Effect of Heat Treatment on Microstructure and Residual Stress of a Nickel-Cobalt-Based Superalloy Produced by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

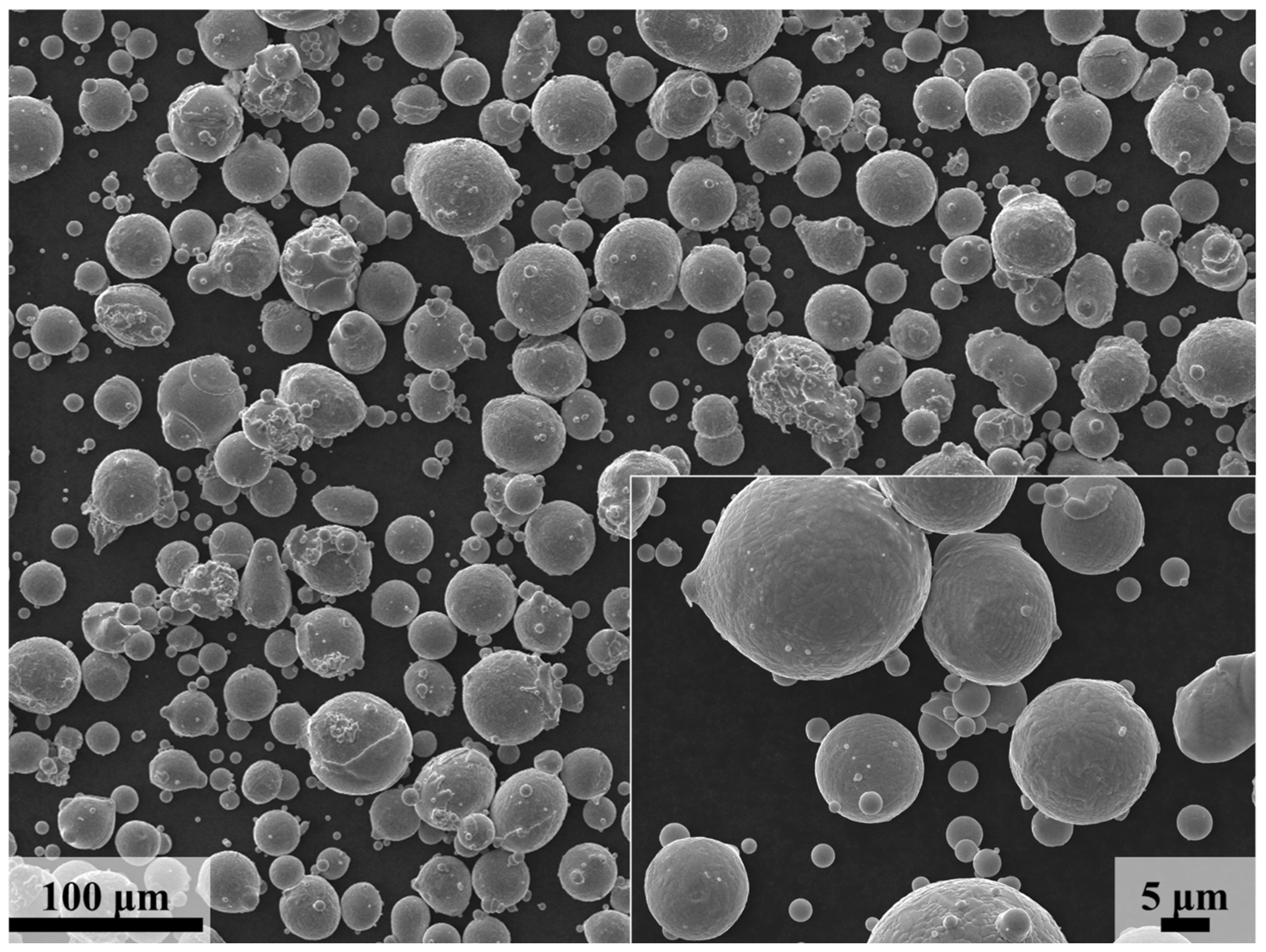

2.1. Materials

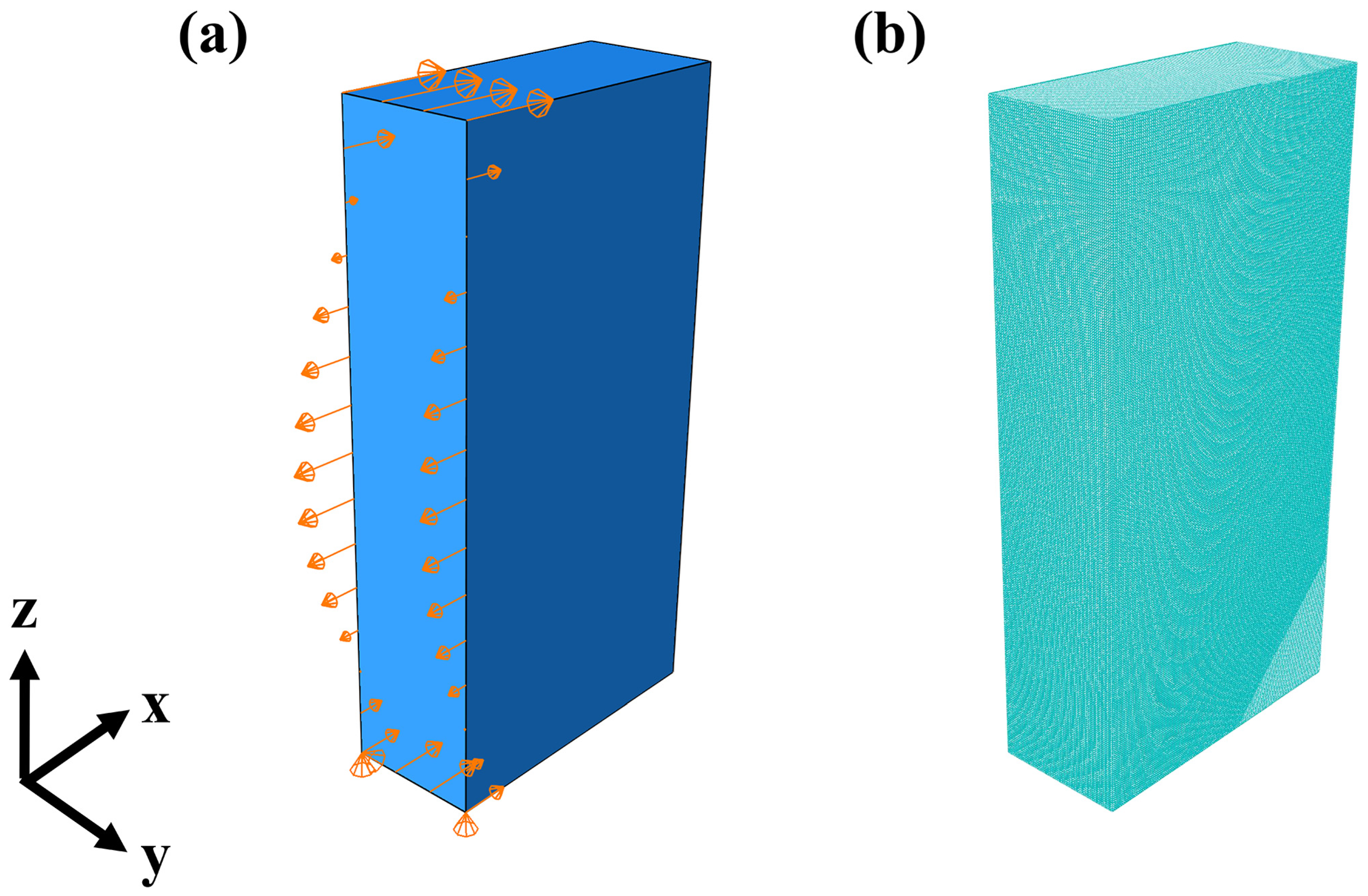

2.2. Measurements of Residual Stresses

2.3. Microstructural Characterization

3. Results

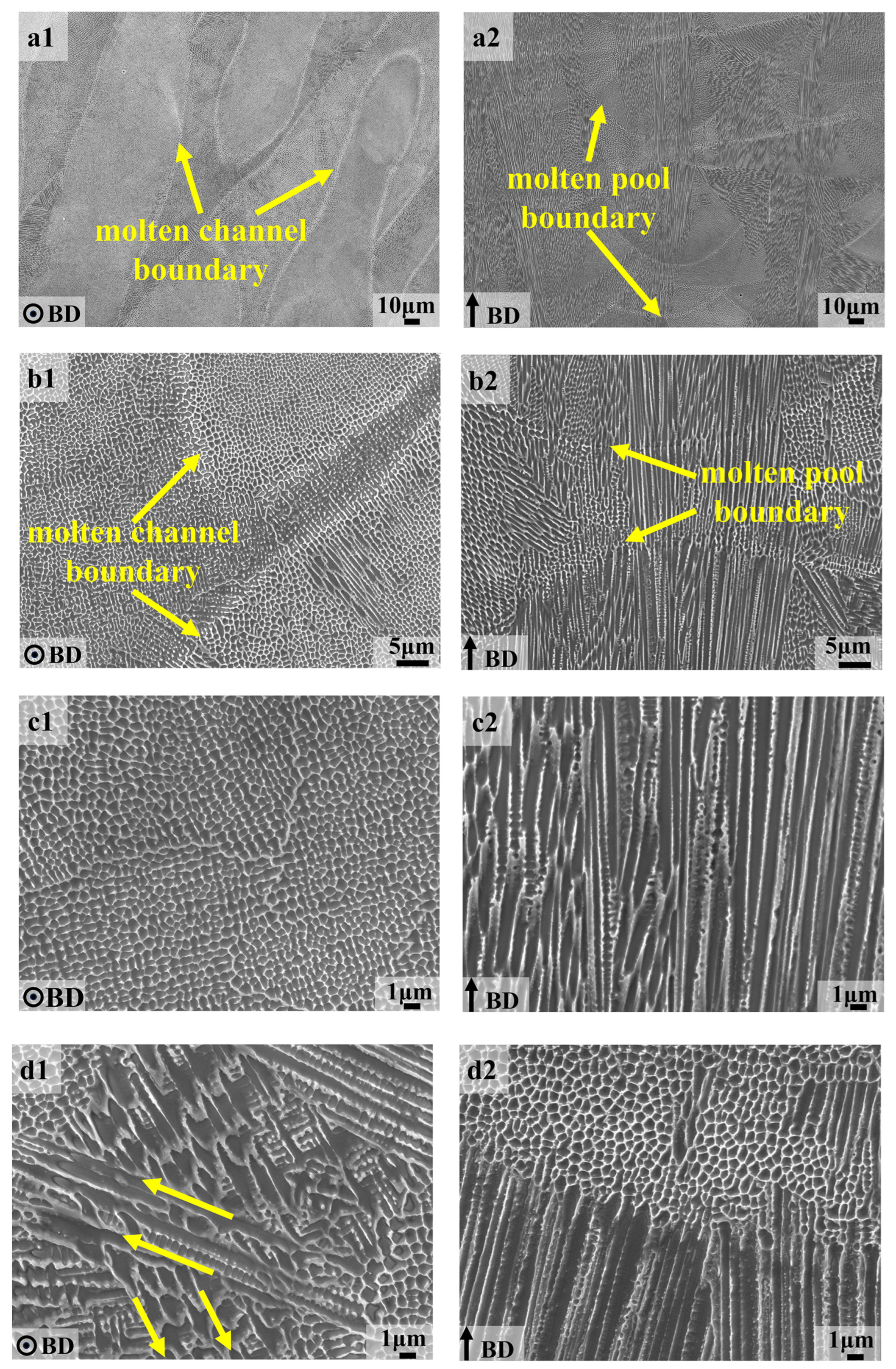

3.1. Microstructural Analysis

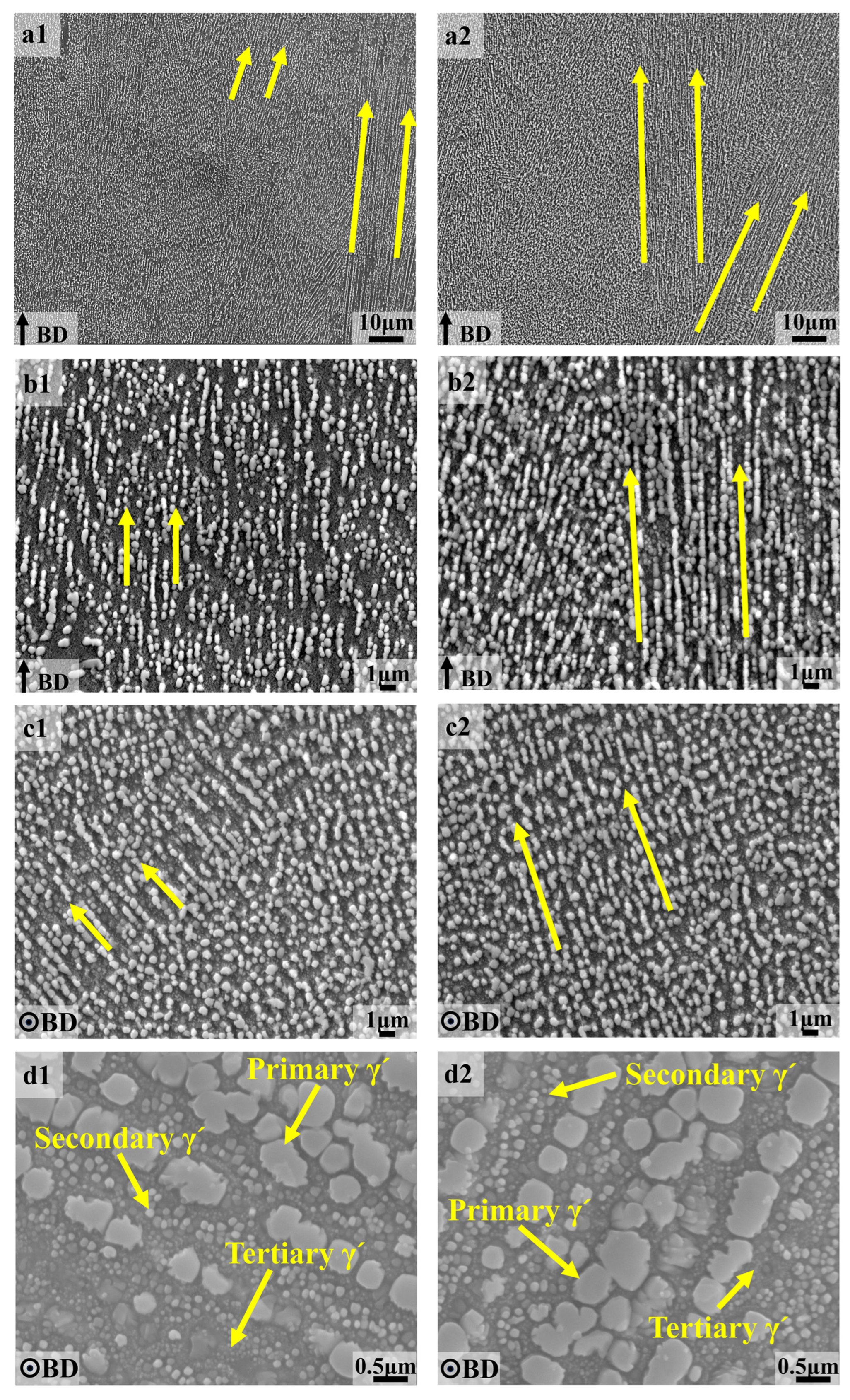

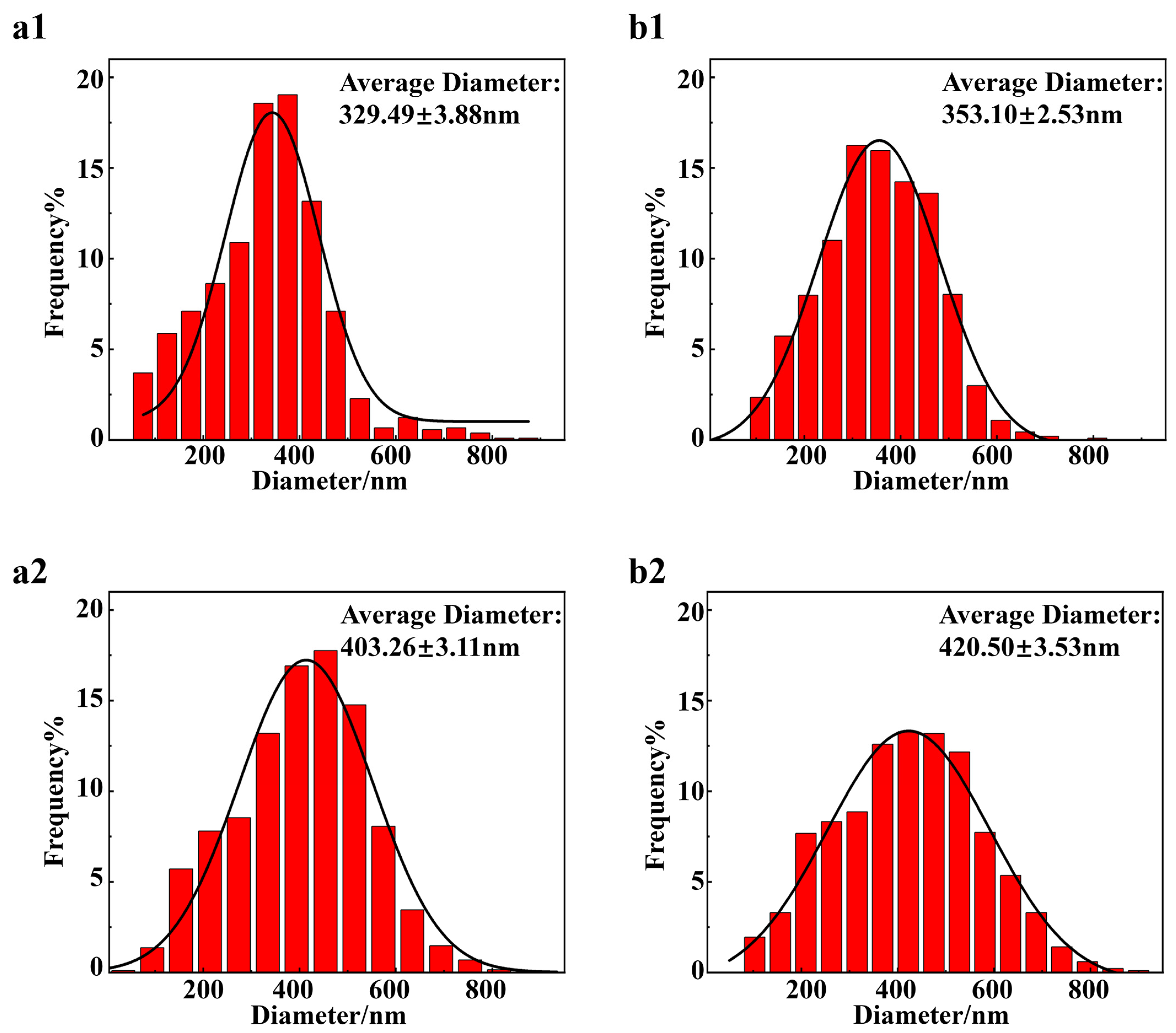

3.2. γ′ Phase Characteristics

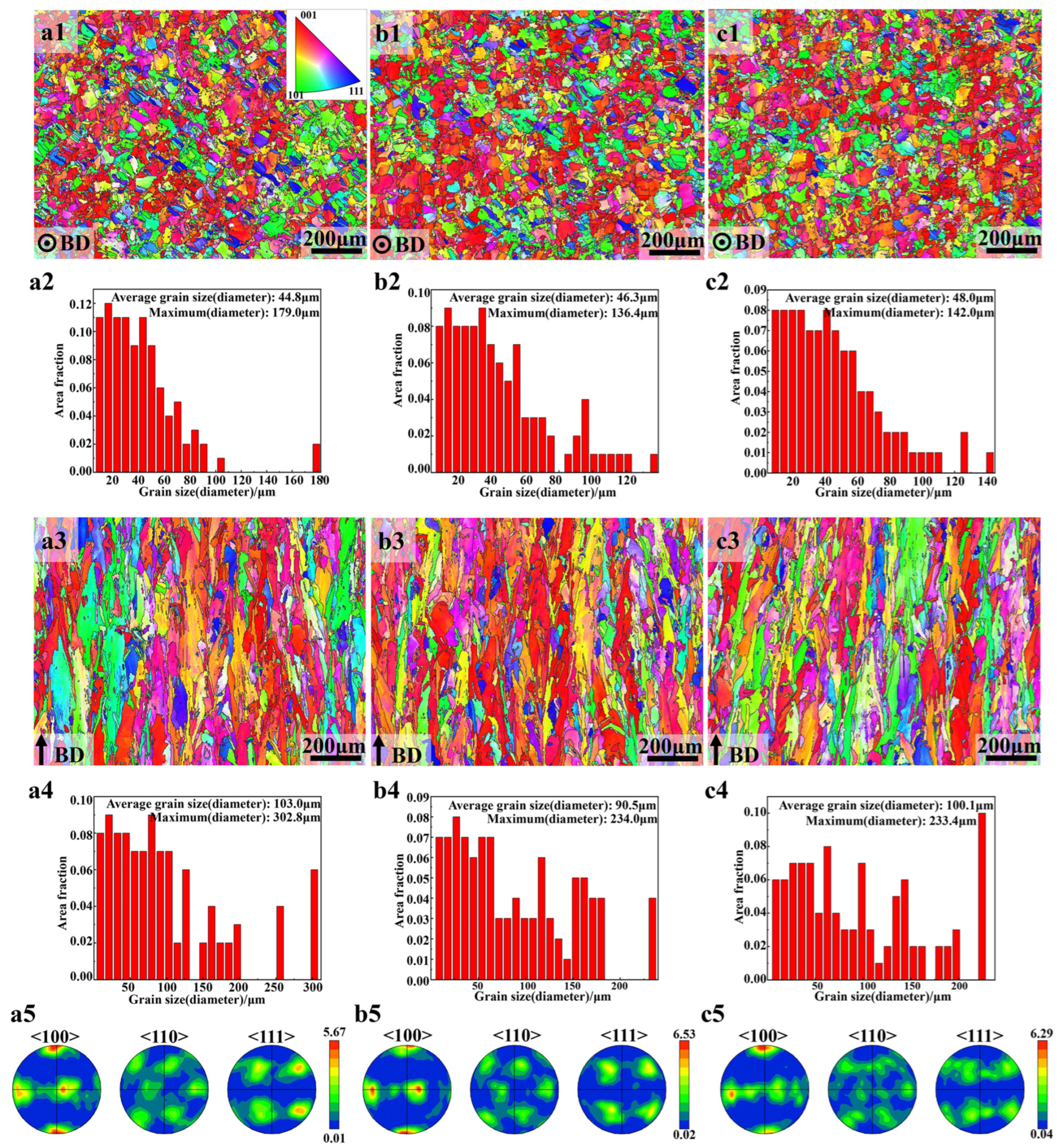

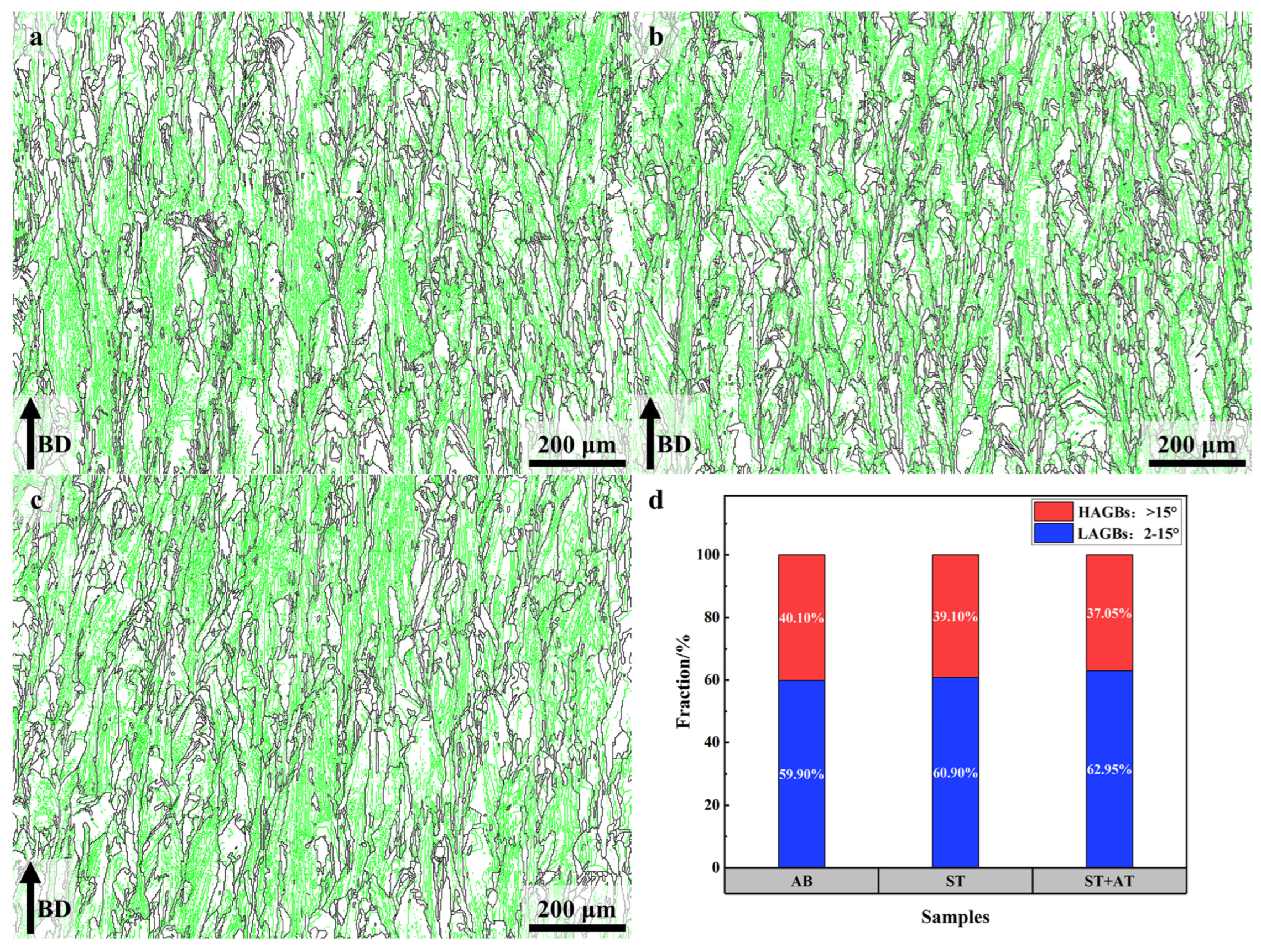

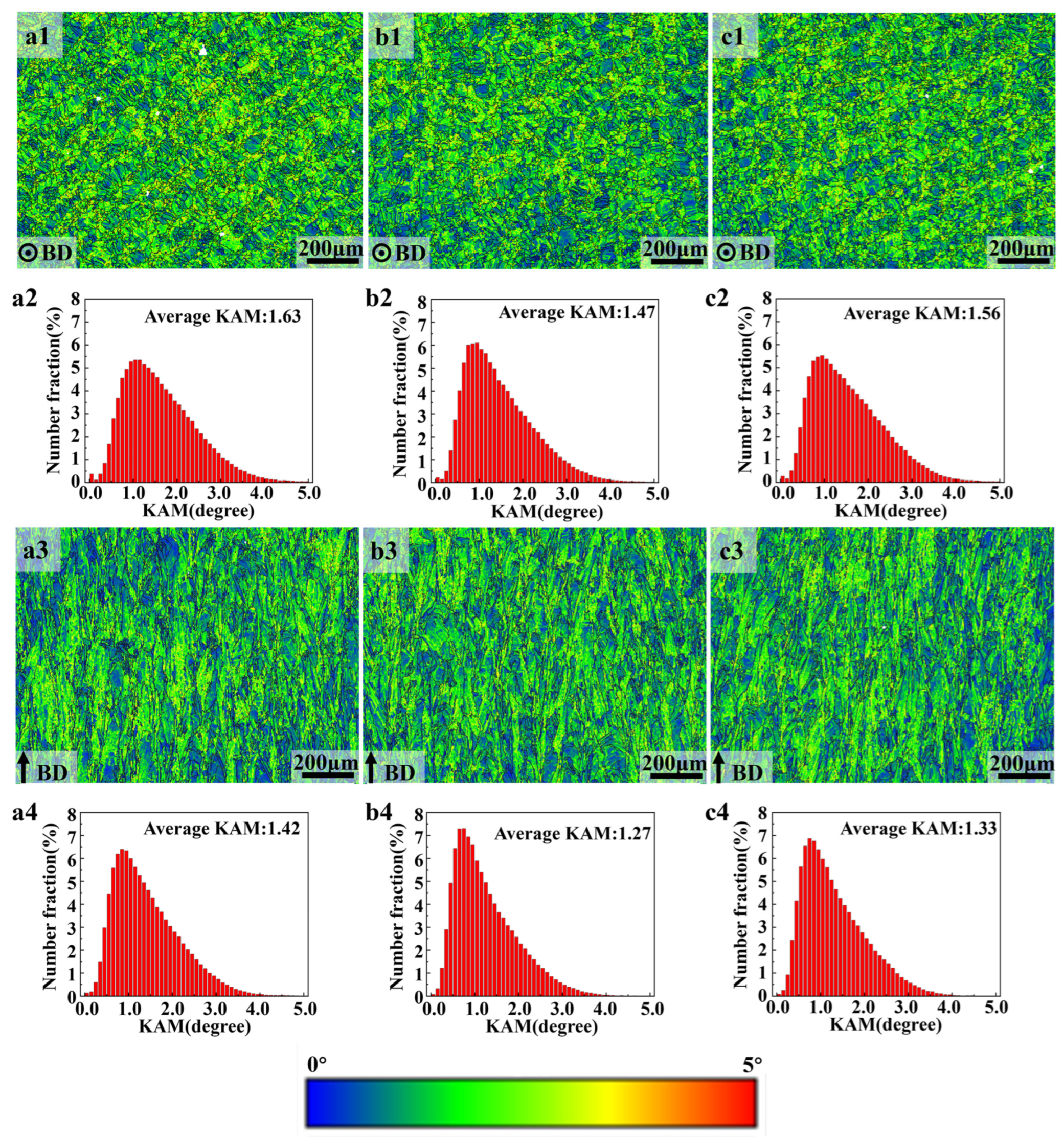

3.3. Grain Characteristics

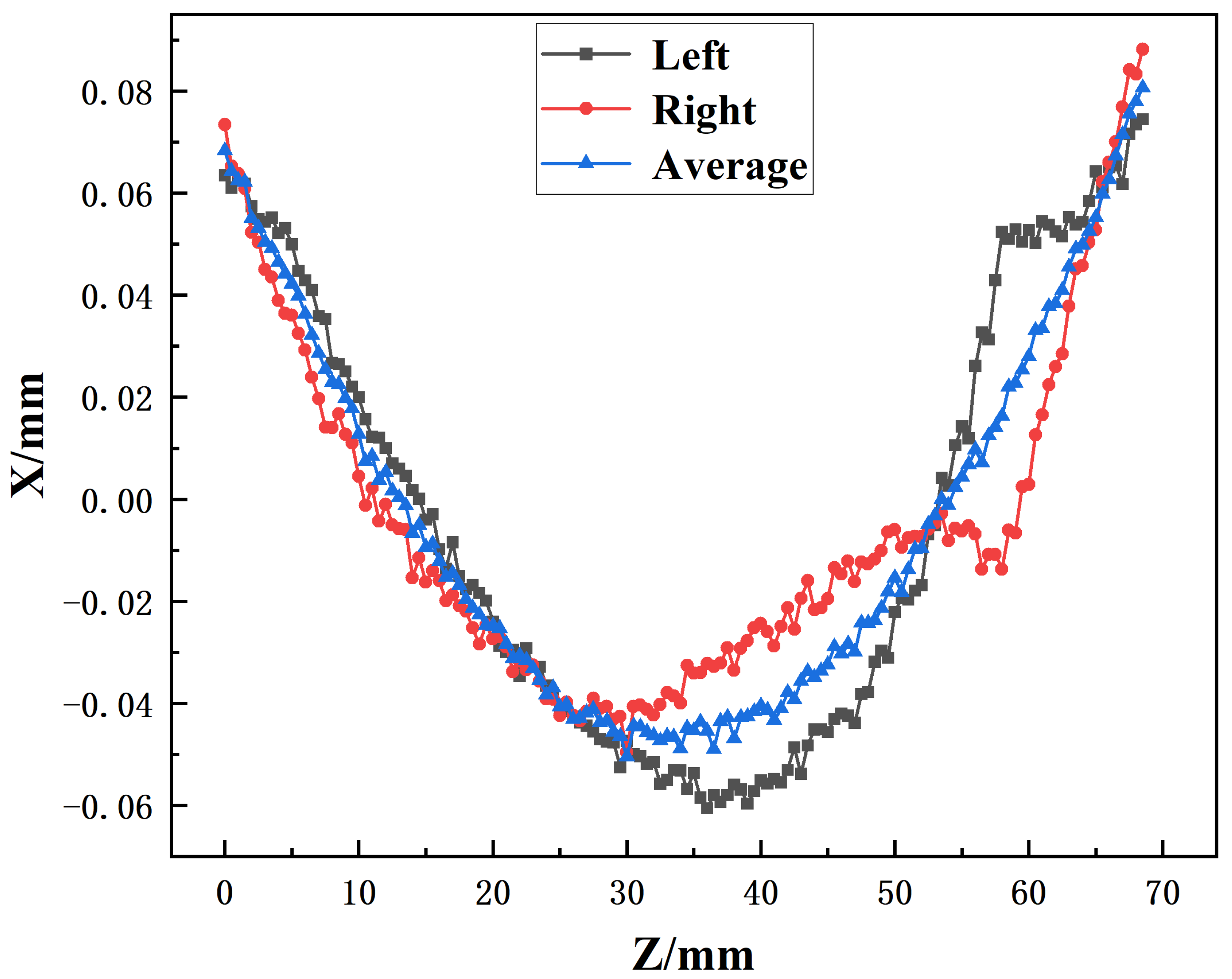

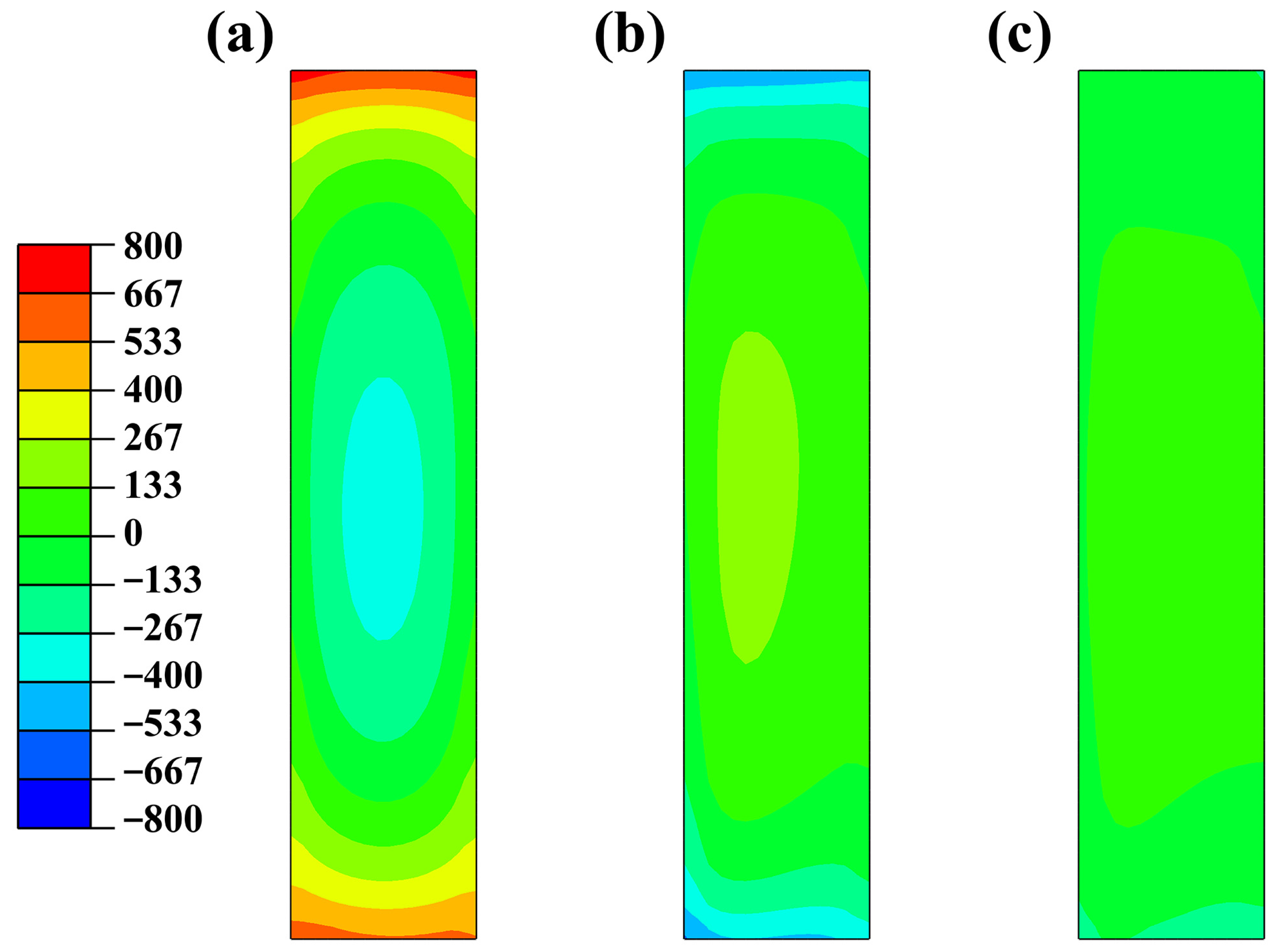

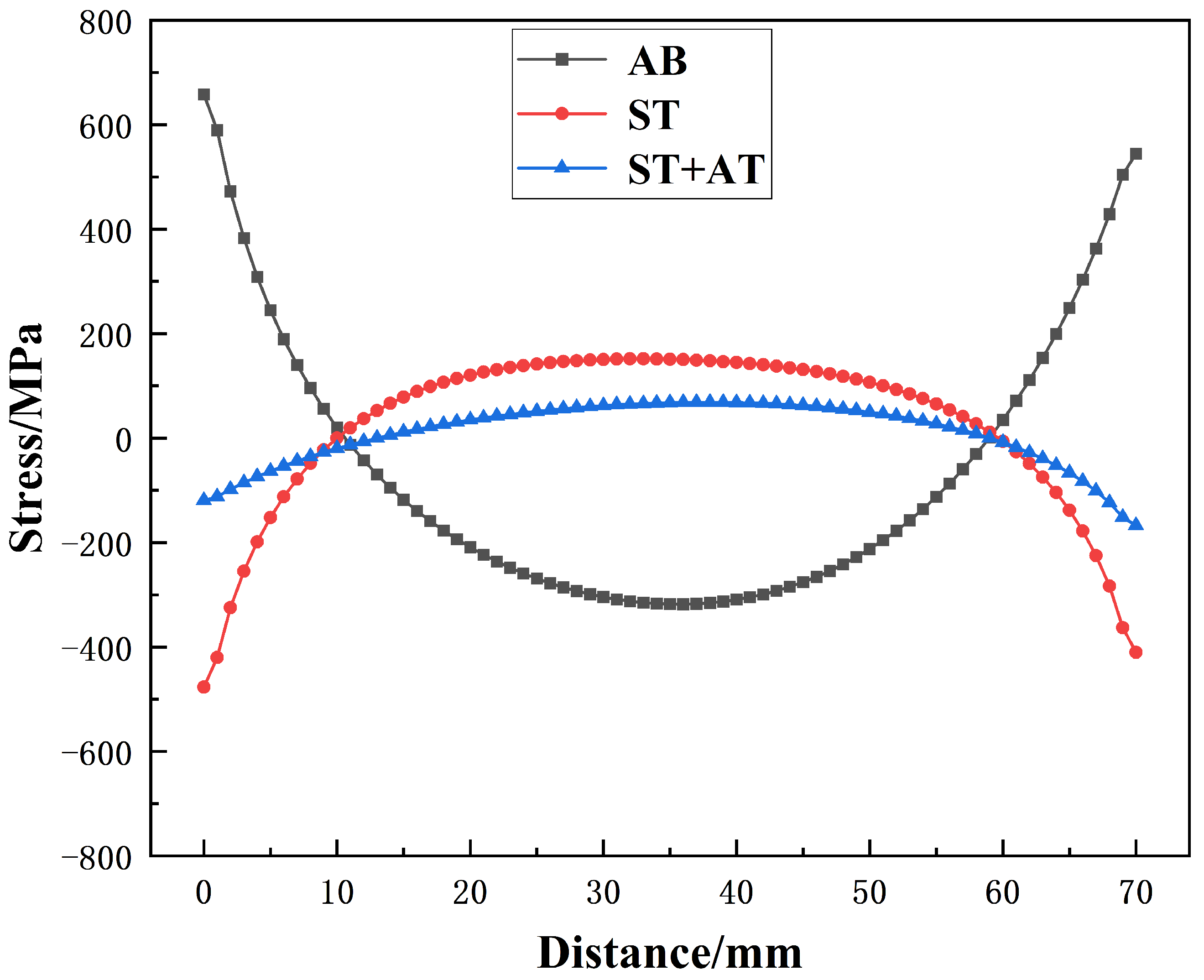

3.4. Residual Stress

4. Discussion

5. Conclusions

- The as-built Ni-Co-based superalloy primarily consists of a single γ phase without the generation of the γ′ phase. In addition, cellular and columnar sub-grain structures can be observed in both the horizontal and vertical planes. EBSD results show that columnar crystals predominate in the vertical section, whereas equiaxed crystals are more prevalent in the horizontal section. Furthermore, the average dimensions of the columnar crystals exceed those of the equiaxed crystals, as well as the width of an individual molten pool. The contour test results show that there is a significant level of residual stress (maximum tensile stress: 757 MPa) in the as-built Ni-Co-based superalloy, and this residual stress is in the form of external tensile stress and internal compressive stress.

- After solution treatment, the cellular/columnar substructure in the nickel-cobalt-based superalloy disappears, while the γ′ phase precipitates in large quantities. The columnar grains in the vertical section are equiaxed and refined due to recrystallization. In addition, the high level of residual stress in the alloy acts as a driving force for recrystallization and γ′ phase nucleation during the solution treatment process, which is greatly reduced after the solution treatment. Consequently, the ST sample exhibited a lower residual stress level internally, with a maximum tensile stress of 163 MPa.

- After aging treatment, the average size of the γ′ phase in the alloy increases compared with the ST sample, which inhibits the recrystallization process. The growth of recrystallized grains and the random merging between grains during aging treatment led to an increase in average grain size. In addition, the random coalescence between grains also leads to the relaxation of intergranular residual stress, and the ST + AT sample exhibits a reduced level of residual stress (maximum tensile stress: 71 MPa).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, Y.; Zhang, R.; Cui, C.; Zhou, Y.; Sun, X. In-situ observation of Ni-Co based wrought superalloy high-temperature deformation: Lattice rotation and grain boundary response. Mater. Res. Lett. 2024, 12, 869–876. [Google Scholar]

- Kalahroudi, F.J.; Lin, F.; Krakhmalev, P.; Grehk, M. Microstructure and Fatigue Behavior of PM-HIPed Ni-Based Superalloys and Martensitic Tool Steels: A Review. Metals 2024, 14, 1159. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, J.; Zhang, X.; Zheng, J.; Hui, X. The Effects of Microstructure on the Thermophysical Properties of the K439B Ni-Based Superalloy. Metals 2024, 14, 1074. [Google Scholar] [CrossRef]

- Hu, J.-C.; Huang, H.-L.; Wu, C.-C.; Sun, X.-Y.; Wang, J.; Yang, Y.-H.; Qu, J.-L.; Jiang, L.; Dou, J.-H.; Chen, Y. Oxidation behavior of Ni-based superalloy GH4738 under tensile stress. Rare Metals 2024, 43, 3913–3920. [Google Scholar]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.-T.; Strayer, S.; Chang, K.-C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.-C.; Tin, S.; et al. Additive manufacturing of nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar]

- Li, Y.; Jiang, D.; Zhu, R.; Yang, C.; Wang, L.; Zhang, L.-C. Revolutionizing medical implant fabrication: Advances in additive manufacturing of biomedical metals. Int. J. Extrem. Manuf. 2024, 7, 022002. [Google Scholar]

- Mannava, V.; Saravanan, T.; Sabari, S.R.; Koundinya, N.; Venugopal, A.; Murty, S.; Govind, B.; Kamaraj, M.; Kottada, R.S. A distinct role of microstructure on hot corrosion behaviour of additively manufactured IN718. Corros. Sci. 2024, 241, 112550. [Google Scholar]

- Prabhu, T.R.; Moganraj, A.; Samuel, M.S.; Praveenkumar, K.; Bobby, S.S.; Prakasam, A. Effect of heat treatment on microstructure and high-temperature wear performance of additive manufactured IN718. J. Manuf. Process. 2024, 127, 683–697. [Google Scholar]

- Wang, H.; Li, B.; Lei, L.; Xuan, F. Multi-physics information-integrated neural network for fatigue life prediction of additively manufactured Hastelloy X superalloy. Virtual Phys. Prototyp. 2024, 19, e2368652. [Google Scholar]

- Tekoglu, E.; Bae, J.-S.; Kim, H.-A.; Lim, K.-H.; Liu, J.; Doležal, T.D.; Kim, S.Y.; Alrizqi, M.A.; Penn, A.; Chen, W.; et al. Superior high-temperature mechanical properties and microstructural features of LPBF-printed In625-based metal matrix composites. Mater. Today 2024, 80, 297–307. [Google Scholar]

- Basak, A. Additive Manufacturing of High-Gamma Prime Nickel-Based Superalloys Through Selective Laser Melting (SLM); University of Texas at Austin: Austin, TX, USA, 2019. [Google Scholar]

- Zhang, F.; Zhou, L.; Xie, X.; Zhang, Z.; Chao, Q.; Fan, G. Crack inhibition and crystallographic texture control in an additively manufactured IN738LC Ni-based superalloy. J. Mater. Res. Technol. 2024, 33, 652–666. [Google Scholar] [CrossRef]

- Guo, C.; Li, S.; Shi, S.; Li, X.; Hu, X.; Zhu, Q.; Ward, R.M. Effect of processing parameters on surface roughness, porosity and cracking of as-built IN738LC parts fabricated by laser powder bed fusion. J. Mater. Process. Technol. 2020, 285, 116788. [Google Scholar] [CrossRef]

- Parent, P.-N.; Paris, J.-Y.; Alexis, J.; Boher, C. Influence of the scanning strategy on the microstructure and the tribological behavior of a Ni-based superalloy processed by L-PBF additive manufacturing. Wear 2025, 564, 205671. [Google Scholar]

- Xu, J.; Ding, Y.; Gao, Y.; Wang, H.; Hu, Y.; Zhang, D. Grain refinement and crack inhibition of hard-to-weld Inconel 738 alloy by altering the scanning strategy during selective laser melting. Mater. Des. 2021, 209, 109940. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; Gao, X.; Wen, X.; Qiao, S.; Yuan, C. Insights into process optimization and induction preheating for crack-free laser metal deposition of nickel-based superalloy K417G. J. Mater. Res. Technol. 2024, 29, 2035–2050. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Prime, M.B. Cross-sectional mapping of residual stresses by measuring the surface contour after a cut. J. Eng. Mater. Technol. 2001, 123, 162–168. [Google Scholar]

- Bueckner, H.F. The propagation of cracks and the energy of elastic deformation. Trans. Am. Soc. Mech. Eng. 1958, 80, 1225–1229. [Google Scholar] [CrossRef]

- Pollard, J.; Rahimi, S.; Watford, A.; Jackson, M.; Wynne, B. The Determination of Residual Stress in Extruded Ti-6Al-4V by Contour Method and Finite Element Analysis. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; Wiley Online Library: Hoboken, NJ, USA, 2016. [Google Scholar]

- Danis, Y.; Lacoste, E.; Arvieu, C. Numerical modeling of inconel 738LC deposition welding: Prediction of residual stress induced cracking. J. Mater. Process. Technol. 2010, 210, 2053–2061. [Google Scholar] [CrossRef]

- Popov, V.; Katz-Demyanetz, A.; Bamberger, M. Heat transfer and phase formation through EBM 3D-printing of Ti-6Al-4V cylindrical parts. in Defect and diffusion forum. Defect Diffus. Forum 2018, 383, 190–195. [Google Scholar] [CrossRef]

- Grange, D.; Bartout, J.-D.; Macquaire, B.; Colin, C. Processing a non-weldable nickel-base superalloy by Selective Laser Melting: Role of the shape and size of the melt pools on solidification cracking. Materialia 2020, 12, 100686. [Google Scholar]

- Zhang, X.; Liang, Y.; Yi, F.; Liu, H.; Zhou, Q.; Yan, Z.; Lin, J. Anisotropy in microstructure and mechanical properties of additively manufactured Ni-based GH4099 alloy. J. Mater. Res. Technol. 2023, 26, 6552–6564. [Google Scholar]

- Dong, J.; Yu, H.; Cao, R.; Liu, Z.; Wang, X.; Wang, J.; Bi, Z. The effect of pre-strain on textures, nano-twins and mechanical properties of a novel Nickel-based superalloy GH4251 with low stacking fault energy. Mater. Sci. Eng. A 2024, 915, 147271. [Google Scholar]

- Cao, Y.; Bai, P.; Liu, F.; Hou, X. Grain growth in IN718 superalloy fabricated by laser additive manufacturing. Mater. Sci. Technol. 2020, 36, 765–769. [Google Scholar]

- Wang, Y.; Shi, J.; Liu, Y. Competitive grain growth and dendrite morphology evolution in selective laser melting of Inconel 718 superalloy. J. Cryst. Growth 2019, 521, 15–29. [Google Scholar]

- Zinovieva, O.; Zinoviev, A.; Ploshikhin, V. Three-dimensional modeling of the microstructure evolution during metal additive manufacturing. Comput. Mater. Sci. 2018, 141, 207–220. [Google Scholar]

- Zhang, X.; Xu, H.; Li, Z.; Dong, A.; Du, D.; Lei, L.; Zhang, G.; Wang, D.; Zhu, G.; Sun, B. Effect of the scanning strategy on microstructure and mechanical anisotropy of Hastelloy X superalloy produced by Laser Powder Bed Fusion. Mater. Charact. 2021, 173, 110951. [Google Scholar]

- Sharma, J.; Nicolaÿ, A.; De Graef, M.; Bozzolo, N. Phase discrimination between δ and η phases in the new nickel-based superalloy VDM Alloy 780 using EBSD. Mater. Charact. 2021, 176, 111105. [Google Scholar]

- Zhang, Z.; Han, Q.; Yang, S.; Yin, Y.; Gao, J.; Setchi, R. Laser powder bed fusion of advanced submicrometer TiB2 reinforced high-performance Ni-based composite. Mater. Sci. Eng. A 2021, 817, 141416. [Google Scholar]

- Zhang, H.; Chen, K.; Lin, S.; Fu, R.; Zhang, B.; Ding, J.; Feng, Z.; Huang, X.; Ma, E. Recovery facilitated by interphase boundary motion circumvents recrystallization in superalloy single crystals. Mater. Res. Lett. 2024, 12, 180–189. [Google Scholar]

- Buerstmayr, R.; Theska, F.; Kozeschnik, E.; Webster, R.F.; Lison-Pick, M.; Street, S.; Primig, S. Investigation and simulation of the effects of nm-scale γ′ Precipitates on the recrystallization of Ni-based superalloys. Metall. Mater. Trans. A 2023, 54, 2259–2276. [Google Scholar]

- Liang, S.; Yan, W. Study on the micro-structure and the nano-indentation responses of laser solid formed epitaxial Ni-based superalloy. J. Alloys Compd. 2022, 921, 166091. [Google Scholar]

- Chauvet, E.; Kontis, P.; Jägle, E.A.; Gault, B.; Raabe, D.; Tassin, C.; Blandin, J.-J.; Dendievel, R.; Vayre, B.; Abed, S.; et al. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron Beam Melting. Acta Mater. 2018, 142, 82–94. [Google Scholar]

- Betanda, Y.A.; Helbert, A.L.; Brisset, F.; Mathon, M.H.; Waeckerlé, T.; Baudin, T. Measurement of stored energy in Fe–48% Ni alloys strongly cold-rolled using three approaches: Neutron diffraction, Dillamore and KAM approaches. Mater. Sci. Eng. A 2014, 614, 193–198. [Google Scholar]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar]

- Zhao, Y.; Ma, Z.; Yu, L.; Liu, Y. New alloy design approach to inhibiting hot cracking in laser additive manufactured nickel-based superalloys. Acta Mater. 2023, 247, 118736. [Google Scholar]

| Elements | Wt.% |

|---|---|

| Ni | Bal |

| Cr | 12.0–14.0 |

| Co | 24.0–26.0 |

| W | 1.0–1.5 |

| Mo | 2.6–3.0 |

| C | 0.01–0.03 |

| Al + Ti | 6.5–7.4 |

| Nb + Ta | 0.8–2.0 |

| B + Zr | 0.02–0.08 |

| Specimen | Treatment Type | Treatment |

|---|---|---|

| AB | as-built | - |

| ST | solution treatment | 1070 °C/4 h/AC |

| ST + AT | solution treatment + aging treatment | 1070 °C/4 h/AC + 760 °C/16 h/AC |

| Specimen | Recrystallized | Sub-Structured Structure | Deformed |

|---|---|---|---|

| AB | 8.50% | 72.06% | 19.44% |

| ST | 9.54% | 74.09% | 16.37% |

| ST + AT | 8.08% | 69.71% | 22.21% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Zheng, R.; Liu, X.; Li, M.; Chen, D. Effect of Heat Treatment on Microstructure and Residual Stress of a Nickel-Cobalt-Based Superalloy Produced by Laser Powder Bed Fusion. Metals 2025, 15, 405. https://doi.org/10.3390/met15040405

Wang C, Zheng R, Liu X, Li M, Chen D. Effect of Heat Treatment on Microstructure and Residual Stress of a Nickel-Cobalt-Based Superalloy Produced by Laser Powder Bed Fusion. Metals. 2025; 15(4):405. https://doi.org/10.3390/met15040405

Chicago/Turabian StyleWang, Chengjun, Renren Zheng, Xiaolong Liu, Meijuan Li, and Dongfeng Chen. 2025. "Effect of Heat Treatment on Microstructure and Residual Stress of a Nickel-Cobalt-Based Superalloy Produced by Laser Powder Bed Fusion" Metals 15, no. 4: 405. https://doi.org/10.3390/met15040405

APA StyleWang, C., Zheng, R., Liu, X., Li, M., & Chen, D. (2025). Effect of Heat Treatment on Microstructure and Residual Stress of a Nickel-Cobalt-Based Superalloy Produced by Laser Powder Bed Fusion. Metals, 15(4), 405. https://doi.org/10.3390/met15040405