The Effect of Ti and Mo Microalloying on Hydrogen Embrittlement Resistance of Ultra-High Strength Medium Mn Steel

Abstract

1. Introduction

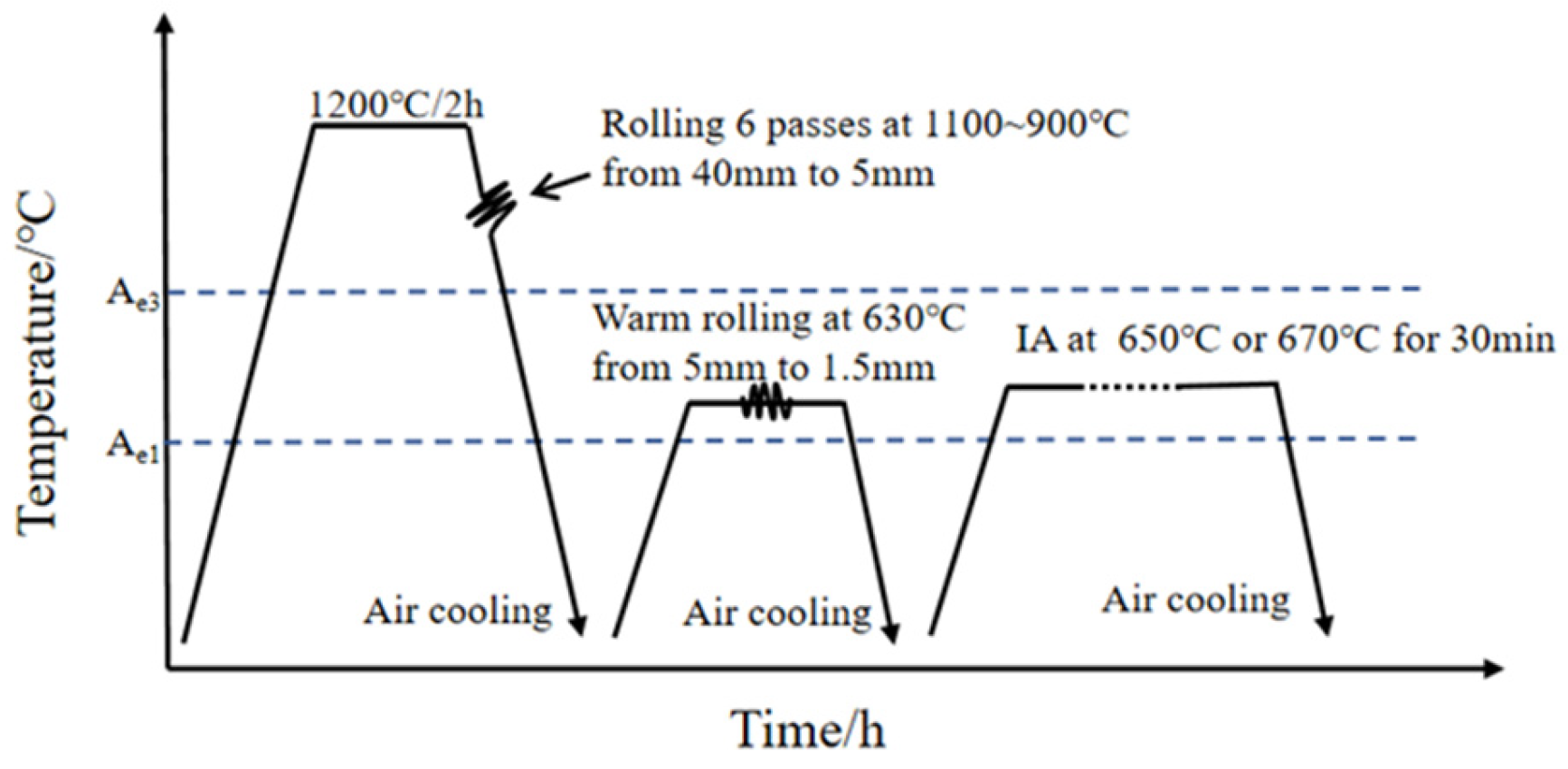

2. Experimental Procedure

2.1. Experimental Materials

2.2. Electrochemical Charging

2.3. Mechanical Properties Measurements

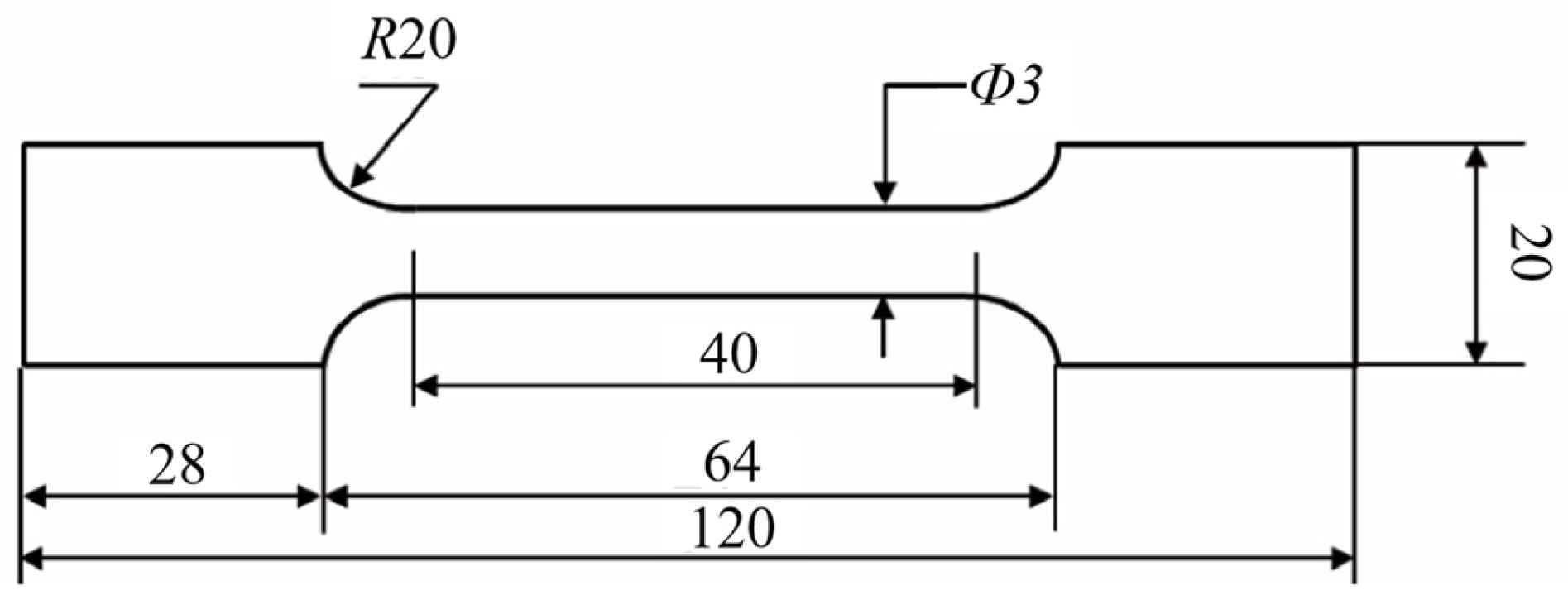

2.4. Slow-Strain Rate Tensile (SSRT) Tests

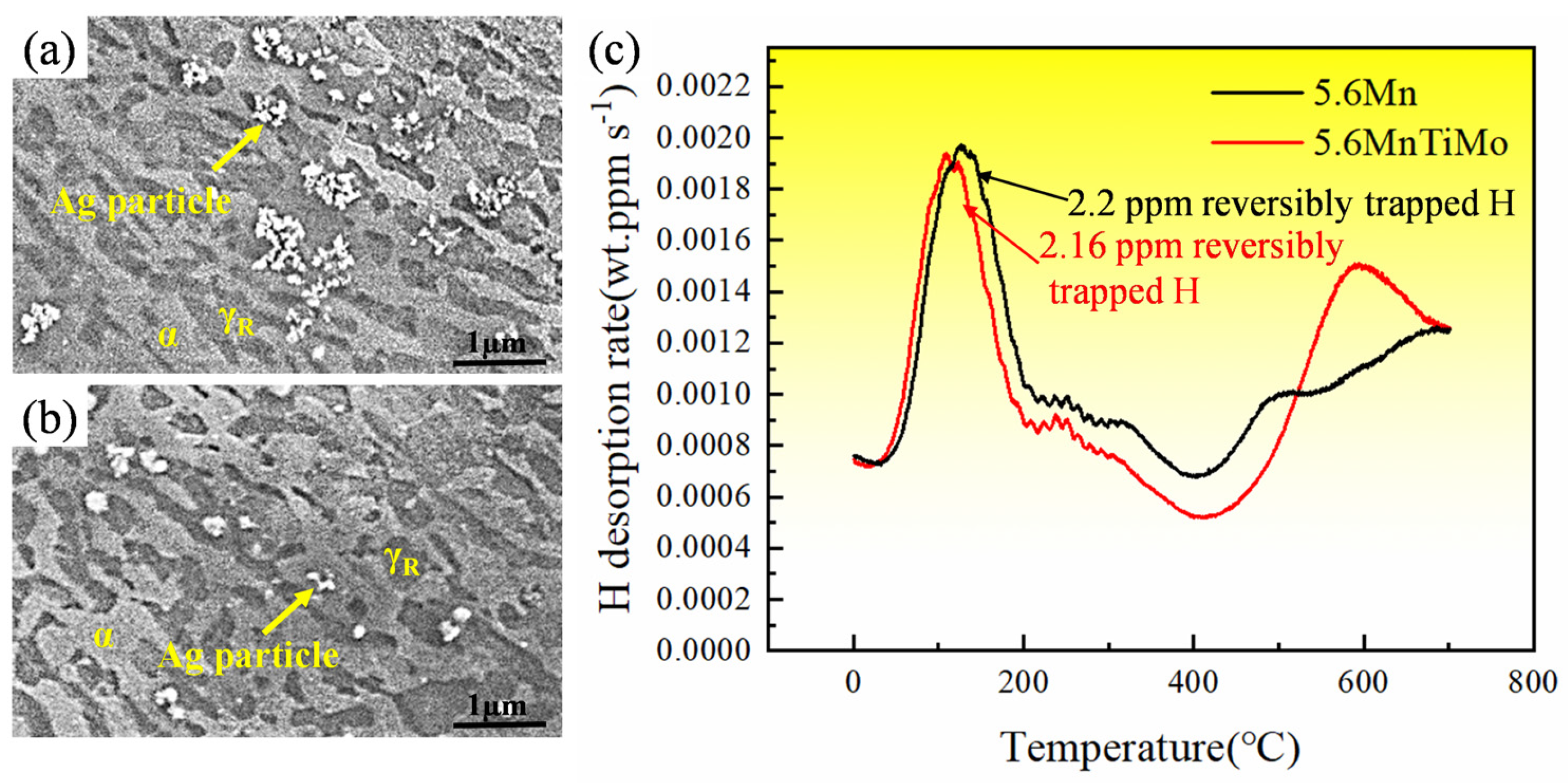

2.5. Hydrogen Content and Distribution Measurements

2.6. Microstructural Characterization

3. Experimental Results

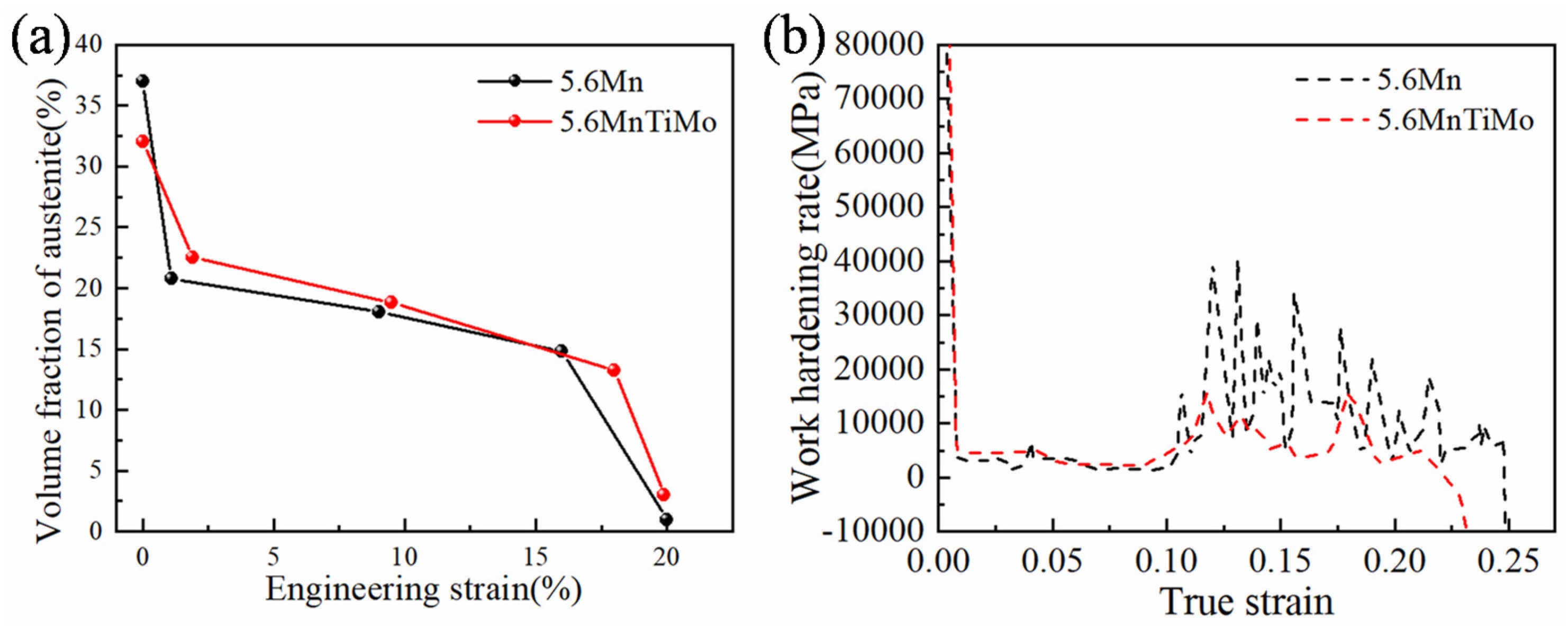

3.1. Mechanical Properties After Intercritical Annealing

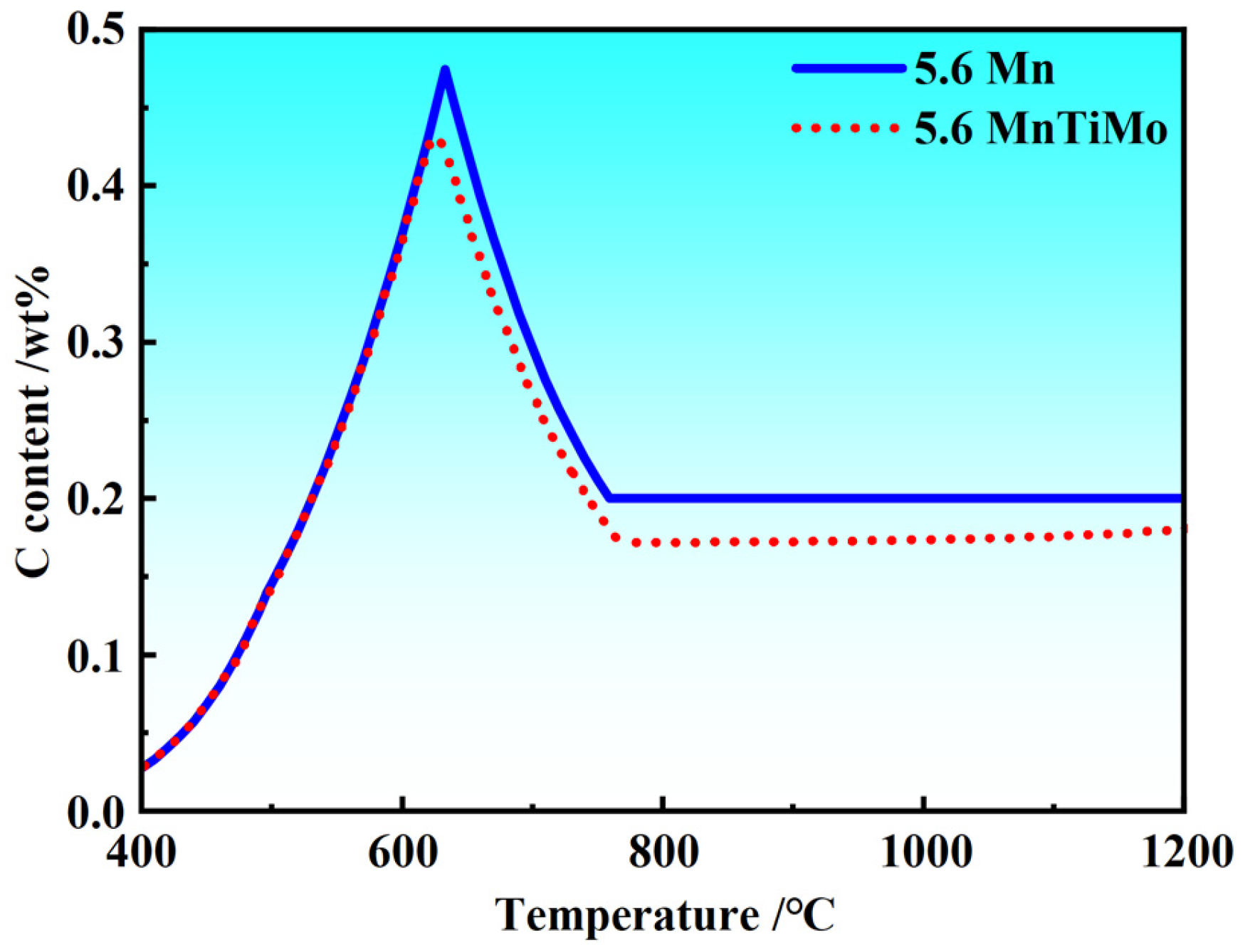

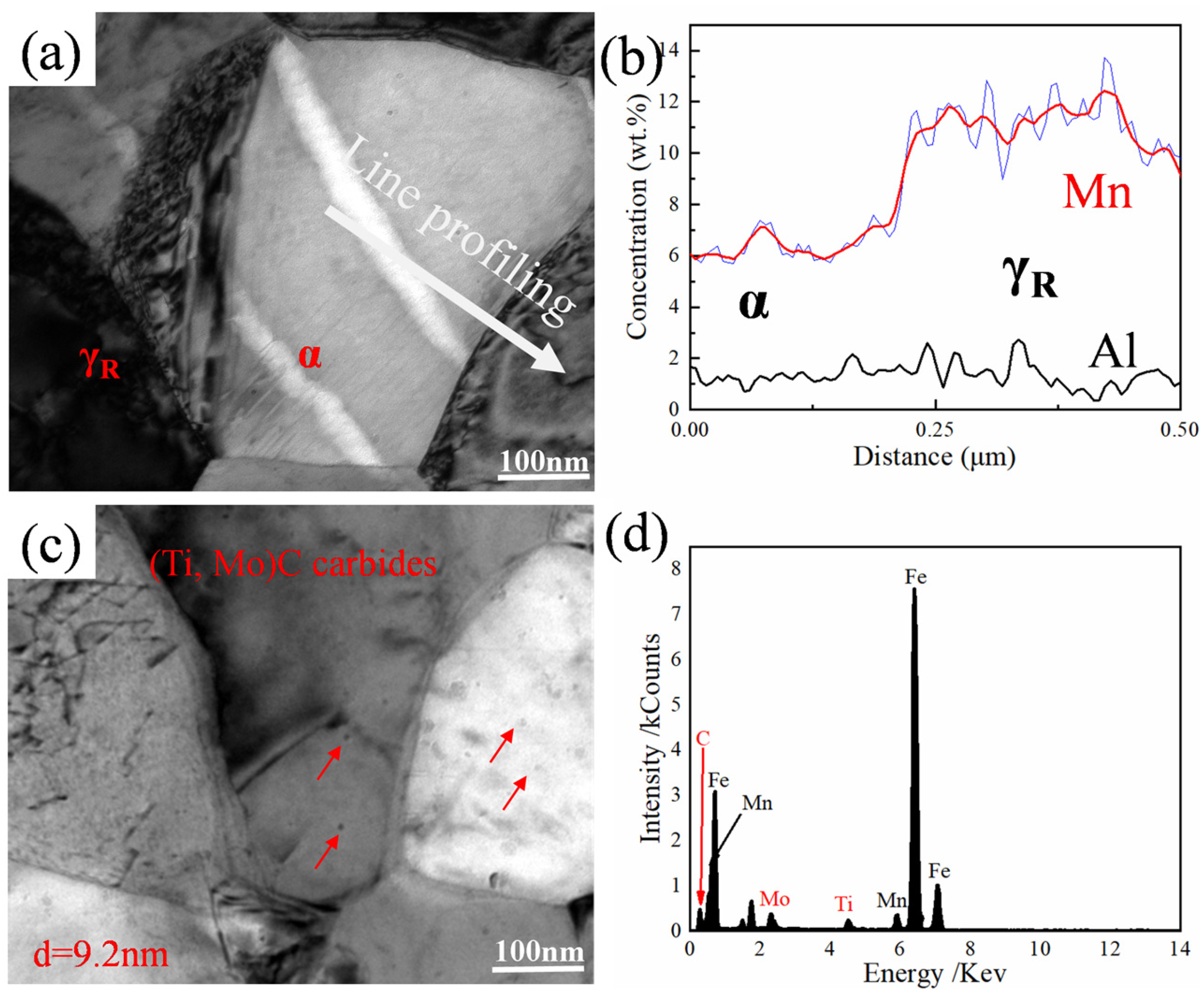

3.2. Microstructure After Intercritical Annealing

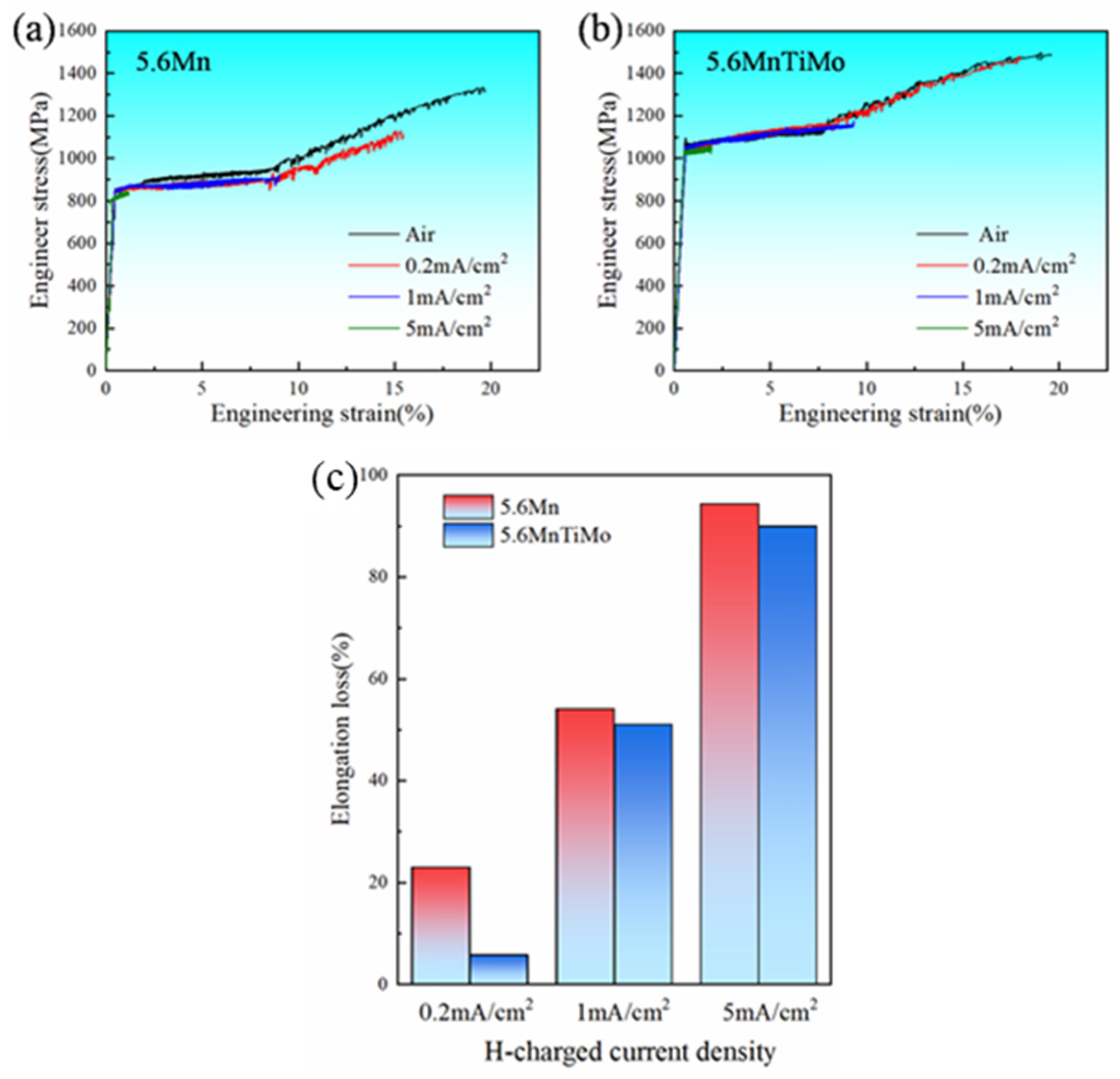

3.3. Hydrogen Embrittlement (HE) Resistance

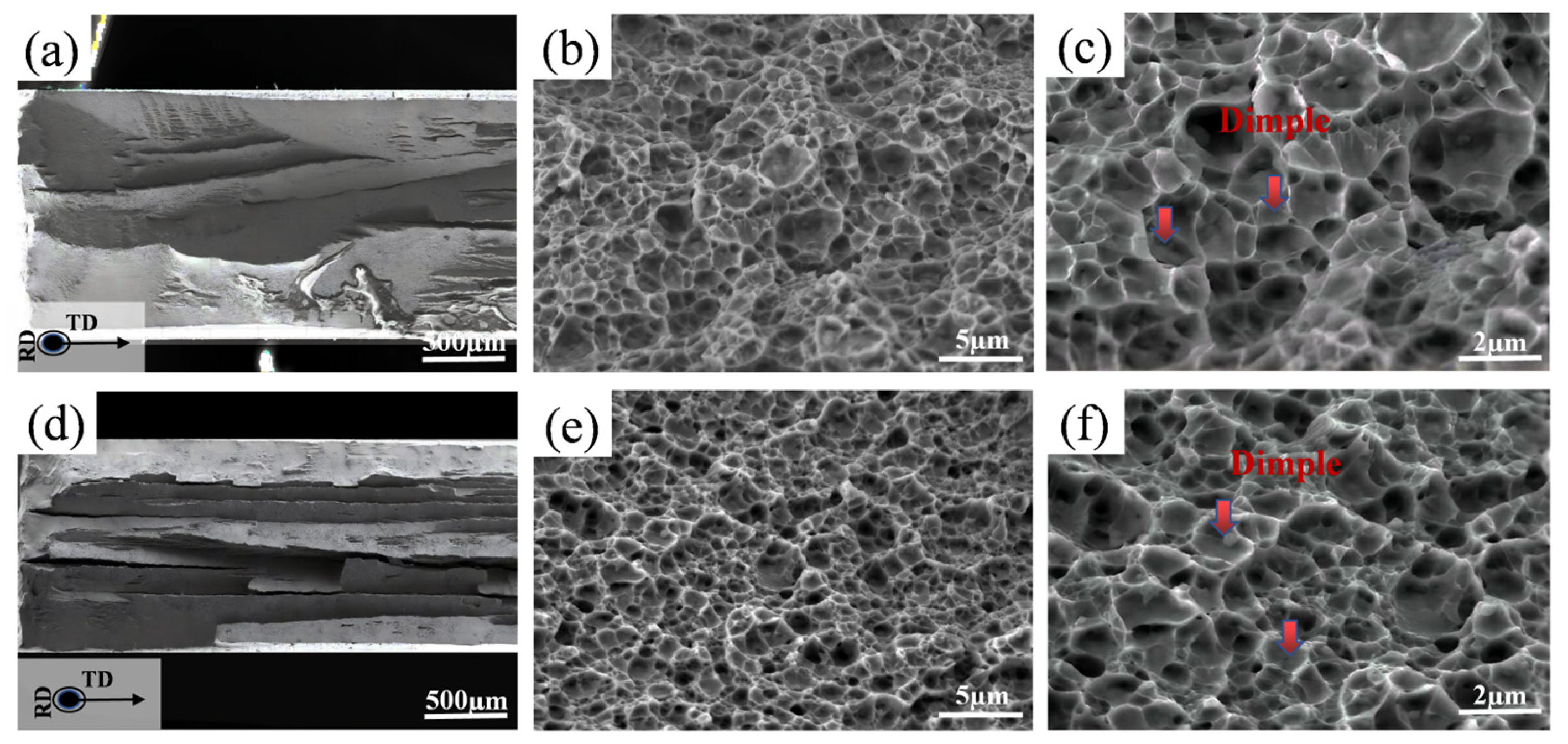

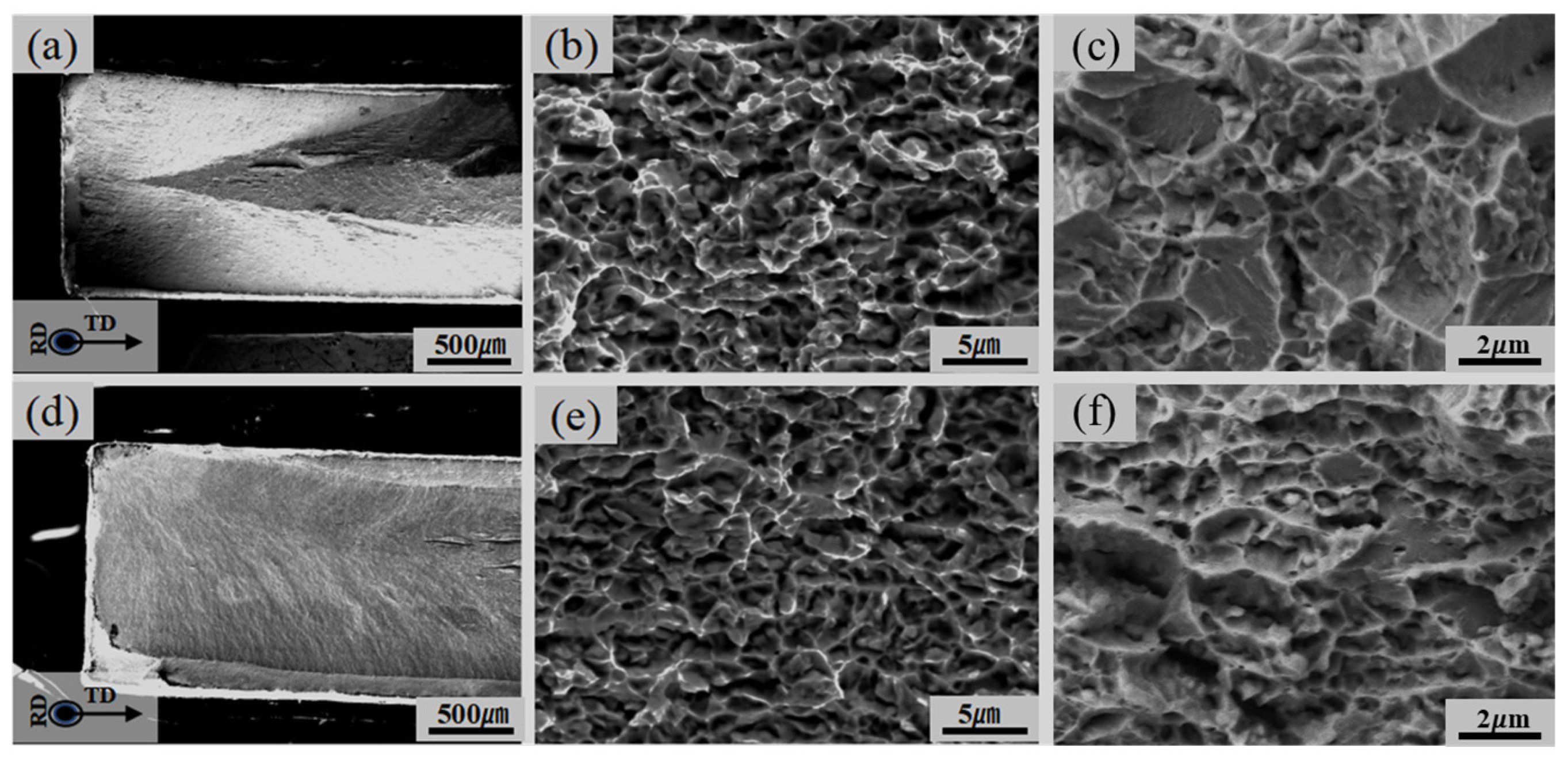

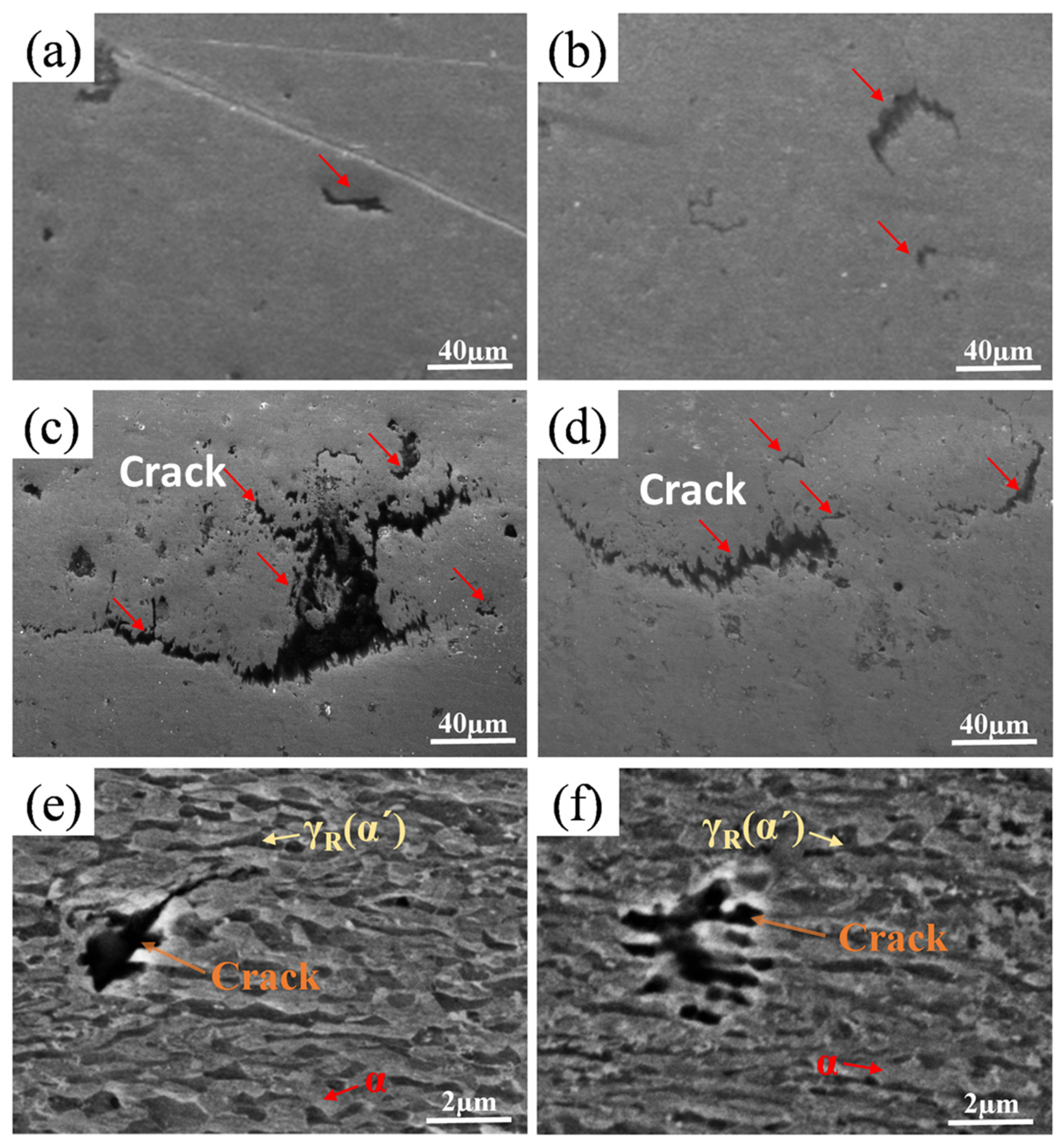

3.4. Fracture Behavior

4. Discussion

4.1. The Effect of γR Volume Fraction and Ti–Mo Addition on CH

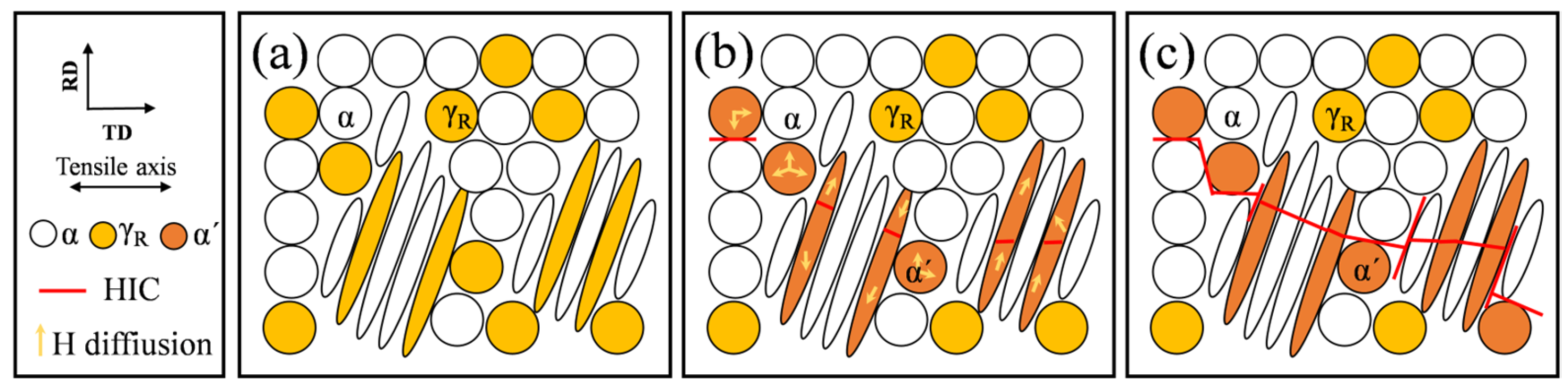

4.2. Effect of Ti–Mo Addition on Hydrogen Embrittlement (HE) Susceptibility

5. Conclusions

- (1)

- The 5.6MnTiMo exhibits smaller grain sizes relative to the 5.6Mn, especially in the α phase grain size. The (Ti, Mo)C carbides were mostly precipitated in the α phase and rarely in the γR phase.

- (2)

- The addition of Ti–Mo increased both yield strength and ultimate tensile strength without sacrificing total elongation due to the synergistic effects of precipitation hardening and grain refinement. The 5.6MnTiMo steel exhibits a strength–ductility product of approximately 35 GPa·% combined with yield strength exceeding 1.2 GPa.

- (3)

- The enhanced hydrogen embrittlement resistance of the 5.6MnTiMo alloy over the 5.6Mn alloy may be associated with the deep hydrogen traps and the improved strain compatibility at α/γ(α′) phase boundaries due to the addition of Ti and Mo.

- (4)

- Upon tensile loading, H-assisted microcracks mainly formed within γ(α′) and propagated along the γ(α′) grain boundaries, causing the intergranular cracking and premature fracture.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | Full writings |

| HE | Hydrogen Embrittlement |

| TRIP | Transformation Induced Plasticity |

| AHSSs | Advanced High-Strength Steels |

| SSRT | Slow-Strain Rate Tensile Test |

| UTS | Ultimate Tensile Strength |

| TEL | Total Elongation |

| YS | Yield Strength |

| CH | Diffusible Hydrogen Content |

| RT | Room Temperature |

| HIC | Hydrogen Induced Cracks |

| MC | MC carbides |

| TDS | Thermal Desorption Spectroscopy |

| k | Mechanical Stability Factor of Retained Austenite |

| EDXS | Energy-Dispersive X-ray Spectroscopy |

| EBSD | Electron Backscatter Diffraction |

| TEM | Transmission Electron Microscopy |

| SEM | Scanning Electron Microscopy |

| XRD | X-Ray Diffraction |

| FCC | Face-Centered Cubic |

| BCC | Body-Centered Cubic |

References

- Cai, Z.H.; Cai, B.; Ding, H.; Chen, Y.; Misra, R.D.K. Microstructure and deformation behavior of the hot-rolled medium manganese steels with varying aluminum-content. Mater. Sci. Eng. A 2016, 676, 263–270. [Google Scholar] [CrossRef]

- Xu, Y.-B.; Hu, Z.-P.; Zou, Y.; Tan, X.-D.; Han, D.-T.; Chen, S.-Q.; Ma, D.-G.; Misra, R.D.K. Effect of two-step intercritical annealing on microstructure and mechanical properties of hot-rolled medium manganese TRIP steel containing δ-ferrite. Mater. Sci. Eng. A 2017, 688, 40–55. [Google Scholar] [CrossRef]

- Sarkar, A.; Sanyal, S.; Bandyopadhyay, T.K.; Mandal, S. Influence of annealing parameters on phase evolution and recrystallization kinetics of a Mn-Al-Si alloyed duplex steel. Mater. Charact. 2017, 134, 213–224. [Google Scholar] [CrossRef]

- Lee, Y.K.; Han, J. Current opinion in medium manganese steel. Mater. Sci. Technol. 2014, 31, 843–856. [Google Scholar] [CrossRef]

- Cai, M.H.; Zhu, W.J.; Stanford, N.; Pan, L.B.; Chao, Q.; Hodgson, P.D. Dependence of deformation behavior on grain size and strain rate in an ultrahigh strength-ductile Mn-based TRIP alloy. Mater. Sci. Eng. A 2016, 653, 35–42. [Google Scholar] [CrossRef]

- Wang, C.; Cao, W.; Shi, J.; Huang, C.; Dong, H. Deformation microstructures and strengthening mechanisms of an ultrafine grained duplex medium-Mn steel. Mater. Sci. Eng. 2013, 562, 89–95. [Google Scholar] [CrossRef]

- Miller, R.L. Ultrafine-grained microstructures and mechanical properties of alloy steels. Metall. Mater. Trans. B 1972, 3, 905–912. [Google Scholar] [CrossRef]

- Han, Y.; Shi, J.; Xu, L.; Cao, W.Q.; Dong, H. TiC precipitation induced effect on microstructure and mechanical properties in low carbon medium manganese steel. Mater. Sci. Eng. A 2011, 530, 643–651. [Google Scholar] [CrossRef]

- Lee, S.; Estrin, Y.; De Cooman, B.C. Constitutive modeling of the mechanical properties of V-added medium manganese TRIP steel. Metall. Mater. Trans. A 2013, 44, 3136–3146. [Google Scholar] [CrossRef]

- Pan, H.; Ding, H.; Cai, M. Microstructural evolution and precipitation behavior of the warm-rolled medium Mn steels containing Nb or Nb-Mo during intercritical annealing. Mater. Sci. Eng. A 2018, 736, 375–382. [Google Scholar] [CrossRef]

- Park, T.M.; Kim, H.-J.; Um, H.Y.; Goo, N.H.; Han, J. The possibility of enhanced hydrogen embrittlement resistance of medium-Mn steels by addition of micro-alloying elements. Mater. Charact. 2020, 165, 110386. [Google Scholar]

- Han, J.; Nam, J.-H.; Lee, Y.-K. The mechanism of hydrogen embrittlement in intercritically annealed medium Mn TRIP steel. Acta Mater. 2016, 113, 1–10. [Google Scholar]

- Ryu, J.H.; Chun, Y.S.; Lee, C.S.; Bhadeshia, H.K.D.H.; Suh, D.W. Effect of deformation on hydrogen trapping and effusion in TRIP-assisted steel. Acta Mater. 2012, 60, 4085–4092. [Google Scholar] [CrossRef]

- Zhu, X.; Li, W.; Hsu, T.Y.; Zhou, S.; Wang, L.; Jin, X. Improved resistance to hydrogen embrittlement in a high-strength steel by quenching–partitioning–tempering treatment. Scr. Mater. 2015, 97, 21–24. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Prevention of hydrogen embrittlement in steels. ISIJ Int. 2016, 56, 24–36. [Google Scholar]

- Liu, Y.; Cao, Z.; Huang, C.; Hu, C.; Huang, M. Enhancing hydrogen embrittlement resistance of TRIP-rich medium Mn steel by morphology optimization. Sci. China Mater. 2023, 66, 4258–4266. [Google Scholar]

- Li, Y.; Li, W.; Min, N.; Liu, H.; Jin, X. Homogeneous elasto-plastic deformation and improved strain compatibility between austenite and ferrite in a co-precipitation hardened medium Mn steel with enhanced hydrogen embrittlement resistance. Int. J. Plast. 2020, 133, 102805. [Google Scholar]

- ASTM G142-98(2013); Standard Test Method for Determination of Susceptibility of Metallic Materials to Hydrogen Embrittlement (HE). ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E8M-04; Standard Test Methods for Tension Testing of Metallic Materials [Metric]. ASTM International: West Conshohocken, PA, USA, 2004.

- Sun, X.Y.; Zhang, B.; Lin, H.Q.; Zhou, Y.; Sun, L.; Wang, J.Q.; Han, E.H.; Ke, W. Correlations between stress corrosion cracking susceptibility and grain boundary microstructures for an Al–Zn–Mg alloy. Corros. Sci. 2013, 77, 103–112. [Google Scholar]

- Vandijk, N.; Butt, A.; Zhao, L.; Sietsma, J.; Offerman, S.; Wright, J.; Vanderzwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar]

- Wang, G.; Yan, Y.; Li, J.; Huang, J.; Qiao, L.; Volinsky, A.A. Microstructure effect on hydrogen-induced cracking in TM210 maraging steel. Mater. Sci. Eng. A 2013, 586, 142–148. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, S.K.; Lee, C.S.; Suh, D.-W.; Bhadeshia, H.K.D.H. Effect of aluminium on hydrogen-induced fracture behaviour in austenitic Fe–Mn–C steel. Proc. R. Soc. A Math. Phys. Eng. Sci. 2013, 469, 2149. [Google Scholar] [CrossRef]

- Tarzimoghadam, Z.; Rohwerder, M.; Merzlikin, S.V.; Bashir, A.; Yedra, L.; Eswara, S.; Ponge, D.; Raabe, D. Multi-scale and spatially resolved hydrogen mapping in a Ni–Nb model alloy reveals the role of the δ phase in hydrogen embrittlement of alloy 718. Acta Mater. 2016, 109, 69–81. [Google Scholar]

- Tsuchida, N.; Tomota, Y.; Nagai, K.; Fukaura, K. A simple relationship between Lüders elongation and work-hardening rate at lower yield stress. Scr. Mater. 2006, 54, 57–60. [Google Scholar]

- Shi, J.; Sun, X.; Wang, M.; Hui, W.; Dong, H.; Cao, W. Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite. Scr. Mater. 2010, 63, 815–818. [Google Scholar]

- Gibbs, P.J.; De Moor, E.; Merwin, M.J.; Clausen, B.; Speer, J.G.; Matlock, D.K. Austenite stability effects on tensile behavior of manganese-enriched-austenite transformation-induced plasticity steel. Metall. Mater. Trans. A 2011, 42, 3691–3702. [Google Scholar]

- Heo, Y.U.; Suh, D.W.; Lee, H.C. Fabrication of an ultrafine-grained structure by a compositional pinning technique. Acta Mater. 2014, 77, 236–247. [Google Scholar] [CrossRef]

- Suh, D.W.; Park, S.J.; Lee, T.H.; Oh, C.S.; Kim, S.J. Influence of Al on the microstructural evolution and mechanical behavior of low-carbon, manganese transformation-induced-plasticity steel. Metall. Mater. Trans. A 2009, 41, 397–408. [Google Scholar] [CrossRef]

- Cai, Z.H.; Ding, H.; Misra, R.D.K.; Ying, Z.Y. Austenite stability and deformation behavior in a cold-rolled transformation-induced plasticity steel with medium manganese content. Acta Mater. 2015, 84, 229–236. [Google Scholar]

- Lee, C.Y.; Jeong, J.; Han, J.; Lee, S.J.; Lee, S.; Lee, Y.K. Coupled strengthening in a medium manganese lightweight steel with an inhomogeneously grained structure of austenite. Acta Mater. 2015, 84, 1–8. [Google Scholar] [CrossRef]

- Jeong, M.S.; Park, T.M.; Choi, S.; Lee, S.J.; Han, J. Recovering the ductility of medium-Mn steel by restoring the original microstructure. Scr. Mater. 2021, 190, 16–21. [Google Scholar]

- Park, S.J.; Hwang, B.; Lee, K.H.; Lee, T.H.; Suh, D.W.; Han, H.N. Microstructure and tensile behavior of duplex low-density steel containing 5mass% aluminum. Scr. Mater. 2013, 68, 365–369. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. Tensile behavior of intercritically annealed 10 pct Mn multi-phase steel. Metall. Mater. Trans. A 2013, 45, 709–716. [Google Scholar] [CrossRef]

- Wang, T.; Hu, J.; Misra, R.D.K. Microstructure evolution and strain behavior of a medium Mn TRIP/TWIP steel for excellent combination of strength and ductility. Mater. Sci. Eng. A 2019, 753, 99–108. [Google Scholar] [CrossRef]

- Ma, Y.; Sun, B.; Schökel, A.; Song, W.; Ponge, D.; Raabe, D.; Bleck, W. Phase boundary segregation-induced strengthening and discontinuous yielding in ultrafine-grained duplex medium-Mn steels. Acta Mater. 2020, 200, 389–403. [Google Scholar] [CrossRef]

- Sun, S.; Cai, M.; Ding, H.; Huang, H.; Pan, H. Deformation mechanisms of a novel Mn-based 1 GPa TRIP/TWIP assisted lightweight steel with 63% ductility. Mater. Sci. Eng. A 2021, 802, 140658. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. Tensile behavior of intercritically annealed ultra-fine grained 8% Mn multi-phase steel. Steel Res. Int. 2015, 86, 1170–1178. [Google Scholar] [CrossRef]

- Lei, M.; Hui, W.; Wang, J.; Zhang, Y.; Zhao, X. Microstructure and mechanical properties of hot-rolled V-microalloyed Al-containing medium-Mn steel. J. Iron Steel Res. Int. 2020, 27, 537–548. [Google Scholar] [CrossRef]

- Cai, M.; Li, Z.; Chao, Q.; Hodgson, P.D. A novel Mo and Nb microalloyed medium Mn TRIP steel with maximal ultimate strength and moderate ductility. Metall. Mater. Trans. A 2014, 45, 5624–5634. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, K.; Li, W.; Jin, X. Effect of retained austenite stability and morphology on the hydrogen embrittlement susceptibility in quenching and partitioning treated steels. Mater. Sci. Eng. A 2016, 658, 400–408. [Google Scholar] [CrossRef]

- Gao, Z.H.; Xue, Y.F.; Li, J.X.; Xu, L.N.; Qiao, L.J. The mechanism of the high resistance to hydrogen-induced strength loss in ultra-high strength high-entropy alloy. Metals 2022, 12, 971. [Google Scholar] [CrossRef]

- Takai, K.; Watanuki, R. Hydrogen in trapping states innocuous to environmental degradation of high-strength steels. ISIJ Int. 2003, 43, 520–526. [Google Scholar]

- Nagao, A.; Hayashi, K.; Ol, K.; Mitao, S. Effect of uniform distribution of fine cementite on hydrogen embrittlement of low carbon martensitic steel plates. ISIJ Int. 2012, 52, 213–221. [Google Scholar]

- Luo, Y.; Lu, H.; Min, N.; Li, W.; Jin, X. Effect of Mo and Nb on mechanical properties and hydrogen embrittlement of hot-rolled medium-Mn steels. Mater. Sci. Eng. A 2022, 844, 143108. [Google Scholar]

- Itakura, M.; Kaburaki, H.; Yamaguchi, M.; Okita, T. The effect of hydrogen atoms on the screw dislocation mobility in bcc: Iron: A first-principles study. Acta Mater. 2013, 61, 6857–6867. [Google Scholar]

- Abe, A.; Suzaki, H.; Takai, K.; Ishikawa, N.; Sueyoshi, H. Identification of hydrogen trapping sites, binding energies, and occupation ratios at vacancies, dislocations and grain boundaries in iron of varying carbon content. Mater. Sci. Technol. Conf. Exhib. 2011, 2011, 1277–1284. [Google Scholar]

- Lee, H.G.; Lee, J.Y. Hydrogen trapping by TiC particles in iron. Acta Metall. 1984, 32, 131–136. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Z.; Li, W.G.; Li, J.X. Unveiling the inconsistent improvement of hydrogen embrittlement resistance by Nb precipitates in medium Mn steels: Impact of hydrogen distribution. Mater. Sci. Eng. A 2025, 922, 147629. [Google Scholar]

- Matsuoka, S.; Homma, N.; Tanaka, H.; Fukushima, Y.; Murakami, Y. Effect of hydrogen on the tensile properties of 900-MPa-class JIS-SCM435 low-alloy-steel for use in storage cylinder of hydrogen station. J. Jpn. Inst. Met. Mater. 2006, 70, 1002–1011. [Google Scholar]

- Sun, B.H.; Lu, W.J.; Gault, B.; Ding, R.; Makineni, S.K.; Wan, D.; Wu, C.H.; Chen, H.; Ponge, D.; Raabe, D. Chemical heterogeneity enhances hydrogen resistance in high-strength steels. Nat. Mater. 2021, 20, 1629–1634. [Google Scholar] [PubMed]

- Zhang, Y.; Hui, W.; Zhao, X.; Wang, C.; Cao, W.; Dong, H. Effect of reverted austenite fraction on hydrogen embrittlement of TRIP-aided medium Mn steel (0.1C-5Mn). Eng. Fail. Anal. 2019, 97, 605–616. [Google Scholar]

- Shao, C.; Hui, W.; Zhang, Y.; Zhao, X.; Weng, Y. Effect of intercritical annealing time on hydrogen embrittlement of warm-rolled medium Mn steel. Mater. Sci. Eng. A 2018, 726, 320–331. [Google Scholar] [CrossRef]

- Sun, B.; Vanderesse, N.; Fazeli, F.; Scott, C.; Chen, J.; Bocher, P.; Jahazi, M.; Yue, S. Discontinuous strain-induced martensite transformation related to the Portevin-Le Chatelier effect in a medium manganese steel. Scr. Mater. 2017, 133, 9–13. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.; Yan, Y.; Li, J.; Wu, M. Effect of hot/warm rolling on the microstructures and mechanical properties of medium-Mn steels. Mater. Charact. 2020, 170, 110682. [Google Scholar] [CrossRef]

- Pan, H.J.; Ding, H.; Cai, M.H.; Kibaroglu, D.; Ma, Y.; Song, W.W. Precipitation behavior and austenite stability of Nb or Nb–Mo micro-alloyed warm-rolled medium-Mn steels. Mater. Sci. Eng. A 2019, 766, 138371. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wang, C.Z.; Li, H.Y.; Xu, D.F.; Zhang, H.T.; Xiao, N.; Cai, M.H.; Lee, Y.K. Ti-Mo microalloyed medium Mn steels: Precipitation and strengthening mechanism. Mater. Sci. Eng. A 2024, 909, 146866. [Google Scholar] [CrossRef]

| Steels | Phase | Average Grain Size (μm) | Volume Fraction of γR | ||

|---|---|---|---|---|---|

| 650 °C | 670 °C | 650 °C | 670 °C | ||

| 5.6Mn | α | 1.33 ± 0.32 | 1.45 ± 0.29 | 33% | 37% |

| γR | 0.38 ± 0.13 | 0.52 ± 0.18 | |||

| 5.6MnTiMo | α | 1.12 ± 0.26 | 1.21 ± 0.28 | 29% | 32% |

| γR | 0.36 ± 0.12 | 0.48 ± 0.15 | |||

| Hydrogen Trap State | Hydrogen Trap Binding Energy Calculated in This Study (kJ/mol) | Hydrogen Trap Binding Energy Reported in the Literature (kJ/mol) [45,46] |

|---|---|---|

| High-angle grain boundary | 51.2 | 47.47 |

| Dislocation | 23.9 | 24.70 |

| Nanosized (Ti, Mo)C precipitate | 28.9 | 28.17 |

| Steels | VRA0 (%) | VRA (%) | k |

|---|---|---|---|

| 5.6Mn | 36 | 1 | 18.8 |

| 5.6MnTiMo | 33 | 3 | 12.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Zhao, Y.; Pan, J.; Hao, W.; Wang, S.; Cai, M. The Effect of Ti and Mo Microalloying on Hydrogen Embrittlement Resistance of Ultra-High Strength Medium Mn Steel. Metals 2025, 15, 397. https://doi.org/10.3390/met15040397

Zhang P, Zhao Y, Pan J, Hao W, Wang S, Cai M. The Effect of Ti and Mo Microalloying on Hydrogen Embrittlement Resistance of Ultra-High Strength Medium Mn Steel. Metals. 2025; 15(4):397. https://doi.org/10.3390/met15040397

Chicago/Turabian StyleZhang, Pujunhuan, Yang Zhao, Jianglong Pan, Weizhuo Hao, Shuyi Wang, and Minghui Cai. 2025. "The Effect of Ti and Mo Microalloying on Hydrogen Embrittlement Resistance of Ultra-High Strength Medium Mn Steel" Metals 15, no. 4: 397. https://doi.org/10.3390/met15040397

APA StyleZhang, P., Zhao, Y., Pan, J., Hao, W., Wang, S., & Cai, M. (2025). The Effect of Ti and Mo Microalloying on Hydrogen Embrittlement Resistance of Ultra-High Strength Medium Mn Steel. Metals, 15(4), 397. https://doi.org/10.3390/met15040397