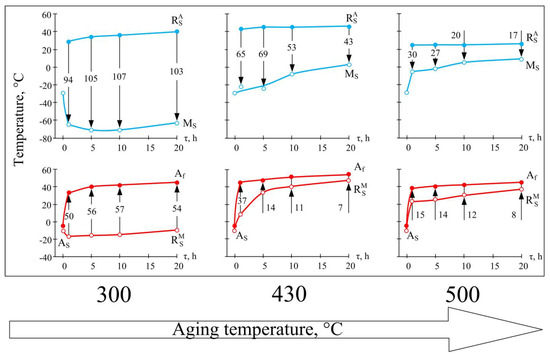

Figure 3.

Temperature ranges –MS (blue curves) and –Af (red curves) of the MTs vs. the aging duration: the 1st column—300 °C; the 2nd column—430 °C; and the 3rd column—500 °C.

In the original recrystallized material, prior to aging, the onset temperature RS cannot be determined (Figure 2) due to a single-stage forward MT B2→B19′. After aging at 300 °C, the Rs temperature shifts from 29 °C (1 h) to 40 °C (20 h). Aging for 1 h brings about a dramatical decrease in the MS point from −29 °C (in the original state) to −65 °C. The minimal magnitude of Ms = −71 °C is detected after aging for 5–10 h and the maximum Ms = −63 °C after aging for 20 h.

After aging at 300 °C (1–20 h), the widest temperature ranges of the forward and reverse MTs are revealed. The range Δ = 94 °C is detected at an early stage of aging (1 h); the increase in the aging duration up to 5–10 h expands the range up to 105–107 °C due to a decrease in the MS point to −71 °C and an increase in the Rs point up to 34–36 °C. In the latest stage of aging (20 h), the Ms magnitude somewhat increases up to −63 °C and the —up to 40 °C, which results in the narrowing of the Rs–Ms range to 103 °C. Under heating, the temperature range of –Af expands from 6 °C in the original state to 50 °C (exposure for 1 h) and up to 57 °C (exposure for 10 h). Generally, the reverse MT exhibits a significantly narrower–Af temperature range than that of the direct one –MS due to the wide hysteresis of the MT.

The higher aging temperature of 430 °C (1–20 h) brings about narrowing of the –MS and –Af ranges under cooling from 65 °C (1 h) to 43 °C (20 h) as well as from −37 to 7 °C under heating.

High-temperature aging at 500 °C brings about narrowing of the –MS ranges under cooling. After aging for 1 h, the magnitudes of the and MS temperatures are detected at 25 and −5 °C, respectively, and the –MS range reaches its maximum at 30 °C. An increase in the aging time up to 20 h brings in the gradual narrowing of this range to 17 °C.

The range of the reverse –Af temperatures significantly expands in the early stages of aging (1 h) if compared to corresponding data obtained after aging at 430 °C. After aging for 1 h, the magnitudes of the and Af points are determined at 23 °C and 38 °C, and the width of the corresponding temperature range of –Af amounts to 15 °C. The development of aging (20 h) is accompanied by the narrowing of this range to 12 °C. The maximum temperatures and Af are detected at 37 °C and 45 °C, respectively.

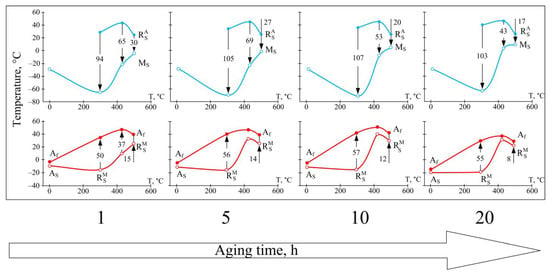

The diagrams presented in Figure 4 permit us to trace the effect of the aging temperature on the forward –MS and reverse –Af MTs at different stages of aging (i.e., under isochronous aging). All the curves exhibit an extremal character, which is most pronounced in the evolution of the Ms and temperatures. The maximum temperatures Rs and Af are revealed after aging at 430 °C, and the minimum magnitudes of —after aging at 500 °C; the maximum MS temperatures are determined after aging at 500 °C regardless of the aging duration.

Figure 4.

Effect of the aging temperature under isochronous aging on the forward −MS (blue curves) and reverse –Af (red curves) MTs: the 1st column—1 h; the 2nd column—5 h; the 3rd column—10 h; and 4th column—20 h.

The minimum Af temperatures correspond to the original unaged structure in all cases; the minimum temperatures MS and are determined after low-temperature aging at 300 °C; the maximum temperatures are detected after aging at 430 °C. The widest temperature ranges of the forward MTs –MS (94–107 °C) are revealed after low-temperature aging at 300 °C. The narrowest ranges –MS (30–17 °C) are detected after aging at 500 °C due to the growth of the MS point and the decrease of the RS point. The ranges –Af of the reverse MTs exhibit a similar evolution—the widest ranges (50–57 °C) correspond to low-temperature aging at 300 °C. The narrowest ranges –Af of the reverse MTs are detected after high-temperature aging at 500 °C; this narrows from 15 to 8 °C with the increase of the aging duration from 1 h to 20 h. The widest temperature range –MS (107 °C) is detected after low-temperature aging at 300 °C for 10 h. The temperature range –Af reaches its minimum (7–8 °C) after aging at 430–500 °C for 20 h.

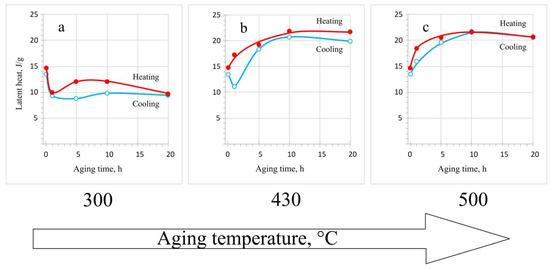

3.3. Latent Heat

The aging temperature strongly affects the magnitude and character of the evolution of the transformation latent heat as well as the difference between cooling and heating. The plots presented in Figure 5 show the summarized magnitude of the latent heat for the forward and reverse MTs regardless of the type of MTs as well as the number of stages.

Figure 5.

Evolution of the exo- and endothermic effects on cooling (blue plots) and heating (red plots) vs. the aging modes: (a) aging at 300 °C; (b) aging at 430 °C; (c) aging at 500 °C.

The effect of the aging time on the latent heat value is most pronounced in the early and intermediate stages of aging up to 10 h. In an original material, prior to aging, the latent heat of a single-stage B2→B19′ forward transformation amounts to 13.5 J/g and 14.2 J/g upon heating for a B19′→B2 transformation. The minimum magnitudes of the latent heat are revealed after low-temperature aging and negligibly depend on the aging time: the exothermic effect of the forward transformation upon cooling remains in the range of 9.9–12 J/g; the endothermic effect on heating remains within values of 9.3–9.7 J/g.

After aging at 430 °C, the latent heat under heating and under cooling strongly increases (Figure 5b). The minimum of the latent heat of 11 J/g is determined at an early stage of aging (1 h) on cooling, and it gradually increases to 20 J/g with aging development (10–20 h). Upon heating, the latent heat of 17.3 J/g is determined after aging for 1 h and increases to 21.6 J/g after aging for 20 h.

After high-temperature aging at 500 °C, the latent heat increases from 16 J/g (exposure 1 h) to 22 J/g (exposure 10 h), and then it somewhat decreases to 20 J/g in the late stage of aging (20 h). The curves upon cooling and heating coincide after aging for 10–20 h.

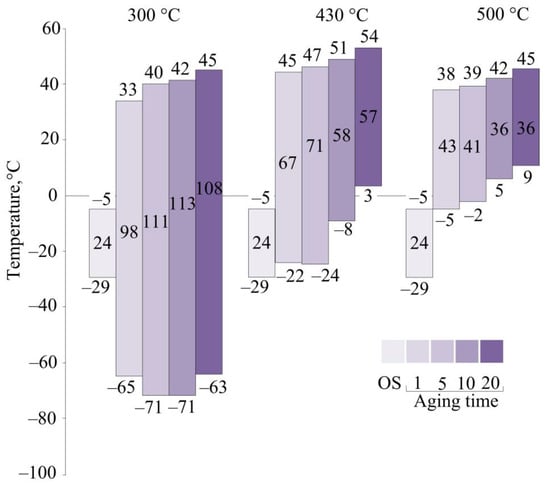

3.4. Hysteresis

The diagrams shown in Figure 6 permit us to trace the evolution of hysteresis vs. the aging time at different temperatures evaluated as a difference between the Ms and Af temperatures (see Table 1). The narrowest value of hysteresis (24 °C) is detected in an original solution-treated material. The widest hysteresis in the range of 98–107 °C is detected after low-temperature aging at 300 °C; this aging also provides the lowest Ms temperatures.

Figure 6.

Time–temperature dependence of hysteresis between Ms (lower values) and Af (upper values) using different aging modes; the magnitude inside the columns designates the hysteresis width.

Aging at 430 °C brings about the hysteresis evolution: it expands from 67 °C (after aging for 1 h) to 71°C (5 h) and narrows to 51 °C (20 h). Aging at 500 °C brings about the narrowest hysteresis respective to the aging time: its maximum of 43 °C is detected after aging for 1 h and it gradually narrows to 36 °C after aging for 20 h.

In all cases, regardless of the aging temperature, we observe the extremal character of hysteresis: it dramatically expands in the early stage of aging (1 h) if compared with an original state and then narrows under an increase in the aging time from 10 to 20 h.

3.5. Stress- and Strain-Temperature Behavior

The results of the tensile tests are presented in Table 2 and in Figure 7, Figure 8, Figure 9 and Figure 10. Table 2 contains the data concerning the measured functional characteristics in the test temperature range from −196 °C to 100 °C (several of them are omitted): the transformation yield stress σtr, the dislocation yield stress of stress-induced martensite (SIM) , the magnitude of Δσ = − σtr and the ductility δy measured as the elongation attributed to ; note that at a test temperature of −196 °C, the critical stress of the reorientation of cooling-induced martensite (σcr) is determined (see Figure 7a–f). The magnitudes of Δσ and δy correlate with the resource for the recovery strain [3,37,38].

Table 2.

The results of the tensile tests at various temperatures.

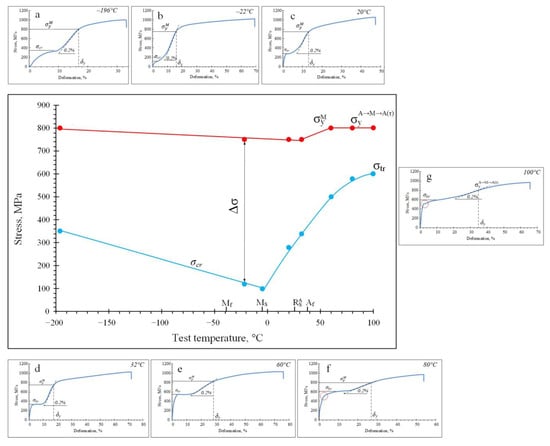

Figure 7.

Stress–temperature dependence of the fine-grained NiTi alloy after aging at 500 °C for 1 h with the corresponding stress-strain diagrams at different temperatures: (a) −196 °C, (b) −22°C, (c) 20 °C, (d) 32 °C, (e) 60 °C, (f) 80 °C, (g) 100 °C; A(T) designates the twinned B2 austenite; it will be discussed in Section 4.4.

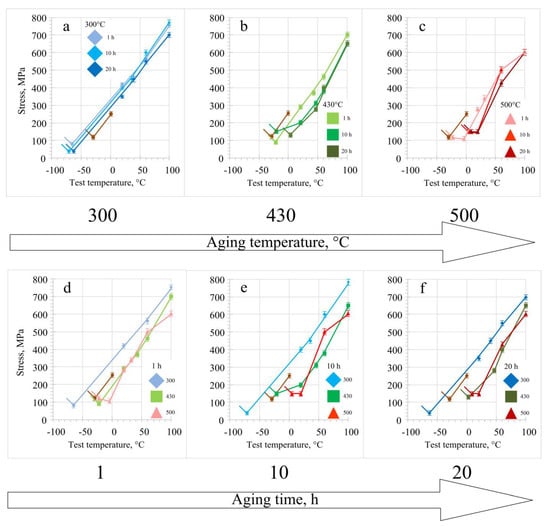

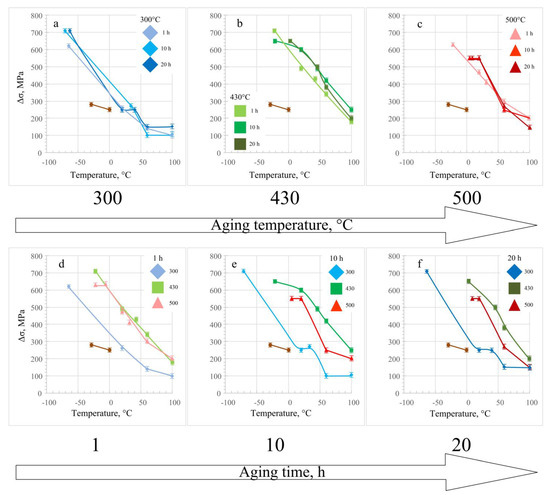

Figure 8.

Comparative stress-temperature diagrams of the transformation yield stress after aging using various modes: (a–c) isothermal aging; (d–f) isochronous aging; the symbol ● is attributed to an original solution-treated material (brown curves).

Figure 9.

Comparable stress-temperature diagrams of Δσ = − σtr after aging using various modes: (a–c) isothermal aging; (d–f) isochronous aging; the symbol ● is attributed to an original solution-treated material (brown curves).

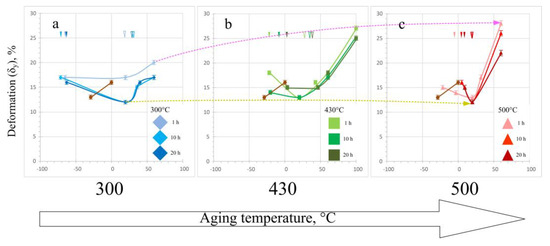

Figure 10.

The temperature dependence of the relative elongation using various aging modes: (a) 300 °C, (b) 430 °C, (c) 500 °C; symbols ▼and ∇ designate the Ms and Rf temperatures, respectively; the symbol ∙ is attributed to an original solution-treated material (brown curves). The dashed lines show the evolution of maximum and minimum magnitudes.

All the stress-temperature plots of the transformation yield stress (σtr) exhibit a V-shaped character with a minimum at Ms (Table 1 and Table 2). The full V-shaped plot obtained after aging at 500 °C for 1 h in all the test temperature ranges is given in Figure 7 with the corresponding stress-strain diagrams obtained at various test temperatures; these diagrams are typical for all the structural states.

The evolution of the dislocation yield stress exhibits a slight extremal character with a minimum at a temperature of Af. The maximum critical stress of the reorientation of cooling-induced martensite σcr = 800 MPa is determined at −196 °C. The same maximum value of = 800 MPa is determined in the test temperature range of 60 ≤ T ≤ −100 °C. The magnitude of Δσ gradually increases from 450 MPa at −196 °C and reaches its maximum of 650 MPa at Ms temperature. The subsequent increase in the test temperature brings about a gradual decrease in the Δσ to 200 MPa at 100 °C.

All the characteristics described above are surely determined in a test temperature range of –196 °C ≤ T ≤ 80 °C (see Figure 7a–f). An increase in the test temperature of Ms ≤ T ≤ 100 °C brings about an expressed decrease between and σtr; at a test temperature of 100 °C, the stress plateau that characterizes the value of σtr can be defined rather conditionally as well as the dislocation yield stress. The observed evolution of the stress-strain diagram is caused by a phenomenon that will be discussed in Section 4.4 as well as the parameter designated as . The ductility, which is determined as δy, remains within the limit of 18% up to the test temperature of 60 °C and dramatically increases up to 34% at 100 °C (see Figure 7g). The stress-strain diagrams shown in Figure 7a–g are typical within the limits of the present research but differ by the values of the measured characteristics.

To avoid the web-like view and for better visualization, the comparative stress-temperature diagrams in Figure 8, Figure 9 and Figure 10 are presented in the test temperature range between the Ms point and 100 °C. In Figure 8a–c, we can trace the effect of the aging time on the evolution of the σtr value vs. the aging temperature (isothermal aging). The curve of an original solution-treated material is presented by two points, because at test temperatures higher than 0 °C, the stress-strain diagrams are similar to the diagram presented in Figure 7g; therefore, the and σtr parameters cannot be determined. The σtr magnitudes grow from 40–80 MPa at Ms temperatures to 700–780 MPa at 100 °C. The value of remains within the limit of 700–780 °C in this temperature range (see Figure 8a).

Isothermal aging at 300 °C brings about somewhat of an increase in the σtr value (see Table 1 and Table 2). The general effect of aging is a dramatic expansion of the temperature range of realization of σtr from −30 ≤ T ≤ 0 °C to −70 ≤ T ≤ 100 °C; such an evolution is associated with a formation of stress-induced martensite (SIM).

After aging at 430 °C, the σtr curves shift to a higher test temperature range if compared to an original state (Figure 8b, Table 1 and Table 2). After aging for 1 h, the maximum difference in the σtr values between the Ms temperature (90 MPa) and 100 °C (700 MPa) is observed. Aging development (10 and 20 h) brings about somewhat of a decrease in this difference due to an increase in the lowest magnitudes at the Ms test temperature and the dimension of the highest values at 100 °C. After aging for 10 and 20 h, and σtr are very close in the test temperature range of 46–100 °C.

An increase in the aging temperature up to 500 °C brings about the degradation of a maxima σtr magnitude to 600 MPa (see Figure 8c) as well as (see Table 2) and at a test temperature of 100 °C regardless of the aging time. The minimum value of σtr at the Ms test temperature somewhat grows if compared to aging at 430 °C. Aging for 1 h provides the highest value of σtr in the test temperature range of 0–100 °C. The values of are somewhat lower than after aging at 430 °C.

The comparative visualization of the same plots described above, presented in Figure 8d–f, permits tracing of the effect of the aging temperature under isochronous aging. While after aging at 430 and 500 °C, the curves are close enough in the test temperature range of MS ≤ T ≤ 60 °C, the curve obtained after aging at 300 °C exhibits the highest values of σtr in this temperature range regardless of the aging time (see Figure 8d). The longer aging duration of 10 and 20 h brings about noticeable differences in the minimum values of σtr at the Ms point in somewhat of a decrease of the σtr parameters to 650 °C while the magnitudes remain similar (see Figure 7e and Table 2).

The maximum difference between the stress-temperature curves is revealed after aging for 10 h (see Figure 8e); for example, at the test temperature of 20 °C, this difference amounts to 2–2.6 times; an increase in the aging time up to 20 h does not bring about significant differences (see Figure 8f).

After aging at 300 °C, the curves obtained using aging for 1–20 h are sufficiently close in all the test temperature ranges. The maximum value of Δσ = 710 MPa is detected at the Ms test temperature after aging for 430 and 500 °C; after aging for 1 h, this magnitude is somewhat lower and amounts to 620 MPa (Figure 9a). This aging temperature brings about the lowest magnitudes of Δσ = 100–150 MPa at a test temperature range of 60–100 °C. The curves obtained after aging at 430 °C for 10 and 20 h remain close enough, and the curve obtained after aging for 1 h remains shifted to lower stress (Figure 9b).

In Figure 9a–c, we can compare the effect of the aging time on the evolution of Δσ after aging at different temperatures (isothermal aging). The curve of an original solution-treated material is presented by the two values of 280 MPa at −29 °C and 250 MPa at 0 °C.

The maximum value of Δσ = 710 MPa is detected at the Ms test temperature after aging for 1 h; the same aging mode brings about the lowest value of Δσ = 180 MPa at 100 °C. After aging for 10 and 20 h, the highest values of Δσ = 650 MPa are detected at the Ms temperatures, and the lowest values of 250 and 200 MPa at 100 °C, respectively.

After aging at 500 °C for 1 h, the highest value of Δσ somewhat decreases to 620 MPa at the Ms test temperature. The curves obtained after aging for 10 and 20 h coincide and exhibit the highest value of Δσ = 550 MPa at the Ms test temperature and the lowest values of 150 and 200 MPa at 100 °C (Figure 9c).

The comparative visualization of the same curves under isochronous aging shows the expressed effect of the aging temperature (Figure 9d–f). In the early stages of aging (1 h), the curves obtained after aging at 300 °C occupy the lowest level of the magnitudes. Aging at 430 and 500 °C brings about comparably high magnitudes of Δσ in all the test temperature range positions (see Figure 9d). Aging development (10–20 h) brings about an expressed difference between the curves obtained after different aging temperatures (see Figure 9e,f).

Thus, an increase in the aging temperature from 300 to 430 °C for 10 h brings about an increase in the magnitude of Δσ by 2–4.2 times in the test temperature range of 20–60 °C. After aging for 20 h, this difference amounts to 2.6 times in the same temperature range and degrades at a test temperature of 100 °C.

The diagrams shown in Figure 10 permit us to compare the ductility of the material in an original state and after aging. In Figure 10a,c the data concerning the ductility are limited by a test temperature of 60 °C, because it cannot be measured at 100 °C (see Figure 7g). All the curves of δy exhibit a V-shaped character with a minimum at a test temperature that corresponds to the Rf temperature (see Table 1 and Table 2). Note that the V-shape of the strain-temperature curves sharpens with an increase in the aging temperature.

The plots presented in Figure 10a show the maximal differences between the curves obtained after aging for 1 h and for 10 and 20 h (which coincide). The effect of the aging time exhibits an ambiguous character. After aging for 1 h, the values of δy dramatically grow and then dramatically degrade with the development of aging in all the test temperature ranges (the nature of the observed phenomenon will be analyzed in Section 4).

4. Discussion

4.1. Microstructure Evolution

The aging mode strongly affects the aging-induced microstructure in an original fine-grained Ni-rich alloy. According to ref. [38], the defect density ρ amounts to 107–8cm−2 in the same material.

As far as Ti3Ni4 precipitates nucleate predominantly on the lattice defects, they grow under similar competing conditions. This explains why the precipitate’s diameter remains in the nano-size range (26–36 nm) at an early stage of aging (430–500 °C, 1 h). Their size increases by 5 times with an increase in the aging time up to 20 h at 430 °C and by 12 times at 500 °C (see Figure 1). After aging at 500 °C, the average particle size is higher than after aging at 430 °C, which is attributed to the acceleration of diffusion vs. the aging temperature: in accordance with the phase diagram of the NiTi alloy [39]), the limiting equilibrium of the Ni concentration in the B2 matrix increases vs. the temperature, thereby reducing the “depth” of aging.

The observed microstructure evolution exhibits agreement with the data in [17]: it was reported that an increase in the aging temperature in the range of 450–500 °C and the aging time in the range of 1–10 h brings about a dramatical increase in the precipitates diameter; however, the precipitates were only detected in the grain boundary area of a coarse-grained alloy with Ni content of 50.7 at.%. Note that in ref. [6] it was proved, however, that the grain size strongly affects the precipitate’s distribution. It was shown in ref. [6] as well that in a coarse-grained NiTi alloy, the Ni concentration is higher in the grain boundary zone as well as the defect density if compared with the grain center. Such heterogeneity causes nucleation and the subsequent growth of precipitates in the grain boundary zone. The grain refinement brings about a rather uniform Ni concentration in the grain volume. In [5], it was revealed that the Ni concentration in the range of 50.6–50.8 at.% Ni strongly affects the precipitate’s distribution.

The peculiarities of the aging-induced microstructure evolution exhibit an accordance with previously published data (see ref. [6]) but also reveal new phenomenon. Thus, in ref. [6], it revealed a heterogeneous distribution of Ti3Ni4 precipitates in a fine-grained Ni50.7Ti at.% alloy (with an average grain size of 3 µm) after aging at 430 °C for 10 h. In the present study, we use an alloy with 50.8 at.% Ni, and we observe that the distribution of Ti3Ni4 precipitates in the grain volume remains homogeneous even after exposure for 20 h. This means that an increase in the Ni content by 0.1 at.%, provides a transition to a homogeneous distribution of precipitates in a material with a coarse grain (grain size is 2 times larger than in the above-cited article). This observation exhibits good agreement with the findings of Nishida [5] devoted to the study of the effect of the Ni concentration on the size and distribution of precipitates in coarse-grained NiTi alloys. The principle difference between the data presented in the cited articles and the data revealed in the present research is that the coarse-grained structure always provides a heterogeneous distribution of precipitates, regardless of the Ni concentration. The fine-grained structure can provide a uniform or non-uniform distribution of precipitates, and this depends on the Ni concentration. A short aging time at 430 °C for 1 h provides the finest precipitates, their highest density, and a rather uniform distribution in the grain volume.

It should be noted that an increase in the aging temperature and time brings about changes in the precipitate’s shape, mainly due to an increase in their diameter; at the same time, the thickness of the particles increases insignificantly. It can be logically assumed that this phenomenon is caused by the stresses developed by the B2 matrix in the {111}B2 plane that prevents the growth of precipitates in the transverse direction ⟨111⟩B2 [40].

4.2. Peculiarities of Martensitic Transformations

The obtained results prove that the aging mode exhibits a pronounced effect on the evolution of the characteristic temperatures and their ranges vs. the exposure time.

The diagrams shown in Figure 3 and Figure 4 permit us to trace the evolution of the temperature ranges of the forward –MS (a–c) and the reverse –Af (d–f) MTs vs. the aging modes. The chosen characteristics matter for practical use; in particular, it was proved that the loading at the Rs temperature with subsequent cooling in a loaded condition provides realization of the abnormally high recovery strain up to 15–18% [29,41]. Considering the Clausius–Clapeyron equation, the difference between the test temperature and the Ms temperature is very important as well, because it determines the magnitude of the transformation yield stress (σtr).

In addition, the –MS temperature range permits us to estimate the effect of aging on the R-phase stabilization; the range–Af allows one to estimate the temperature range of the start and finish temperatures of shape recovery upon heating: the lower the training deformation, the closer the temperature range of shape recovery is to the –Af temperature range determined from the calorimetric curves under heating [42,43].

To discuss the link between the aging-induced microstructure and the MTs, we must analyze all the relevant factors. The majority of them are as follows: (i) stabilization or destabilization of the B2-matrix or R-phase: a high defect density stabilizes B2-austenite, which shifts the temperature of the B2→R transformation to lower values [6,29]; Ti3Ni4 precipitates stabilize the R-phase, and as a sequence, bring about a decrease in the onset temperature of the R→B19′ transformation [7]; (ii) the depletion of the nickel content in the B2 matrix caused by the precipitates’ growth shifts all the characteristic temperatures to higher values [29,30,44]; the precipitates coarsening narrows the ranges between the B2→R and R→B19′ transformations [18,19,30,45,46].

In the present research, the Ti3Ni4 precipitates are not detected in the SAED after aging at 300 °C even after exposure for 20 h. Despite this, we observe a suppression of the B2→B19′ transformation inherent to an original solution-treated material due to the precursor phenomenon [47,48,49,50], which is responsible for a lattice distortion sufficient for the appearance of R-martensite, and on the other hand, effective pinning points for preventing movement of the interphase boundaries; the precursor phenomenon is associated with the atomic rearrangement in the B2 matrix. Thus, the low-temperature aging suppresses the B2→B19′ transformation and brings about expansion of the forward –MS temperature range, which is associated with the stabilization of R-martensite; moreover, aging at 300 °C provides the most effective stabilization of the R-martensite (see Figure 3 and Figure 4).

The observed evolution of the characteristic temperatures of the MTs under low-temperature aging and intensive aging at 430 °C are identical in a fine-grained recrystallized alloy, which can be associated with the accumulation of distortions at the pre-precipitation stage. Note that the similar evolution of the MTs was revealed in a weakly aging alloy of Ni50.2Ti under intensive aging at 430 °C for 10 h [49].

The suppression of the B2→B19′ and B19′→ B2 transformations by low-temperature aging was first described in a coarse-grained Ni50.9Ti alloy in ref. [51]. In our study, this phenomenon is revealed in a fine-grained alloy.

4.3. Latent Heat and Thermal Hysteresis

The observed differences in the latent heat determined on cooling and heating, as well as the hysteresis width, are caused by the effects of the internal friction due to the movement of the interphase boundaries [52,53]. In accordance with findings first established by G.V. Kurdyumov and L. G. Khandros [54], the sequence of the nucleation of B192-martensite crystals upon cooling and their disappearance upon heating is being reproduced, i.e., the crystal of B192-martensite, which nucleates first, disappears last under the reverse MTs, and the last one will disappear first. This unique “exactly backward” path of the atomic displacements is ensured by an additional monoclinic shift of the martensite crystal lattice [54].

The minimum difference in the latent heat between cooling and heating we discover after high-temperature aging at 500 °C in the stage of developed aging (5–20 h) due to the coarsening of the precipitates and the reduction of the defect density. This observation exhibits an excellent agreement with the data obtained in refs. [55,56]. The authors of ref. [57] reported that the precipitation at the dislocations’ sub-boundaries hinders the movement of the dislocations and increases the temperatures of the recovery up to somewhere above 500 °C.

A coupling between the latent heat and hysteresis vs. the Ni concentration was revealed in homogenized NiTi alloys in several works. It was documented in refs. [30,58,59,60] that an increase in the Ni content causes a shift of the MS (as well as other critical temperatures) to lower temperatures, as well as a decrease in the latent heat and width of the thermal hysteresis. The above-cited studies were performed using NiTi with an Ni concentration in the range of 48.0–51.2%. Based on the analysis discussed in ref. [60], the value of latent heat in Ni-rich NiTi alloys with the recrystallized structure is determined in the range of 20–35 J/g. The latent heat in an original solution-treated NiTi alloy (Figure 5) shows 15 J/g [60], which coincides with the data obtained in ref. [30] in a homogenized Ni50.8Ti alloy and somewhat differs from the value of 20 J/g obtained in the same alloy in [48,61]. According to data in ref. [62], an increase in the Ni concentration is responsible for the decrease in the latent heat because the crystal lattice of B2-austenite and B19′-martensite in NiTi alloys become more similar.

Analyzing the plots of the Ms temperature vs. the aging temperature in Figure 3 and the plots of the latent heat in Figure 5, we find a coupling of their evolution. The authors of ref. [30] discovered an identical link, which they associate with the stabilization or destabilization of the B2-matrix and B19′-martensite.

A correlation between the latent heat and thermal hysteresis was revealed by Frenzel and co-authors using more than 12 NiTi-based alloys subjected to remelting and homogenization at a temperature of 1223 K. Note, however, that the obtained data show a considerable scatter [30].

In accordance with ref. [59], the dislocations, polygonized sub-boundaries, and grain boundaries are mainly responsible for the widening of the peaks of the MTs as well as the thermal hysteresis. Thus, if we summarize the findings of refs. [60,63,64,65,66,67], thermal hysteresis characterizes the homogeneity of the alloy composition. In the above-cited articles, however, the authors did not study hysteresis itself. To estimate the effect of aging on hysteresis under aging, we have analyzed the results of DSC studies.

Thus, in a coarse-grained Ni50,7Ti alloy (after solution treatment at 850 °C, 15 min), the hysteresis between the Ms and Af temperatures expands after aging at 450 °C for 0.25–25 h and then narrows after aging for 40 h [63]. The same alloy with the same grain size exhibits an expansion of hysteresis after aging at 500 °C for 1 h, and then narrowing after aging for 10 h [64]. In the Ni51,0Ti alloy (after solution treatment at 900 °C, 2.5 h), the hysteresis increases after aging at 500 °C for 1 h and then narrows after aging for 12 h [16].

An increase in the latent heat, associated with the development of aging at elevated temperatures of 430–500 °C (see Figure 5), accords with the data in ref. [67] observed in a coarse-grained Ni50.8Ti alloy. The same effect of the aging temperature on the latent heat was reported in [51]; the measured ΔH values exhibit fine agreement with the data obtained in a coarse-grained material alloy using aging at 430 °C.

After aging at 300 °C (Figure 5a), the observed decrease in the latent heat on cooling can be attributed to the appearance of areas with elevated concentrations of Ni [3,47,50,68]. After aging at 430 °C for 1 h, we observe a similar decrease in the latent heat under cooling caused by the finest precipitates with a comparatively high density of distribution. After subsequent heating, the value of the latent heat exceeds that under cooling. A similar evolution of the latent heat was reported in the Ni50.8Ti alloy after aging at 400 °C, 1 h [69].

All the above-cited findings were obtained using a coarse-grained NiTi alloy and exhibit fine agreement with the above-described results presented in Figure 6. Note, however, that in the diagrams presented in Figure 6, we observe somewhat of a delay in the hysteresis narrowing, which starts after aging at 300 °C for 10 h and at 430 °C for 10 h. The observed difference, however, exhibits good agreement with the data in ref [6]. The reason for the observed delay is the suppression of the precipitate’s growth in the fine-grained structure. This finding exhibits fine agreement with the data in refs. [19,20,21], where the evolution of thermal hysteresis in a fine-grained material was not analyzed; however, the data concerning the critical temperatures permits one to estimate the hysteresis under aging.

Thus, the results discussed above show the different evolution of the latent heat and hysteresis vs. the aging duration; this finding remains fair when using different aging temperatures.

Based on the conclusions of previous studies, we can suppose that the general factor affecting an increase in the latent heat when using elevated temperatures is a decrease in the Ni concentration in the matrix due to precipitation; herewith, the general factor affecting the non-monotonic evolution of hysteresis is a decrease in the defect density.

The effect of the aging mode on the evolution of latent heat and hysteresis in the fine-grained Ni-rich NiTi alloy is first revealed and discussed in the present study.

4.4. Stress- and Strain-Temperature Behavior

To discuss the effect of the aging modes on the stress- and strain-temperature behavior, we must first analyze the stress-strain and stress-temperature V-shaped diagrams shown in Figure 7. These diagrams are typical for all the structural states described in the present study but differ at various test temperatures and in the magnitudes of the measured characteristics.

From the tensile tests, three types of stress-strain diagrams are extracted; they are associated with different test temperature ranges. The first type of stress-strain diagram is observed at test temperatures lower than the Af temperature (see Figure 7a–d); however, the processes attributed to the measured characteristics are different. In accordance with the Clapeyron–Clausius equation, in a test temperature range of Ms < T < Af (Figure 7a), the martensitic transformation starts at a temperature above Ms, and the higher the test temperature, the higher the stress [3]. Upon reaching the stress plateau, the deformation accumulates only due to the formation of favorably oriented stress-induced martensite until the deformation resource is exhausted. At test temperatures lower than Ms, the cooling-induced martensite reorientates at a stress σcr. After reaching the dislocation yield stress of stress-induced martensite , the conventional plastic deformation of reorientated martensite starts [55]. Regardless of the structural state, the stress plateau in the stress-strain diagrams remains within the strain limits of 10% and the value of does not exceed the strain limits of 18%.

At test temperatures higher than the Af temperatures, the V-shaped curve shows an increase in the magnitude to 800 MPa. The stress-strain diagrams in Figure 7e,f (obtained at test temperatures of 60 and 80 °C) exhibit a convergence of and σtr characteristics; at the same time, the curve of exhibits a decrease in an angle of inclination to the abscissa axis, resulting in a significant increase in elongation up to 28% (the second type of stress-strain diagram). In Figure 7f, an extended zone of gradual increase in stress precedes the appearance of a plateau, which can be logically associated with the simultaneous processes of SIM formation and its hardening.

At a test temperature of 100 °C, the stress plateau in the stress-strain diagram (third type) is hardly determined, and the ductility δy reaches 35%.

The observed phenomenon at elevated test temperatures was first studied and described in [25,26] using modeling and TEM studies. A new mechanism of plastic deformation in NiTi alloys was revealed. This mechanism is associated with the B2→B19′→B2(T) transformation into B2-austenite twins {114}, which was revealed in the deformed microstructure under TEM observations. The authors claim that “this transformation becomes activated in any thermomechanical load in which the oriented B19′ martensite is exposed to high stresses at high temperatures” [26]. The abnormally high strain observed in the stress-strain curves at elevated test temperatures becomes irreversible.

To analyze the efficiency of the aging mode in terms of the transformation yield stress σtr, we must consider the Clausius–Clapeyron equation: the stress corresponding to the formation of stress-induced martensite (SIM) is determined by the relation of the critical stress and test temperature and the corresponding Ms point [39]. As far as the V-shaped curves with different Ms points are shifted relative to each other, the task of estimating the efficiency of aging seems problematic. On the other hand, it is easy to imagine that in shifting all the Ms points to a single virtual axis, we would hardly find that the difference between the curves obtained after different aging times will become less pronounced.

The general effect that brings about aging is a dramatic expansion of the temperature range of the realization of σtr from −30 ≤ T ≤ 0 °C of an original solution-treated material to −70 ≤ T ≤ 100 °C; such an evolution is associated with the formation of the stress-induced martensite (SIM).

Considering that the temperature dependence of the σtr curves exhibits a similar character upon varying the aging time, and analyzing the relative position of the curves to each other, we can conclude that the position of the Ms temperature after various aging modes is mostly responsible for the magnitude of σtr at a chosen test temperature.

Thus, if aging brings about a shift in the Ms point to lower temperatures relative to the original state, the magnitude of σtr will be higher (see Figure 8a); on the contrary, if aging shifts the Ms point to higher temperatures relative to the original state, the magnitude of σtr will be lower (see Figure 8b,c).

The relatively close position of the curves in Figure 8a–c (isothermal aging) and the expressed difference between them in Figure 8d–f (isochronous aging) brings us to the conclusion that varying the aging temperature is significantly more effective than varying the aging time from the point of view of the evolution of σtr. The same statement is also true for the evolution of the Δσ (see Figure 9). The general reason for the observed regularities is the dependence of the diffusion process on the temperature and time of the heat treatment: the effect of the temperature on accelerating the diffusion process is incomparably higher [56].

This result seems logical if considering the link between the microstructure and the transformation evolution, which are finally are responsible for mechanical behavior.

Since the stabilization of R-martensite is caused by intensive and extensive precipitation (see Figure 3 and Figure 4), which is associated with the creation of pinning points that prevent the migration of the interphase boundaries under cooling, the same factor determines the σtr value associated with the formation of stress-induced martensite under tensile tests.

In the aging-induced microstructure, the most effective pinning points are the Ti3Ni4 precipitates; their size and distribution strongly depend on the aging mode (see Figure 1).

On the other hand, the precipitates create internal stresses in the matrix, which initiate the B2→R transformation, and as a sequence, promote the R→B19′ transformation. These factors are competing; the obtained results illustrate their contribution to stress-temperature behavior after aging using various modes. Low-temperature aging brings about an increase in the σtr magnitude: aging at 430–500 °C brings about a decrease in the σtr magnitude relative to the original state (see Figure 8).

The observed regularities also exhibit agreement with the latent heat: low-temperature aging at 300 °C provides the lowest intensity and completeness of the MTs, and aging at 430–500 °C brings about the highest exothermic and endothermic effects.

The maximum differences in the σtr values vs. the aging time relative to the original state are revealed after aging at 430 °C and 500 °C in the test temperature range between 0 °C and 50 °C (see Figure 8b,c,e,f).

The efficiency of the aging temperature under isochronous aging is significantly higher than the efficiency of the aging time under isothermal aging (Figure 8d–f). The observed regularities exhibit good agreement with comparative studies of the microstructure evolution described above: an increase in the aging temperature exhibits higher efficiency in the precipitate’s growth than the aging time (see Figure 1). For the most effective regulation of the functional and mechanical characteristics, it is advisable to vary the aging temperature regardless of the duration of aging.

The maximum values of Δσ = 620–710 MPa are realized after aging at 300 °C in the test temperature range of −70 ≤ T ≤ −30 °C, which excludes using this aging for practical applications. From this point of view, an aging temperature of 430 °C for 10–20 h turns out to be the most preferable, because it permits reaching the values of Δσ = 500–650 MPa in the temperature range of 20 ≤ T ≤ 60 °C, which meets the conditions of medical use.

The strain-temperature plots presented in Figure 10a exhibit a V-shaped character with a minimum at a Rf temperature (see Table 1 and Table 2), which corresponds with an increase in the aging temperature.

To explain the nature of the observed evolution, we must consider that the ductility is determined by the mean free path of a dislocation under load.

The magnitude of the ductility exhibits the maximal differences between the curves obtained after aging for 1 h and for 10 and 20 h (which coincide). The effect of the aging time exhibits an ambiguous character. After aging for 1 h, the values of δy dramatically grow and then dramatically degrade with the development of aging in all the test temperature ranges. It can be supposed that an increase in ductility (if compared with an original state) can be attributed to the relaxation of quenching stresses in the original material and the appearance of the R→B19′ transformation (see Figure 2 and Table 1). The longer aging duration of 10–20 h brings about a predominance of the atomic rearrangement known as a precursor phenomenon, which creates pinning points for dislocations.

The highest magnitudes of δy = 27–28% are realized after aging at 430 and 500 °C at test temperatures 100 °C and 60 °C, respectively, due to the above-described mechanism associated with the B2→B19′→B2(T) transformation into B2-austenite twins {114}. When loading close to the Rf temperature, the dislocation slip takes place simultaneously with the formation of SIM when the interphase boundaries create serious obstacles for dislocations and provide the minimum of plasticity. At the lowest test temperatures, the dislocation slip in the reoriented cooling-induced martensite brings about a somewhat increased δy.

Aa shown in Figure 10, the V-shaped curves sharpen with an increase in the aging temperature; this is caused by the convergence of the Rs and Ms points. Thus, the relative position of these characteristic temperatures strongly affects the strain-temperature behavior of the Ni-rich NiTi alloy upon aging. This phenomenon was first revealed in the present research.

The obtained results seem quite logical and regular; the stress-temperature behavior of the studied parameters exhibits agreement with the known data [3,38]. The regularities obtained can be used to predict the set of functional and mechanical properties formed as a result of the aging of titanium nickelide with different initial structures. For the most effective regulation of the functional and mechanical characteristics, it is advisable to vary the aging temperature.

The following major conclusions can be drawn from the analysis of the aging-induced microstructure, calorimetric studies and tensile tests.

5. Conclusions

After low-temperature aging at 300 °C, the Ti3Ni4 precipitates are not detected even after an aging duration of 20 h; nevertheless, the transformation behavior exhibits suppression of the B2→B19′ transformation and the appearance of the sequential B2→R and R→B19′ transformations associated with the precursor phenomenon.

The precipitate’s distribution remains uniform after aging at 430 and 500 °C, while their diameter and interparticle distance increases by 10–12 times with an increase in the aging temperature and time.

The aging-induced microstructure permits precise tuning of the characteristic temperature of martensitic transformations and thermal hysteresis; the correlation between hysteresis and the difference in the latent heats upon cooling and heating is revealed.

The structural and transformation peculiarities provide a dramatical expansion of a temperature range of realization of the σtr from −30 ≤ T ≤ 0 °C of an original solution-treated material to −70 ≤ T ≤ 100 °C due to the formation of the stress-induced martensite. The efficiency of the aging temperature is more pronounced than the efficiency of the aging time.

The V-shaped strain-temperature curves sharpen with an increase in the aging temperature due to convergence of the Rs and Ms temperatures.

An increase in the aging temperature from 300 to 430 °C for 10 h brings about an increase in the magnitude of Δσ by 2–4.2 times in the test temperature range of 20–60 °C. The maximum magnitudes of Δσ = 500–600 MPa are realized after aging at 430 °C for 10–20 h in a temperature range of 20 ≤ T ≤ 60 °C, which meets the conditions for medical use.

The regularities obtained can be used to predict the set of functional and mechanical properties formed as a result of the aging of titanium nickelide with different initial structures.

Author Contributions

Conceptualization, E.R.; methodology, E.R., K.P., V.K., S.M., A.K. and A.U.; software, K.P., V.K. and S.M.; validation, E.R. and K.P.; formal analysis, E.R. and K.P.; investigation, E.R., K.P., A.K., A.U. and V.A.; resources, V.A.; data curation, E.R. and K.P.; writing—original draft preparation, E.R.; writing—review and editing, E.R. and K.P.; visualization, K.P. and S.M.; supervision, E.R. and K.P.; project administration, V.K. All authors have read and agreed to the published version of the manuscript.

Funding

The reported study was performed with financial support from NUST MISIS (project code FSME-2023-0006) in the part of the TEM, SEM, mechanical properties studies and analysis. The additional DSC studies were performed with the support of the Russian Science Foundation (project no.24-79-10322, https://rscf.ru/project/24-79-10322/, accessed on 17 December 2024).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The TEM study was carried out on the equipment of the Center Collective Use “Materials Science and Metallurgy” of theNUST MISIS.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dobrzański, L.A.; Dobrzański, L.B.; Dobrzańska-Danikiewicz, A.D.; Dobrzańska, J. Nitinol type Alloys general characteristics and applications in endodontics. Processes 2020, 10, 101. [Google Scholar] [CrossRef]

- Nespoli, A.; Passaretti, F.; Szentmiklósi, L.; Maróti, B.; Placidi, E.; Cassetta, M.; Yada, R.Y.; Farrar, D.H.; Tian, K.V. Biomedical NiTi and β-Ti alloys: From composition, microstructure and thermo-mechanics to application. Metals 2022, 12, 406. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Wang, X.; Verlinden, B.; Kustov, S. Multi-stage martensitic transformation in Ni-rich NiTi shape memory alloys. Funct. Mater. Lett. 2017, 10, 1740004. [Google Scholar] [CrossRef]

- Ravari, B.K.; Farjami, S.; Nishida, M. Effects of Ni concentration and aging conditions on multistage martensitic transformation in aged Ni-rich Ti–Ni alloys. Acta Mater. 2014, 69, 17–29. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Polyakova, K.A.; Resnina, N.N. Role of Structural Heredity in Aging-Induced Microstructure and Transformation Behavior in Ni-rich Titanium Nickelide. Shape Mem. Superelast. 2022, 8, 200–214. [Google Scholar] [CrossRef]

- Liu, S.; Lin, Y.; Wang, G.; Wang, X. Effect of varisized Ni4Ti3 precipitate on the phase transformation behavior and functional stability of Ti-50.8 at.% Ni alloys. Mater. Charact. 2021, 172, 110832. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Khmelevskaya, I.Y.; Prokoshkin, S.D.; Inaekyan, K.E.; Ipatkin, R.V. Effects of strain aging on two-way shape memory effect in a nickel–titanium alloy for medical application. Mater. Sci. Eng. A 2006, 438, 1093–1096. [Google Scholar] [CrossRef]

- Poletika, T.M.; Girsova, S.L.; Bitter, S.M.; Lotkov, A.I.; Zheronkina, K.A. Structure, Martensitic Transformations, and Mechanical Properties of Aging Nanocrystalline Ti–50.9 at% Ni Alloy. Phys. Mesomech. 2024, 27, 152–162. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Polyakova, K.A.; Murygin, S.R.; Komarov, V.S.; Resnina, N.N.; Andreev, V.A. Role of structural heredity in control of functional and mechanical characteristics of Ni-rich titanium nickelide. Phys. Met. Metallogr. 2022, 123, 1226–1233. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E.; Libertini, R. Effect of Temperature on the Mechanical Behaviour of Ni-Ti Shape Memory Sheets. In TMS 2016: 145thAnnual Meeting & Exhibition: Supplemental Proceedings; Springer: Berlin/Heidelberg, Germany, 2016; pp. 433–439. [Google Scholar]

- Ostropiko, E.; Yu Konstantinov, A. Functional behaviour of TiNi shape memory alloy after high strain rate deformation. Mater. Sci. Technol. 2021, 37, 794–804. [Google Scholar] [CrossRef]

- Churakova, A.; Gunderov, D.; Kayumova, E. The Investigation of Microstructure and Mechanical Behavior and the Fractographic Analysis of the Ti49.1Ni50.9 Alloy in States with Different Activation Deformation Volumes. Appl. Sci. 2021, 11, 3052. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, J.; Lin, Y.; Wang, G.; Wang, X. Effect of stretching-bending deformation and aging treatment on phase transformation behavior and superelasticity of Ti-50.8 at.% Ni alloy. Intermetallics 2021, 129, 107051. [Google Scholar] [CrossRef]

- Kuranova, N.N.; Makarov, V.V.; Pushin, V.G.; Popov, N.A. The structure and mechanical properties of the aging shape-memory Ti49Ni51 alloy after thermomechanical treatment. Phys. Met. Metallogr. 2023, 124, 230–237. [Google Scholar] [CrossRef]

- Fan, Q.C.; Zhang, Y.H.; Wang, Y.Y.; Sun, M.Y.; Meng, Y.T.; Huang, S.K.; Wen, Y.H. Influences of transformation behavior and precipitates on the deformation behavior of Ni-rich NiTi alloys. Mater. Sci. Eng. A 2017, 700, 269–280. [Google Scholar] [CrossRef]

- Pu, Z.; Chen, C.; Du, D.; Xi, R.; Jiang, H.; Wang, K.; Sun, L.; Wang, X.; Chang, B. Accelerated improvement in tensile superelasticity of electron beam directed energy deposition manufactured NiTi alloys by artificial thermal cycling combined with low temperature aging treatment. Virtual Phys. Prototyp. 2024, 19, e2352782. [Google Scholar] [CrossRef]

- Kim, J.I.; Miyazaki, S. Effect of nano-scaled precipitates on shape memory behavior of Ti-50.9 at.% Ni alloy. Acta Mater. 2005, 53, 4545–4554. [Google Scholar] [CrossRef]

- Wang, X.; Verlinden, B.; Van Humbeeck, J. Effect of post-deformation annealing on the R-phase transformation temperatures in NiTi shape memory alloys. Intermetallics 2015, 62, 43–49. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Verlinden, B.; Van Humbeeck, J. Effect of grain size on aging microstructure as reflected in the transformation behavior of a low-temperature aged Ti–50.8 at.% Ni alloy. Scr. Mater. 2013, 69, 545–548. [Google Scholar] [CrossRef]

- Wang, X.; Kustov, S.; Li, K.; Schryvers, D.; Verlinden, B.; Van Humbeeck, J. Effect of nanoprecipitates on the transformation behavior and functional properties of a Ti–50.8 at.% Ni alloy with micron-sized grains. Acta Mater. 2015, 82, 224–233. [Google Scholar] [CrossRef]

- Komarov, V.; Karelin, R.; Khmelevskaya, I.; Yusupov, V.; Gunderov, D. Effect of post-deformation annealing on structure and properties of nickel-enriched Ti-Ni shape memory alloy deformed in various initially deformation-induced structure states. Crystals 2022, 12, 506. [Google Scholar] [CrossRef]

- Poletika, T.M.; Girsova, S.L.; Lotkov, A.I.; Kudryachov, A.N.; Girsova, N.V. Structure and Multistage Martensite Transformation in Nanocrystalline Ti-50.9 Ni Alloy. Metals 2021, 11, 1262. [Google Scholar] [CrossRef]

- Vojtěch, D.; Voděrová, M.; Kubásek, J.; Novák, P.; Šedá, P.; Michalcová, A.; Fojt, J.; Hanus, J.; Mestek, O. Effects of short-time heat treatment and subsequent chemical surface treatment on the mechanical properties, low-cycle fatigue behavior and corrosion resistance of a Ni–Ti (50.9 at.% Ni) biomedical alloy wire used for the manufacture of stents. Mater. Sci. Eng. A 2011, 528, 1864–1876. [Google Scholar] [CrossRef]

- Chen, Y.; Tyc, O.; Molnárová, O.; Heller, L.; Šittner, P. Tensile deformation of superelastic NiTi wires in wide temperature and microstructure ranges. Shape Mem. Superelast. 2019, 5, 42–62. [Google Scholar] [CrossRef]

- Šittner, P.; Heller, L.; Sedlák, P.; Chen, Y.; Tyc, O.; Molnárová, O.; Kadeřávek, L.; Seiner, H. B2 ⇒ B19′ ⇒ B2 T Martensitic Transformation as a Mechanism of Plastic Deformation of NiTi. Shape Mem. Superelast. 2019, 5, 383–396. [Google Scholar] [CrossRef]

- Wollants, P.; Roos, J.R.; Delaey, L. Thermally-and stress-induced thermoelastic martensitic transformations in the reference frame of equilibrium thermodynamics. Prog. Mater. Sci. 1993, 37, 227–288. [Google Scholar] [CrossRef]

- Tyc, O.; Iaparova, E.; Molnárová, O.; Heller, L.; Šittner, P. Stress induced martensitic transformation in NiTi at elevated temperatures: Martensite variant microstructures, recoverable strains and plastic strains. Acta Mater. 2024, 279, 120287. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Polyakova, K.A.; Prokoshkin, S.D. Role of nickel content in one-way and two-way shape recovery in binary Ti-Ni alloys. Metals 2021, 11, 119. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Ryklina, E.; Murygin, S.; Komarov, V.; Polyakova, K.; Resnina, N.; Andreev, V. On Structural Sensitivity of Young’s Modulus of Ni-Rich Ti-Ni Alloy. Metals 2023, 13, 1428. [Google Scholar] [CrossRef]

- ASTM E112-13; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM F2004-24; Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis. ASTM International: West Conshohocken, PA, USA, 2004. [CrossRef]

- ASTM F2516-22; Standard Test Method for Tension Testing of Nickel-Titanium Superelastic Materials. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Ryklina, E.P.; Polyakova, K.A.; Murygin, S.R.; Isaenkova, M.G.; Zaripova, M.M.; Fesenko, V.A.; Komarov, V.S.; Andreev, N.V.; Resnina, N.N.; Andreev, V.A. On Textural Heredity of Ni-rich Ti–Ni alloy: Specific Features of Transformation and Tensile Behavior. Shape Mem. Superelast. 2023, 9, 384–401. [Google Scholar] [CrossRef]

- Zhuravlev, V.N.; Pushin, V.G. Thermomechanical Shape Memory Alloys and Their Application in Medicine; UrB Russian Academy of Science: Ekaterinburg, Russia, 2000. [Google Scholar]

- Polyakova, K.A.; Ryklina, E.P.; Prokoshkin, S.D. Effect of grain size and ageing-induced microstructure on functional characteristics of a Ti-50.7 at.% Ni alloy. Shape Mem. Superelast. 2020, 6, 139–147. [Google Scholar] [CrossRef]

- Prokoshkin, S.D. Chapter 4. Shape memory effects. In Shape Memory Alloys: Fundamentals, Modeling, Applications; Brailovski, V., Prokoshkin, S., Terriault, P., Trochu, F., Eds.; ÉTS: Montreal, Canada, 2003. [Google Scholar]

- Massalski, T.B.; Okamoto, H.; Subramanian, P.R.; Kacprzak, L. (Eds.) Binary Alloy Phase Diagrams, 2nd ed.; ASM International: Materials Park, OH, USA, 1990; Volume 3, p. 2874. [Google Scholar]

- Tadaki, T.; Nakata, Y.; Shimizu, K.I.; Otsuka, K. Crystal structure, composition and morphology of a precipitate in an aged Ti-51 at% Ni shape memory alloy. Trans. Jpn. Inst. Met. 1986, 27, 731–740. [Google Scholar] [CrossRef]

- Polyakova, K.; Ryklina, E.; Prokoshkin, S. Thermomechanical response of titanium nickelide on austenite grain/subgrain size. Mater. Today Proc. 2017, 4, 4836–4840. [Google Scholar] [CrossRef]

- Ryklina, E.; Polyakova, K.; Murygin, S.; Komarov, V.; Andreev, V. On stress-and strain-temperature behavior of titanium nickelide with various grain/subgrain size. Mater. Lett. 2022, 328, 133135. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Ashimbaev, D.A.; Murygin, S.R. Thermokinetics of shape recovery of nanostructured titanium nickelide. Lett. Mater. 2022, 12, 89–93. [Google Scholar] [CrossRef]

- Li, G.; Yu, T.; Zhang, N.; Chen, M. The effect of Ni content on phase transformation behavior of NiTi alloys: An atomistic modeling study. Comput. Mater. Sci. 2022, 215, 111804. [Google Scholar] [CrossRef]

- Kang, J.; Li, R.; Zheng, R.; Wu, H.; Wang, M.; Niu, P.; Li, J.; Liu, X.; Lai, D.; Yuan, T. Unconventional precipitation and martensitic transformation behaviour of Ni-rich NiTi alloy fabricated via laserdirected energy deposition. Virtual Phys. Prototyp. 2023, 18, e2231415. [Google Scholar] [CrossRef]

- Kaya, I.; Karaca, H.E.; Nagasako, M.; Kainuma, R. Effects of aging temperature and aging time on the mechanism of martensitic transformation in nickel-rich NiTi shape memory alloys. Mater. Charact. 2020, 159, 110034. [Google Scholar] [CrossRef]

- Pushin, V.G. (Ed.) Titanium Nickelide Shape Memory Alloys, Part 1: Structure, Phase Transformations and Properties; Ural Branch of the Russian Academy of Sciences: Yekaterinburg, Russia, 2006. (In Russian) [Google Scholar]

- Somsen, C.; Wassermann, E.F.; Kästner, J.; Schryvers, D. Precursorphenomenon in a quenched and aged Ni52Ti48 shape memory alloy. J. Phys. IV Proc. 2003, 112, 777–780. [Google Scholar]

- Ryklina, E.P.; Abduraimova, N.U.; Resnina, N.N. Alloy Ti–50.2 at.% Ni for Actuators: Evolution of Structure and Shape Memory Effects Under Post-Deformation Annealing. Part 1. Structure and Phase Transformations. Met. Sci. Heat Treat. 2021, 63, 203–209. [Google Scholar] [CrossRef]

- Shindo, D.; Murakami, Y.; Ohba, T. Understanding precursorphenomenon for the R-phase transformation in Ti-Ni-based alloys. MRS Bull. 2002, 27, 121–127. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiang, F.; Li, L.; Yang, H.; Liu, Y. Effect of ageing treatment on the transformation behaviour of Ti–50.9 at.% Ni alloy. Acta Mater. 2008, 56, 736–745. [Google Scholar] [CrossRef]

- Wasilewski, R.J. 55-Nitinol-the Alloy with a Memory: Its Physical Metallurgy, Properties and Applications—A Report; NASA: Washington, DC, USA, 1972. [Google Scholar]

- Wayman, C.M. Phase Transformations, Non-Diffusive. In Physical Mettalurgy; RW Cahn, R.W., Haasen, P., Eds.; North-Holland: New York, NY, USA, 1983; pp. 1031–1075. [Google Scholar]

- Kurdyumov, G.V.; Khandros, L.G. On the thermoelastic equilibrium on martensitic transformations. Dokl. Akad. Nauk SSSR 1949, 66, 211–214. [Google Scholar]

- Chrobak, D.; Stróż, D.; Morawiec, H. Effect of early stages of precipitation and recovery on the multi-step transformation in deformed and annealed near-equiatomic NiTi alloy. Scr. Mater. 2003, 48, 571–576. [Google Scholar] [CrossRef]

- Chrobak, D.; Stróż, D. Two-stage R phase transformation in a cold-rolled and annealed Ti–50.6 at.% Ni alloy. Scr. Mater. 2005, 52, 757–760. [Google Scholar] [CrossRef]

- Adharapurapu, R.R.; Vecchio, K.S. Effects of aging and cooling rate on the transformation of nanostructured Ti-50.8 Ni. J. Alloys Compd. 2017, 693, 150–163. [Google Scholar] [CrossRef]

- Ball, J.M.; James, R.D. Proposed experimental tests of a theory of fine microstructure and the two-well problem. Philos. Trans. R. Soc. London Ser. A Phys. Eng. Sci. 1992, 338, 389–450. [Google Scholar] [CrossRef]

- Mañosa, L. Magnetism and Structure in Functional Materials; Planes, A., Saxena, A., Eds.; Springer: Berlin, Germany, 2005; Volume 1. [Google Scholar]

- Kato, H. Latent heat storage capacity of NiTi shape memory alloy. J. Mater. Sci. 2021, 56, 8243–8250. [Google Scholar] [CrossRef]

- Otubo, J.; Rigo, O.D.; Coelho, A.A.; Neto, C.M.; Mei, P.R. The influence of carbon and oxygen content on the martensitic transformation temperatures and enthalpies of NiTi shape memory alloy. Mat. Sci. Eng. A 2008, 481, 639–642. [Google Scholar]

- Prokoshkin, S.D.; Korotitskiy, A.V.; Brailovski, V.; Turenne, S.; Khmelevskaya, I.Y.; Trubitsyna, I.B. On the lattice parameters of phases in binary Ti–Ni shape memory alloys. Acta Mater. 2004, 52, 4479–4492. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Dlouhy, A.; Eggeler, G. Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Mater. 2002, 50, 4255–4274. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Eggeler, G.; Schmahl, W.W.; Sheptyakov, D. Quantitative phase analysis in microstructures which display multiple step martensitic transformations in Ni-rich NiTi shape memory alloys. Mater. Sci. Eng. A 2006, 438, 593–596. [Google Scholar] [CrossRef]

- Eftifeeva, A.S.; Panchenko, E.Y.; Fatkullin, I.D.; Volochaev, M.N.; Tagiltsev, A.I.; Chumlyakov, Y.I. The Cyclic Stability of Superelasticity in Aged Ti49.3Ni50.7 Single Crystals with Oxide Surface. Metals 2022, 12, 2113. [Google Scholar] [CrossRef]

- Shen, J.J.; Lu, N.H.; Chen, C.H. Mechanical and elastocaloric effect of aged Ni-rich TiNi shape memory alloy under load-controlled deformation. Mater. Sci. Eng. A 2020, 788, 139554. [Google Scholar] [CrossRef]

- Yamazaki, T.; Montagnoli, A.L.; Young, M.L.; Takeuchi, I. Tuning the temperature range of superelastic Ni-Ti alloys for elastocaloric cooling via thermal processing. J. Phys. Energy 2023, 5, 024020. [Google Scholar] [CrossRef]

- Niitsu, K.; Kimura, Y.; Kainuma, R. Transformation entropy change and precursorphenomenon in Ni-rich Ti-Ni shape memory alloys. J. Mater. Res. 2017, 32, 3822–3830. [Google Scholar] [CrossRef]

- Sun, B.; Fu, M.W.; Lin, J.; Ning, Y.Q. Effect of low-temperature aging treatment on thermally-and stress-induced phase transformations of nanocrystalline and coarse-grained NiTi wires. Mater. Des. 2017, 131, 49–59. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).