Research on the Structure and Mechanical Properties of Mesh Powder Composite Copper Microporous Materials

Abstract

1. Introduction

2. Preparation and Structural Characterization of Copper-Based Porous Materials

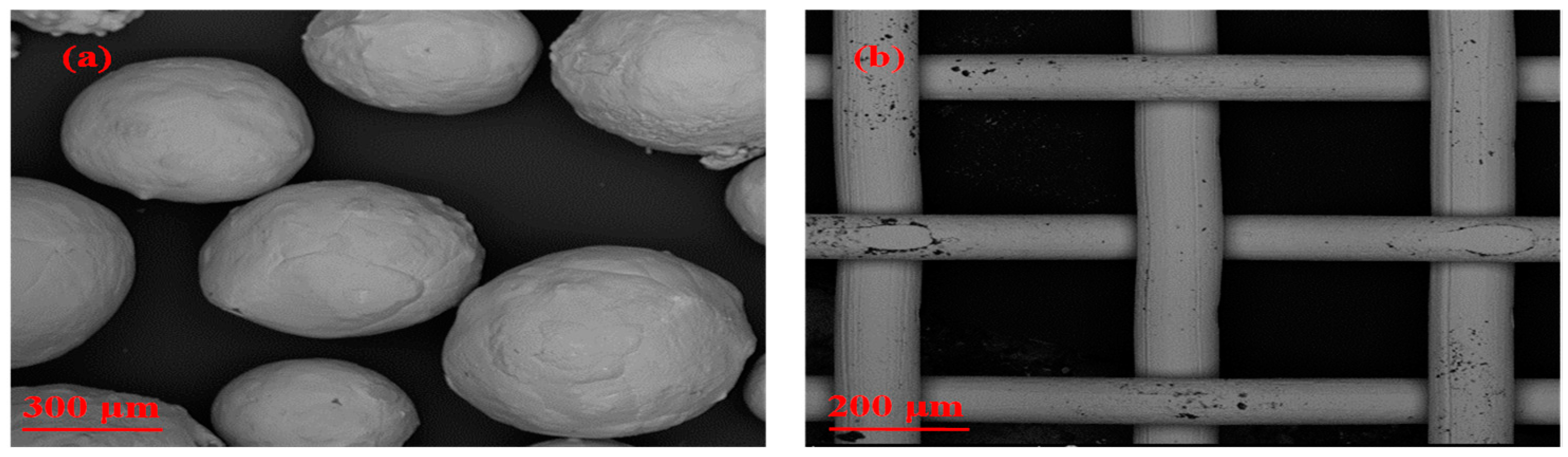

2.1. Materials

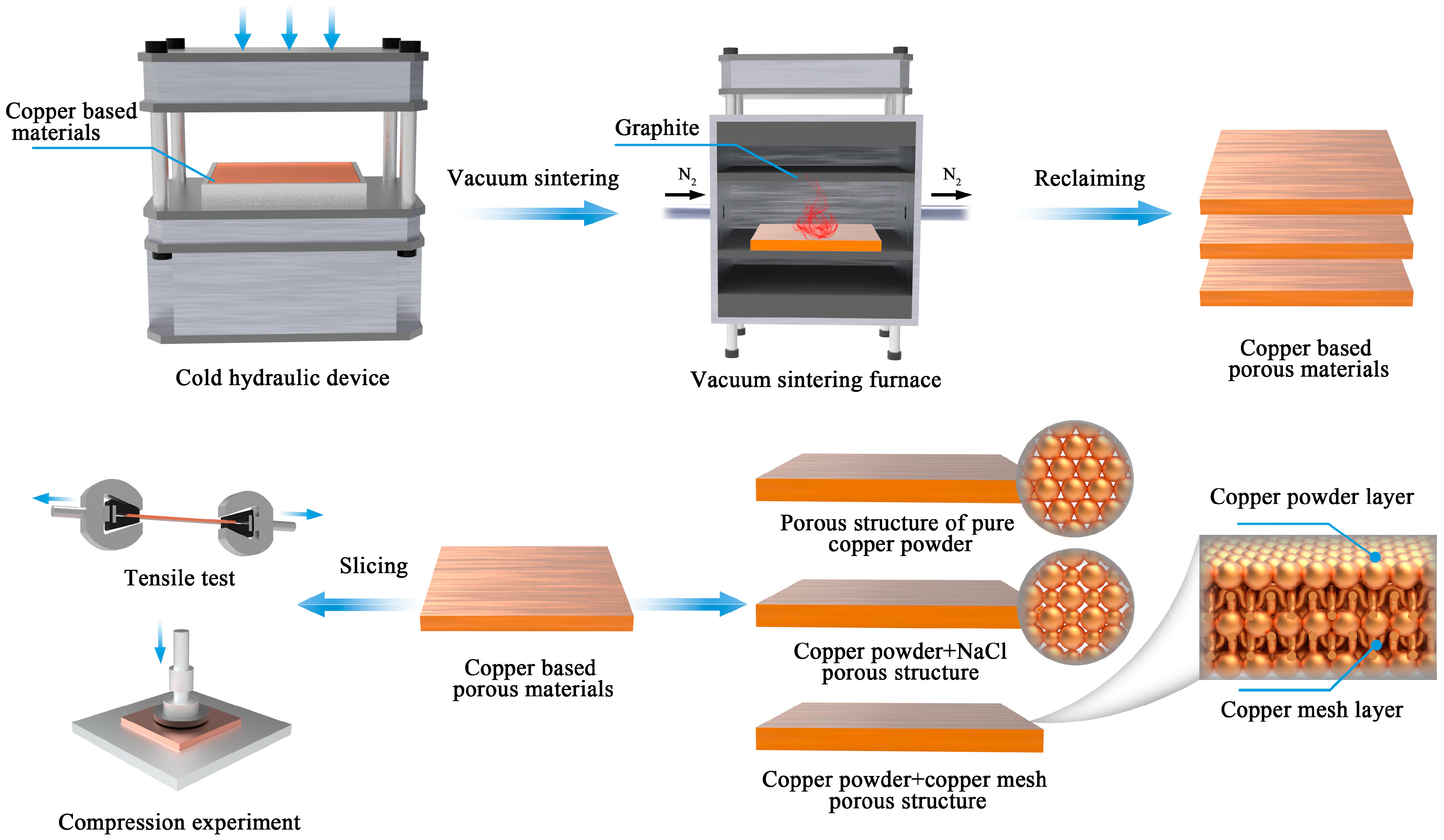

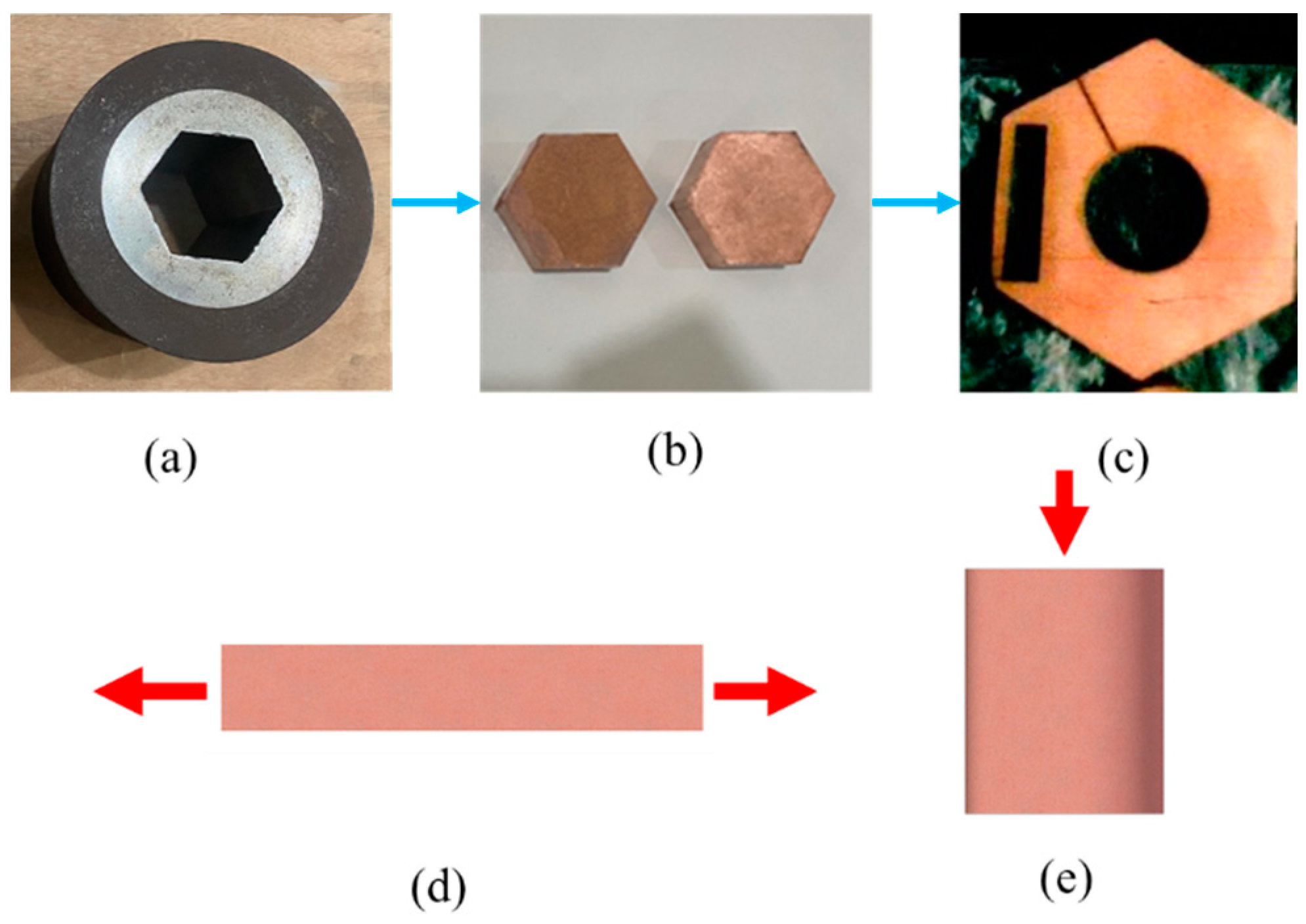

2.2. Preparation of Copper-Based Porous Materials

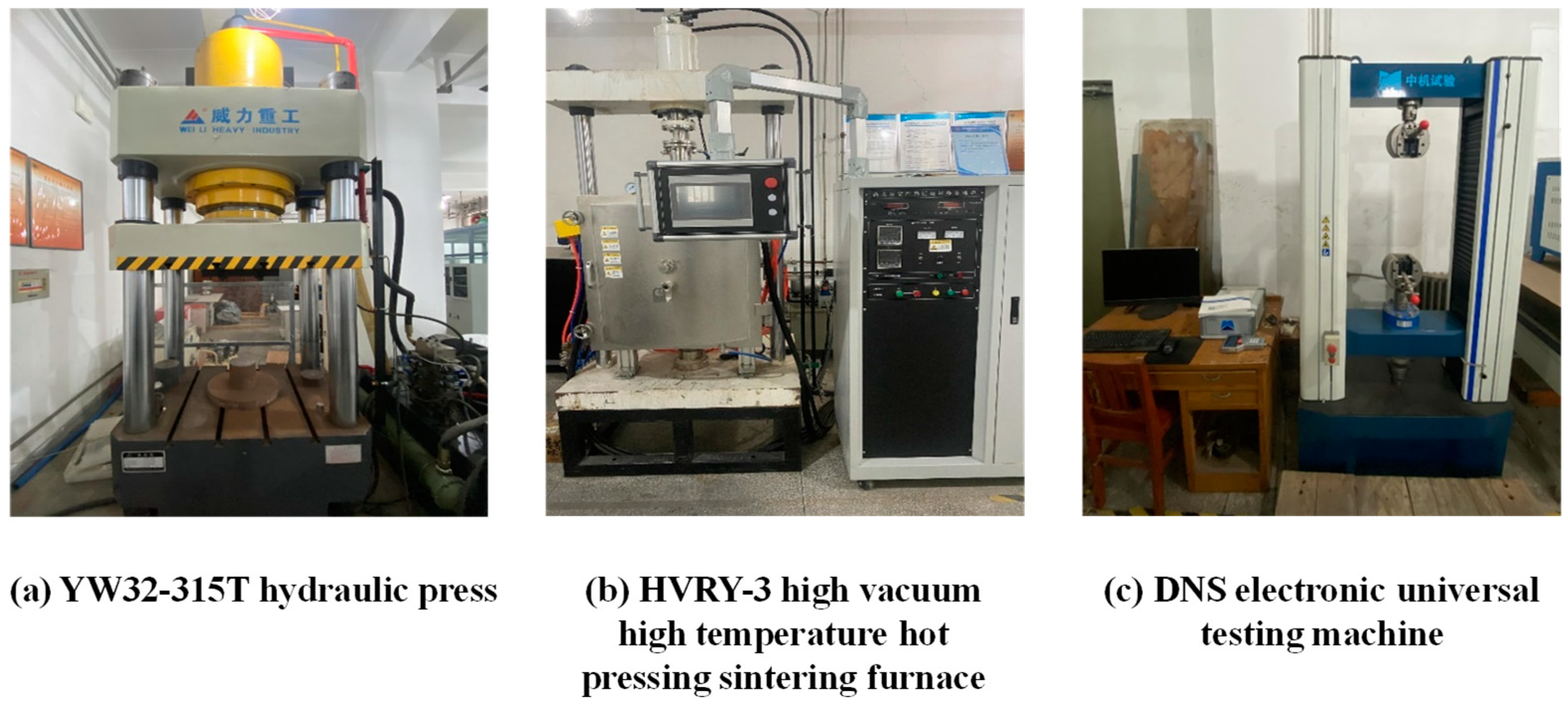

2.3. Microstructural Characterization and Mechanical Property Measurements

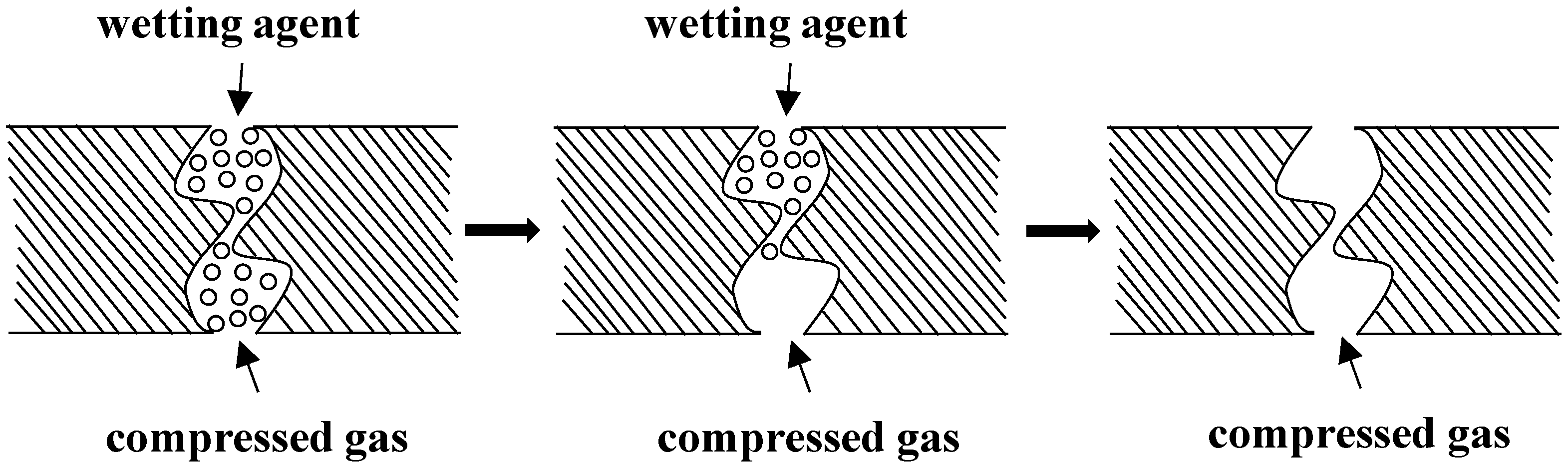

2.3.1. Aperture Testing

2.3.2. Tensile and Compression Tests

3. Experimental Results and Analysis

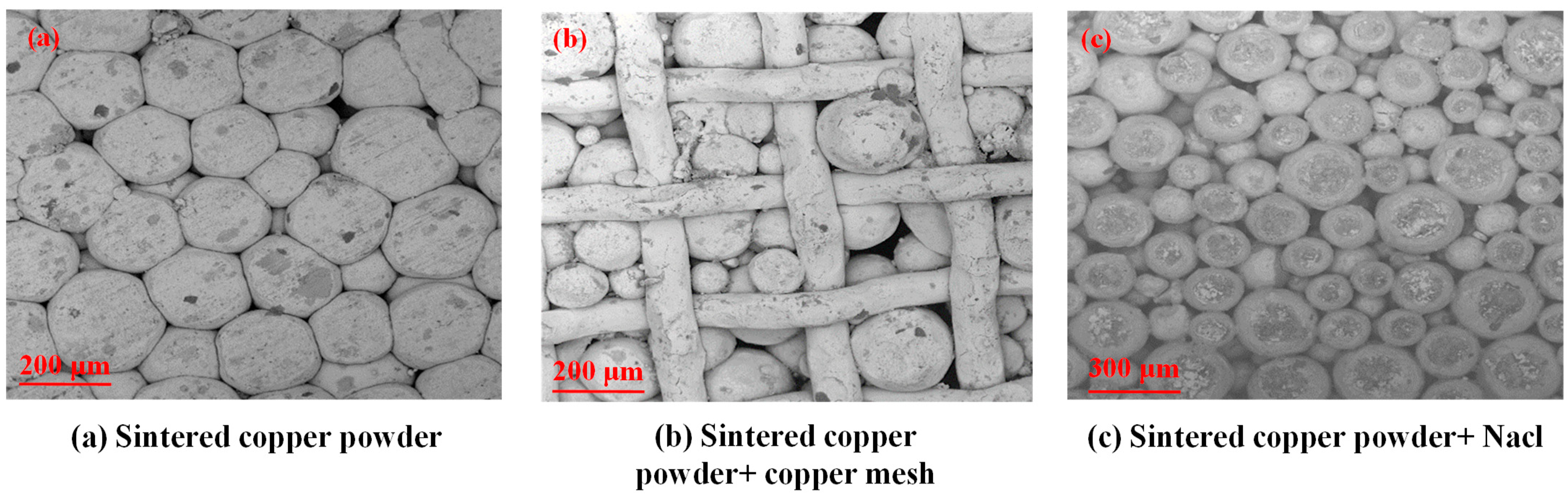

3.1. Aperture Size Distribution of Porous Materials

3.2. Permeability of Porous Materials

3.3. Effect of Sintering Temperature on Aperture Size Distribution of Porous Materials

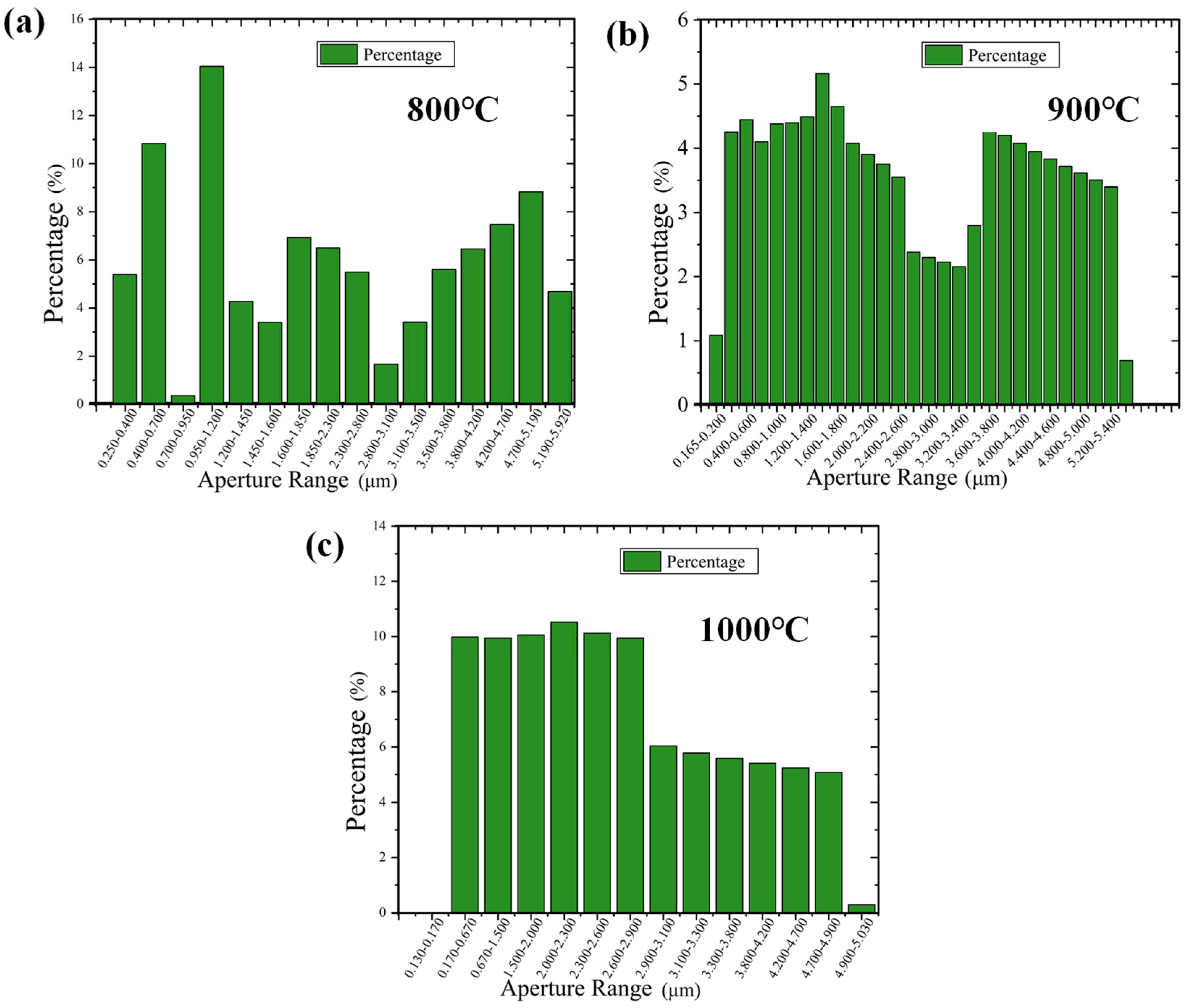

3.4. Effect of Sintering Temperature on the Tensile Mechanical Properties of Copper-Based Porous Materials

3.4.1. Porous Materials Made of Pure Copper Powder

3.4.2. Copper Powder + Copper Mesh Porous Material

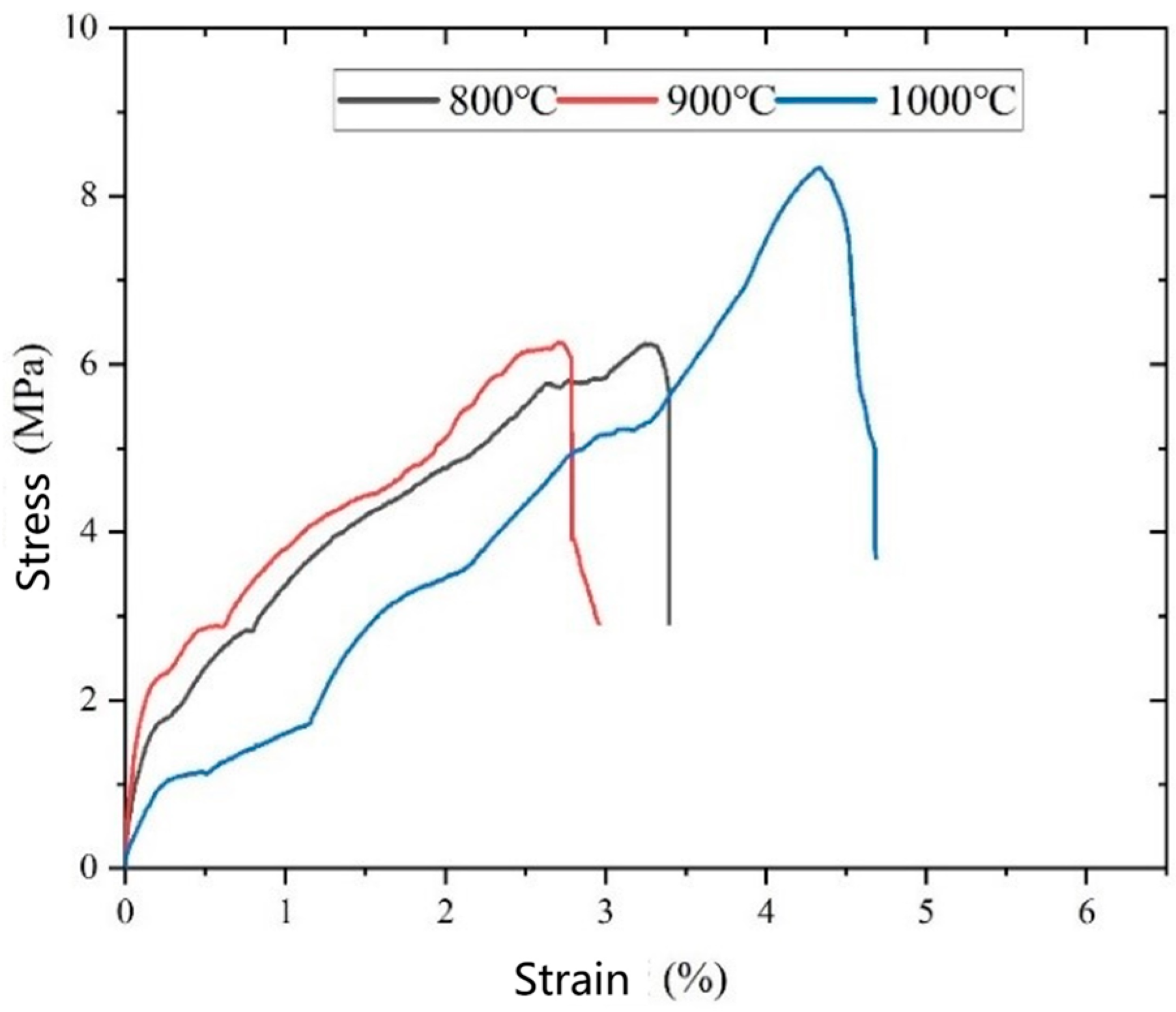

3.4.3. Copper Powder + NaCl Porous Material

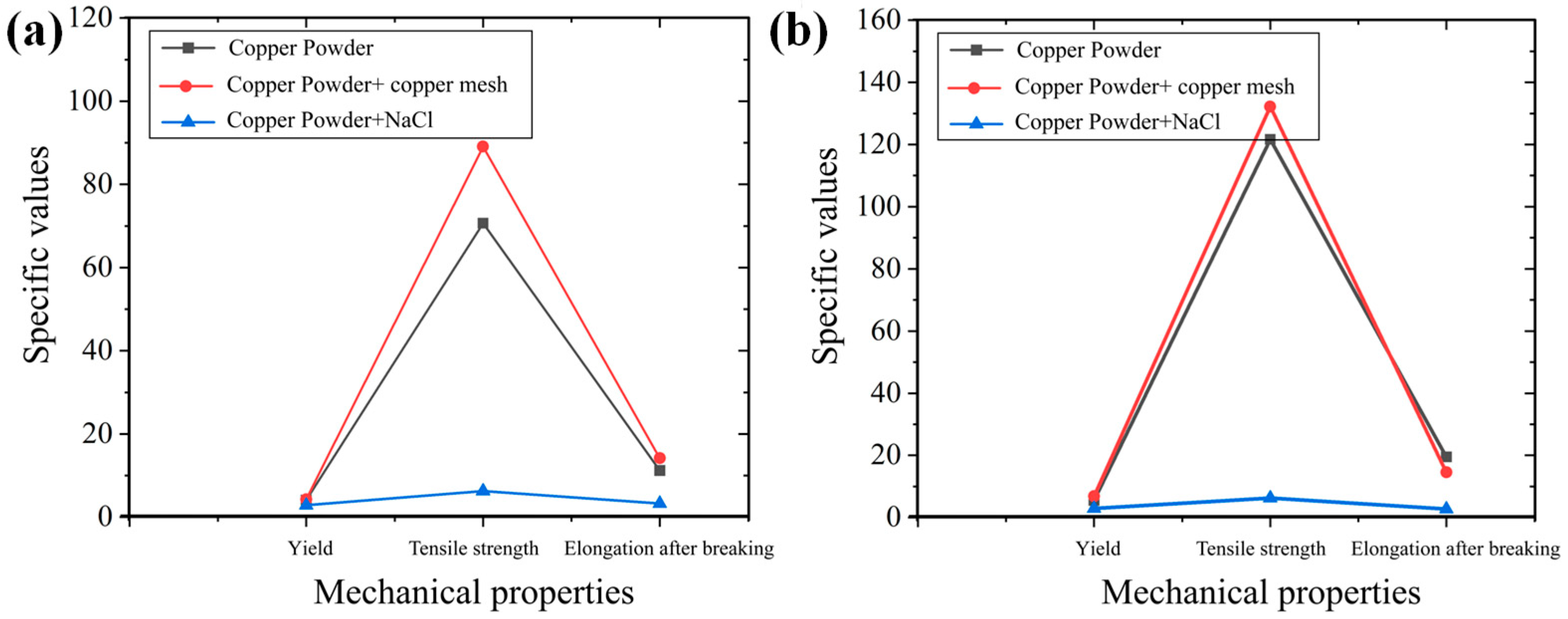

3.4.4. Comparing the Mechanical Properties of the Three Structures

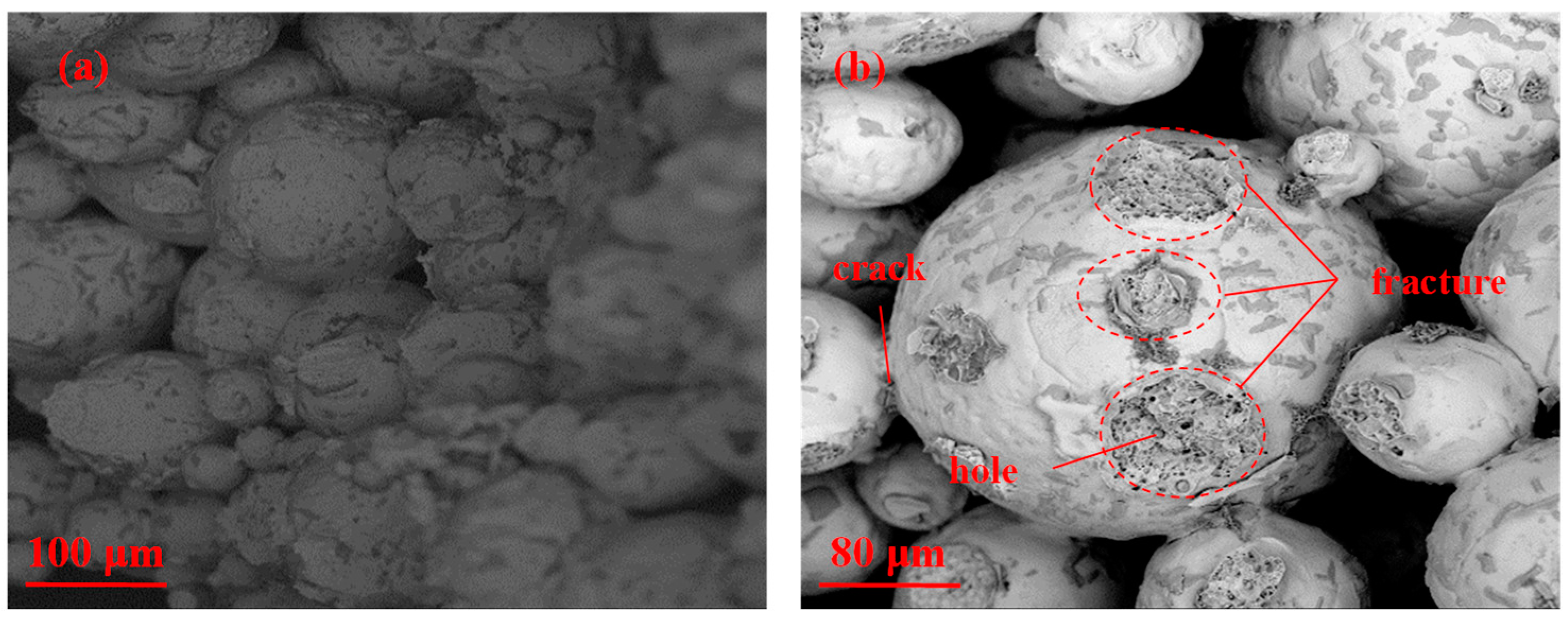

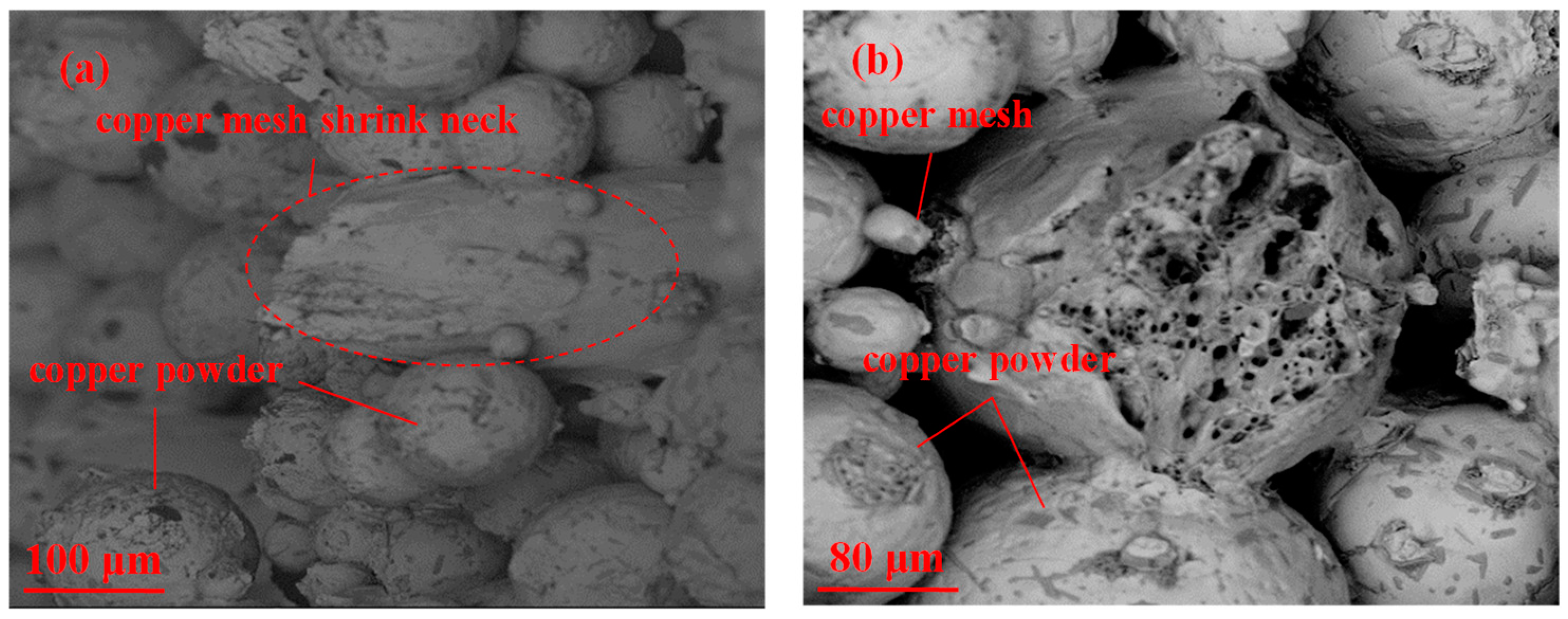

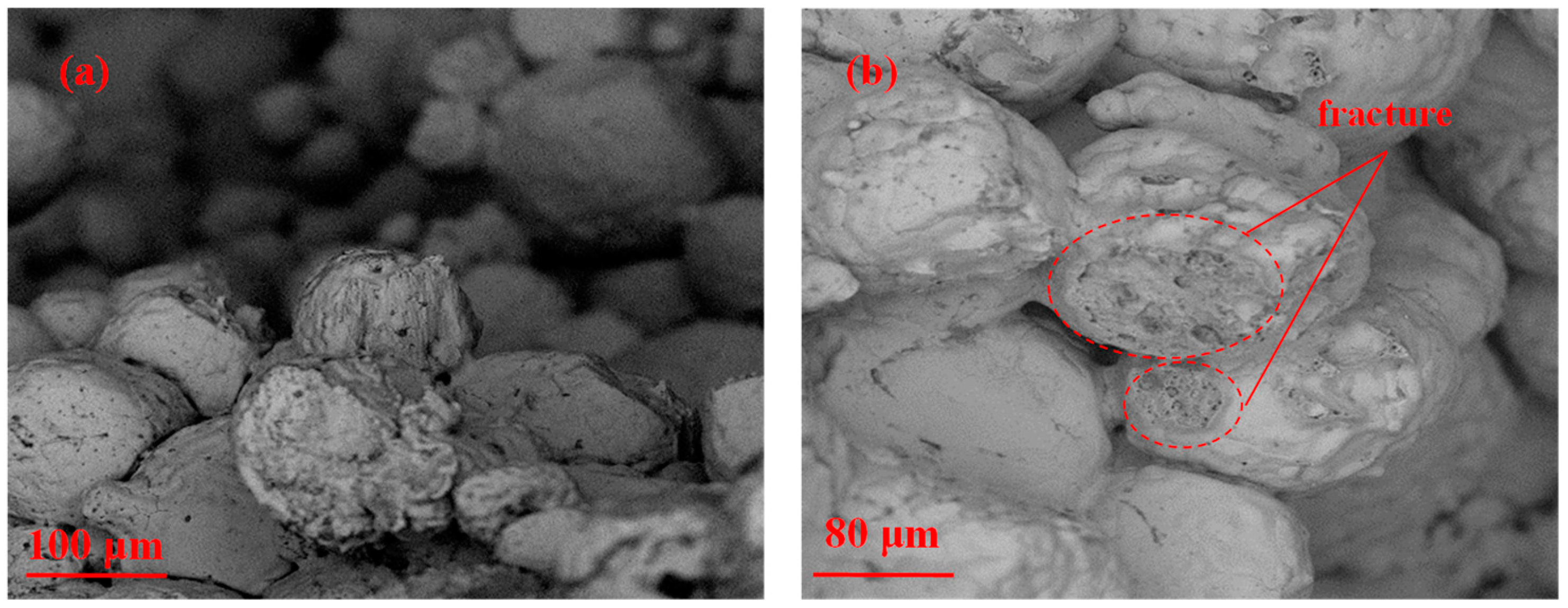

3.4.5. Tensile Fracture Mechanisms of Sintered Copper-Based Porous Materials

3.5. Effect of Sintering Temperature on the Compressive Mechanical Properties of Copper-Based Porous Materials

3.5.1. Porous Materials Made of Pure Copper Powder

3.5.2. Copper Powder + Copper Mesh Porous Material

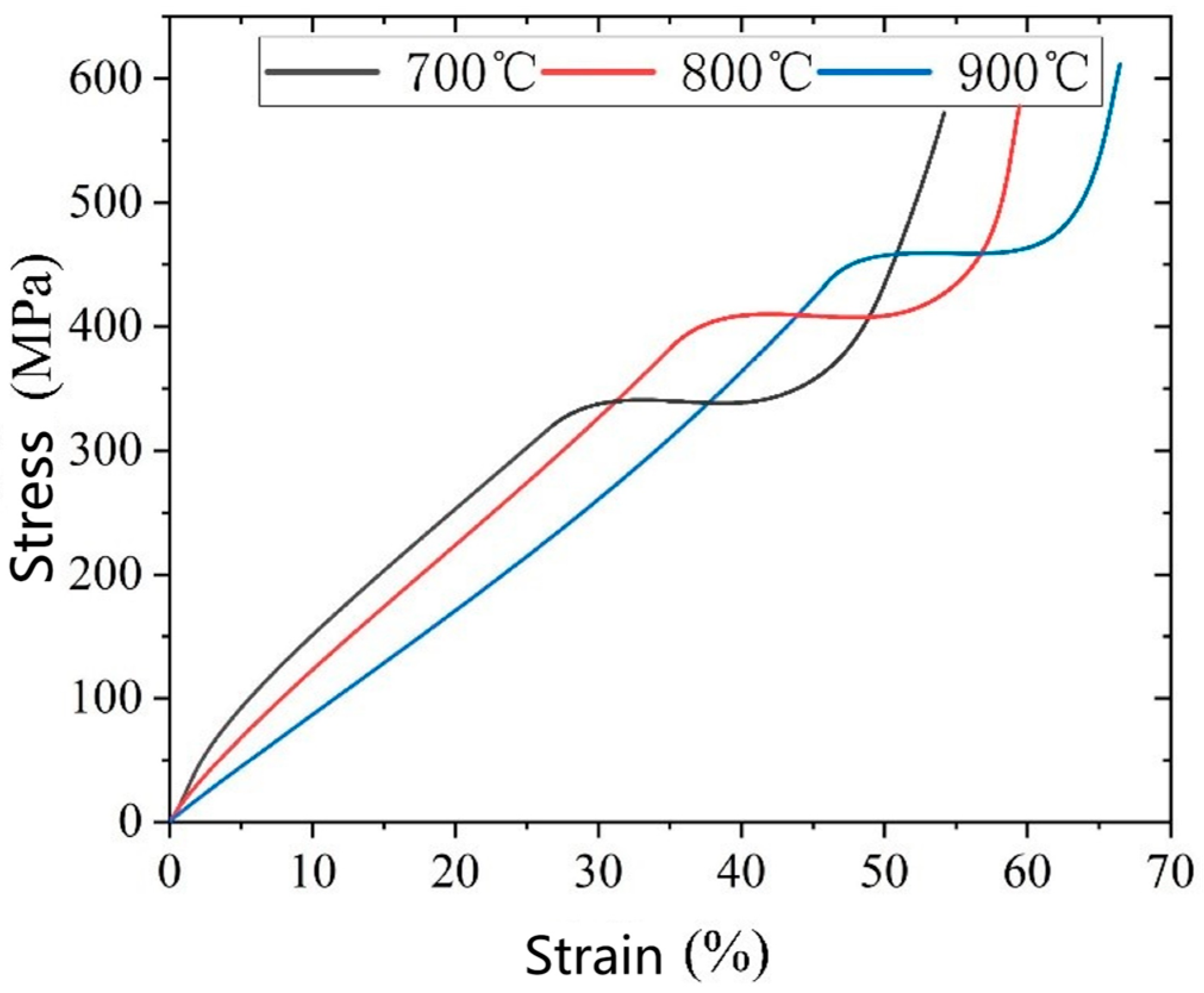

3.5.3. Copper Powder + NaCl Porous Material

3.5.4. Compressive Mechanical Properties of Different Porous Materials

4. Conclusions

- The increase of sintering temperature promotes the diffusion between particles and metallurgical combination so, with the increase of sintering temperature, the tensile strength of pure copper powder sinter, copper powder + copper mesh sinter and copper powder + NaCl sinter will increase. However, for the materials sintered at the same temperature, the tensile strength and compressive strength of copper powder + copper mesh sintered body are the highest, which indicates that the copper mesh, as a continuous metal skeleton embedded in the copper powder matrix, directly bears most of the stress and significantly improves the overall mechanical properties.

- Adding NaCl into pure copper powder as pore forming agent can significantly improve the porosity of the material, and can significantly increase the pore diameter of the material and improve the permeability of the material. However, from the point of view of the material mechanical properties test, adding the pore forming agent significantly weakened the mechanical properties of the material, including tensile strength, compressive strength and plastic properties. This material is suitable for filtration, but it is not suitable for ultra-thin heat pipes, especially flexible heat pipes. The strength and plastic properties of the porous material with copper mesh have been significantly improved, which can be expected to be used in flexible heat pipes.

- Although adding copper mesh to copper powder can effectively improve the mechanical properties of this material, the improvement in pore size and permeability is not obvious, so we should focus on this direction in subsequent research.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, C.; Li, Y.; Liu, Y.; Xie, H. A critical review of the preparation strategies of thermally conductive and electrically insulating polymeric materials and their applications in heat dissipation of electronic devices. Adv. Compos. Hybrid Mater. 2022, 6, 1–27. [Google Scholar] [CrossRef]

- Rafal, W.; David, R. Heat pipe based thermal management of electrical machines—A feasibility study. Therm. Sci. Eng. Prog. 2022, 33, 101366. [Google Scholar]

- Szymanski, P.; Paluch, R. Beeswax and Palmitic Acid Utilization with Heat Pipes for Electronics Cooling. Adv. Eng. Mater. 2024, 26, 2301704. [Google Scholar] [CrossRef]

- Górski, B.; Rein, J.; Norris, S.; Ji, Y.; McEuen, P.L.; Lin, S. Light-harvesting microelectronic devices for wireless electro synthesis. Nature 2025, 637, 354–361. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Cui, J.; Ma, Y.; Hu, Z.; Qi, Y.; Li, X.; Zhong, Y.; Luo, T.; Chu, X.; Wu, L.; et al. Adaptative two-phase thermal circulation system for complex-shaped electronic device cooling. Nat. Commun. 2025, 16, 1713. [Google Scholar] [CrossRef]

- Noe, C.; Morankar, S.; Rattner, S.A.; Potts, A.; Goode, Z.; Dannaoui, T.E.; Sherbondy, J.R.; Chawla, N.; Sixel, W.; Bilén, S.; et al. Structured, sintered, and rastered strategies for fluid wicking in additively manufactured heat pipes. Addit. Manuf. 2025, 99, 104669. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, J.; Han, Y. Thermoelectric performance analysis of the novel direct-expansion photovoltaic thermal heat pump/power heat pipe compound cycle system in summer. Appl. Energy 2024, 362, 122969. [Google Scholar] [CrossRef]

- Lu, L.S.; Tang, Y.; Yuan, D.; Jiang, L.L. Micro heat pipe manufacturing technology of vacuuming and filling work fluid. J. Mech. Eng. 2009, 45, 122–127. [Google Scholar] [CrossRef]

- Li, Y.; He, J.; He, H.; Yan, Y.; Zeng, Z.; Li, B. Investigation of ultra-thin flattened heat pipes with sintered wick structure. Appl. Therm. Eng. 2015, 86, 106–118. [Google Scholar] [CrossRef]

- Zhang, G.; Liang, J.; Song, S.; Zhou, Y.; Zuo, X. Microstructure and properties of copper honeycombs prepared by powder extruding and sintering process. J. Porous Mater. 2022, 29, 1969–1979. [Google Scholar] [CrossRef]

- Kun, L.T.J.; Patterson, E.; Learn, R.; Atwater, M. Mechanical Properties of Microporous Copper Powder Compacts Produced by Oxide Reduction. Metals 2023, 13, 1942. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, Z. Study on the Permeability and Mechanical Properties of Copper Powder/Mesh Porous Plates. JOM 2023, 76, 1235–1244. [Google Scholar] [CrossRef]

- Bętkowska, A.; Podsiadło, M.; Polkowska, A.; Włoch, G.; Polkowski, W. Microstructure and mechanical properties of highly porous Hastelloy-X nickel superalloy produced by a space holder approach. Sci. Rep. 2025, 15, 598. [Google Scholar] [CrossRef] [PubMed]

- Zou, S.; Wan, Z.; Lu, L.; Tang, Y. Experimental Study on Tensile Properties of a Novel Porous Metal Fiber/Powder Sintered Composite Sheet. Materials 2016, 9, 712. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Jie, Z.; Zeng, Z. Effect of copper powder particle size on heat transfer performance of sintered heat pipe. J. S. China Univ. Technol. Nat. Sci. Ed. 2012, 40, 6. [Google Scholar]

- Liu, P.-S. Determination method of pore size and pore size distribution of porous materials. Titan. Ind. Prog. 2006, 2, 29–34. [Google Scholar]

- Deng, D.; Tang, Y.; Huang, G.; Lu, L.; Yuan, D. Characterization of capillary performance of composite wicks for two-phase heat transfer devices. Int. J. Heat Mass Transf. 2013, 56, 283–293. [Google Scholar] [CrossRef]

- Espinosa, D.F.; Peters, T.; Brisson, J. Effect of fabrication parameters on the thermophysical properties of sintered wicks for heat pipe applications. Int. J. Heat Mass Transf. 2012, 55, 7471–7486. [Google Scholar] [CrossRef]

- Weibel, A.J.; Garimella, V.S.; North, T.M. Characterization of evaporation and boiling from sintered powder wicks fed by capillary action. Int. J. Heat Mass Transf. 2010, 53, 4204–4215. [Google Scholar] [CrossRef]

- Wang, T.; Qin, Q. Effect of sintering temperature on the structure and properties of copper-based powder metallurgy friction materials. Mech. Eng. Mater. 2016, 40, 39–42. [Google Scholar]

- Huang, C.; Lv, Z.; Wang, Y.; Zhao, X. Nanoparticle surface premelting-induced low-temperature sintering and large shrinkage of particle beds in additive manufacturing. Ceram. Int. 2024, 50, 13935–13942. [Google Scholar] [CrossRef]

- Inoue, T.; Qiu, H.; Ueji, R.; Kimura, Y. Ductile-to-brittle transition and brittle fracture stress of ultrafine-grained low-carbon steel. Materials 2021, 14, 1634. [Google Scholar] [CrossRef] [PubMed]

- Kazakeviciute, J.; Rouse, J.P.; Focatiis, D.; Hyde, C. Small specimen techniques for estimation of tensile, fatigue, fracture and crack propagation material model parameters. J. Strain Anal. Eng. Des. 2022, 57, 227–254. [Google Scholar] [CrossRef]

- Guo, K.; Li, M.; Gong, Q.; Li, C.; Li, C.; Zhong, H.; Zhou, Y. Experimental investigation on steel foams fabricated by sintering-dissolution process. Mater. Manuf. Process. 2016, 31, 1597–1602. [Google Scholar] [CrossRef]

- Guo, S.; Yue, X.; Kitazono, K. Anisotropic compression behavior of additively manufactured porous titanium with ordered open-cell structures at different temperatures. Mater. Trans. 2021, 62, 1771–1776. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Z.; Liu, B.; Huo, P. Compression properties of porous Inconel 718 alloy formed by selective laser melting. Adv. Compos. Hybrid Mater. 2021, 4, 1309–1321. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wang, D.; Song, C.; Chen, J. Microstructure and mechanical properties of CuSn/18Ni300 bimetallic porous structures manufactured by selective laser melting. Mater. Des. 2019, 165, 107583. [Google Scholar] [CrossRef]

- Liu, R.; Chen, J.; Xiong, X. Influence of porogen type and copper powder morphology on property of sintering copper porous materials. J. Cent. South Univ. 2018, 25, 2143–2149. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Liu, Z.; Zheng, P.; Zhang, Q.; Han, B. Multifunctional open-cell copper foam with sphere pores by a modified sintering–dissolution process. Metals 2023, 13, 791. [Google Scholar] [CrossRef]

| Structure Type | Porosity | Minimum-Value Aperture (μm) | Maximum-Value Aperture (μm) | Average-Value Aperture (μm) | The Most Probable Aperture (μm) |

|---|---|---|---|---|---|

| copper powder | 9.3% | 0.17 | 0.46 | 0.31 | 0.18 |

| copper powder + copper mesh | 10.7% | 0.18 | 0.80 | 0.48 | 0.39 |

| copper powder + Nacl | 21.3% | 0.20 | 5.44 | 2.44 | 1.60 |

| Structure Type | Porosity | Permeability/m2 |

|---|---|---|

| copper powder | 9.3% | 1.908 × 10−14 |

| copper powder + copper mesh | 10.7% | 2.788 × 10−13 |

| copper powder + NaCl | 21.3% | 2.832 × 10−12 |

| Sintering Temperature/°C | Porosity | Minimum-Value Aperture (μm) | Maximum-Value Aperture (μm) | Average-Value Aperture (μm) | The Most Probable Aperture (μm) |

|---|---|---|---|---|---|

| 800 | 22.3% | 0.25 | 5.92 | 2.58 | 1.90 |

| 900 | 21.3% | 0.20 | 5.44 | 2.44 | 1.60 |

| 1000 | 20.0% | 0.17 | 5.03 | 2.19 | 1.2 |

| Sintering Temperature/°C | m/MPa | /% |

|---|---|---|

| 700 | 59.0 | 7.0 |

| 750 | 62.6 | 7.0 |

| 800 | 70.7 | 11.2 |

| 850 | 92.9 | 14.1 |

| 900 | 121.6 | 19.5 |

| Sintering Temperature/°C | m/MPa | /% |

|---|---|---|

| 700 | 63.5 | 10.8 |

| 750 | 68.2 | 10.8 |

| 800 | 89.1 | 14.2 |

| 850 | 112.5 | 14.4 |

| 900 | 132.2 | 14.6 |

| Sintering Temperature/°C | m/MPa | /% |

|---|---|---|

| 800 | 6.2 | 3.2 |

| 900 | 6.3 | 3.7 |

| 1000 | 8.3 | 4.3 |

| Sintering Temperature/°C | Compression Strength/MPa | Compression Ratio/% |

|---|---|---|

| 700 °C | 270.2 | 17.6 |

| 800 °C | 375.1 | 26.2 |

| 900 °C | 443.5 | 38.8 |

| Sintering Temperature/°C | Compression Strength/MPa | Compression Ratio/% |

|---|---|---|

| 700 °C | 321.5 | 26.9 |

| 800 °C | 401.8 | 36.2 |

| 900 °C | 458.4 | 48.7 |

| Sintering Temperature/°C | Compression Strength/MPa | Compression Ratio/% |

|---|---|---|

| 800 °C | 351.968 | 44.425 |

| 900 °C | 400.631 | 46.667 |

| 1000 °C | 518.521 | 48.125 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, L.; Zhao, Z.; Ming, W. Research on the Structure and Mechanical Properties of Mesh Powder Composite Copper Microporous Materials. Metals 2025, 15, 498. https://doi.org/10.3390/met15050498

Duan L, Zhao Z, Ming W. Research on the Structure and Mechanical Properties of Mesh Powder Composite Copper Microporous Materials. Metals. 2025; 15(5):498. https://doi.org/10.3390/met15050498

Chicago/Turabian StyleDuan, Liuyang, Zhiwen Zhao, and Wuyi Ming. 2025. "Research on the Structure and Mechanical Properties of Mesh Powder Composite Copper Microporous Materials" Metals 15, no. 5: 498. https://doi.org/10.3390/met15050498

APA StyleDuan, L., Zhao, Z., & Ming, W. (2025). Research on the Structure and Mechanical Properties of Mesh Powder Composite Copper Microporous Materials. Metals, 15(5), 498. https://doi.org/10.3390/met15050498