Application of Artificial Intelligence to Support Design and Analysis of Steel Structures

Abstract

1. Introduction

Objectives of This Review

- Providing a Focused Overview of ML in Steel Structure Engineering:

- Exploring the Role of IML in Steel Structure Design:

- Investigating XML for Transparent Structural Engineering

- Addressing Challenges, Limitations, and Future Directions

2. Research Data Extraction Process

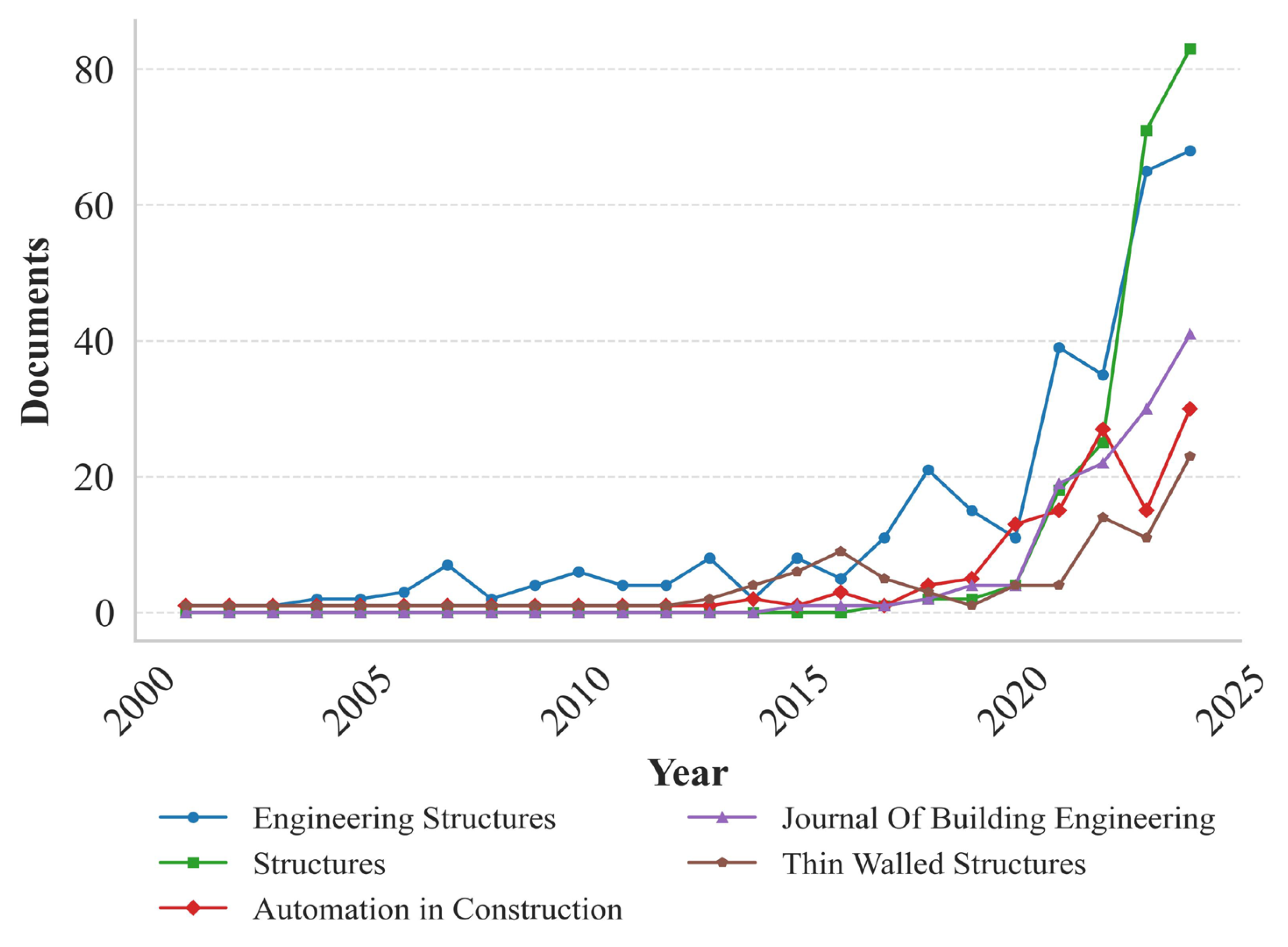

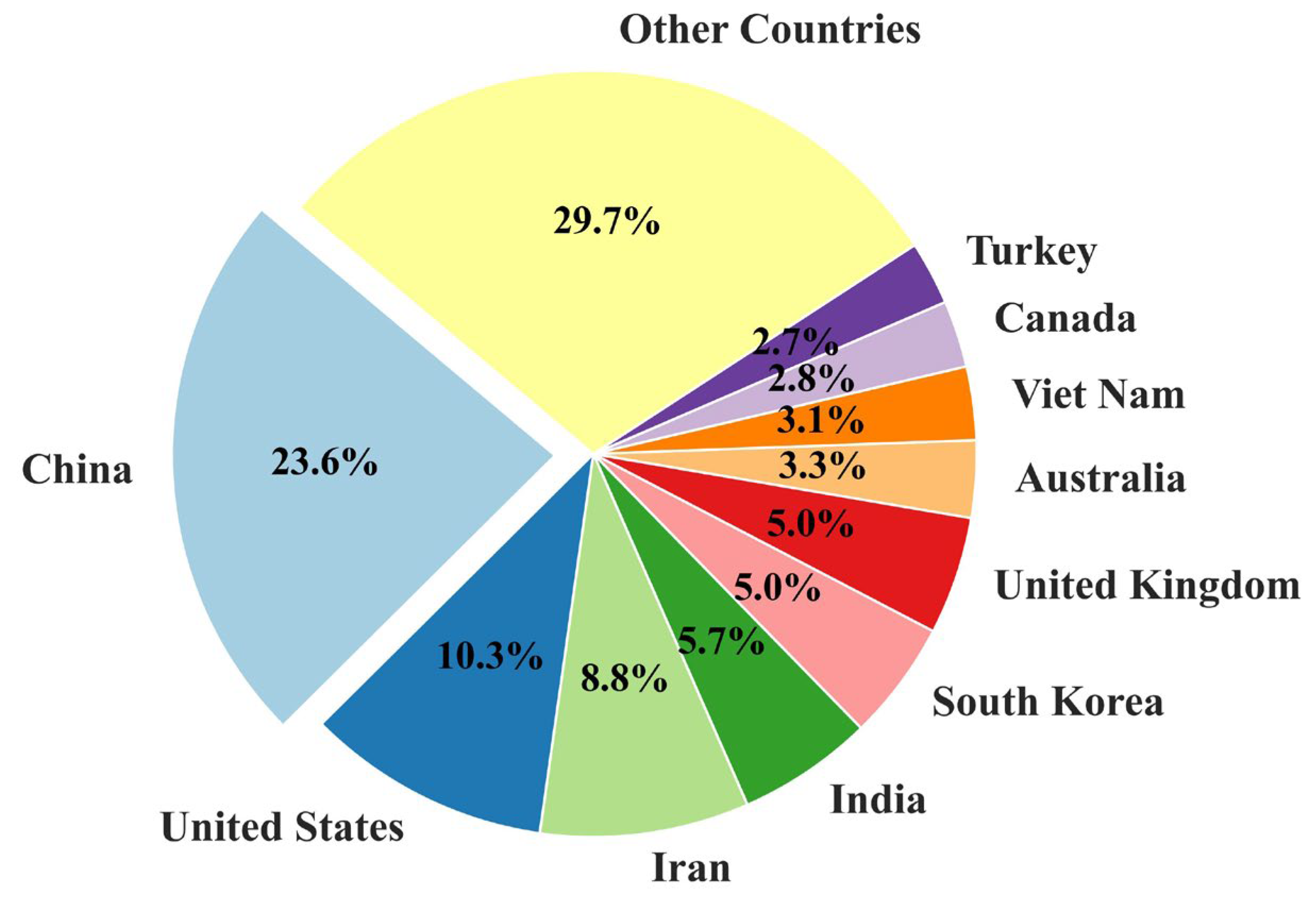

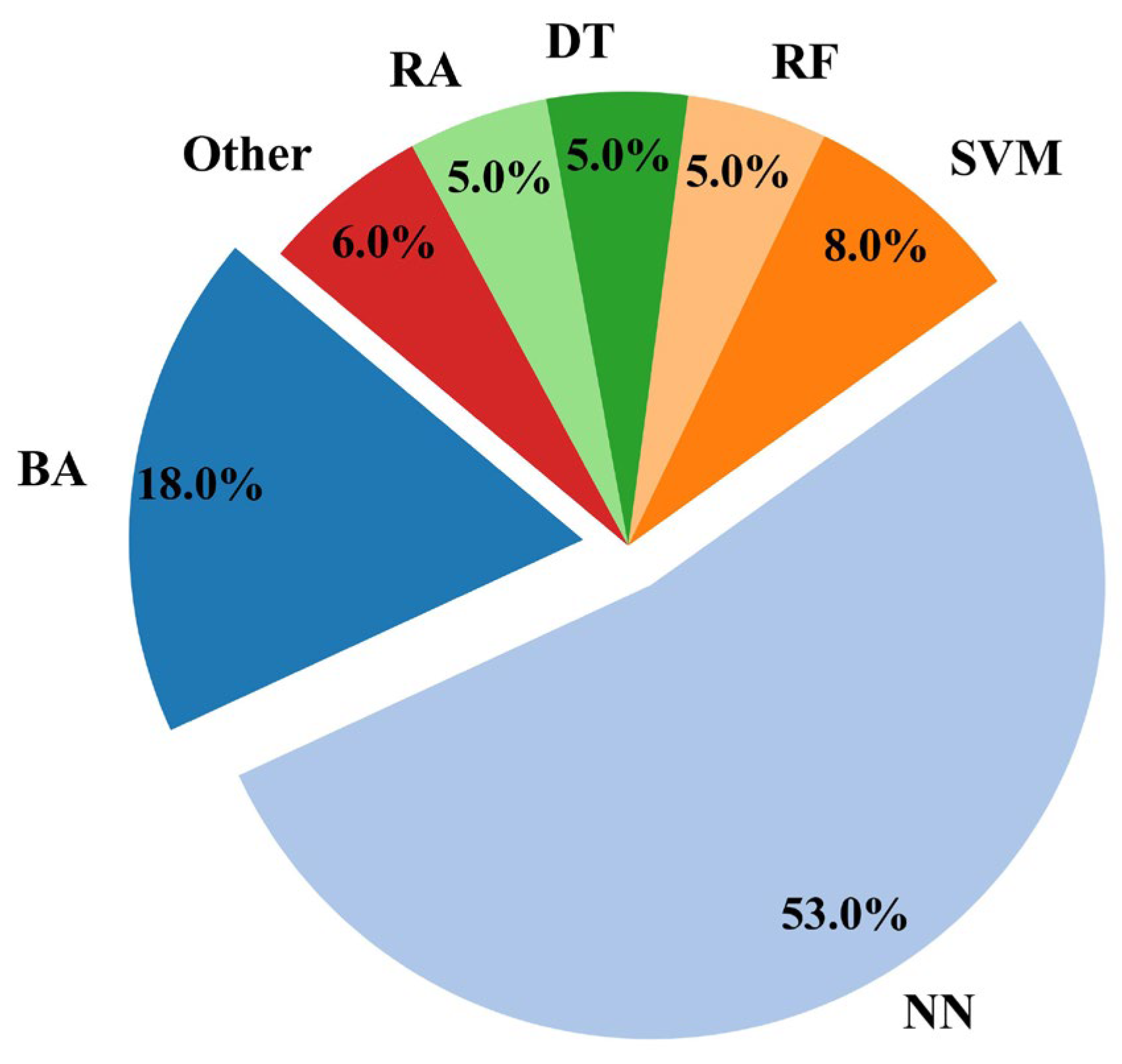

Overview of Research Contributions in AI-Driven Steel Structure Studies

3. An Overview of ML Application in Steel Structures

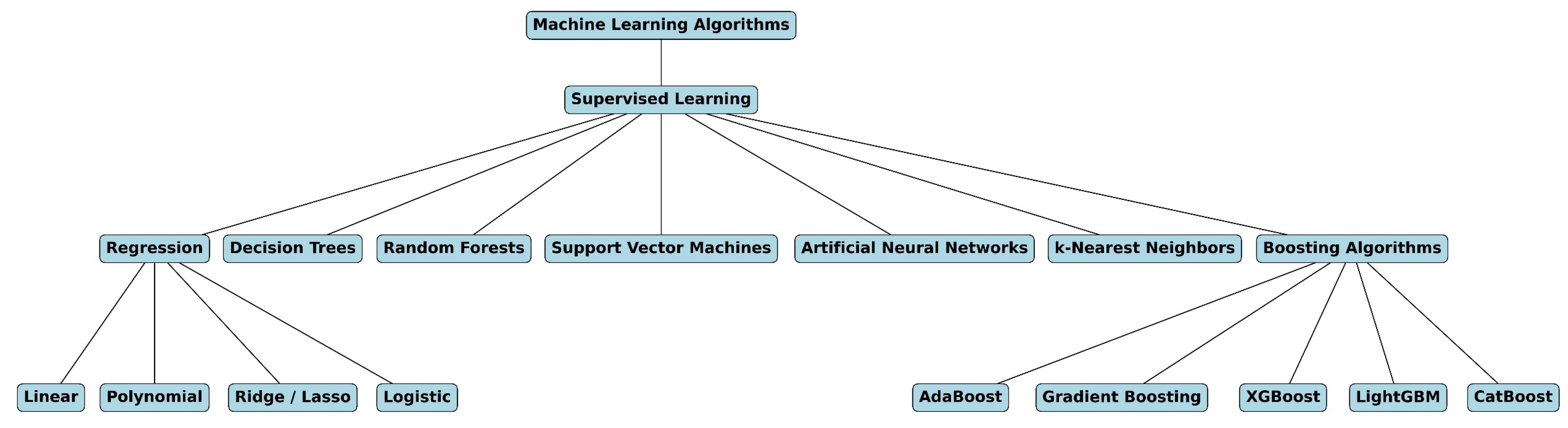

3.1. Supervised ML Algorithms

3.1.1. Regression Algorithms

3.1.2. Decision Tree

3.1.3. Random Forest

3.1.4. Support Vector Machines

3.1.5. Artificial Neural Networks

3.1.6. k-Nearest Neighbor

3.1.7. Boosting Algorithms

3.2. ML for Steel Joints, Connections, and Rotational Stiffness Prediction

3.3. ML for Buckling and Stability Analysis

3.4. ML for Strength Prediction and Optimization of Cold-Formed Steel Structures

3.5. ML Applications in Steel Frame Design, Optimization, and Damage Detection

3.6. ML-Based Structural Health Monitoring in Steel Structures

3.7. ML-Based Prediction of Structural Performance in Steel Components

3.8. ML-Based Seismic Performance Assessment and Optimization

3.9. AI Applications in Real-World Steel Structures

4. Inverse Machine Learning (IML) for Design Optimization and Performance Enhancement in Steel Structures

IML Application in Steel Structures

5. Enhancing Explainability in ML: Concepts, Methods, and Applications in Structural Engineering

5.1. SHapley Additive exPlanations (SHAP)

5.2. XML Application in Steel Structures

6. Addressing Challenges, Limitations, and Future Directions

6.1. Rethinking Model Training: Advancing from Accuracy to Engineering Reliability

6.1.1. Generalization and Overfitting in Structural ML Models

6.1.2. Addressing the Gap in Physics-Based Learning

6.1.3. Future Directions for Reliability-Oriented Model Training

- Creating PIML Models

- Hybrid Engineering-ML Models

- Uncertainty Quantification (UQ)

6.2. The Overlooked Role of Feature Engineering and Domain Expertise

6.2.1. The Difficulties Using Raw Data Without Engineering Context

6.2.2. Why Structural Analysis Driven by ML Requires Domain Knowledge

6.2.3. Future Directions for Feature Engineering and Domain-Driven Learning

- Creating feature selection techniques grounded in engineering

- Incorporating Expert Knowledge into Feature Engineering

- Automated Feature Extraction Techniques

6.3. From Deterministic to Probabilistic Modeling

6.3.1. The Importance of Uncertainty Quantification in Structural Predictions

6.3.2. The Role of Bayesian ML and Monte Carlo Simulations

6.3.3. Future Directions for Probabilistic and Uncertainty-Aware Modeling

- Adopting Bayesian ML techniques

- Integrating ML with probabilistic design codes

- Developing uncertainty-aware ML models

6.4. Bridging the Gap Between Research and Practice

6.4.1. Why ML Still Is Not Often Applied in Industry?

- ML models lack a universal benchmarking system unlike FEA, which follows accepted verification processes.

- Some deep learning architectures demand significant computational resources, thus they are useless for real-time analysis.

- Regulatory and Code Compliance Problems; a highly regulated discipline, structural engineering lacks formal approval of engineering codes using ML-based design methods.

6.4.2. Future Directions for Bridging the Gap Between Research and Practice

- Creating Industry-Standard Validation Benchmarks

- Developing ML-Integrated Engineering Software

- Regulatory Frameworks for AI in Structural Engineering

6.5. Expanding the Role of IML in Structural Design

6.5.1. IML and Generative AI as the Next Frontier in Structural Design Automation

6.5.2. Future Directions for Inverse and Generative AI in Structural Design

- Integration of GANs and VAEs into Structural Topology Optimization

- Coupling Generative Design with FEM and BIM Systems

- Data-Driven Evolutionary Design Platforms for Custom Steel Systems

6.6. Regulatory Acceptance and Validation of AI Models in Structural Engineering

6.6.1. Current Regulatory Limitations and Engineering Concerns

6.6.2. Role of Explainable AI (XAI) in Meeting Regulatory Demands

6.6.3. Future Directions for Regulatory Approval and Model Certification

- Establishing formal AI regulatory frameworks tailored for civil/structural engineering

- Defining interpretability thresholds and validation protocols

- Creating certification pathways for hybrid models combining AI and physical principles

6.7. Practical Barriers to Industry Adoption of AI in Structural Engineering

6.7.1. Data Scarcity, Trust, and the Need for Validation

6.7.2. Future Directions for Industry Adoption of AI in Structural Engineering

- Enhancing access to shared structural datasets

- Promoting model transparency in safety-critical use cases

- Aligning industrial validation with regulatory expectations

6.8. Advancing Seismic Modeling Through Multi-Physics AI

6.8.1. Limitations of Current Seismic AI Models

6.8.2. Emerging Research on Multi-Physics AI Integration

6.8.3. Feature Direction for Advancing Seismic Modeling Through Multi-Physics AI

- Coupling PINNs with seismic time-history simulations

- Creating benchmark datasets for earthquake-driven ML training

- Developing real-time digital twins for seismic assessment

- Standardizing validation protocols in Eurocode 8, ASCE 41, etc.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thai, H.-T. Machine learning for structural engineering: A state-of-the-art review. Structures 2022, 38, 448–491. [Google Scholar] [CrossRef]

- Sun, H.; Burton, H.V.; Huang, H. Machine learning applications for building structural design and performance assessment: State-of-the-art review. J. Build. Eng. 2021, 33, 101816. [Google Scholar] [CrossRef]

- Salehi, H.; Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- Málaga-Chuquitaype, C. Machine learning in structural design: An opinionated review. Front. Built Environ. 2022, 8, 815717. [Google Scholar] [CrossRef]

- Haber, E.; Ascher, U.M.; Oldenburg, D. On optimization techniques for solving nonlinear inverse problems. Inverse Probl. 2000, 16, 1263. [Google Scholar] [CrossRef]

- Gallet, A.; Rigby, S.; Tallman, T.N.; Kong, X.; Hajirasouliha, I.; Liew, A.; Liu, D.; Chen, L.; Hauptmann, A.; Smyl, D. Structural engineering from an inverse problems perspective. Proc. R. Soc. A Math. Phys. Eng. Sci. 2022, 478, 20210526. [Google Scholar] [CrossRef]

- Barredo Arrieta, A.; Díaz-Rodríguez, N.; Del Ser, J.; Bennetot, A.; Tabik, S.; Barbado, A.; Garcia, S.; Gil-Lopez, S.; Molina, D.; Benjamins, R.; et al. Explainable artificial intelligence (XAI): Concepts, taxonomies, opportunities, and challenges toward responsible AI. Inf. Fusion 2020, 58, 82–115. [Google Scholar] [CrossRef]

- Angelov, P.P.; Soares, E.A.; Jiang, R.; Arnold, N.I.; Atkinson, P.M. Explainable artificial intelligence: An analytical review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2021, 11, e1424. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.I. A unified approach to interpreting model predictions. Adv. Neural Inf. Process. Syst. 2017, 30, 2493. [Google Scholar]

- Minh, D.; Wang, H.X.; Li, Y.F.; Nguyen, T.N. Explainable artificial intelligence: A comprehensive review. Artif. Intell. Rev. 2022, 55, 3503–3568. [Google Scholar] [CrossRef]

- Jiang, T.; Gradus, J.L.; Rosellini, A.J. Supervised machine learning: A brief primer. Behav. Ther. 2020, 51, 675–687. [Google Scholar] [CrossRef] [PubMed]

- Alloghani, M.; Al-Jumeily, D.; Mustafina, J.; Hussain, A.; Aljaaf, A.J. A systematic review on supervised and unsupervised machine learning algorithms for data science. In Supervised and Unsupervised Learning for Data Science; Springer: Cham, Switzerland, 2020; pp. 3–21. [Google Scholar]

- Nian, R.; Liu, J.; Huang, B. A review on reinforcement learning: Introduction and applications in industrial process control. Comput. Chem. Eng. 2020, 139, 106886. [Google Scholar] [CrossRef]

- Adeli, H. Neural networks in civil engineering: 1989–2000. Comput.-Aided Civ. Infrastruct. Eng. 2001, 16, 126–142. [Google Scholar] [CrossRef]

- Song, B.; Zhou, R.; Ahmed, F. Multi-modal machine learning in engineering design: A review and future directions. J. Comput. Inf. Sci. Eng. 2024, 24, 010801. [Google Scholar] [CrossRef]

- Daneshfar, R.; Esmaeili, M.; Mohammadi-Khanaposhtani, M.; Baghban, A.; Habibzadeh, S.; Eslamian, S. Advanced machine learning techniques: Multivariate regression. In Handbook of Hydroinformatics; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–38. [Google Scholar] [CrossRef]

- Mienye, I.D.; Jere, N. A survey of decision trees: Concepts, algorithms, and applications. IEEE Access 2024, 12, 86716–86727. [Google Scholar] [CrossRef]

- Schonlau, M.; Zou, R.Y. The random forest algorithm for statistical learning. Stata J. 2020, 20, 3–29. [Google Scholar] [CrossRef]

- Tanveer, M.; Rajani, T.; Rastogi, R.; Shao, Y.H.; Ganaie, M.A. Comprehensive review on twin support vector machines. Ann. Oper. Res. 2024, 339, 1223–1268. [Google Scholar] [CrossRef]

- Abd-elaziem, A.H.; Soliman, T.H. A multi-layer perceptron (MLP) neural network for stellar classification: A review of methods and results. Int. J. Adv. Appl. Comput. Intell. 2023, 3, 54216. [Google Scholar]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef]

- Halder, R.K.; Uddin, M.N.; Uddin, M.A.; Aryal, S.; Khraisat, A. Enhancing K-nearest neighbor algorithm: A comprehensive review and performance analysis of modifications. J. Big Data 2024, 11, 113. [Google Scholar] [CrossRef]

- Freund, Y.; Schapire, R.E. Experiments with a new boosting algorithm. ICML 1996, 96, 148–156. [Google Scholar]

- Friedman, J.H. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A scalable tree boosting system. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar] [CrossRef]

- Ke, G.; Meng, Q.; Finley, T.; Wang, T.; Chen, W.; Ma, W.; Liu, T.Y. LightGBM: A highly efficient gradient boosting decision tree. Adv. Neural Inf. Process. Syst. 2018, 30, 1998–2007. [Google Scholar] [CrossRef]

- Prokhorenkova, L.; Gusev, G.; Vorobev, A.; Dorogush, A.V.; Gulin, A. CatBoost: Unbiased boosting with categorical features. In Advances in Neural Information Processing Systems; Bengio, S., Wallach, H., Larochelle, H., Grauman, K., Cesa-Bianchi, N., Garnett, R., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2018; Volume 31, pp. 6638–6648. Available online: https://proceedings.neurips.cc/paper/2018/file/14491b756b3a51daac41c24863285549-Paper.pdf (accessed on 1 April 2025).

- Mascolo, I.; Guarracino, F.; Sarfarazi, S.; Della Corte, G. A proposal for a simple characterization of stainless steel connections through an equivalent yield strength. Structures 2024, 68, 107043. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Shamass, R.; Mascolo, I.; Della Corte, G.; Guarracino, F. Some considerations on the behaviour of bolted stainless-steel beam-to-column connections: A simplified analytical approach. Metals 2023, 13, 753. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Shamass, R.; Della Corte, G.; Guarracino, F. Assessment of design approaches for stainless-steel joints through an equivalent FE modelling technique. ce/papers 2022, 5, 271–281. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Saffari, H.; Fakhraddini, A. Shear behavior of panel zone considering axial force for flanged cruciform columns. Civ. Eng. Infrastruct. J. 2020, 53, 359–377. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Fakhraddini, A.; Modaresahmadi, K. Evaluation of panel zone shear strength in cruciform columns, box-columns and double web-columns. Int. J. Struct. Civ. Eng. 2016, 5, 52–56. [Google Scholar]

- Saffari, H.; Sarfarazi, S.; Fakhraddini, A. A mathematical steel panel zone model for flanged cruciform columns. Steel Compos. Struct. 2016, 20, 851–867. [Google Scholar] [CrossRef]

- Paral, A.; Roy, D.K.S.; Samanta, A.K. A deep learning-based approach for condition assessment of semi-rigid joint of steel frame. J. Build. Eng. 2021, 34, 101946. [Google Scholar] [CrossRef]

- Kueh, A.B.H. Artificial neural network and regressed beam-column connection explicit mathematical moment-rotation expressions. J. Build. Eng. 2021, 43, 103195. [Google Scholar] [CrossRef]

- Tran, V.L. Investigating the behavior of steel flush endplate connections at elevated temperatures using FEM and ANN. Int. J. Steel Struct. 2022, 22, 1433–1451. [Google Scholar] [CrossRef]

- Sarothi, S.Z.; Ahmed, K.S.; Khan, N.I.; Ahmed, A.; Nehdi, M.L. Predicting bearing capacity of double shear bolted connections using machine learning. Eng. Struct. 2022, 251, 113497. [Google Scholar] [CrossRef]

- Jiang, K.; Liang, Y.; Zhao, O. Machine-learning-based design of high-strength steel bolted connections. Thin-Walled Struct. 2022, 179, 109575. [Google Scholar] [CrossRef]

- Rabbani, A.; Ghiami Azad, A.R.; Rahami, H. Enhancing prediction of the moment-rotation behavior in flush end plate connections using Multi-Gene Genetic Programming (MGGP). Struct. Eng. Mech. 2024, 91, 643–656. [Google Scholar] [CrossRef]

- Ferreira, F.P.V.; Shamass, R.; Limbachiya, V.; Tsavdaridis, K.D.; Martins, C.H. Lateral–torsional buckling resistance prediction model for steel cellular beams generated by artificial neural networks (ANN). Thin-Walled Struct. 2022, 170, 108592. [Google Scholar] [CrossRef]

- Shamass, R.; Ferreira, F.P.V.; Limbachiya, V.; Santos, L.F.P.; Tsavdaridis, K.D. Web-post buckling prediction resistance of steel beams with elliptically-based web openings using artificial neural networks (ANN). Thin-Walled Struct. 2022, 180, 109959. [Google Scholar] [CrossRef]

- Silva de Carvalho, A.; Hosseinpour, M.; Rossi, A.; Martins, C.H.; Sharifi, Y. New formulas for predicting the lateral–torsional buckling strength of steel I-beams with sinusoidal web openings. Thin-Walled Struct. 2022, 181, 110067. [Google Scholar] [CrossRef]

- Xing, Z.; Wu, K.; Su, A.; Wang, Y.; Zhou, G. Intelligent local buckling design of stainless steel I-sections in fire via Artificial Neural Network. Structures 2023, 58, 105356. [Google Scholar] [CrossRef]

- Rossi, A.; Hosseinpour, M.; Silva de Carvalho, A.; Martins, C.H.; Sharifi, Y. Lateral torsional capacity of steel beams in different loading conditions by neural network. Proc. Inst. Civ. Eng. Struct. Build. 2023, 177, 892–910. [Google Scholar] [CrossRef]

- Cheng, J.; Li, X.; Jiang, K.; Li, S.; Su, A.; Zhao, O. Machine-learning-assisted design of high-strength steel I-section columns. Eng. Struct. 2024, 308, 118018. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, M.; Zheng, B. Design of cold-formed stainless steel circular hollow section columns using machine learning methods. Structures 2021, 33, 2755–2770. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Tran, N.L.; Nguyen, D.D. Prediction of axial compression capacity of cold-formed steel oval hollow section columns using ANN and ANFIS models. Int. J. Steel Struct. 2022, 22, 1–26. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Padiyara, S.; Chen, B.; Raftery, G.M.; Lim, J.B.P. Web crippling design of cold-formed stainless steel channels under interior-two-flange loading condition using deep belief network. Structures 2023, 47, 1967–1990. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, B.; Li, W.; Zhou, T.; Li, Y. Regression-classification ensemble machine learning model for loading capacity and buckling mode prediction of cold-formed steel built-up I-section columns. Thin-Walled Struct. 2024, 205, 112427. [Google Scholar] [CrossRef]

- Shaheen, M.A.; Presswood, R.; Afshan, S. Application of machine learning to predict the mechanical properties of high-strength steel at elevated temperatures based on the chemical composition. Structures 2023, 52, 17–29. [Google Scholar] [CrossRef]

- Shahin, R.I.; Ahmed, M.; Liang, Q.Q.; Yehia, S.A. Predicting the web crippling capacity of cold-formed steel lipped channels using hybrid machine learning techniques. Eng. Struct. 2024, 309, 118061. [Google Scholar] [CrossRef]

- Yılmaz, Y.; Demir, S.; Öztürk, F. Predicting the load-bearing capacity of lipped channel section cold-formed steel profiles under combined effects using machine learning. Structures 2024, 66, 106898. [Google Scholar] [CrossRef]

- Kim, B.; Yuvaraj, N.; Park, H.W.; Sri Preethaa, K.R.; Pandian, R.A.; Lee, D.-E. Investigation of steel frame damage based on computer vision and deep learning. Autom. Constr. 2021, 132, 103941. [Google Scholar] [CrossRef]

- Truong, V.-H.; Pham, H.-A.; Van, T.H.; Tangaramvong, S. Evaluation of machine learning models for load-carrying capacity assessment of semi-rigid steel structures. Eng. Struct. 2022, 273, 115001. [Google Scholar] [CrossRef]

- Jahjouh, M. An experience-based artificial neural network in the design optimization of steel frames. Eng. Res. Express 2022, 4, 045031. [Google Scholar] [CrossRef]

- Shan, W.; Liu, J.; Zhou, J. Integrated method for intelligent structural design of steel frames based on optimization and machine learning algorithm. Eng. Struct. 2023, 284, 115980. [Google Scholar] [CrossRef]

- Pal, J.; Sikdar, S.; Banerjee, S. A deep-learning approach for health monitoring of a steel frame structure with bolted connections. Struct. Control Health Monit. 2022, 29, e2873. [Google Scholar] [CrossRef]

- Naresh, M.; Kumar, V.; Pal, J. A machine learning approach for health monitoring of a steel frame structure using statistical features of vibration data. Asian J. Civ. Eng. 2024, 25, 39–49. [Google Scholar] [CrossRef]

- Vu, V.T.; Thom, D.V.; Tran, T.D. Identification of damage in steel beam by natural frequency using machine learning algorithms. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 9644–9659. [Google Scholar] [CrossRef]

- Li, H.; Yin, X.; Sha, L.; Yang, D.; Hu, T. Data-driven prediction model for high-strength bolts in composite beams. Buildings 2023, 13, 2769. [Google Scholar] [CrossRef]

- Dissanayake, M.; Nguyen, H.; Poologanathan, K.; Perampalam, G.; Upasiri, I.; Rajanayagam, H.; Suntharalingam, T. Prediction of shear capacity of steel channel sections using machine learning algorithms. Thin-Walled Struct. 2022, 175, 109152. [Google Scholar] [CrossRef]

- Dai, Y.; Roy, K.; Fang, Z.; Chen, B.; Raftery, G.M.; Lim, J.B.P. A novel machine learning model to predict the moment capacity of cold-formed steel channel beams with edge-stiffened and un-stiffened web holes. J. Build. Eng. 2022, 53, 104592. [Google Scholar] [CrossRef]

- Liu, J.-Z.; Li, S.; Guo, J.; Xue, S.; Chen, S.; Wang, L.; Zhou, Y.; Luo, T.X. Machine learning (ML)-based models for predicting the ultimate bending moment resistance of high-strength steel welded I-section beam under bending. Thin-Walled Struct. 2023, 191, 111051. [Google Scholar] [CrossRef]

- Su, A.; Cheng, J.; Li, X.; Zhong, Y.; Li, S.; Zhao, O.; Jiang, K. Unified machine-learning-based design method for normal and high-strength steel I-section beam–columns. Thin-Walled Struct. 2024, 199, 111835. [Google Scholar] [CrossRef]

- Tusnin, A.R.; Alekseytsev, A.V.; Tusnina, O.A. Load identification in steel structural systems using machine learning elements: Uniform length loads and point forces. Buildings 2024, 14, 1711. [Google Scholar] [CrossRef]

- Sediek, O.A.; Wu, T.-Y.; McCormick, J.; El-Tawil, S. Prediction of seismic collapse behavior of deep steel columns using machine learning. Structures 2022, 40, 163–175. [Google Scholar] [CrossRef]

- Imam, M.H.; Mohiuddin, M.; Shuman, N.M.; Oyshi, T.I.; Debnath, B.; Liham, M.I.M.H. Prediction of seismic performance of steel frame structures: A machine learning approach. Structures 2024, 69, 107547. [Google Scholar] [CrossRef]

- Shin, D.-H.; Kim, H.-J. Machine learning-based prediction of hysteretic behaviors of two-side clamped steel shear walls. Structures 2024, 60, 105875. [Google Scholar] [CrossRef]

- Cho, E.; Han, S.W. A numerical model simulating cyclic behavior of high-strength steel. Adv. Struct. Eng. 2024, 27, 1490–1508. [Google Scholar] [CrossRef]

- Hu, S.; Zhu, S.; Alam, M.S.; Wang, W. Machine learning-aided peak and residual displacement-based design method for enhancing seismic performance of steel moment-resisting frames by installing self-centering braces. Eng. Struct. 2022, 271, 114935. [Google Scholar] [CrossRef]

- Samadian, D.; Muhit, I.B.; Occhipinti, A.; Dawood, N. Surrogate models for seismic and pushover response prediction of steel special moment resisting frames. Eng. Struct. 2024, 314, 118307. [Google Scholar] [CrossRef]

- Salama, A.H.E.S. Optimization seismic resilience: A machine learning approach for vertical irregular buildings. Asian J. Civ. Eng. 2024, 25, 6233–6248. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, J.; Li, J.; Deng, Z.; Luo, J. Damage identification of steel bridge based on data augmentation and adaptive optimization neural network. Struct. Health Monit. 2024; in press. [Google Scholar] [CrossRef]

- Iacussi, L.; Chiariotti, P.; Cigada, A. AI-enhanced IoT system for assessing bridge deflection in drive-by conditions. Sensors 2025, 25, 158. [Google Scholar] [CrossRef]

- Wang, X.; Yue, Q.; Liu, X. SBDNet: A deep learning-based method for the segmentation and quantification of fatigue cracks in steel bridges. Adv. Eng. Inform. 2025, 65, 103186. [Google Scholar] [CrossRef]

- Svendsen, B.T.; Øiseth, O.; Frøseth, G.T.; Rønnquist, A. A hybrid structural health monitoring approach for damage detection in steel bridges under simulated environmental conditions using numerical and experimental data. Struct. Health Monit. 2022, 22, 540–561. [Google Scholar] [CrossRef]

- Zhou, K.; Duan, M.-G.; Wu, Z.-L.; Zhi, L.-H.; Hu, F. Dynamic behavior monitoring of twin supertall buildings during Super Typhoon Soksuri using social sensing data. J. Build. Eng. 2024, 95, 110119. [Google Scholar] [CrossRef]

- Ghaffari, A.; Shahbazi, Y.; Mokhtari Kashavar, M.; Fotouhi, M.; Pedrammehr, S. Advanced predictive structural health monitoring in high-rise buildings using recurrent neural networks. Buildings 2024, 14, 3261. [Google Scholar] [CrossRef]

- Wang, M.; Incecik, A.; Tian, Z.; Zhang, M.; Kujala, P.; Gupta, M.; Krolczyk, G.; Li, Z. Structural health monitoring on offshore jacket platforms using a novel ensemble deep learning model. Ocean Eng. 2024, 301, 117510. [Google Scholar] [CrossRef]

- Martzikos, N.; Ruzzo, C.; Malara, G.; Fiamma, V.; Arena, F. Applying neural networks to predict offshore platform dynamics. J. Mar. Sci. Eng. 2024, 12, 2001. [Google Scholar] [CrossRef]

- Kouchaki, M.; Salkhordeh, M.; Mashayekhi, M.; Mirtaheri, M.; Amanollah, H. Damage detection in power transmission towers using machine learning algorithms. Structures 2023, 56, 104980. [Google Scholar] [CrossRef]

- Kiyoki, S.; Yoshida, S.; Rushdi, M.A. Machine learning-based prediction of 2 MW wind turbine tower loads during power production based on nacelle behavior. Energies 2025, 18, 216. [Google Scholar] [CrossRef]

- Vlasenko, T.; Hutsol, T.; Vlasovets, V.; Glowacki, S.; Nurek, T.; Horetska, I.; Kukharets, S.; Firman, Y.; Bilovod, O. Ensemble learning based sustainable approach to rebuilding metal structures prediction. Sci. Rep. 2025, 15, 1210. [Google Scholar] [CrossRef]

- Shang, Z.; Qin, X.; Zhang, Z.; Jiang, H. Bolt loosening and preload loss detection technology based on machine vision. Buildings 2024, 14, 3897. [Google Scholar] [CrossRef]

- Huang, X.; Duan, Z.; Hao, S.; Hou, J.; Chen, W.; Cai, L. A deep learning framework for corrosion assessment of steel structures using Inception v3 model. Buildings 2025, 15, 512. [Google Scholar] [CrossRef]

- Badini, S.; Regondi, S.; Pugliese, R. Enhancing mechanical and bioinspired materials through generative AI approaches. Next Mater. 2025, 6, 100275. [Google Scholar] [CrossRef]

- Arridge, S.; Maass, P.; Öktem, O.; Schönlieb, C.-B. Solving inverse problems using data-driven models. Acta Numer. 2019, 28, 1–174. [Google Scholar] [CrossRef]

- Masurkar, F.; Aggarwal, S.; Tham, Z.W.; Zhang, L.; Yang, F.; Cui, F. Estimating the elastic constants of orthotropic composites using guided waves and an inverse problem of property estimation. Appl. Acoust. 2024, 216, 109750. [Google Scholar] [CrossRef]

- Challapalli, A.; Patel, D.; Li, G. Inverse machine learning framework for optimizing lightweight metamaterials. Mater. Des. 2021, 208, 109937. [Google Scholar] [CrossRef]

- Liao, W.; Lu, X.; Huang, Y.; Zheng, Z.; Lin, Y. Automated structural design of shear wall residential buildings using generative adversarial networks. Autom. Constr. 2021, 132, 103931. [Google Scholar] [CrossRef]

- Danhaive, R.; Mueller, C.T. Design subspace learning: Structural design space exploration using performance-conditioned generative modeling. Autom. Constr. 2021, 127, 103664. [Google Scholar] [CrossRef]

- Teimouri, A.; Challapalli, A.; Konlan, J.; Li, G. Machine learning assisted design and optimization of plate-lattice structures with superior specific recovery force. Giant 2024, 18, 100282. [Google Scholar] [CrossRef]

- Glaesener, R.N.; Kumar, S.; Lestringant, C.; Butruille, T.; Portela, C.M.; Kochmann, D.M. Predicting the influence of geometric imperfections on the mechanical response of 2D and 3D periodic trusses. Acta Mater. 2023, 254, 118918. [Google Scholar] [CrossRef]

- McClarren, R.G.; Tregillis, I.L.; Urbatsch, T.J.; Dodd, E.S. High-energy density hohlraum design using forward and inverse deep neural networks. Phys. Lett. A 2021, 396, 127243. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Kim, S.-H.; Jeong, H.-B.; Lee, K.; Cho, K.; Lee, Y.-K. Inverse design of high-strength medium-Mn steel using a machine learning-aided genetic algorithm approach. J. Mater. Res. Technol. 2024, 33, 2672–2682. [Google Scholar] [CrossRef]

- Wang, Z.-L.; Adachi, Y. Property prediction and properties-to-microstructure inverse analysis of steels by a machine-learning approach. Mater. Sci. Eng. A 2019, 744, 661–670. [Google Scholar] [CrossRef]

- Pei, Z.; Rozman, K.A.; Doğan, Ö.N.; Wen, Y.; Gao, N.; Holm, E.A.; Hawk, J.A.; Alman, D.E.; Gao, M.C. Machine-learning microstructure for inverse material design. Adv. Sci. 2021, 8, 2101207. [Google Scholar] [CrossRef]

- Lertkiatpeeti, K.; Janya-Anurak, C.; Uthaisangsuk, V. Effects of spatial microstructure characteristics on mechanical properties of dual-phase steel by inverse analysis and machine learning approach. Comput. Mater. Sci. 2024, 245, 113311. [Google Scholar] [CrossRef]

- Adachi, Y.; Chen, T.-T.; Sun, F. A review on inverse analysis models in steel material design. MGE Adv. 2024, 2, e71. [Google Scholar] [CrossRef]

- He, L.; Wang, Z.; Akebono, H.; Sugeta, A. Machine learning-based predictions of fatigue life and fatigue limit for steels. J. Mater. Sci. Technol. 2021, 90, 9–19. [Google Scholar] [CrossRef]

- Kolesnikov, I.; Pashkov, D.M.; Belyak, O.A.; Guda, A.A.; Danilchenko, S.A.; Manturov, D.S.; Novikov, E.S.; Kudryakov, O.V.; Guda, S.A.; Soldatov, A.V.; et al. Design of double-layer protective coatings: Finite element modeling and machine learning approximations. Acta Astronaut. 2023, 204, 869–877. [Google Scholar] [CrossRef]

- Islam, F.; Wanigasekara, C.; Rajan, G.; Swain, A.; Prusty, B.G. An approach for process optimization of the Automated Fibre Placement (AFP) based thermoplastic composites manufacturing using machine learning, photonic sensing and thermo-mechanics modelling. Manuf. Lett. 2022, 32, 10–14. [Google Scholar] [CrossRef]

- Shen, X.; Yan, K.; Zhu, D.; Hu, Q.; Wu, H.; Qi, S.; Yuan, M.; Qian, X. Inverse machine learning framework for optimizing gradient honeycomb structure under impact loading. Eng. Struct. 2024, 309, 118079. [Google Scholar] [CrossRef]

- Challapalli, A.; Konlan, J.; Li, G. Inverse machine learning discovered metamaterials with record high recovery stress. Int. J. Mech. Sci. 2023, 244, 108029. [Google Scholar] [CrossRef]

- Kusampudi, N.; Diehl, M. Inverse design of dual-phase steel microstructures using generative machine learning model and Bayesian optimization. Int. J. Plast. 2023, 171, 103776. [Google Scholar] [CrossRef]

- Confalonieri, R.; Coba, L.; Wagner, B.; Besold, T.R. A historical perspective of explainable artificial intelligence. WIREs Data Min. Knowl. Discov. 2021, 11, e1391. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Zhu, Y.; Chen, G. Explainable AI based slip prediction of steel-UHPC interface connected by shear studs. Expert Syst. Appl. 2025, 259, 125293. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, T.; Long, Z.; Wang, J.; Zhang, J. Predicting the drift capacity of precast concrete columns using an explainable machine learning approach. Eng. Struct. 2023, 282, 115771. [Google Scholar] [CrossRef]

- Lai, D.; Demartino, C.; Xiao, Y. Interpretable machine-learning models for maximum displacements of RC beams under impact loading predictions. Eng. Struct. 2023, 281, 115723. [Google Scholar] [CrossRef]

- Karathanasopoulos, N.; Singh, A.; Hadjidoukas, P. Machine learning-based modelling, feature importance and Shapley additive explanations analysis of variable-stiffness composite beam structures. Structures 2024, 62, 106206. [Google Scholar] [CrossRef]

- Wang, S.; Liu, J.; Wang, Q.; Dai, R.; Chen, K. Prediction of non-uniform shrinkage of steel-concrete composite slabs based on explainable ensemble machine learning model. J. Build. Eng. 2024, 88, 109002. [Google Scholar] [CrossRef]

- Le, H.-A.; Le, D.-A.; Le, T.-T.; Le, H.-P.; Le, T.-H.; Hoang, H.-G.T.; Nguyen, T.-A. An extreme gradient boosting approach to estimate the shear strength of FRP reinforced concrete beams. Structures 2022, 45, 1307–1321. [Google Scholar] [CrossRef]

- Zhang, S.; Lei, H.; Zhou, Z.; Wang, G.; Qiu, B. Fatigue life analysis of high-strength bolts based on machine learning method and SHapley Additive exPlanations (SHAP) approach. Structures 2023, 51, 275–287. [Google Scholar] [CrossRef]

- Junda, E.; Málaga-Chuquitaype, C.; Chawgien, K. Interpretable machine learning models for the estimation of seismic drifts in CLT buildings. J. Build. Eng. 2023, 70, 106365. [Google Scholar] [CrossRef]

- Parvizi, M.; Nasserasadi, K.; Tafakori, E. Development of fragility functions of low-rise steel moment frame by artificial neural networks and identifying effective parameters using SHAP theory. Structures 2023, 58, 105315. [Google Scholar] [CrossRef]

- Shahnazaryan, D.; O’Reilly, G.J. Next-generation non-linear and collapse prediction models for short- to long-period systems via machine learning methods. Eng. Struct. 2024, 306, 117801. [Google Scholar] [CrossRef]

- Liu, T.; Cakiroglu, C.; Islam, K.; Wang, Z.; Nehdi, M.L. Explainable machine learning model for predicting punching shear strength of FRC flat slabs. Eng. Struct. 2024, 301, 117276. [Google Scholar] [CrossRef]

- Ribeiro, M.T.; Singh, S.; Guestrin, C. Why should I trust you? Explaining the predictions of any classifier. arXiv 2016, arXiv:1602.04938. [Google Scholar]

- Kim, B.; Glassman, E.; Johnson, B.; Shah, J. iBCM: Interactive Bayesian Case Model Empowering Humans via Intuitive Interaction. MIT-CSAIL Tech. Rep. 2015, 30, 03z. [Google Scholar]

- Rani, P.; Liu, C.; Sarkar, N.; Vanman, E. An empirical study of machine learning techniques for affect recognition in human–robot interaction. Pattern Anal. Appl. 2006, 9, 58–69. [Google Scholar] [CrossRef]

- Huysmans, J.; Dejaeger, K.; Mues, C.; Vanthienen, J.; Baesens, B. An empirical evaluation of the comprehensibility of decision table, tree and rule-based predictive models. Decis. Support Syst. 2011, 51, 141–154. [Google Scholar] [CrossRef]

- Szegedy, C.; Zaremba, W.; Sutskever, I.; Bruna, J.; Erhan, D.; Goodfellow, I.; Fergus, R. Intriguing properties of neural networks. arXiv 2014, arXiv:1312.6199. [Google Scholar]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning; Springer: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Yu, B.; Chen, X.; Gupta, A.; Ribeiro, C. Stability. Bernoulli 2013, 19, 1484–1500. [Google Scholar] [CrossRef]

- Samek, W.; Müller, K.R. Towards explainable artificial intelligence. In Explainable AI: Interpreting, Explaining and Visualizing Deep Learning; Samek, W., Montavon, G., Vedaldi, A., Hansen, L., Müller, K.R., Eds.; Springer: Cham, Switzerland, 2019; Volume 11700, pp. 5–22. [Google Scholar] [CrossRef]

- Došilović, F.K.; Brčić, M.; Hlupić, N. Explainable artificial intelligence: A survey. In Proceedings of the 41st International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 21–25 May 2018; pp. 210–215. [Google Scholar] [CrossRef]

- Ahmed, G.; Jeon, G.; Piccialli, F. From artificial intelligence to explainable artificial intelligence in Industry 4.0: A survey on what, how, and where. IEEE Trans. Ind. Inform. 2022, 18, 5031–5042. [Google Scholar] [CrossRef]

- Mojtabaei, S.M.; Becque, J.; Hajirasouliha, I.; Khandan, R. Predicting the buckling behaviour of thin-walled structural elements using machine learning methods. Thin-Walled Struct. 2023, 184, 110518. [Google Scholar] [CrossRef]

- Hu, S.; Wang, W.; Lu, Y. Explainable machine learning models for probabilistic buckling stress prediction of steel shear panel dampers. Eng. Struct. 2023, 288, 116235. [Google Scholar] [CrossRef]

- Hou, Z.; Hu, S.; Wang, W. Interpretable machine learning models for predicting probabilistic axial buckling strength of steel circular hollow section members considering discreteness of geometries and material. Adv. Struct. Eng. 2024, 28, 828–844. [Google Scholar] [CrossRef]

- Samadian, D.; Muhit, I.B.; Occhipinti, A.; Dawood, N. Meta databases of steel frame buildings for surrogate modelling and machine learning-based feature importance analysis. Resilient Cities Struct. 2024, 3, 20–43. [Google Scholar] [CrossRef]

- Liu, K.; Yu, M.; Liu, Y.; Chen, W.; Fang, Z.; Lim, J.B.P. Fire resistance time prediction and optimization of cold-formed steel walls based on machine learning. Thin-Walled Struct. 2024, 203, 112207. [Google Scholar] [CrossRef]

- Tang, P.; Dai, Y.; Lu, C.; Hu, S. A machine learning framework for predicting the axial capacity of cold-formed steel face-to-face built-up channel sections at elevated temperatures. Structures 2024, 68, 107144. [Google Scholar] [CrossRef]

- Degtyarev, V.V.; Hicks, S.J.; Ferreira, F.P.V.; Tsavdaridis, K.D. Probabilistic resistance predictions of laterally restrained cellular steel beams by natural gradient boosting. Thin-Walled Struct. 2024, 205, 112367. [Google Scholar] [CrossRef]

- Widanage, C.; Mohotti, D.; Lee, C.K.; Wijesooriya, K.; Meddage, D.P.P. Use of explainable machine learning models in blast load prediction. Eng. Struct. 2024, 312, 118271. [Google Scholar] [CrossRef]

- Anand, T.P.; Pandikkadavath, M.S.; Mangalathu, S.; Sahoo, D.R. Machine learning models for seismic analysis of buckling-restrained braced frames. J. Build. Eng. 2024, 98, 111398. [Google Scholar] [CrossRef]

- Fan, X.; Yang, L.; Zhao, X.; Yan, G.; Yang, Y.; Zhang, H.; Chen, S. Prediction of axial compressive capacity and interpretability analysis of web perforated Σ-shaped cold-formed steel. Structures 2024, 70, 107880. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Shamass, R.; Guarracino, F.; Mascolo, I.; Modano, M. Advanced predictive modeling of shear strength in stainless-steel column web panels using explainable AI insights. Results Eng. 2024, 24, 103454. [Google Scholar] [CrossRef]

- Aloko, M.N.; De Risi, R.; De Luca, F. Capacity prediction and failure mode classification of cold-formed steel built-up columns using machine learning methods. Thin-Walled Struct. 2025, 210, 112873. [Google Scholar] [CrossRef]

- Gharagoz, M.M.; Noureldin, M.; Kim, J. Explainable machine learning (XML) framework for seismic assessment of structures using Extreme Gradient Boosting (XGBoost). Eng. Struct. 2025, 327, 119621. [Google Scholar] [CrossRef]

- Su, A.; Cheng, J.; Wang, Y.; Pan, Y. Machine learning-based processes with active learning strategies for the automatic rapid assessment of seismic resistance of steel frames. Structures 2025, 72, 108227. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Ranasinghe, R.S.S.; Simwanda, L.; Meddage, D.P.P.; Mohotti, D. Machine learning prediction of web-crippling strength in cold-formed steel beams with staggered slotted perforations. Structures 2025, 71, 108079. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Shamass, R.; Guarracino, F.; Modano, M. Exploring the stainless-steel beam-to-column connections response: A hybrid explainable machine learning framework for characterization. Front. Struct. Civ. Eng. 2025, 19, 34–59. [Google Scholar] [CrossRef]

- Habib, A.; Houri, A.A.; Junaid, M.T.; Barakat, S. A systematic and bibliometric review on physics-based neural networks applications as a solution for structural engineering partial differential equations. Structures 2024, 69, 107361. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Haghighat, E.; Raissi, M.; Moure, A.; Gomez, H.; Juanes, R. A physics-informed deep learning framework for inversion and surrogate modeling in solid mechanics. Comput. Methods Appl. Mech. Eng. 2021, 379, 113741. [Google Scholar] [CrossRef]

- Lu, L.; Meng, X.; Mao, Z.; Karniadakis, G.E. DeepXDE: A deep learning library for solving differential equations. SIAM Rev. 2021, 63, 208–228. [Google Scholar] [CrossRef]

- Pak, M.; Kim, S. A review of deep learning in image recognition. In Proceedings of the 4th International Conference on Computer Applications and Information Processing Technology (CAIPT), Kuta Bali, Indonesia, 8–10 August 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Olsson, F. A Literature Survey of Active Machine Learning in the Context of Natural Language Processing. Swed. Inst. Comput. Sci. Tech. Rep. 2009, 1, 59. [Google Scholar]

- Weiss, K.; Khoshgoftaar, T.M.; Wang, D. A survey of transfer learning. J. Big Data 2016, 3, 9. [Google Scholar] [CrossRef]

- Hospedales, T.; Antoniou, A.; Micaelli, P.; Storkey, A. Meta-learning in neural networks: A survey. IEEE Trans. Pattern Anal. Mach. Intell. 2021, 44, 5149–5169. [Google Scholar]

- Farahani, A.; Voghoei, S.; Rasheed, K.; Arabnia, H.R. A brief review of domain adaptation. In Advances in Data Science and Information Engineering: Proceedings from ICDATA 2020 and IKE 2020; Springer: Cham, Switzerland, 2021; pp. 877–894. [Google Scholar]

- Khodabakhshian, A.; Puolitaival, T.; Kestle, L. Deterministic and probabilistic risk management approaches in construction projects: A systematic literature review and comparative analysis. Buildings 2023, 13, 1312. [Google Scholar] [CrossRef]

- Harrison, R.L. Introduction to Monte Carlo simulation. AIP Conf. Proc. 2010, 1204, 17. [Google Scholar] [CrossRef]

- Gal, Y.; Ghahramani, Z. Dropout as a Bayesian approximation: Representing model uncertainty in deep learning. In Proceedings of the 33rd International Conference on Machine Learning (ICML), New York, NY, USA, 20–22 June 2016; Volume 48, pp. 1050–1059. Available online: https://proceedings.mlr.press/v48/gal16.html (accessed on 23 March 2025).

- Marrel, A.; Iooss, B. Probabilistic surrogate modeling by Gaussian process: A review on recent insights in estimation and validation. Reliab. Eng. Syst. Saf. 2024, 247, 110094. [Google Scholar]

- Sudret, B.; Marelli, S.; Wiart, J. Surrogate models for uncertainty quantification: An overview. In Proceedings of the 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 793–797. [Google Scholar]

- García-Risueño, P.; Ibáñez, P.E. A review of high performance computing foundations for scientists. Int. J. Mod. Phys. C 2012, 23, 1230001. [Google Scholar]

- Parekh, R.; Mitchell, O. Progress and obstacles in the use of artificial intelligence in civil engineering: An in-depth review. Int. J. Sci. Res. Arch. 2024, 13, 1059–1080. [Google Scholar]

- Lundberg Patel, D.; Raut, G.; Cheetirala, S.N.; Nadkarni, G.N.; Freeman, R.; Glicksberg, B.S.; Timsina, P.; Klang, E. Cloud platforms for developing generative AI solutions: A scoping review of tools and services. arXiv 2024, arXiv:2412.06044. [Google Scholar]

- American Society of Civil Engineers (ASCE). Policy Statement 573—Artificial Intelligence and Engineering Responsibility; American Society of Civil Engineers: Reston, VA, USA, 2024. Available online: https://www.asce.org/advocacy/policy-statements/ps573---artificial-intelligence-and-engineering-responsibility (accessed on 25 March 2025).

- American Society of Civil Engineers (ASCE). AI and Civil Engineering; American Society of Civil Engineers: Reston, VA, USA, 2024. Available online: https://www.asce.org/topics/ai-and-civil-engineering (accessed on 25 March 2025).

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and adoption challenges of AI in the construction industry: A PRISMA review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- International Organization for Standardization/International Electrotechnical Commission (ISO/IEC) Joint Technical Committee 1, Subcommittee 42 (JTC 1/SC 42). Artificial Intelligence—Overview of Trustworthiness; ISO: Geneva, Switzerland, 2023. Available online: https://www.iso.org/committee/6794475.html (accessed on 25 March 2025).

- WorkOrb. Barriers to Adopting AI in AEC Firms. WorkOrb Blog. 2024. Available online: https://www.workorb.com/blog/barriers-to-adopting-ai-in-aec-firms (accessed on 25 March 2025).

- RICS. To AI or Not to AI: Five Trends in the Adoption of AI in Construction; Royal Institution of Chartered Surveyors: London, UK, 2024. Available online: https://www.rics.org/news-insights/wbef/to-ai-or-not-to-ai-five-trends-in-the-adoption-of-ai-in-construction (accessed on 25 March 2025).

- American Society of Civil Engineers (ASCE). What Do Civil Engineers Need to Know About Artificial Intelligence? Civ. Eng. Mag. 2024, 94, pp. 46–53. Available online: https://www.asce.org/publications-and-news/civil-engineering-source/civil-engineering-magazine/issues/magazine-issue/article/2024/11/what-do-civil-engineers-need-to-know-about-artificial-intelligence (accessed on 25 March 2025).

- Habib, A.; Yildirim, U. Developing a physics-informed and physics-penalized neural network model for preliminary design of multi-stage friction pendulum bearings. Eng. Appl. Artif. Intell. 2022, 113, 104953. [Google Scholar] [CrossRef]

- Yao, H.; Gao, Y.; Liu, Y. FEA-Net: A physics-guided data-driven model for efficient mechanical response prediction. Comput. Methods Appl. Mech. Eng. 2020, 363, 112892. [Google Scholar] [CrossRef]

| ML Category | Core Principle | Common Algorithms | Applications in Structural Engineering | Limitations |

|---|---|---|---|---|

| Supervised Learning | Learns from labeled datasets to predict outcomes | Linear Regression, Random Forest, ANN | Material property estimation, damage classification, load prediction | Requires large, labeled datasets; limited in extrapolation |

| Unsupervised Learning | Finds hidden patterns or groupings in unlabeled data | K-means, PCA, Autoencoders | Structural health monitoring, design clustering, pattern discovery in sensor data | Results may lack clear interpretation; requires expert analysis |

| Reinforcement Learning | Learns via trial-and-error interactions to maximize rewards over time | Q-learning, Deep Q-Networks | Real-time structural control, decision-making under uncertainty, adaptive load redistribution | High computational cost; limited adoption due to training complexity |

| Detailed Overview | Outcomes |

|---|---|

| Citations | 50,893 |

| Authors | 1277 |

| Organization | 1367 |

| Countries | 85 |

| Journal | 159 |

| Documents | 2291 |

| Average citations per year | 2035.72 |

| Average citations per document | 22.21 |

| Time span | 1994–2025 |

| Technique | Strengths | Limitations | Key Structural Applications |

| Machine Learning (ML) | - Rapid prediction of structural responses once trained. - Capable of handling large, nonlinear, high-dimensional datasets. - Useful for surrogate modeling, failure classification, and load capacity estimation. | - Often acts as a “black box” with low interpretability. - Requires large and high-quality labeled datasets. - Limited generalization outside trained domains. | - Performance prediction under complex loads. - Data-driven structural health monitoring. - Load-carrying capacity and failure mode prediction. |

| Inverse Machine Learning (IML) | - Directly maps performance goals to optimal design parameters. - Reduces manual iteration in parametric design. - Efficient for optimization in multi-variable, constrained problems. | - Inverse problems can be ill-posed and unstable. - Often requires regularization or surrogate models to ensure convergence. - Experimental validation still limited in structural contexts. | - Automated design of cross-sections and steel profiles. - Topology optimization. - Material and microstructure tuning in steel alloy design. |

| Explainable AI (XAI) | - Automated design of cross-sections and steel profiles. - Topology optimization. - Material and microstructure tuning in steel alloy design. | - Still emerging in regulatory practice. - Trade-off between complexity and explainability. - Interpretations can be misused if not domain-verified. | - Code validation and transparency for AI-driven designs. - SHAP/LIME interpretation of failure risk. - Engineering decision support in safety-critical systems. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarfarazi, S.; Mascolo, I.; Modano, M.; Guarracino, F. Application of Artificial Intelligence to Support Design and Analysis of Steel Structures. Metals 2025, 15, 408. https://doi.org/10.3390/met15040408

Sarfarazi S, Mascolo I, Modano M, Guarracino F. Application of Artificial Intelligence to Support Design and Analysis of Steel Structures. Metals. 2025; 15(4):408. https://doi.org/10.3390/met15040408

Chicago/Turabian StyleSarfarazi, Sina, Ida Mascolo, Mariano Modano, and Federico Guarracino. 2025. "Application of Artificial Intelligence to Support Design and Analysis of Steel Structures" Metals 15, no. 4: 408. https://doi.org/10.3390/met15040408

APA StyleSarfarazi, S., Mascolo, I., Modano, M., & Guarracino, F. (2025). Application of Artificial Intelligence to Support Design and Analysis of Steel Structures. Metals, 15(4), 408. https://doi.org/10.3390/met15040408