Rate Equation Analysis of the Effect of Damage Distribution on Defect Evolution in Self-Ion Irradiated Fe

Abstract

1. Introduction

2. Methods

- (1)

- Mobile defects are interstitials, di-interstitials, vacancies, and di-vacancies.

- (2)

- Quadri-interstitials (loops) and quadri-vacancies (voids) are set to stable nuclei of clusters.

- (3)

- Thermal dissociation occurs in clusters containing fewer than three point defects.

- (4)

- The effect of cascade damage is represented in the direct formation of tri-interstitials and tri-vacancies as AIC × P(x) and AVC × P(x) in the following equations.

| EI [24] | EV [24] | EI2 [24] | EV2 | AIC | AVC | ZI_I | ZV_I | ZV_V | ZI2_I | ZI2_V | |

| 0.33 eV | 0.68 eV | 0.42 eV | 2.0 eV | 0.00014 | 0.0014 | 10 | 9 | 8 | 10 | 9 | |

| ZV2_I | ZV2_V | ZI2_I2 | ZI2_V2 | ZV2_I2 | ZV2_V2 | ZI3_I | ZI3_V | ZV3_I | ZV3_V | ZI3_I2 | ZI3_V2 |

| 9 | 8 | 10 | 9 | 9 | 8 | 10 | 9 | 9 | 8 | 10 | 9 |

| ZV3_I2 | ZV3_V2 | ZSI_I | ZSV_I | ZSI_V | ZSV_V | ZSI_I2 | ZSV_I2 | ZSI_V2 | ZSV_V2 | ||

| 9 | 8 | 10 | 9 | 9 | 8 | 10 | 9 | 9 | 8 |

3. Results

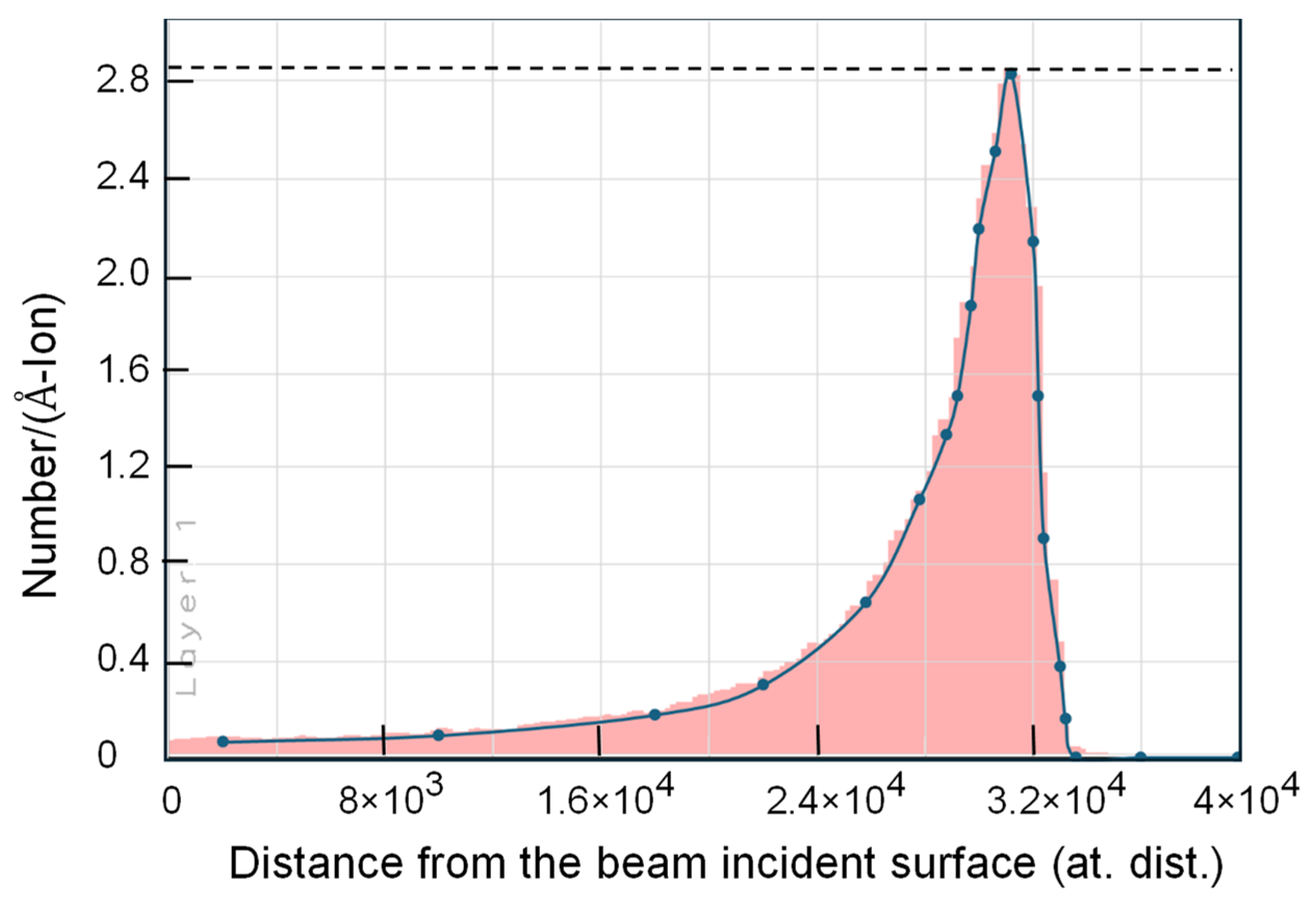

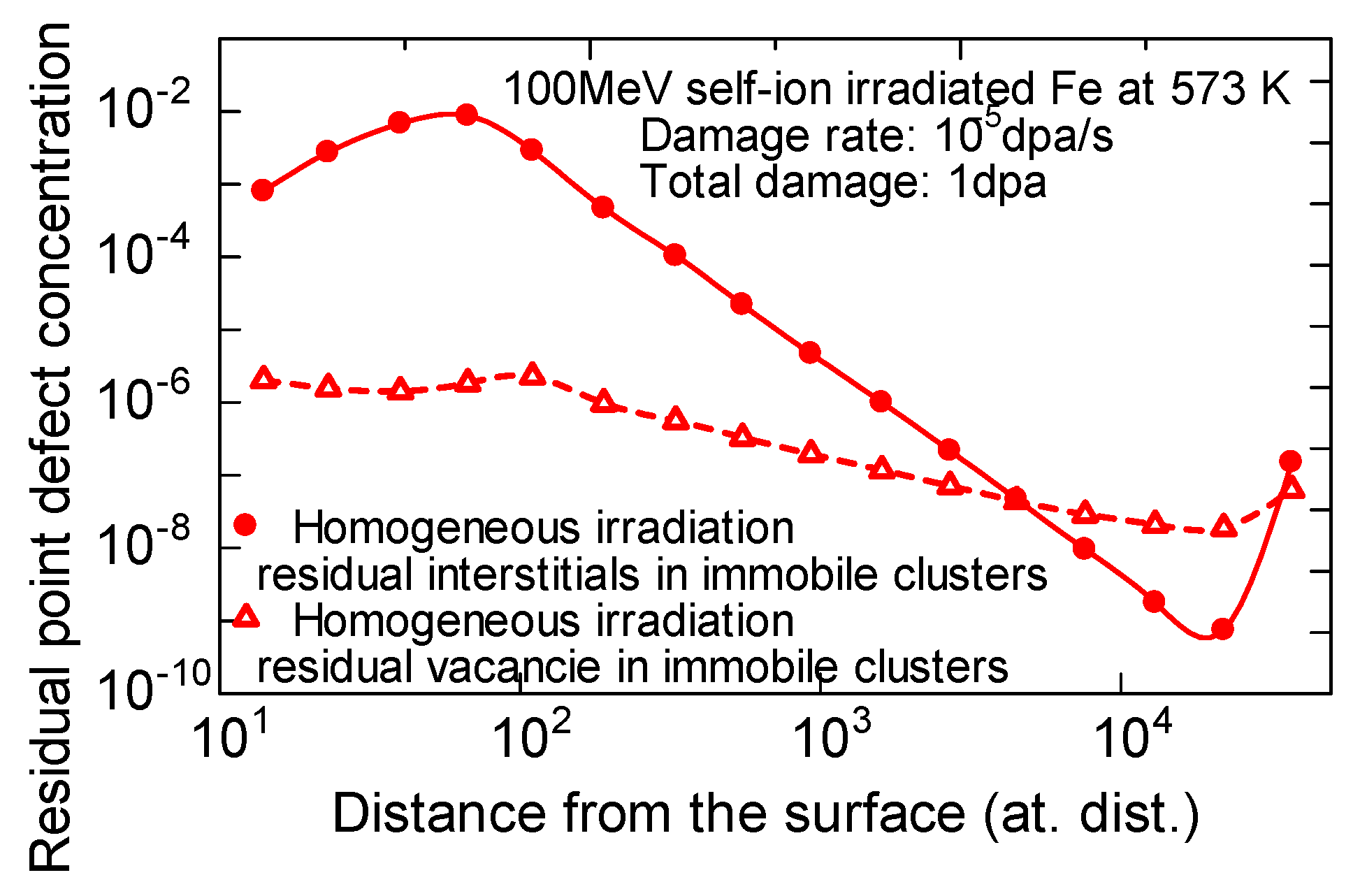

3.1. Self-Ion Irradiated Iron at 100 MeV

3.1.1. Irradiation at 573 K

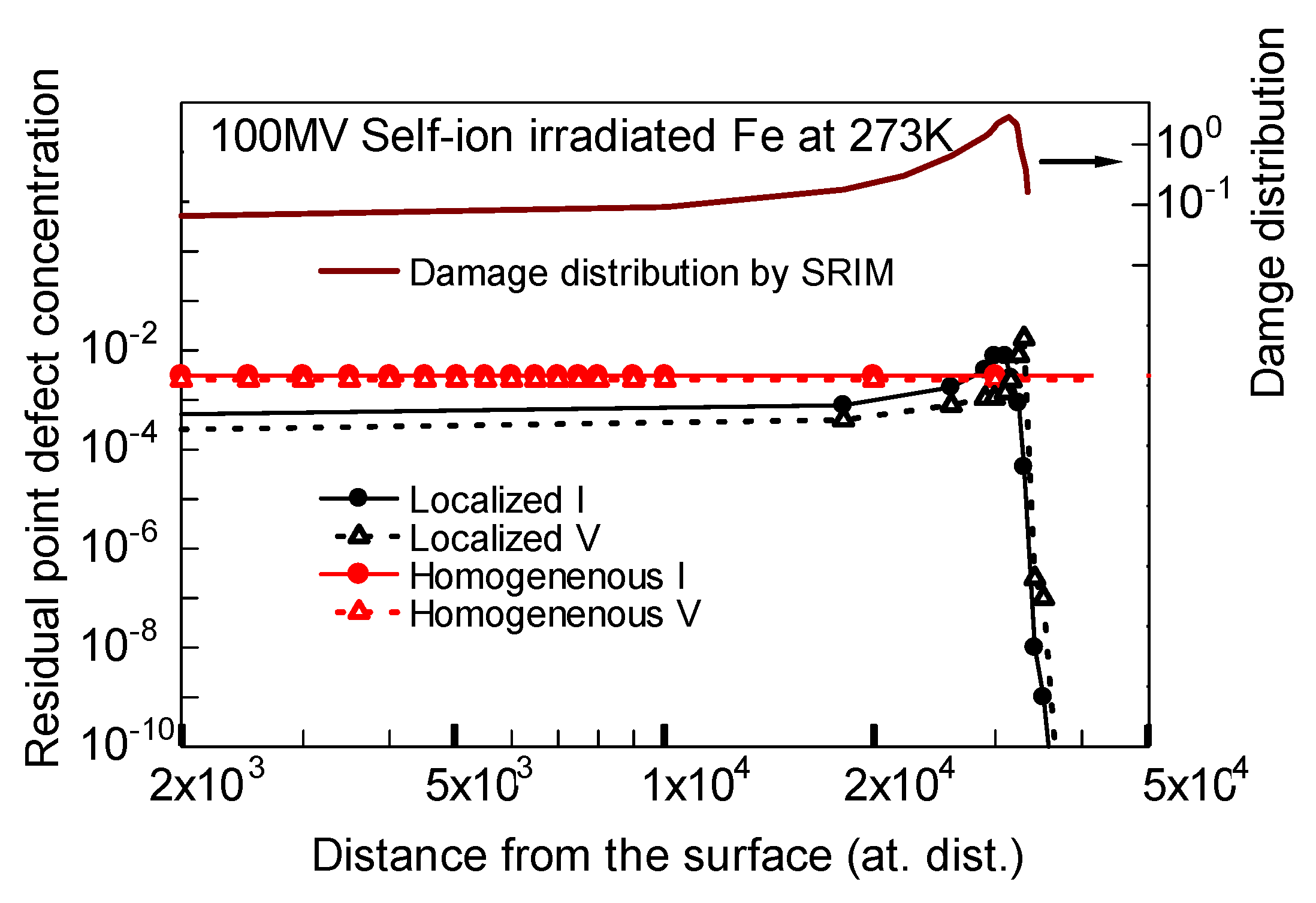

3.1.2. Irradiation at 273 K

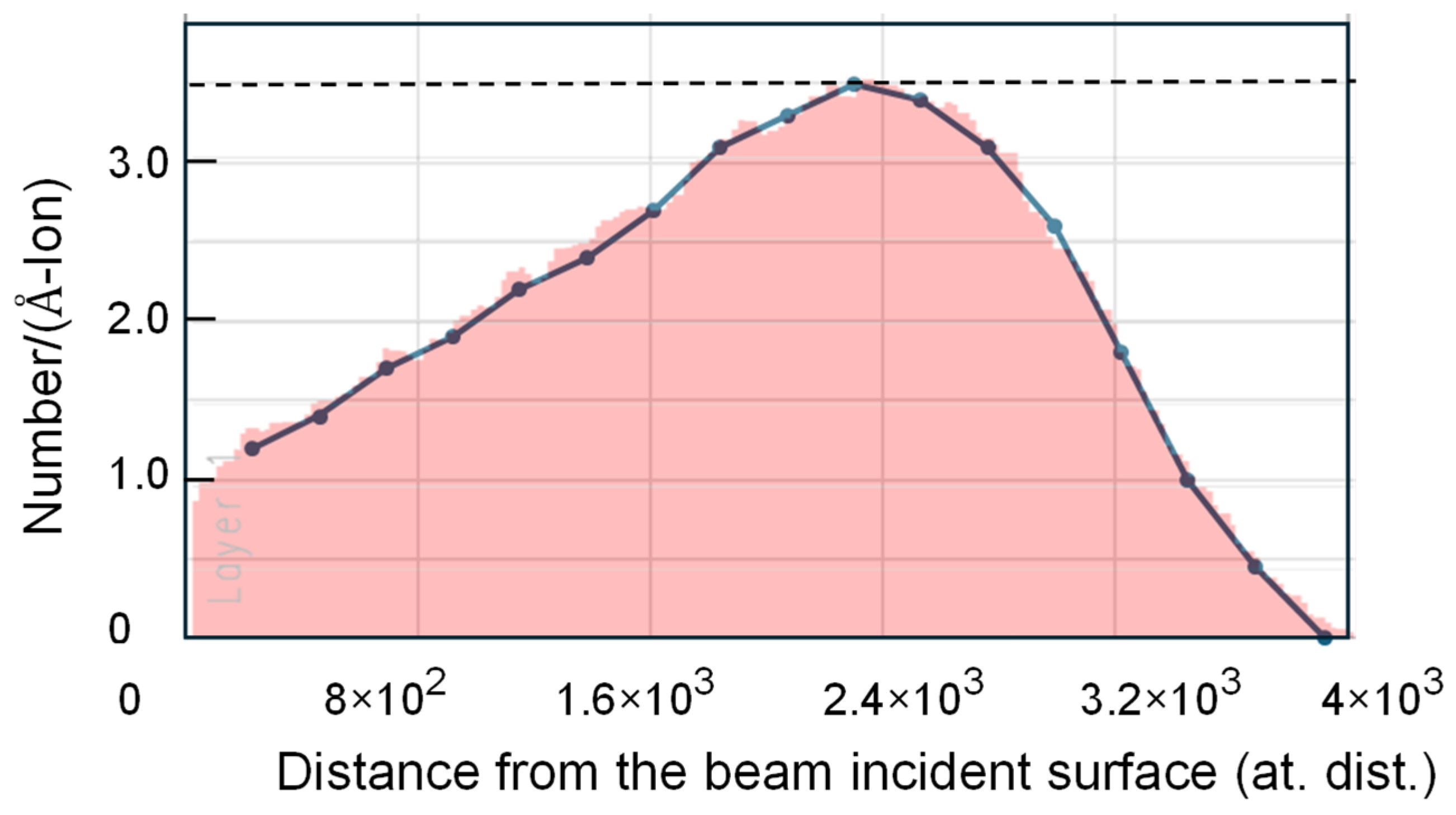

3.2. Self-Ion Irradiated Iron at 2 MeV

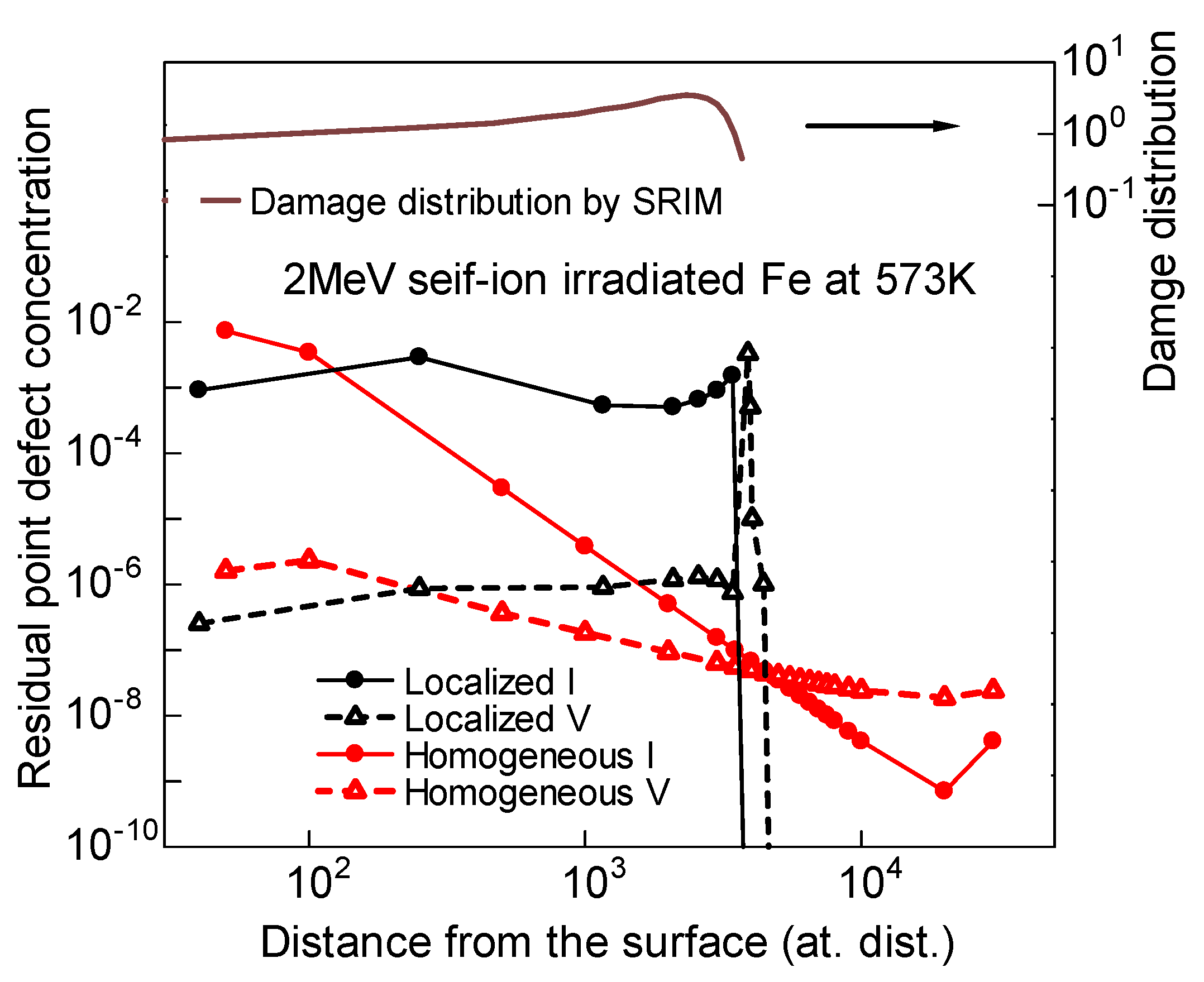

3.2.1. Irradiation at 573 K

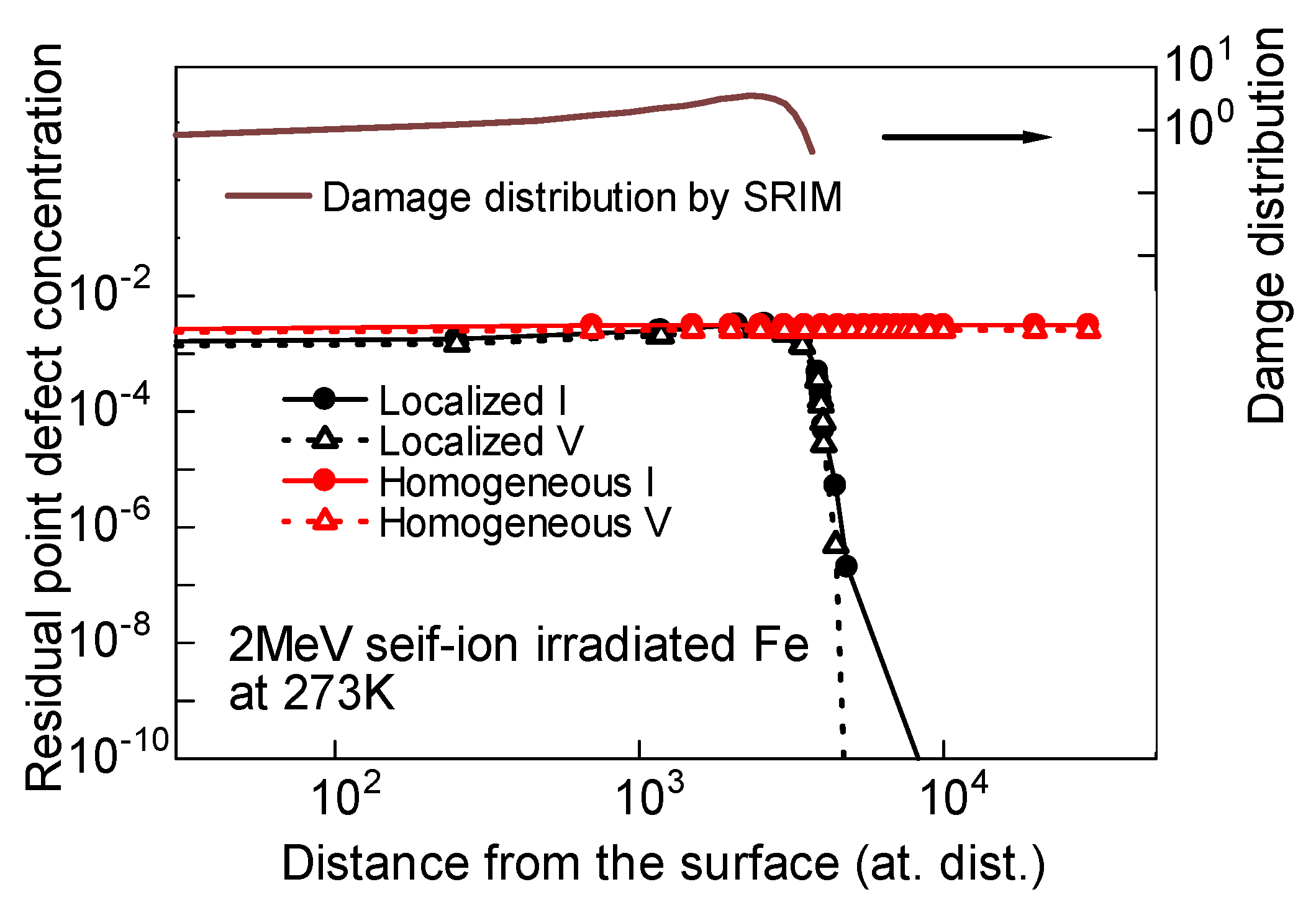

3.2.2. Irradiation at 273 K

4. Discussions

5. Concluding Remarks

Funding

Data Availability Statement

Conflicts of Interest

References

- Taller, S.; Chen, Y.; Song, R.; Chen, W.Y.; Jokisaari, A. An approach to combine neutron and ion irradiation data to accelerate material qualification for nuclear reactors. J. Nucl. Mater. 2025, 603, 155385. [Google Scholar] [CrossRef]

- Khiara, N.; Coulombier, M.; Raskin, J.P.; Bréchet, Y.; Pardoen, T.; Onimus, F. Helium nano-bubbles in copper thin films slows down creep under ion irradiation. Acta Mater. 2025, 288, 120854. [Google Scholar] [CrossRef]

- Robert Lürbke, R.; Riesch, J.; Feichtmayer, A.; Curzadd, B.; Höschen, T.; Neu, R. Experimental investigation of the impact of irradiation damages on the mechanical properties of tungsten. Nucl. Mater. Energy 2025, 42, 101858. [Google Scholar] [CrossRef]

- Liu, H.; Ge, W.; Wang, Y. Re-evaluating ion and neutron irradiation data with calculated applicable arc-dpa. Radiat. Eff. Defects Solids 2021, 176, 441–452. [Google Scholar] [CrossRef]

- Huang, J.; Gao, Z.; Liu, H.; Ma, P.; Liu, Y.; Ge, W.; Luo, F.; Cao, L.; Huang, J.; Xue, J.; et al. Effect of Damage Rate on the Cavity Swelling of Pure Nickel Irradiated with Triple Ion Beams. Metals 2022, 12, 1106. [Google Scholar] [CrossRef]

- Li, Y.; French, A.; Hu, Z.; Garner, F.A.; Shao, L. The dependence on displacement rate and temperature of near-surface void-denuding in self-ion irradiated pure polycrystalline and single-crystal iron. J. Nucl. Mater. 2024, 599, 155262. [Google Scholar] [CrossRef]

- Yoshiie, T.; Kinomura, K. Effect of pulse irradiation on the evolution of damage structure. Nucl. Instrum. Methods Phys. Res. Sect. B 2020, 479, 51–54. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM-The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Kiritani, M. Observation and analysis of defect structures evolution from radiation damage by D-T fusion neutrons. J. Nucl. Mater. 1986, 137, 261–278. [Google Scholar] [CrossRef]

- Sizmann, R. The effect of radiation upon diffusion in metals. J. Nucl. Mater. 1978, 69–70, 386–412. [Google Scholar]

- Yoshida, N.; Kiritani, M. Point Defect Clusters in Electron-Irradiated Gold. J. Phys. Soc. Jpn. 1973, 35, 1418–1429. [Google Scholar] [CrossRef]

- Kiritani, M.; Yoshida, N.; Takata, T.; Maehara, Y. Growth of Interstitial Type Dislocation Loops and Vacancy Mobility in Electron Irradiated Metals. J. Phys. Soc. Jpn. 1975, 38, 1677–1686. [Google Scholar] [CrossRef]

- Stoller, R.E.; Odette, G.R. Microstructural evolution in an austenitic stainless steel fusion reactor first wall. J. Nucl. Mater. 1986, 141–143, 647–653. [Google Scholar] [CrossRef]

- Was, G.S. Fundamentals of Radiation Materials Science: Metal and Alloys; Springer: Berlin/Heidelberg, Germany, 2007; Section 5. [Google Scholar]

- Adjanor, G. Complete characterization of sink-strengths for mutually 1D-mobile defect clusters: Extension to diffusion anisot ropy analog cases. J. Nucl. Mater. 2022, 572, 153970. [Google Scholar] [CrossRef]

- Yoshiie, T.; Xu, Q.; Sato, K. Reaction kinetic analysis of damage rate effects on defect structural evolution in Fe-Cu. Nucl. Instrum. Methods Phys. Res. Sect. B 2013, 303, 37–41. [Google Scholar] [CrossRef][Green Version]

- Yoshiie, T.; Sato, K.; Xu, Q.; Nagai, Y. Reaction kinetic analysis of reactor surveillance data. Nucl. Instrum. Methods Phys. Res. Sect. B 2015, 352, 125–129. [Google Scholar] [CrossRef]

- Yoshiie, T.; Kinomura, A.; Nagai, Y. Reaction kinetic analysis of reactor surveillance data II. Nucl. Instrum. Methods Phys. Res. Sect. B 2017, 393, 97–100. [Google Scholar] [CrossRef]

- Kuramoto, E.; Ohsawa, K.; Tsutsumi, T. Study of fundamental features of bias effect in metals under irradiation. J. Nucl. Mater. 2002, 307–311, 982–987. [Google Scholar] [CrossRef]

- Hindmarsh, C.; Brown, P.N.; Grant, K.E.; Lee, S.L.; Serban, R.; Shumaker, D.E.; Woodward, C.S. SUNDIALS: Suite of nonlinear and differential/algebraic equation solvers. ACM Trans. Math. Softw. 2005, 31, 363–396. [Google Scholar] [CrossRef]

- Morishita, K.; Sekimura, N.; de Rubia, T.D.L. A molecular dynamics study for ultrafast process of radiation damage in materials. J. Nucl. Mater. 1997, 248, 400–404. [Google Scholar] [CrossRef]

- Hou, M.; Souidi, A.; Becquart, C.S. Replacement collision sequence studies in iron. Nucl. Instrum. Methods Phys. Res. Sect. B 2002, 196, 31–38. [Google Scholar] [CrossRef]

- Becquart, C.S.; Backer, A.D.; Olsson, P.; Domain, C. Modelling the primary damage in Fe and W: Influence of the short range interactions on the cascade properties: Part 1—Energy transfer. J. Nucl. Mater. 2021, 547, 152816. [Google Scholar] [CrossRef]

- Goryaeva, A.M.; Dérès, J.; Lapointe, C.; Grigorev, P.; Swinburne, T.D.; Kermode, J.R.; Ventelon, L.; Baima, J.; Marinica, M.-C. Efficient and transferable machine learning potentials for the simulation of crystal defects in bcc Fe and W. Phys. Rev. Mater. 2021, 5, 103803. [Google Scholar] [CrossRef]

- Yoshiie, T.; Kojima, S.; Satoh, Y.; Hamada, K.; Kiritani, M. Detection of the role of free point defects from the variation of defect structures near permanent sinks in neutron irradiated metals. J. Nucl. Mater. 1992, 191–194, 1160–1165. [Google Scholar] [CrossRef]

- Lin, Y.R.; Bhattacharya, A.; Zinkle, S.J. Analysis of position-dependent cavity parameters in irradiated metals to obtain insight on fundamental defect migration phenomena. Mater. Des. 2023, 226, 111668. [Google Scholar] [CrossRef]

- Kiritani, M.; Tanakata, H.; Moriyama, K.; Fujita, F.E. Mobility of Latice Vacancies in Iron. Philos. Mag. A 1979, 40, 779–802. [Google Scholar] [CrossRef]

- Kuramoto, E.; Abe, H.; Takenaka, M.; Hori, F.; Kamimura, Y.; Kimura, M.; Ueno, K. Positron annihilation lifetime study of irradiated and deformed Fe and Ni. J Nucl. Mater. 1996, 239, 54–60. [Google Scholar] [CrossRef]

- Hu, Z.; Shao, L. Effects of Carbon on Void Nucleation in Self-Ion-Irradiated Pure Iron. Nucl. Sci. Eng. 2024, 198, 145–157. [Google Scholar] [CrossRef]

- Li, Z.C.; Abe, H.; Sekimura, N. Analysis of defects formation and mobility during ion irradiation by coherent precipitates. Mater. Trans. 2006, 47, 259–262. [Google Scholar] [CrossRef]

- Mulewska, K.; Dominguez-Gutierrez, F.J.; Kalita, D.; Byggmästar, J.; Wei, G.Y.; Chromiński, W.; Papanikolaou, S.; Alava, M.J.; Kurpaska, Ł.; Jagielski, J. Self–ion irradiation of high purity iron: Unveiling plasticity mechanisms through nanoindentation experiments and large-scale atomistic simulations. J. Nucl. Mater. 2023, 586, 154690. [Google Scholar] [CrossRef]

- Bergner, F.; Kaden, C.; Das, A.; Merino, S.; Diego, G.; Hähner, P. Nanoindentation applied to ion-irradiated and neu-tron-irradiated Fe-9Cr-NiSiP model alloys. J. Appl. Phys. 2022, 132, 045101. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, H.; Li, Y.; Jin, S.; Wu, Y.; Zhou, C.; Li, X.; Tang, H.; Yu, W.; Xia, Z. Characteristics of solar wind radiation damage in lunar soil: PAT and TEM study. Nanomaterials 2022, 12, 1135. [Google Scholar] [CrossRef] [PubMed]

- Slugen, V.; Brodziansky, T.; Veternikova, J.S.; Sojak, S.; Petriska, M.; Hinca, R.; Farkas, G. Positron annihilation atudy of RPV ateels radiation loaded by hydrogen ion implantation. Materials 2022, 15, 7091. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoshiie, T. Rate Equation Analysis of the Effect of Damage Distribution on Defect Evolution in Self-Ion Irradiated Fe. Metals 2025, 15, 555. https://doi.org/10.3390/met15050555

Yoshiie T. Rate Equation Analysis of the Effect of Damage Distribution on Defect Evolution in Self-Ion Irradiated Fe. Metals. 2025; 15(5):555. https://doi.org/10.3390/met15050555

Chicago/Turabian StyleYoshiie, Toshimasa. 2025. "Rate Equation Analysis of the Effect of Damage Distribution on Defect Evolution in Self-Ion Irradiated Fe" Metals 15, no. 5: 555. https://doi.org/10.3390/met15050555

APA StyleYoshiie, T. (2025). Rate Equation Analysis of the Effect of Damage Distribution on Defect Evolution in Self-Ion Irradiated Fe. Metals, 15(5), 555. https://doi.org/10.3390/met15050555