Abstract

Wire-based laser metal deposition is an additive manufacturing process that can be used in the efficient manufacturing of complex structures. This paper utilizes a three-beam coaxial laser wire system to explore the effect of process parameters on the resultant deposition density. The reduction in or elimination of defects is important to the mechanical properties of the additively manufactured material and the widespread adoption of additive manufacturing processes. In this work, two-bead-wide walls were deposited under varying experimental conditions, including the traverse feed rate and workpiece illumination proportion. A method for calculating the bead pitch and layer height increment based on the geometry of the deposited material was developed. The deposited samples were micro-CT-scanned to characterize internal defects at a high resolution. The volume of the detected defects was measured and compared to the total sample volume to calculate a defect rate for each run of the experiment. The traverse feed rate and defocusing level were found to have a significant impact on the output defect rate. As these process parameters were increased, the defect rate decreased. Across the experimental levels, the defect volume percentage was reduced from 1.021% to 0.062%. This reduction in internal defect size enhances the material’s mechanical performance and ensures its suitability for aerospace applications.

1. Introduction

Directed energy deposition (DED) is an additive manufacturing (AM) method that can be used to make metal components directly or to repair existing structures [1]. DED features the simultaneous delivery of a feedstock material and an energy source. Incoming material is melted and then cooled, forming a single layer. This process continues layer-by-layer as the component is built up. Metal deposition using a laser heat source is an energy- and material-efficient process for making near-net-shape components with excellent material properties [2]. Because the process is material-efficient, there is less waste produced when compared to traditional and alternative processes, like machining, forging, and casting. In applications where the material consumption cost is an important factor, DED shines as a promising candidate process. These applications are commonly found in the aerospace industry in parts, such as fan case mount rings [3], lightweight aerostructures [4], and rocket nozzles [5]. The feedstock material is commonly in the form of metal powder or metal wire. Wire processes benefit from very high achievable deposition rates, a reduced defect rate, reduced waste, and simple feedstock production at the expense of a lower achievable resolution and increased surface roughness [6]. Though the wire diameter and laser spot size will determine the AM process resolution, the process is commonly paired with machining to achieve improved feature resolution and smooth-finished surfaces.

Wire-fed DED processes share many challenges that are actively being addressed through process control, parameter development, and post-deposition analysis. The deposition of a component involves the stacking of adjacent beads to achieve a desired geometry. Throughout this process, the material is repeatedly heated and cooled and the final mechanical properties of the build are highly influenced by the amount of heat input to the part [7]. If the heat input to the deposition process is too low, it can lead to inadequate substrate dilution and lack-of-fusion defects, causing a weaker resulting structure [8]. With excessive heat input, high residual stress formation and part warping [9] as well as hot cracking and uneven microstructure development can occur [10]. Thus, to ensure optimal performance of the DED component, the heat input must be carefully considered and understood.

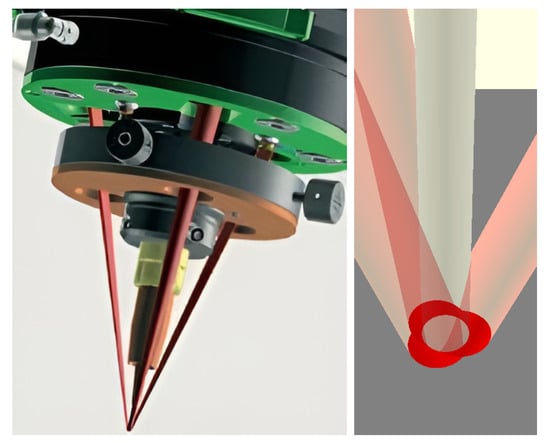

In wire-based laser metal deposition systems, there are many wire and laser arrangements that are used for various purposes and result in various melt pool heat distributions. The coaxial wire setup features the feedstock and laser delivery along a single axis, resulting in reduced directional effects [11,12] at the expense of the complex optical assembly of the deposition head [13,14]. Figure 1 shows a coaxial deposition head that delivers three output laser beams to the process. Other coaxial systems have different amounts of output beams or have an annular laser profile. Since the wire has distributed heating around its diameter, the coaxial delivery style requires less input laser power for a given wire feeding rate [15]. The primary parameters in the process are laser power, traverse feed speed, wire feed speed, and the laser delivery strategy [16]. Because of the arrangement of the laser input and the feedstock wire, the standoff distance can be used to alter the energy distribution between the incoming wire and the substrate. This standoff adjustment parameter is described by the workpiece illumination proportion (WIP), coined by Kotar et al. The WIP is an important process parameter that has significant impacts on the resulting deposit quality, geometry, and properties [17,18].

Figure 1.

The Fraunhofer processing optic delivers the three laser beams to the wire for the process. Reprinted from Fraunhofer IPT [19].

Prior studies of the effects of the WIP in the coaxial process have focused on process stability [17,20,21,22,23,24], bead geometry and substrate dilution [18,21,24], and mechanical properties [24]. The primary yield of these works confirms that the standoff distance is a critical parameter in the determination of the stable process window. They find that too small of a standoff results in a high energy concentration and dripping, while too large of a standoff results in a high energy distribution and wire stubbing. Kotar et al. found that for a given parameter set, a WIP of 99% resulted in a process window that was 400 W of laser power wider than a WIP of 7% [17]. In other work, Kotar et al. further studied process stability and concluded that the bead height generated by lower WIP values caused instabilities over a wider parameter range [21,22]. Govekar et al. and Mathenia et al. showed that changes to the WIP parameter resulted in varying bead shapes, including different bead widths, heights, and wetting angles [18,20]. Ji et al. developed a 1 mm range in focal position where the process was optimally stable. Bead geometry measurements show that with increasing defocusing, the bead height decreases while the bead width increases [24]. The existing literature on the defocus distance and WIP in coaxial wire deposition is limited to single-bead structures or single-bead-wide walls. To extend the study of WIP toward the deposition of large and complex parts, the effects of WIP on deposits that are multiple beads wide and multiple beads tall must be better characterized.

An important effect to study is the formation of defects, which can be detrimental to the mechanical performance of a component. Internal defects reduce material density and act as stress concentrators and crack initiation sites. In wire-fed DED, the two most common types of internal defects are a lack of fusion and porosity. A lack of fusion refers to the defect that is characterized by inadequate bonding between the deposited material. These defects are usually elongated in shape and follow the interfaces between beads. It is caused by insufficient heat input, inappropriate heat distribution, or a substrate temperature that is too low. Research groups like Polamuri et al. were able to reduce the occurrence of a lack of fusion by altering the deposition path strategy [25]. Suwannatee et al. found that additional heat input using hot wire up to 44% of the total deposition rate was useful in the deposition of deposits that were free of a lack of fusion [26]. Porosity, on the other hand, refers to the trapping of gas bubbles in the melt pool causing small circular voids in the solidified material. It is usually caused by excessive heat input, material contamination, or ineffective shielding gas. Because of their shape, porosity defects are more commonly tolerated, while lack-of-fusion defects compromise the structural capability of a part due to their propensity to concentrate stress. To demonstrate this, Emminghaus et al. found a 32.2% reduction in stiffness of additively manufactured Ti-6Al-4V (Ti64) with a lack of fusion compared to no significant stiffness decrease for material with spherical pores [27]. It is important to reduce or eliminate all lack-of-fusion defects in a build so that the component does not experience unexpected failure. The work of Bernauer et al. varied process parameters to reduce defects in the resulting material for a single standoff distance setting [28]. The goal of the present research is to work toward the deposition of defect-free structures. Until defects are eliminated fully or greatly reduced in size, the fracture process and mechanical performance of the material will be dominated by the defect pore size, not by the microstructure of the deposit [29]. Kumar et al. found that the hardness and ductility of printed Ti64 was highly dependent on the amount of internal porosity [30]. The defects produced in this work are within a pore size regime that dominate part failure; thus, the deposited samples were not studied for their metallographic or mechanical properties. With the aim of reducing and eventually eliminating defects, the deposited samples were X-ray-imaged to determine the size of internal defects.

This paper presents an experimental study aimed at characterizing the effects of process parameters on defects formed during the deposition of Ti64 using the coaxial wire-based laser metal deposition strategy. The experimental deposits and their internal defects as measured by the micro-CT technology are then presented, and the results are analyzed. Finally, conclusions drawn from this work are discussed and extensions of this research are proposed in the pursuit of defect-free deposits.

2. Materials and Methods

2.1. Experimental Setup

The coaxial wire laser metal deposition cell is composed of the three-beam coaxial optical head, the wire-feeder, the laser, and the robot used for positioning. The Fraunhofer COAXwire Laser Wire Processing Optic (Fraunhofer IWS, Dresden, Germany) marries the laser and wire inputs and delivers them to the process [19,31]. The system has a single laser input and splits the laser beam into three output beams that are spaced evenly around the wire and have an outer beam aperture angle of 40°. A 4 kW Laserline LDF 4000-40 diode near-infrared laser (Laserline GmbH, Mülheim-Kärlich, Germany) provides the laser input for the system. The laser has a top-hat beam profile. A push–pull wire feed system using a Miller Auto-Continuum Wire Drive (Miller Electric, Appleton, WI, USA) and a DINSE DIX FD 200 M feeder (DINSE GmbH, Norderstedt, Germany) enables precise control over the incoming wire. A 1.2 mm diameter Ti64 wire (Perryman Company, Houston, PA, USA) is used as the feedstock and 6 mm thick Ti64 plates (TIMET, Warrensville Heights, OH, USA) are used as the substrates. Ti64, also known as Grade 5 titanium, is the most widely used titanium alloy in the aerospace industry because of its excellent mechanical properties, high-temperature performance, and good weldability and machinability. It was selected for the experimental analysis to develop and characterize the AM capabilities of Ti64. A three-axis delta robot locates the optic head for deposition. The process is contained in a positively pressured argon inert environment to reduce surface oxidation during solidification. The melt pool is further protected by argon shielding gas to prevent oxidation, reduce contamination, and improve process stability.

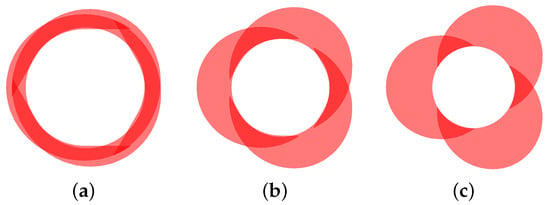

The coaxial wire and laser delivery strategy enables some unique features of the process. Because there are three beams spaced around the wire, the input feedstock has distributed heating around its diameter, as shown in Figure 1 [18]. There is a position where the three lasers converge (hereafter referred to as the beam convergence position) to make the smallest possible combined spot on the substrate. Deviations from this position result in varying laser spot patterns and the proportion of energy that is delivered directly to the wire and directly to the substrate. The WIP parameter describes this proportion by expressing a percentage of the incoming laser energy that is incident on the substrate. By changing the work offset away from the beam convergence position, the effective spot size and heat distribution are changed. Figure 2 shows different settings of this offset and the resulting spot patterns.

Figure 2.

Variations in the WIP value for this experiment were achieved by placing the beam convergence position below the work plane, resulting in the beam spot patterns indicated in (a–c) [18]. (a) The spot pattern with beam convergence at the work plane produces a WIP value of 25.2%; (b) the spot pattern with beam convergence 0.64 mm below the work plane results in a WIP of 40%; and (c) the spot pattern with beam convergence 1.29 mm below the work plane results in a WIP of 55%.

2.2. Experimental Design

To investigate the impact of process parameters on material density and defect formation, we need to deposit structures that are multiple beads wide and multiple beads tall. The internal structure of deposits can be examined to characterize voids in the material. To achieve this, stable parameter sets for single-bead deposits must first be identified. The wire feed speed (WFS) was held constant to reduce the parameter space explored in this study. In order to maintain a stable process, the incoming wire needs to be fully melted. Equation (1) describes the proposed relationship for a stable process. This relationship attempts to keep the amount of laser energy incident on the wire per unit wire length constant. From this relationship, the laser power (LP) was calculated for a chosen constant value and given WIP and WFS settings. Three levels for a traverse feed rate (hereafter referred to as feed) of 10.58 mm/s, 12.28 mm/s, and 13.97 mm/s and three levels for a WIP of 25.2%, 40%, and 55% were selected for the parameter space. Table 1 shows the treatment combinations (TCs) and their randomized run order for the experiment. The aspect ratio was calculated as the ratio between the bead width and bead height for each TC. The following paragraphs will describe how the pitch (stepover between beads) and height (height increment between layers) were measured and calculated.

Table 1.

Experimental process parameters.

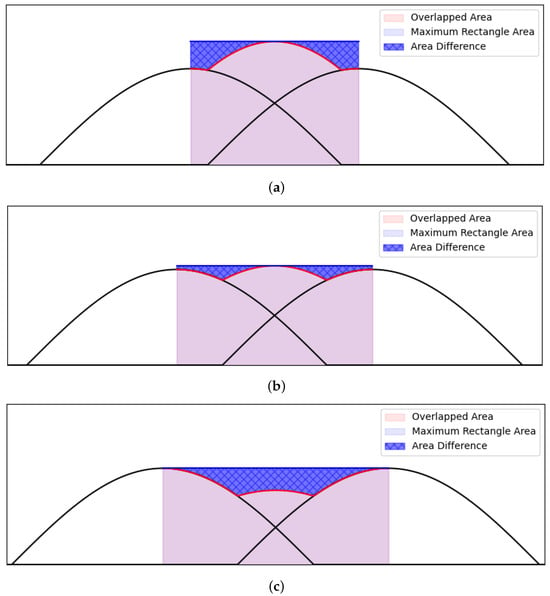

To make each of the treatment combinations directly comparable, a repeatable method for determining the pitch for each parameter set was developed. This method uses the cross-sectional profile of the deposited bead and aims to produce a flat surface between beads. For a given bead profile, an overlapped model is made by offsetting the profile by a pitch increment. Then, an area difference between the overlapped area and a maximum circumscribed rectangle is calculated. Figure 3 shows example calculations of this area difference for three pitches. The calculated pitch for a given bead profile is the pitch that results in the minimized area difference.

Figure 3.

Example calculations of the area difference between the overlapped area of the beads and a rectangle circumscribing the overlapped area. The black lines represent the cross-sectional bead profile of two adjacent beads and the red lines represent the sum of the two black lines between the peaks of the beads. (a) The pitch between the overlapped beads is too small. The material accumulates between the beads, making an uneven surface at the interface; (b) the pitch between the overlapped beads is calculated to minimize the area difference and make a flat profile; and (c) the pitch between the overlapped beads is too large. This creates a depression between the beads and an uneven surface at the interface.

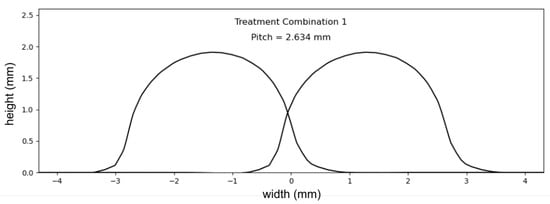

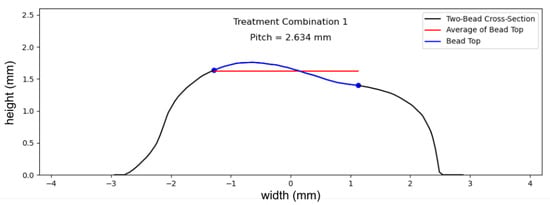

For each of the treatment combinations, a single bead was deposited. To obtain the bead profile produced by each treatment combination, the surface of each bead was 3D-scanned using a Revopoint MINI 3D Scanner (Revopoint, Xi’an and Shenzhen, China) that has a precision of 0.02 mm. AESUB Orange Scanning Spray (AESUB, Recklinghausen, Germany) was used to make the surface of the beads non-reflective. The midpoint cross-sectional profile from each bead was then used to calculate the pitch using the method described above. Table 1 records these calculated pitch values and Figure 4 shows a sample calculation result for treatment combination 1.

Figure 4.

Pitch as calculated by the area difference method for treatment combination 1.

Next, the height increment for each treatment combination was determined. A two-bead-wide layer was deposited for each treatment combination with the spacing between the beads set as the calculated pitch. Each deposit was scanned with the Revopoint scanner, and the midpoint cross-sectional profile was considered. A region in the center of the profile referred to as the bead top was constructed by offsetting the start and end of the bead top by half of the pitch from both sides of the bead. The layer height increment for each treatment combination was set to the average height of the bead top. Table 1 shows all of the calculated heights and Figure 5 shows the bead top construction and average height calculation for treatment combination 1. With all the experiment parameters determined, the multiple-bead-wide and multiple-bead-tall walls could be deposited.

Figure 5.

The average height of the top of the bead is measured for a two-bead-wide deposit for treatment combination 1. The bead top was captured by removing half of the pitch from either side of the bead.

2.3. Experimental Procedure

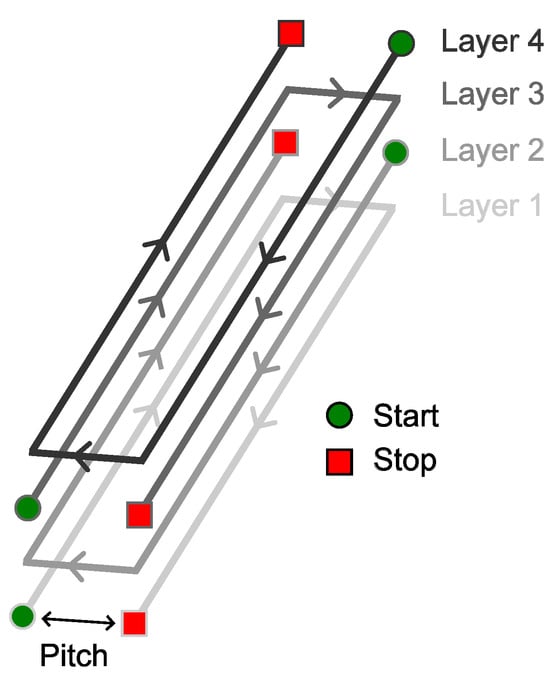

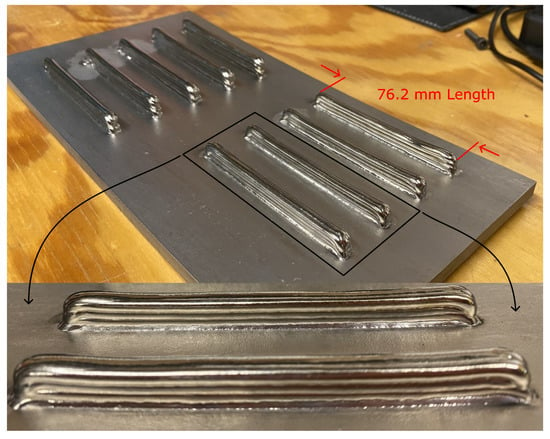

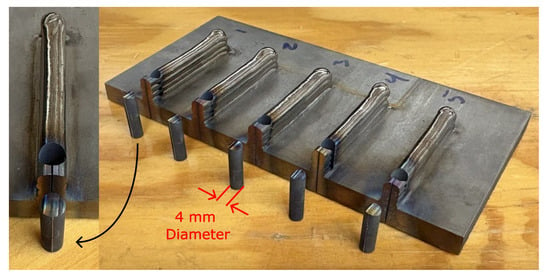

According to the run order and the process parameters designated in Table 1, nine two-bead-wide and four-bead-tall walls were deposited. Each deposit had a length of 76.2 mm with varying widths and heights. The path plan for the deposits is shown in Figure 6. The start and stop positions alternate both along and across the walls to make the process more stable and to make the resulting deposit as flat as possible. Figure 7 shows the nine deposited samples. Then, 4 mm diameter samples from the center of each deposit were cut using a wire EDM, as pictured in Figure 8. The experimental samples were analyzed in the as-deposited condition and did not undergo any stress-relief annealing or heat treatment. The samples were cut in preparation for micro-CT scanning using the ZEISS Xradia 620 Versa (ZEISS, Oberkochen, Germany) to obtain the internal tomography of the deposits. The instrument has a true spatial resolution of 500 nm, and for very small samples, it has an achievable voxel size of 40 nm. Each sample was scanned at a cubic voxel size of 12 μm × 12 μm × 12 μm using 160 kV at 25 W. To produce clear images, the micro-CT X-rays must adequately penetrate the sample. The density of the sample and the X-ray source power drive the maximum sample thickness to achieve X-ray penetration, resulting in the selected 4 mm diameter sample size. The image analysis software Dragonfly Pro 2022.1 (Object Research Systems, Montréal, QC, Canada) was used to analyze the scan data and identify voids in the samples using dynamic thresholding.

Figure 6.

Path plan for the deposited two-bead-wide walls. The four-layer deposits alternate the start position of the path to benefit process stability and to achieve a flatter surface to deposit on. The arrow on each line indicates travel direction.

Figure 7.

Deposited experimental samples for all treatment combinations. Each deposit is two beads wide and four beads tall.

Figure 8.

Samples EDM cut from the center of each of the experimental deposits. The samples are each 4 mm in diameter and span the entire height of the substrate and deposit.

3. Results

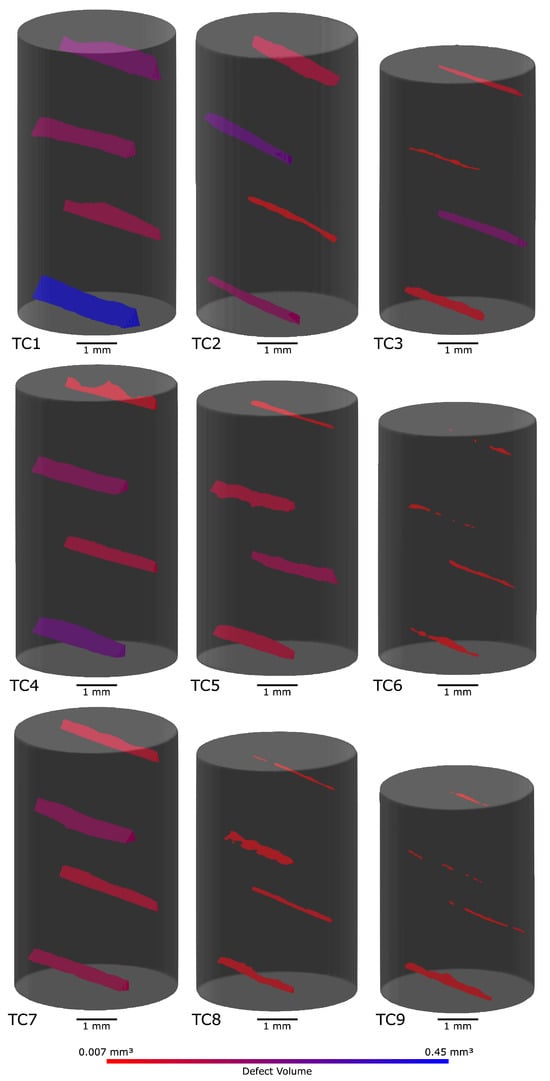

For each of the nine scanned samples, the number of detected defects was counted and the total volume of the defects was measured. Since all the detected defects are all elongated in shape and occur at the interface between the beads, they are all classified as lack-of-fusion defects. There was no gas porosity detected. The defect volume as a percentage of the total sample volume was calculated to make the results directly comparable. Table 2 shows these measured and calculated experimental results. The scanned samples and their defects are shown in Figure 9. The samples had varying heights and volumes due to the treatment combinations having different layer heights.

Table 2.

Experimental results.

Figure 9.

Three-dimensional representations of micro-CT data for all treatment combinations. The colored volumes represent voids in the printed samples.

4. Discussion

When looking at the micro-CT images in Figure 9, there is a meaningful pattern to all the detected defects. Throughout these deposits, defects were only observed at interfaces between adjacent beads and layers. There were no gas porosity defects detected within a deposited bead or in the bulk material. From this observation, we can conclude that the shielding gas in the process is sufficient and that the melt pool is not being overheated. The pattern and shape of the defects indicates a lack of fusion, where the material did not fully wet and fuse together. It is clear that along each row, the size of the internal defects decreases with increasing WIP. The effect of the traverse feed rate across rows is less clear, but the defects seem to get smaller (become more red) as the feed is increased.

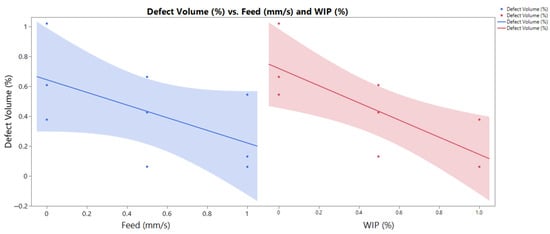

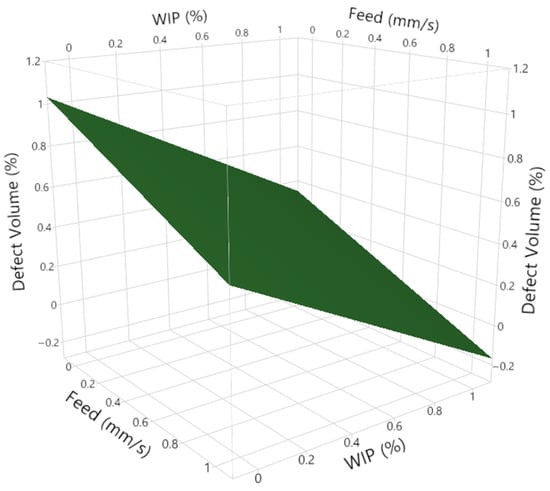

To visualize the relationship between the normalized input parameters and the output defect percentage, the effects plots and surface plots were generated, as shown in Figure 10 and Figure 11, using JMP (JMP Statistical Discovery, Cary, NC, USA). The effects plots show that the response defect volume percentage decreases with an increasing feed rate and with increasing WIP. Over the experimental parameter ranges, the defect volume percentage was more sensitive to changes in the WIP variable than the feed rate variable. A first-order linear regression model was made with only the normalized factors of the feed rate and WIP, as shown in Table 3. The model has an R-squared value of 0.943, indicating a good fit between the experiential data and the model. Over the experimental parameter ranges, the model predicts the defect volume percentage. The surface plot shows the response to the input parameters graphically. Combinations of a low feed rate and WIP result in the highest observed defect volume percentage, while the highest tested levels resulted in the reduced defect size. The samples with larger defects are expected to perform worse in mechanical strength testing, as shown by the work of Zhang et al. and Kobryn and Semiatin [32,33]. They showed that larger induced defect sizes resulted in reduced fatigue life and a lower stress amplitude at failure. For any structural part, a lack of fusion is detrimental to mechanical properties and should be avoided [34].

Figure 10.

Effects plots of the experimental variables.

Figure 11.

Surface plot of the response defect volume vs. the experimental parameters. The green plotted surface represents the predicted output defect volume for given input settings of feed and WIP.

Table 3.

Parameter estimates.

The aspect ratio of the deposited bead helps to explain the reason for the decrease in defect size with increasing parameters. As the WIP is increased, the effective spot size of the three-beam laser and the width of the bead get wider. As the traverse feed rate is increased, the bead height decreases. For a given input material feed rate, increases to these factors result in a wider and flatter bead and a higher aspect ratio. The measured aspect ratios recorded in Table 1 for the single-bead deposits quantitatively describe this effect. With a higher aspect ratio, it is hypothesized that more of the laser energy can be conducted to the interfaces between the beads, helping them to more fully fuse together. A tall and narrow bead profile is undesirable as the raised geometry of previously deposited beads creates shadowing effects, preventing uniform laser irradiation at the bead interface. Instead of evenly spreading the heat input across the melt pool, the shadowed laser energy concentrates away from the bead interface. The surface tension of the melt pool resists the proper wetting of the liquid metal. In a tall bead, the higher curvature of the melt pool increases the influence of surface tension forces, pulling the liquid metal inward and restricting lateral spreading. A wider and flatter bead profile mitigates these effects and results in a more even energy distribution. Additional heat energy is delivered directly to the bead interface to improve wetting and ensure more complete fusion between beads.

This experimental study was limited to only one experimental run for each treatment combination due to the high cost associated with micro-CT imaging. While the micro-CT machine was useful in providing high-quality imaging data, the cost limited the scope of the experimental parameters and the inclusion of experimental replications. As the trends in the collected data show, an increase in the feed rate or in the WIP beyond the tested experimental settings would likely reduce or fully eliminate these lack-of-fusion defects. Other process parameters like wire feed speed or laser power can also be altered to change the bead geometry and resulting defects. A reduction in the wire feed speed would decrease the process build rate but would likely increase the aspect ratio and total fusion between the beads. An increased melt pool temperature caused by increasing the laser power could help to better fuse adjacent beads. This work provides the foundation of the experimental study and analysis of defect formation in coaxial wire laser metal deposition from which similar experiments can be designed and conducted for an extension of the experimental factors or for other process parameters entirely. Process improvements to reduce or eliminate defects are a trade-off between the deposition rate, overall heat input, and build quality. As these parameters are adjusted for build improvements, it is important to consider which trade-offs are appropriate for the component’s functional needs and for the capabilities of the system hardware. This research group intends to continue the study of defect formation, extending this study to various part geometries, path planning strategies, and process parameters.

5. Conclusions

This paper experimentally studied defect formation in the coaxial wire-based laser metal deposition process. An experiment with a method for calculating the bead pitch and layer height increment based on the geometry of the deposited bead was designed. The experimental factors of the traverse feed rate and workpiece illumination proportion (WIP) were tested at three levels each in the deposition of two-bead-wide, four-bead-tall walls. The deposited samples were micro-CT-scanned and the internal defects in each sample were measured. This research yields the following conclusions:

- Over the experimental settings, the traverse feed rate and WIP were found to have a linear effect on the resulting defect rate in the deposited material. The volume of internal defects decreases with an increasing traverse feed rate and WIP. Across the experimental levels, the defect volume percentage was reduced from 1.021% to 0.062%.

- To achieve a further reduction in defect volume or eliminate defects entirely, the traverse feed rate and WIP can be increased beyond the experimental levels or the wire feed speed can be reduced. These adjustments aim to increase the aspect ratio of the deposited bead but come at the expense of increased necessary laser power and/or a reduced deposition rate.

- The micro-CT technology provides a very useful and high-resolution view of the internal structure of a deposit. Though the technology is limited in its maximum sample size, it can be used to detect extremely small voids.

This work can be further extended to include additional levels of the experimental factors, other process parameters, and various metal deposition technologies in the pursuit of defect-free deposits. For widespread use in advanced manufacturing, improvements in the material density and mechanical performance of additively manufactured material is essential.

Author Contributions

Conceptualization, R.M., B.M. and T.S.; formal analysis, R.M. and B.M.; funding acquisition, F.L.; investigation, R.M. and B.M.; methodology, R.M. and T.S.; project administration, R.M., T.S. and F.L.; software, B.M. and T.S.; supervision, T.S. and F.L.; validation, R.M.; visualization, R.M. and T.S.; writing—original draft, R.M. and T.S.; writing—review and editing, R.M., B.M., T.S. and F.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was made possible by the financial support and in-kind contributions by GKN Aerospace and the Center for Aerospace Manufacturing Technologies (CAMT). This work was partially supported by the Missouri University of Science and Technology’s Kummer Institute for Student Success, Research, and Economic Development through the Kummer Innovation and Entrepreneurship Doctoral Fellowship.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in this article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Todd Sparks was employed by the company Product Innovation and Engineering. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AM | additive manufacturing |

| DED | directed energy deposition |

| LP | laser power |

| Ti64 | Ti-6Al-4V |

| TC | treatment combination |

| WFS | wire feed speed |

| WIP | workpiece illumination proportion |

References

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Abdulrahman, K.O.; Akinlabi, E.T.; Mahamood, R.M. Laser metal deposition technique: Sustainability and environmental impact. Procedia Manuf. 2018, 21, 109–116. [Google Scholar] [CrossRef]

- GKN Aerospace. GKN Aerospace Expands RRSP Contract with Pratt & Whitney and Injects New Additive Manufacturing and Composite Technologies in Key Components. 2019. Available online: https://www.gknaerospace.com/news-insights/news/gkn-aerospace-expands-rrsp-contract-with-pratt-whitney-and-injects-new-additive-manufacturing-and-composite-technologies-in-key-components/ (accessed on 9 April 2025).

- GKN Aerospace. GKN Aerospace and Northrop Grumman Achieve Additive Manufacturing Milestone. 2022. Available online: https://www.gknaerospace.com/news-insights/news/gkn-aerospace-northrop-grumman-collaboration-achieves-additive-manufacturing-milestone/ (accessed on 9 April 2025).

- GKN Aerospace. GKN Aerospace Engine Systems’ Journey to Introduce Additive Manufacturing. 2018. Available online: https://www.gknaerospace.com/news-insights/news/gkn-aerospace-engine-systems-journey-to-introduce-additive-manufacturing/ (accessed on 9 April 2025).

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Kisielewicz, A.; Thalavai Pandian, K.; Sthen, D.; Hagqvist, P.; Valiente Bermejo, M.A.; Sikström, F.; Ancona, A. Hot-Wire Laser-Directed Energy Deposition: Process Characteristics and Benefits of Resistive Pre-Heating of the Feedstock Wire. Metals 2021, 11, 634. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Simpson, T.W. Additive Manufacturing with Wire: This system has the benefits of cheaper cost and easier handling. But there can be some drawbacks as well. Mod. Mach. Shop 2019, 91, 38–40. [Google Scholar]

- Xu, S.; Lei, D.; Yang, X.; Lu, X.; Chen, J.; Li, M.V. Wire arc additive manufacturing of components using TiC/Ti reinforced Al-Zn-Mg-Cu alloy wire: Microstructure evolution, strengthening mechanism, and fracture behavior. Mater. Charact. 2024, 217, 114452. [Google Scholar] [CrossRef]

- Ocylok, S.; Leichnitz, R.; Thieme, S.; Schmidt, M. Investigations on Laser Metal Deposition of Stainless Steel 316L with Coaxial Wire Feeding. In Proceedings of the Laser Assisted Net Shape Engineering 9 (LANE 2016), Fürth, Germany, 19–22 September 2016; pp. 1158–1163. [Google Scholar]

- Mathenia, R.; McLain, B.; Sparks, T.; Liou, F. A Study of Directionality Effects in Three-Beam Coaxial Titanium Wire-Based Laser Metal Deposition. Materials 2024, 17, 3201. [Google Scholar] [CrossRef]

- Kuznetsov, A.; Jeromen, A.; Levy, G.; Fujishima, M.; Govekar, E. Annular Laser Beam Cladding Process Feasibility Study. Phys. Procedia 2016, 83, 647–656. [Google Scholar] [CrossRef]

- Zapata, A.; Bernauer, C.; Stadter, C.; Kolb, C.G.; Zaeh, M.F. Investigation on the Cause-Effect Relationships between the Process Parameters and the Resulting Geometric Properties for Wire-Based Coaxial Laser Metal Deposition. Metals 2022, 12, 455. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, X.; Jiang, M.; Lei, Z.; Wang, Z.; Liang, J.; Wu, S.; Ma, S.; Jiang, N.; Chen, Y. Coaxial laser metal wire deposition of Ti6Al4V alloy: Process, microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 20, 2578–2590. [Google Scholar] [CrossRef]

- Wang, Y.K.; Shi, S.H.; Fu, G.Y.; Li, C.S. Research on the Key Process Parameters in Direct Laser Deposition Using Coaxial Inside-Beam Wire Feeding. Appl. Mech. Mater. 2011, 43, 401–404. [Google Scholar] [CrossRef]

- Kotar, M.; Govekar, E. The influence of the workpiece illumination proportion in annular laser beam wire deposition process. Procedia CIRP 2018, 74, 228–232. [Google Scholar] [CrossRef]

- Mathenia, R.; Flood, A.; McLain, B.; Sparks, T.; Liou, F. Effects of Laser Defocusing on Bead Geometry in Coaxial Titanium Wire-Based Laser Metal Deposition. Materials 2024, 17, 889. [Google Scholar] [CrossRef]

- Wire-Based Laser Metal Deposition (LMD-w). Available online: https://www.ipt.fraunhofer.de/en/technologies/additive-manufacturing/wire-based-laser-metal-deposition.html (accessed on 21 December 2023).

- Govekar, E.; Jeromen, A.; Kuznetsov, A.; Kotar, M.; Kondo, M. Annular laser beam based direct metal deposition. Procedia CIRP 2018, 74, 222–227. [Google Scholar] [CrossRef]

- Kotar, M.; Fujishima, M.; Levy, G.; Govekar, E. Initial transient phase and stability of annular laser beam direct wire deposition. CIRP Ann. 2019, 68, 233–236. [Google Scholar] [CrossRef]

- Kotar, M.; Fujishima, M.; Levy, G.N.; Govekar, E. Advances in the understanding of the annular laser beam wire cladding process. J. Mater. Process. Technol. 2021, 294, 117105. [Google Scholar] [CrossRef]

- Motta, M.; Demir, A.G.; Previtali, B. High-speed imaging and process characterization of coaxial laser metal wire deposition. Addit. Manuf. 2018, 22, 497–507. [Google Scholar] [CrossRef]

- Ji, S.; Liu, F.; Shi, T.; Fu, G.; Shi, S. Effects of Defocus Distance on Three-Beam Laser Internal Coaxial Wire Cladding. Chin. J. Mech. Eng. 2021, 34, 45. [Google Scholar] [CrossRef]

- Polamuri, S.K.; Chitral, S.; Adapa, M.K.; Nayak, A.; Kiran, D.V. A strategic approach to minimize lack of fusion defects in wire arc additive manufacturing. Prog. Addit. Manuf. 2025, 1–16. [Google Scholar] [CrossRef]

- Suwannatee, N.; Yamamoto, M.; Shinohara, S. Optimization of hot-wire fraction for enhance quality in GMAW. Weld. World 2023, 68, 1017–1032. [Google Scholar] [CrossRef]

- Emminghaus, N.; Paul, J.; Hoff, C.; Hermsdorf, J.; Kaierle, S. Development of an empirical process model for adjusted porosity in laser-based powder bed fusion of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2022, 118, 1239–1254. [Google Scholar] [CrossRef]

- Bernauer, C.; Merk, T.; Zapata, A.; Zaeh, M. Laser Metal Deposition with Coaxial Wire Feeding for the Automated and Reliable Build-Up of Solid Metal Parts. Key Eng. Mater. 2022, 926, 65–79. [Google Scholar] [CrossRef]

- Furton, E.T.; Beese, A.M. Ductile fracture model describing the impact of internal pores: Model development and validation for additively manufactured Ti-6Al-4V. Addit. Manuf. 2025, 102, 104722. [Google Scholar] [CrossRef]

- Sai Deepak Kumar, A.; Pattanayak, D.K.; Fayaz Anwar, M.; Rajendran, A.; Vanitha, C. The Effect of Porosity, Oxygen and Phase Morphology on the Mechanical Properties of Selective Laser Melted Ti-6Al-4V with Respect to Annealing Temperature. Trans. Indian Inst. Met. 2023, 76, 1789–1798. [Google Scholar] [CrossRef]

- Shakhverdova, I.; Nowotny, S.; Thieme, S.; Kubisch, F.; Beyer, E.; Leyens, C. Coaxial Laser Wire Deposition. J. Phys. Conf. Ser. 2018, 1109, 012026. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, L.; Zhang, Z.; Qu, Z.; Liu, R.; Zhou, G.; Chen, L.; Zhang, Z. Effects of artificial embedded defect size and position on the fatigue lives of additive manufacturing Ti–6Al–4V alloy. Mater. Sci. Eng. A 2024, 909, 146863. [Google Scholar] [CrossRef]

- Kobryn, P.; Semiatin, S. Mechanical Properties of Laser-Deposited Ti-6Al-4V. Solid Freeform Fabrication Proceedings. 2001. Available online: https://utw10945.utweb.utexas.edu/Manuscripts/2001/2001-21-Kobryn.pdf (accessed on 9 April 2025).

- Harkin, R.; Wu, H.; Nikam, S.; Yin, S.; Lupoi, R.; Walls, P.; McKay, W.; McFadden, S. Evaluation of the role of hatch-spacing variation in a lack-of-fusion defect prediction criterion for laser-based powder bed fusion processes. Int. J. Adv. Manuf. Technol. 2023, 126, 659–673. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).