Intermetallic Phase Control in Cast Aluminum Alloys by Utilizing Heterogeneous Nucleation on Oxides

Abstract

1. Introduction

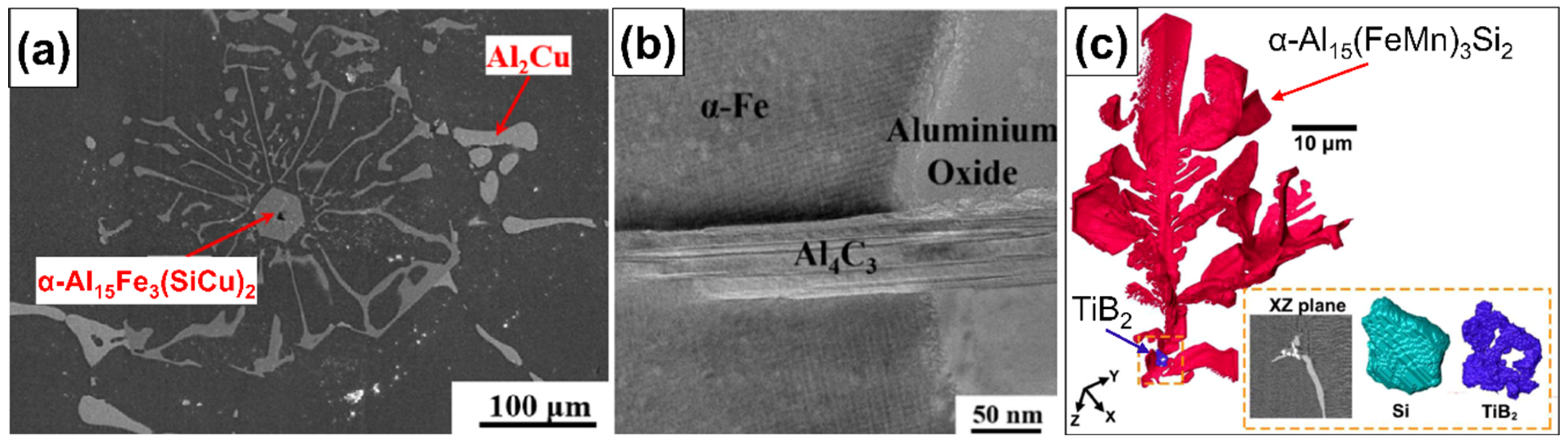

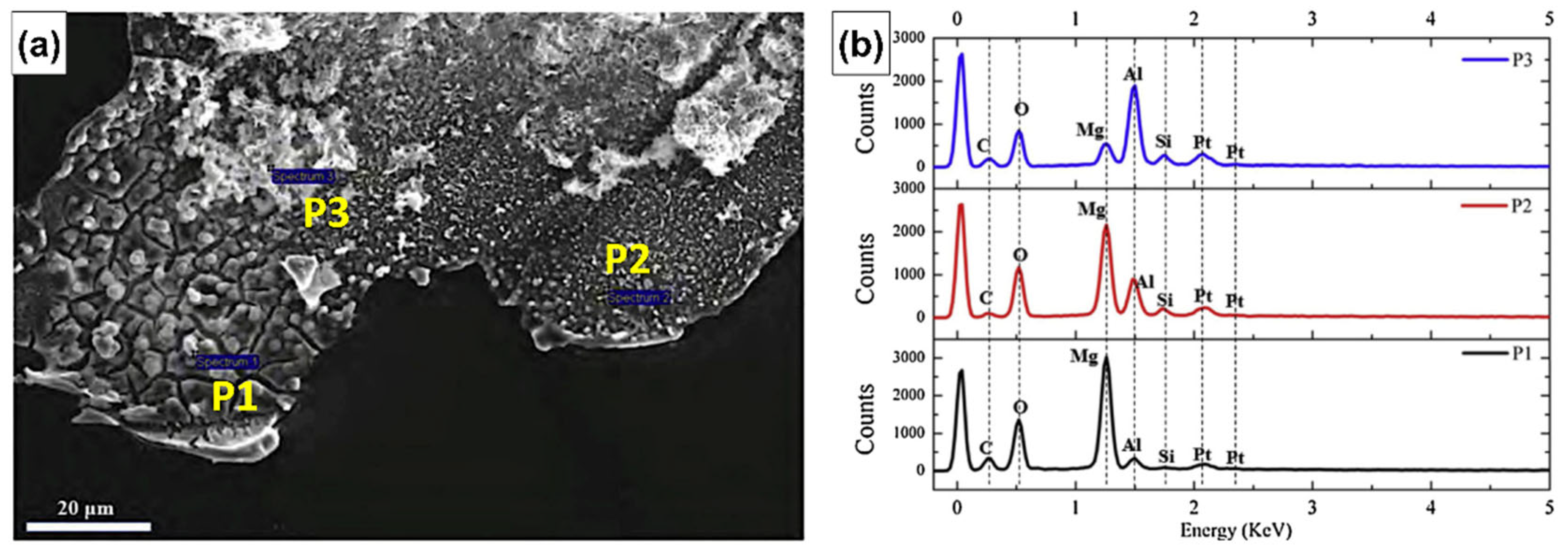

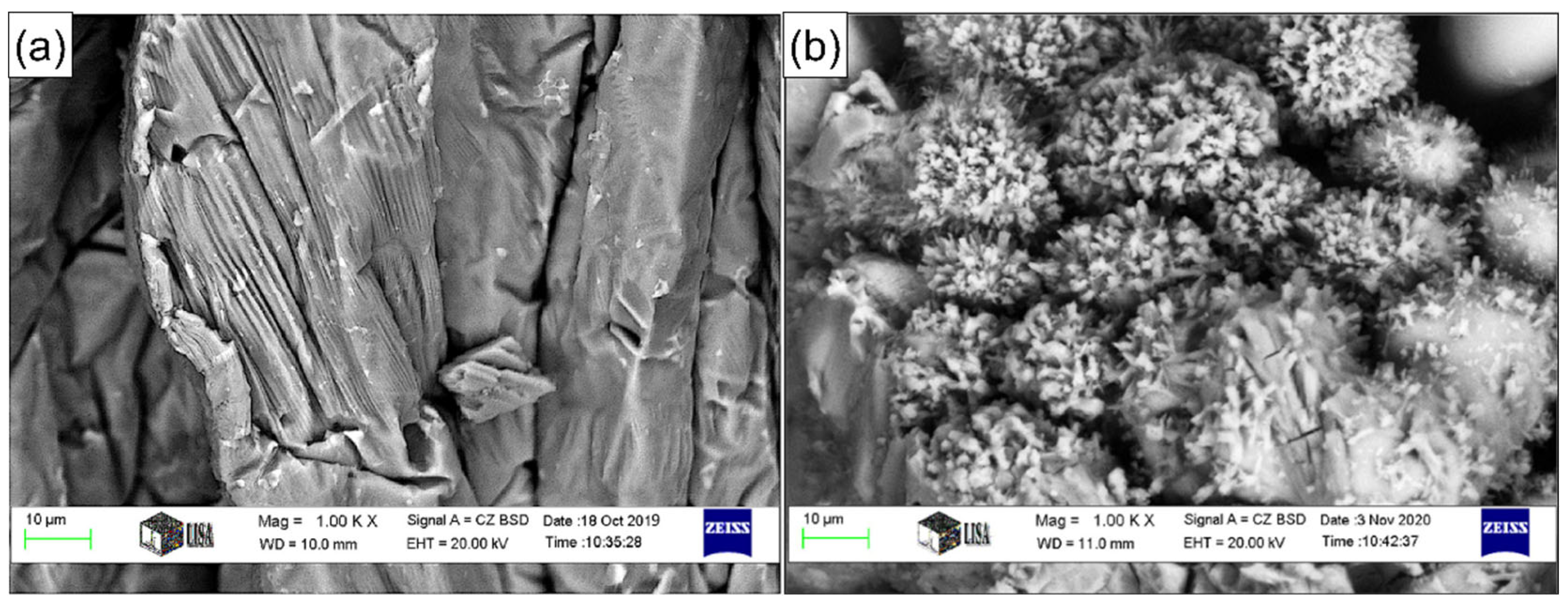

2. Oxides in Casting Aluminum Alloys

3. Heterogeneous Nucleation of Intermetallic Particles on Oxides

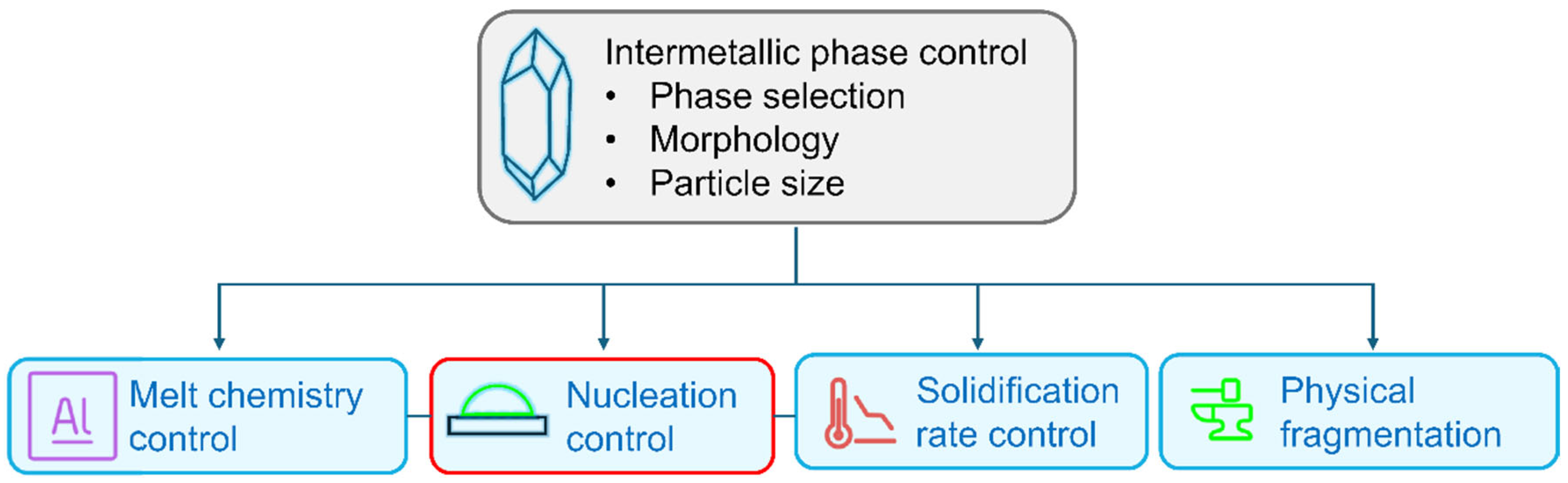

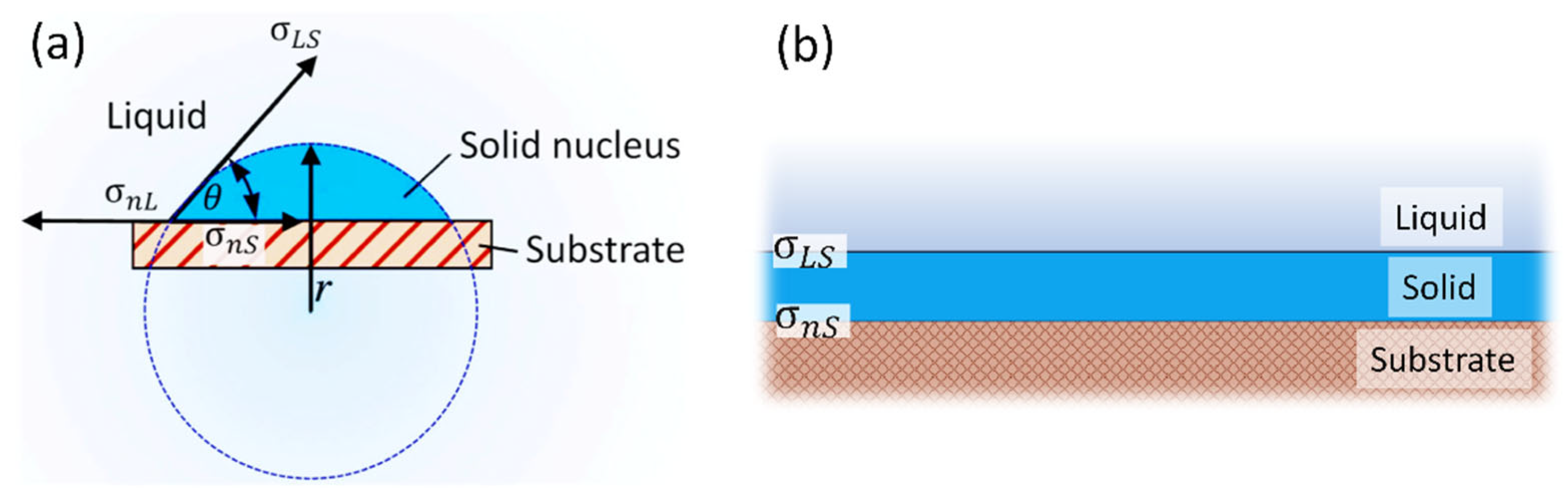

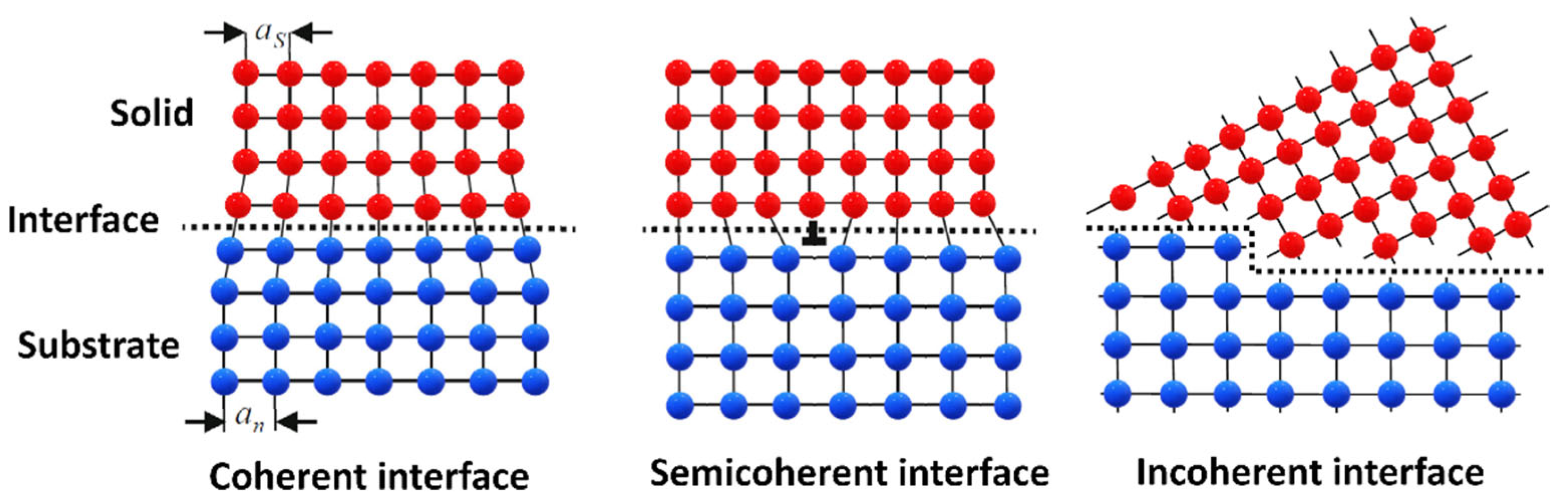

3.1. The Potency of Oxide Phases to Heterogeneously Nucleate Intermetallics

3.2. Experimental Evidence of Intermetallic Nucleation on Oxide Phases

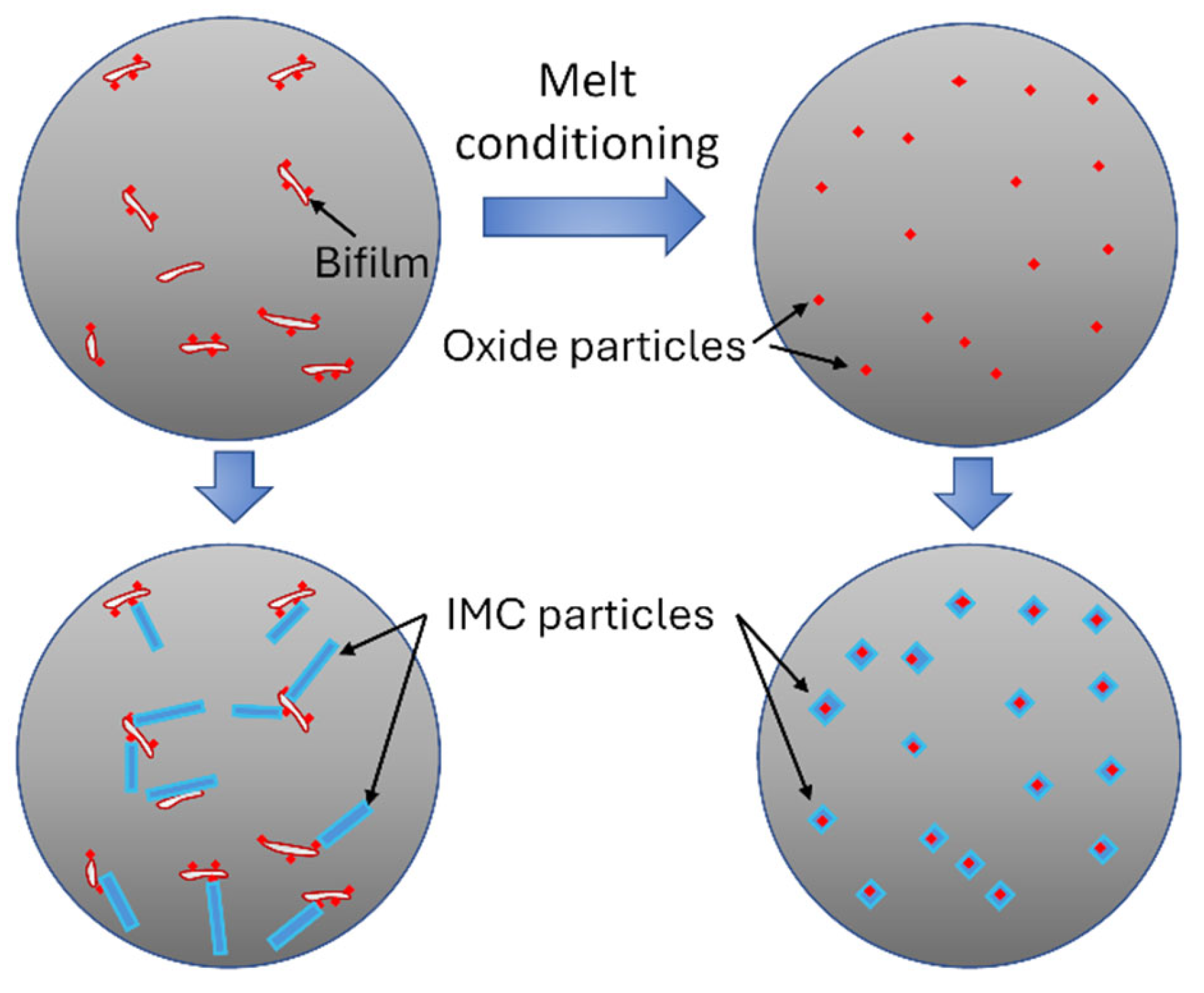

4. Methods of Melt Conditioning to Gain a Favorable Oxide Dispersion

4.1. Ultrasonic Melt Treatment

4.2. Intensive Melt Shearing

4.3. Melt Superheating

4.4. In Situ Oxide Formation by Chemical Reaction

4.5. Ex Situ Oxide Addition

5. Conclusions and Outlook

- Oxides are generally present in liquid aluminum alloys in the form of double oxide films that can be interpreted as sites of oxide particle agglomeration. Novel melt treatment methods should aim to transform these agglomerations into well-dispersed particles through the fragmentation of the bifilms. Using this approach holds the potential to simultaneously mitigate the negative effects of oxide inclusions and coarse IMCs.

- Ultrasonic melt processing and intensive melt shearing are sustainable melt treatment technologies that provide microstructural refinement without the need for any additives (master alloys, fluxes, etc.). These treatment methods can increase the tolerance of the given alloy to impurity elements, which enables the utilization of an increased portion of secondary alloys to produce quality castings. However, more research is needed on how ultrasonic melt treatment and intensive melt shearing affects double oxide film defects and whether these processing techniques make it possible to eliminate bifilm defects completely, which would enable the production of castings of unprecedented quality. Research should focus on increasing the efficiency of transforming bifilms into fine oxide particles.

- It should be examined whether the application of small quantities of in situ oxide-forming reactants is capable of refining intermetallic phases in casting aluminum alloys. The minimum quantity of reactants that can refine intermetallics through in situ oxide-forming reactions is currently not known for most aluminum alloy and reactant combinations. Also, combining in situ oxide-forming reactions with melt processing techniques like ultrasonic melt processing and intensive melt shearing can result in increased refining efficiency.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Reaction No. | [kJ/mol] | Notes | |

|---|---|---|---|

| (1) | −1129.07 | −913.56 | α-Al2O3 |

| −1114.20 | −903.51 | γ-Al2O3 | |

| (2) | −950.52 | −787.94 | α-Al2O3 |

| −928.22 | −772.85 | γ-Al2O3 | |

| (3) | −1217.50 | −992.74 | liquid Mg |

| −1483.87 | −1068.21 | Mg vapor | |

| (4) | −132.65 | −118.77 | α-Al2O3 (no data for am-Al2O3) |

| −154.96 | −133.86 | γ-Al2O3 (no data for am-Al2O3) | |

| (5) | −1162.73 | −948.08 | - |

| (6) | −1144.47 | −933.18 | - |

| (7) | −23.11 | −29.44 | α-Al2O3 |

| (15) | −262.24 | −236.55 | β-quartz |

| (16) | −414.93 | −383.78 | β-quartz |

| (17) | −521.41 | −472.12 | β-quartz, α-Al2O3 |

| (18) | −567.63 | −531.00 | β-quartz |

References

- Luo, A.A.; Sachdev, A.K.; Apelian, D. Alloy Development and Process Innovations for Light Metals Casting. Mater. Process. Technol. 2022, 306, 117606. [Google Scholar] [CrossRef]

- Lehmhus, D. Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part I: Changing Markets, Changing Products. Metals 2022, 12, 165–166. [Google Scholar]

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and Applications of Aluminum Alloys for Aerospace Industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Ducker Aluminum Content in Passenger Vehicles (Europe). 2023. Available online: https://european-aluminium.eu/wp-content/uploads/2023/05/2023_04_Aluminum-Content_Ducker-Study_EA-Public-Summary_190423.pdf (accessed on 1 December 2024).

- Wang, Q.G.; Wang, A.; Coryell, J. Ultra-Large Aluminum Shape Casting: Opportunities and Challenges. China Foundry 2024, 21, 397–408. [Google Scholar] [CrossRef]

- Burggräf, P.; Bergweiler, G.; Kehrer, S.; Krawczyk, T.; Fiedler, F. Mega-Casting in the Automotive Production System: Expert Interview-Based Impact Analysis of Large-Format Aluminium High-Pressure Die-Casting (HPDC) on the Vehicle Production. J. Manuf. Process. 2024, 124, 918–935. [Google Scholar] [CrossRef]

- Raabe, D.; Ponge, D.; Uggowitzer, P.; Roscher, M.; Paolantonio, M.; Liu, C.; Antrekowitsch, H.; Kozeschnik, E.; Seidmann, D.; Gault, B.; et al. Making Sustainable Aluminum by Recycling Scrap: The Science of “Dirty” Alloys. Prog. Mater. Sci. 2022, 128, 100947. [Google Scholar] [CrossRef]

- Nunes, H.; Emadinia, O.; Soares, R.; Vieira, M.F.; Reis, A. Adding Value to Secondary Aluminum Casting Alloys: A Review on Trends and Achievements. Materials 2023, 16, 895. [Google Scholar] [CrossRef]

- Zhu, H.; Xia, C.; Zhang, H.; Zhao, D.; Wang, M.; Wang, H. Design of Non-Heat Treatable High Pressure Die Casting Al Alloys: A Review. J. Mater. Eng. Perform. 2024, 33, 8601–8626. [Google Scholar] [CrossRef]

- Zhan, H.; Zeng, G.; Wang, Q.; Wang, C.; Wang, P.; Wang, Z.; Xu, Y.; Hess, D.; Crepeau, P.; Wang, J. Unified Casting (UniCast) Aluminum Alloy—A Sustainable and Low-Carbon Materials Solution for Vehicle Lightweighting. J. Mater. Sci. Technol. 2023, 154, 251–268. [Google Scholar] [CrossRef]

- Sacinti, M.; Cubuklusu, E.; Birol, Y. Effect of Iron on Microstructure and Mechanical Properties of Primary AlSi7Mg0.3 Alloy. Int. J. Cast. Met. Res. 2017, 30, 96–102. [Google Scholar] [CrossRef]

- Liu, K.; Cao, X.; Chen, X.G. Effects of Iron-Rich Intermetallics on Tensile Deformation of Al-Cu 206 Cast Alloys. Metall. Mater. Trans. B 2015, 46, 1566–1575. [Google Scholar] [CrossRef]

- Ferraro, S.; Timelli, G. Influence of Sludge Particles on the Tensile Properties of Die-Cast Secondary Aluminum Alloys. Metall Mater. Trans. B 2015, 46, 1022–1034. [Google Scholar] [CrossRef]

- Elsharkawi, E.A.; Abdelaziz, M.H.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Effect of β-Al5FeSi and π-Al8Mg3FeSi6 Phases on the Impact Toughness and Fractography of Al–Si–Mg-Based Alloys. Int. J. Metalcast. 2018, 12, 148–163. [Google Scholar] [CrossRef]

- Mathew, J.; Remy, G.; Williams, M.A.; Tang, F.; Srirangam, P. Effect of Fe Intermetallics on Microstructure and Properties of Al-7Si Alloys. JOM 2019, 71, 4362–4369. [Google Scholar] [CrossRef]

- Zahedi, H.; Emamy, M.; Razaghian, A.; Mahta, M.; Campbell, J.; Tiryakioǧlu, M. The Effect of Fe-Rich Intermetallics on the Weibull Distribution of Tensile Properties in a Cast Al-5 Pct Si-3 Pct Cu-1 Pct Fe-0.3 Pct Mg Alloy. Metall. Mater. Trans. A 2007, 38, 659–670. [Google Scholar] [CrossRef]

- Mahta, M.; Emamy, M.; Cao, X.; Campbell, J. Overview of β-Al5FeSi Phase in Al-Si Alloys. Materials Science Research Trends; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2008; pp. 251–271. [Google Scholar]

- Puncreobutr, C.; Lee, P.D.; Kareh, K.M.; Connolley, T.; Fife, J.L.; Phillion, A.B. Influence of Fe-Rich Intermetallics on Solidification Defects in Al-Si-Cu Alloys. Acta Mater. 2014, 68, 42–51. [Google Scholar] [CrossRef]

- Lu, L.; Dahle, A.K. Iron-Rich Intermetallic Phases and Their Role in Casting Defect Formation in Hypoeutectic Al-Si Alloys. Metall. Mater. Trans. A 2005, 36, 819–935. [Google Scholar] [CrossRef]

- Bas, E.N.; Alper, S.; Tuncay, T.; Dispinar, D.; Kirtay, S. Influence of Melt Quality on the Formation of Fe Intermetallic in A360 Alloy. Arch. Foundry Eng. 2022, 22, 53–59. [Google Scholar] [CrossRef]

- Khalifa, W.; Samuel, A.M.; Samuel, F.H.; Doty, H.W.; Valtierra, S. Metallographic Observations of β-AlFeSi Phase and Its Role in Porosity Formation in Al-7%Si Alloys. Int. J. Cast Met. Res. 2006, 19, 156–166. [Google Scholar] [CrossRef]

- Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Beta Al5FeSi Phase Platelets-Porosity Formation Relationship in A319.2 Type Alloys. Int. J. Metalcast. 2018, 12, 55–70. [Google Scholar] [CrossRef]

- Taylor, J.A.; Schaffer, G.B.; Stjohn, D.H. The Role of Iron in the Formation of Porosity in Al-Si-Cu-Based Casting Alloys: Part I. Initial Experimental Observations. Metall. Mater. Trans. A 1999, 30, 1643–1650. [Google Scholar]

- Cinkilic, E.; Ridgeway, C.D.; Yan, X.; Luo, A.A. A Formation Map of Iron-Containing Intermetallic Phases in Recycled Cast Aluminum Alloys. Metall. Mater. Trans. A 2019, 50, 5945–5956. [Google Scholar] [CrossRef]

- Taylor, J.A. Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys. Proc. Mat. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

- Sigworth, G.K.; Donahue, R.J. The Metallurgy of Aluminum Alloys for Structural High-Pressure Die Castings. Int. J. Metalcast. 2020, 15, 1031–1046. [Google Scholar] [CrossRef]

- Becker, H.; Leineweber, A. Dealing with Fe in Secondary Al-Si Alloys Including Metal Melt Filtration. In Multifunctional Ceramic Filter Systems for Metal Melt Filtration; Springer International Publishing: Berlin/Heidelberg, Germany, 2024; pp. 191–213. ISBN 9783031409301. [Google Scholar]

- Belov, N.A.; Aksenov, A.A.; Eskin, D.G. Iron in Aluminium Alloys; CRC Press: Boca Raton, FL, USA, 2002; ISBN 9780429189906. [Google Scholar]

- Allen, C.M.; O’Reilly, K.A.Q.; Cantor, B.; Evans, P.V. Intermetallic Phase Selection in 1XXX Al Alloys. Prog. Mater. Sci. 1998, 43, 89–170. [Google Scholar] [CrossRef]

- Que, Z.; Wang, Y.; Mendis, C.L.; Fang, C.; Xia, J.; Zhou, X.; Fan, Z. Understanding Fe-Containing Intermetallic Compounds in Al Alloys: An Overview of Recent Advances from the LiME Research Hub. Metals 2022, 12, 1677. [Google Scholar] [CrossRef]

- Sigworth, G.K. Refining of Secondary Aluminum: Important Chemical Factors. JOM 2021, 73, 2594–2602. [Google Scholar] [CrossRef]

- Wiesner, S. Cast Alloy. Aluminium Rheinfelden Alloys GmbH. EP3235916B1, 19 April 2016. [Google Scholar]

- Liu, C.; Jiao, X.; Nishat, H.; Akhtar, S.; Wiesner, S.; Guo, Z.; Xiong, S. Characteristics of Fe-Rich Intermetallics Compounds and Their Influence on the Cracking Behavior of a Newly Developed High-Pressure Die Cast Al–4Mg–2Fe Alloy. J. Alloys Compd. 2021, 854, 157121. [Google Scholar] [CrossRef]

- Aluminium Rheinfelden Alloys Castaduct. Available online: https://rheinfelden-alloys.eu/en/alloys/castaduct/ (accessed on 1 December 2024).

- Sigworth, G. Aluminum Casting Alloys and Casting Processes. Alum. Sci. Technol. 2018, 2, 119–142. [Google Scholar] [CrossRef]

- Samuel, E.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Intermetallics Formation, Hardness and Toughness of A413.1 Type Alloys: Role of Melt and Aging Treatments. Inter. J. Met. 2023, 17, 1095–1113. [Google Scholar] [CrossRef]

- Slyudova, A.; Trudonoshyn, O.; Prach, O.; Lisovskii, V. Morphology and Nucleation of Intermetallic Phases in Casting Al—Mg—Si Alloys. Metallogr. Microstruct. Anal. 2020, 9, 873–883. [Google Scholar] [CrossRef]

- Ji, S.; Wang, Y.U.N.; Watson, D.; Fan, Z. Microstructural Evolution and Solidification Behavior of Al-Mg-Si Alloy in High-Pressure Die Casting. Metall. Mater. Trans. A 2013, 44, 3185–3197. [Google Scholar] [CrossRef]

- Talamantes-Silva, M.A.; Rodríguez, A.; Talamantes-Silva, J.; Valtierra, S.; Colás, R. Characterization of an Al-Cu Cast Alloy. Mater. Charact. 2008, 59, 1434–1439. [Google Scholar] [CrossRef]

- Samuel, E.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Highlights on the Role of Fe, Sr, and Solidification Time on Porosity Formation in Al–Si Cast Alloys. Int. J. Met. 2024, 1–22. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Ibrahim, M.F.; Samuel, E.; Samuel, A.M.; Samuel, F.H.; Doty, H.W. Assessment of the Effect of Mg Addition on the Solidification Behavior, Tensile and Impact Properties of Al–Si–Cu Cast Alloys. Int. J. Met. 2023, 17, 82–108. [Google Scholar] [CrossRef]

- Fortini, A.; Lattanzi, L.; Merlin, M.; Garagnani, G.L. Comprehensive Evaluation of Modification Level Assessment in Sr-Modified Aluminium Alloys. Inter. J. Met. 2018, 12, 697–711. [Google Scholar] [CrossRef]

- Samuel, E.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H.; Samuel, E.; et al. Intermetallic Phases in Al–Si Based Cast Alloys: New Perspective. Int. J. Cast Met. Res. 2014, 27, 107–114. [Google Scholar] [CrossRef]

- Ganesh, M.R.S.; Reghunath, N.J.; Levin, M.; Prasad, A.; Doondi, S.; Shankar, K.V. Strontium in Al–Si–Mg Alloy: A Review. Met. Mat. Int. 2021, 28, 1–40. [Google Scholar] [CrossRef]

- Samuel, A.M.; Samuel, E.; Songmene, V.; Samuel, F.H. A Comparative Study of Grain Refining of Al-(7–17%) Si Cast Alloys Using Al-10% Ti and Al-4% B Master Alloys. Materials 2023, 16, 2867. [Google Scholar] [CrossRef]

- Jaffarnia, A.; Ghomashchi, R. AlTiSi Intermetallics: Morphology and Its Role on Nozzle Blockage during Semi-Continous Casting. Inter. J. Met. 2015, 9, 61–68. [Google Scholar] [CrossRef]

- Samuel, A.M.; Mohamed, S.S.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Grain Refining of Al-Si Alloys Using Al-10% Ti Master Alloy: Role of Zr Addition. Int. J. Cast Met. Res. 2019, 32, 46–58. [Google Scholar] [CrossRef]

- Lazaro-Nebreda, J.; Patel, J.B.; Chang, I.T.H.; Stone, I.C.; Fan, Z. Solidification Processing of Scrap Al-Alloys Containing High Levels of Fe. In Proceedings of the IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2019; Volume 529. [Google Scholar]

- Liu, Y.; Luo, L.; Han, C.; Ou, L.; Wang, J.; Liu, C. Effect of Fe, Si and Cooling Rate on the Formation of Fe- and Mn-Rich Intermetallics in Al-5Mg-0.8Mn Alloy. J. Mater. Sci. Technol. 2016, 32, 305–312. [Google Scholar] [CrossRef]

- Kishor, M.; Chopra, K.; Ayyagari, K.P.R. Tackling Fe-Rich Intermetallics in Al-Si Alloy: A Critical Review. Trans. Ind. Inst. Met. 2023, 77, 3031–3036. [Google Scholar] [CrossRef]

- Balasubramani, N.; Moodispaw, M.; Luo, A.A. Controlling the Fe-Intermetallic Phases and Mechanical Properties of Secondary Al-9Si-1Fe Alloy with Cr and Mn Additions. J. Mater. Sci. Technol. 2024, 206, 135–152. [Google Scholar] [CrossRef]

- Kishor, M.; Ram, K.Y.P.; Rao, A.K.P.; Nahid, S.A.G.; Ramavajjala, A.K. Synergistic Effect of Mo and V Addition on Al–Si Alloys Containing High Iron Impurity. Inter. J. Met. 2024, 18, 3538–3548. [Google Scholar] [CrossRef]

- Balasubramani, N.; Moodispaw, M.; Cinkilic, E.; Miao, J.; Luo, A.A. Strontium Effects on the Formation of Iron-Intermetallic Phases in Secondary Al–9Si–0.6Fe Alloys. Metall. Mater. Trans. A 2023, 55, 550–568. [Google Scholar] [CrossRef]

- Song, D.; Zhao, Y.; Jia, Y.; Li, X.; Fu, Y. Synergistic Effects of Mn and B on Iron-Rich Intermetallic Modification of Recycled Al Alloy. J. Mater. Res. Technol. 2023, 24, 527–541. [Google Scholar] [CrossRef]

- Song, D.F.; Zhao, Y.L.; Wang, Z.; Jia, Y.W.; Li, D.X.; Fu, Y.N.; Zhang, D.T.; Zhang, W.W. 3D Fe-Rich Phases Evolution and Its Effects on the Fracture Behavior of Al–7.0Si–1.2Fe Alloys by Mn Neutralization. Acta Metall. Sin. 2022, 35, 163–175. [Google Scholar] [CrossRef]

- Li, Z.; Limodin, N.; Tandjaoui, A.; Quaegebeur, P.; Zhu, X.; Balloy, D. Effect of Fe and Mn Content on the Microstructures and Tensile Behaviour of AlSi7Cu3 Alloy: Thermal Analysis and Tensile Tests. Met. Mat. Int. 2022, 28, 2118–2133. [Google Scholar] [CrossRef]

- Podprocká, R.; Bolibruchová, D. Iron Intermetallic Phases in the Alloy Based on Al-Si-Mg by Applying Manganese. Arch. Foundry Eng. 2017, 17, 217–221. [Google Scholar] [CrossRef]

- Ferraro, S.; Fabrizi, A.; Timelli, G. Evolution of Sludge Particles in Secondary Die-Cast Aluminum Alloys as Function of Fe, Mn and Cr Contents. Mater. Chem. Phys. 2015, 153, 168–179. [Google Scholar] [CrossRef]

- Moustafa, M.A.; Lepage, C.; Samuel, F.H.; Doty, H.W. Metallographic Observations on Phase Precipitation in Strontium-Modified Al-11.7% Si Alloys: Role of Alloying Elements. Int. J. Cast Met. Res. 2003, 15, 609–626. [Google Scholar] [CrossRef]

- Mikel, J.; Arribas, M.; Galarraga, H.; Garcia, M.; Cortazar, D.; Ellero, M.; Girot, F. Effects of Mn Addition, Cooling Rate and Holding Temperature on the Modification and Purification of Iron-Rich Compounds in AlSi10MnMg(Fe) Alloy. Heliyon 2023, 9, e13005. [Google Scholar] [CrossRef]

- Song, D.; Zhao, Y.; Jia, Y.; Li, R.; Zhou, N.; Zheng, K.; Fu, Y.; Zhang, W. Study of the Evolution Mechanisms of Fe-Rich Phases in Al-Si-Fe Alloys with Mn Modification Using Synchrotron X-Ray Imaging. J. Alloys. Compd. 2022, 915, 165378. [Google Scholar] [CrossRef]

- Liu, B.; Ma, C.; Li, L.; Yang, C.; Yu, N. Morphologies and Compositions of α–Al15Fe3Si2-Type Intermetallics in Al–Si–Fe–Mn–Cr Alloys. Inter. J. Met. 2022, 17, 1156–1164. [Google Scholar] [CrossRef]

- Fabrizi, A.; Timelli, G. The Influence of Cooling Rate and Fe/Cr Content on the Evolution of Fe-Rich Compounds in a Secondary Al-Si-Cu Diecasting Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2016, 117, 012017. [Google Scholar] [CrossRef]

- Gorny, A.; Manickaraj, J.; Cai, Z.; Shankar, S. Evolution of Fe Based Intermetallic Phases in Al-Si Hypoeutectic Casting Alloys: Influence of the Si and Fe Concentrations, and Solidification Rate. J. Alloys Compd. 2013, 577, 103–124. [Google Scholar] [CrossRef]

- Ourfali, M.F.; Todd, I.; Jones, H. Effect of Solidification Cooling Rate on the Morphology and Number per Unit Volume of Primary Mg2Si Particles in a Hypereutectic Al-Mg-Si Alloy. Metall. Mater. Trans. A 2005, 36, 1368–1372. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Gruzleski, J.E. The Effect of Solidification Condition and Chemistry on the Formation and Morphology of Complex Intermetallic Compounds in Aluminium—Silicon Alloys. Cast Metals. 1994, 6, 217–224. [Google Scholar] [CrossRef]

- Bolibruchova, D.; Podprocká, R. The Effect of Different Mn/Fe Ratio on Microstructure Alloy Based on Al-Si-Mg. Arch. Foundry Eng. 2019, 19, 15–20. [Google Scholar]

- Belmares-Perales, S.; Castro-Román, M.; Herrera-Trejo, M.; Ramirez-Vidaurri, L.E. Effect of Cooling Rate and Fe/Mn Weight Ratio on Volume Fractions of α-AlFeSi and β-AlFeSi Phases in Al-7.3Si-3.5Cu Alloy. Met. Mat. Int. 2008, 14, 307–314. [Google Scholar] [CrossRef]

- Que, Z.; Wang, Y.; Fan, Z. Formation of the Fe-Containing Intermetallic Compounds during Solidification of Al-5Mg-2Si-0.7Mn-1.1Fe Alloy. Metall. Mater. Trans. A 2018, 49, 2173–2181. [Google Scholar] [CrossRef]

- Que, Z.; Fang, C.; Mendis, C.L.; Wang, Y.; Fan, Z. Effects of Si Solution in θ-Al13Fe4 on Phase Transformation between Fe-Containing Intermetallic Compounds in Al Alloys. J. Alloys Compd. 2023, 932, 167587. [Google Scholar] [CrossRef]

- Jin, L.; Liu, K.; Chen, X.G. Evolution of Fe-Rich Intermetallics in Al-Si-Cu 319 Cast Alloy with Various Fe, Mo, and Mn Contents. Metall. Mater. Trans. B 2019, 50, 1896–1907. [Google Scholar] [CrossRef]

- Eidhed, W. Modification of β-Al5FeSi Compound in Recycled Al-Si-Fe Cast Alloy by Using Sr, Mg and Cr Additions. J. Mat. Sci. Technol. 2008, 24, 45–47. [Google Scholar]

- Santos, J.; Jarfors, A.E.W.; Dahle, A.K. Formation of Iron-Rich Intermetallic Phases in Al-7Si-Mg: Influence of Cooling Rate and Strontium Modification. Metall. Mater. Trans. A 2019, 50, 4148–4165. [Google Scholar] [CrossRef]

- Zhao, Y.; Jia, Y.; Huang, G.; Zhang, Z. Effect of B Addition on the Formation of Fe-Rich Phases in Al-Si-Fe Alloys. J. Alloys Compd. 2023, 930, 167426. [Google Scholar] [CrossRef]

- Nafisi, S.; Emadi, D.; Shehata, M.T.; Ghomashchi, R. Effects of Electromagnetic Stirring and Superheat on the Microstructural Characteristics of Al-Si-Fe Alloy. Mat. Sci. Eng. A 2006, 432, 71–83. [Google Scholar] [CrossRef]

- Fan, Z.; Fang, X.; Ji, S. Microstructure and Mechanical Properties of Rheo-Diecast (RDC) Aluminium Alloys. Mat. Sci. Eng. A 2005, 412, 298–306. [Google Scholar] [CrossRef]

- Feng, S.; Liotti, E.; Lui, A.; Wilson, M.D.; Grant, P.S. Nucleation Bursts of Primary Intermetallic Crystals in a Liquid Al Alloy Studied Using in Situ Synchrotron X-Ray Radiography. Acta Mater. 2021, 221, 117389. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Xue, C.; Miao, Y.; Hou, Q.; Meng, Y.; Yang, X.; Li, X. Quantifying the effects of cooling rates on Fe-rich intermetallics in recycled Al-Si-Cu alloys by machine learning. J. Alloys Compd. 2025, 1014, 178718. [Google Scholar] [CrossRef]

- Verma, A.; Kumar, S.; Grant, P.S.; O’Reilly, K.A.Q. Influence of Cooling Rate on the Fe Intermetallic Formation in an AA6063 Al Alloy. J. Alloys Compd. 2013, 555, 274–282. [Google Scholar] [CrossRef]

- Szczygiel, P.; Roven, H.J.; Reiso, O. On the Effect of SPD on Recycled Experimental Aluminium Alloys: Nanostructures, Particle Break-up and Properties. Mat. Sci. Eng. A 2005, 410–411, 261–264. [Google Scholar] [CrossRef]

- Shuai, G.; Zhang, M.; Li, Z.; Valiev, R.Z.; Medvedev, A.E.; Zhang, D.; Elhefnawey, M.; Chen, F.; Li, L. Microstructural Evolution and Superior Properties of Conductive Al–Fe Alloy Processed by ECAP. Int. J. Lightweight Mater. Manuf. 2023, 6, 552–562. [Google Scholar] [CrossRef]

- Farshidi, M.H.; Rifai, M.; Miyamoto, H. Microstructure Evolution of a Recycled Al–Fe–Si–Cu Alloy Processed by Tube Channel Pressing. Int. J. Miner. Metall. Mater. 2018, 25, 1166–1172. [Google Scholar] [CrossRef]

- Okeke, U.; Yilmazer, H.; Sato, S.; Boehlert, C.J. Strength Enhancement of an Aluminum Alloy through High Pressure Torsion. Mat. Sci. Eng. A 2019, 760, 195–205. [Google Scholar] [CrossRef]

- Tang, Y.; Tomita, Y.; Horita, Z. Mechanical Properties and Microstructures of Highly Fe-Containing AlMgSi Alloys Processed by Severe Plastic Deformation under High Pressure. Mater. Trans. 2023, 64, 448–457. [Google Scholar] [CrossRef]

- Duchaussoy, A.; Sauvage, X.; Edalati, K.; Horita, Z.; Renou, G.; Deschamps, A.; De Geuser, F. Structure and Mechanical Behavior of Ultrafine-Grained Aluminum-Iron Alloy Stabilized by Nanoscaled Intermetallic Particles. Acta Mater. 2019, 167, 89–102. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Ghanbari, M. Effect of Plastic Deformation and Semisolid Forming on Iron-Manganese Rich Intermetallics in Al-8Si-3Cu-4Fe-2Mn Alloy. J. Alloys Compd. 2010, 508, 315–319. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Parshizfard, E. Effect of Semi-Solid Forming on the Microstructure and Mechanical Properties of the Iron Containing Al-Si Alloys. J. Alloys Compd. 2011, 509, 7973–7978. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; Taylor & Francis Group, LLC: Boca Raton, FL, USA, 2015; ISBN 978-1-4665-7799-2. [Google Scholar]

- Eskin, D.G.; Tzanakis, I. High-Frequency Vibration and Ultrasonic Processing. In Solidification Processing of Metallic Alloys Under External Fields; Eskin, D.G., Mi, J., Eds.; Springer Nature: Cham, Switzerland, 2018; pp. 153–194. ISBN 978-3-319-94841-6. [Google Scholar]

- Priyadarshi, A.; Khavari, M.; Subroto, T.; Conte, M.; Prentice, P.; Pericleous, K.; Eskin, D.; Durodola, J.; Tzanakis, I. On the Governing Fragmentation Mechanism of Primary Intermetallics by Induced Cavitation. Ultrason. Sonochem. 2021, 70, 105260. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Tzanakis, I.; Eskin, D.; Mi, J.; Connolley, T. In Situ Observation of Ultrasonic Cavitation-Induced Fragmentation of the Primary Crystals Formed in Al Alloys. Ultrason. Sonochem. 2017, 39, 66–76. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Jie, J.; Gao, Y.; Lu, Y.; Li, T. Effects of Ultrasonic Treatment on the Formation of Iron-Containing Intermetallic Compounds in Al-12%Si-2%Fe Alloys. Intermetallics 2013, 42, 120–125. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Qian, M.; Das, A. Microstructural Modification of Recycled Aluminium Alloys by High-Intensity Ultrasonication: Observations from Custom Al–2Si–2Mg–1.2Fe–(0.5,1.0)Mn Alloys. J. Alloys Compd. 2020, 823, 153833. [Google Scholar] [CrossRef]

- Kim, S.B.; Jung, J.G.; Cho, Y.H.; Kim, S.H.; Euh, K.; Lee, J.M. Effect of Ultrasonic Melt Treatment on Solidification Microstructure of Al–5Ti–1B Alloy Containing Numerous Inoculant Particles. Met. Mat. Int. 2021, 28, 1549–1560. [Google Scholar] [CrossRef]

- Kim, J.K.; Rohatgi, P.K. Nucleation on Ceramic Particles in Cast Metal-Matrix Composites. Metall. Mater. Trans. A 2000, 31, 1295–1304. [Google Scholar] [CrossRef]

- Kaptay, G. Interfacial Aspects to Produce Particulate Reinforced Metal Matrix Composites. In Affordable Metal-Matrix Composites for High Performance Applications; Pabdey, A.B., Kendig, K.L., Watson, T.J., Eds.; TMS: Pittsburgh, PA, USA, 2001; pp. 72–99. [Google Scholar]

- Stawarz, M.; Dojka, M. Bifilm Inclusions in High Alloyed Cast Iron. Materials 2021, 14, 3067. [Google Scholar] [CrossRef]

- Xiao, S.; Xiao, Z.; Gao, X.; Zhao, D.; Dai, Z. Synergistic Effects of TiCp on Microstructure Refinement and Mechanical Enhancement in Al-Si-Cu-Ni-Mg Alloys. J. Alloys Compd. 2024, 1006, 176226. [Google Scholar] [CrossRef]

- Stefanescu, D.M.; Alonso, G.; Suarez, R. Recent Developments in Understanding Nucleation and Crystallization of Spheroidal Graphite in Iron-Carbon-Silicon Alloys. Metals 2020, 10, 221. [Google Scholar] [CrossRef]

- Götz, A.; Michels, L.; Akola, J. Density Functional Investigation of the Heterogeneous Nucleation of Graphite on Divalent Metal Oxides and Sulfides. Acta Mater. 2024, 282, 120427. [Google Scholar] [CrossRef]

- Alonso, G.; Stefanescu, D.M.; Bravo, B.; Suárez, R. Graphite Spheroids: The Place Where They Are Born. Inter. J. Met. 2024, 18, 1854–1868. [Google Scholar] [CrossRef]

- Campbell, J. The Pre-Existing Microcrack Population in Metals a Personal Overview. Procedia Struct. Integr. 2023, 43, 234–239. [Google Scholar] [CrossRef]

- Jia, Y.; Song, D.; Zhou, N.; Zheng, K.; Fu, Y.; Shu, D. The Growth Restriction Effect of TiCN Nanoparticles on Al-Cu-Zr Alloys via Ultrasonic Treatment. Ultrason. Sonochem. 2021, 80, 105829. [Google Scholar] [CrossRef]

- Campbell, J. Modification of Al-Si Alloys. Trans. Am. Foundry Soc. 2011, 119, 171–176. [Google Scholar]

- Khalifa, W.; Samuel, F.H.; Gruzleski, J.E.; Doty, H.W.; Valtierra, S. Nucleation of Fe-Intermetallic Phases in the Al-Si-Fe Alloys. Metall. Mater. Trans. A 2005, 36, 1017–1032. [Google Scholar] [CrossRef]

- Lui, A.; Grant, P.S.; Stone, I.C.; O’Reilly, K.A.Q. The Role of Grain Refiner in the Nucleation of AlFeSi Intermetallic Phases During Solidification of a 6xxx Aluminum Alloy. Metall. Mater. Trans. A 2019, 50, 5242–5252. [Google Scholar] [CrossRef]

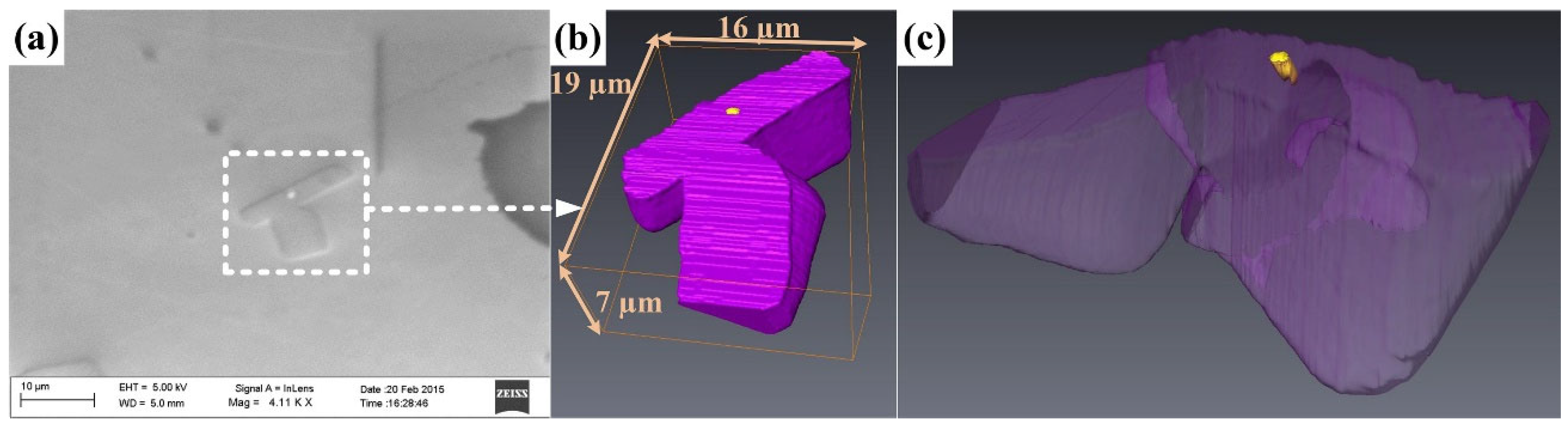

- Yang, W.; Ji, S.; Zhou, X.; Stone, I.; Scamans, G.; Thompson, G.E.; Fan, Z. Heterogeneous Nucleation of α-Al Grain on Primary α-AlFeMnSi Intermetallic Investigated Using 3D Sem Ultramicrotomy and HRTEM. Metall. Mater. Trans. A 2014, 45, 3971–3980. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, D.; Wang, H.; Li, X.; Chen, L.; Sun, Z.; Wang, Z.; Zhai, T.; Fu, Y.; Wang, Y.; et al. Revealing the Nucleation and Growth Mechanisms of Fe-Rich Phases in Al—Cu—Fe (-Si) Alloys under the Influence of Al—Ti—B. Intermetallics 2022, 146, 107584. [Google Scholar] [CrossRef]

- Wang, W.; Xu, R.; Xiang, L.; Han, Y.; Li, E.; Zhang, S.; Zheng, H. Effect of B4C Nanoparticles Addition on the Refinement of Fe-Rich Phase in ZL108 Alloy. Mater. Des. 2024, 247, 113424. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Timelli, G.; Bonollo, F. Influence of Melt Superheat, Sr Modifier, and Al-5Ti-1B Grain Refiner on Microstructural Evolution of Secondary Al-Si-Cu Alloys. Metall. Mater. Trans. A 2016, 47, 5510–5521. [Google Scholar] [CrossRef]

- Yu, J.M.; Hashimoto, T.; Li, H.T.; Wanderka, N.; Zhang, Z.; Cai, C.; Zhong, X.L.; Qin, J.; Dong, Q.P.; Nagaumi, H.; et al. Formation of Intermetallic Phases in Unrefined and Refined AA6082 Al Alloys Investigated by Using SEM-Based Ultramicrotomy Tomography. J. Mater. Sci. Technol. 2022, 120, 118–128. [Google Scholar] [CrossRef]

- Zhou, Y. Solidification Behaviour of Fe-Rich Intermetallic Compounds in Aluminium Alloys. Ph.D. Thesis, Brunel University, Uxbridge, UK, 2018. [Google Scholar]

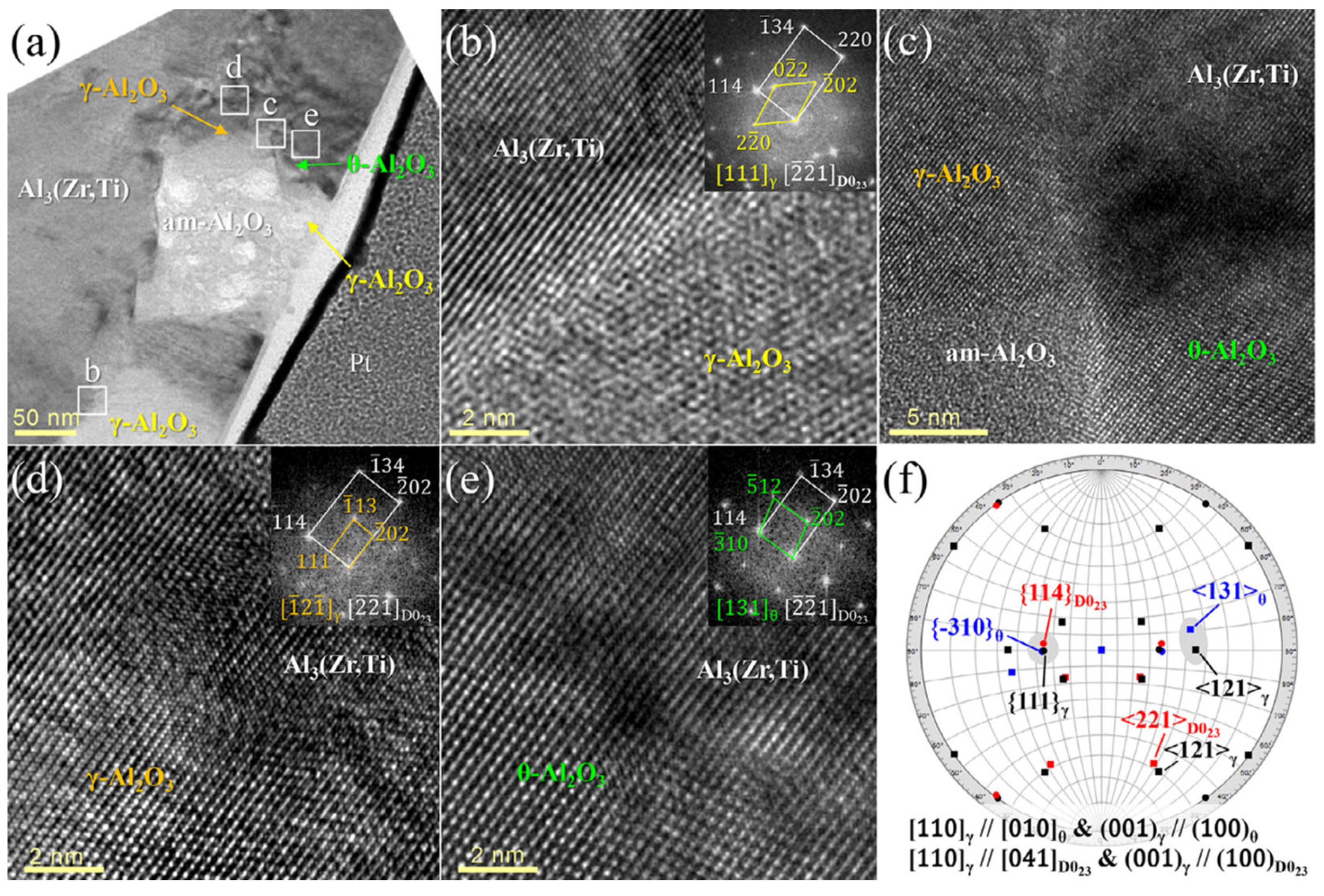

- Que, Z.; Wang, Y.; Fan, Z.; Hashimoto, T.; Zhou, X.R. Composition Templating for Heterogeneous Nucleation of Intermetallic Compounds. Sci. Rep. 2024, 14, 8968. [Google Scholar] [CrossRef]

- Kaptay, G. Beyond the Parallel Tangent Method to Predict the Composition of the First Nucleating Phase from Oversaturated Solutions. J. Phase Equilibria Diffus. 2023, 44, 445–455. [Google Scholar] [CrossRef]

- Feng, S.; Liotti, E.; Lui, A.; Wilson, M.D.; Connolley, T.; Mathiesen, R.H.; Grant, P.S. In-Situ X-Ray Radiography of Primary Fe-Rich Intermetallic Compound Formation. Acta Mater. 2020, 196, 759–769. [Google Scholar] [CrossRef]

- Que, Z.; Wang, Y.; Fan, Z.; Hashimoto, T.; Zhou, X. Enhanced Heterogeneous Nucleation of Al6(Fe,Mn) Compound in Al Alloys by Interfacial Segregation of Mn on TiB2 Particles Surface. Mater. Lett. 2022, 323, 132570. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, W.; Song, D.; Lin, B.; Shen, F.; Zheng, D.; Xie, C.X.; Sun, Z.; Fu, Y.; Li, R. Nucleation and Growth of Fe-Rich Phases in Al-5Ti-1B Modified Al-Fe Alloys Investigated Using Synchrotron X-Ray Imaging and Electron Microscopy. J. Mater. Sci. Technol. 2021, 80, 84–99. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Timelli, G.; Bonollo, F.; Arnberg, L. Influence of Grain Refiner Addition on the Precipitation of Fe-Rich Phases in Secondary AlSi7Cu3Mg Alloys. Inter. J. Met. 2017, 11, 294–304. [Google Scholar] [CrossRef]

- Wang, F.; Fan, Z. Characterization of AlN Inclusion Particles Formed in Commercial Purity Aluminum. Metall. Mater. Trans. A 2019, 50, 2519–2526. [Google Scholar] [CrossRef]

- Hudson, S.W.; Apelian, D. Inclusion Detection in Molten Aluminum: Current Art and New Avenues for in Situ Analysis. Inter. J. Met. 2016, 10, 315–321. [Google Scholar] [CrossRef]

- Que, Z.; Mendis, C.L. Effects of Native AlN Particles on Heterogeneous Nucleation in an Al-3Fe Alloy. Metall Mater Trans A 2021, 52, 553–559. [Google Scholar] [CrossRef]

- Niu, Z.; Que, Z.; Patel, J.B.; Fan, Z. Assessment and Improvement of Melt Quality of Recycled Secondary A357 Alloy by Application of the High Shear Melt Conditioning (HSMC) Technology. Crystals 2024, 14, 1044. [Google Scholar] [CrossRef]

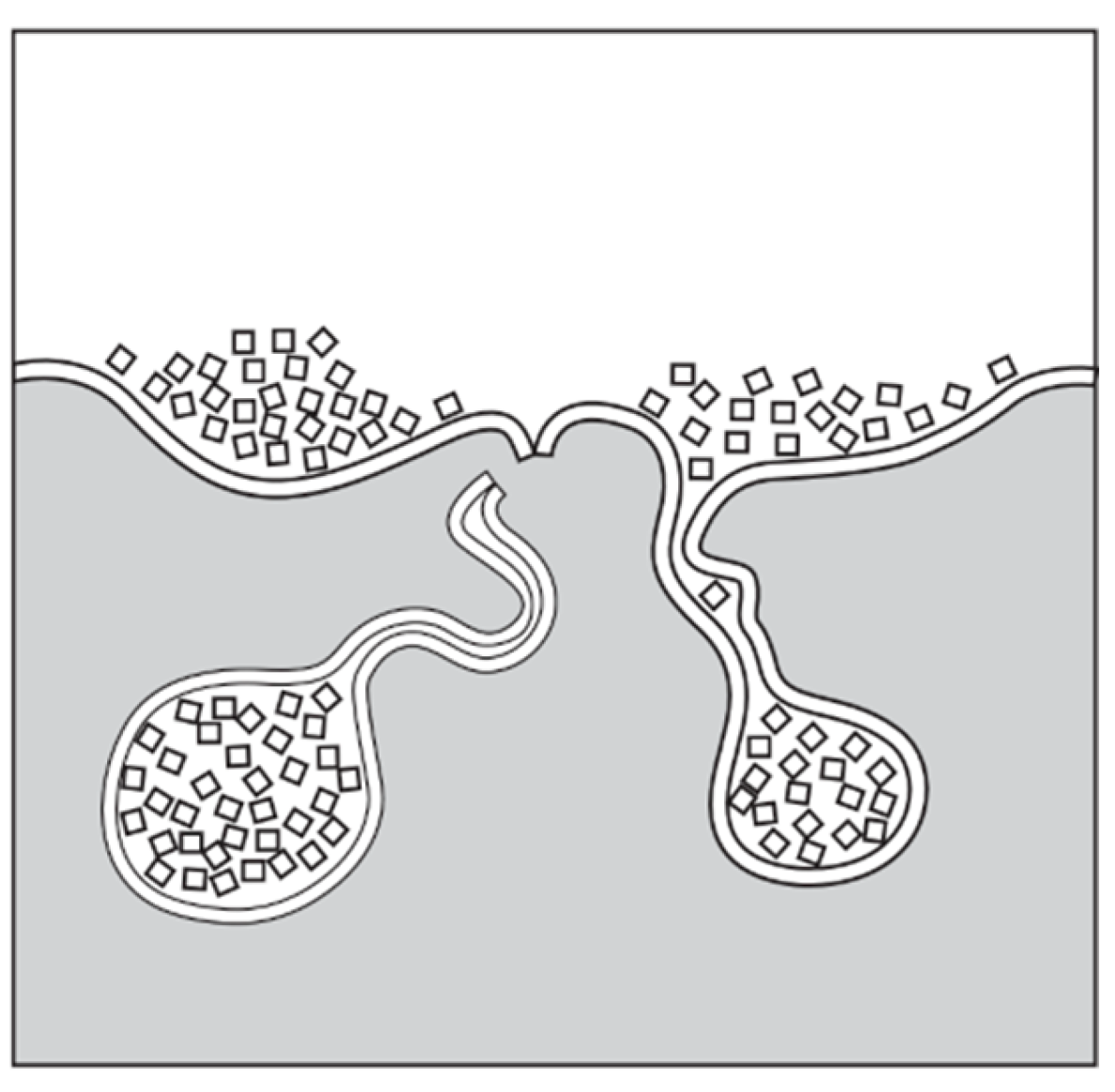

- Campbell, J. The Consolidation of Metals: The Origin of Bifilms. J. Mater. Sci. 2016, 51, 96–106. [Google Scholar] [CrossRef]

- Campbell, J. An Overview of the Effects of Bifilms on the Structure and Properties of Cast Alloys. Metall. Mater. Trans. B 2006, 37, 857–863. [Google Scholar] [CrossRef]

- Niu, Z.; Wang, S.; Gao, F.; Fan, Z. Nature of Oxides in Al–Mg Alloys. Trans. Indian Inst. Met. 2024, 77, 2929–2933. [Google Scholar] [CrossRef]

- Song, H.; Zhang, L.; Cao, F.; Gu, X.; Sun, J. Oxide Bifilm Defects in Aluminum Alloy Castings. Mater. Lett. 2021, 285, 129089. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.T.; Fan, Z. Oxidation of Aluminium Alloy Melts and Inoculation by Oxide Particles. Trans. Indian Inst. Met. 2012, 65, 653–661. [Google Scholar] [CrossRef]

- Campbell, J. The Mechanisms of Metallurgical Failure: On the Origin of Fracture; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; ISBN 978-0-12-822411-3. [Google Scholar]

- Campbell, J. Defects in Aluminum Alloy Castings. In Encyclopedia of Aluminum and Its Alloys; Taylor & Francis: Abingdon, UK, 2019; pp. 587–592. ISBN 9781351045636. [Google Scholar]

- Campbell, J. Entrainment Defects. In Encyclopedia of Aluminum and Its Alloys; Taylor & Francis: Abingdon, UK, 2018; pp. 873–892. [Google Scholar]

- Tiryakioglu, M.; Campbell, J. Metal Casting Research: Application to Aluminum Alloy Casting. In Encyclopedia of Aluminum and Its Alloys; Taylor & Francis: Abingdon, UK, 2019; pp. 1456–1460. ISBN 9781351045636. [Google Scholar]

- Campbell, J. A Personal View of Microstructure and Properties of Al Alloys. Materials 2021, 14, 1297. [Google Scholar] [CrossRef]

- Çolak, M.; Kayikci, R.; Dispinar, D. Melt Cleanliness Comparison of Chlorine Fluxing and Ar Degassing of Secondary Al-4Cu. Metall. Mater. Trans. B 2016, 47, 2705–2709. [Google Scholar] [CrossRef]

- Gyarmati, G.; Fegyverneki, G.; Tokár, M.; Mende, T. The Effects of Rotary Degassing Treatments on the Melt Quality of an Al–Si Casting Alloy. Int. J. Met. 2020, 14, 372–380. [Google Scholar] [CrossRef]

- Yüksel, C.; Dispinar, D.; Cigdem, M. An Analytical Approach for the Correlation between Bifilm Index and Tensile Properties of AlSi7Mg0.3 (A356) Aluminum Alloy Cleaned via Rotary Degassing and Different Fluxes. Int. J. Met. 2022, 16, 1615–1627. [Google Scholar] [CrossRef]

- Máté, M.; Tokár, M.; Fegyverneki, G.; Gyarmati, G. The Comparative Analysis of the Inclusion Removal Efficiency of Different Fluxes. Arch. Foundry Eng. 2020, 20, 53–58. [Google Scholar] [CrossRef]

- Li, C.; Li, J.G.; Mao, Y.Z.; Ji, J.C. Mechanism to Remove Oxide Inclusions from Molten Aluminum by Solid Fluxes Refining Method. China Foundry 2017, 14, 233–243. [Google Scholar] [CrossRef]

- Li, H.T.; Xia, M.; Jarry, P.; Scamans, G.M.; Fan, Z. Grain Refinement in a AlZnMgCuTi Alloy by Intensive Melt Shearing: A Multi-Step Nucleation Mechanism. J. Cryst. Growth 2011, 314, 285–292. [Google Scholar] [CrossRef]

- Wang, F.; Eskin, D.; Mi, J.; Connolley, T.; Lindsay, J.; Mounib, M. A Refining Mechanism of Primary Al3Ti Intermetallic Particles by Ultrasonic Treatment in the Liquid State. Acta Mater. 2016, 116, 354–363. [Google Scholar] [CrossRef]

- Hinton, E.M. The Oxidation of Liquid Aluminium and the Potential for Oxides in Grain Refinement of Aluminium Alloys. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2014. [Google Scholar]

- Cao, X.; Campbell, J. Oxide Inclusion Defects in Al-Si-Mg Cast Alloys. Can. Metall. Q. 2005, 44, 435–448. [Google Scholar] [CrossRef]

- Campbell, J. Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; ISBN 9780444635099. [Google Scholar]

- Wu, G.; Dash, K.; Galano, M.L.; O’Reilly, K.A.Q. Oxidation Studies of Al Alloys: Part II Al-Mg Alloy. Corros. Sci. 2019, 155, 97–108. [Google Scholar] [CrossRef]

- Wu, G.; Dash, K.; Galano, M.L.; O’Reilly, K.A.Q. Oxidation Studies of Al Alloys: Part I Al-Cu (Liquid Phase) Alloy. Corros. Sci. 2019, 157, 41–50. [Google Scholar] [CrossRef]

- Bonner, S.J. A Microstructural and Kinetic Study of Molten Aluminium Oxidation in Relation to Dross Formation. Ph.D. Thesis, University of Queensland, St. Lucia, Australia, 2015. [Google Scholar]

- Miresmaeili, S.M. Oxidation of Liquid Al-7Si Alloys Containing Strontium and Magnesium. In Proceedings of the 13th International Scientific Conference on Achievements in Mechanical and Materials Engineering, Gliwice-Wisla, Poland, 16–19 May 2005. [Google Scholar]

- Impey, S.A.; Stephenson, D.J.; Nicholls, J.R. Mechanism of Scale Growth on Liquid Aluminium. Mater. Sci. Technol. 1988, 4, 1126–1132. [Google Scholar] [CrossRef]

- Impey, S.; Stephenson, D.; Nicholls, J.R. A Study of the Effect of Magnesium Additions on the Oxide Growth Morphologies on Liquid Aluminium Alloys. In Microscopy of Oxidation; CRC Press: Boca Raton, FL, USA, 1991; pp. 238–244. [Google Scholar]

- Kim, K. Formation of Fine Clusters in High-Temperature Oxidation of Molten Aluminum. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 3650–3660. [Google Scholar] [CrossRef]

- Maity, P.C.; Chakraborty, P.N.; Panigrahi, S.C. Preparation of Al-Al2O3 in-Situ Particle Composites by Addition of Fe2O3 Particles to Pure Al Melt. J. Mater. Sci. Lett. 1997, 16, 1224–1226. [Google Scholar] [CrossRef]

- Rong, X.; Zhao, D.; He, C.; Zhao, N. Review: Recent Progress in Aluminum Matrix Composites Reinforced by in Situ Oxide Ceramics. J. Mater. Sci. 2024, 59, 9657–9684. [Google Scholar] [CrossRef]

- Ritchie, I.M.; Sanders, J.V.; Weickhardt, P.L. Oxidation of a Dilute Aluminum Magnesium Alloy. Oxid. Met. 1971, 3, 91–101. [Google Scholar] [CrossRef]

- Haginoya, I.; Fukusako, T. Oxidation of Molten Al-Mg Alloys. Trans. Jpn. Inst. Met. 1983, 24, 613–619. [Google Scholar]

- Bloch, J.; Bottomley, D.J.; Mihaychuk, J.G.; van Driel, H.M.; Timsit, R.S. Magnesium Surface Segregation and Its Effect on the Oxidation Rate of the (111) Surface of Al-1.45at%Mg. Surf. Sci. 1995, 322, 168–176. [Google Scholar] [CrossRef]

- Impey, S.; Stephenson, D.J.; Nicholls, J.R. The Influence of Surface Preparation and Pretreatments on the Oxidation of Liquid Aluminum and Al-Mg Alloys. In Microscopy of Oxidation; CRC Press: Boca Raton, FL, USA, 1993; pp. 323–337. [Google Scholar]

- Kim, K.H. Formation of Endogenous MgO and MgAl2O4 Particles and Their Possibility of Acting as Substrate for Heterogeneous Nucleation of Aluminum Grains. Surf. Interface Anal. 2015, 47, 429–438. [Google Scholar] [CrossRef]

- Kim, K.H. Detection of a Layer of Al2O3 at the Interface of Al/MgAl2O4 by High-Resolution Observation Using Dual-Beam FIB and TEM. Metallogr. Microstruct. Anal. 2014, 3, 233–237. [Google Scholar] [CrossRef]

- Kim, K.; Green, N.; Griffiths, W. Focused Ion Beam Milling and Imaging: An Advanced Method to Detect Fine Inclusions in Cast Aluminium Alloys. Mater. Sci. Forum 2013, 765, 150–154. [Google Scholar] [CrossRef]

- More, K.L.; Tortorelli, P.F.; Walker, L.R.; Hryn, J.; Krumdick, G. Microstructural Evaluation of Dross Formation on Mg- and Non-Mg-Containing Al Alloys from Industrial Furnaces. Mater. High Temp. 2003, 20, 453–460. [Google Scholar] [CrossRef]

- Bagh, N.T.; Divandari, M.; Shahmiri, M.; Akbarifar, M. Characteristics of Dynamically Formed Oxide Films in Al-Zn Melt. Int. J. Met. 2020, 15, 747–762. [Google Scholar] [CrossRef]

- Gyarmati, G.; Vincze, F.; Fegyverneki, G.; Kéri, Z.; Mende, T.; Molnár, D. The Effect of Rotary Degassing Treatments with Different Purging Gases on the Double Oxide- and Nitride Film Content of Liquid Aluminum Alloys. Metall. Mater. Trans. B 2022, 53, 1244–1257. [Google Scholar] [CrossRef]

- Campbell, J. Stop Pouring, Start Casting. Int. J. Met. 2012, 6, 7–18. [Google Scholar] [CrossRef]

- Tiryakioğlu, T. The Effect of Hydrogen on Pore Formation in Aluminum Alloy Castings: Myth Versus Reality. Metals 2020, 10, 368. [Google Scholar] [CrossRef]

- Yousefian, P.; Tiryakioğlu, M. Pore Formation During Solidification of Aluminum: Reconciliation of Experimental Observations, Modeling Assumptions, and Classical Nucleation Theory. Metall. Mater. Trans. A 2018, 49, 563–575. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Yousefian, P. Hot Tear Nucleation During Solidification of Aluminum and Its Alloys. In Encyclopedia of Aluminum and Its Alloys; Totten, M.G.E., Tiryakioğlu, O.K., Eds.; Taylor & Francis: Abingdon, UK, 2019; pp. 1263–1269. ISBN 9781351045636. [Google Scholar]

- Uludağ, M.; Çetin, R.; Dispinar, D. Freezing Range, Melt Quality, and Hot Tearing in Al-Si Alloys. Metall. Mater. Trans. A 2018, 49, 1948–1961. [Google Scholar] [CrossRef]

- Patel, J.B.; Yang, X.; Mendis, C.L.; Fan, Z. Melt Conditioning of Light Metals by Application of High Shear for Improved Microstructure and Defect Control. JOM 2017, 69, 1071–1076. [Google Scholar] [CrossRef]

- Li, H.T.; Wang, Y.; Fan, Z. Mechanisms of Enhanced Heterogeneous Nucleation during Solidification in Binary Al-Mg Alloys. Acta Mater. 2012, 60, 1528–1537. [Google Scholar] [CrossRef]

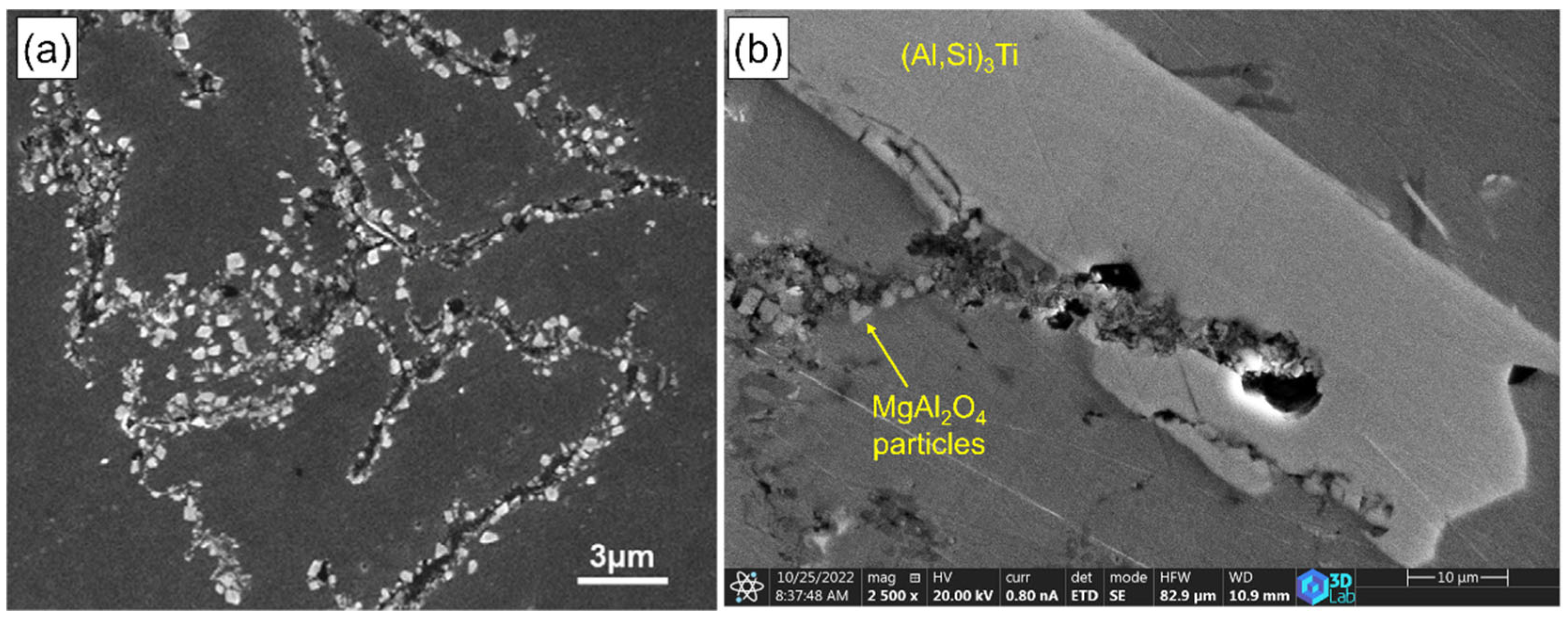

- Gyarmati, G.; Koncz-Horváth, D.; Karacs, G.; Mende, T. The Interactions of Primary (Al,Si)3Ti Intermetallic Particles and Oxide Phases in a Liquid Al-Si-Mg-Ti Alloy. In Proceedings of the The 8th International Conference on Solidification and Gravity, Miskolc-Lillafüred, Hungary, 2–5 September 2024. [Google Scholar]

- Pilling, N.B.; Bedworth, R.E. The Oxidation of Metals at High Temperatures. J. Inst. Met. 1923, 29, 529–591. [Google Scholar]

- Xu, C.; Gao, W. Pilling-Bedworth Ratio for Oxidation of Alloys. Mater. Res. Innov. 2000, 3, 231–235. [Google Scholar] [CrossRef]

- Stefanescu, D.M. Nucleation and Growth Kinetics—Nanoscale. In Science and Engineering of Casting Solidification; Springer International Publishing: Cham, Switzerland, 2015; pp. 29–59. ISBN 9783319156934. [Google Scholar]

- Fredriksson, H.; Akerlind, U. Nucleation. In Solidification and Crystallization Processing in Metals and Alloys; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 166–200. [Google Scholar]

- Kurz, W.; Fisher, D.J.; Rappaz, M. Fundamentals of Solidification, 5th ed.; Trans Tech Publications Ltd.: Seestrasse, Switzerland, 2023. [Google Scholar]

- Kaptay, G. The Chemical (Not Mechanical) Paradigm of Thermodynamics of Colloid and Interface Science. Adv. Colloid. Interface Sci. 2018, 256, 163–192. [Google Scholar] [CrossRef]

- Cantor, B. Heterogeneous Nucleation and Adsorption. Philos. Trans. Math. Phys. Eng. Sci. 2003, 361, 409–417. [Google Scholar] [CrossRef]

- Quested, T.E.; Greer, A.L. Athermal Heterogeneous Nucleation of Solidification. Acta Mater. 2005, 53, 2683–2692. [Google Scholar] [CrossRef]

- Fan, Z.; Men, H. An Overview on Atomistic Mechanisms of Heterogeneous Nucleation. Metals 2022, 12, 1547. [Google Scholar] [CrossRef]

- Fan, Z.; Men, H.; Wang, Y.; Que, Z. A New Atomistic Mechanism for Heterogeneous Nucleation in the Systems with Negative Lattice Misfit: Creating a 2D Template for Crystal Growth. Metals 2021, 11, 478. [Google Scholar] [CrossRef]

- Men, H.; Fan, Z. Prenucleation Induced by Crystalline Substrates. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 2766–2777. [Google Scholar] [CrossRef]

- Fan, Z.; Men, H. Heterogeneous Nucleation and Grain Initiation on a Single Substrate. Metals 2022, 12, 1454. [Google Scholar] [CrossRef]

- Fan, Z.; Gao, F. Grain Initiation and Grain Refinement: An Overview. Metals 2022, 12, 1728. [Google Scholar] [CrossRef]

- Turnbull, D.; Vonnegut, B. Vonnegut Nucleation Catalysis. Ind. Eng. Chem. 1952, 44, 1292–1298. [Google Scholar] [CrossRef]

- Bramfitt, B.L. The Effect of Carbide and Nitride Additions on the Heterogeneous Nucleation Behavior of Liquid Iron. Metall. Trans. 1970, 1, 1987–1995. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M.; Easton, M.A.; Taylor, J.A. Crystallographic Study of Grain Refinement in Aluminum Alloys Using the Edge-to-Edge Matching Model. Acta Mater. 2005, 53, 1427–1438. [Google Scholar] [CrossRef]

- Men, H.; Fang, C.; Fan, Z. Prenucleation at the Liquid/Substrate Interface: An Overview. Metals 2022, 12, 1704. [Google Scholar] [CrossRef]

- Kaptay, G. Method for Estimating Solid-Solid Interface Energies in Metal-Ceramic Systems: The Aluminum-Silicon Carbide System. Mater. Sci. Forum 1996, 216, 475–484. [Google Scholar] [CrossRef]

- Voigt, C.; Ditscherlein, L.; Werzner, E.; Zienert, T.; Nowak, R.; Peuker, U.; Sobczak, N.; Aneziris, C.G. Wettability of AlSi7Mg Alloy on Alumina, Spinel, Mullite and Rutile and Its Influence on the Aluminum Melt Filtration Efficiency. Mater. Des. 2018, 150, 75–85. [Google Scholar] [CrossRef]

- Fankhänel, B.; Stelter, M.; Voigt, C.; Aneziris, C.G. Interaction of AlSi7Mg with Oxide Ceramics. Adv. Eng. Mater. 2017, 19, 1700084. [Google Scholar] [CrossRef]

- Kaptay, G. Interfacial Criterion of Spontaneous and Forced Engulfment of Reinforcing Particles by an Advancing Solid/Liquid Interface. Metall. Mater. Trans. A 2001, 32, 993–1005. [Google Scholar] [CrossRef]

- Kaptay, G.; Bader, E. Ion-Dipole Adhesion Energy Model for Wettability of Oxide Ceramics by Non-Reactive Liquid Metals. Trans. Join. Weld. Res. Inst. 2001, 30, 55–60. [Google Scholar]

- Liu, Y.; Huang, Y.; Xiao, Z. Study of Orientation Relationship between Al Matrix and Several Typical Inclusions in Al Alloy by Edge-to-Edge Matching Model. J. Mater. Res. 2017, 32, 2092–2099. [Google Scholar] [CrossRef]

- Fredriksson, H.; Åkerlind, U. Solidification and Crystallization Processing in Metals and Alloys; Wiley: Hoboken, NJ, USA, 2012; ISBN 9781119993056. [Google Scholar]

- Kaptay, G. Interfacial Energy of Strained Coherent Interfaces and a New Design Rule to Select Phase Combinations for In Situ Coherent Nanocomposites. Langmuir 2023, 39, 6316–6323. [Google Scholar] [CrossRef]

- Kaptay, G. On the Interfacial Energy of Coherent Interfaces. Acta Mater. 2012, 60, 6804–6813. [Google Scholar] [CrossRef]

- Kaptay, G. A Coherent Set of Model Equations for Various Surface and Interface Energies in Systems with Liquid and Solid Metals and Alloys. Adv. Colloid. Interface Sci. 2020, 283, 102212. [Google Scholar] [CrossRef]

- Fang, C.M.; Fan, Z. Atomic Ordering at the Liquid-Al/MgAl2O4 Interfaces from Ab Initio Molecular Dynamics Simulations. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 6318–6326. [Google Scholar] [CrossRef]

- Fang, C.; Yasmin, S.; Fan, Z. Interfacial Interaction and Prenucleation at Liquid-Al/γ-Al2O3{1 1 1} Interfaces. J. Phys. Commun. 2021, 5, 015007. [Google Scholar] [CrossRef]

- Fang, C.; Fan, Z. Prenucleation at the Liquid-Al/α-Al2O3 and the Liquid-Al/MgO Interfaces. Comput. Mater. Sci. 2020, 171, 109258. [Google Scholar] [CrossRef]

- Fang, C.; Fan, Z. Ab Initio Molecular Dynamics Investigation of Prenucleation at Liquid—Metal/Oxide Interfaces: An Overview. Metals 2022, 12, 1618. [Google Scholar] [CrossRef]

- Askeland, D.R.; Phulé, P.P.; Wright, W.J.; Bhattacharya, D.K. The Science and Engineering of Materials, 7th ed.; Cengage Learning: Boston, MA, USA, 2016. [Google Scholar]

- Russell, A.M. Ductility in Intermetallic Compounds. Adv. Eng. Mater. 2003, 5, 629–639. [Google Scholar] [CrossRef]

- Cui, Y.; King, D.J.M.; Horsfield, A.P.; Gourlay, C.M. Solidification orientation relationships between Al3Ti and TiB2. Acta Mater. 2020, 186, 149–161. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Que, Z.; Fang, C.; Hashimoto, T.; Zhou, X.; Ramasse, Q.M.; Fan, Z. Manipulating Nucleation Potency of Substrates by Interfacial Segregation: An Overview. Metals 2022, 12, 1636. [Google Scholar] [CrossRef]

- Greer, A.L.; Bunn, A.M.; Tronche, A.; Evans, P.V.; Bristow, D.J. Modelling of Inoculation of Metallic Melts: Application to Grain Refinement of Aluminium by Al-Ti-B. Acta Mater. 2000, 48, 2823–2835. [Google Scholar] [CrossRef]

- Campbell, J. The Origin of Griffith Cracks. Metall. Mater. Trans. B 2011, 42, 1091–1097. [Google Scholar] [CrossRef]

- Sahin, U.; Campbell, J.; Brown, D.N.; Griffiths, W.D. Precipitation of Sr-Rich and Fe-Rich Intermetallic Compounds in Al Alloys. Mater. Sci. Technol. 2024, 0, 02670836241302686. [Google Scholar] [CrossRef]

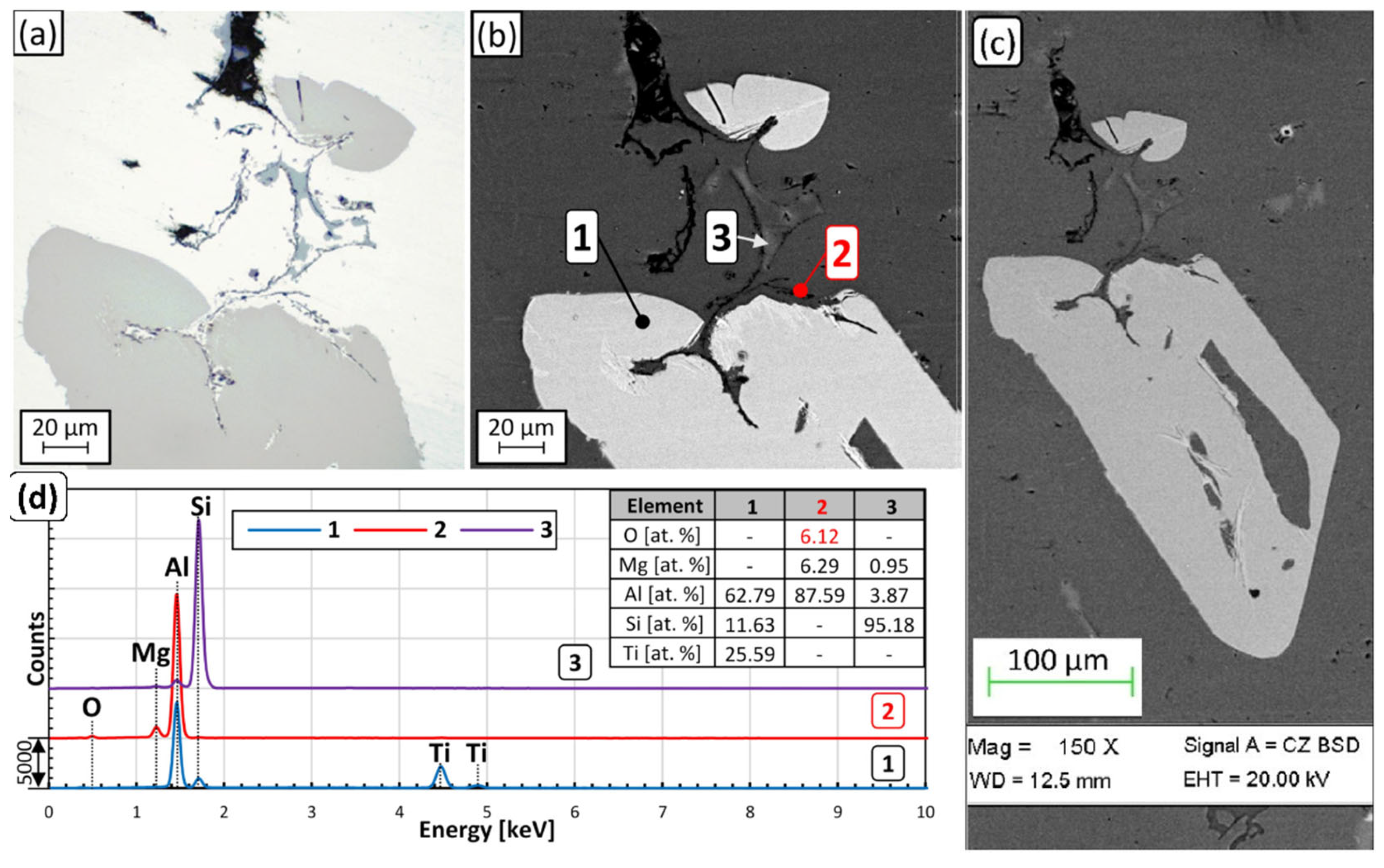

- Gyarmati, G.; Fegyverneki, G.; Kéri, Z.; Molnár, D.; Tokár, M.; Varga, L.; Mende, T. Controlled Precipitation of Intermetallic (Al,Si)3Ti Compound Particles on Double Oxide Films in Liquid Aluminum Alloys. Mater. Charact. 2021, 181, 111467. [Google Scholar] [CrossRef]

- Gyarmati, G.; Bubonyi, T.; Fegyverneki, G.; Tokár, M.; Mende, T. Interactions of Primary Intermetallic Compound Particles and Double Oxide Films in Liquid Aluminum Alloys. Intermetallics 2022, 149, 107681. [Google Scholar] [CrossRef]

- Gyarmati, G. Kettős Oxidhártyák és Ti Tartalmú Vegyületfázisok Kölcsönhatásainak Vizsgálata AlSi7MgCu Ötvözet Esetén. Ph.D. Thesis, University of Miskolc, Miskolc, Hungary, 2024. [Google Scholar]

- Cao, X.; Campbell, J. The Nucleation of Fe-Rich Phases on Oxide Films in Al-11.5Si-0.4Mg Cast Alloys. Metall. Mater. Trans. A 2003, 34, 1409–1420. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Precipitation of Primary Intermetallic Compounds in Liquid Al 11.5Si 0.4Mg Alloy. Int. J. Cast Met. Res. 2000, 13, 175–184. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Effect of Melt Superheating on Convection-Free Precipitation and Sedimentation of Primary α-Fe Phase in Liquid Al-11.5Si-0.4Mg Alloy. Int. J. Cast Met. Res. 2003, 15, 595–608. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Effect of Precipitation and Sedimentation of Primary α-Fe Phase on Liquid Metal Quality of Cast Al-11·1Si-0·4Mg Alloy. Int. J. Cast Met. Res. 2004, 17, 1–11. [Google Scholar] [CrossRef]

- Liu, K.; Cao, X.; Chen, X.G. Precipitation of Iron-Rich Intermetallic Phases in Al-4.6Cu-0.5Fe-0.5Mn Cast Alloy. J. Mater. Sci. 2012, 47, 4290–4298. [Google Scholar] [CrossRef]

- Liu, K.; Cao, X.; Chen, X.G. Formation and Phase Selection of Iron-Rich Intermetallics in Al-4.6Cu-0.5Fe Cast Alloys. Metall. Mater. Trans. A 2013, 44, 682–695. [Google Scholar] [CrossRef]

- Narayanan, L.A.; Samuel, F.H.; Gruzleski, J.E. Crystallization Behavior of Iron-Containing Intermetallic Compounds in 319 Aluminum Alloy. Metall. Mater. Trans. A 1994, 25, 1761–1773. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, Y.; Zhang, Z.F.; Xia, M.; Li, H.T.; Xu, J.; Granasy, L.; Scamans, G.M. Shear Enhanced Heterogeneous Nucleation in Some Mg- and Al-Alloys. Int. J. Cast. Met. Res. 2009, 22, 318–322. [Google Scholar] [CrossRef]

- Wang, F.; Eskin, D.; Connolley, T.; MI, J. Wei Influence of Ultrasonic Treatment on Formation of Primary Al3Zr in Al–0.4Zr Alloy. Trans. Nonferrous Met. Soc. China 2017, 27, 977–985. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, W.; Koe, B.; Du, W.; Wang, M.; Wang, W.; Boller, E.; Rack, A.; Sun, Z.; Da Shu, B.S.; et al. Multiscale Characterization of the Nucleation and 3D Structure of Al3Sc Phases Using Electron Microscopy and Synchrotron X-Ray Tomography. Mater. Charact. 2020, 164, 183135. [Google Scholar] [CrossRef]

- Yan, K.; Chen, Z.W.; Zhao, Y.N.; Ren, C.C.; Lu, W.J.; Aldeen, A.W. Morphological Characteristics of Al3Sc Particles and Crystallographic Orientation Relationships of Al3Sc/Al Interface in Cast Al-Sc Alloy. J. Alloys Compd. 2021, 861, 158491. [Google Scholar] [CrossRef]

- Trudonoshyn, O.; Prach, O. Multistep Nucleation and Multi-Modification Effect of Sc in Hypoeutectic Al-Mg-Si Alloys. Heliyon 2019, 5, e01202. [Google Scholar] [CrossRef] [PubMed]

- Trudonoshyn, O.; Prach, O.; Slyudova, A.; Lisovskii, V. Structure Formation and Multistep Nucleation in CASTING Al-Mg-Si Alloys. Int. J. Cast Met. Res. 2020, 33, 184–193. [Google Scholar] [CrossRef]

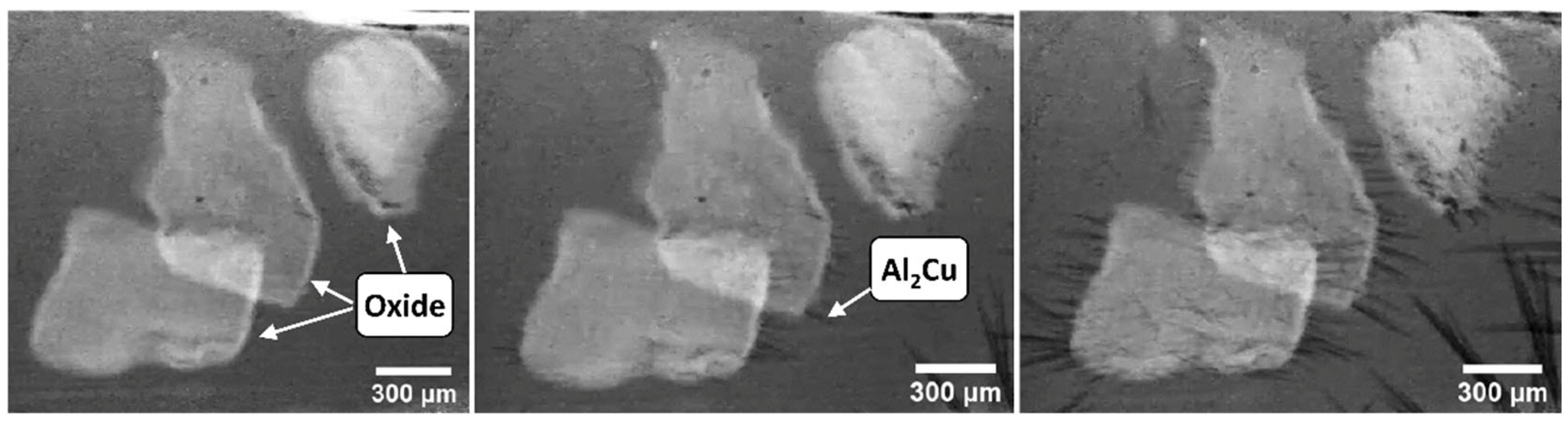

- Wang, F.; Eskin, D.; Connolley, T.; Wang, C.; Koe, B.; King, A.; Reinhard, C.; Mi, J. In-Situ Synchrotron X-Ray Radiography Observation of Primary Al2Cu Intermetallic Growth on Fragments of Aluminium Oxide Film. Mater. Lett. 2018, 213, 303–305. [Google Scholar] [CrossRef]

- Peng, L.; Zeng, G.; Su, T.C.; Yasuda, H.; Nogita, K.; Gourlay, C.M. Al8Mn5 Particle Settling and Interactions with Oxide Films in Liquid AZ91 Magnesium Alloys. JOM 2019, 71, 2235–2244. [Google Scholar] [CrossRef]

- Jung, J.G.; Cho, Y.H.; Kim, S.D.; Kim, S.B.; Lee, S.H.; Song, K.; Euh, K.; Lee, J.M. Mechanism of Ultrasound-Induced Microstructure Modification in Al–Zr Alloys. Acta Mater. 2020, 199, 73–84. [Google Scholar] [CrossRef]

- Liu, K.; Cao, X.; Chen, X.G. Solidification of Iron-Rich Intermetallic Phases in Al-4.5Cu-0.3Fe Cast Alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 2004–2016. [Google Scholar] [CrossRef]

- Zhou, Z.P.Q.Y.P.; Fan, Y.W.Z. Effect of MgO on Phase Selection in Al—Mg—Si—Fe—Mn Alloys. Trans. Indian Inst. Met. 2015, 68, 1167–1172. [Google Scholar] [CrossRef]

- Que, Z.; Mendis, C.L. Heterogeneous Nucleation and Phase Transformation of Fe-Rich Intermetallic Compounds in Al-Mg-Si Alloys. J. Alloys Compd. 2020, 836, 155515. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Wei, Q.; He, W.; Song, D.; Sun, Z.; Fu, Y.; Xiao, F.; Shu, D. Tailoring Thermal Conductivity and Microstructure of Al–Fe Alloys by Addition of Sc2O3 and Variable Cooling Rates. J. Mater. Res. Technol. 2024, 32, 2547–2562. [Google Scholar] [CrossRef]

- Zhang, L.; Eskin, D.G.; Miroux, A.G.; Katgerman, L. On the Mechanism of the Formation of Primary Intermetallics under Ultrasonic Melt Treatment in an Al-Zr-Ti Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2011, 27, 012002. [Google Scholar] [CrossRef]

- Hu, J.; Liu, J.; Yang, Y.; Wei, Z.; Li, M.; Liu, G.; Gao, T.; Liu, S. On the Interactions Between y–Al2O3 Nanoparticles and Primary or Eutectic Al2Cu in Hypereutectic Al-Cu Alloy. JOM 2025, 77, 1044–1049. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, S.H.; Kim, S.D.; Mao, Z.; Seidman, D.N.; Kim, K.; Cho, Y.H.; Kim, S.H.; Euh, K.; Lee, J.M.; et al. Ultrasound Alters the Nucleation Pathway of Primary Mg2Si in a Chemically Modified Multicomponent Al–Mg2Si Alloy. J. Alloys Compd. 2024, 1009, 177001. [Google Scholar] [CrossRef]

- Al-Helal, K.; Wang, Y.; Stone, I.; Fan, Z. Effect of Ca Level on the Formation of Silicon Phases during Solidification of Hypereutectic Al-Si Alloys. Mater. Sci. Forum 2013, 765, 117–122. [Google Scholar] [CrossRef]

- Miresmaeili, S.M.; Campbell, J.; Shabestari, S.G.; Boutorabi, S.M.A. Precipitation of Sr-Rich Intermetallic Particles and Their Influence on Pore Formation in Sr-Modified A356 Alloy. Metall. Mat. Trans. A 2005, 36, 2341–2349. [Google Scholar] [CrossRef]

- Chen, Q.I.; Griffiths, W.D. Modification of Double Oxide Film Defects with the Addition of Mo to An Al-Si-Mg Alloy. Metall. Mater. Trans. B 2021, 52, 502–516. [Google Scholar] [CrossRef]

- Eskin, D.G.; Tzanakis, I.; Wang, F.; Lebon, G.S.B.; Subroto, T.; Pericleous, K.; Mi, J. Fundamental Studies of Ultrasonic Melt Processing. Ultrason. Sonochem. 2019, 52, 455–467. [Google Scholar] [CrossRef]

- Jaime, R.F.; Puga, H.; Prokic, M.; Söderhjelm, C.; Apelian, D. Fundamentals of Ultrasonic Treatment of Aluminum Alloys. Int. J. Met. 2024, 18, 2783–2807. [Google Scholar] [CrossRef]

- Barbosa, J.; Puga, H. Ultrasonic Melt Treatment of Light Alloys. Int. J. Metalcasting 2019, 13, 180–189. [Google Scholar] [CrossRef]

- Osawa, Y.; Takamori, S.; Kimura, T.; Minagawa, K.; Kakisawa, H. Morphology of Intermetallic Compounds in Al-Si-Fe Alloy and Its Control by Ultrasonic Vibration. Mater. Trans. 2007, 48, 2467–2475. [Google Scholar] [CrossRef]

- Puga, H.; Costa, S.; Barbosa, J.; Ribeiro, S.; Prokic, M. Influence of Ultrasonic Melt Treatment on Microstructure and Mechanical Properties of AlSi9Cu3 Alloy. J. Mater. Process. Technol. 2011, 211, 1729–1735. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Q.; Wang, K.; Hu, P. Effects of Ultrasonic Treatment on Microstructure and Mechanical Properties of Recycled Al-9Si-1Fe Alloy. Int. J. Met. 2024, 1–13. [Google Scholar] [CrossRef]

- Wang, F.; Eskin, D.; Connolley, T.; Mi, J. Effect of Ultrasonic Melt Treatment on the Refinement of Primary Al3Ti Intermetallic in an Al-0.4Ti Alloy. J. Cryst. Growth 2016, 435, 24–30. [Google Scholar] [CrossRef]

- Campbell, J. Cavitation in Liquid and Solid Metals: Role of Bifilms. Mater. Sci. Technol. 2015, 31, 565–572. [Google Scholar] [CrossRef]

- Lan, J.; Yang, Y.; Li, X. Microstructure and Microhardness of SiC Nanoparticles Reinforced Magnesium Composites Fabricated by Ultrasonic Method. Mater. Sci. Eng. A 2004, 386, 284–290. [Google Scholar] [CrossRef]

- Priyadarshi, A.; Khavari, M.; Subroto, T.; Prentice, P.; Pericleous, K.; Eskin, D.; Durodola, J.; Tzanakis, I. Mechanisms of Ultrasonic De-Agglomeration of Oxides through in-Situ High-Speed Observations and Acoustic Measurements. Ultrason. Sonochem. 2021, 79, 105792. [Google Scholar] [CrossRef]

- Sun, J.; Higashi, K.; Romankov, S.; Yamamoto, T.; Komarov, S. Free Surface Entrainment of Oxide Particles and Their Role in Ultrasonic Treatment Performance of Aluminum Alloys. Ultrason. Sonochem. 2022, 90, 106209. [Google Scholar] [CrossRef]

- Chen, Y.-J.; Huang, L.-W.; Shih, T.-S. Diagnosis of Oxide Films by Cavitation Micro-Jet Impact. Mater. Trans. 2003, 44, 327–335. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, R.; Li, X.; Yang, Y.; Chen, P.; Dong, F.; Jiang, R. Possible Effects and Mechanisms of Ultrasonic Cavitation on Oxide Inclusions during Direct-Chill Casting of an Al Alloy. Metals 2018, 8, 814. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Lordan, E.; Wang, Y.; Fan, Z. Improve Mechanical Properties of High Pressure Die Cast Al9Si3Cu Alloy via Dislocation Enhanced Precipitation. J. Alloys Compd. 2019, 785, 1015–1022. [Google Scholar] [CrossRef]

- Czerwinski, F.; Benkel, F.; Birsan, G. Gas-Enhanced Ultrahigh-Shear Mixing: An Application to Molten Aluminum Alloys. Metall. Mater. Trans. B 2020, 51, 1079–1087. [Google Scholar] [CrossRef]

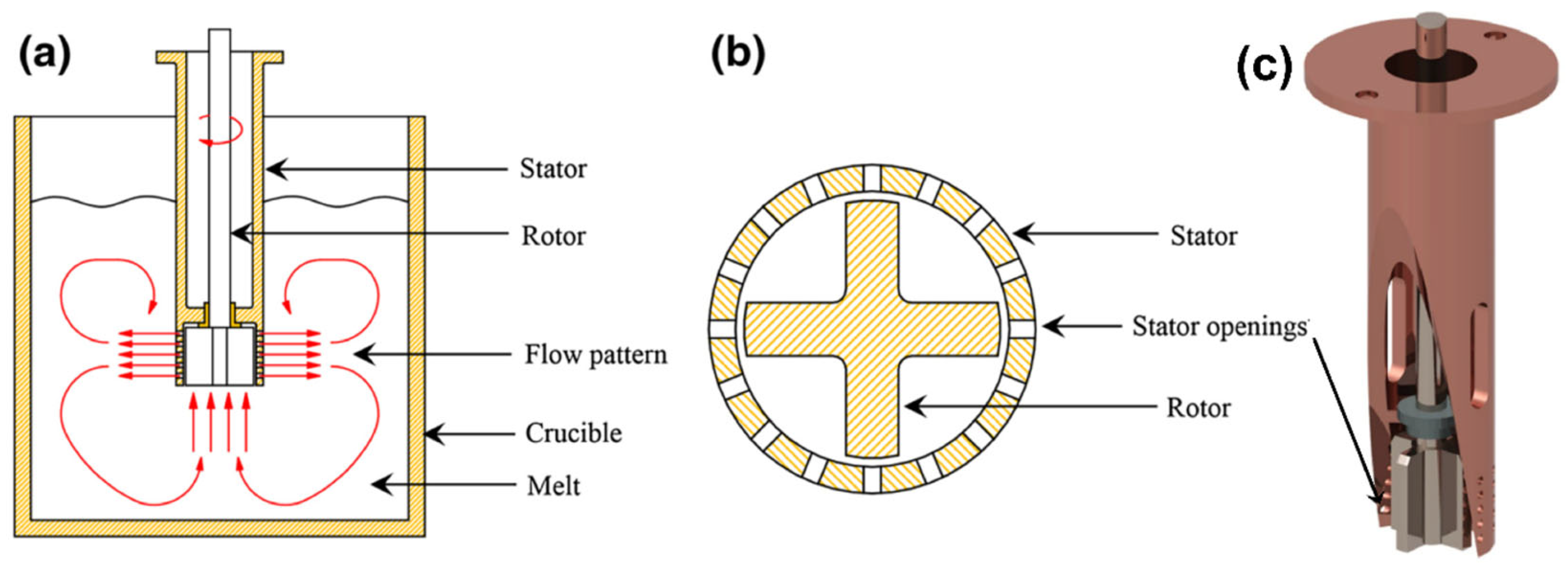

- Fan, Z.; Zuo, Y.B.; Jiang, B. A New Technology for Treating Liquid Metals with Intensive Melt Shearing. Mater. Sci. Forum 2011, 690, 141–144. [Google Scholar] [CrossRef]

- Scamans, G.; Li, H.T.; Nebreda, J.L.; Patel, J.; Stone, I.; Wang, Y.; Yang, X.; Fan, Z. Advanced Casting Technologies Using High Shear Melt Conditioning. In Fundamentals of Aluminium Metallurgy: Recent Advances; Elsevier: Amsterdam, The Netherlands, 2018; pp. 249–277. ISBN 9780081020630. [Google Scholar]

- Lazaro-Nebreda, J.; Patel, J.B.; Lordan, E.; Zhang, Y.; Karakulak, E.; Al-Helal, K.; Scamans, G.M.; Fan, Z. Degassing of Aluminum Alloy Melts by High Shear Melt Conditioning Technology an Overview. Metals 2022, 12, 1772. [Google Scholar] [CrossRef]

- Lazaro-Nebreda, J.; Patel, J.B.; Fan, Z. Improved Degassing Efficiency and Mechanical Properties of A356 Aluminium Alloy Castings by High Shear Melt Conditioning (HSMC) Technology. J. Mater. Process. Technol. 2021, 294, 117146. [Google Scholar] [CrossRef]

- Zhang, Y.; Patel, J.B.; Lazaro-Nebreda, J.; Fan, Z. Improved Defect Control and Mechanical Property Variation in High-Pressure Die Casting of A380 Alloy by High Shear Melt Conditioning. JOM 2018, 70, 2726–2730. [Google Scholar] [CrossRef]

- Himmler, D.; Randelzhofer, P.; Körner, C. Formation Kinetics and Phase Stability of In-Situ Al3Ti Particles in Aluminium Casting Alloys with Varying Si Content. Results Mater. 2020, 7, 100103. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Patel, J.B.; Fan, Z. Numerical Studies of Batch and Inline High Shear Melt Conditioning Technology Using Different Rotors. Crystals 2022, 12, 1299. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Lazaro-Nebreda, J.; Patel, J.B.; Fan, Z. Numerical Assessment of In-Line Rotor–Stator Mixers in High-Shear Melt Conditioning (HSMC) Technology. JOM 2020, 72, 4092–4100. [Google Scholar] [CrossRef]

- Tong, M.; Patel, J.B.; Stone, I.; Fan, Z.; Browne, D.J. Identification of Key Liquid Metal Flow Features in the Physical Conditioning of Molten Aluminium Alloy with High Shear Processing. Comput. Mater. Sci. 2017, 131, 35–43. [Google Scholar] [CrossRef]

- Al-Helal, K.; Lazaro-Nebreda, J.; Patel, J.B.; Scamans, G.M. High-Shear de-Gassing and de-Ironing of an Aluminum Casting Alloy Made Directly from Aluminum End-of-Life Vehicle Scrap. Recycling 2021, 6, 66. [Google Scholar] [CrossRef]

- Li, H.T.; Ji, S.; Wang, Y.; Xia, M.; Fan, Z. Effect of Intensive Melt Shearing on the Formation of Fe-Containing Intermetallics in LM24 Al-Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2011, 27, 012075. [Google Scholar] [CrossRef]

- Li, H.T.; Patel, J.B.; Kotadia, H.R.; Fan, Z. Controlling the Formation of Iron-Bearing Intermetallics in Wrought Al Alloys by Melt Conditioned DC (MC-DC) Casting Technology. In Materials Science Forum; Trans Tech Publications Ltd.: Seestrasse, Switzerland, 2015; Volume 828–829, pp. 43–47. [Google Scholar]

- Lazaro-Nebreda, J.; Patel, J.B.; Al-helal, K.; Gao, F.; Stone, I.; Chang, I.T.H.; Scamans, G.M.; Fan, Z. De-Ironing of Aluminium Alloy Melts by High Shear Melt Conditioning Technology: An Overview. Metals 2022, 12, 1579. [Google Scholar] [CrossRef]

- Campbell, J. Intrinsic and Extrinsic Metallurgy. In Shape Casting: 3rd International Symposium 2009; Wiley: Hoboken, NJ, USA, 2009; pp. 3–10. [Google Scholar]

- Campbell, J.; Tiryakioǧlu, M. Fatigue Failure in Engineered Components and How It Can Be Eliminated: Case Studies on the Influence of Bifilms. Metals 2022, 12, 1320. [Google Scholar] [CrossRef]

- Ahmadt, R.; Marshall, R.I. Effect of Superheating on Iron-Rich Plate-Type Compounds in Aluminium-Silicon Alloys. Int. J. Cast Met. Res. 2003, 15, 497–504. [Google Scholar] [CrossRef]

- Mathew, J.; Williams, M.A.; Srirangam, P. Effect of Superheat on Microstructure and Mechanical Properties of Al-7Si-2Fe Alloy. JOM 2024, 76, 464–472. [Google Scholar] [CrossRef]

- Azarniya, A.; Azarniya, A.; Abdollah-zadeh, A.; Madaah Hosseini, H.R.; Ramakrishna, S. In Situ Hybrid Aluminum Matrix Composites: A Review of Phase Transformations and Mechanical Aspects. Adv. Eng. Mater. 2019, 21, 1801269. [Google Scholar] [CrossRef]

- Thakur, A.; Bandhu, D.; Peshwe, D.R.; Mahajan, Y.Y.; Saxena, K.K.; Eldin, S.M. Appearance of Reinforcement, Interfacial Product, Heterogeneous Nucleant and Grain Refiner of MgAl2O4 in Aluminium Metal Matrix Composites. J. Mater. Res. Technol. 2023, 26, 267–302. [Google Scholar] [CrossRef]

- Afkham, Y.; Khosroshahi, R.A.; Rahimpour, S.; Aavani, C.; Brabazon, D.; Mousavian, R.T. Enhanced Mechanical Properties of in Situ Aluminium Matrix Composites Reinforced by Alumina Nanoparticles. Arch. Civ. Mech. Eng. 2018, 18, 215–226. [Google Scholar] [CrossRef]

- Huang, Z.-J.; Yang, B.; Cui, H.; Zhang, J.-S. Study on the Fabrication of Al Matrix Composites Strengthened by Combined In-Situ Alumina Particle and in-Situ Alloying Elements. Mater. Sci. Eng. A 2003, 351, 15–22. [Google Scholar]

- Xu, T.; Li, G.; Xie, M.; Liu, M.; Zhang, D.; Zhao, Y.; Chen, G.; Kai, X. Microstructure and Mechanical Properties of In-Situ Nano γ-Al2O3p/A356 Aluminum Matrix Composite. J. Alloys Compd. 2019, 787, 72–85. [Google Scholar] [CrossRef]

- Thakur, A.; Gupta, R.K.; Udhayabanu, V.; Peshwe, D.R.; Mahajan, Y.Y. Ultrasonic Assisted Reactive Synthesis and Characterization of Al–MgAl2O4 in-Situ Composite. Mater. Chem. Phys. 2023, 297, 127311. [Google Scholar] [CrossRef]

- Yang, B.; Sun, M.; Gan, G.; Xu, C.; Huang, Z.; Zhang, H.; Fang, Z.Z. In Situ Al2O3 Particle-Reinforced Al and Cu Matrix Composites Synthesized by Displacement Reactions. J. Alloys Compd. 2010, 494, 261–265. [Google Scholar] [CrossRef]

- Sreekumar, V.M.; Babu, N.H.; Eskin, D.G. Potential of an Al-Ti-MgAl2O4 Master Alloy and Ultrasonic Cavitation in the Grain Refinement of a Cast Aluminum Alloy. Metall. Mater. Trans. B 2017, 48, 208–219. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Sun, C.; Cheng, Z.; Pang, Z.; Wang, L.; Chen, H.; Liu, N. Hypereutectic Al-Si Matrix Composites Prepared by In Situ Fe2O3/Al System. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2021, 36, 636–643. [Google Scholar] [CrossRef]

- Zhu, H.; Min, J.; Li, J.; Ai, Y.; Ge, L.; Wang, H. In Situ Fabrication of (α-Al2O3+Al3Zr)/Al Composites in an Al-ZrO2 System. Compos. Sci. Technol. 2010, 70, 2183–2189. [Google Scholar] [CrossRef]

- Najarian, A.R.; Emadi, R.; Hamzeh, M. Fabrication of As-Cast Al Matrix Composite Reinforced by Al2O3/Al3Ni Hybrid Particles via in-Situ Reaction and Evaluation of Its Mechanical Properties. Mater. Sci. Eng. B 2018, 231, 57–65. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; Zhao, Y.; Chen, G. In Situ Fabrication and Microstructure of Al2O3 Particles Reinforced Aluminum Matrix Composites. Mater. Sci. Eng. A 2010, 527, 2881–2885. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, H.; Zhang, D.; Li, C.; Li, J.; Huang, J. Reaction Mechanisms and Tensile Properties of the Composites Fabricated by Al-B2O3 System. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019, 34, 1024–1029. [Google Scholar] [CrossRef]

- Sreekumar, V.M.; Hari Babu, N.; Eskin, D.G.; Fan, Z. Structure-Property Analysis of in-Situ Al-MgAl2O4 Metal Matrix Composites Synthesized Using Ultrasonic Cavitation. Mater. Sci. Eng. A 2015, 628, 30–40. [Google Scholar] [CrossRef]

- Sreekumar, V.M.; Pillai, R.M.; Pai, B.C.; Chakraborty, M. Synthesis of an Al/MgAl2O4 in Situ Metal Matrix Composite from Silica Gel. J. Am. Ceram. Soc. 2007, 90, 2905–2911. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, J. Metal Matrix Composites: Production by the Stir Casting Method. J. Mater. Process. Technol. 1999, 92–93, 1–7. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Du, Y.H.; Zhang, P. Vortex-Free Stir Casting of Al-1.5 wt% Si-SiC Composite. J. Alloys Compd. 2019, 787, 206–215. [Google Scholar] [CrossRef]

- Lu, Y.; Du, Y.; Zhang, W.; Tan, H.; Zhang, N.; Luo, Y.; Zhang, P. Nano-Al2O3 Particle Incorporated in Al Matrix Composite by Vortex-Free High-Speed Stir Casting. Int. J. Met. 2024, 19, 761–776. [Google Scholar] [CrossRef]

- Li, M.; Gao, T.; Li, C.; Sun, Y.; Wu, Y.; Liu, X. On the Nano–Treating Effect of Al2O3 on the Eutectic Si in Al–Si Alloy. Micron 2023, 168, 103443. [Google Scholar] [CrossRef]

- Campbell, J. Entrainment. In Complete Casting Handbook; Butterworth-Heinemann: Oxford, UK, 2015; pp. 17–90. [Google Scholar] [CrossRef]

- Bale, C.W.; Bélisle, E.; Chartrand, P.; Decterov, S.A.; Eriksson, G.; Gheribi, A.E.; Hack, K.; Jung, I.H.; Kang, Y.B.; Melançon, J.; et al. FactSage Thermochemical Software and Databases, 2010–2016. CALPHAD 2016, 54, 35–53. [Google Scholar] [CrossRef]

| Intermetallic | Oxide(s) | Method | References |

|---|---|---|---|

| α-Al15(Fe,Mn)3Si2 | α- and γ-Al2O3, MgAl2O4, MgO | Lattice misfit calculations | [211,213] |

| Al3(Zr,Ti) | γ-Al2O3 | TEM observation, lattice misfit calculations | [226] |

| β-Al7Cu2Fe | MgAl2O4, MgO | Lattice misfit calculations | [227] |

| η-Al6(Fe,Mn) | MgO | Lattice misfit calculations | [228] |

| θ-Al13Fe4 | MgAl2O4 | TEM observation, lattice misfit calculations | [229] |

| θ-Al13Fe4 | Sc2O3 | Lattice misfit calculations | [230] |

| Al3Ti | α-Al2O3 | TEM observation, edge-to-edge matching model | [139] |

| (Al,Si)3Ti | MgAl2O4, MgO | Edge-to-edge matching model | [169] |

| Al3Zr | γ-Al2O3 | Lattice misfit calculations | [231] |

| Al2Cu | γ-Al2O3 | TEM observation | [232] |

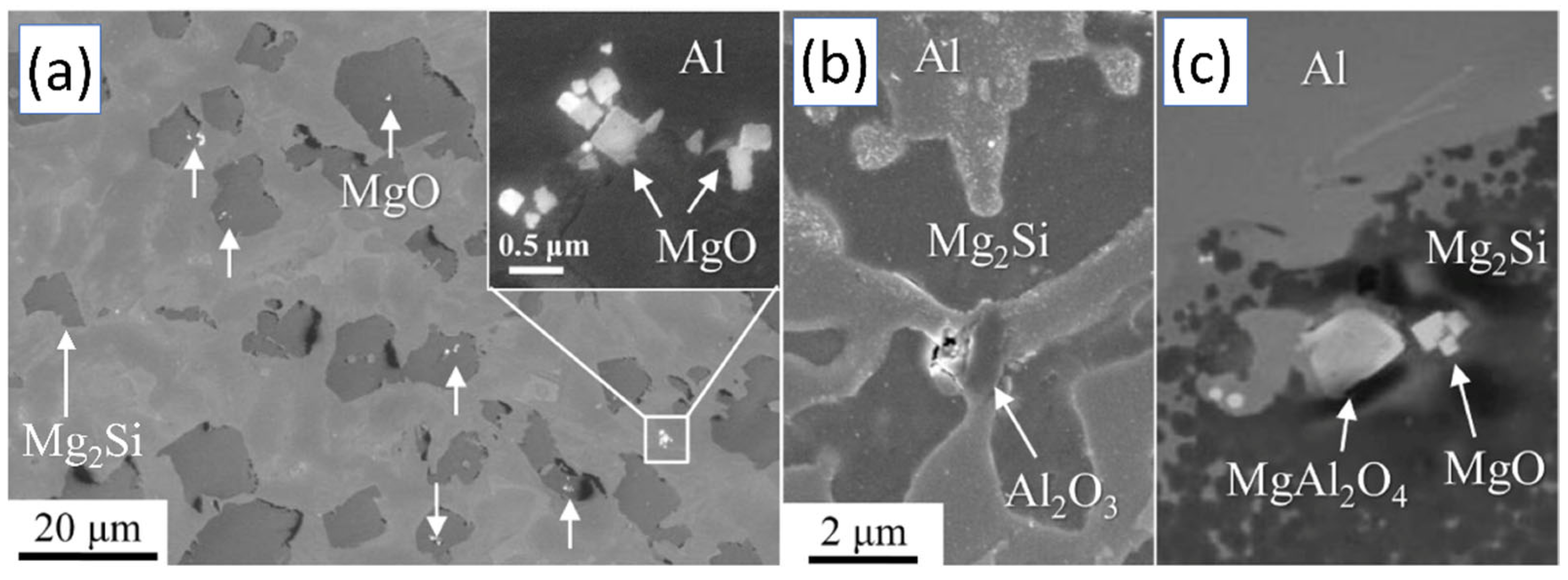

| Mg2Si | MgO | TEM observation, lattice misfit calculations, first-principles interfacial energy calculations | [233] |

| Al2CaSi2 | α- and γ-Al2O3 | Lattice misfit calculations | [234] |

| SrAl2Si2 | γ-Al2O3, MgAl2O4 | Lattice misfit calculations | [235] |

| Mo(Si,Al)2 | MgAl2O4 | Lattice misfit calculations | [236] |

| Main Phenomenon |

|

| Technological Significance |

|

| Challenges and Potential for Future Research |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gyarmati, G.; Erdélyi, J. Intermetallic Phase Control in Cast Aluminum Alloys by Utilizing Heterogeneous Nucleation on Oxides. Metals 2025, 15, 404. https://doi.org/10.3390/met15040404

Gyarmati G, Erdélyi J. Intermetallic Phase Control in Cast Aluminum Alloys by Utilizing Heterogeneous Nucleation on Oxides. Metals. 2025; 15(4):404. https://doi.org/10.3390/met15040404

Chicago/Turabian StyleGyarmati, Gábor, and János Erdélyi. 2025. "Intermetallic Phase Control in Cast Aluminum Alloys by Utilizing Heterogeneous Nucleation on Oxides" Metals 15, no. 4: 404. https://doi.org/10.3390/met15040404

APA StyleGyarmati, G., & Erdélyi, J. (2025). Intermetallic Phase Control in Cast Aluminum Alloys by Utilizing Heterogeneous Nucleation on Oxides. Metals, 15(4), 404. https://doi.org/10.3390/met15040404